Pores Evolution of Soft Clay under Loading/Unloading Process

Abstract

1. Introduction

2. Experimental Program

2.1. Soil Sample

2.2. Experimental Method

3. Experimental Results

3.1. The Compression and Swelling Indices

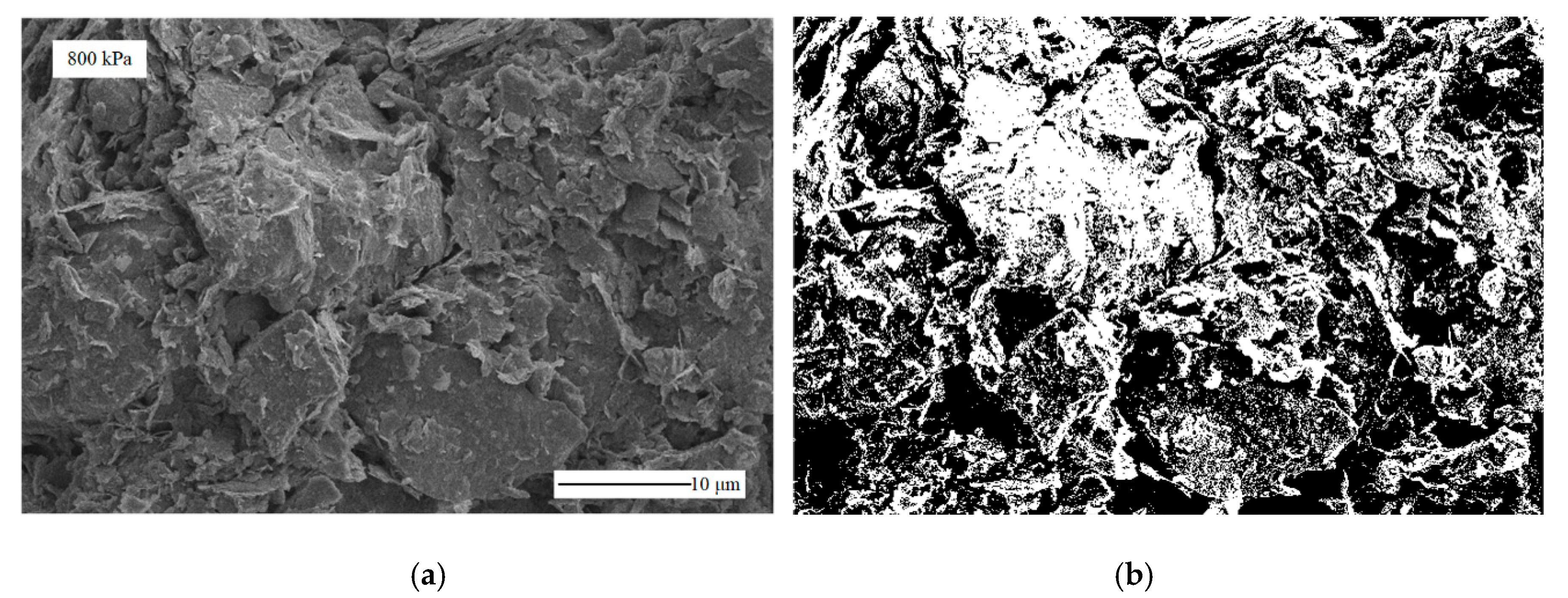

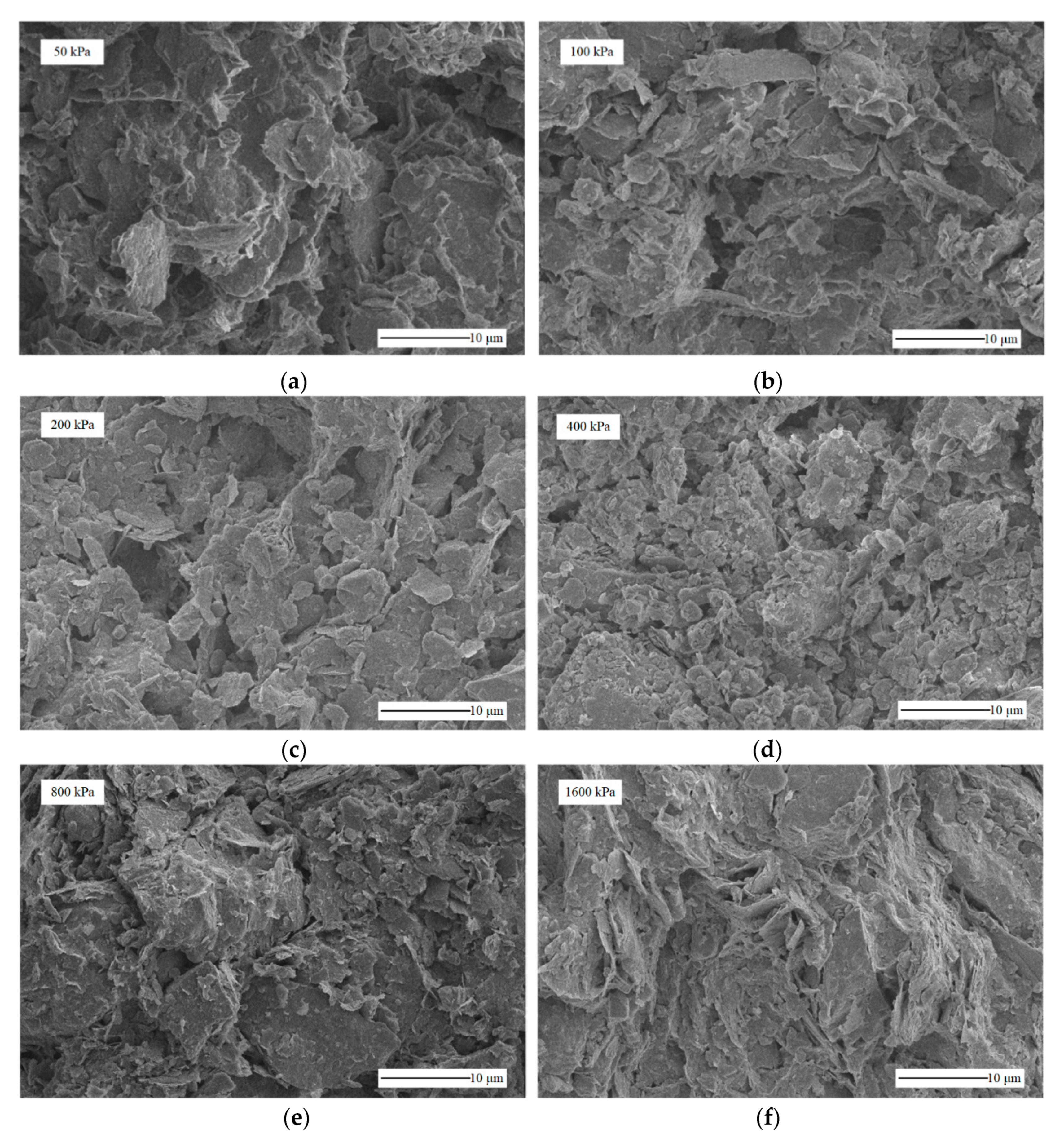

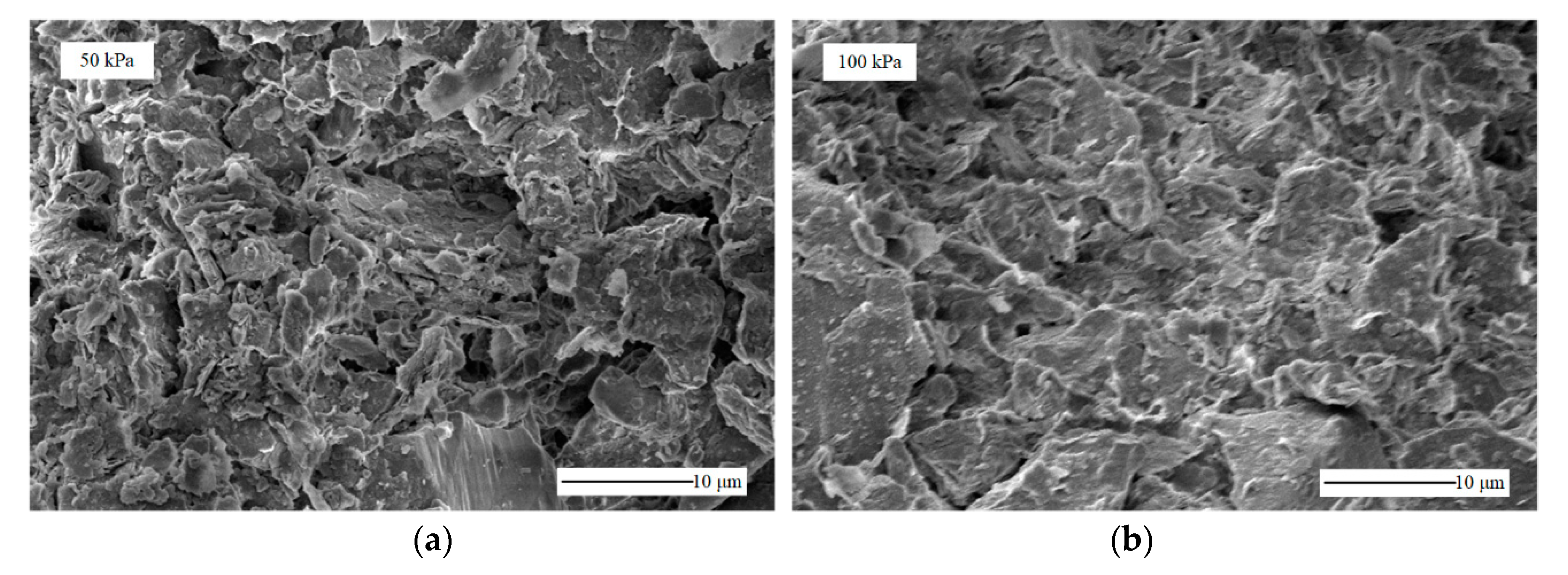

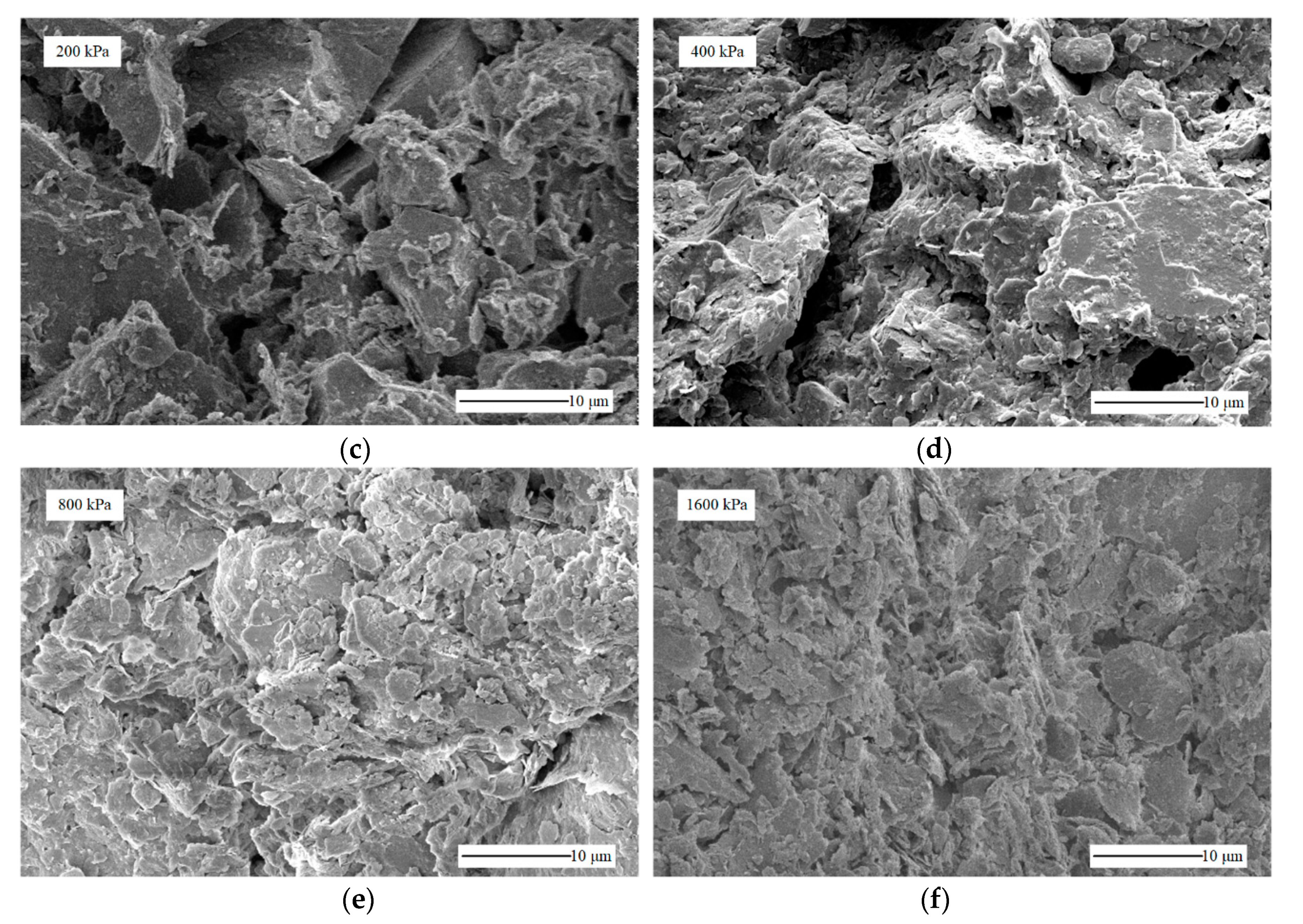

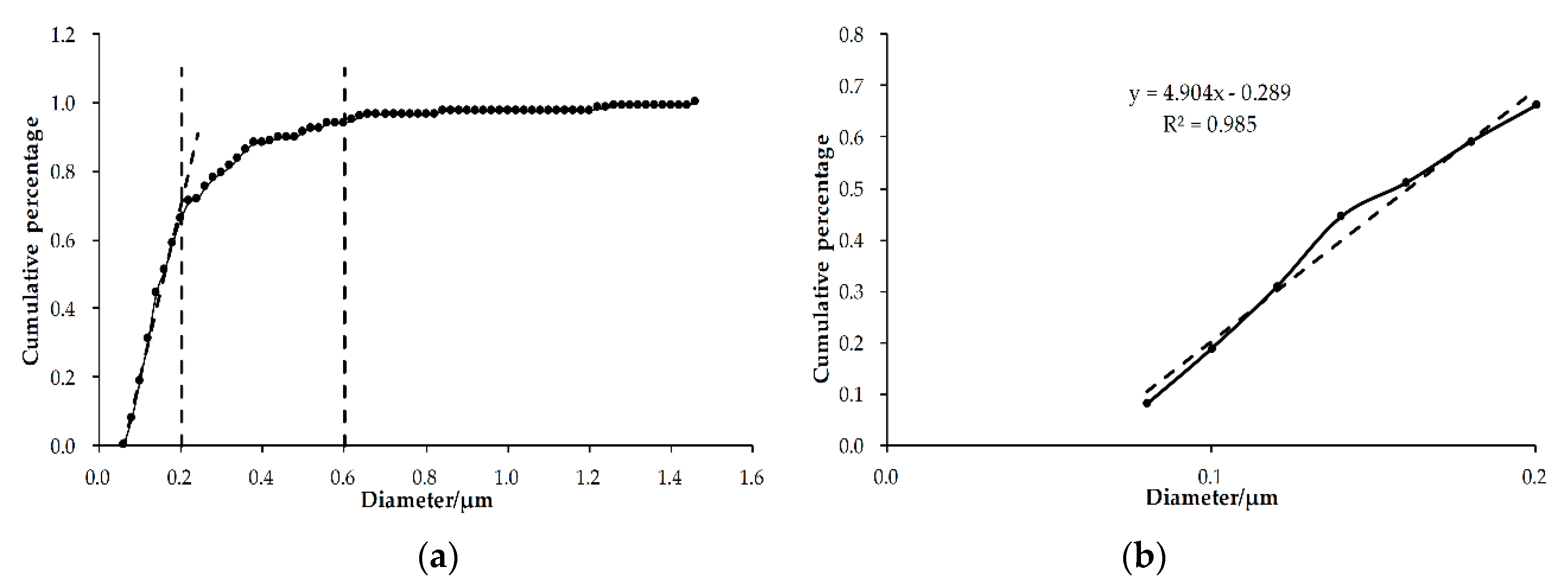

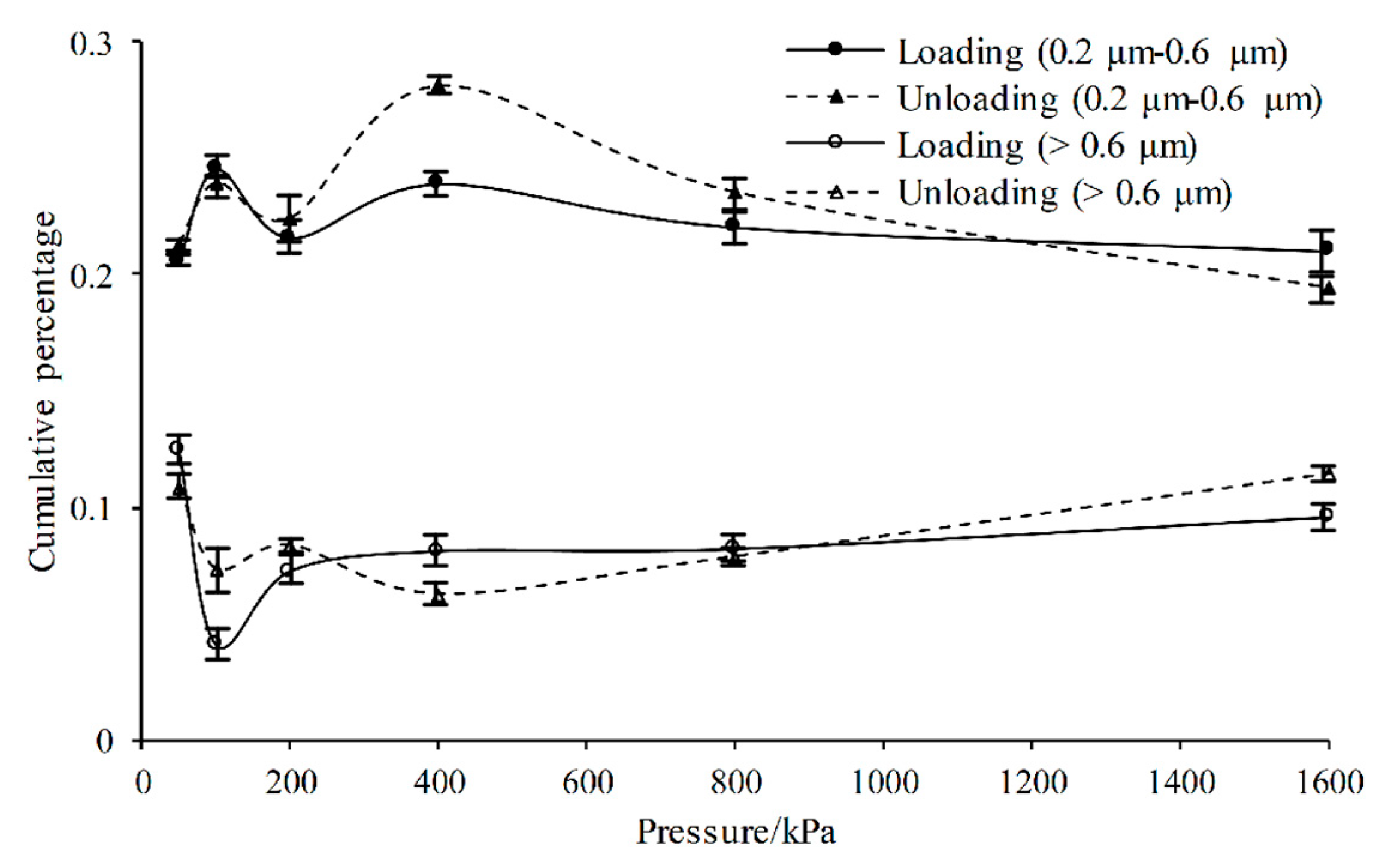

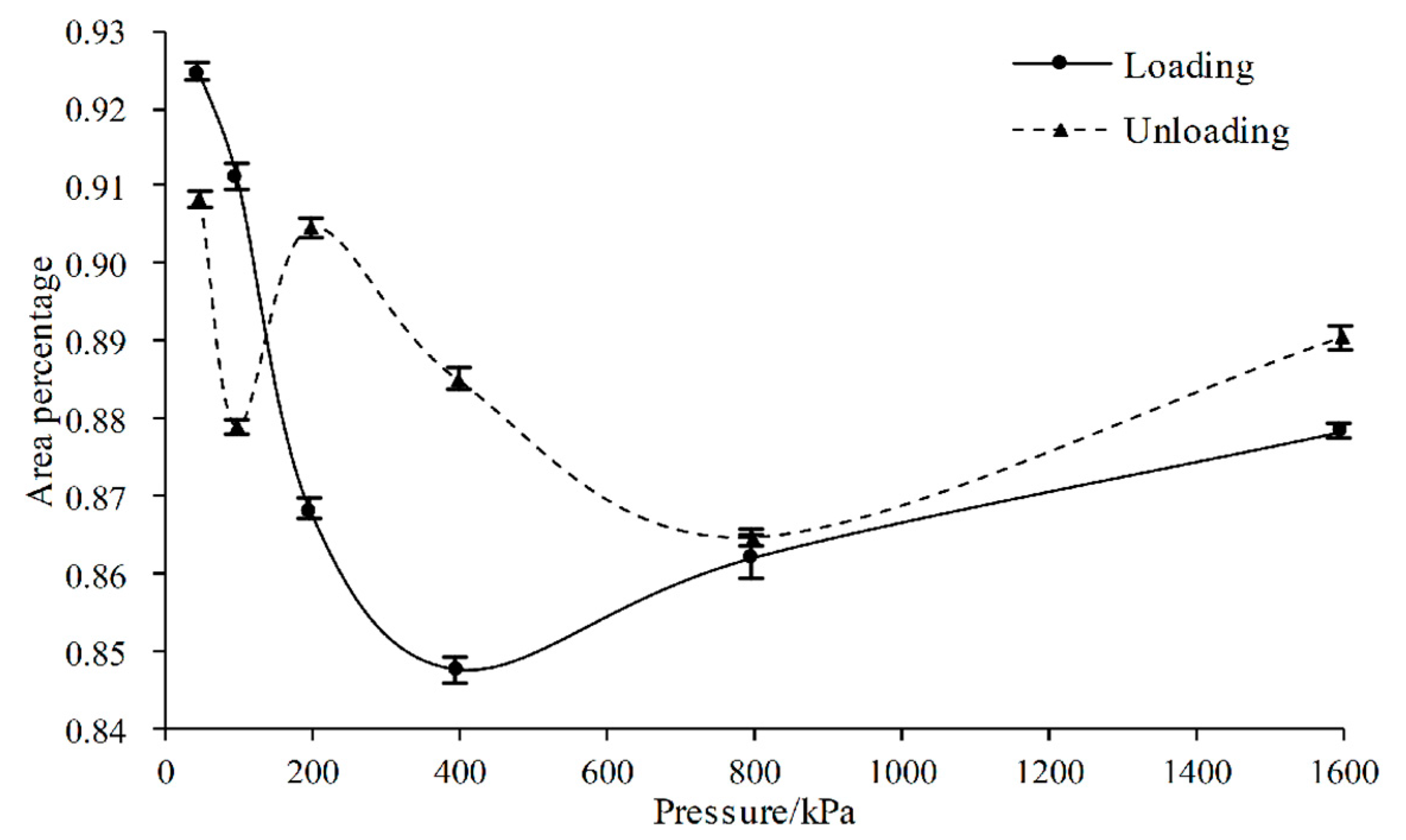

3.2. FESEM Images and Pore Size Distribution

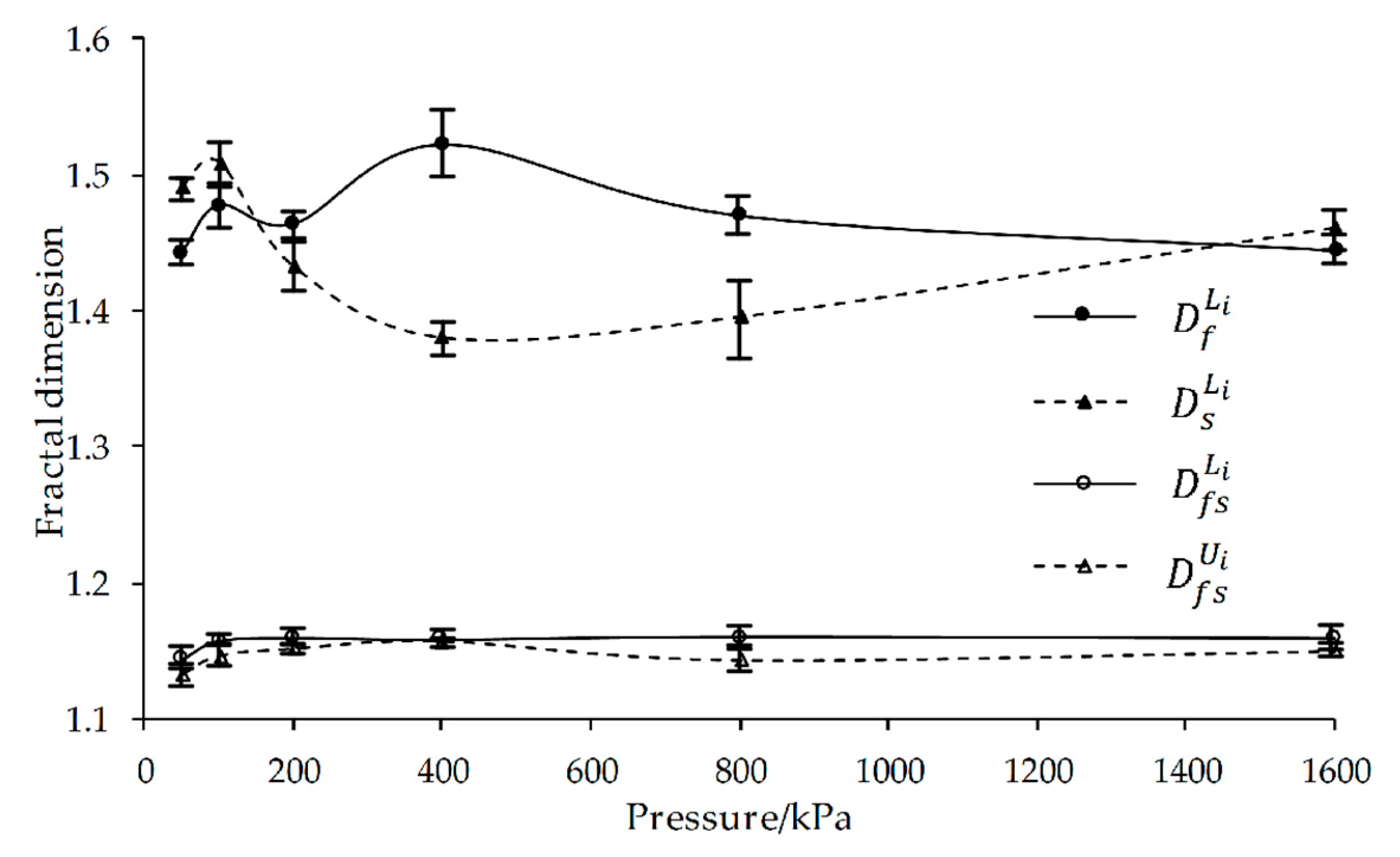

3.3. Fractal Analysis

4. Discussion

5. Conclusions

- Small pores with diameters smaller than 0.2 μm had intrinsic characteristics, their and size distribution was basically unchanged with pressure. Large pores, bigger than 0.6 μm, changed greatly under loading/unloading, and the pore-size distribution was mainly influenced by large pores.

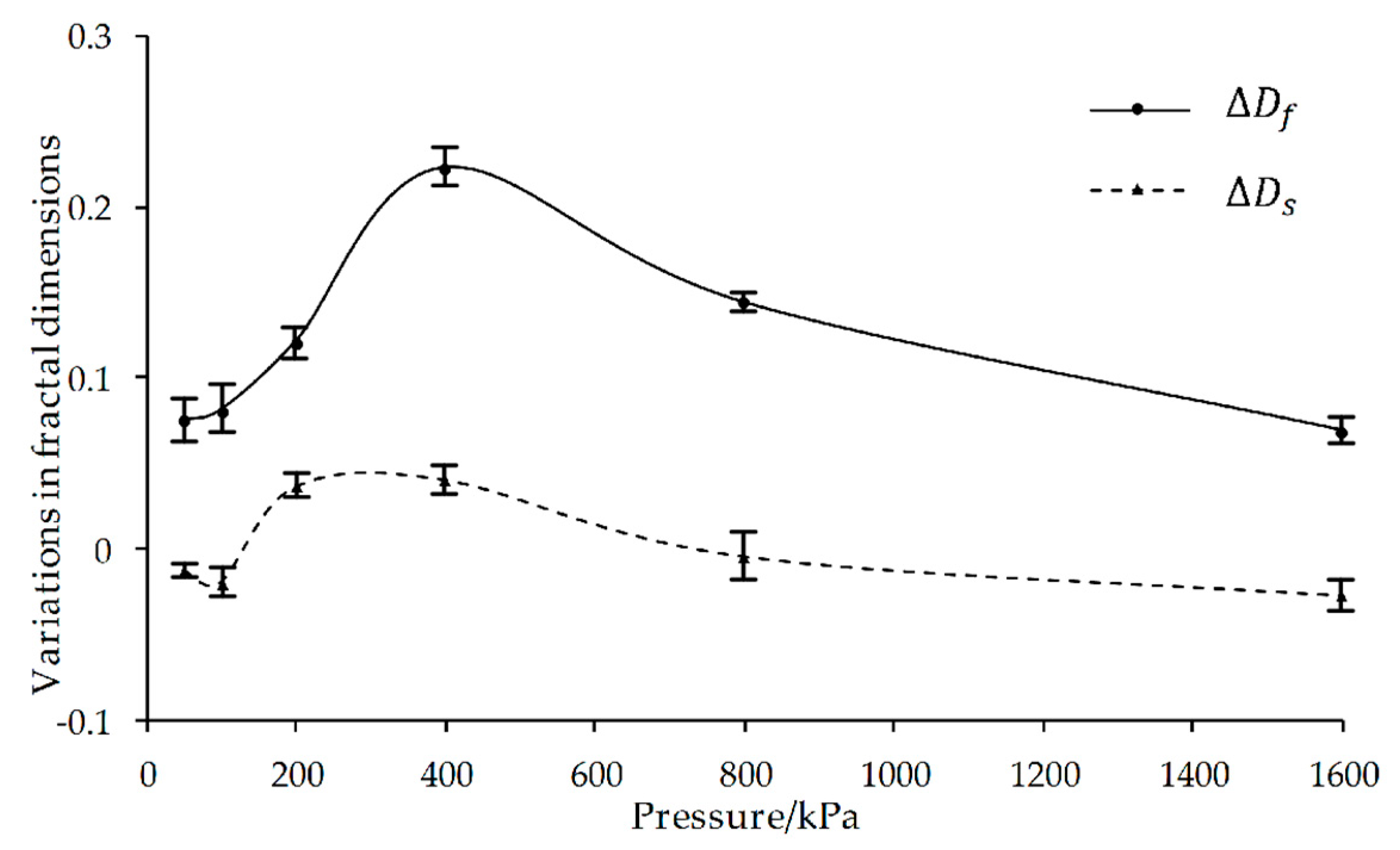

- Based on the evolution of the fractal characteristics of pores, the loading/unloading process could be divided into three stages: the natural structural stage (<100 kPa), the structural adjustment stage (from 100 kPa to 400 kPa), and the new equilibrium stage (>400 kPa).

- The state of microstructure of soft clay before unloading influenced the change of and the pore evolution under unloading. The increased greatly as the and large pore area decreased, and the increased, under loading; and the , , and large pore area increased under each unloading process.

- The changed nonlinearly with the pore evolution under loading. Below 100 kPa, fractal dimensions and the area of large pores increased slightly under loading, and the changed by a small degree. From 100 kPa to 400 kPa, the and area of large pores decreased and increased, and increased greatly to the peak value of 0.464. Above 400 kPa, the change rates of the above parameters slowed down.

Author Contributions

Funding

Conflicts of Interest

References

- Indraratna, B.; Chu, J.; Cholachat, R. Embankments with Special Reference to Consolidation and Other Physical Methods. Ground Improvement Case Histories; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Huang, W.; Wen, K.; Liu, D.; Dong, Q.; Li, J.; Li, Y.; Li, L. Experimental study on influence of excess pore water pressure and unloading ratio on unloading mechanical properties of marine sedimentary soft soils. Ocean Eng. 2020, 195, 106680. [Google Scholar] [CrossRef]

- Lim, A.; Ou, C.-Y. Stress paths in deep excavations under undrained conditions and its influence on deformation analysis. Tunn. Undergr. Space Technol. 2017, 63, 118–132. [Google Scholar] [CrossRef]

- Tanaka, H.; Tsutsumi, A.; Ohashi, T. Unloading Behaviour of Clays Measured by CRS Test. Soils Found. 2014, 54, 81–93. [Google Scholar]

- Kawaguchi, T.; Tanaka, H. Formulation of Gmax from Reconstituted Clayey Soils and its Application to Gmax Measured in the Field. Soils Found. 2008, 48, 821–831. [Google Scholar] [CrossRef]

- Cui, Y.; Nguyen, X.; Tang, A.M.; Li, X. An insight into the unloading/reloading loops on the compression curve of natural stiff clays. Appl. Clay Sci. 2013, 83, 343–348. [Google Scholar] [CrossRef]

- Millogo, Y.; Morel, J.-C.; Traoré, K.; Ouedraogo, R. Microstructure, geotechnical and mechanical characteristics of quicklime-lateritic gravels mixtures used in road construction. Constr. Build. Mater. 2012, 26, 663–669. [Google Scholar] [CrossRef]

- Collins, K.; Mcgown, A. The form and function of micro fabric features in a variety of natural soils. Géotechnique 1974, 24, 223–254. [Google Scholar]

- Hu, Y.; Li, Y.A.; Ruan, C.K.; Lin, J.L.; Chen, S.J.; Tang, H.M.; Duan, W.H. Transformation of pore structure in consolidated silty clay: New insights from quantitative pore profile analysis. Constr. Build. Mater. 2018, 186, 615–625. [Google Scholar] [CrossRef]

- Aldaood, A.; Bouasker, M.; Al-Mukhtar, M. Impact of wetting–drying cycles on the microstructure and mechanical properties of lime-stabilized gypseous soils. Eng. Geol. 2014, 174, 11–21. [Google Scholar] [CrossRef]

- Cui, Z.-D.; Jia, Y.-J. Analysis of electron microscope images of soil pore structure for the study of land subsidence in centrifuge model tests of high-rise building groups. Eng. Geol. 2013, 164, 107–116. [Google Scholar] [CrossRef]

- Lin, B.; Cerato, A.B.; Lin, B. Applications of SEM and ESEM in Microstructural Investigation of Shale-Weathered Expansive Soils along Swelling-Shrinkage Cycles. Eng. Geol. 2014, 177, 66–74. [Google Scholar] [CrossRef]

- Roberto, A.; Edmundo, R.E. Saturated Anisotropic Hydraulic Conductivity of a Compacted Lateritic Soil. J. Rock Mech. Geotech. Eng. 2018, 10, 986–991. [Google Scholar]

- Asskar, J.C.; Saman, S.K. Microstructure Characteristics of Cement-Stabilized Sandy Soil Using Nanosilica. J. Rock Mech. Geotech. Eng. 2017, 9, 981–988. [Google Scholar]

- Saba, S.; Barnichon, J.-D.; Cui, Y.-J.; Tang, A.M.; Delage, P. Microstructure and anisotropic swelling behaviour of compacted bentonite/sand mixture. J. Rock Mech. Geotech. Eng. 2014, 6, 126–132. [Google Scholar] [CrossRef]

- Sun, Q.; Zheng, J.; Coop, M.R.; Altuhafi, F.N. Minimum image quality for reliable optical characterizations of soil particle shapes. Comput. Geotech. 2019, 114, 103110. [Google Scholar] [CrossRef]

- Cheng, Q.; Tang, C.; Zeng, H.; Zhu, C.; An, N.; Shi, B. Effects of microstructure on desiccation cracking of a compacted soil. Eng. Geol. 2020, 265, 105418. [Google Scholar] [CrossRef]

- Tong, C.; Zhang, K.-F.; Zhang, S.; Sheng, D. A stochastic particle breakage model for granular soils subjected to one-dimensional compression with emphasis on the evolution of coordination number. Comput. Geotech. 2019, 112, 72–80. [Google Scholar] [CrossRef]

- Cui, Z.-D.; Tang, Y.-Q. Land subsidence and pore structure of soils caused by the high-rise building group through centrifuge model test. Eng. Geol. 2010, 113, 44–52. [Google Scholar] [CrossRef]

- Eyo, E.; Ng’Ambi, S.; Abbey, S. Effect of intrinsic microscopic properties and suction on swell characteristics of compacted expansive clays. Transp. Geotech. 2019, 18, 124–131. [Google Scholar] [CrossRef]

- Ministry of Water Resources of the People’s Republic of China. Standard for Soil Test Method; China Planning Press: Beijing, China. (In Chinese)

- Zhu, Z.C.; Li, J.W.; Lin, F.L.; Chen, F.; Sun, D.A.; Liu, T. Experimental Research on Desorption Curves of Soil Samples under Different Mineral Compositions. Chin. J. Geotech. Eng. 2020, 42, 175–180. (In Chinese) [Google Scholar]

- Tang, C.S.; Shi, B.; Wang, B.J. Factors Affecting Analysis of Soil Microstructure Using SEM. Chin. J. Geotech. Eng. 2008, 30, 560–565. (In Chinese) [Google Scholar]

- Chen, Q.; Li, W.; Chen, Z.; Qilin, C.; Wei, L.; Zhu, C. Analysis of microstructure characteristics of high sulfur steel based on computer image processing technology. Results Phys. 2019, 12, 392–397. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, W.L.; Ying, W. Application of Image-Pro Plus in the Groove Filter Rod Characteristic Parameters Measurement. Appl. Mech. Mater. 2015, 742, 111–117. [Google Scholar] [CrossRef]

- Zhang, J.R.; Zhu, J.; Huang, L.; Huang, W.J. IPP Image Technique Used for Quantitative Analysis of Soil Microstructure. J. Wuhan Univ. Technol. 2008, 30, 80–83. (In Chinese) [Google Scholar]

- Anderson, A.N.; McBratney, A.B.; Crawford, J.W. Applications of Fractals to Soil Studies. Adv. Agron. 1997, 63, 1–76. [Google Scholar] [CrossRef]

- Araujo, G.S.; Bicalho, K.V.; Tristão, F.A. Use of digital image analysis combined with fractal theory to determine particle morphology and surface texture of quartz sands. J. Rock Mech. Geotech. Eng. 2017, 9, 1131–1139. [Google Scholar] [CrossRef]

- Liu, D.; Li, D.; Zhao, F.; Wang, C. Fragmentation characteristics analysis of sandstone fragments based on impact rockburst test. J. Rock Mech. Geotech. Eng. 2014, 6, 251–256. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Q.; Wang, W. Research on the Fractal Characteristics of Granularity Composition of Dispers in the West of Jilin Province. Subgrade Eng. 2018, 3, 16–19. (In Chinese) [Google Scholar]

- Wu, H.; Li, Q.; Liu, G.B. Characteristics of One-dimensional Compressibility of Shanghai Clay. Chinese. J. Geotech. Eng. 2011, 33, 630–636. (In Chinese) [Google Scholar]

- Milligan, G.; Houlsby, G. Basic Soil Mechanics; Elsevier BV: Amsterdam, The Netherlands, 1984. [Google Scholar]

- Ke, W.H.; Chen, J.; Sheng, Q. One-dimension Elasto-viscoplastic Model for Structured Soft Clays. Chin. J. Geotech. Eng. 2016, 38, 494–503. (In Chinese) [Google Scholar]

- Sun, H.; Hou, M.; Chen, C.; Ge, X. Microstructure investigation of soft clay subjected to triaxial loading. Eng. Geol. 2020, 274, 105735. [Google Scholar] [CrossRef]

- Mesri, G.; Godlewski, P.M.J. Time and stress-compressibility interrelationship. International. J. Rock Mech. Min. Sci. Geomech. Abstr. 1977, 103, 417–430. [Google Scholar]

- Lv, H.B.; Wang, R.; Kong, L.W.; Shan, H.G. The Influences of Soil Structure on Compressibility of Qiongzhou Strait Soft Marine Clay. Rock Soil Mech. 2001, 22, 467–473. [Google Scholar]

- He, P.; Wang, W.D.; Xu, Z.H. Empirical Correlation of Compression Index and Swelling Index for Shanghai Clay. Rock Soil Mech. 2018, 39, 3773–3782. (In Chinese) [Google Scholar]

- Wang, J.; Gao, H. Size and shape dependent steady-state pull-off force in molecular adhesion between soft elastic materials. Int. J. Fract. 2010, 166, 13–19. [Google Scholar] [CrossRef]

- Delage, P.; Lefebvre, G. Study of the structure of a sensitive Champlain clay and of its evolution during consolidation. Can. Geotech. J. 1984, 21, 21–35. [Google Scholar] [CrossRef]

| Density ρ g/cm3 | Water Content ω % | Specific Gravity ds - | Dried Density ρd g/cm3 | Porosity Ratio - | Liquid Limit IL % | Plastic Limit Ip % |

|---|---|---|---|---|---|---|

| 1.73 | 45.7 | 2.70 | 1.18 | 1.28 | 49.7 | 23.5 |

| The Step Load/kPa | |

|---|---|

| 1 | 0→12.5→25→50→25→12.5→0 |

| 2 | 0→12.5→25→50→100→50→25→12.5→0 |

| 3 | 0→12.5→25→50→100→200→100→50→25→12.5→0 |

| 4 | 0→12.5→25→50→100→200→400→200→100→50→25→12.5→0 |

| 5 | 0→12.5→25→50→100→200→400→800→400→200→100→50→25→12.5→0 |

| 6 | 0→12.5→25→50→100→200→400→800→1600→800→400→200→100→50→25→12.5→0 |

| P (kPa) | Loading | Unloading | ||||

|---|---|---|---|---|---|---|

| Percentage (%) | Percentage (%) | |||||

| 50 | 67.013 | 4.737 | 0.955 | 67.829 | 4.853 | 0.978 |

| 100 | 70.469 | 4.859 | 0.962 | 68.726 | 4.860 | 0.975 |

| 200 | 70.915 | 4.731 | 0.965 | 69.231 | 4.751 | 0.990 |

| 400 | 68.046 | 4.639 | 0.958 | 65.625 | 4.854 | 0.963 |

| 800 | 69.799 | 4.846 | 0.950 | 68.601 | 4.941 | 0.987 |

| 1600 | 69.466 | 4.943 | 0.956 | 69.198 | 4.834 | 0.959 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, M.; Sun, H.; Song, C.; Li, Y.; Hou, M. Pores Evolution of Soft Clay under Loading/Unloading Process. Appl. Sci. 2020, 10, 8468. https://doi.org/10.3390/app10238468

Zhang M, Sun H, Song C, Li Y, Hou M. Pores Evolution of Soft Clay under Loading/Unloading Process. Applied Sciences. 2020; 10(23):8468. https://doi.org/10.3390/app10238468

Chicago/Turabian StyleZhang, Mengyu, Hong Sun, Chunyu Song, Yue Li, and Mingxun Hou. 2020. "Pores Evolution of Soft Clay under Loading/Unloading Process" Applied Sciences 10, no. 23: 8468. https://doi.org/10.3390/app10238468

APA StyleZhang, M., Sun, H., Song, C., Li, Y., & Hou, M. (2020). Pores Evolution of Soft Clay under Loading/Unloading Process. Applied Sciences, 10(23), 8468. https://doi.org/10.3390/app10238468