Balancing Workload and Workforce Capacity in Lean Management: Application to Multi-Model Assembly Lines

Abstract

Featured Application

Abstract

1. Introduction

- (i)

- Low flexibility with respect to changes in demand. In addition, when models change, it is necessary to re-balance the line. Traditional lines were completely inflexible because they were designed for a single product but, currently, we may have multi-model and mixed-model lines as described in this paper. They allow production to meet demand.

- (ii)

- Balance loss due to an imperfect balance of the line and stochastic task times, resulting in blockage (parts have to wait before a workstation) and starvation (workers have to wait) [11].

- (iii)

- (iv)

- High costs of material handling (although this depends on the characteristics of the product) and high work-in-process, if lines are long. However, work-in-process is always smaller than in traditional batch-and-queue systems [12].

2. Relevant Literature on Multi-Model Assembly Lines

3. Materials and Methods: Workforce Capacity and Workload

3.1. A Few Definitions

3.2. From Single-Model to Multi-Model Production

3.3. Computing the Required Workforce

4. Staffing a Multi-Model Assembly Line

4.1. Problem Statement

4.2. Solution for a Combined Equivalent Model

4.3. Computing Manpower through Workload and Capacity

4.4. Balancing the Multi-Model Line

4.5. Optimizing the Assignation

5. Results of Computational Experiences

6. Discussion

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Mor, R.; Bhardwaj, A.; Singh, S.; Sachdeva, A. Productivity gains through standardization-of-work in a manufacturing company. J. Manuf. Technol. Manag. 2019, 30, 899–919. [Google Scholar] [CrossRef]

- Krafcik, J.F. Triumph of the lean production system. Sloan Manag. Rev. 1988, 30, 41–52. [Google Scholar]

- Womack, J.P.; Jones, D.T.; Roos, D. The Machine That Changed the World; Rawson Associates—Simon & Schuster: New York, NY, USA, 1990. [Google Scholar]

- Sugimori, Y.; Kusunoki, K.; Cho, F.; Uchikawa, S. Toyota production system and Kanban system: Materialization of just-in-time and respect-for-human system. Int. J. Prod. Res. 1977, 15, 553–564. [Google Scholar] [CrossRef]

- Monden, Y. Toyota Production System: Practical Approach to Production Management; Industrial Engineering and Management Press, Institute of Industrial Engineers: Norcross, GA, USA, 1983. [Google Scholar]

- Shah, R.; Ward, P.T. Defining and developing measures of lean production. J. Oper. Manag. 2007, 25, 785–805. [Google Scholar] [CrossRef]

- Cuatrecasas, L.; Fortuny-Santos, J.; Vintro, C. The operations-time chart: A graphical tool to evaluate the performance of production systems—From batch-and-queue to lean manufacturing. Comput. Ind. Eng. 2011, 61, 663–675. [Google Scholar] [CrossRef]

- Gjeldum, N.; Salah, B.; Aljinovic, A.; Khan, S. Utilization of Industry 4.0 related equipment in assembly line balancing procedure. Processes 2020, 8, 864. [Google Scholar] [CrossRef]

- Ghosh, S.; Gagnon, R.J. A comprehensive literature review and analysis of the design, balancing and scheduling of assembly systems. Int. J. Prod. Res. 1989, 27, 637–670. [Google Scholar] [CrossRef]

- Colim, A.; Faria, C.; Braga, A.C.; Sousa, N.; Rocha, L.; Carneiro, P.; Costa, N.; Arezes, P. Towards an ergonomic assessment framework for industrial assembly workstations—A case study. Appl. Sci. 2020, 10, 3048. [Google Scholar] [CrossRef]

- Bukchin, J.; Dar-El, E.M.; Rubinovitz, J. Mixed model assembly line design in a make-to-order environment. Comput. Ind. Eng. 2002, 41, 405–421. [Google Scholar] [CrossRef]

- Cuatrecasas-Arbós, L.; Fortuny-Santos, J.; Ruiz-de-Arbulo-López, P.; Vintró-Sanchez, C. Monitoring processes through inventory and manufacturing lead time. Ind. Manag. Data Syst. 2015, 115, 951–970. [Google Scholar] [CrossRef]

- Boysen, N.; Fliedner, M.; Scholl, A. Assembly line balancing: Which model to use when? Int. J. Prod. Econ. 2008, 111, 509–528. [Google Scholar] [CrossRef]

- Ohno, T. Toyota Production System: Beyond Large-Scale Production; Productivity Press: New York, NY, USA, 1988. [Google Scholar]

- Bukchin, J.; Darel, E.; Rubinovitz, J. Team-oriented assembly systems design: A new approach. Int. J. Prod. Econ. 1997, 51, 47–57. [Google Scholar] [CrossRef]

- Ben-Gal, I.; Bukchin, J. The ergonomic design of workstations using virtual manufacturing and response surface methodology. IIE Trans. 2002, 34, 375–391. [Google Scholar] [CrossRef]

- Seppälä, P.; Klemola, S. How do employees perceive their organization and job when companies adopt principles of lean production? Hum. Factors Ergon. Manuf. 2004, 14, 157–180. [Google Scholar] [CrossRef]

- Cevikcan, E. An optimization methodology for multi model walking-worker assembly systems: An application from busbar energy distribution systems. Assem. Autom. 2016, 36, 439–459. [Google Scholar] [CrossRef]

- Chutima, P.; Suphapruksapongse, H. Practical assembly-line balancing in a monitor manufacturing company. Thammasat Int. J. Sci. Technol. 2004, 9, 62–70. [Google Scholar]

- Erel, E.; Sarin, S.C. A survey on the assembly line procedures. Prod. Plan. Control 1998, 9, 414–434. [Google Scholar] [CrossRef]

- Roser, C.H. Line Balancing Part 6—Tips and Tricks for Balancing. Available online: https://www.allaboutlean.com/line-balancing-6/ (accessed on 24 September 2020).

- Nagi, M.; Chen, F.F.; Wan, H.-D. Throughput rate improvement in a multiproduct assembly line using lean and simulation modeling and analysis. Procedia Manuf. 2017, 11, 593–601. [Google Scholar] [CrossRef]

- Agpak, K.; Gökçen, H. Assembly line balancing: Two resource constrained cases. Int. J. Prod. Econ. 2005, 96, 129–140. [Google Scholar] [CrossRef]

- Corominas, A.; Pastor, R.; Plans, J. Balancing assembly line with skilled and unskilled workers. Omega 2008, 36, 1126–1132. [Google Scholar] [CrossRef]

- Sivasankaran, P.; Shahabudeen, P. Literature review of assembly line balancing problems. Int. J. Adv. Manuf. Technol. 2014, 73, 1665–1694. [Google Scholar] [CrossRef]

- Roberts, S.D.; Villa, C.D. On a multiproduct assembly line balancing problem. AIIE Trans. 1970, 2, 361–364. [Google Scholar] [CrossRef]

- Becker, C.; Scholl, A. A survey on problems and methods in generalized assembly line balancing. Eur. J. Oper. Res. 2006, 168, 694–715. [Google Scholar] [CrossRef]

- Thomopoulos, N.T. Line balancing-sequencing for mixed-model assembly. Manag. Sci. 1967, 14, B59–B75. [Google Scholar] [CrossRef]

- Thomopoulos, N.T. Mixed model line balancing with smoothed station assignments. Manag. Sci. 1970, 16, 593–603. [Google Scholar] [CrossRef]

- Buxey, G.M.; Slack, N.D.; Wild, R. Production flow line system design—A review. AIIE Trans. 1973, 5, 37–48. [Google Scholar] [CrossRef]

- Eryuruk, S.H.; Kaloglu, F.; Baskak, M. Assembly line balancing in a clothing company. Fibres Text. East. Eur. 2008, 16, 93–98. [Google Scholar]

- Al-Zubaidy, S.S.; Alrazaq, F.F.A. Multi-model production and assembly line balancing (Caravans production workshop). J. Univ. Babylon Eng. Sci. 2013, 21, 1301–1312. [Google Scholar]

- Kabir, M.A.; Tabucanon, M.T. Batch-model assembly line balancing: A multi attribute decision making approach. Int. J. Prod. Econ. 1995, 41, 193–201. [Google Scholar] [CrossRef]

- Roser, C.H. Line Balancing Part 2—Duration of Tasks. Available online: https://www.allaboutlean.com/line-balancing-2/ (accessed on 24 September 2020).

- Pastor, R.; Andres, C.; Duran, A.; Perez, M. Tabu search algorithms for an industrial multi-product and multi-objective assembly line balancing problem, with reduction of the task dispersion. J. Oper. Res. Soc. 2002, 53, 1317–1323. [Google Scholar] [CrossRef]

- Qu, S.; Jiang, Z. A memetic algorithm approach for batch-model assembly line balancing problem of sub-block in shipbuilding. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2014, 228, 1290–1304. [Google Scholar] [CrossRef]

- Berger, I.; Bourjolly, J.M.; Laporte, G. Branch-and-bound algorithms for the multi-product assembly line balancing problem. Eur. J. Oper. Res. 1992, 58, 215–222. [Google Scholar] [CrossRef]

- Zhao, C.; Li, J. Analysis and improvement of multi-product assembly systems: An application study at a furniture manufacturing plant. Int. J. Prod. Res. 2014, 52, 6399–6413. [Google Scholar] [CrossRef]

- Aqlan, F.; Al-Fandi, L. Prioritizing process improvement initiatives in manufacturing environments. Int. J. Prod. Econ. 2018, 196, 261–268. [Google Scholar] [CrossRef]

- Coleman, J.B.; Vaghefi, R.A. Heijunka (?): A key to the Toyota Production System. Prod. Invent. Manag. J. 1994, 35, 31–35. [Google Scholar]

- Cuatrecasas, L. Ingeniería de Procesos y de Planta; Profit Editorial: Barcelona, Spain, 2017. [Google Scholar]

- Hirano, H. JIT Implementation Manual; CRC Press: Boca Raton, FL, USA, 2009; Volume 4. [Google Scholar]

- Meyers, F.E.; Stewart, J.R. Motion and Time Study for Lean Manufacturing; Prentice Hall: Upper Saddle River, NJ, USA, 2002. [Google Scholar]

- Baybars, I. A survey of exact algorithms for the simple assembly line balancing problem. Manag. Sci. 1986, 32, 909–932. [Google Scholar] [CrossRef]

- Matsui, Y. An empirical analysis of just-in-time production in Japanese manufacturing companies. Int. J. Prod. Econ. 2007, 108, 153–164. [Google Scholar] [CrossRef]

- Koo, P.-H. A new self-balancing assembly line based on collaborative ant behavior. Appl. Sci. 2020, 10, 6845. [Google Scholar] [CrossRef]

- Faganello, R.; Amaral, V. Logic-based Benders decomposition for the heterogeneous fixed fleet vehicle routing problem with time windows. Comput. Ind. Eng. 2020, 148, 106641. [Google Scholar]

- Valdron, M.; Pu, K.Q. Data Driven Relational Constraint Programming. In Proceedings of the IEEE 21st International Conference on Information Reuse and Integration for Data Science (IRI), Las Vegas, NV, USA, 11–13 August 2020; pp. 156–163. Available online: https://doi.ieeecomputersociety.org/10.1109/IRI49571.2020.00030 (accessed on 24 September 2020).

- Cevikcan, E.; Durmusoglu, M.B.; Unal, M.E. A team-oriented design methodology for mixed model assembly systems. Comput. Ind. Eng. 2009, 56, 576–599. [Google Scholar] [CrossRef]

- Erel, E.; Gokcen, H. Shortest-route formulation of mixed-model assembly line balancing problem. Eur. J. Oper. Res. 1999, 116, 194–204. [Google Scholar] [CrossRef]

- Fortuny-Santos, J.; Ruiz-de-Arbulo López, P.; Luján-Blanco, I.; Chen, P.K. Assessing the synergies between lean manufacturing and Industry 4.0. Dir. Organ. 2020, 71, 71–86. [Google Scholar] [CrossRef]

- Chutima, P. Research Trends and Outlooks in Assembly Line Balancing Problems. Eng. J. 2020, 24, 93–134. [Google Scholar] [CrossRef]

- Christensen, M.K.; Janardhanan, M.N.; Nielsen, P. Heuristics for solving a multi-model robotic assembly line balancing problem. Prod. Manuf. Res. 2017, 5, 410–424. [Google Scholar] [CrossRef]

- Rubinovitz, J.; Bukchin, J.; Lenz, E. RALB—A Heuristic Algorithm for Design and Balancing of Robotic Assembly Lines. CIRP Ann. Manuf. Technol. 1993, 4, 497–500. [Google Scholar] [CrossRef]

| Operation X | Operation Y | Total Unit Workload per Model TWuk = ΣWuik | |||

|---|---|---|---|---|---|

| Model (k) | Load (Man- Hours) qik | Unit Workload Wuik = qik/CPik | Load (Man- Hours) qik | Unit Workload Wuik = qik/CPik | |

| Model A (1) | 48 | 48/8 = 6 | 16 | 16/8 = 2 | 6 + 2 = 8 |

| Model B (2) | 8 | 8/8 = 1 | 24 | 24/8 = 3 | 1 + 3 = 4 |

| Total multi-model unit workload TWu = ΣTWuk = | 12 | ||||

| Model (k) | Demand per Month (Units/Month) | Daily Production (qk) (Units/Day) | Production Proportion (ωk = qk/Σqk) | |

|---|---|---|---|---|

| 1 | Alpha | 30,800 | 1400 | 4/7 |

| 2 | Beta | 15,400 | 700 | 2/7 |

| 3 | Gamma | 7700 | 350 | 1/7 |

| Total | 53,900 | 2450 | 1 | |

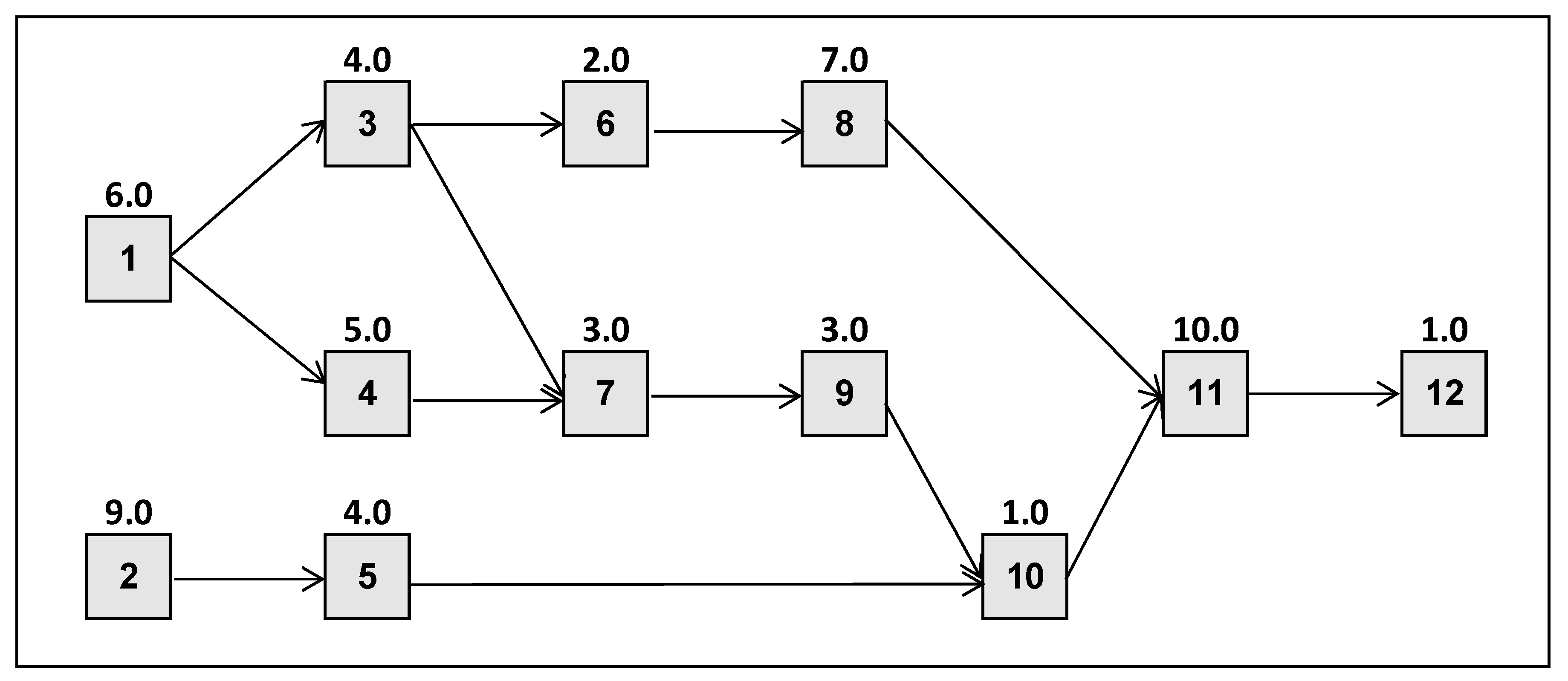

| Task | Alpha | Beta | Gamma |

|---|---|---|---|

| 1 | 6.0 | 5.0 | 8.0 |

| 2 | 7.0 | 11.0 | 13.0 |

| 3 | 4.0 | 6.0 | - |

| 4 | 5.0 | 5.0 | 5.0 |

| 5 | 5.0 | 3.0 | 2.0 |

| 6 | 2.0 | 1.0 | 4.0 |

| 7 | 4.0 | 1.0 | 3.0 |

| 8 | 7.0 | 4.0 | 13.0 |

| 9 | 3.0 | 4.0 | 1.0 |

| 10 | 1.0 | 1.0 | 1.0 |

| 11 | 10.0 | 11.0 | 8.0 |

| 12 | 1.0 | - | 3.0 |

| Sum | 55.0 | 52.0 | 61.0 |

| Workstation (j) | Tasks (i) | Station Time (*) (s) |

|---|---|---|

| 1 | 1–4 | 11.0 |

| 2 | 2 | 9.0 |

| 3 | 3–5–6 | 10.0 |

| 4 | 7–8 | 10.0 |

| 5 | 9–10 | 4.0 |

| 6 | 11–12 | 11.0 |

| Model (k): | Alpha (1) | Beta (2) | Gamma (3) | |||

|---|---|---|---|---|---|---|

| Daily Volume qi | 1400 Units | 700 Units | 350 Units | |||

| Task (i) | Capacity (Units/Day) CPik | Unit Load Wuik | Capacity (Units/Day) CPik | Unit Load Wuik | Capacity (Units/Day) WPik | Unit Load Wuik |

| 1 | 4800.0 | 0.292 | 5760.0 | 0.122 | 3600.0 | 0.097 |

| 2 | 4114.3 | 0.340 | 2618.2 | 0.267 | 2215.4 | 0.158 |

| 3 | 7200.0 | 0.194 | 4800.0 | 0.146 | - | 0.000 |

| 4 | 5760.0 | 0.243 | 5760.0 | 0.122 | 5760.0 | 0.061 |

| 5 | 5760.0 | 0.243 | 9600.0 | 0.073 | 14,400.0 | 0.024 |

| 6 | 14,400.0 | 0.097 | 28,800.0 | 0.024 | 7200.0 | 0.049 |

| 7 | 7200.0 | 0.194 | 28,800.0 | 0.024 | 9600.0 | 0.036 |

| 8 | 4114.3 | 0.340 | 7200.0 | 0.097 | 2215.4 | 0.158 |

| 9 | 9600.0 | 0.146 | 7200.0 | 0.097 | 28,800.0 | 0.012 |

| 10 | 28,800.0 | 0.049 | 28,800.0 | 0.024 | 28,800.0 | 0.012 |

| 11 | 2880.0 | 0.486 | 2618.2 | 0.267 | 3600.0 | 0.097 |

| 12 | 28,800.0 | 0.049 | - | 0.000 | 9600.0 | 0.036 |

| TWuk = ΣWuik | 2.674 | 1.264 | 0.741 | |||

| Total multi-model unit load (TWu) = ΣTWuk = 4.679 | ||||||

| Task (i) | Alpha | Beta | Gamma |

|---|---|---|---|

| 1 | 0.00021 | 0.00017 | 0.00028 |

| 2 | 0.00024 | 0.00038 | 0.00045 |

| 3 | 0.00014 | 0.00021 | 0 |

| 4 | 0.00017 | 0.00017 | 0.00017 |

| 5 | 0.00017 | 0.00010 | 0.00007 |

| 6 | 0.00007 | 0.00003 | 0.00014 |

| 7 | 0.00014 | 0.00003 | 0.00010 |

| 8 | 0.00024 | 0.00014 | 0.00045 |

| 9 | 0.00010 | 0.00014 | 0.00003 |

| 10 | 0.00003 | 0.00003 | 0.00003 |

| 11 | 0.00035 | 0.00038 | 0.00028 |

| 12 | 0.00003 | 0 | 0.00010 |

| Σ(1/CPik) | 0.00191 | 0.00181 | 0.00212 |

| TWu/Σ(1/CPik) (units/day) | 2450.00 | 2591.35 | 2209.02 |

| Task (i) | Alpha | Beta | Gamma |

|---|---|---|---|

| 1 | 0.51042 | 0.44989 | 0.61362 |

| 2 | 0.59549 | 0.98975 | 0.99713 |

| 3 | 0.34028 | 0.53986 | 0 |

| 4 | 0.42535 | 0.44989 | 0.38351 |

| 5 | 0.42535 | 0.26993 | 0.15340 |

| 6 | 0.17014 | 0.08998 | 0.30681 |

| 7 | 0.34028 | 0.08998 | 0.23011 |

| 8 | 0.59549 | 0.35991 | 0.99713 |

| 9 | 0.25521 | 0.35991 | 0.07670 |

| 10 | 0.08507 | 0.08998 | 0.07670 |

| 11 | 0.85069 | 0.98975 | 0.61362 |

| 12 | 0.08507 | 0 | 0.23011 |

| TWuk = ΣWu*ik | 4.679 | 4.679 | 4.679 |

| Model (k) | Unit Load TWuk | Production Time (min/Day) TPk | Production Rate (Units/Day) Pik | Daily Output (Units) Pk |

|---|---|---|---|---|

| Alpha | 2.674 | 274.0 | 2450.00 | 1400 |

| Beta | 1.264 | 130.0 | 2591.35 | 700 |

| Gamma | 0.741 | 76.0 | 2209.02 | 350 |

| Total | 4.679 | 480.0 | - | 2450 |

| Model (k): | Alpha | Beta | Gamma | |||

|---|---|---|---|---|---|---|

| Workstation (j) | Tasks (i) | Unit Load ΣWu*ik | Tasks (i) | Unit Load ΣWu*ik | Tasks (i) | Unit Load ΣWu*ik |

| 1 | 1–4 | 0.94 | 1–4 | 0.90 | 1–4 | 1.00 |

| 2 | 2–3 | 0.94 | 2 | 0.99 | 2 | 1.00 |

| 3 | 5–6–7 | 0.94 | 3–5–6–7 | 0.99 | 5–6–7 | 0.69 |

| 4 | 8–9–10 | 0.94 | 8–9–10 | 0.81 | 8 | 1.00 |

| 5 | 11–12 | 0.94 | 11 | 0.99 | 9–10–11–12 | 1.00 |

| Model (k): | Alpha | Beta | Gamma | |||

|---|---|---|---|---|---|---|

| Workstation (j) | Tasks (i) | Unit Load ΣWu*ik | Tasks (i) | Unit Load ΣWu*ik | Tasks (i) | Unit Load ΣWu*ik |

| 1 | 2 | 0.60 | 2 | 0.99 | 2 | 1.00 |

| 2 | 1–4 | 0.94 | 1–4 | 0.90 | 1–4 | 0.65 |

| 3 | 3–5–6 | 0.94 | 3–5–6 | 0.90 | 5–6 | 0.46 |

| 4 | 8 | 0.60 | 8 | 0.36 | 8 | 1.00 |

| 5 | 7–9–10 | 0.68 | 7–9–10 | 0.54 | 7–9–10 | 0.38 |

| 6 | 11–12 | 0.94 | 11 | 0.99 | 11–12 | 0.85 |

| Workstation (j) | Model 1 (β2 = 1) | Model 2 (β2 = 1) | Model 3 (β2 = 1) | Models 1, 2 and 3 (β2 = 4) |

|---|---|---|---|---|

| 1 | 1–2 | 1–2–5 | 1–2–3 | 1–2 |

| 2 | 3–4–9 | 3–4–9 | 4–5–9 | 3–4 |

| 3 | 5–6–7 | 6–7 | 6–7 | 6–7 |

| 4 | 8–10–12 | 8–10–12 | 8–10–12 | 5–10 |

| 5 | 11–13–14–15 | 11–13–14–15 | 11–13–14–15 | 8–9–12–14 |

| 6 | - | - | - | 11–13–15 |

| Available Time (min) | Theoretical Minimum Number of Workstations | Number of Workstations in Multi-Model Line | Tasks Assigned to Constant Workstations | Efficiency | Average (*) CPU Time (s) |

|---|---|---|---|---|---|

| 480 | 2.59 | 3 | 19 | 0.86 | 0.09 |

| 458 | 2.71 | 3 | 19 | 0.90 | 0.09 |

| 436 | 2.85 | 3 | 18 (Except task 18) | 0.95 | 0.12 |

| 414 | 3.00 | 4 | 19 | 0.75 | 0.14 |

| Workstation | Model 1, 2, 5 and 6 | Model 3 and 4 |

|---|---|---|

| 1 | 3230-3255-3265-3285 | 3230-3240-3255-3265-3285 |

| 2 | 3245-3290-3335 | 3245-3290-3335 |

| 3 | 3235-3305-3360 | 3235-3305-3360 |

| 4 | 3275-3295-3300 | 3275-3295-3300 |

| 5 | 3310-3315-3340 | 3310-3315-3340 |

| 6 | 3250-3280-3365 | 3250-3280-3365 |

| 7 | 3330-3370 | 3330-3370 |

| 8 | 3345 | 3345 |

| 9 | 3320-3375-3380 | 3320-3375-3380 |

| 10 | 3385-3405 | 3385-3405 |

| 11 | 3325-3390-3395 | 3325-3390-3395 |

| 12 | 3350 | 3350 |

| 13 | 3240-3270-3355 | 3270-3355 |

| 14 | 3400 | 3400 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fortuny-Santos, J.; Ruiz-de-Arbulo-López, P.; Cuatrecasas-Arbós, L.; Fortuny-Profitós, J. Balancing Workload and Workforce Capacity in Lean Management: Application to Multi-Model Assembly Lines. Appl. Sci. 2020, 10, 8829. https://doi.org/10.3390/app10248829

Fortuny-Santos J, Ruiz-de-Arbulo-López P, Cuatrecasas-Arbós L, Fortuny-Profitós J. Balancing Workload and Workforce Capacity in Lean Management: Application to Multi-Model Assembly Lines. Applied Sciences. 2020; 10(24):8829. https://doi.org/10.3390/app10248829

Chicago/Turabian StyleFortuny-Santos, Jordi, Patxi Ruiz-de-Arbulo-López, Lluís Cuatrecasas-Arbós, and Jordi Fortuny-Profitós. 2020. "Balancing Workload and Workforce Capacity in Lean Management: Application to Multi-Model Assembly Lines" Applied Sciences 10, no. 24: 8829. https://doi.org/10.3390/app10248829

APA StyleFortuny-Santos, J., Ruiz-de-Arbulo-López, P., Cuatrecasas-Arbós, L., & Fortuny-Profitós, J. (2020). Balancing Workload and Workforce Capacity in Lean Management: Application to Multi-Model Assembly Lines. Applied Sciences, 10(24), 8829. https://doi.org/10.3390/app10248829