Facilitating Vulnerable Supplier Network Management Using Bicriterion Network Resilience Management Approach

Abstract

1. Introduction

2. Literature Review

2.1. Supply Chain Network Resilience

2.2. SC Network Resilience and SC Capabilities

2.3. SC Network Resilience Management and Supplier Management Prioritization Approach

3. The Proposed Framework

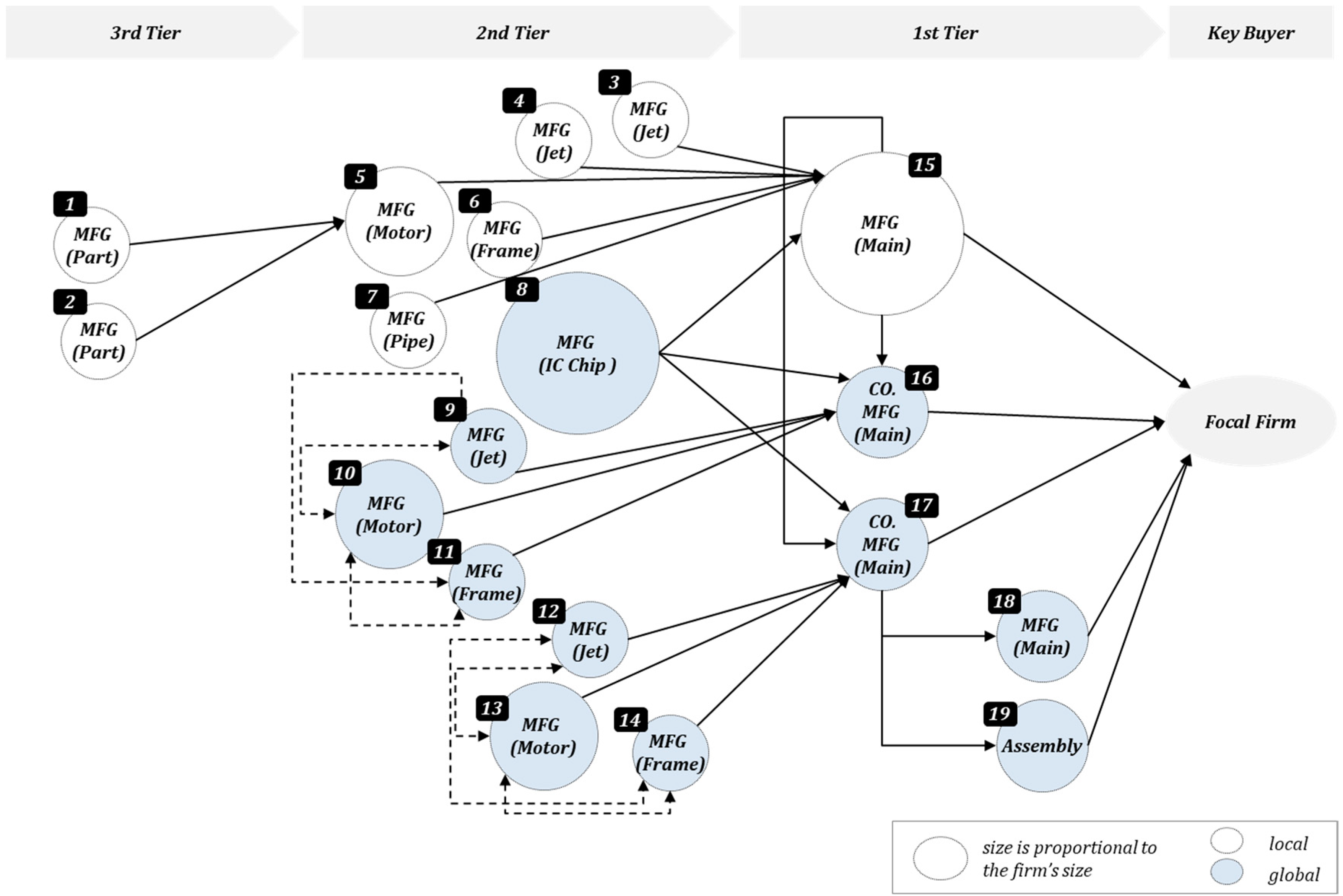

4. Case Study

4.1. Problem Definition

4.2. Evaluating and Ranking of Suppliers

4.2.1. Criteria Used

- Efficiency [C3, )]: Efficiency is the level of resources utilized for the derived operational results [83] (i.e., how easily can SCs control resources while managing lean management practices?)

- Alertness [C4, )]: Alertness the degree of readiness in dealing with environmental and operational risks and emergencies [84] (i.e., how fast can SCs detect disruptive events?)

- Degree of centrality [C5, )]: The degree centrality of a node i, , is measured by the number of direct links that are connected to node i. xij takes a binary value of 1 if there is a link between nodes i and j, and 0 otherwise.

- Betweenness centrality [C6, )]: The betweenness centrality of a node i, , is measured by the total number of links that contain node i. gjk is the total number of geodesics, shortest path length, between node j and k, while is the number of geodesics that contain node i. node i’s betweenness is simply the probability that the node lies between other nodes.

4.2.2. Ranking of Suppliers

5. Conclusions and Limitations

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bellamy, M.A.; Ghosh, S.; Hora, M. The influence of supply network structure on firm innovation. J. Oper. Manag. 2014, 32, 357–373. [Google Scholar] [CrossRef]

- Yoon, J.; Yildiz, H.; Talluri, S.S. Risk Management Strategies in Transportation Capacity Decisions: An Analytical Approach. J. Bus. Logist. 2016, 37, 364–381. [Google Scholar] [CrossRef]

- Ali, A.; Mahfouz, A.; Arisha, A. Analysing supply chain resilience: Integrating the constructs in a concept mapping framework via a systematic literature review. Supply Chain Manag. Int. J. 2017, 22, 16–39. [Google Scholar] [CrossRef]

- Shin, N.; Park, S. Evidence-Based Resilience Management for Supply Chain Sustainability: An Interpretive Structural Modelling Approach. Sustainability 2019, 11, 484. [Google Scholar] [CrossRef]

- Reyes Levalle, R.; Nof, S.Y. Resilience in supply networks: Definition, dimensions, and levels. Annu. Rev. Control 2017, 43, 224–236. [Google Scholar] [CrossRef]

- Kim, Y.; Chen, Y.S.; Linderman, K. Supply network disruption and resilience: A network structural perspective. J. Oper. Manag. 2015, 33–34, 43–59. [Google Scholar] [CrossRef]

- Greening, P.; Rutherford, C. Disruptions and supply networks: A multi-level, multi-theoretical relational perspective. Int. J. Logist. Manag. 2011, 22, 104–126. [Google Scholar] [CrossRef]

- Pettit, T.J.; Fiksel, J.; Croxton, K.L. Ensuring supply chain resilience: Development of a conceptual framework. J. Bus. Logist. 2010, 31, 1–21. [Google Scholar] [CrossRef]

- Pettit, T.J.; Croxton, K.L.; Fiksel, J. The Evolution of Resilience in Supply Chain Management: A Retrospective on Ensuring Supply Chain Resilience. J. Bus. Logist. 2019, 40, 56–65. [Google Scholar] [CrossRef]

- Wagner, S.M.; Neshat, N. Assessing the vulnerability of supply chains using graph theory. Int. J. Prod. Econ. 2010, 126, 121–129. [Google Scholar] [CrossRef]

- Eltantawy, R.A. The role of supply management resilience in attaining ambidexterity: A dynamic capabilities approach. J. Bus. Ind. Mark. 2016, 31, 123–134. [Google Scholar] [CrossRef]

- Amindoust, A. A resilient-sustainable based supplier selection model using a hybrid intelligent method. Comput. Ind. Eng. 2018, 126, 122–135. [Google Scholar] [CrossRef]

- Dolgui, A.; Ivanov, D.; Sokolov, B. Ripple effect in the supply chain: An analysis and recent literature. Int. J. Prod. Res. 2018, 56, 414–430. [Google Scholar] [CrossRef]

- Hou, Y.; Wang, X.; Wu, Y.J.; He, P. How does the trust affect the topology of supply chain network and its resilience? An agent-based approach. Transp. Res. Part E Logist. Transp. Rev. 2018, 116, 229–241. [Google Scholar] [CrossRef]

- Baek, B. Samsung, SK hynix rush to find new suppliers. The Korea Times, July 2019. [Google Scholar]

- Kim, H. Stock Woes Deepen in South Korea as a New Trade War Roils Market. Bloomberg, July 2019. [Google Scholar]

- Kırılmaz, O.; Erol, S. A proactive approach to supply chain risk management: Shifting orders among suppliers to mitigate the supply side risks. J. Purch. Supply Manag. 2017, 23, 54–65. [Google Scholar] [CrossRef]

- Tang, O.; Musa, S.N. Identifying risk issues and research advancements in supply chain risk management. Int. J. Prod. Econ. 2011, 133, 25–34. [Google Scholar] [CrossRef]

- Pettit, T.J.; Croxton, K.L.; Fiksel, J. Ensuring supply chain resilience: Development and implementation of an assessment tool. J. Bus. Logist. 2013, 34, 46–76. [Google Scholar] [CrossRef]

- Jüttner, U.; Maklan, S. Supply chain resilience in the global financial crisis: An empirical study. Supply Chain Manag. Int. J. 2011, 16, 246–259. [Google Scholar] [CrossRef]

- Ambulkar, S.; Blackhurst, J.; Grawe, S. Firm’s resilience to supply chain disruptions: Scale development and empirical examination. J. Oper. Manag. 2015, 33–34, 111–122. [Google Scholar] [CrossRef]

- Chopra, S.; Sodhi, M.S. Managing risk to avoid supply-chain breakdown. MIT Sloan Management Review, 15 October 2004. [Google Scholar]

- Park, J.; Yamazaki, M. Supply-chain pain: South Korea chipmakers and their suppliers seek to bypass Tokyo curbs. Reuters, 8 July 2019. [Google Scholar]

- Hosseini, S.; Barker, K. A Bayesian network model for resilience-based supplier selection. Int. J. Prod. Econ. 2016, 180, 68–87. [Google Scholar] [CrossRef]

- Ivanov, D.; Sokolov, B. Control and system-theoretic identification of the supply chain dynamics domain for planning, analysis and adaptation of performance under uncertainty. Eur. J. Oper. Res. 2013, 224, 313–323. [Google Scholar] [CrossRef]

- Ivanov, D.; Sokolov, B.; Dolgui, A. The ripple effect in supply chains: Trade-off ‘efficiency-flexibility-resilience’ in disruption management. Int. J. Prod. Res. 2014, 52, 2154–2172. [Google Scholar] [CrossRef]

- Sawik, T. Selection of resilient supply portfolio under disruption risks. Omega 2013, 41, 259–269. [Google Scholar] [CrossRef]

- Hosseini, S.; Ivanov, D.; Dolgui, A. Review of quantitative methods for supply chain resilience analysis. Transp. Res. Part E Logist. Transp. Rev. 2019, 125, 285–307. [Google Scholar] [CrossRef]

- Zimmer, K.; Fröhling, M.; Schultmann, F. Sustainable supplier management—A review of models supporting sustainable supplier selection, monitoring and development. Int. J. Prod. Res. 2016, 54, 1412–1442. [Google Scholar] [CrossRef]

- Fallahpour, A.; Udoncy Olugu, E.; Nurmaya Musa, S.; Yew Wong, K.; Noori, S. A decision support model for sustainable supplier selection in sustainable supply chain management. Comput. Ind. Eng. 2017, 105, 391–410. [Google Scholar] [CrossRef]

- Luthra, S.; Govindan, K.; Kannan, D.; Mangla, S.K.; Garg, C.P. An integrated framework for sustainable supplier selection and evaluation in supply chains. J. Clean. Prod. 2017, 140, 1686–1698. [Google Scholar] [CrossRef]

- Sopadang, A.; Wichaisri, S.; Banomyong, R. Sustainable supply chain performance measurement a case study of the sugar industry. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Rabat, Morocco, 11–13 April 2017; pp. 1079–1080. [Google Scholar]

- Nielsen, I.E.; Banaeian, N.; Golińska, P.; Mobli, H.; Omid, M. Green Supplier Selection Criteria: From a Literature Review to a Flexible Framework for Determination of Suitable Criteria. In Logistics Operations, Supply Chain Management and Sustainability; Golinska, P., Ed.; EcoProduction; Springer International Publishing: Cham, Switzerland, 2014; pp. 79–99. ISBN 978-3-319-07286-9. [Google Scholar]

- Cardoso, S.R.; Paula Barbosa-Póvoa, A.; Relvas, S.; Novais, A.Q. Resilience metrics in the assessment of complex supply-chains performance operating under demand uncertainty. Omega 2015, 56, 53–73. [Google Scholar] [CrossRef]

- Hearnshaw, E.J.S.; Wilson, M.M.J. A complex network approach to supply chain network theory. Int. J. Oper. Prod. Manag. 2013, 33, 442–469. [Google Scholar] [CrossRef]

- Gao, G.Y.; Xie, E.; Zhou, K.Z. How does technological diversity in supplier network drive buyer innovation? Relational process and contingencies. J. Oper. Manag. 2015, 36, 165–177. [Google Scholar] [CrossRef]

- Yang, B.; Yang, Y. Postponement in supply chain risk management: A complexity perspective. Int. J. Prod. Res. 2010, 48, 1901–1912. [Google Scholar] [CrossRef]

- Erol, O.; Sauser, B.J.; Mansouri, M. A framework for investigation into extended enterprise resilience. Enterp. Inf. Syst. 2010, 4, 111–136. [Google Scholar] [CrossRef]

- Brusset, X.; Teller, C. Supply chain capabilities, risks, and resilience. Int. J. Prod. Econ. 2017, 184, 59–68. [Google Scholar] [CrossRef]

- Rajesh, R. Technological capabilities and supply chain resilience of firms: A relational analysis using Total Interpretive Structural Modeling (TISM). Technol. Forecast. Soc. Change 2017, 118, 161–169. [Google Scholar] [CrossRef]

- Li, X.; Wu, Q.; Holsapple, C.W.; Goldsby, T. An empirical examination of firm financial performance along dimensions of supply chain resilience. Manag. Res. Rev. 2017, 40, 254–269. [Google Scholar] [CrossRef]

- Purvis, L.; Spall, S.; Naim, M.; Spiegler, V. Developing a resilient supply chain strategy during ‘boom’ and ‘bust’. Prod. Plan. Control 2016, 27, 579–590. [Google Scholar] [CrossRef]

- Jazairy, A.; von Haartman, R. Analysing the institutional pressures on shippers and logistics service providers to implement green supply chain management practices. Int. J. Logist. Res. Appl. 2019, 1–41. [Google Scholar] [CrossRef]

- Hohenstein, N.-O.; Feisel, E.; Hartmann, E.; Giunipero, L. Research on the phenomenon of supply chain resilience. Int. J. Phys. Distrib. Logist. Manag. 2015, 45, 90–117. [Google Scholar] [CrossRef]

- Scholten, K.; Schilder, S. The role of collaboration in supply chain resilience. Supply Chain Manag. Int. J. 2015, 20, 471–484. [Google Scholar] [CrossRef]

- Ellis, S.C.; Henry, R.M.; Shockley, J. Buyer perceptions of supply disruption risk: A behavioral view and empirical assessment. J. Oper. Manag. 2010, 28, 34–46. [Google Scholar] [CrossRef]

- Nair, A.; Vidal, J.M. Supply network topology and robustness against disruptions—An investigation using multi-agent model. Int. J. Prod. Res. 2011, 49, 1391–1404. [Google Scholar] [CrossRef]

- Stone, J.; Rahimifard, S. Resilience in agri-food supply chains: A critical analysis of the literature and synthesis of a novel framework. Supply Chain Manag. Int. J. 2018, SCM-06-2017-0201. [Google Scholar] [CrossRef]

- Carvalho, H.; Azevedo, S.G.; Cruz-Machado, V. Agile and resilient approaches to supply chain management: Influence on performance and competitiveness. Logist. Res. 2012, 4, 49–62. [Google Scholar] [CrossRef]

- Rajesh, R.; Ravi, V.; Venkata Rao, R. Selection of risk mitigation strategy in electronic supply chains using grey theory and digraph-matrix approaches. Int. J. Prod. Res. 2015, 53, 238–257. [Google Scholar] [CrossRef]

- Sheffi, Y.; Rice, J.B., Jr. A supply chain view of the resilient enterprise. MIT Sloan Manag. Rev. 2005, 47, 41–48. [Google Scholar]

- Tang, C.; Tomlin, B. The power of flexibility for mitigating supply chain risks. Int. J. Prod. Econ. 2008, 116, 12–27. [Google Scholar] [CrossRef]

- Roberta Pereira, C.; Christopher, M.; Lago Da Silva, A. Achieving supply chain resilience: The role of procurement. Supply Chain Manag. Int. J. 2014, 19, 626–642. [Google Scholar] [CrossRef]

- Chiang, C.; Kocabasoglu-Hillmer, C.; Suresh, N. An empirical investigation of the impact of strategic sourcing and flexibility on firm’s supply chain agility. Int. J. Oper. Prod. Manag. 2012, 32, 49–78. [Google Scholar] [CrossRef]

- Simangunsong, E.; Hendry, L.C.; Stevenson, M. Supply-chain uncertainty: A review and theoretical foundation for future research. Int. J. Prod. Res. 2012, 50, 4493–4523. [Google Scholar] [CrossRef]

- Spiegler, V.L.M.; Naim, M.M.; Wikner, J. A control engineering approach to the assessment of supply chain resilience. Int. J. Prod. Res. 2012, 50, 6162–6187. [Google Scholar] [CrossRef]

- Rice, J.B., Jr.; Caniato, F. Building a secure and resilient supply network. Supply Chain Manag. Int. J. 2003, 7, 22–30. [Google Scholar] [CrossRef]

- Blackhurst, J.; Dunn, K.S.; Craighead, C.W. An empirically derived framework of global supply resiliency. J. Bus. Logist. 2011, 32, 374–391. [Google Scholar] [CrossRef]

- Baker, P. Designing distribution centres for agile supply chains. Intenational J. Logist. 2006, 9, 207–221. [Google Scholar] [CrossRef]

- Swafford, P.M.; Ghosh, S.; Murthy, N. The antecedents of supply chain agility of a firm: Scale development and model testing. J. Oper. Manag. 2006, 24, 170–188. [Google Scholar] [CrossRef]

- Manuj, I.; Mentzer, J.T. Global supply chain risk management strategies. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 192–223. [Google Scholar] [CrossRef]

- Li, G.; Lin, Y.; Wang, S.; Yan, H. Enhancing agility by timely sharing of supply information. Supply Chain Manag. Int. J. 2006, 11, 425–435. [Google Scholar] [CrossRef]

- Christopher, M.; Holweg, M. “Supply Chain 2.0”: Managing supply chains in the era of turbulence. Int. J. Phys. Distrib. Logist. Manag. 2011, 41, 63–82. [Google Scholar] [CrossRef]

- Stevenson, M.; Spring, M. Flexibility from a Supply Chain Perspective: Definition and Review. Int. J. Oper. Prod. Manag. 2007, 27, 685–713. [Google Scholar] [CrossRef]

- Li, X.; Goldsby, T.J.; Holsapple, C.W. Supply chain agility: Scale development. Int. J. Logist. Manag. 2009, 20, 408–424. [Google Scholar] [CrossRef]

- Rajesh, R.; Ravi, V. Modeling enablers of supply chain risk mitigation in electronic supply chains: A Grey-DEMATEL approach. Comput. Ind. Eng. 2015, 87, 126–139. [Google Scholar] [CrossRef]

- Duryan, M.; Smyth, H. Cultivating sustainable communities of practice within hierarchical bureaucracies: The crucial role of an executive sponsorship. Int. J. Manag. Proj. Bus. 2018, 12, 400–422. [Google Scholar] [CrossRef]

- Rajesh, R.; Ravi, V. Supplier selection in resilient supply chains: A grey relational analysis approach. J. Clean. Prod. 2015, 86, 343–359. [Google Scholar] [CrossRef]

- Onstein, A.T.C.; Ektesaby, M.; Rezaei, J.; Tavasszy, L.A.; van Damme, D.A. Importance of factors driving firms’ decisions on spatial distribution structures. Int. J. Logist. Res. Appl. 2020, 23, 24–43. [Google Scholar] [CrossRef]

- Choi, T.Y.; Dooley, K.J.; Rungtusanatham, M. Supply networks and complex adaptive systems: Control versus emergence. J. Oper. Manag. 2001, 19, 351–366. [Google Scholar] [CrossRef]

- Hsu, C.I.; Wen, Y.H. Application of Grey theory and multiobjective programming towards airline network design. Eur. J. Oper. Res. 2000, 127, 44–68. [Google Scholar] [CrossRef]

- Capaldo, A.; Giannoccaro, I. How does trust affect performance in the supply chain? the moderating role of interdependence. Int. J. Prod. Econ. 2015, 166, 36–49. [Google Scholar] [CrossRef]

- Erker, S.; Stangl, R.; Stoeglehner, G. Resilience in the light of energy crises—Part II: Application of the regional energy resilience assessment. J. Clean. Prod. 2017, 164, 495–507. [Google Scholar] [CrossRef]

- Gören, H.G. A decision framework for sustainable supplier selection and order allocation with lost sales. J. Clean. Prod. 2018, 183, 1156–1169. [Google Scholar] [CrossRef]

- Machado, S.M.; Paiva, E.L.; da Silva, E.M. Counterfeiting: Addressing mitigation and resilience in supply chains. Int. J. Phys. Distrib. Logist. Manag. 2018, 48, 139–163. [Google Scholar] [CrossRef]

- Perera, S.; Perera, H.N.; Kasthurirathna, D. Structural characteristics of complex supply chain networks. In Proceedings of the 2017 Moratuwa Engineering Research Conference (MERCon), Moratuwa, Sri Lanka, 29–31 May 2017; pp. 135–140. [Google Scholar] [CrossRef]

- Tsoukiàs, A.; Perny, P.; Vincke, P. From Concordance/Discordance to the Modelling of Positive and Negative Reasons in Decision Aiding. In Annals of Mathematics and Artificial Intelligence; Springer: Boston, MA, USA, 2002; Volume 77, pp. 147–174. [Google Scholar]

- Rebai, A.; Aouni, B.; Martel, J.-M. A multi-attribute method for choosing among potential alternatives with ordinal evaluation. Eur. J. Oper. Res. 2006, 174, 360–373. [Google Scholar] [CrossRef]

- Spiegler, V.L.M.; Potter, A.T.; Naim, M.M.; Towill, D.R. The value of nonlinear control theory in investigating the underlying dynamics and resilience of a grocery supply chain. Int. J. Prod. Res. 2016, 54, 265–286. [Google Scholar] [CrossRef]

- Cimellaro, G.P.; Asce, A.M.; Renschler, C.; Reinhorn, A.M.; Asce, F.; Arendt, L. PEOPLES: A Framework for Evaluating Resilience Introduction and Definition of Resilience. J. Struct. Eng. 2016, 142, 04016063. [Google Scholar] [CrossRef]

- Hosseini, S.; Barker, K.; Ramirez-Marquez, J.E. A review of definitions and measures of system resilience. Reliab. Eng. Syst. Saf. 2016, 145, 47–61. [Google Scholar] [CrossRef]

- Melnyk, S.A.; Davis, E.W.; Spekman, R.E.; Sandor, J. Outcome-Driven Supply Chains. MIT Sloan Management Review, 1 January 2010. [Google Scholar]

- Gligor, D.M.; Esmark, C.L.; Holcomb, M.C. Performance outcomes of supply chain agility: When should you be agile? J. Oper. Manag. 2015, 33–34, 71–82. [Google Scholar] [CrossRef]

- Matook, S.; Lasch, R.; Tamaschke, R. Supplier development with benchmarking as part of a comprehensive supplier risk management framework. Int. J. Oper. Prod. Manag. 2009, 29, 241–267. [Google Scholar] [CrossRef]

- Kim, Y.; Choi, T.Y.; Yan, T.; Dooley, K. Structural investigation of supply networks: A social network analysis approach. J. Oper. Manag. 2011, 29, 194–211. [Google Scholar] [CrossRef]

- Perera, S.; Bell, M.G.H.; Bliemer, M.C.J. Network science approach to modelling the topology and robustness of supply chain networks: A review and perspective. Appl. Netw. Sci. 2017, 2, 33. [Google Scholar] [CrossRef]

- Haimes, Y.Y. On the definition of vulnerabilities in measuring risks to infrastructures. Risk Anal. 2006, 26, 293–296. [Google Scholar] [CrossRef]

- Bertolini, L. Spatial Development Patterns and Public Transport: The Application of an Analytical Model in the Netherlands. Plan. Pract. Res. 1999, 14, 199–210. [Google Scholar] [CrossRef]

- Papa, E.; Bertolini, L. Accessibility and Transit-Oriented Development in European metropolitan areas. J. Transp. Geogr. 2015, 47, 70–83. [Google Scholar] [CrossRef]

| Supplier (i) | Weighted Average | ||||||

|---|---|---|---|---|---|---|---|

| 1 | 9.0 | 7.0 | 4.0 | 5.0 | 8.89 | 10.00 | 6.5 |

| 2 | 6.0 | 7.0 | 6.0 | 4.0 | 8.89 | 10.00 | 6.0 |

| 3 | 6.0 | 4.0 | 1.0 | 2.0 | 8.89 | 10.00 | 3.5 |

| 4 | 8.0 | 8.0 | 10.0 | 10.0 | 8.89 | 10.00 | 9.3 |

| 5 | 0.0 | 9.0 | 9.0 | 8.0 | 6.67 | 6.60 | 8.2 |

| 6 | 8.0 | 8.0 | 6.0 | 10.0 | 8.89 | 10.00 | 8.3 |

| 7 | 7.0 | 5.0 | 7.0 | 5.0 | 8.89 | 10.00 | 6.3 |

| 8 | 0.0 | 6.0 | 3.0 | 10.0 | 6.67 | 10.00 | 5.6 |

| 9 | 5.0 | 7.0 | 3.0 | 10.0 | 4.44 | 10.00 | 7.6 |

| 10 | 2.0 | 4.0 | 10.0 | 5.0 | 4.44 | 10.00 | 6.6 |

| 11 | 2.0 | 10.0 | 1.0 | 9.0 | 4.44 | 10.00 | 6.9 |

| 12 | 0.0 | 10.0 | 1.0 | 2.0 | 4.44 | 10.00 | 4.6 |

| 13 | 8.0 | 7.0 | 6.0 | 6.0 | 4.44 | 10.00 | 8.1 |

| 14 | 8.0 | 10.0 | 5.0 | 5.0 | 4.44 | 10.00 | 8.4 |

| 15 | 3.0 | 2.0 | 8.0 | 10.0 | 0.00 | 0.00 | 10.8 |

| 16 | 5.0 | 4.0 | 2.0 | 5.0 | 3.33 | 9.06 | 5.9 |

| 17 | 0.0 | 2.0 | 7.0 | 7.0 | 1.11 | 2.26 | 8.2 |

| 18 | 1.0 | 3.0 | 1.0 | 4.0 | 7.78 | 10.00 | 2.8 |

| 19 | 7.0 | 6.0 | 5.0 | 1.0 | 7.78 | 10.00 | 5.3 |

| Resilience Values | Network Values | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Supplier (i) | S1 | I1 | R1 | S2 | I2 | R2 | S3 | I3 | R3 | S4 | I4 | R4 | S5 | I5 | R5 | S6 | I6 | R6 |

| 1 | 18 | 0 | 18C | 9 | 6 | 9C | 7 | 11 | 11D | 5 | 9 | 9D | 0 | 13 | 13D | 0 | 4 | 4D |

| 2 | 10 | 7 | 10C | 9 | 6 | 9C | 10 | 6 | 10C | 3 | 14 | 14D | 0 | 13 | 13D | 0 | 4 | 4D |

| 3 | 10 | 7 | 10C | 3 | 13 | 13D | 0 | 15 | 15D | 1 | 16 | 16D | 0 | 13 | 13D | 0 | 4 | 4D |

| 4 | 14 | 1 | 14C | 13 | 4 | 13C | 17 | 0 | 17C | 14 | 0 | 14C | 0 | 13 | 13D | 0 | 4 | 4D |

| 5 | 0 | 15 | 15D | 15 | 3 | 15C | 16 | 2 | 16C | 12 | 6 | 12C | 8 | 9 | 9D | 16 | 2 | 16C |

| 6 | 14 | 1 | 14C | 13 | 4 | 13C | 10 | 6 | 10C | 14 | 0 | 14C | 0 | 13 | 13D | 0 | 4 | 4D |

| 7 | 12 | 5 | 12C | 6 | 12 | 12D | 13 | 4 | 13C | 5 | 9 | 9D | 0 | 13 | 13D | 0 | 4 | 4D |

| 8 | 0 | 15 | 15D | 7 | 10 | 10D | 5 | 12 | 12D | 14 | 0 | 14C | 8 | 9 | 9D | 0 | 4 | 4D |

| 9 | 8 | 9 | 9D | 9 | 6 | 9C | 5 | 12 | 12D | 14 | 0 | 14C | 10 | 3 | 10C | 0 | 4 | 4D |

| 10 | 5 | 12 | 12D | 3 | 13 | 13D | 17 | 0 | 17C | 5 | 9 | 9D | 10 | 3 | 10C | 0 | 4 | 4D |

| 11 | 5 | 12 | 12D | 16 | 0 | 16C | 0 | 15 | 15D | 13 | 5 | 13C | 10 | 3 | 10C | 0 | 4 | 4D |

| 12 | 0 | 15 | 15D | 16 | 0 | 16C | 0 | 15 | 15D | 1 | 16 | 16D | 10 | 3 | 10C | 0 | 4 | 4D |

| 13 | 14 | 1 | 14C | 9 | 6 | 9C | 10 | 6 | 10C | 10 | 8 | 10C | 10 | 3 | 10C | 0 | 4 | 4D |

| 14 | 14 | 1 | 14C | 16 | 0 | 16C | 8 | 9 | 9D | 5 | 9 | 9D | 10 | 3 | 10C | 0 | 4 | 4D |

| 15 | 7 | 11 | 11D | 0 | 17 | 17D | 15 | 3 | 15C | 14 | 0 | 14C | 18 | 0 | 18C | 18 | 0 | 18C |

| 16 | 8 | 9 | 9D | 3 | 13 | 13D | 4 | 14 | 14D | 5 | 9 | 9D | 16 | 2 | 16C | 15 | 3 | 15C |

| 17 | 0 | 15 | 15D | 0 | 17 | 17D | 13 | 4 | 13C | 11 | 7 | 11C | 17 | 1 | 17C | 17 | 1 | 17C |

| 18 | 4 | 14 | 14D | 2 | 16 | 16D | 0 | 15 | 15D | 3 | 14 | 14D | 6 | 11 | 11D | 0 | 4 | 4D |

| 19 | 12 | 5 | 12C | 7 | 10 | 10D | 8 | 9 | 9D | 0 | 18 | 18D | 6 | 11 | 11D | 0 | 4 | 4D |

| Supplier | Gap | Observation | |||||

|---|---|---|---|---|---|---|---|

| 1 | 9.33 | 4.33 | 522.67 | 112.67 | 410.00 | Concordant | |

| 2 | 8.17 | 5.50 | 400.17 | 181.50 | 218.67 | Concordant | |

| 3 | 5.17 | 8.50 | 160.17 | 433.50 | – | 273.33 | Discordant |

| 4 | 12.50 | 0.83 | 937.50 | 4.17 | 933.33 | Concordant | |

| 5 | 9.00 | 8.33 | 486.00 | 416.67 | 69.33 | Concordant | |

| 6 | 11.33 | 1.83 | 770.67 | 20.17 | 750.50 | Concordant | |

| 7 | 8.83 | 5.00 | 468.17 | 150.00 | 318.17 | Concordant | |

| 8 | 6.50 | 7.50 | 253.50 | 337.50 | – | 84.00 | Discordant |

| 9 | 7.17 | 6.17 | 308.17 | 228.17 | 80.00 | Concordant | |

| 10 | 6.17 | 7.33 | 228.17 | 322.67 | – | 94.50 | Discordant |

| 11 | 6.83 | 7.00 | 280.17 | 294.00 | – | 13.83 | Discordant |

| 12 | 4.00 | 9.33 | 96.00 | 522.67 | – | 426.67 | Discordant |

| 13 | 8.33 | 5.17 | 416.67 | 160.17 | 256.50 | Concordant | |

| 14 | 8.33 | 4.83 | 416.67 | 140.17 | 276.50 | Concordant | |

| 15 | 6.00 | 11.17 | 216.00 | 748.17 | – | 532.17 | Discordant |

| 16 | 4.17 | 12.67 | 104.17 | 962.67 | – | 858.50 | Discordant |

| 17 | 4.33 | 12.83 | 112.67 | 988.17 | – | 875.50 | Discordant |

| 18 | 4.00 | 10.83 | 96.00 | 704.17 | – | 608.17 | Discordant |

| 19 | 7.00 | 8.00 | 294.00 | 384.00 | – | 90.00 | Discordant |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, N.; Park, S. Facilitating Vulnerable Supplier Network Management Using Bicriterion Network Resilience Management Approach. Appl. Sci. 2020, 10, 8502. https://doi.org/10.3390/app10238502

Shin N, Park S. Facilitating Vulnerable Supplier Network Management Using Bicriterion Network Resilience Management Approach. Applied Sciences. 2020; 10(23):8502. https://doi.org/10.3390/app10238502

Chicago/Turabian StyleShin, Nina, and Sangwook Park. 2020. "Facilitating Vulnerable Supplier Network Management Using Bicriterion Network Resilience Management Approach" Applied Sciences 10, no. 23: 8502. https://doi.org/10.3390/app10238502

APA StyleShin, N., & Park, S. (2020). Facilitating Vulnerable Supplier Network Management Using Bicriterion Network Resilience Management Approach. Applied Sciences, 10(23), 8502. https://doi.org/10.3390/app10238502