A Hybrid Soft Actuator Inspired by Grass-Spike: Design Approach, Dynamic Model, and Applications

Abstract

1. Introduction

2. Hybrid Soft Actuator Design

2.1. Appearance Inspired by a Grass-Spike

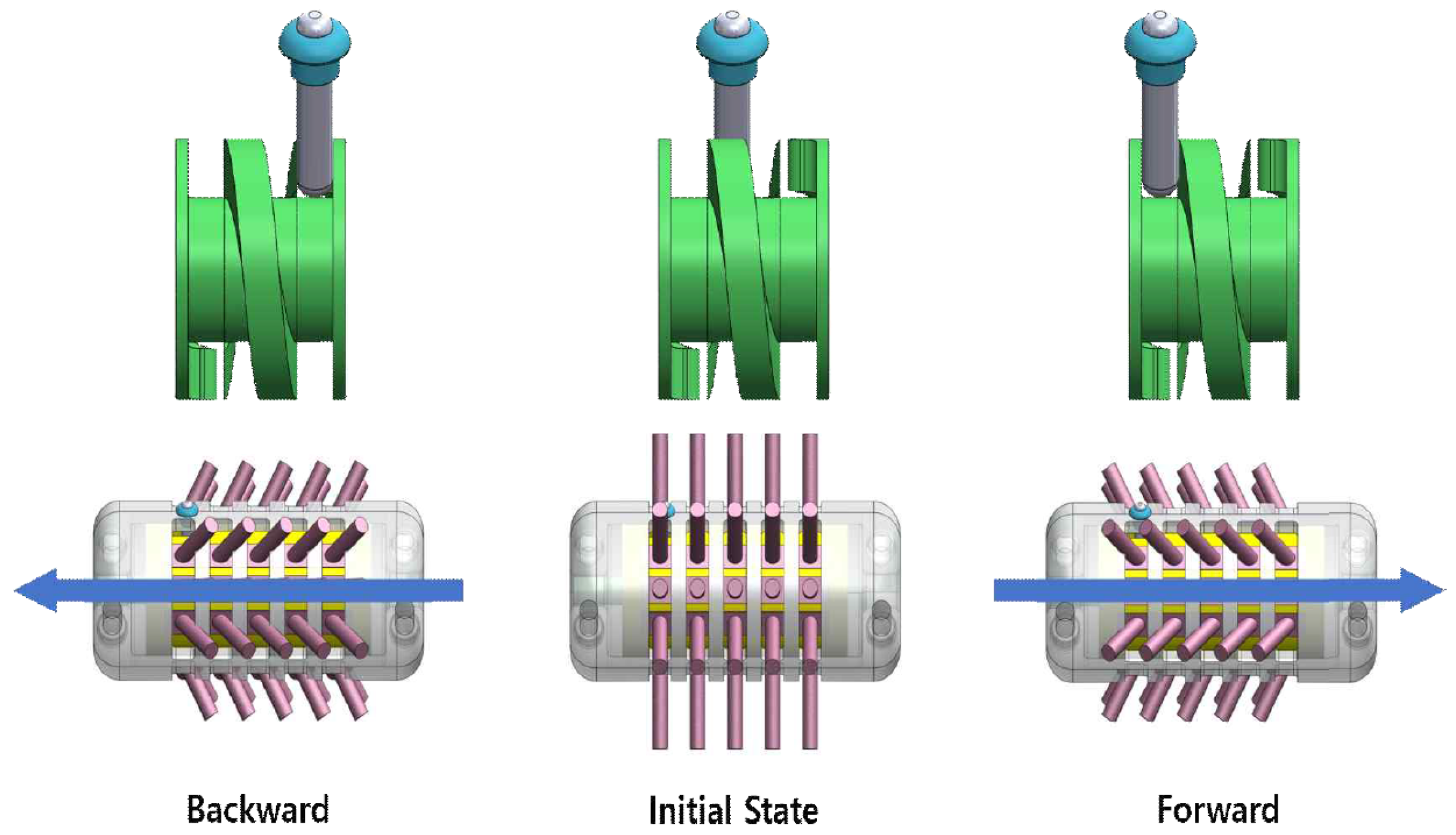

2.2. All-in-One Mechanism to Move and Change Direction

3. Dynamic Models

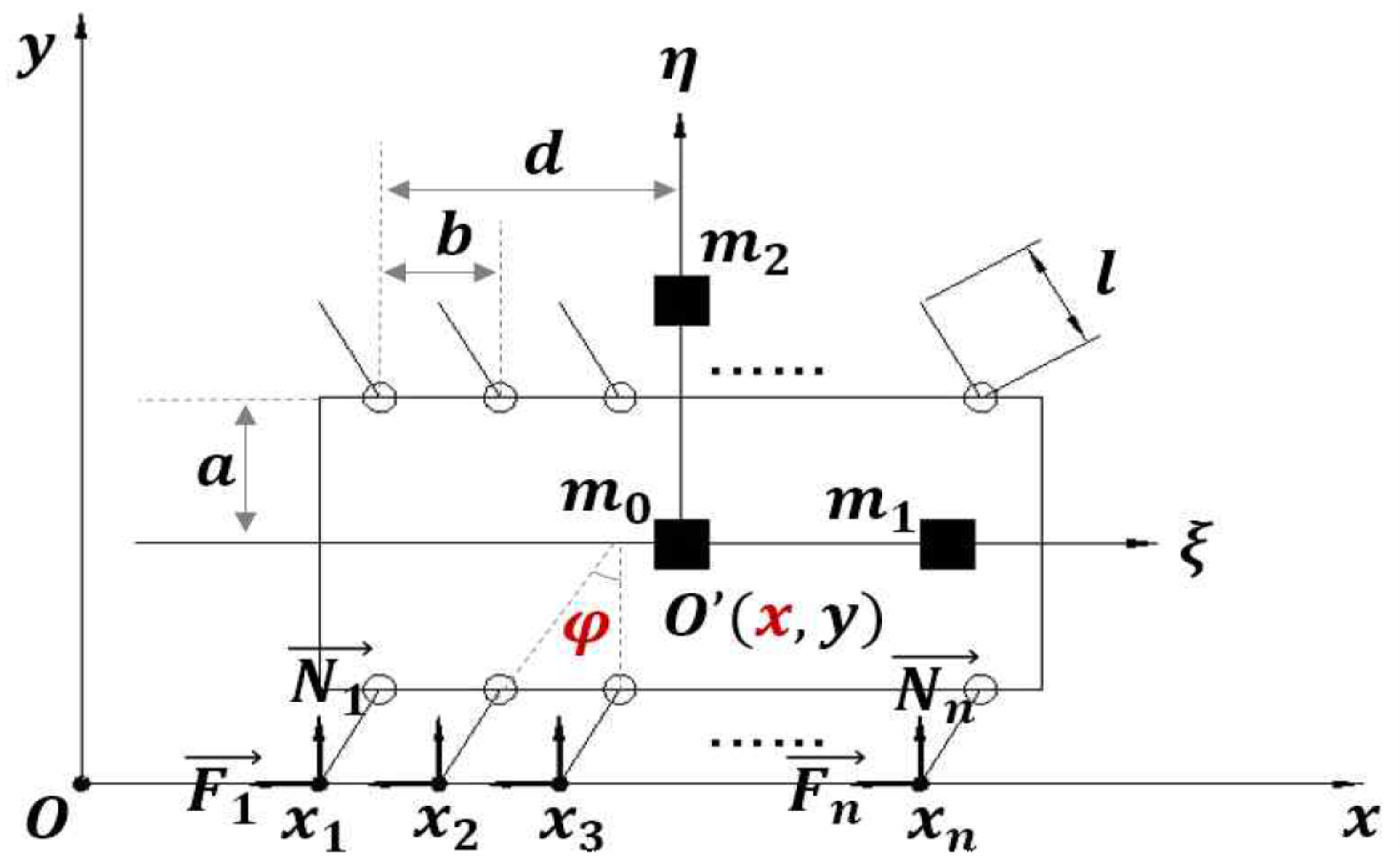

3.1. A Single HSA Model

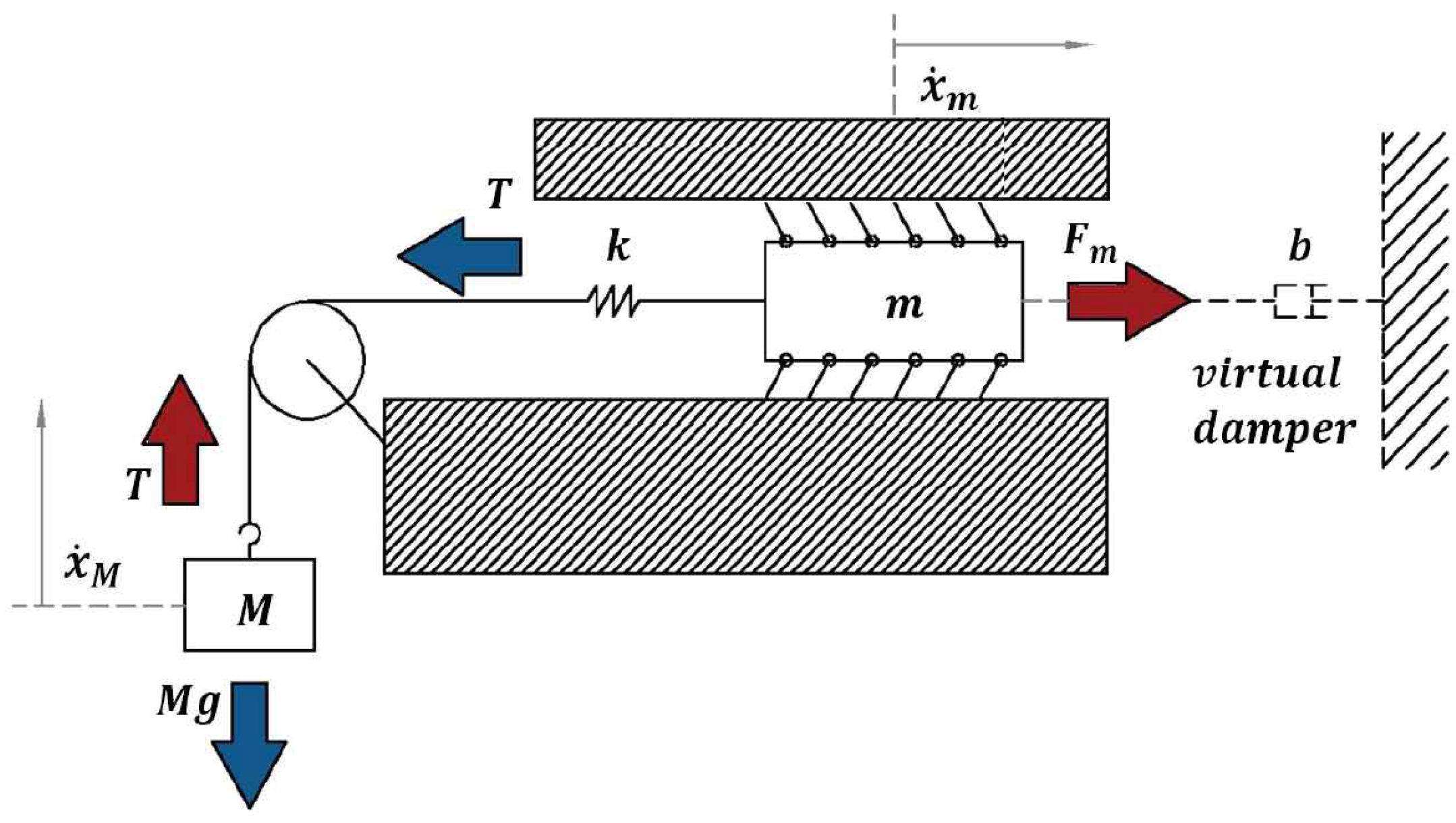

3.2. The Interactive Control Model for an HSAM and a Wire-Attached Mass

4. Experiments

4.1. Preliminary Experiment

4.2. System Identification to Estimate the Friction Coefficient

- Apply various motor revolution speeds to a real HSA and record the traveled distance x after 5 s. was set to 80, 120, 160, and 200 rev/s. For each value, ten traveled distances were recorded. Then, the recorded distances were averaged after excluding the minimum and the maximum value.

- Initialize as an arbitrary value. Let s, and run the simulations using Equations (20)–(23). Store the outputs (here, the subscript “s” is employed to distinguish the real measurement value from the simulation outputs).

- Define the error function to be , and find the that minimizes e.

4.3. Estimating the Virtual Damping Coefficient b

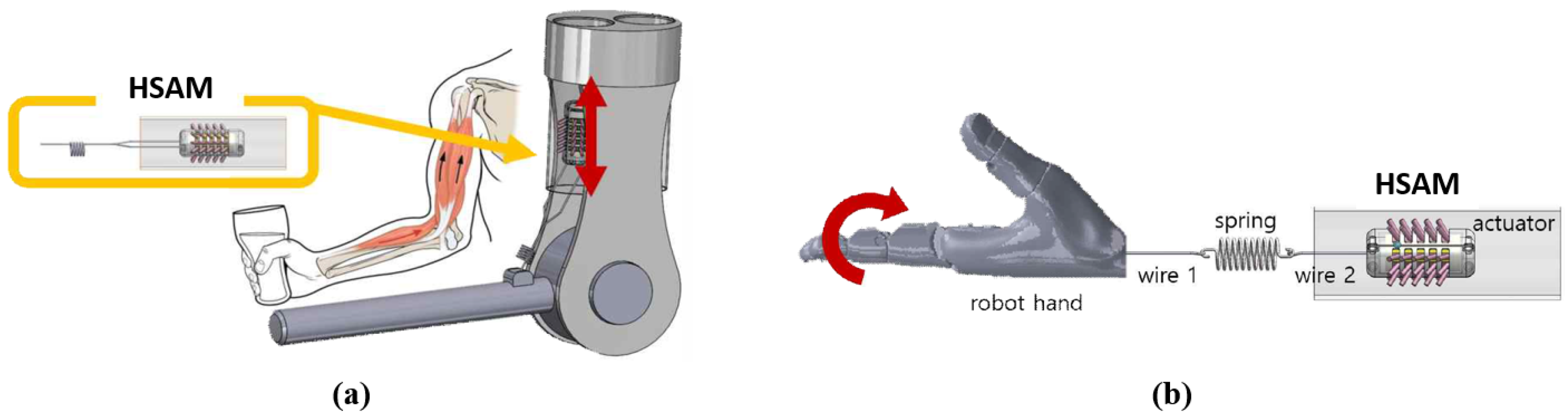

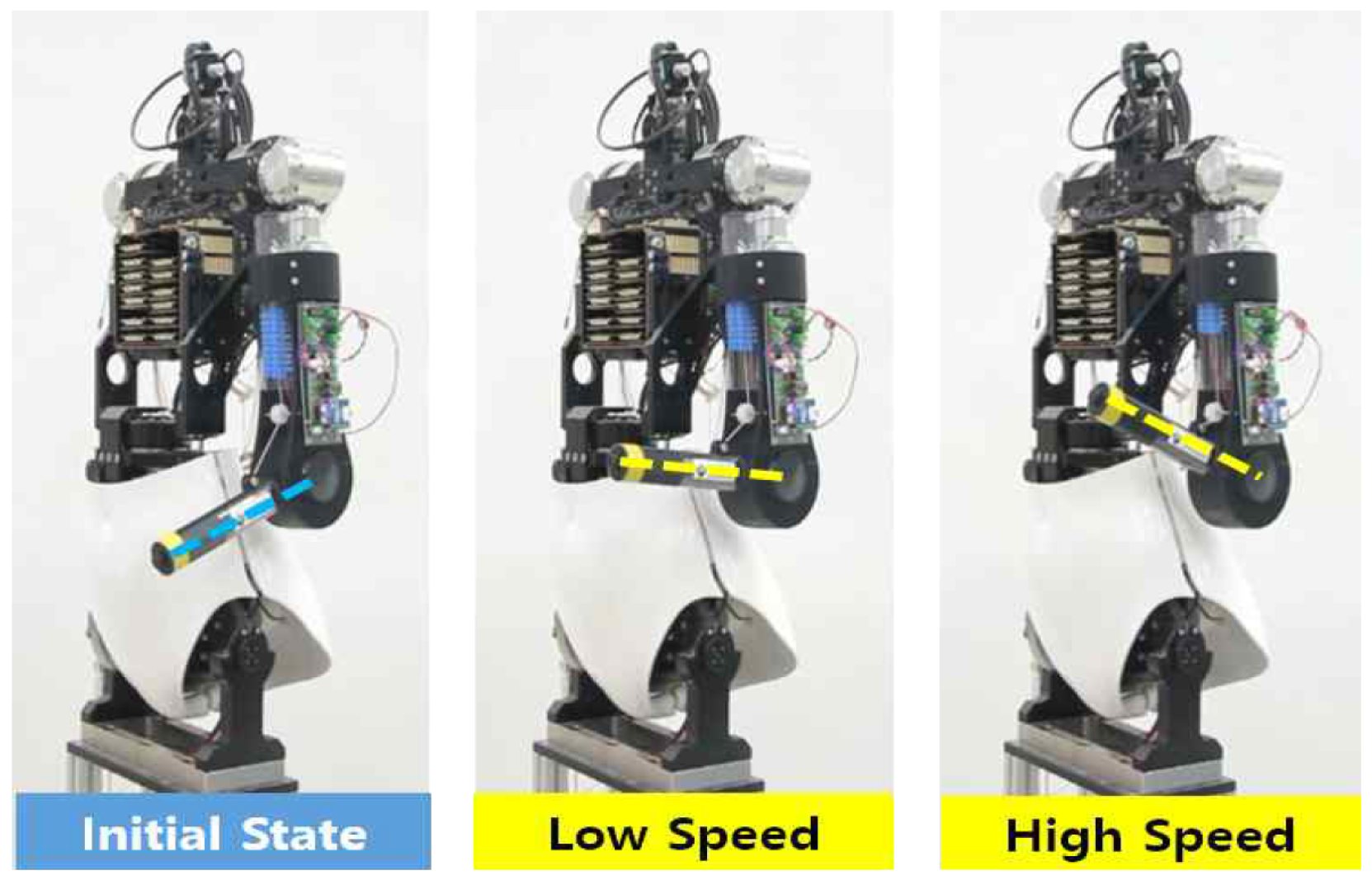

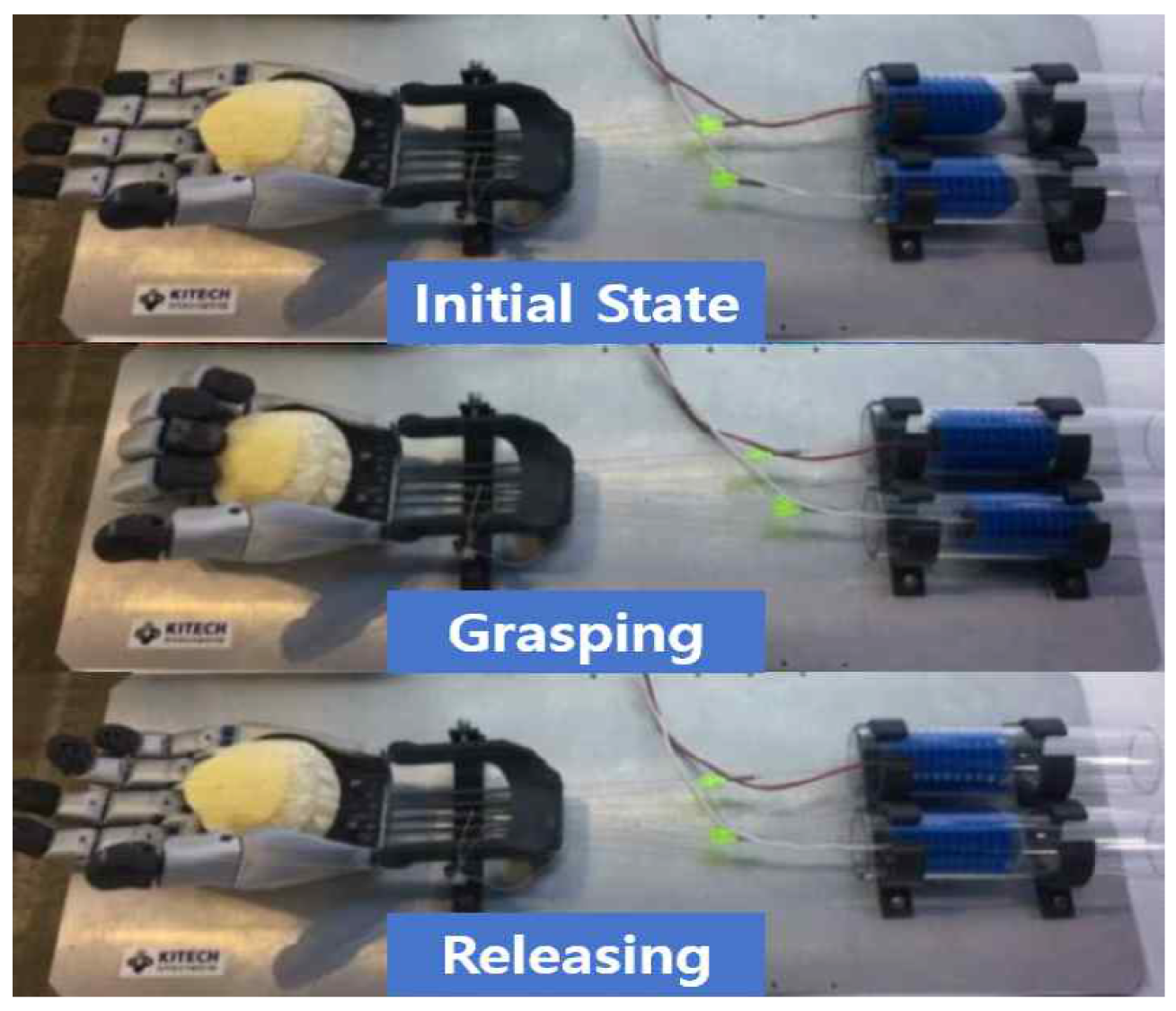

4.4. Two Real Manipulating Applications

5. Results

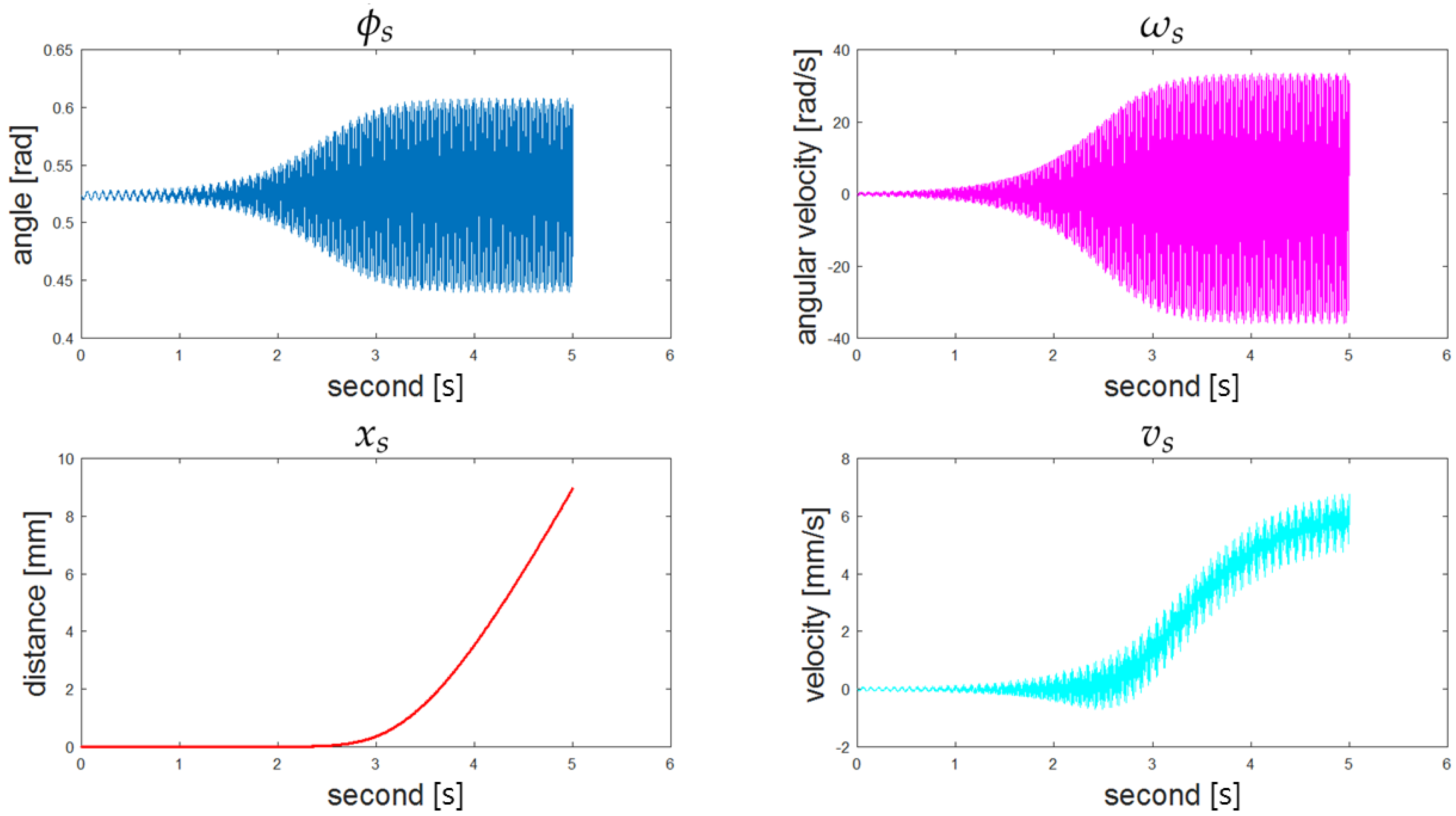

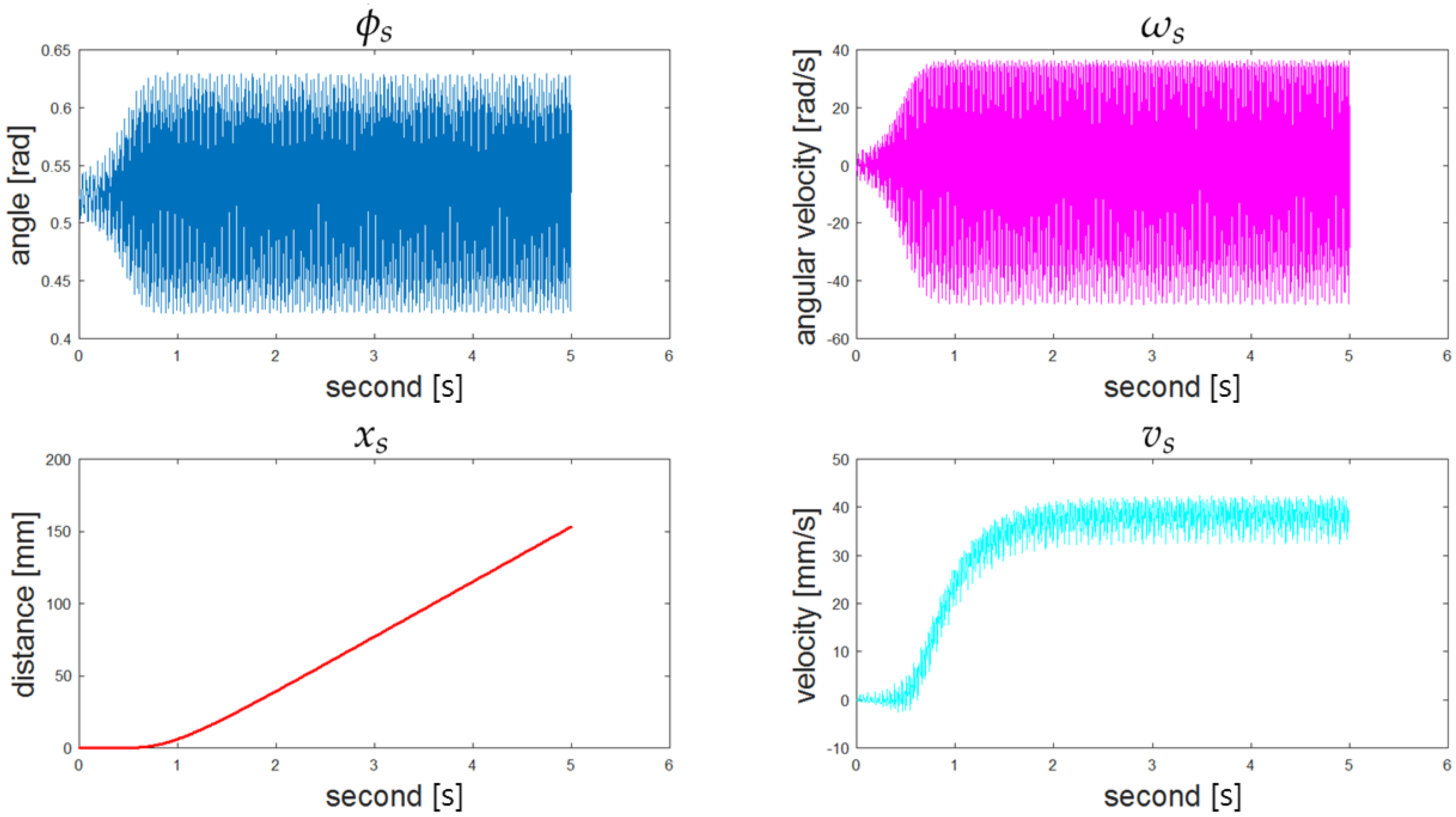

5.1. The Simulation Result of the HSA and the Estimation of the Friction Coefficient

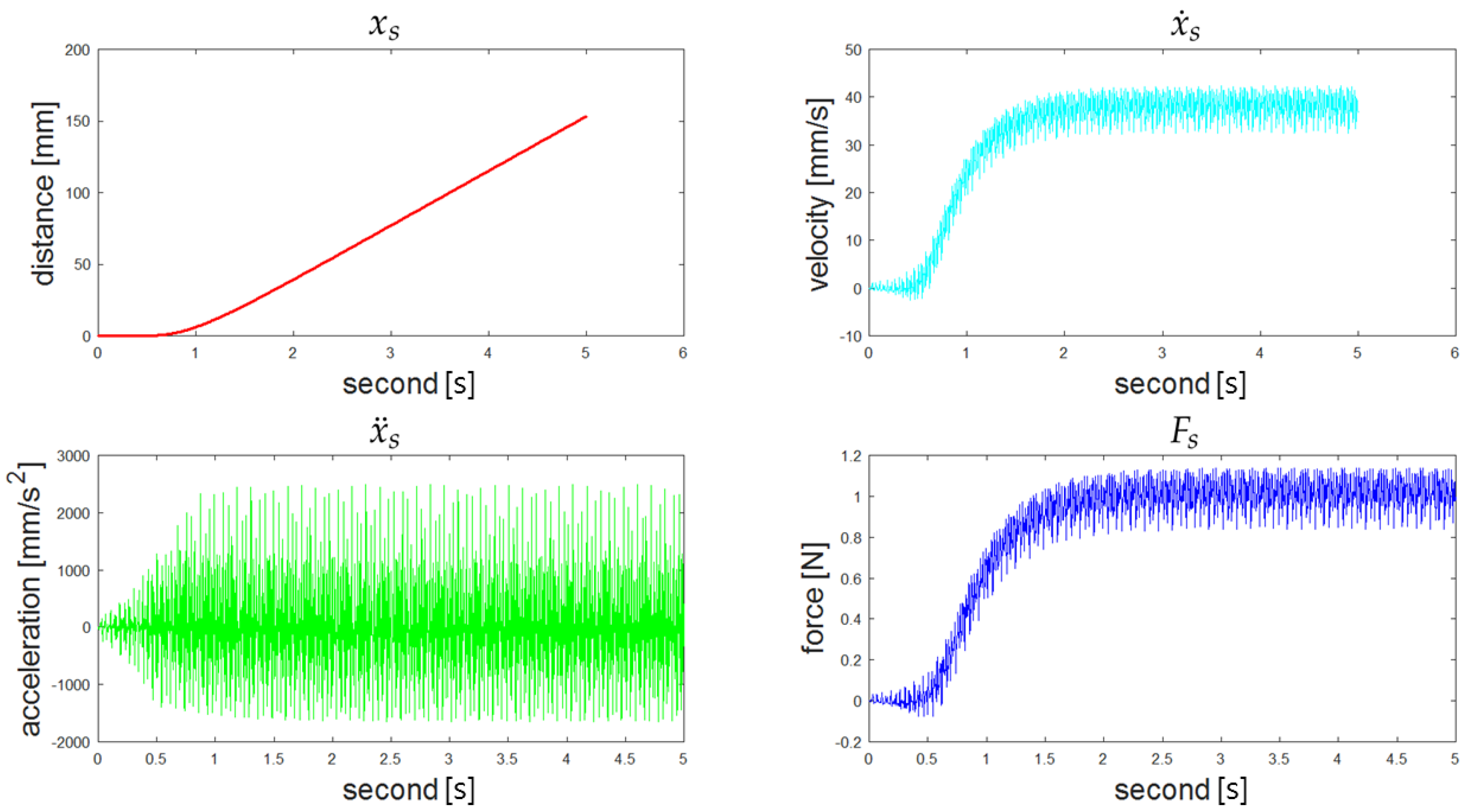

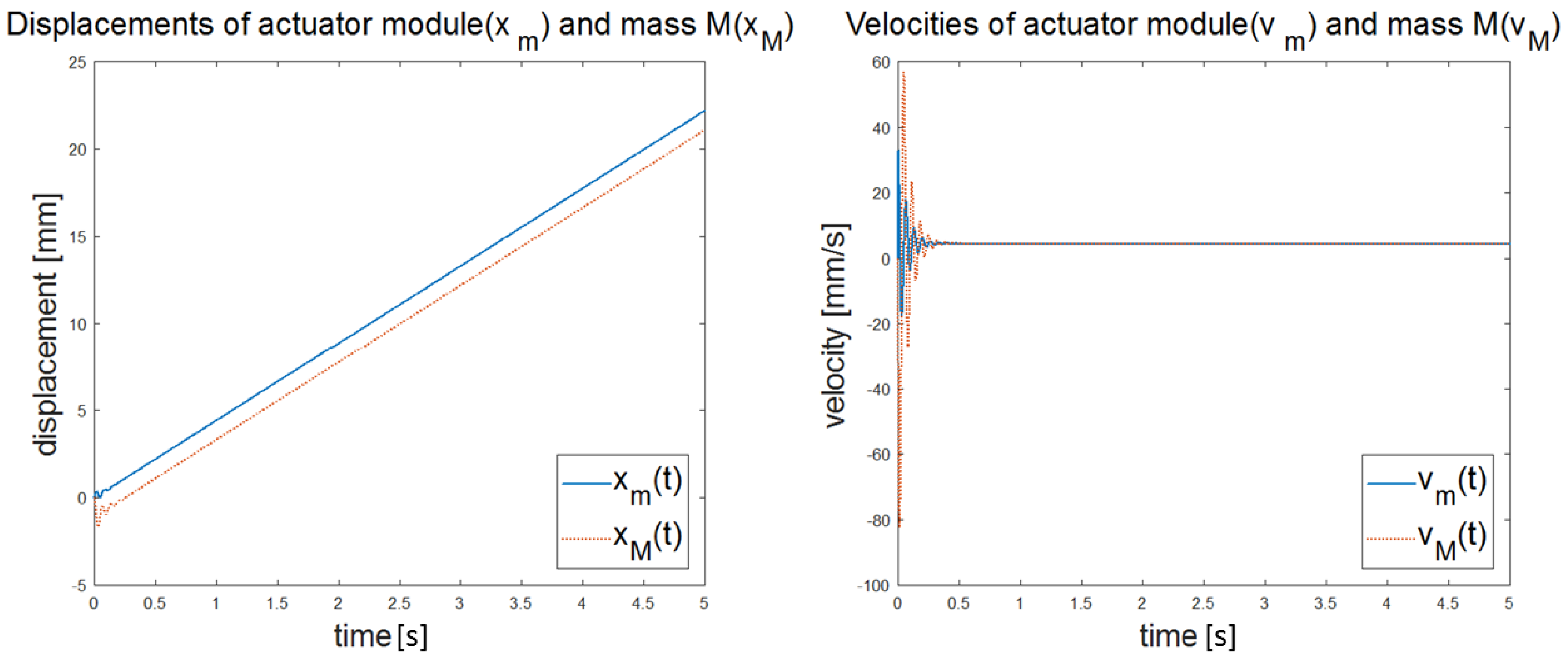

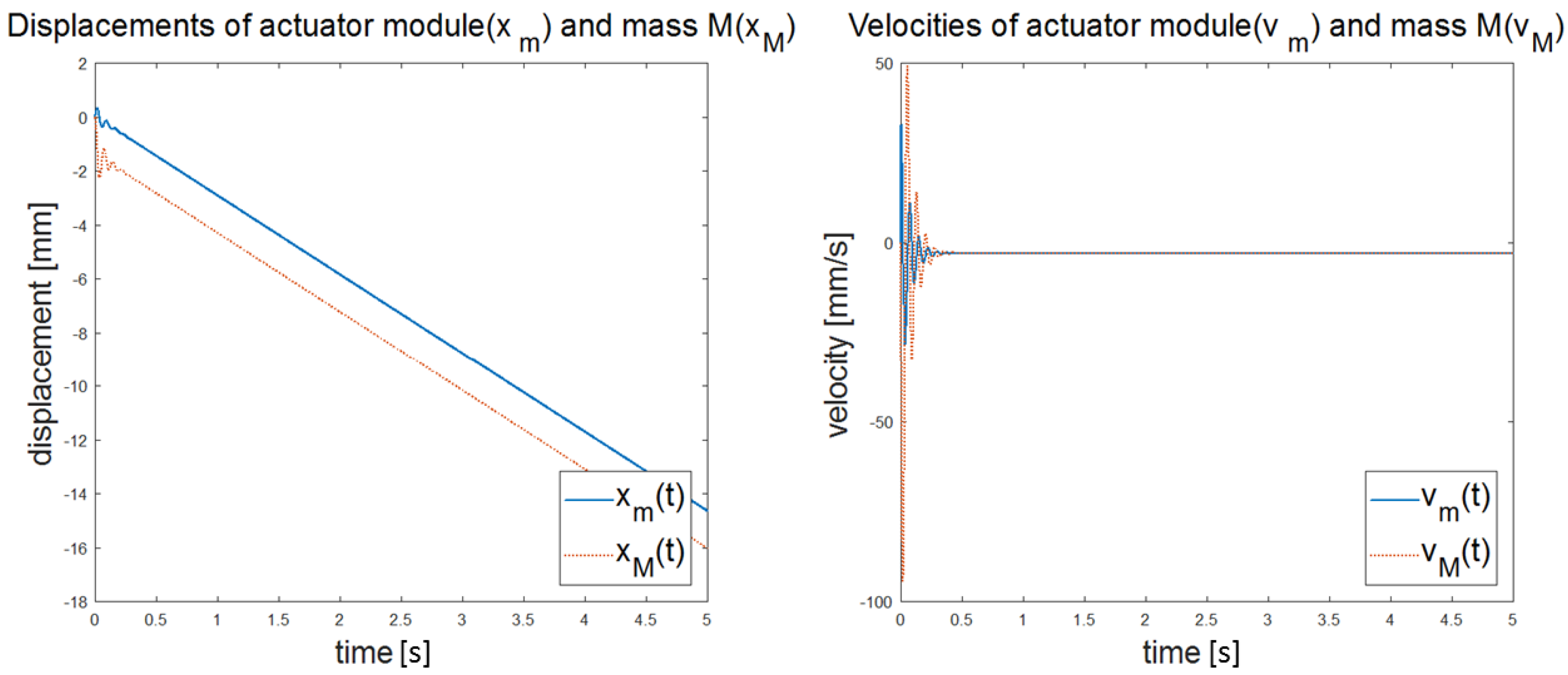

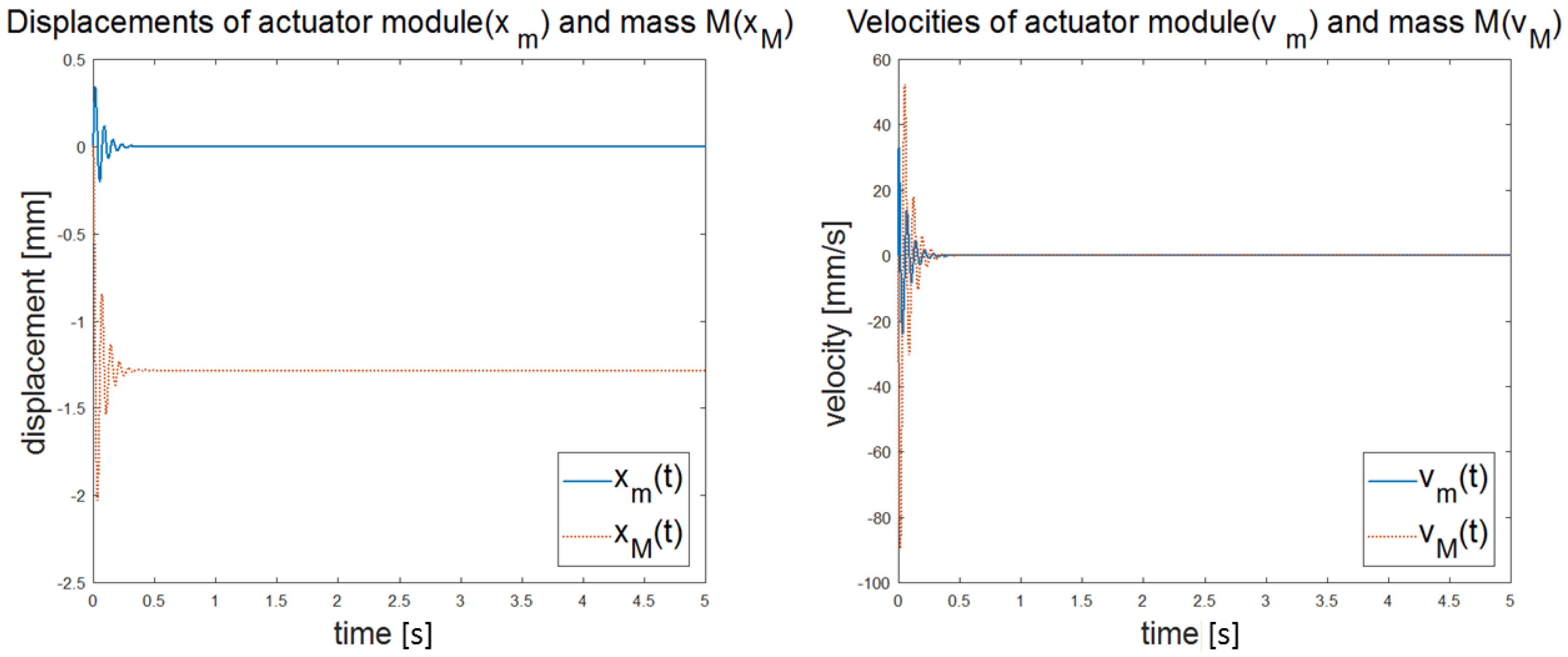

5.2. The Simulation Result of the HSAM and Finding the Virtual Damping Coefficient b

5.3. The Result of Manipulating Two Applications

5.4. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| HSA | Hybrid soft actuator |

| HSAM | Hybrid soft actuator module |

References

- Autumn, K.; Dittmore, A.; Santos, D.; Spenko, M.; Cutkosky, M. Frictional adhesion: A new angle on gecko attachment. J. Exp. Biol. 2006, 209, 3569–3579. [Google Scholar] [CrossRef] [PubMed]

- Cianchetti, M.; Calisti, M.; Margheri, L.; Kuba, M.; Laschi, C. Bioinspired locomotion and grasping in water: The soft eight-arm OCTOPUS robot. Bioeinspiration Biomim. 2015, 10, 035003. [Google Scholar] [CrossRef] [PubMed]

- Hawkes, E.; Blumenschein, L.; Greer, J.; Okamura, A. A soft robot that navigates its environment through growth. Sci. Robot. 2017, 2, eaan3028. [Google Scholar] [CrossRef] [PubMed]

- Shin, B.; Ha, J.; Lee, M.; Park, K.; Park, G.; Choi, T.; Cho, K.; Kim, H. Hygrobot: A self-locomotive ratcheted actuator powered by environmental humidity. Sci. Robot. 2018, 3, eaar2629. [Google Scholar] [CrossRef] [PubMed]

- Agostino, D.; Siciliano, B. Safety issues for human-robot cooperation in manufacturing systems. Tools Perspect. Virtual Manuf. 2008. [Google Scholar]

- Michalos, G.; Makris, S.; Spiliotopoulos, J.; Misios, I.; Tsarouchi, P.; Chryssolouris, G. ROBO-PARTNER: Seamless human-robot cooperation for intelligent, flexible and safe operations in the assembly factories of the future. Procedia CIRP 2014, 23, 71–76. [Google Scholar] [CrossRef]

- Majidi, C. Soft robotics: A perspective-current trends and prospects for the future. Soft Robot. 2014, 1, 5–11. [Google Scholar] [CrossRef]

- Rus, D.; Tolley, M. Design, fabrication and control of soft robots. Nature 2015, 521, 467–475. [Google Scholar] [CrossRef] [PubMed]

- Pfeifer, R.; Lungarella, M.; Iida, F. The challenges ahead for bio-inspired ‘soft’ robotics. Commun. ACM 2012, 55, 76–87. [Google Scholar] [CrossRef]

- Cao, C.; Diteesawat, R.; Rossiter, J.; Conn, A. A reconfigurable crawling robot driven by electroactive artificial muscle. In Proceedings of the 2nd IEEE International Conference ON Soft Robotics (RoboSoft), Seoul, Korea, 14–18 April 2019; pp. 840–845. [Google Scholar]

- Shepherd, R.; Ilievski, F.; Choi, W.; Morin, S.; Stokes, A.; Mazzeo, A.; Whitesides, G. Multigait soft robot. Proc. Natl. Acad. Sci. USA 2011, 108, 20400–20403. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.; Leisk, G.; Trimmer, B. GoQBot: A caterpillar–inspired soft-bodied rolling robot. Bioinspiration Biomim. 2011, 6, 026007. [Google Scholar] [CrossRef] [PubMed]

- Zhan, X.; Xu, J.; Fang, H. A vibration-driven planar locomotion robot-Shell. Robotica 2018, 36, 1402–1420. [Google Scholar] [CrossRef]

- Cicconofri, G.; Becker, F.; Noselli, G.; Desimone, A.; Zimmermann, K. The inversion of motion of bristle bots: Analytical and experimental analysis. In Symposium on Robot Design, Dynamics and Control; Springer: Cham, Switzerland, 2016; pp. 225–232. [Google Scholar]

- Giomi, L.; Hawley-Weld, N.; Mahadevan, L. Swarming, swirling and stasis in sequestered bristle-bots. Proc. R. Soc. A Math. Phys. Eng. Sci. 2013, 469, 20120637. [Google Scholar] [CrossRef]

- Kim, D.; Hao, Z.; Mohazab, A.R.; Ansari, A. On the forward and backward motion of milli-bristle-bots. arXiv 2020, arXiv:2002.10344. [Google Scholar]

- Marchese, A.; Tedrake, R.; Rus, D. Dynamics and trajectory optimization for a soft spatial fluidic elastomer manipulator. Int. J. Robot. Res. 2016, 35, 1000–1019. [Google Scholar] [CrossRef]

- Marchese, A.; Rus, D. Design, kinematics, and control of a soft spatial fluidic elastomer manipulator. Int. J. Robot. Res. 2016, 35, 840–869. [Google Scholar] [CrossRef]

- Becker, F. An approach to the dynamics of a vibration-driven robot. CISM Courses Lect. 2013, 544, 299–308. [Google Scholar]

- Becker, F.; Böorner, S.; Köstner, T.; Lysenko, V.; Zeidis, I.; Zimmermann, K. Spy bristle bot—A vibration-driven robot for the inspection of pipelines. In Proceedings of the 58th Ilmenau Scientific Colloquium, Ilmenau, Germany, 8–12 September 2014; pp. 1–7. [Google Scholar]

- Becker, F. An approach to the dynamics of vibration-driven robots with bristles. IFAC-PapersOnLine 2015, 48, 842–843. [Google Scholar] [CrossRef]

| NAME | SYMBOL | VALUE | UNIT |

|---|---|---|---|

| Total mass | 34 | g | |

| whiteHorizontal mass | 10.5 | g | |

| Vertical mass | 10.5 | g | |

| Spike length | l | 8 | mm |

| Initial spike angle | rad | ||

| Number of spikes | n | 140 | EA |

| Stiffness constant of spikes | c | Nm/rad | |

| Coefficient of friction | Needs to be identified | ||

| Sampling time | 0.0001 | s | |

| Motor revolution speed | input variable | rev/s | |

| HSA displacement | x | state variable | mm |

| Spike leaning angle | state variable | rad |

| 80 | 120 | 160 | 200 | |

|---|---|---|---|---|

| 0.259 | 0.368 | 0.539 | 0.757 | |

| x | 8.85 | 57.14 | 153.00 | 231.28 |

| 8.68 | 57.45 | 153.21 | 231.75 | |

| e | 0.0289 | 0.0961 | 0.0441 | 0.2209 |

| 80 | 120 | 160 | 200 | |

|---|---|---|---|---|

| 39.4 | 34.4 | 26.6 | 27.2 | |

| F | 0.27 | 0.63 | 1.00 | 1.28 |

| 0.2701 | 0.6296 | 1.0011 | 1.2821 | |

| e |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, D.-W.; Lee, C.-W.; Lee, D.-Y.; Lee, D.-W.; Yoon, H.-U. A Hybrid Soft Actuator Inspired by Grass-Spike: Design Approach, Dynamic Model, and Applications. Appl. Sci. 2020, 10, 8525. https://doi.org/10.3390/app10238525

Choi D-W, Lee C-W, Lee D-Y, Lee D-W, Yoon H-U. A Hybrid Soft Actuator Inspired by Grass-Spike: Design Approach, Dynamic Model, and Applications. Applied Sciences. 2020; 10(23):8525. https://doi.org/10.3390/app10238525

Chicago/Turabian StyleChoi, Dong-Woon, Cho-Won Lee, Duk-Yeon Lee, Dong-Wook Lee, and Han-Ul Yoon. 2020. "A Hybrid Soft Actuator Inspired by Grass-Spike: Design Approach, Dynamic Model, and Applications" Applied Sciences 10, no. 23: 8525. https://doi.org/10.3390/app10238525

APA StyleChoi, D.-W., Lee, C.-W., Lee, D.-Y., Lee, D.-W., & Yoon, H.-U. (2020). A Hybrid Soft Actuator Inspired by Grass-Spike: Design Approach, Dynamic Model, and Applications. Applied Sciences, 10(23), 8525. https://doi.org/10.3390/app10238525