The Study of Economic and Environmental Viability of the Treatment of Organic Fraction of Municipal Solid Waste Using Monte Carlo Simulation

Abstract

1. Introduction

2. Materials and Methods

2.1. Description of Scenarios

2.2. Cost/Benefit Assessment

2.3. Fee and Financial Net Present Value (NPV)

2.4. Social NPV

2.5. Monte Carlo Simulation

3. Results and Discussions

3.1. Economic Analysis: Cost and Benefit

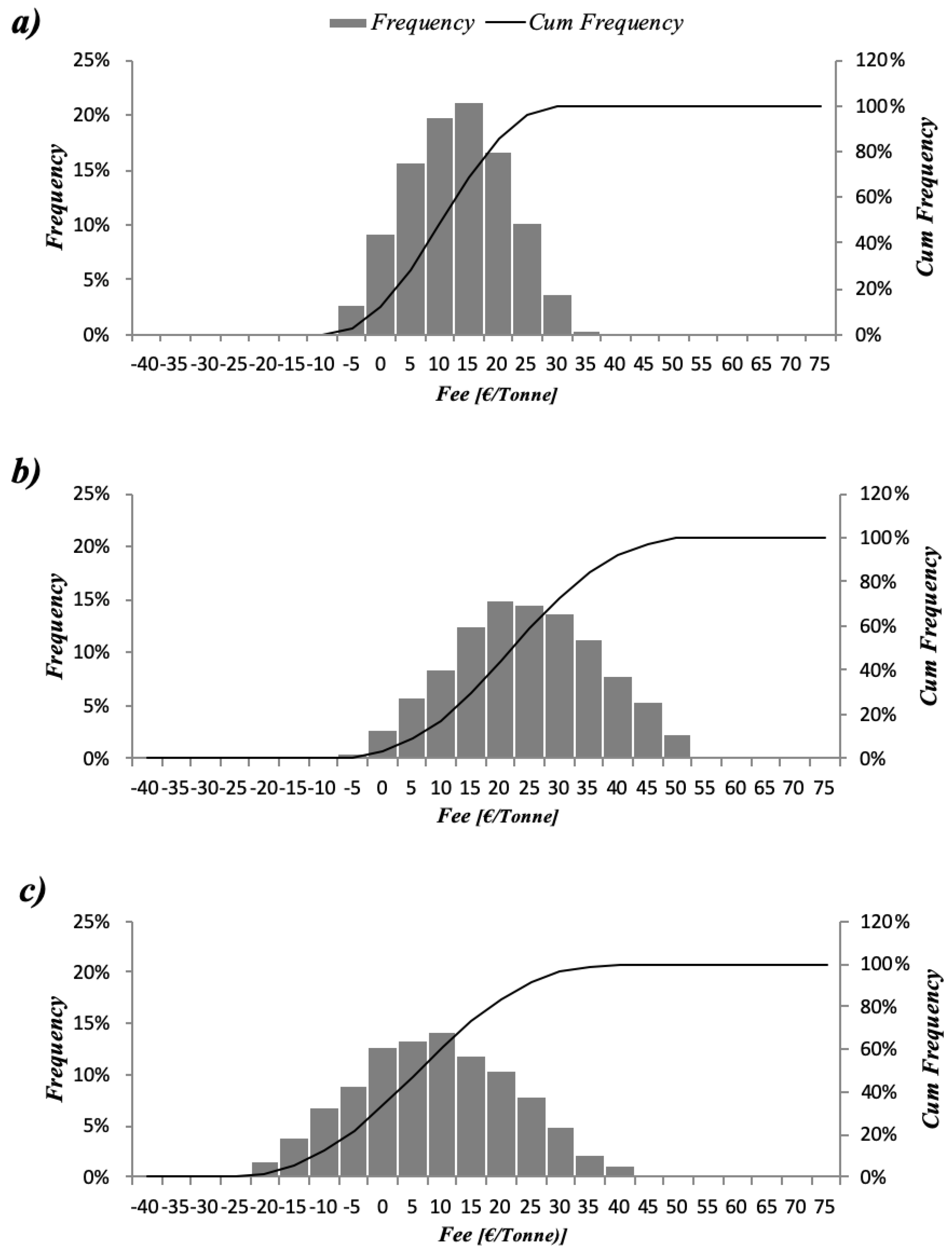

3.2. Fee Analysis

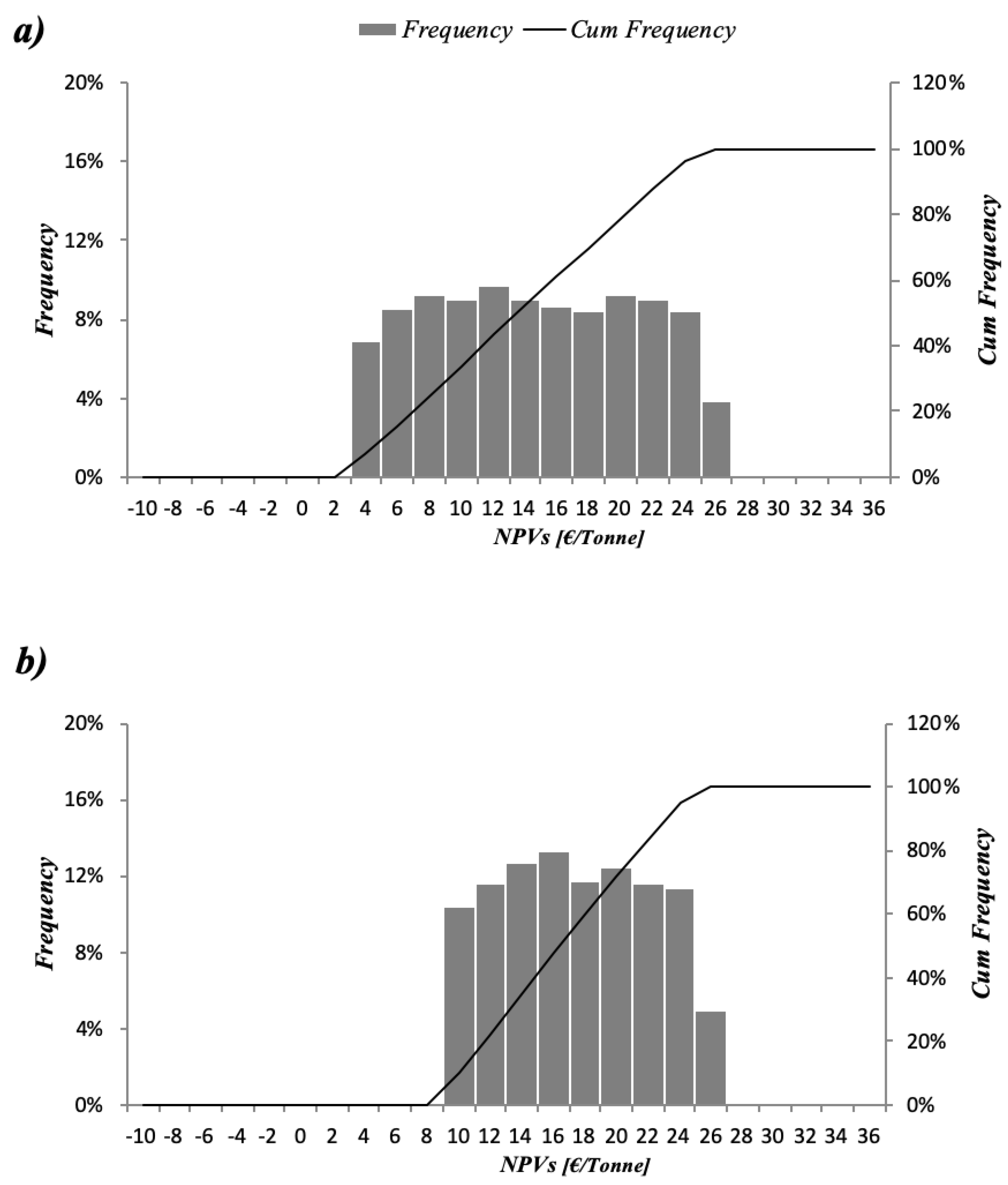

3.3. Social NPV

4. Conclusions

- Monte Carlo simulation is a useful tool for quantitative analysis and decision making in OFMSW management.

- Although the initial costs for Scenarios 2 and 3 are consistently higher than the initial costs reported for Scenario 1, the revenues that rise with an increase in the final quality of the product are higher and they present a social benefit.

- The lowest average fee that neutralizes the NPVf is 6.38 €/tonne treated in Scenario 3, and the highest is estimated in Scenario 2 (22.09 €/tonne), therefore, Scenario 3 is the most financially viable scenario.

- The average NPVs calculated in Scenario 3 (16.60 €/tonne) is higher than that obtained in Scenario 2 (13.59 €/tonne), therefore, Scenario 3 is the most socially viable scenario.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sisto, R.; Sica, E.; Lombardi, M.; Prosperi, M. Organic fraction of municipal solid waste valorisation in southern Italy: The stakeholders’ contribution to a long-term strategy definition. J. Clean. Prod. 2017, 168, 302–310. [Google Scholar] [CrossRef]

- Liu, Y.; Ni, Z.; Kong, X.; Liu, J. Greenhouse gas emissions from municipal solid waste with a high organic fraction under different management scenarios. J. Clean. Prod. 2017, 147, 451–457. [Google Scholar] [CrossRef]

- Ayodele, T.R.; Ogunjuyigbe, A.S.O.; Alao, M.A. Economic and environmental assessment of electricity generation using biogas from organic fraction of municipal solid waste for the city of Ibadan, Nigeria. J. Clean. Prod. 2018, 203, 718–735. [Google Scholar] [CrossRef]

- Alwaeli, M. Economic calculus of the effectiveness of waste utilization processed as substitutes of primary materials. Environ. Prot. Eng. 2011, 37, 51–58. [Google Scholar]

- Expósito, A.; Velasco, F. Municipal solid-waste recycling market and the European 2020 Horizon Strategy: A regional efficiency analysis in Spain. J. Clean. Prod. 2018, 172, 938–948. [Google Scholar] [CrossRef]

- Scarlat, N.; Fahl, F.; Dallemand, J.F.; Monforti, F.; Motola, V. A spatial analysis of biogas potential from manure in Europe. Renew. Sustain. Energy Rev. 2018, 94, 915–930. [Google Scholar] [CrossRef]

- Aye, L.; Widjaya, E.R. Environmental and economic analyses of waste disposal options for traditional markets in Indonesia. Waste Manag. 2006, 26, 1180–1191. [Google Scholar] [CrossRef]

- Pergola, M.; Persiani, A.; Palese, A.M.; Di Meo, V.; Pastore, V.; D’Adamo, C.; Celano, G. Composting: The way for a sustainable agriculture. Appl. Soil Ecol. 2018, 123, 744–750. [Google Scholar] [CrossRef]

- Rajaeifar, M.A.; Ghanavati, H.; Dashti, B.D.; Heijungs, R.; Aghbashlo, M.; Tabatabaei, M. Electricity generation and GHG emission reduction potentials through different municipal solid waste management technologies: A comparative review. Renew. Sustain. Energy Rev. 2017, 79, 414–439. [Google Scholar] [CrossRef]

- Mancini, E.; Arzoumanidis, I.; Raggi, A. Evaluation of potential environmental impacts related to two organic waste treatment options in Italy. J. Clean. Prod. 2019, 214, 927–938. [Google Scholar] [CrossRef]

- Laramee, J.; Tilmans, S.; Davis, J. Costs and benefits of biogas recovery from communal anaerobic digesters treating domestic wastewater: Evidence from peri-urban Zambia. J. Environ. Manag. 2018, 210, 23–35. [Google Scholar] [CrossRef] [PubMed]

- Cucchiella, F.; D’Adamo, I.; Gastaldi, M.; Miliacca, M. A profitability analysis of small-scale plants for biomethane injection into the gas grid. J. Clean. Prod. 2018, 184, 179–187. [Google Scholar] [CrossRef]

- Ruiz, D.; San Miguel, G.; Corona, B.; Gaitero, A.; Domínguez, A. Environmental and economic analysis of power generation in a thermophilic biogas plant. Sci. Total Environ. 2018, 636, 1418–1428. [Google Scholar] [CrossRef] [PubMed]

- Rafieenia, R.; Girotto, F.; Peng, W.; Cossu, R.; Pivato, A.; Raga, R.; Lavagnolo, M.C. Effect of aerobic pre-treatment on hydrogen and methane production in a two-stage anaerobic digestion process using food waste with different compositions. Waste Manag. 2017, 59, 194–199. [Google Scholar] [CrossRef]

- Malinauskaite, J.; Jouhara, H.; Czajczyńska, D.; Stanchev, P.; Katsou, E.; Rostkowski, P.; Thorne, R.J.; Colón, J.; Ponsá, S.; Al-Mansour, F.; et al. Municipal solid waste management and waste-to-energy in the context of a circular economy and energy recycling in Europe. Energy 2017, 141, 2013–2044. [Google Scholar] [CrossRef]

- Marchioni, A.; Magni, C.A. Investment decisions and sensitivity analysis: NPV-consistency of rates of return. Eur. J. Oper. Res. 2018, 268, 361–371. [Google Scholar] [CrossRef]

- Mahdiyar, A.; Tabatabaee, S.; Sadeghifam, A.N.; Mohandes, S.R.; Abdullah, A.; Meynagh, M.M. Probabilistic private cost-benefit analysis for green roof installation: A Monte Carlo simulation approach. Urban For. Urban Green. 2016, 20, 317–327. [Google Scholar] [CrossRef]

- SendeCO2. Precios CO2—Sendeco2. Available online: https://www.sendeco2.com/es/precios-co2 (accessed on 10 December 2018).

- Souza, S.V.; Gimenes, R.M.T.; Binotto, E. Economic viability for deploying hydroponic system in emerging countries: A differentiated risk adjustment proposal. Land Use Policy 2019, 83, 357–369. [Google Scholar] [CrossRef]

- Zore, Ž.; Čuček, L.; Širovnik, D.; Novak Pintarič, Z.; Kravanja, Z. Maximizing the sustainability net present value of renewable energy supply networks. Chem. Energy Res. Des. 2018, 131, 245–265. [Google Scholar] [CrossRef]

- European Union. Guide to Cost-Benefit Analysis of Investment Projects, Economic Appraisal tool for Cohesion Policy 2014–2020; European Commission: Brussels. Beligum, 2014. [Google Scholar]

- Ćetković, J.; Lakić, S.; Knežević, M.; Bogdanović, P.; Žarković, M. Financial and socioeconomic analysis of waste management projects. Građevinar 2017, 11, 1007–1016. [Google Scholar] [CrossRef]

- Steffen, B. Estimating the cost of capital for renewable energy projects. Energy Econ. 2020, 88, 104783. [Google Scholar] [CrossRef]

- Bekchanov, M.; Mirzabaev, A. Circular economy of composting in Sri Lanka: Opportunities and challenges for reducing waste related pollution and improving soil health. J. Clean. Prod. 2018, 202, 1107–1191. [Google Scholar] [CrossRef]

- Lin, L.; Xu, F.; Ge, X.; Li, Y. Improving the sustainability of organic waste management practices in the food-energy-water nexus: A comparative review of anaerobic digestion and composting. Renew. Sustain. Energy Rev. 2018, 89, 151–167. [Google Scholar] [CrossRef]

- Rosa, M.D. Economic assessment of producing and selling biomethane into a regional market. Energy Environ. 2018, 31, 1–17. [Google Scholar] [CrossRef]

- Chan Gutiérrez, E.; Wall, D.M.; O’Shea, R.; Novelo, R.M.; Gómez, M.M.; Murphy, J.D. An economic and carbon analysis of biomethane production from food waste to be used as a transport fuel in Mexico. J. Clean. Prod. 2018, 196, 852–862. [Google Scholar] [CrossRef]

- Vo, T.T.Q.; Wall, D.M.; Ring, D.; Rajendran, K.; Murphy, J.D. Techno-economic analysis of biogas upgrading via amine scrubber, carbon capture and ex-situ methanation. Appl. Energy 2018, 212, 1191–1202. [Google Scholar] [CrossRef]

- Rasheed, R.; Khan, N.; Yasar, A.; Su, Y.; Tabinda, A.B. Design and cost-benefit analysis of a novel anaerobic industrial bioenergy plant in Pakistan. Renew. Energy 2016, 90, 242–247. [Google Scholar] [CrossRef]

- De Clercq, D.; Wen, Z.; Fei, F. Economic performance evaluation of bio-waste treatment technology at the facility level. Resour. Conserv. Recycl. 2017, 116, 178–184. [Google Scholar] [CrossRef]

- Mengistu, M.G.; Simane, B.; Eshete, G.; Workneh, T.S. The environmental benefits of domestic biogas technology in rural Ethiopia. Biomass Bioenergy 2016, 90, 131–138. [Google Scholar] [CrossRef]

- Masebinu, S.O.; Akinlabi, E.T.; Muzenda, E.; Aboyade, A.O.; Mbohwa, C. Experimental and feasibility assessment of biogas production by anaerobic digestion of fruit and vegetable waste from Joburg Market. Waste Manag. 2018, 75, 236–250. [Google Scholar] [CrossRef]

- Budzianowski, W.M.; Budzianowska, D.A. Economic analysis of biomethane and bioelectricity generation from biogas using different support schemes and plant configurations. Energy 2015, 88, 658–666. [Google Scholar] [CrossRef]

- Ulusoy, Y.; Ulukardesler, A.H.; Arslan, R.; Tekin, Y. Energy and emission benefits of chicken manure biogas production—A case study. Environ. Sci. Pollut. Res. 2018, 1–6. [Google Scholar] [CrossRef]

| Items | Scenario 1 (€/(tonne*Y)) min–MAX | Scenario 2 (€/(tonne*Y)) min–MAX | Scenario 3 (€/(tonne*Y)) min–MAX | Reference | |

|---|---|---|---|---|---|

| Cost | Initial costs | 18.49–78.15 | 50.62–243.51 | 39.9–131.58 | [7,8,12,13,25,26,27,28] |

| Operation and maintenance costs | 13.33–25.93 | 9.23–14.43 | 7.56–35.53 | [7,8,12,13,24,27,28,29,30,31] | |

| Benefit | Revenue from compost | 5.60–29.91 | X | X | [7,8,32] |

| Revenue from electricity energy sales | X | 3.87–27.63 | X | [13,29] | |

| Revenue from biomethane sales | X | X | 13.57–47.16 | [27,28,30,31,32] | |

| CO2 emissions avoided | 0 | 0.44–4.39 | 1.47–4.39 | [7,8,25,31,32,33,34] | |

| FEE (NPVf = 0) (€/tonne) Average (Min, Max) | NPVs (€/tonne) Average (Min, Max) | |

|---|---|---|

| SCENARIO 1 | 10.49 (−11.43, 33.02) | x |

| SCENARIO 2 | 22.09 (−8.64, 52.09) | 13.59 (2.49, 24.81) |

| SCENARIO 3 | 6.38 (−29.56, 42.54) | 16.60 (8.31, 24.81) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martín-Pascual, J.; Fernández-González, J.M.; Ceccomarini, N.; Ordoñez, J.; Zamorano, M. The Study of Economic and Environmental Viability of the Treatment of Organic Fraction of Municipal Solid Waste Using Monte Carlo Simulation. Appl. Sci. 2020, 10, 9028. https://doi.org/10.3390/app10249028

Martín-Pascual J, Fernández-González JM, Ceccomarini N, Ordoñez J, Zamorano M. The Study of Economic and Environmental Viability of the Treatment of Organic Fraction of Municipal Solid Waste Using Monte Carlo Simulation. Applied Sciences. 2020; 10(24):9028. https://doi.org/10.3390/app10249028

Chicago/Turabian StyleMartín-Pascual, Jaime, José María Fernández-González, Nicolò Ceccomarini, Javier Ordoñez, and Montserrat Zamorano. 2020. "The Study of Economic and Environmental Viability of the Treatment of Organic Fraction of Municipal Solid Waste Using Monte Carlo Simulation" Applied Sciences 10, no. 24: 9028. https://doi.org/10.3390/app10249028

APA StyleMartín-Pascual, J., Fernández-González, J. M., Ceccomarini, N., Ordoñez, J., & Zamorano, M. (2020). The Study of Economic and Environmental Viability of the Treatment of Organic Fraction of Municipal Solid Waste Using Monte Carlo Simulation. Applied Sciences, 10(24), 9028. https://doi.org/10.3390/app10249028