Properties of the Fine Granular Area and Postulated Models for Its Formation during Very High Cycle Fatigue—A Review

Abstract

1. Introduction

2. Properties of Fine Granular Area

2.1. Influences Regarding the Formation Process of FGA

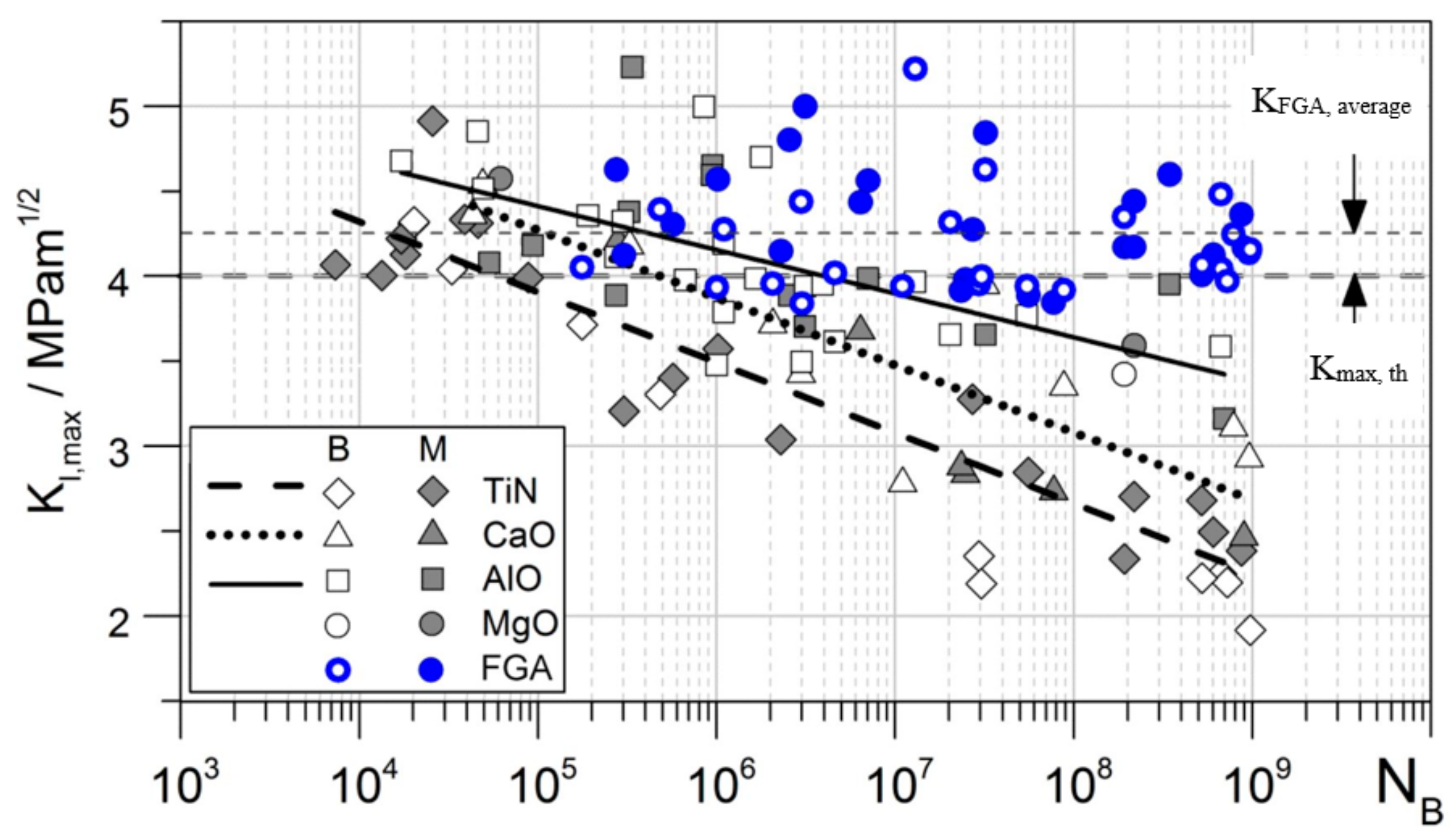

2.1.1. Influence of the Cycles to Failure

2.1.2. Influence of the Material and Purity

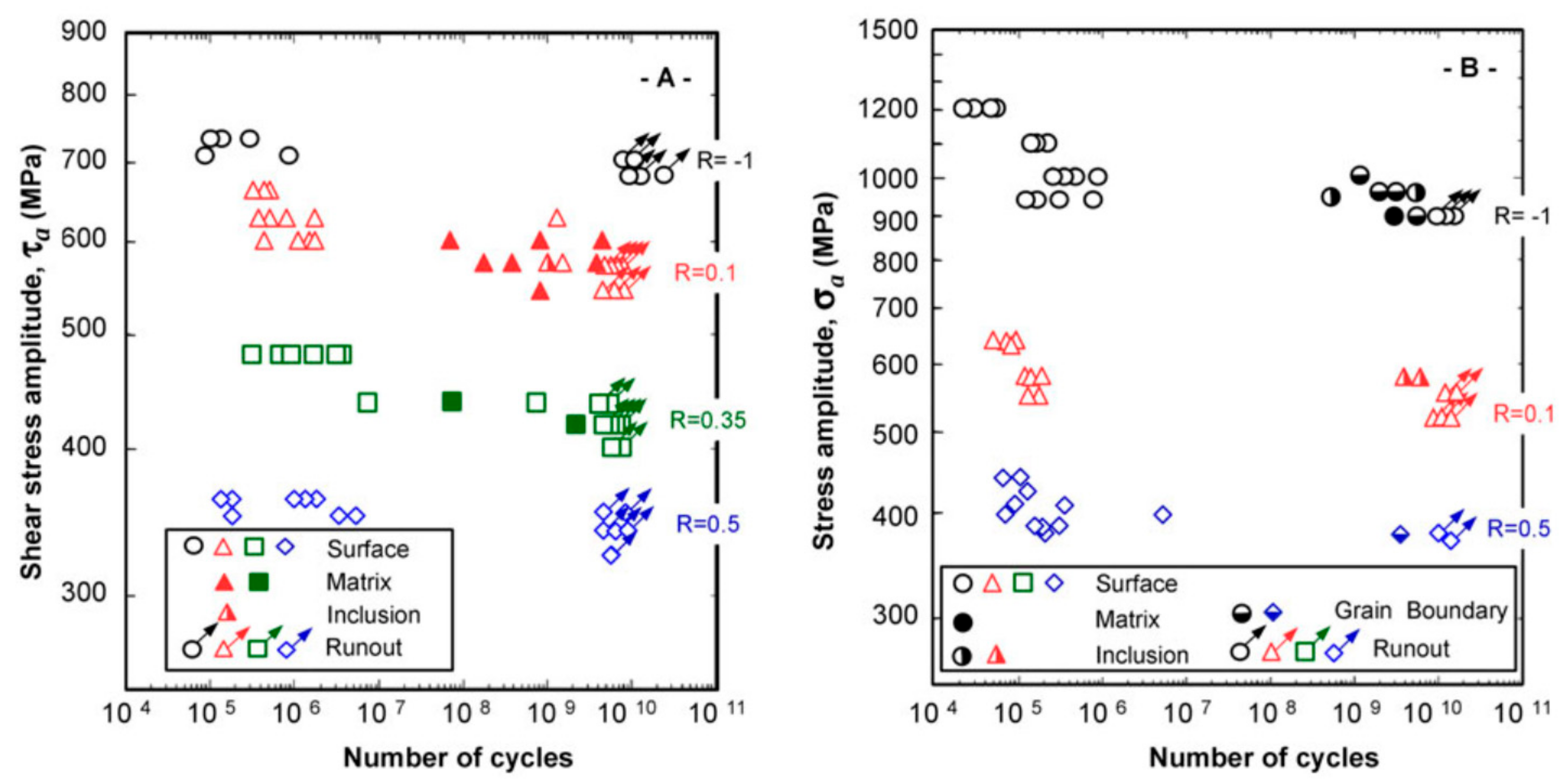

2.1.3. Influence of the Loading Type

2.1.4. Influence of the Stress Ratio

2.1.5. Influence of the Loading Frequency

2.1.6. Influence of the Environment

2.2. Characteristics of the FGA

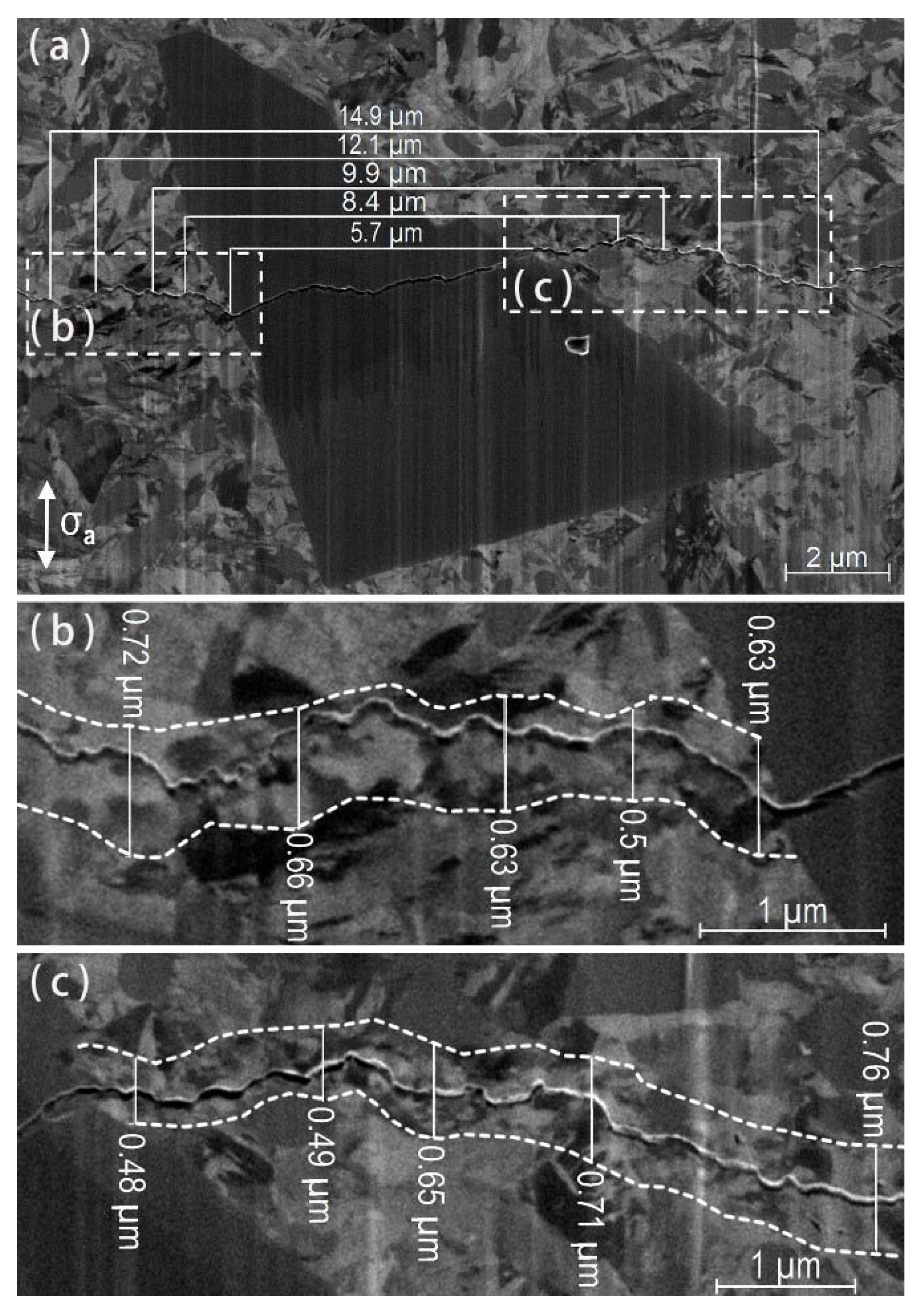

2.2.1. Characteristics Observed on the Fracture Surface

2.2.2. Characteristics Observed by Computed Tomography

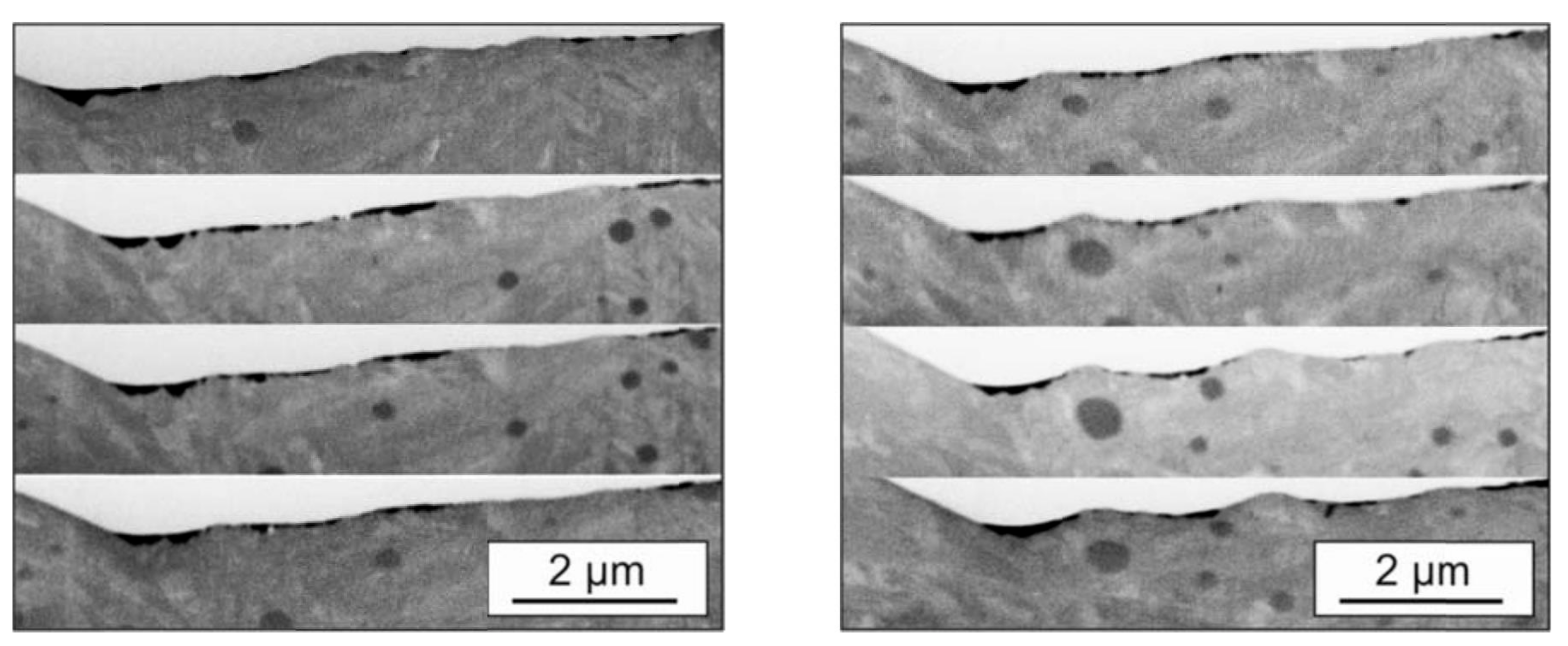

2.2.3. Characteristics Observed by Focused Ion Beam and Ion-Induced Secondary Electron Imaging

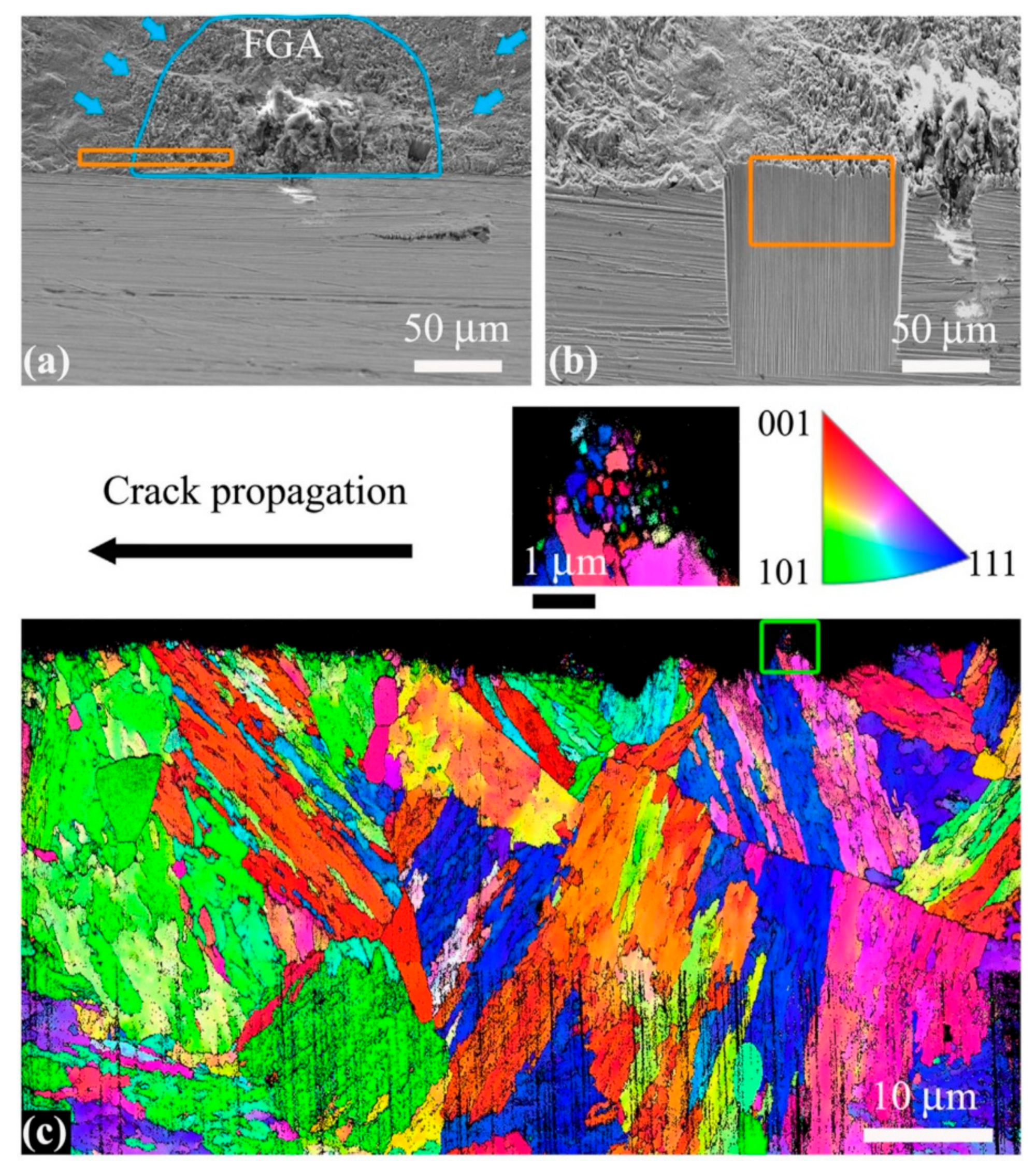

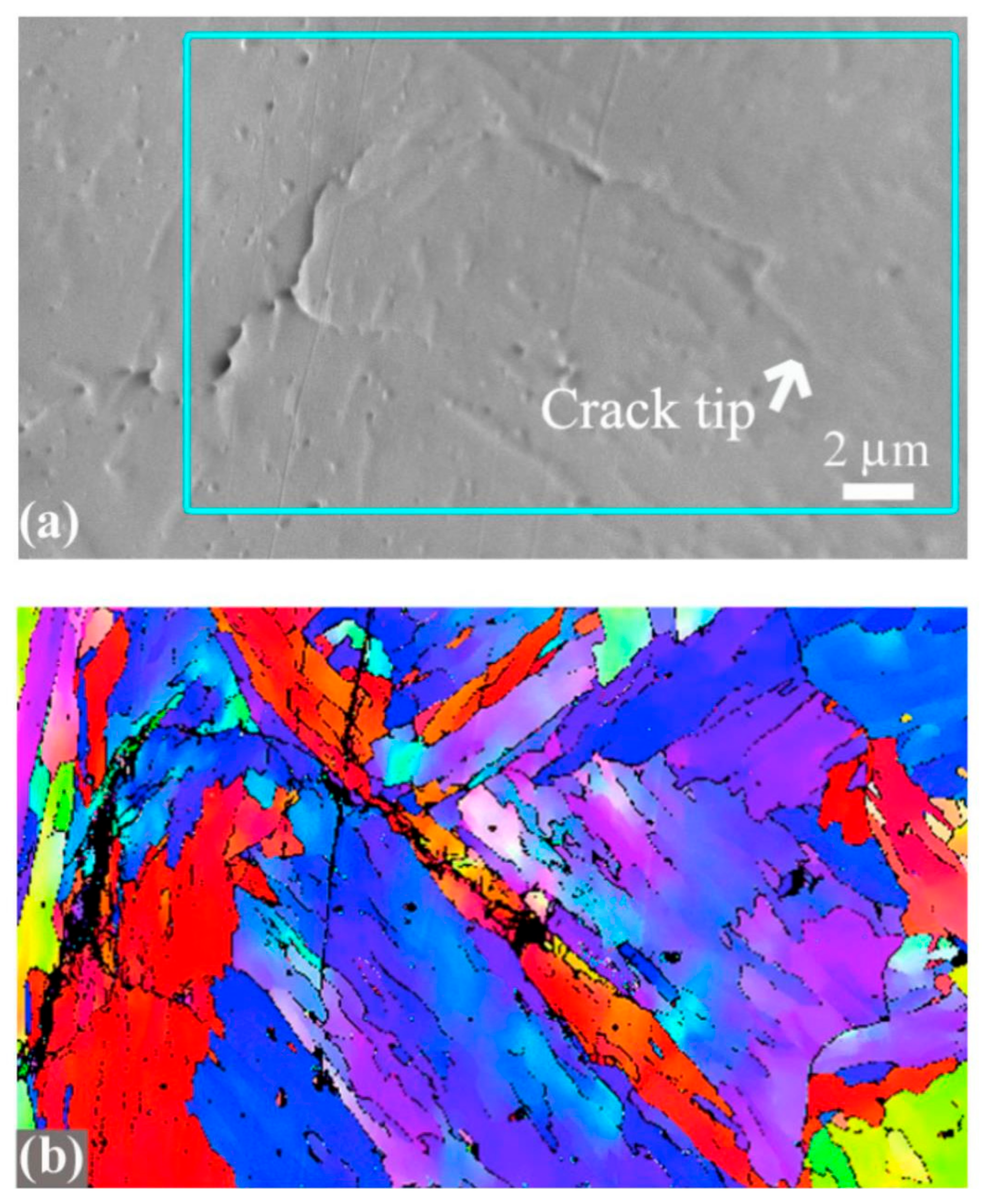

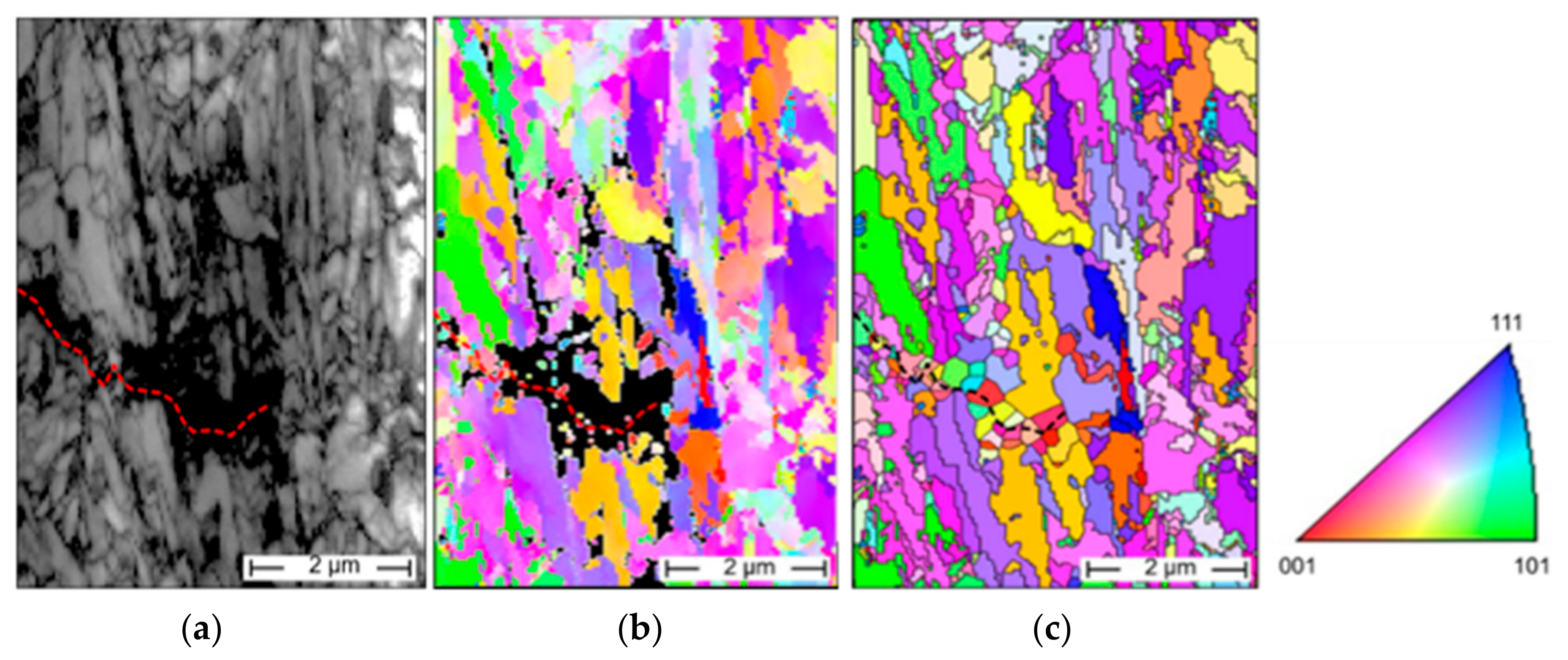

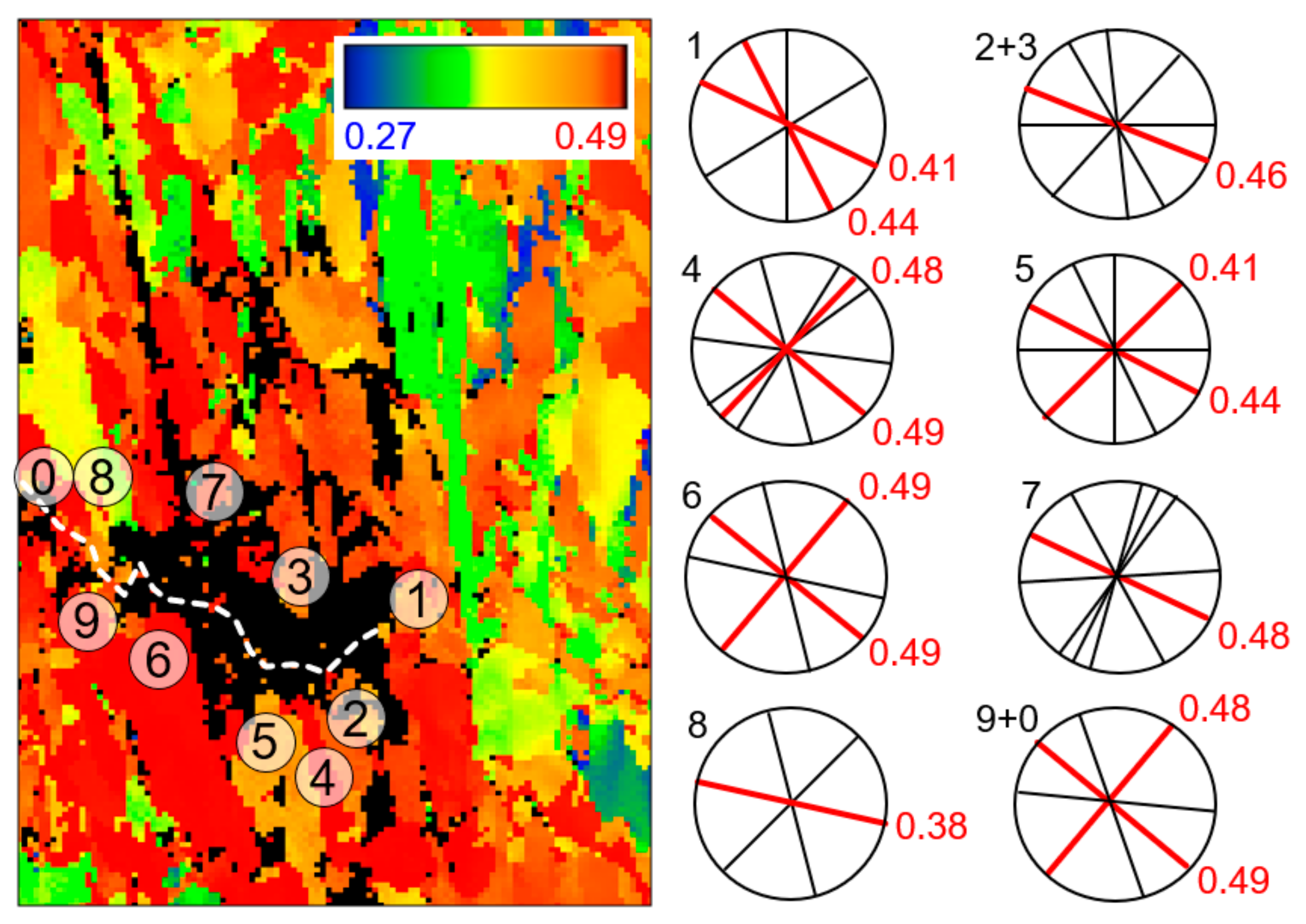

2.2.4. Characteristics Observed by Electron Backscatter Diffraction and Inverse Pole Figure

2.2.5. Characteristics Observed by Transmission Electron Microscopy and Selected Area Diffraction

2.2.6. Characteristics Observed by Atom Probe Tomography

3. Postulated Models Describing the Mechanism of Very High Cycle Crack Initiation and FGA-Formation

3.1. Hydrogen-Assisted Crack Growth of Short Cracks

3.2. Dispersive Decohesion of Spherical Carbide Model

3.3. Polygonization with Nucleation and Coalescence of Micro-Debondings

3.4. Superplastic Effects and Vortex Shaped Flow Resulting in FGA

3.5. Numerous Cyclic Pressing

3.6. Cold Welding-Induced Grain Refinement for Titanium Alloys

3.7. Stage I like Crack Propagation with Grain Refinement in the Crack Wakes

3.8. Local Grain Refinement at the Crack Tip

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Stanzl, S.E.; Tschegg, E.K.; Mayer, H. Lifetime measurements for random loading in the very high cycle fatigue range. Int. J. Fatigue 1986, 8, 195–200. [Google Scholar] [CrossRef]

- Lukas, P.; Kunz, L. Specific features of high-cycle and ultra-high-cycle fatigue. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 747–753. [Google Scholar] [CrossRef]

- Murakami, Y. Mechanism of fatigue failure in ultralong life regime. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 735–746. [Google Scholar] [CrossRef]

- Bathias, C. There is no infinite fatigue life in metallic materials. Fatigue Fract. Eng. Mater. Struct. 1999, 22, 559–565. [Google Scholar] [CrossRef]

- Christ, H.-J. (Ed.) Preface. In Fatigue of Materials at Very High Numbers of Loading Cycles; Springer Fachmedien: Wiesbaden, Germany, 2018. [Google Scholar]

- Shaniavski, A.A.; Skvortsov, G.V. Crack growth in the gigacycle fatigue regime for helicopter gears. Fatigue Fract. Eng. Mater. Struct. 1999, 22, 609–619. [Google Scholar] [CrossRef]

- Bathias, C. Designing Components against Gigacycle Fatigue. In Proceedings of the International Conference on Fatigue in the Very High Cycle Regime, Vienna, Austria, 2–4 July 2001; pp. 97–109. [Google Scholar]

- Sakai, T.; Sato, Y.; Oguma, N. Characteristic S-N properties of high-carbon-chromium-bearing steel under axial loading in long-life fatigue. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 765–773. [Google Scholar] [CrossRef]

- Murakami, Y.; Nomoto, T.; Ueda, T. Factors influencing the mechanism of superlong fatigue failure in steels. Fatigue Fract. Eng. Mater. Struct. 1999, 22, 581–590. [Google Scholar] [CrossRef]

- Shiozawa, K.; Morii, Y.; Nishino, S. Subsurface Crack Initiation and Propagation Mechanism under the Super-Long Fatigue Regime for High Speed Tool Steel (JIS SKH51) by Fracture Surface Topographic Analysis. JSME Int. J. 2006, 49, 1–10. [Google Scholar] [CrossRef][Green Version]

- Ochi, Y.; Matsumura, T.; Masaki, K.; Yoshida, S.-Y. High Cycle Rotating Bending Fatigue Property in Very Long Life Regime of High Strength Steels. In Proceedings of the International Conference on Fatigue in the Very High Cycle Regime, Vienna, Austria, 2–4 July 2001; pp. 81–88. [Google Scholar]

- Sakai, T.; Harada, H.; Oguma, N. Crack initiation mechanism of bearing steel in very high cycle fatigue. In Proceedings of the ECF, Alexandroupolis, Greece, 3–7 July 2006; p. 16. [Google Scholar]

- Grad, P. Rissinitiierung und Rissausbreitung im VHCF-Bereich des hochfesten Stahls 100Cr6 Dissertation; Fachbereich Maschinenbau und Verfahrenstechnik; Technische Universität Kaiserslautern: Kaiserslautern, Germany, 2013. [Google Scholar]

- Hong, Y.; Liu, X.; Lei, Z.; Sun, C. The formation mechanism of characteristic region at crack initiation for very-high-cycle fatigue of high-strength steels. Int. J. Fatigue 2016, 89, 108–118. [Google Scholar] [CrossRef]

- Grad, P.; Reuscher, B.; Brodyanski, A.; Kopnarski, M.; Kerscher, E. Mechanism of fatigue crack initiation and propagation in the very high cycle fatigue regime of high-strength steels. Scr. Mater. 2012, 67, 838–841. [Google Scholar] [CrossRef]

- Jiang, Q.; Sun, C.; Liu, X.; Hong, Y. Very-high-cycle fatigue behavior of a structural steel with and without induced surface defects. Int. J. Fatigue 2016, 93, 352–362. [Google Scholar] [CrossRef]

- Hong, Y.; Sun, C. The nature and the mechanism of crack initiation and early growth for very-high-cycle fatigue of metallic materials—An overview. Theor. Appl. Fract. Mech. 2017, 92, 331–350. [Google Scholar] [CrossRef]

- Jeddi, D.; Palin-Luc, T. A review about the effects of structural and operational factors on the gigacycle fatigue of steels. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 969–990. [Google Scholar] [CrossRef]

- Mughrabi, H. On ‘multi-stage’ fatigue life diagrams and the relevant life-controlling mechanisms in ultrahigh-cycle fatigue. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 755–764. [Google Scholar] [CrossRef]

- Stanzl-Tschegg, S.E.; Schönbauer, B. Mechanisms of strain localization, crack initiation and fracture of polycrystalline copper in the VHCF regime. Int. J. Fatigue 2010, 32, 886–893. [Google Scholar] [CrossRef]

- Stanzl-Tschegg, S.E. Fracture mechanical characterization of the initiation and growth of interior fatigue cracks. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 1741–1751. [Google Scholar] [CrossRef]

- Shiozawa, K.; Lu, L. Very high-cycle fatigue behaviour of shot-peened high-carbon-chromium bearing steel. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 813–822. [Google Scholar] [CrossRef]

- Shiozawa, K.; Morii, Y.; Nishino, S.; Lu, L. Subsurface crack initiation and propagation mechanism in high-strength steel in a very high cycle fatigue regime. Int. J. Fatigue 2006, 28, 1521–1532. [Google Scholar] [CrossRef]

- Stanzl-Tschegg, S.E. Time Saving Method for Measuring VHC Fatigue and Fatigue Crack Growth Data with the Ultrasonic Fatigue Technique. Procedia Struct. Integr. 2016, 2, 3–10. [Google Scholar] [CrossRef]

- Grad, P.; Kerscher, E. Reason for the transition of fatigue crack initiation site from surface to subsurface inclusions in high-strength steels. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 1718–1730. [Google Scholar] [CrossRef]

- Tofique, M.W.; Bergström, J.; Burman, C. Very high cycle fatigue crack initiation mechanisms in different engineering alloys. Procedia Struct. Integr. 2016, 2, 1181–1190. [Google Scholar] [CrossRef]

- Ruffing, C.; Ivanisenko, Y.; Kerscher, E. A comparison of the fatigue and fracture behavior of high strength ultrafine grained medium carbon steel SAE 1045 with high strength bearing steel SAE 52100. Procedia Struct. Integr. 2016, 2, 3240–3247. [Google Scholar] [CrossRef]

- Furuya, Y. Specimen size effects on gigacycle fatigue properties of high-strength steel under ultrasonic fatigue testing. Scr. Mater. 2008, 58, 1014–1017. [Google Scholar] [CrossRef]

- Furuya, Y. Size effects in gigacycle fatigue of high-strength steel under ultrasonic fatigue testing. Procedia Eng. 2010, 2, 485–490. [Google Scholar] [CrossRef]

- Fitzka, M.; Pennings, B.; Karr, U.; Schönbauer, B.; Schuller, R.; Tran, M.D.; Mayer, H. Influence of cycling frequency and testing volume on the VHCF properties of 18Ni maraging steel. Eng. Fract. Mech. 2019, 216, 106525. [Google Scholar] [CrossRef]

- Furuya, Y. Notable size effects on very high cycle fatigue properties of high-strength steel. Mater. Sci. Eng. A 2011, 528, 5234–5240. [Google Scholar] [CrossRef]

- Tridello, A.; Paolino, D.S.; Rossetto, M. Ultrasonic VHCF Tests on Very Large Specimens with Risk-Volume Up to 5000 mm3. Appl. Sci. 2020, 10, 2210. [Google Scholar] [CrossRef]

- Paolino, D.S.; Tridello, A.; Chiandussi, G.; Rossetto, M. On specimen design for size effect evaluation in ultrasonic gigacycle fatigue testing. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 570–579. [Google Scholar] [CrossRef]

- Murakami, Y.; Kodama, S.; Konuma, S. Quantitative evaluation of effects of non-metallic inclusions on fatigue strength of high strength steels.: I: Basic fatigue mechanism and evaluation of correlation between the fatigue fracture stress and the size and location of non-metallic inclusions. Int. J. Fatigue 1989, 11, 291–298. [Google Scholar] [CrossRef]

- Murakami, Y. Metal Fatigue: Effects of Small Defects & Nonmetallic Inclusions; Elsevier Science Ltd.: Oxford, UK, 2002. [Google Scholar]

- Gao, G.; Xu, Q.; Guo, H.; Gui, X.; Zhang, B.; Bai, B. Effect of inclusion and microstructure on the very high cycle fatigue behaviors of high strength bainite/martensite multiphase steels. Mater. Sci. Eng. A 2019, 739, 404–414. [Google Scholar] [CrossRef]

- Zettl, B.; Mayer, H.; Ede, C.; Stanzl-Tschegg, S. Very high cycle fatigue of normalized carbon steels. Int. J. Fatigue 2006, 28, 1583–1589. [Google Scholar] [CrossRef]

- Akiniwa, Y.; Stanzl-Tschegg, S.; Mayer, H.; Wakita, M.; Tanaka, K. Fatigue strength of spring steel under axial and torsional loading in the very high cycle regime. Int. J. Fatigue 2008, 30, 2057–2063. [Google Scholar] [CrossRef]

- Liu, X.; Sun, C.; Hong, Y. Effects of stress ratio on high-cycle and very-high-cycle fatigue behavior of a Ti–6Al–4V alloy. Mater. Sci. Eng. A 2015, 622, 228–235. [Google Scholar] [CrossRef]

- Heinz, S.; Balle, F.; Wagner, G.; Eifler, D. Analysis of fatigue properties and failure mechanisms of Ti6Al4V in the very high cycle fatigue regime using ultrasonic technology and 3D laser scanning vibrometry. Ultrasonics 2013, 53, 1433–1440. [Google Scholar] [CrossRef]

- Zuo, J.H.; Wang, Z.G.; Han, E.H. Effect of microstructure on ultra-high cycle fatigue behavior of Ti–6Al–4V. Mater. Sci. Eng. A 2008, 473, 147–152. [Google Scholar] [CrossRef]

- Chai, G. The formation of subsurface non-defect fatigue crack origins. Int. J. Fatigue 2006, 28, 1533–1539. [Google Scholar] [CrossRef]

- Krupp, U.; Giertler, A.; Söker, M.; Fu, H.; Dönges, B.; Christ, H.J.; Istomin, K.; Hüsecken, A.; Pietsch, U.; Fritzen, C.-P.; et al. Significance and Mechanism of the Crack Initiation Process during Very High Cycle Fatigue of Duplex Stainless Steel. Procedia Eng. 2014, 74, 143–146. [Google Scholar] [CrossRef]

- Miller, K.J. Materials science perspective of metal fatigue resistance. An. De Mec. De La Fract. 1995, 12, 1–10. [Google Scholar] [CrossRef]

- Krupp, U. Fatigue Crack Propagation in Metals and Alloys: Microstructural Aspects and Modelling Concepts; Wiley-VCH-Verl.: Weinheim, Germany, 2007. [Google Scholar]

- Pineau, A.; Forest, S. Effects of inclusions on the very high cycle fatigue behaviour of steels. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 1694–1707. [Google Scholar] [CrossRef]

- Yang, Z.G.; Li, S.X.; Zhang, J.M.; Zhang, J.F.; Li, G.Y.; Li, Z.B.; Hui, W.J.; Weng, Y.Q. The fatigue behaviors of zero-inclusion and commercial 42CrMo steels in the super-long fatigue life regime. Acta Mater. 2004, 52, 5235–5241. [Google Scholar] [CrossRef]

- Zhang, J.; Li, S.; Yang, Z.; Li, G.; Hui, W.; Weng, Y. Influence of inclusion size on fatigue behavior of high strength steels in the gigacycle fatigue regime. Int. J. Fatigue 2007, 29, 765–771. [Google Scholar] [CrossRef]

- Yang, C.; Luan, Y.; Li, D.; Li, Y.; ul Haq Tariq, N. Very high cycle fatigue behavior of bearing steel with rare earth addition. Int. J. Fatigue 2020, 131. [Google Scholar] [CrossRef]

- McGreevy, T.E.; Socie, D.F. Competing roles of microstructure and flaw size. Fatigue Fract. Eng. Mater. Struct. 1999, 22, 495–508. [Google Scholar] [CrossRef]

- Murakami, Y.; Nomoto, T.; Ueda, T. On the mechanism of fatigue failure in the superlong life regime (N>10^7 cycles).: Part I: Influence of hydrogen trapped by inclusions. Fatigue Fract. Eng. Mater. Struct. 2000, 23, 893–902. [Google Scholar] [CrossRef]

- Furuya, Y.; Hirukawa, H.; Hayakawa, M. Gigacycle Fatigue Properties of Hydrogen-Charged JIS-SCM440 Low-Alloy Steel Under Ultrasonic Fatigue Testing. Metall. Mater. Trans. A 2010, 41, 2248–2256. [Google Scholar] [CrossRef]

- Karsch, T.; Bomas, H.; Zoch, H.-W.; Mändl, S. Influence of hydrogen content and microstructure on the fatigue behaviour of steel SAE 52100 in the VHCF regime. Int. J. Fatigue 2014, 60, 74–89. [Google Scholar] [CrossRef]

- Mayer, H.; Schuller, R.; Karr, U.; Fitzka, M.; Irrasch, D.; Hahn, M.; Bacher-Höchst, M. Mean stress sensitivity and crack initiation mechanisms of spring steel for torsional and axial VHCF loading. Int. J. Fatigue 2016, 93, 309–317. [Google Scholar] [CrossRef]

- Nakajima, M.; Tokaji, K.; Itoga, H.; Shimizu, T. Effect of loading condition on very high cycle fatigue behavior in a high strength steel. Int. J. Fatigue 2010, 32, 475–480. [Google Scholar] [CrossRef]

- Li, W.; Sakai, T.; Li, Q.; Lu, L.T.; Wang, P. Effect of loading type on fatigue properties of high strength bearing steel in very high cycle regime. Mater. Sci. Eng. A 2011, 528, 5044–5052. [Google Scholar] [CrossRef]

- Hu, Y.; Sun, C.; Xie, J.; Hong, Y. Effects of Loading Frequency and Loading Type on High-Cycle and Very-High-Cycle Fatigue of a High-Strength Steel. Materials 2018, 11, 1456. [Google Scholar] [CrossRef]

- Maierhofer, J.; Pippan, R.; Gänser, H.-P. Modified NASGRO equation for physically short cracks. Int. J. Fatigue 2014, 59, 200–207. [Google Scholar] [CrossRef]

- Maierhofer, J.; Kolitsch, S.; Pippan, R.; Gänser, H.-P.; Madia, M.; Zerbst, U. The cyclic R-curve—Determination, problems, limitations and application. Eng. Fract. Mech. 2018, 198, 45–64. [Google Scholar] [CrossRef]

- Kovacs, S.; Beck, T.; Singheiser, L. Influence of mean stresses on fatigue life and damage of a turbine blade steel in the VHCF-regime. Int. J. Fatigue 2013, 49, 90–99. [Google Scholar] [CrossRef]

- Nakamura, T.; Oguma, H.; Shinohara, Y. The effect of vacuum-like environment inside sub-surface fatigue crack on the formation of ODA fracture surface in high strength steel. Procedia Eng. 2010, 2, 2121–2129. [Google Scholar] [CrossRef]

- Abdesselam, H.; Crépin, J.; Pineau, A.; Rouffie, A.L.; Gaborit, P.; Menut-Tournadre, L.; Morgeneyer, T.F. On the crystallographic, stage I-like, character of fine granular area formation in internal fish-eye fatigue cracks. Int. J. Fatigue 2018, 106, 132–142. [Google Scholar] [CrossRef]

- Karsch, T. Einfluss von Wasserstoff und Nichtmetallischen Einschlüssen auf die Versagensmechanismen des Wälzlagerstahles 100Cr6 im VHCF-Bereich; Dissertation Fachbereich Produktionstechnik; Universität Bremen: Bremen, Germany, 2015. [Google Scholar]

- Deng, H.; Li, W.; Zhao, H.; Sakai, T. Multiple Fatigue Failure Behaviors and Long-Life Prediction Approach of Carburized Cr-Ni Steel with Variable Stress Ratio. Materials 2017, 10, 1084. [Google Scholar] [CrossRef]

- Shiozawa, K.; Hasegawa, T.; Kashiwagi, Y.; Lu, L. Very high cycle fatigue properties of bearing steel under axial loading condition. Int. J. Fatigue 2009, 31, 880–888. [Google Scholar] [CrossRef]

- Ritz, F.; Beck, T. Influence of mean stress and notches on the very high cycle fatigue behaviour and crack initiation of a low-pressure steam turbine steel. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 1762–1771. [Google Scholar] [CrossRef]

- Mayer, H.; Papakyriacou, M.; Pippan, R.; Stanzl-Tschegg, S. Influence of loading frequency on the high cycle fatigue properties of AlZnMgCu1.5 aluminium alloy. Mater. Sci. Eng. A 2001, 314, 48–54. [Google Scholar] [CrossRef]

- Furuya, Y.; Matsuoka, S.; Abe, T.; Yamaguchi, K. Gigacycle fatigue properties for high-strength low-alloy steel at 100 Hz, 600 Hz, and 20 kHz. Scr. Mater. 2002, 46, 157–162. [Google Scholar] [CrossRef]

- Marines, I.; Dominguez, G.; Baudry, G.; Vittori, J.F.; Rathery, S.; Doucet, J.P.; Bathias, C. Ultrasonic fatigue tests on bearing steel AISI-SAE 52100 at frequency of 20 and 30 kHz. Int. J. Fatigue 2003, 25, 1037–1046. [Google Scholar] [CrossRef]

- Zhao, A.; Xie, J.; Sun, C.; Lei, Z.; Hong, Y. Effects of strength level and loading frequency on very-high-cycle fatigue behavior for a bearing steel. Int. J. Fatigue 2012, 38, 46–56. [Google Scholar] [CrossRef]

- Bach, J.; Göken, H.; Höppel, W. Fatigue of low alloyed carbon steels in the HCF/VHCF-regimes. In Fatigue of Materials at Very High Numbers of Loading Cycles; Christ, H.-J., Ed.; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2018; pp. 10–23. [Google Scholar]

- Zhu, X.; Jones, J.W.; Allison, J.E. Effect of Frequency, Environment, and Temperature on Fatigue Behavior of E319 Cast Aluminum Alloy: Stress-Controlled Fatigue Life Response. Metall. Mater. Trans. A 2008, 39, 2681–2688. [Google Scholar] [CrossRef]

- Palin-Luc, T.; Pérez-Mora, R.; Bathias, C.; Domínguez, G.; Paris, P.C.; Arana, J.L. Fatigue crack initiation and growth on a steel in the very high cycle regime with sea water corrosion. Eng. Fract. Mech. 2010, 77, 1953–1962. [Google Scholar] [CrossRef]

- Li, S.X.; Zhang, P.Y.; Yu, S.R. Experimental study on very high cycle fatigue of martensitic steel of 2Cr13 under corrosive environment. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 1146–1152. [Google Scholar] [CrossRef]

- Qian, G.; Zhou, C.; Hong, Y. A model to predict S–N curves for surface and subsurface crack initiations in different environmental media. Int. J. Fatigue 2015, 71, 35–44. [Google Scholar] [CrossRef]

- Pérez-Mora, R.; Palin-Luc, T.; Bathias, C.; Paris, P.C. Very high cycle fatigue of a high strength steel under sea water corrosion: A strong corrosion and mechanical damage coupling. Int. J. Fatigue 2015, 74, 156–165. [Google Scholar] [CrossRef]

- Petit, J.; Sarrrazin-Baudox, C. An overview on the influence of the atmosphere environment on ultra-high-cycle fatigue and ultra-slow fatigue crack propagation. Int. J. Fatigue 2006, 28, 1471–1478. [Google Scholar] [CrossRef]

- Alekseenko, E.N.; Grinberg, N.M. Effect of vacuum on the plastic zone around a fatigue crack in armco iron. Probl. Prochnosti 1979, 11, 101–104. [Google Scholar] [CrossRef]

- Ohta, A.; Sasaki, E. Plastic Zone around Fatigue Cracks of Pure Iron in Vacuum and Dry Air. Acta Metall. 1972, 20, 657–660. [Google Scholar] [CrossRef]

- Grinberg, N.M. The Effect of Vacuum on Fatigue Crack Growth. Int. J. Fatigue 1982, 4, 83–95. [Google Scholar] [CrossRef]

- Oguma, H.; Nakamura, T. Fatigue crack propagation properties of Ti–6Al–4V in vacuum environments. Int. J. Fatigue 2012, 50, 89–93. [Google Scholar] [CrossRef]

- Stanzl-Tschegg, S.; Schönbauer, B. Near-threshold fatigue crack propagation and internal cracks in steel. Procedia Eng. 2010, 2, 1547–1555. [Google Scholar] [CrossRef]

- Spriestersbach, D.; Brodyanski, A.; Lösch, J.; Kopnarski, M.; Kerscher, E. Very high cycle fatigue of high-strength steels: Crack initiation by FGA formation investigated at artificial defects. Procedia Struct. Integr. 2016, 2, 1101–1108. [Google Scholar] [CrossRef]

- Spriestersbach, D.; Brodyanski, A.; Lösch, J.; Kopnarski, M.; Kerscher, E. Very high cycle fatigue of bearing steels with artificial defects in vacuum. Mater. Sci. Technol. 2016, 32, 1111–1118. [Google Scholar] [CrossRef]

- Tofique, M.W.; Bergström, J.; Svensson, K. Very high cycle fatigue of cold rolled stainless steels, crack initiation and formation of the fine granular area. Int. J. Fatigue 2017, 100, 238–250. [Google Scholar] [CrossRef]

- Murakami, Y.; Nomoto, T.; Ueda, T. On the mechanism of fatigue failure in the superlong life regime (N>10^7 cycles).: Part II: A fractographic investigation. Fatigue Fract. Eng. Mater. Struct. 2000, 23, 903–910. [Google Scholar] [CrossRef]

- Murakami, Y.; Endo, M. Effects of Hardness and Crack Geometries on Delta Kth of Small Cracks Emanating from Small Defects. In The Behaviour of Short Fatigue Cracks; Miller, K.J., Ed.; Mechanical Engineering Publications: London, UK, 1986; pp. 275–293. [Google Scholar]

- Sun, C.; Song, Q.; Zhou, L.; Liu, J.; Wang, Y.; Wu, X.; Wei, Y. The formation of discontinuous gradient regimes during crack initiation in high strength steels under very high cycle fatigue. Int. J. Fatigue 2019, 124, 483–492. [Google Scholar] [CrossRef]

- Mayer, H.; Haydn, W.; Schuller, R.; Issler, S.; Bacher-Höchst, M. Very high cycle fatigue properties of bainitic high carbon–chromium steel under variable amplitude conditions. Int. J. Fatigue 2009, 31, 1300–1308. [Google Scholar] [CrossRef]

- Spriestersbach, D.; Kerscher, E. The role of local plasticity during very high cycle fatigue crack initiation in high-strength steels. Int. J. Fatigue 2018, 111, 93–100. [Google Scholar] [CrossRef]

- Spriestersbach, D. VHCF-Verhalten des Hochfesten Stahls 100Cr6: Rissinitiierungsmechanismen und Schwellenwerte. Ph.D. Dissertation, Technische Universität Kaiserslautern, Kaiserslautern, Germany, 2019. [Google Scholar]

- Sakai, T.; Sato, Y.; Nagano, Y.; Takeda, M.; Oguma, N. Effect of stress ratio on long life fatigue behavior of high carbon chromium bearing steel under axial loading. Int. J. Fatigue 2006, 28, 1547–1554. [Google Scholar] [CrossRef]

- Ogawa, T.; Stanzl-Tschegg, S.E.; Schönbauer, B.M. A fracture mechanics approach to interior fatigue crack growth in the very high cycle regime. Eng. Fract. Mech. 2014, 115, 241–254. [Google Scholar] [CrossRef]

- Wang, C.; Petit, J.; Huang, Z.; Wagner, D. Investigation of crack initiation mechanisms responsible for the fish eye formation in the Very High Cycle Fatigue regime. Int. J. Fatigue 2019, 119, 320–329. [Google Scholar] [CrossRef]

- Yang, Z.G.; Li, S.X.; Liu, Y.B.; Li, Y.D.; Li, G.Y.; Hui, W.J.; Weng, Y.Q. Estimation of the size of GBF area on fracture surface for high strength steels in very high cycle fatigue regime. Int. J. Fatigue 2008, 30, 1016–1023. [Google Scholar] [CrossRef]

- Bayraktar, E.; Garcias, I.; Bathias, C. Failure mechanisms of automotive metallic alloys in very high cycle fatigue range. Int. J. Fatigue 2006, 28, 1590–1602. [Google Scholar] [CrossRef]

- Hong, Y.; Lei, Z.; Sun, C.; Zhao, A. Propensities of crack interior initiation and early growth for very-high-cycle fatigue of high strength steels. Int. J. Fatigue 2014, 58, 144–151. [Google Scholar] [CrossRef]

- Tanaka, K.; Akiniwa, Y. Fatigue crack propagation behaviour derived from S-N data in very high cycle regime. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 775–784. [Google Scholar] [CrossRef]

- Fischer, G.; Nellesen, J.; Anar, N.B.; Ehrig, K.; Riesemeier, H.; Tillmann, W. 3D analysis of micro-deformation in VHCF-loaded nodular cast iron by μCT. Mater. Sci. Eng. A 2013, 577, 202–209. [Google Scholar] [CrossRef]

- Nakamura, T.; Yoshinaka, F.; Nakayama, S.; Oguma, H.; Shiozawa, D.; Nakai, Y.; Uesugi, K. Detection of small internal fatigue cracks in Ti-6Al-4V by using synchrotron radiation μCT imaging. Mech. Eng. Lett. 2016, 2, 16-00233. [Google Scholar] [CrossRef]

- Yoshinaka, F.; Nakamura, T.; Nakayama, S.; Shiozawa, D.; Nakai, Y.; Uesugi, K. Non-destructive observation of internal fatigue crack growth in Ti–6Al–4V by using synchrotron radiation μCT imaging. Int. J. Fatigue 2016, 93, 397–405. [Google Scholar] [CrossRef]

- Yoshinaka, F.; Nakamura, T.; Takeuchi, A.; Uesugi, M.; Uesugi, K. Initiation and growth behaviour of small internal fatigue cracks in Ti-6Al-4V via synchrotron radiation microcomputed tomography. Fatigue Fract. Eng. Mater. Struct. 2019. [Google Scholar] [CrossRef]

- Liu, L.; Hou, N.; Li, B.; Ma, B.; Hu, S.; Ding, N. Structure characterization within the vicinity of the fine granular area by synchrotron radiation nano-CT. Fatigue Fract. Eng. Mater. Struct. 2020, 39, 103. [Google Scholar] [CrossRef]

- Song, Q.; Sun, C. Mechanism of crack initiation and early growth of high strength steels in very high cycle fatigue regime. Mater. Sci. Eng. A 2020, 771. [Google Scholar] [CrossRef]

- Chai, G.; Forsman, T.; Gustavsson, F.; Wang, C. Formation of fine grained area in martensitic steel during very high cycle fatigue. Fatigue Fract. Eng. Mater. Struct. 2015, 38, 1315–1323. [Google Scholar] [CrossRef]

- Chang, Y.; Zheng, L.; Pan, X.; Hong, Y. Further investigation on microstructure refinement of internal crack initiation region in VHCF regime of high-strength steels. Frattura ed Integrità Strutturale 2019, 13, 1–11. [Google Scholar] [CrossRef]

- Sauvage, X.; Ganeev, A.; Ivanisenko, Y.; Enikeev, N.; Murashkin, M.; Valiev, R. Grain Boundary Segregation in UFG Alloys Processed by Severe Plastic Deformation. Adv. Eng. Mater. 2012, 14, 968–974. [Google Scholar] [CrossRef]

- Abramova, M.M.; Enikeev, N.A.; Valiev, R.Z.; Etienne, A.; Radiguet, B.; Ivanisenko, Y.; Sauvage, X. Grain boundary segregation induced strengthening of an ultrafine-grained austenitic stainless steel. Mater. Lett. 2014, 136, 349–352. [Google Scholar] [CrossRef]

- Kang, J.; Williams, C.; Hosseinkhani, B.; Rivera Diaz del Castillo, P.E.; Bagot, P.A.; Moody, M.P. Atom Probe Tomography Characterization of a White Etching Area in a Bearing Steel. Microsc. Microanal. 2013, 19, 1016–1017. [Google Scholar] [CrossRef][Green Version]

- Kang, J.-H.; Hosseinkhani, B.; Williams, C.A.; Moody, M.P.; Bagot, P.A.J.; Rivera-Díaz-del-Castillo, P.E.J. Solute redistribution in the nanocrystalline structure formed in bearing steels. Scr. Mater. 2013, 69, 630–633. [Google Scholar] [CrossRef]

- Li, Y.J.; Herbig, M.; Goto, S.; Raabe, D. Formation of nanosized grain structure in martensitic 100Cr6 bearing steels upon rolling contact loading studied by atom probe tomography. Mater. Sci. Technol. 2016, 32, 1100–1105. [Google Scholar] [CrossRef]

- Li, Y.J.; Herbig, M.; Goto, S.; Raabe, D. Atomic scale characterization of white etching area and its adjacent matrix in a martensitic 100Cr6 bearing steel. Mater. Charact. 2017, 123, 349–353. [Google Scholar] [CrossRef]

- Takai, K.; Seki, J.I.; Homma, Y. Observation of Trapping Sites of Hydrogen and Deuterium in High-Strength Steels by Using Secondary Ion Mass Spectrometry. Mater. Trans. JIM 1995, 36, 1134–1139. [Google Scholar] [CrossRef]

- Narita, N.; Shiga, T.; Higashida, K. Crack-impurity interactions and their role in the embrittlement of Fe alloy crystals charged with light elements. Mater. Sci. Eng. 1994, 176, 209. [Google Scholar] [CrossRef]

- Shiozawa, K.; Lu, L. Internal Fatigue Failure Mechanism of High Strength Steels in Gigacycle Regime. Key Eng. Mater. 2008, 378, 65–80. [Google Scholar] [CrossRef]

- Chai, G.; Forsman, T.; Gustavsson, F. Microscopic and nanoscopic study on subsurface damage and fatigue crack initiation during very high cycle fatigue. Int. J. Fatigue 2016, 83, 288–292. [Google Scholar] [CrossRef]

- Zhu, M.-L.; Jin, L.; Xuan, F.-Z. Fatigue life and mechanistic modeling of interior micro-defect induced cracking in high cycle and very high cycle regimes. Acta Mater. 2018, 157, 259–275. [Google Scholar] [CrossRef]

- van Swarm, L.F.; Pelloux, R.M.; Grant, N.J. Fatigue behavior of maraging steel 300. Metall. Mater. Trans. A 1975, 6, 45–54. [Google Scholar]

- Koster, M.; Wagner, G.; Eifler, D. Cyclic deformation behavior of a medium carbon steel in the VHCF regime. Procedia Eng. 2010, 2, 2189–2197. [Google Scholar] [CrossRef]

- Shanyavskiy, A.A. Mechanisms and modeling of subsurface fatigue cracking in metals. Eng. Fract. Mech. 2013, 110, 350–363. [Google Scholar] [CrossRef]

- Miller, K.J. The two thresholds of fatigue behaviour. Fatigue Fract. Eng. Mater. Struct. 1993, 16, 931–939. [Google Scholar] [CrossRef]

- Chai, G.; Zhou, N.; Ciurea, S.; Andersson, M.; Lin Peng, R. Local plasticity exhaustion in a very high cycle fatigue regime. Scr. Mater. 2012, 66, 769–772. [Google Scholar] [CrossRef]

- Niendorf, T.; Rubitschek, F.; Maier, H.J.; Canadinc, D.; Karaman, I. On the fatigue crack growth–microstructure relationship in ultrafine-grained interstitial-free steel. J. Mater. Sci. 2010, 45, 4813–4821. [Google Scholar] [CrossRef]

- Hockauf, K.; Halle, T.; Hockauf, M.; Wagner, M.F.X.; Lampke, T. Near-Threshold Fatigue Crack Propagation in an ECAP-Processed Ultrafine-Grained Aluminium Alloy. MSF 2011, 667, 873–878. [Google Scholar] [CrossRef]

- Vinogradov, A. Fatigue limit and crack growth in ultra-fine grain metals produced by severe plastic deformation. J. Mater. Sci. 2007, 42, 1797–1808. [Google Scholar] [CrossRef]

- Silva, F. Fatigue crack propagation after overloading and underloading at negative stress ratios. Int. J. Fatigue 2007, 29, 1757–1771. [Google Scholar] [CrossRef]

- Morales-Rivas, L.; Ram, F.; Spriestersbach, D.; Sippel, J.; Graef, M.; de Kerscher, E. Fine granular area linked to very high cycle fatigue in martensitic and bainitic steels: characterization by means of EBSD-dictionary indexing. Scr. Mater. 2021, 194, 113644. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sippel, J.P.; Kerscher, E. Properties of the Fine Granular Area and Postulated Models for Its Formation during Very High Cycle Fatigue—A Review. Appl. Sci. 2020, 10, 8475. https://doi.org/10.3390/app10238475

Sippel JP, Kerscher E. Properties of the Fine Granular Area and Postulated Models for Its Formation during Very High Cycle Fatigue—A Review. Applied Sciences. 2020; 10(23):8475. https://doi.org/10.3390/app10238475

Chicago/Turabian StyleSippel, Jan Patrick, and Eberhard Kerscher. 2020. "Properties of the Fine Granular Area and Postulated Models for Its Formation during Very High Cycle Fatigue—A Review" Applied Sciences 10, no. 23: 8475. https://doi.org/10.3390/app10238475

APA StyleSippel, J. P., & Kerscher, E. (2020). Properties of the Fine Granular Area and Postulated Models for Its Formation during Very High Cycle Fatigue—A Review. Applied Sciences, 10(23), 8475. https://doi.org/10.3390/app10238475