1. Introduction

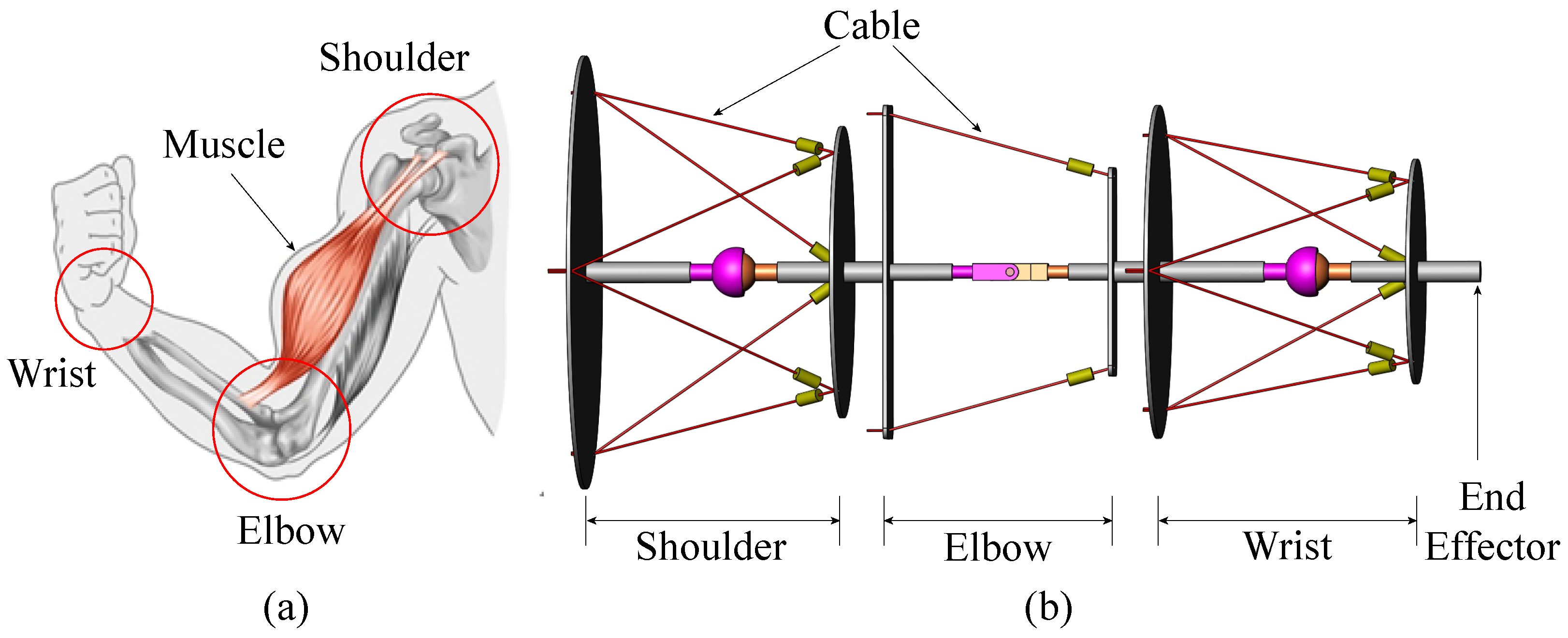

Unlike conventional robots that work in structured environments, safe human–robot interactions have been a key element for the robots that work in unstructured and unpredictable environments. Inspired by the structure of human arms, a modular

cable-driven human-like robotic arm (CHRA) is developed for safe human–robot interaction, which employs cables to mimic the functionality of the human muscles. As shown in

Figure 1, the CHRA consists of a shoulder joint, an elbow joint and a wrist joint in series, where the shoulder joint and the wrist joint have

three degrees of freedom (3-DOF) and the elbow joint has

one degree of freedom (1-DOF). The CHRA employs lightweight cables to drive the rigid links and the cables can be wound into winches mounted onto the base of the CHRA. A

variable-stiffness device (VSD) is designed and placed along with each driving cable to increase the flexibility of the cables. With these arrangements, the CHRA has flexibility advantages [

1], low moving mass [

2], large workspace [

3] and high payload-to-weight ratio [

4]. Due to these advantages, the CHRA is intrinsically safe for human–robot interactions. The proposed CHRA and its joint modules are one kind of

cable-driven mechanisms (CDMs). In the last decades, various CDMs have been designed for various applications, such as medical robots [

5,

6,

7], rehabilitation robots [

8,

9,

10,

11,

12], inspection and repair [

13,

14,

15], and moving payloads [

16,

17,

18,

19].

Unlike rigid links, the cables have the unilateral driving property (i.e., they can only pull, but can not push). Hence, the CHRA and its joint modules are redundantly actuated. For a given pose, a lot of cable tension solutions are feasible for the CHRA. Furthermore, the stiffness of the CHRA can be adjusted by regulating the cable tensions. The characteristic of variable stiffness increases the flexibility and safety of the CHRA.

The problem of

stiffness-oriented cable tension distribution (SCTD) of a CDM aims at finding the optimal cable tensions to achieve a desired stiffness. However, in the last decades, most studies on cable tension distribution have been carried out to minimize the cable tensions to reduce the energy consumption [

20,

21,

22,

23,

24,

25,

26,

27]. In [

28], the SCTD problem of a CDM was studied by formulating it as an optimization model, and a gradient-projection-based algorithm was presented to solve the optimization problem. However, it utilized the determinant of the stiffness matrix as the objective function. With this method, the desired stiffness cannot be achieved accurately. In [

29], the SCTD problem of a 3-DOF cable-driven spherical mechanism was studied and it established the optimization model with all entries of the stiffness matrix, not only the determinant of the stiffness matrix. However, it employed the conventional stiffness model of the CDM, which was derived by the conventional differential formula of the load to the displacement. Since the trajectory of the 3-DOF cable-driven spherical mechanism is a curve on Lie group SO(3) and SO(3) is nonlinear, the stiffness model based on the conventional differential formula is not exactly accurate on SO(3). Its stiffness should be evaluated by the variation of its load against its displacement on SO(3).

In order to study the SCTD problem of the proposed CHRA, the SCTD problems of the 1-DOF and 3-DOF joint modules should be studied first. Due to the simple structure of the 1-DOF joint module, its SCTD problem can be solved easily. For the 3-DOF joint module (3DJM) of the CHRA, its trajectory is a curve on SO(3). We derive the stiffness model of the 3DJM by the covariant derivative of the load to the displacement on SO(3), and call it the enhanced stiffness model of the 3DJM. In this paper, we focus on investigating how the cable tension distribution problem oriented the enhanced stiffness of the 3DJM. Due the complexity of the enhanced stiffness model, it is difficult to solve the cable tensions from the desired stiffness of the 3DJM analytically. We formulate the SCTD problem of the 3DJM as a nonlinear constrained optimization problem. Due to the symmetry of the enhanced stiffness model of the 3DJM, the desired stiffness matrix can be transformed to a diagonal matrix by an orthogonal transformation. Based on the analysis of the rank of the Jacobian matrix of the 3DJM, the six cables can be divided into two groups: one group with three cables for position adjustment by regulating the cable lengths, and another group with the remaining three cables for stiffness adjustment by regulating the cable tensions. In this manner, the position and stiffness of the 3DJM can be adjusted simultaneously. Furthermore, three cable tensions for position adjustment can be expressed by another three cable tensions for stiffness adjustment using the equilibrium equation of the 3DJM. That means the six decision variables of the optimization model can be reduced to three. Since the objective function of the optimization model is too complicated to compute the gradient, a direct optimization method based on the genetic algorithm is proposed for solving the optimization problem, which only utilizes the objective function values. A comprehensive simulation is carried out to validate the effectiveness of the proposed method. The results show that the proposed method provides an accurate and efficient way to adjust the stiffness of the 3DJM by regulating the cable tensions. In summary, the main contribution of this paper is solving the cable tension distribution problem with the enhanced stiffness model of the 3DJM using a method based on the genetic algorithm.

2. Enhanced Stiffness Model of the 3DJM

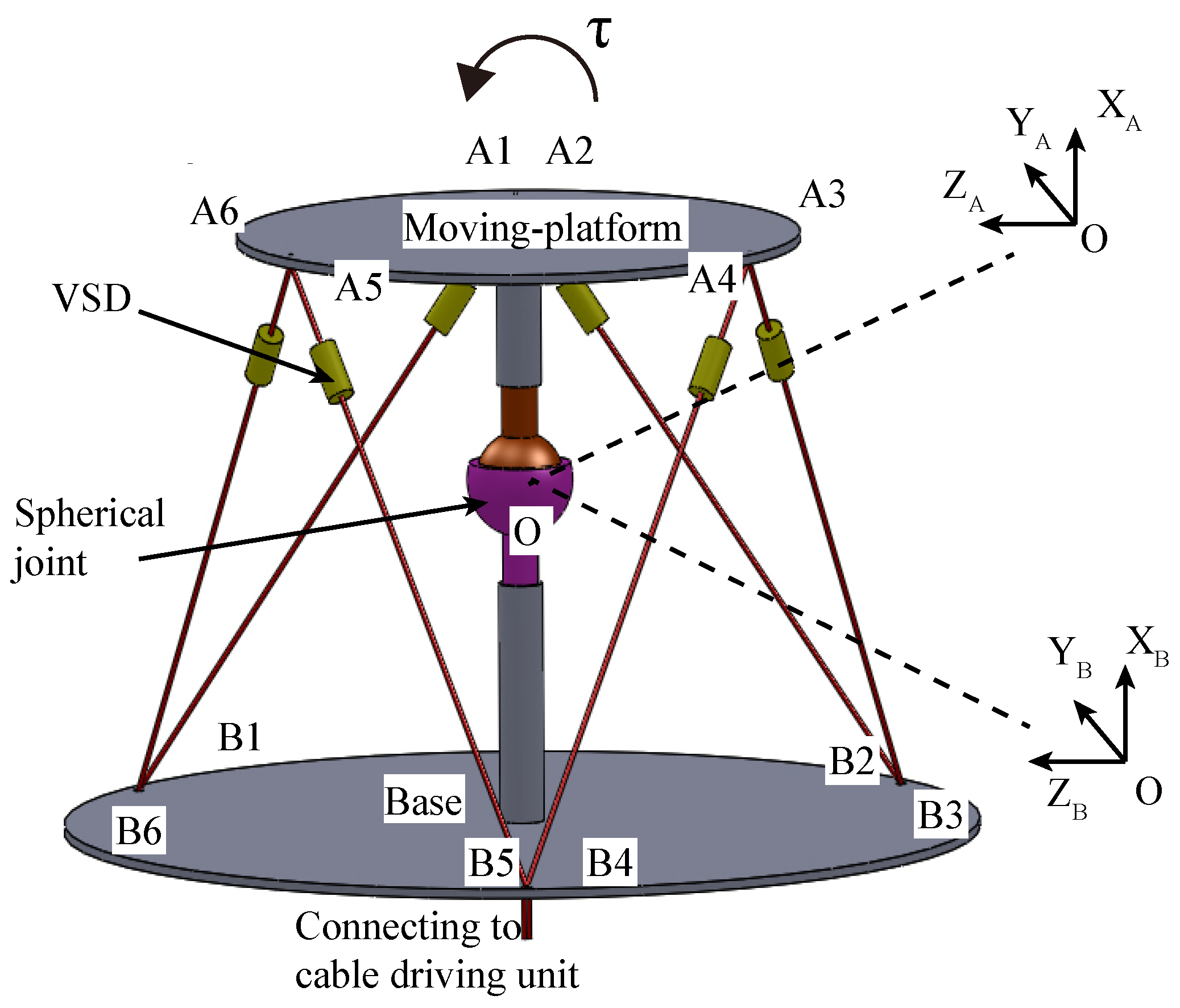

As shown in

Figure 2, the 3-DOF joint module (3DJM) of the CHRA was made up with a base, a moving-platform and a passive spherical joint connecting them. Six cables were employed to drive the moving-platform and a

variable-stiffness device (VSD) was placed along with each driving cable. For routing the cables, six small holes were drilled in the moving-platform and the base, denoted by

and

, respectively. In this design,

,

,

,

, where

and

. The distance between the moving-platform and the spherical joint is denoted as

, and the distance between the base and the spherical joint is denoted as

. Each cable was actuated by a cable driving unit.

To describe the pose of the 3DJM, two frames were attached to the moving-platform (named moving frame {A}) and the base (named base frame {B}), which were both located at the center of the joint

O. With the two frames, the pose of the 3DJM can be represented by a rotation matrix

. Thus, the motion trajectory of the 3DJM was a parameterized curve

on

. The enhanced stiffness model of the 3DJM was established by using the covariant derivative of the load to the displacement on SO(3) [

30].

2.1. Displacement and Load of the 3DJM on SO(3)

According to the exponential formula [

31], the trajectory curve of the 3DJM

yields

where

is an element of Lie algebra

and satisfies

Here,

is called the coordinates of

. The derivative of

to time

t, i.e.,

, is an element of the tangent space of

at the point

, denoted as

. According to (

1),

satisfies the following equation

where

is the angular velocity of the 3DJM. Given

as the basis of

, where

,

and

, then

can be expressed as

where

are taken as the basis of

and

are always written as

for short. From (

4), it can be concluded that

is isomorphic to

.

Since

describes the velocity of the 3DJM, the instantaneous displacement of the 3DJM can be represented by

, yielding

That means the instantaneous displacement of the 3DJM can be described on the tangent space of

. Similarly, since the moment load

is an element of

, the dual space of

, by analogy with

and

, we define

as an element of the dual space of the tangent space

at

, called

cotangent space and denoted as

. The element of the cotangent space is named as the cotangent vector. Given

as the basis of

and

as the basis of

, then

satisfies

It shows that is isomorphic to . Thus, can be employed to represent the load applied on the 3DJM. That means the load applied on the 3DJM can be described on the cotangent space of .

2.2. Enhanced Stiffness Model of the 3DJM on SO(3)

According to the definition, the stiffness of the 3DJM is evaluated by the variation of its load against its displacement. However, the loads and displacements for different poses of the 3DJM are in different cotangent spaces and tangent spaces of SO(3). Considering the property of the motion of the 3DJM, an affine connection called

Levi-Civita connection is introduced into

to connect different tangent spaces on SO(3) [

32]. Given a curve

and a vector field

on

, the affine connection specifies how a vector

in the tangent space at point

can be mapped to another vector

of the tangent space at some other point

. The vector

is called the parallel transport of

along the curve

[

33]. Then, a differentiation operation can be defined on SO(3) as below

where

is called the

covariant derivative of

along the curve

. For two vectors,

and

, in the tangent spaces of SO(3),

is employed to represent the covariant derivative of

in the direction

. For a real-valued function

f on

, the covariant derivative

is usually written as

. According to the property of covariant derivative, the covariant derivative of the load

to the instantaneous displacement

can be written as

and

is employed as the stiffness of the 3DJM. The components of the stiffness matrix

, i.e.,

, yield

According to the property of the Levi–Civita connection [

30], we have

where the coefficients

are zero except

Furthermore, since the 3DJM is a conservative mechanical system, its stiffness matrix

can be proved to be symmetric at every pose, even if there is an external load applied on it [

30].

2.3. Parametric Stiffness Formulation of the 3DJM

In

Figure 2,

are the position vectors of points

and

, respectively. The vector from

to

along the

cable, denoted as

, yields

where

is the length of the cable from

to

and

is the unitary vector of

.

Let

be the cable tension vector of the

cable, where

is the value of the cable tension. According to the equilibrium equation, the moment load

applied on the moving platform with respect to the point

O satisfies

Denoting

as the vector of six cable tension values, the moment load

can be written as

where

is called the Jacobian matrix of the 3DJM and yields

Denoting

and

as the components of

, the components of

yield

Then, the expression

in (

10) can be written as

where

are the components of

when the 3DJM stays at the pose

.

Writing the six cable lengths as a vector

, then we have the following equation according to the principle of virtual work, i.e.,

Substituting (

14) into (

18), we have

It shows that

, where

is the component of

. Writing

as the stiffness of the

cable, the expression

in (

17) satisfies

Substituting (

16), (

17) and (

20) into the stiffness model (

10),

can be written as

Since

, the parametric formulation of the enhanced stiffness model (

10) is given below

where

and

.

3. Modeling of the Cable Tension Distribution Problem Oriented the Enhanced Stiffness of the 3DJM

For a given pose, the Jacobian matrix of the 3DJM is constant. The stiffness of the 3DJM only depends on the cable tensions according to (

22). That means the stiffness of the 3DJM can be adjusted by regulating the cable tensions. Given a desired feasible stiffness matrix

for the 3DJM at a given pose

with a load

, the corresponding cable tensions should be solved from the following equation

Due to the complexity of the stiffness formulation of the 3DJM, it is difficult to solve the cable tensions

from (

23) analytically.

As the stiffness

is a

real symmetric matrix in the frame {A}, there exists a real orthogonal matrix

to transfer the stiffness matrix from the frame {A} to another frame {E}, in which the symmetric stiffness matrix can be represented by a diagonal matrix [

34], i.e.,

where the orthogonal matrix

satisfies

and

represents the desired stiffness in the frame {E}. Here,

is the diagonal component of the diagonal matrix

.

Since the desired stiffness is a diagonal matrix in the frame {E}, we can discuss the SCTD problem in the frame {E} to make it simple. On the other hand, as the actual stiffness matrix

may not be exactly symmetric, a symmetric stiffness matrix

can be obtained as below

In the frame {E}, the symmetric actual stiffness

is represented by

, which yields

Denote

as the diagonal elements of

, the SCTD problem can be formulated as an optimization model

where

represents the minimum of the tension vector

to avoid the cable be slack and

represents the maximum of the tension vector

to avoid the cable tensions exceeding the capability of the cable driving units. Here,

represents that each element of

is no more than the corresponding element of

.

According to analysis of the rank of the Jacobian matrix of the 3DJM in the

Appendix A, we have

. Then, the column vectors of

can be divided into two parts,

. Here

yields

and it is called a basis of matrix

. Correspondingly, the cable tension vector

can be divided into two parts,

. That means the six driving cables can be divided into two groups: one group with three cables for position adjustment by regulating the cable lengths, and another group with the remaining three cables for stiffness adjustment by regulating the cable tensions. In this manner, the position and stiffness of 3DJM can be adjusted simultaneously. According to equilibrium Equation (

14), the tensions for the position adjustment cables, i.e.,

, can be represented by the tensions for the stiffness adjustment cables, i.e.,

, as follows

Substituting

into the optimization model (

28), the objective function

is simplified to

, i.e.,

and the linear inequality constraints are written as

where

and

Here,

represent the minimum of the tension vector

, respectively, and

represent the maximum of the tension vector

, respectively. Then, the optimization model (

28) is simplified to an equivalent model, where six decision variables are reduced to three and the linear equality constraint are eliminated, i.e.,

4. Cable Tension Solution Based on the Genetic Algorithm for the 3DJM

Since the objective function of the optimization model (

34) is complicated and the stiffness of the VSD relative to the cable tension does not need to be different at each point, the widely used gradient-based algorithms for nonlinear optimization problems are not suitable for this optimization model. The direct optimization methods, which do not need the gradient of the objective function, can be employed for this optimization model, such as Complex method, Nelder–Mead algorithm [

35] and genetic algorithm. In this paper, a generic method based on the genetic algorithm is proposed to solve the nonlinear constrained optimization model.

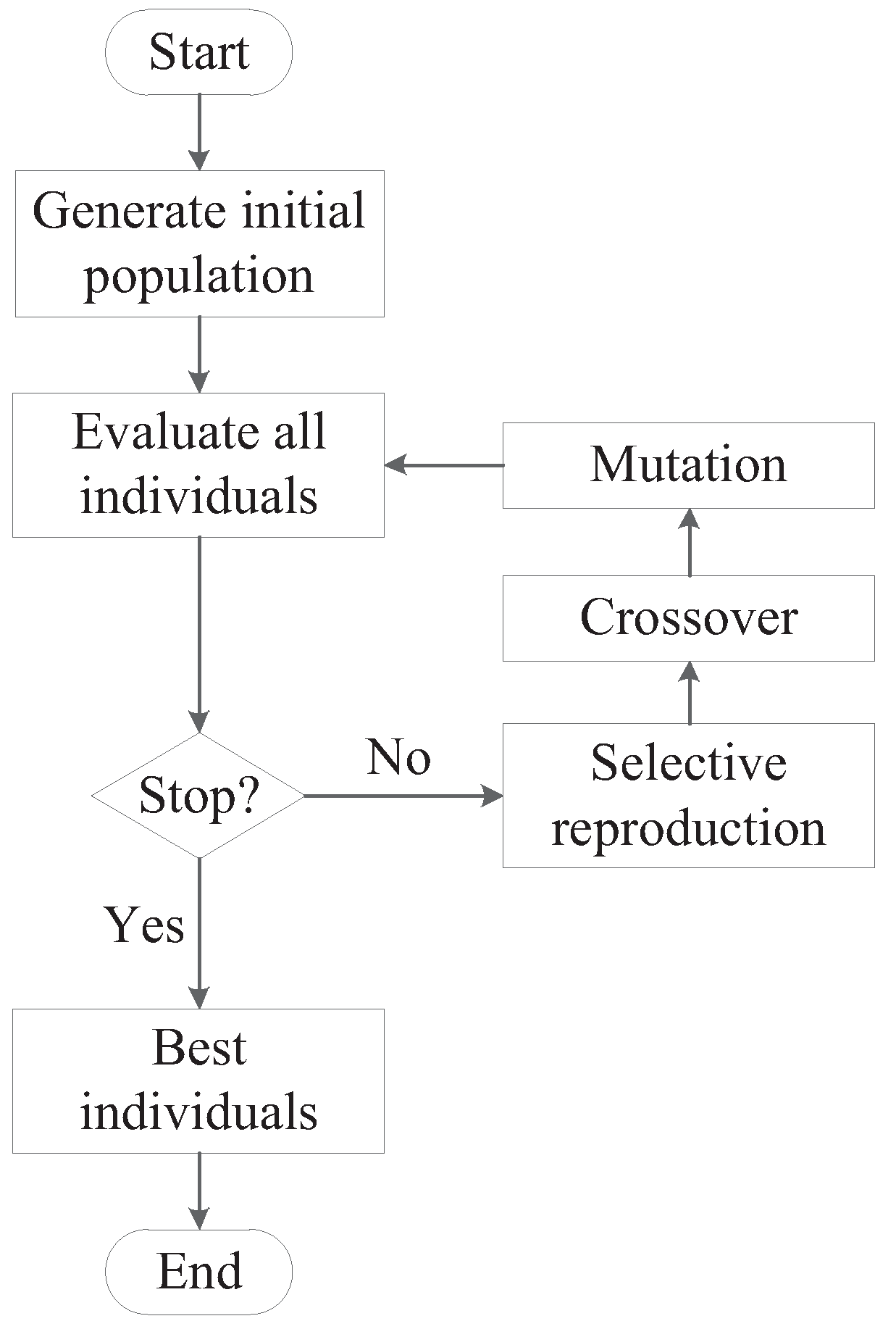

A genetic algorithm is inspired by biological evolutionary theory. It is an iterative procedure which usually operates on a population of constant size [

36]. In order to apply the genetic algorithm, we revise the optimization model (

34) as follows

where

is taken as an individual (also called a

chromosomes), and

is taken as the fitness function of the individual

.

The genetic algorithm is a stochastic iterative algorithm, where each iteration step is also called a

generation. Since the genetic algorithm cannot guarantee convergence [

36], the termination condition of the proposed method is commonly triggered by finding an acceptable solution for the problem or by reaching a maximum number of generations. Here, we define a parameter

to evaluate the closeness of two matrices

,

where

is the vector form of

and

is the norm of

. The iterative procedure of the proposed method is shown below, and it terminates when the following condition achieves

- Step 1:

Generate an initial population

Generate an initial population of individuals randomly or heuristically. Each individual can be represented by a binary string.

- Step 2:

Evaluate all individuals

Compute

via (

29), and evaluate the fitness function

for the individuals of the current population. If

does not satisfy

, set the fitness value as zero.

- Step 3:

Check termination condition

Check if the current population satisfies the termination condition. Stop the iterative procedure if it satisfies, and generate a new population if not.

- Step 4:

Selective reproduction

Select the individuals of the current population (usually with a probability proportional to their relative fitness values) and produce offspring candidates.

- Step 5:

Crossover and mutation

Perform two operators, named crossover and mutation, on the above offspring candidates for producing a new population. Execute Step 3 for the new population.

Crossover is the primary genetic operator, which swaps the substrings of two individuals, called parents, before and after a randomly selected crossover point to produce two new individuals, called offsprings.

Mutation is essentially an arbitrary modification, which flips bits randomly in a string with a certain probability called the mutation rate.

The diagram of the proposed method is shown in

Figure 3.

5. Simulation Examples

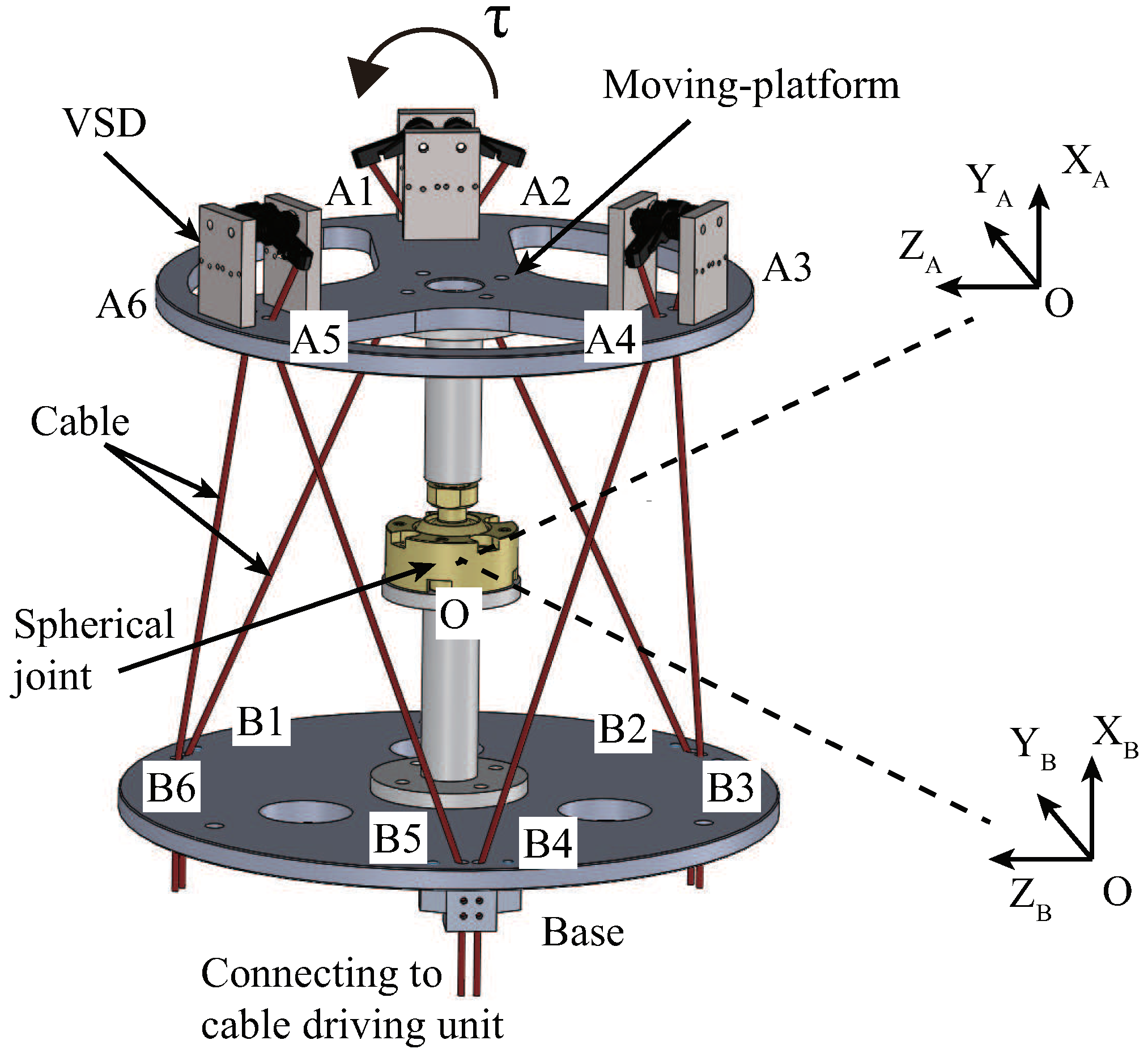

In order to validate the proposed method, a simulation was carried out on a certain 3DJM. As shown in

Figure 4, the dimensions of the 3DJM are given by

[m],

[m],

[m] and

[m].

The VSDs were designed to fix onto the moving platform of the 3DJM to extend the range of stiffness variation of each cable. The CAD model of the VSD is shown in

Figure 5a. According to the diagram of the VSD, as shown in

Figure 5b, the length of the cable in the VSD yields

and the cable tension

applied on the VSD yields

where

is the height of the revolute joint,

is the length of the rigid-link,

is the stiffness of the spring,

is the angle of the rigid-link, and

is the initial value of

. Then the stiffness of the VSD, denoted as

, can be described by

Given the parameters of the designed VSD, i.e.,

Nm/rad,

m,

m, and

rad, the stiffness of the VSD can be approximated by a polynomial expression

The corresponding stiffness–tension curve is shown in

Figure 5c. For this 3DJM, the lower limits of the cable tensions are given by

and the upper limits of the cable tensions are given by

The simulation examples are implemented for two different desired poses

and

with different loads, where

For each desired pose, three desired stiffness matrices are given. Thus, the simulation examples can be divided into six sub-cases, as listed in

Table 1.

Here, we take Case 1a as an example to perform the proposed method. The other five sub-cases are similar to Case 1a. In Case 1a, the rotation matrix

is computed according to (

24),

which transforms

to a diagonal matrix

[Nm/rad]. According to (

15), the transpose of the Jacobian matrix

of the 3DJM at the given pose

is computed

The matrix

is divided into two parts as below

The proposed method is implemented to solve the optimization model (

34) to find out the cable tension distribution for the desired stiffness

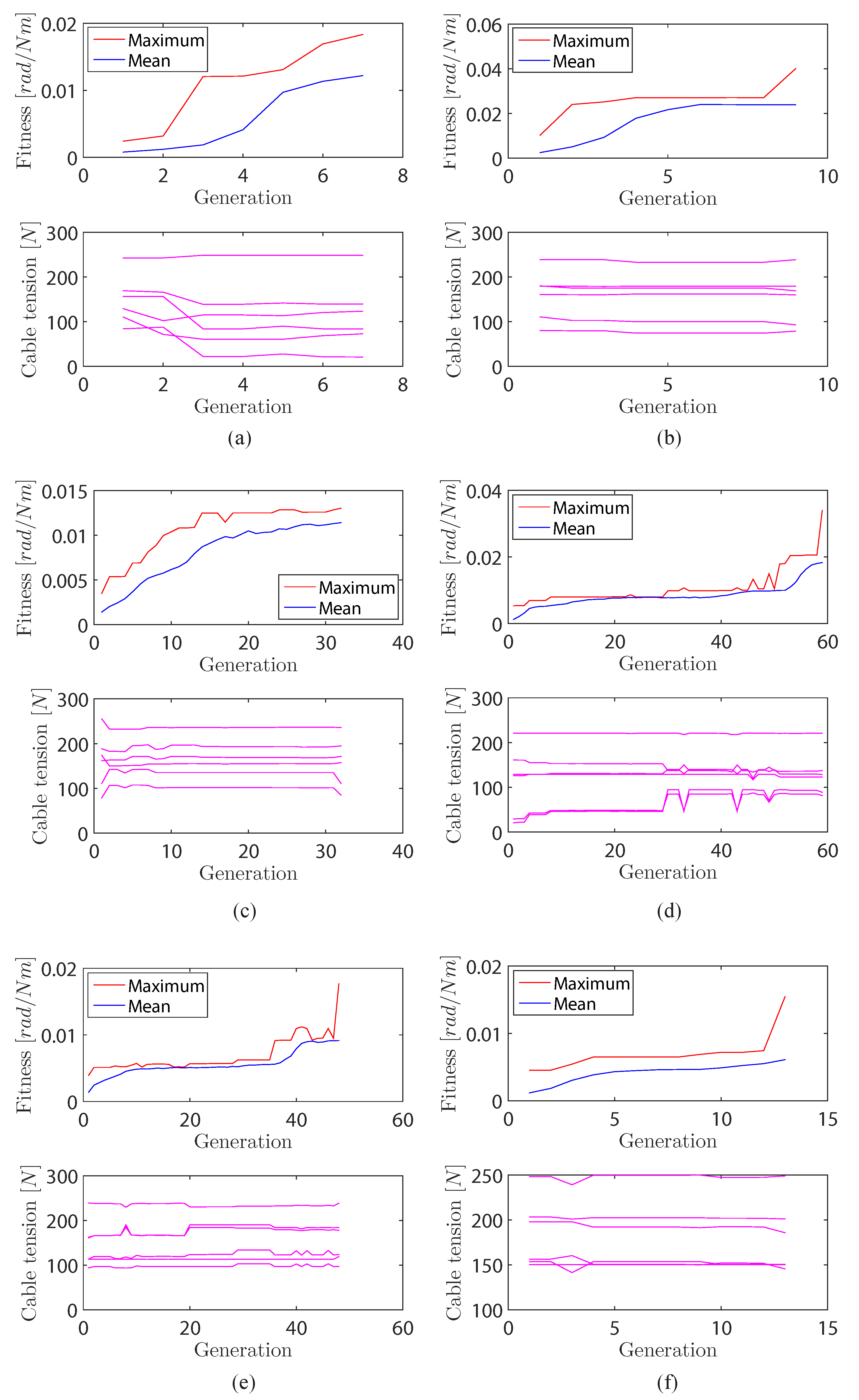

. The iteration curve of the proposed method for Case 1a is shown in

Figure 6a, which shows that the optimization process achieves the termination condition within 7 generations and the optimal cable tension distribution for the desired stiffness

is

The corresponding actual stiffness

and

are computed as below

According to (

36), in Case 1a,

. It shows that, when the cable tensions achieve

, the actual stiffness approaches the desired stiffness

.

The results of the simulation for all the six sub-cases are summarized in

Table 2 and the corresponding iteration curves of the proposed method are given in

Figure 6. The results show that the proposed method can achieve the desired stiffness accurately and efficiently. It is effective for the SCTD problem of the 3DJM.

6. Conclusions

Inspired by the structure of human arms, a modular cable-driven human-like robotic arm (CHRA) was developed for safe human–robot interaction, since it has advantage of flexibility, low moving mass and intrinsic safety. Due to the unilateral driving properties of the cables, the CHRA is redundantly actuated and its stiffness can be adjusted by regulating the cable tensions. The cable tension distribution problem becomes a key element for the stiffness adjustment of the CHRA. Since the trajectory of the 3-DOF joint module (3DJM) of the CHRA is a curve on Lie group SO(3), the stiffness of the 3DJM was evaluated by the covariant derivative of the load to the displacement on SO(3), called an enhanced stiffness model of the 3DJM. In this paper, we focus on analyzing how the cable tension distribution problem oriented the enhanced stiffness of the 3DJM. Since the enhanced stiffness model of the 3DJM is too complicated for solving the cable tensions from the desired stiffness analytically, the SCTD problem was formulated as a nonlinear optimization problem. By analyzing the rank of the Jacobian matrix and the equilibrium equation of the 3DJM, a variable elimination technique was employed to simplify the optimization model. A method based on the genetic algorithm was proposed to solve the optimization model, which only utilized the objective function values. The results of a comprehensive simulation show that the proposed method can solve the cable tension distribution from the desired stiffness accurately and efficiently.