Design of a Segmented Mirror with a Global Radius of Curvature Actuation System: Contributions of Multiple Surrogates

Abstract

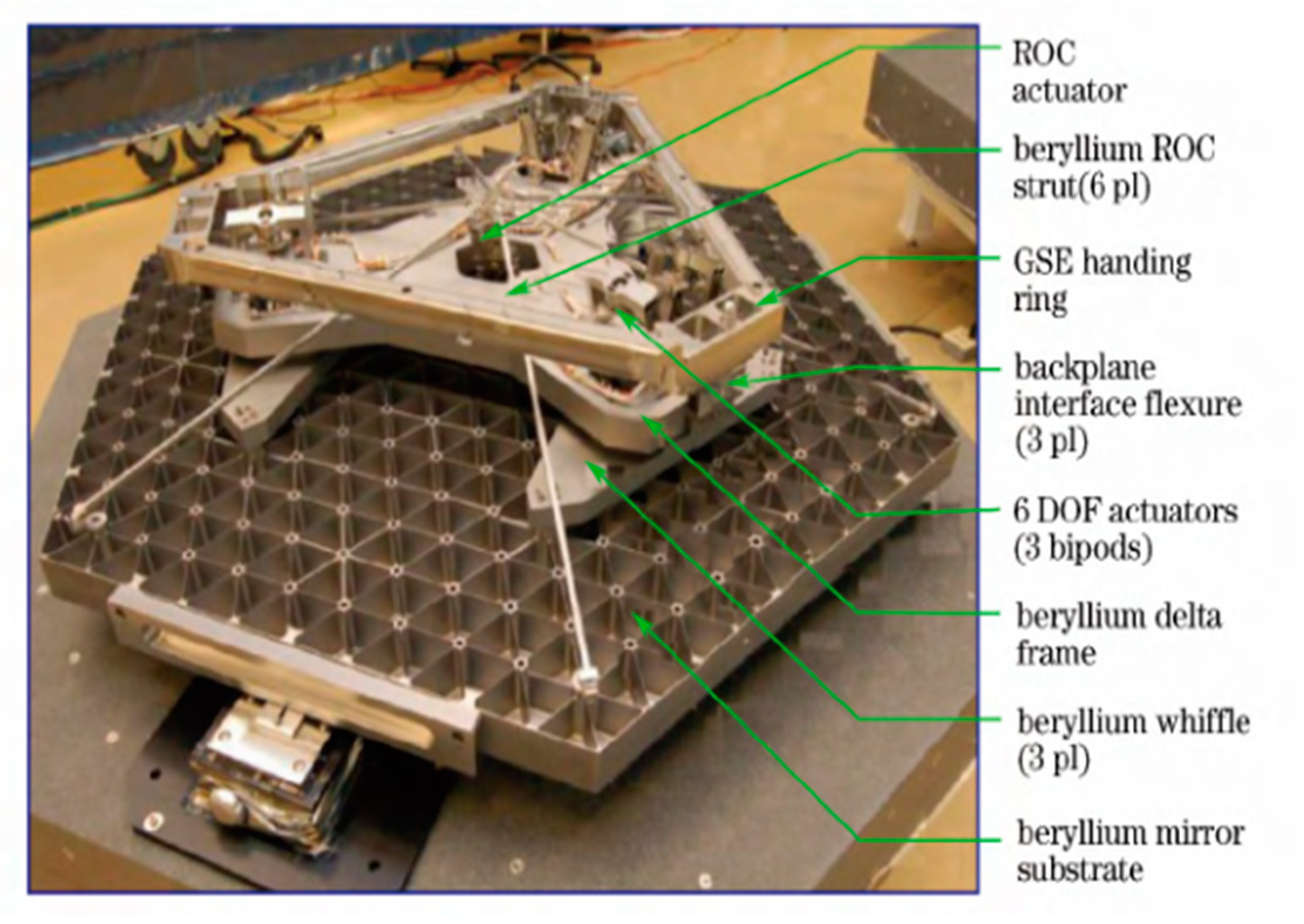

1. Introduction

2. Proposed Multiple-Surrogate-Based Optimization Methodology

2.1. Multiple Surrogates

2.2. Procedure of Multiple-Surrogate-Based Optimization

- Determine the optimization problem, including objectives, constraints, and design variables, etc., and generate sample points of design variables as training points and testing points with the help of Latin hypercube sampling (LHS) [23]. LHS can more efficiently estimate the overall mean of response than estimation based on random sampling.

- Perform the numerical simulation at the training points and testing points to obtain the interest responses.

- Build the surrogates, including PRS, RBFNN, and KRG (reference for the method of construction [9, 20, 21]), respectively. With the minimum GMSE of the test points, solve the coefficients in Equation (10) and construct the multiple surrogates.

- According to Equation (13), solve the determination coefficient . Check whether is greater than 0.9. If it is greater than 0.9, go to the next step. Otherwise add the current training points, and return to step 2 to rebuild the multiple surrogates.

- Optimize the multiple surrogates and check the boundary conditions by numerical simulation. If not, add the current training points, and return to step 2 to rebuild the multiple surrogates. Otherwise, the optimization is completed.

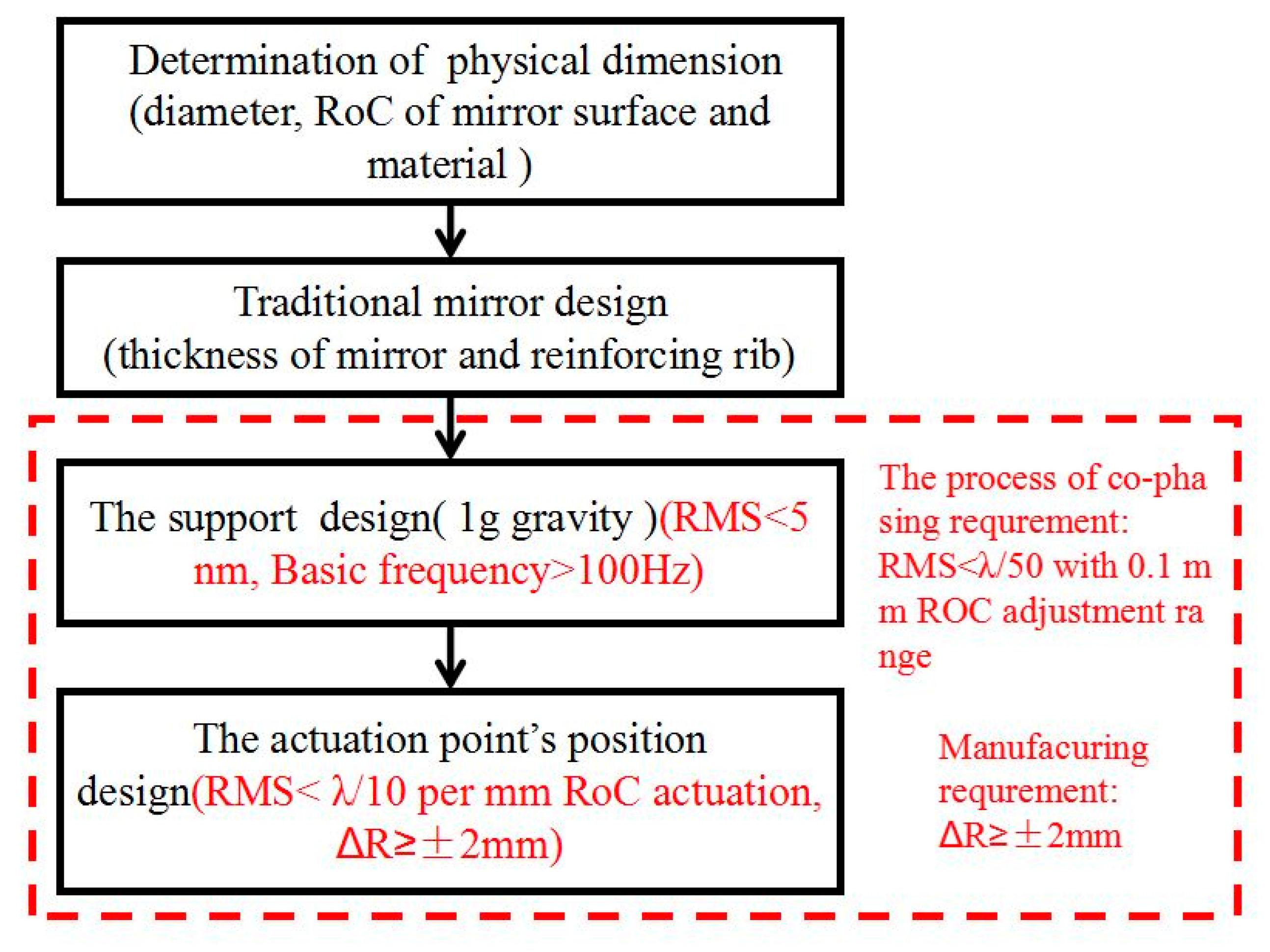

3. Design of Segmented Mirror with a GRoC Actuation System

3.1. Design Requirements

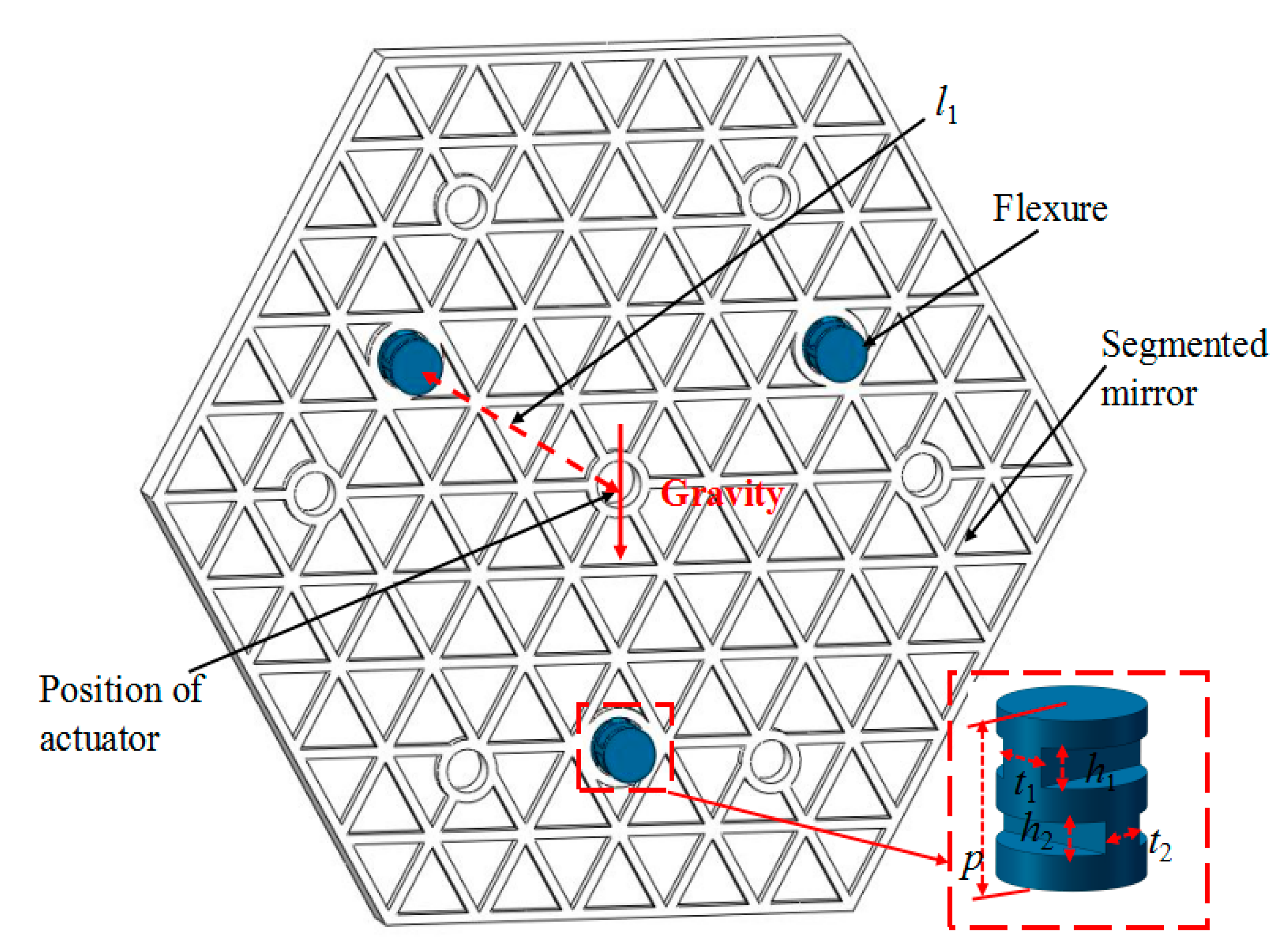

3.2. Support Design of the Segmented Mirror

3.2.1. Problem Description

3.2.2. Results of Optimization

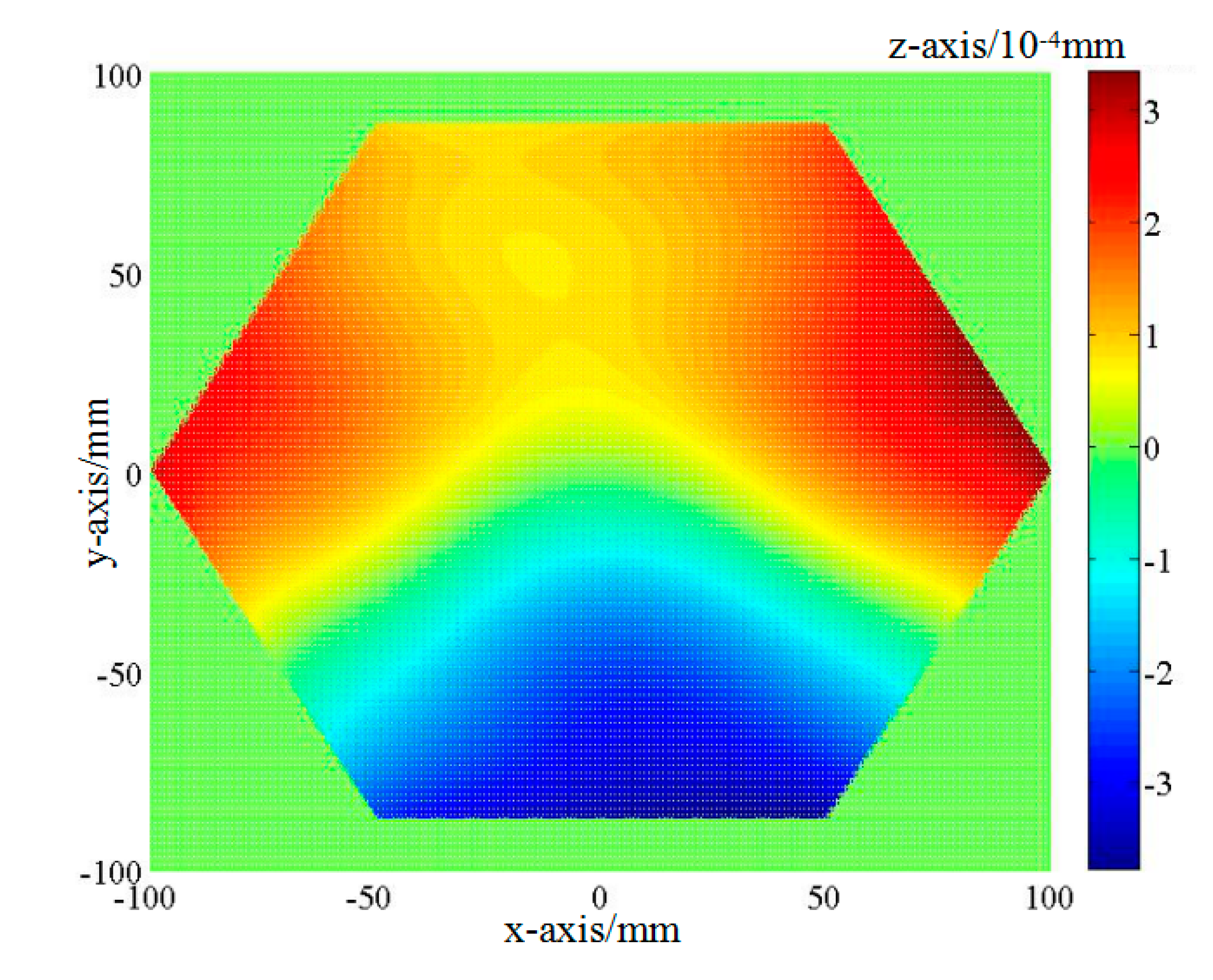

3.3. Actuation Point’s Position Design of Segmented Mirror

3.3.1. Problem Description

3.3.2. Procedure of the Actuation Point’s Position Optimization

- Generate 20 training points and 10 testing points of design variables by LHS.

- Take the sampled points into the numerical simulation. In the numerical simulation, a geometric model is built at a sampled point by computer-aided design (CAD) software, Solidworks. Then analyze the geometric model to get figure deformation and the maximum local stress of the mirror with the finite element analysis (FEA) software Patran and Nastran. Finally, the surface shape error RMS and the amount of GRoC actuation are evaluated by using MATLAB.

- Divide the surface shape error RMS and the maximum local stress by the amount of GRoC actuation to get and . Build RBFNN, PRS, and KRG, respectively, using , , and training points, then construct multiple surrogates according to Section 2.1.

- Solve the determination coefficient of multiple surrogates and check whether it is greater than 0.9. If not, add 5 training points and return to step 2.

- Search the optimum of the multiple surrogates through MIGA (population number is 5, island number is 4, evolution number is 10).

- Verify whether the optimum meets boundary conditions. If not, add 5 training points and return to step 2.

3.3.3. Results of Optimization

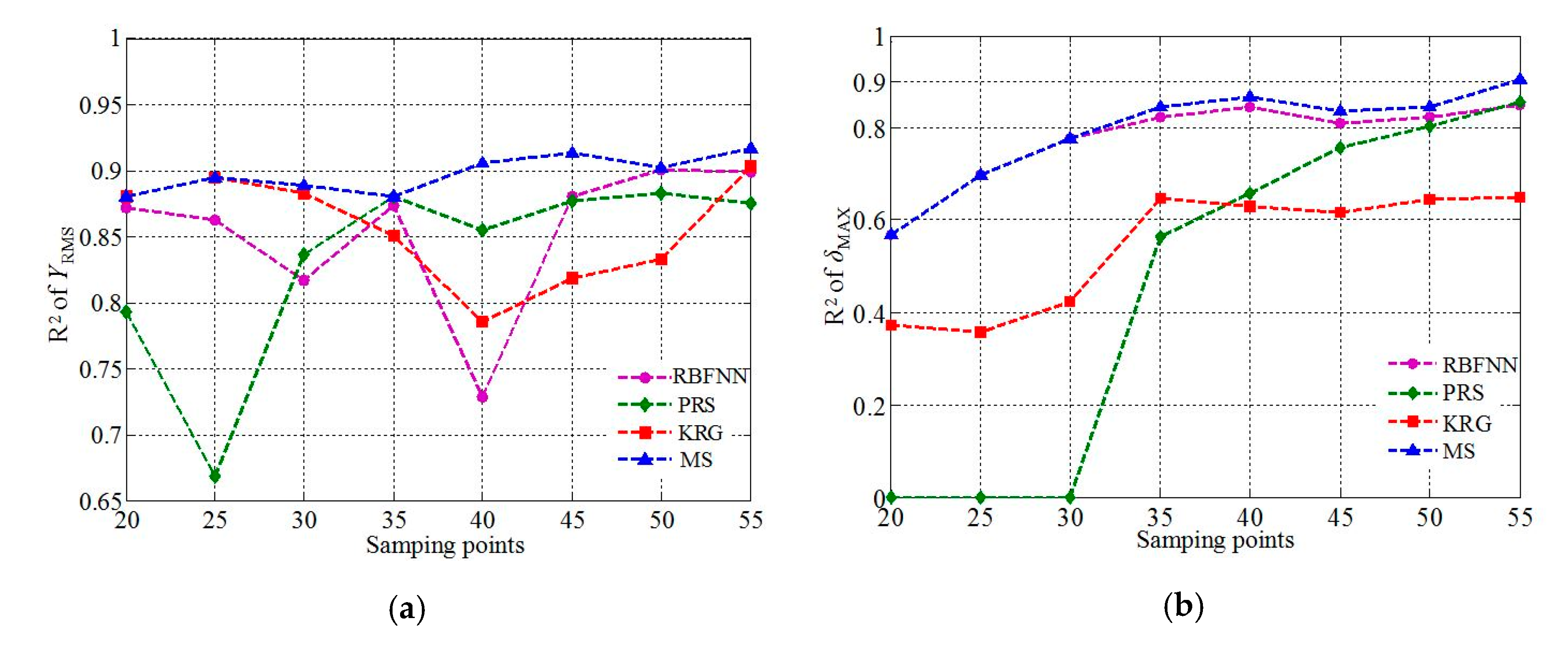

3.3.4. Approximation Ability Analysis

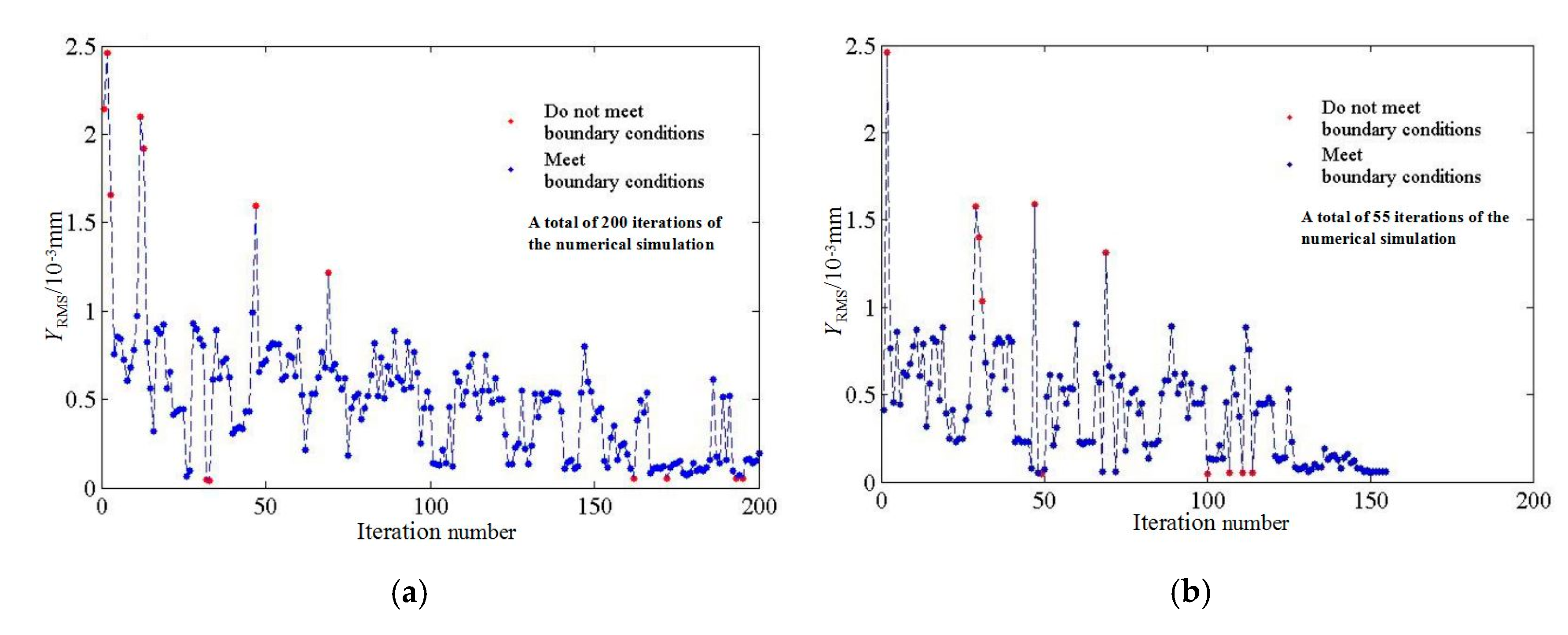

3.3.5. Computational Efficiency Analysis

4. Discussion

- The optimization methodology used in this work provides a solution for designing a segmented mirror with a GRoC actuation system.

- The proposed multiple surrogates have higher approximation ability than a single surrogate (PRS, RBFNN, and KRG), and at the same time, solve the problem of difficulty in choosing a reasonable surrogate in an approximation optimization.

- The proposed multiple-surrogate-based optimization methodology effectively reduces the computational cost of optimization problems and makes the optimization problems easier to converge. In addition, this methodology is also suitable to be extended to other complex optimization problems.

Author Contributions

Funding

Conflicts of Interest

References

- Jiang, Y.H.; Chen, X.L.; Wu, Y.J.; Li, Y. Error analysis of curvature radius of segmented mirror. Spacecr. Recovery Remote Sens. 2017, 38, 102–108. [Google Scholar]

- Annu, J.; Padmakar, P.; Melvin, K.J. Creating a large aspheric primary mirror using spherical segments. Exp. Astron. 2020. [Google Scholar] [CrossRef]

- Nijenhuis, J.; Hamelinck, R.; Braam, B. The opto-mechanical performance prediction of thin mirror segment for the E-ELT. In Modern Technologies in Space-and Ground-Based Telescopes and Instrumentation II; International Society for Optics and Photonics: Bellingham, DC, USA, 2012; Volume 7733, p. 7732H. [Google Scholar]

- David, M.; James, B.; Jake, L. Cryogenic radius of curvature matching for JWST primary mirror segments. In Astronomical and Space Optical Systems; International Society for Optics and Photonics: Bellingham, DC, USA, 2009; Volume 7439, p. 743916. [Google Scholar]

- James, B.H.; David, M.C.; Larkin, B.C. The optical metrology system for cryogenic testing of the JWST primary mirror segments. In Optical Manufacturing and Testing IX; International Society for Optics and Photonics: Bellingham, DC, USA, 2011; Volume 8126, p. 81260P. [Google Scholar]

- Adam, R.C.; Acton, D.S.; Paul, D.A.; Allison, A.B.; Paul, A.L.; Duncan, M.S. Aligning and maintaining the optics for the James Webb Space Telescope(JWST) on-orbit: The wavefront sensing and control concept of operations. In Space Telescopes and Instrumentation I: Optical, Infrared, and Millimeter; International Society for Optics and Photonics: Bellingham, DC, USA, 2006; Volume 6265, p. 62650X. [Google Scholar]

- Wang, Z.S.; Zhang, J.X.; Wang, J.X.; He, X.; Fu, L.L.; Tian, F.X.; Liu, X.F.; Zhao, Y.C. A back propagation network based optimizing model of space-based large mirror structure. Optik 2019, 179, 780–786. [Google Scholar] [CrossRef]

- Hong, Z.; Yu, S.; Chenchen, L.; Haoran, W. Optimal design of the sealing structure of a hydraulic cylinder on the basis of a surrogated model. Adv. Mater. Sci. Eng. 2020, 2020, 1753964. [Google Scholar]

- Xiang, X.S.; Tian, Y.; Xiao, J.H.; Zhang, X.Y. A clustering-based surrogate-assisted multi-objective evolutionary algorithm for shelter location problem under uncertainty of road networks. IEEE Trans. Ind. Informat. 2020, 16, 7544–7555. [Google Scholar] [CrossRef]

- Ribeiro, L.G.; Maia, M.A.; Parente, E.; Cartaxo de melo, A.M. Surrogate based optimization of functionally graded plates using radial basis functions. Compos. Struct. 2020, 252, 112677. [Google Scholar] [CrossRef]

- Wang, P.H.; Chen, Z.G.; Feng, Y.K. Many-objective optimization for a deep-sea aquaculture vessel based on improved RBF neural network surrogate model. J. Mar. Sci. Technol. 2020, 1–24. [Google Scholar] [CrossRef]

- Hsiao, J.C.; Kumar, S.; Chou, C.L.; Kam, T.Y. Shape design optimization of a robot arm using a surrogate-based evolutionary approach. Appl. Sci. 2020, 10, 2223. [Google Scholar] [CrossRef]

- Ahmed, S.; Grabher, C.; Kim, H.J.; Koseki, T. Multifidelity surrogate assisted rapid design of transverse-flux permanent magnet linear synchronous motor. IEEE Trans. Ind. Electron. 2020, 67, 7280–7289. [Google Scholar] [CrossRef]

- Rafiee, V.; Faiz, J. Robust design of an outer rotor permanent magnet motor through six-sigma methodology using response surface surrogate model. IEEE Trans. Magn. 2019, 55, 8107110. [Google Scholar] [CrossRef]

- Chau, N.L.; Le, H.G.; Dao, T.P.; Dang, V.A. Design and optimization for a new compliant planar spring of upper limb assistive device using hybrid approach of RSM-FEM and MOGA. Arab. J. Sci. Eng. 2019, 44, 7441–7456. [Google Scholar] [CrossRef]

- Hakjin, L.; Yeongmin, J.; Duck-Joo, L.; Seongim, C. Surrogate model based design optimization of multiple wing sails considering flow interaction effect. Ocean Eng. 2016, 121, 422–436. [Google Scholar]

- Zhenxu, S.; Ye, Z.; Guowei, Y. Surrogate based optimization of aerodynamic noise for streamlined shape of high speed trains. Appl. Sci. 2017, 7, 196. [Google Scholar]

- Guo, Q.; Hang, J.T.; Wang, S.A.; Hui, W.Z.; Xie, Z.H. Buckling optimization of variable stiffness composite cylinders by using multi-fidelity surrogate models. Thin Walled Struct. 2020, 156, 107014. [Google Scholar] [CrossRef]

- Das, S.; Tesfamariam, S.; Chen, Y.Y.; Qian, Z.C.; Tan, P.; Zhou, F.L. Reliability-based optimization of nonlinear energy sink with negative stiffness and sliding friction. J. Sound Vib. 2020, 485, 115560. [Google Scholar] [CrossRef]

- Deng, S.Y.; Yao, J.Y.; Wang, L.L.; Xin, J.Q.; Hu, N. Comparative studies of surrogate models for response analysis of mistuned bladed disks. Int. J. Comput. Methods 2020, 17, 2050012. [Google Scholar] [CrossRef]

- Gao, H.F.; Zio, E.; Wang, A.E.; Bai, G.C.; Fei, C.W. Probabilistic-based combined high and low cycle fatigue assessment for turbine blades using a substructure-based kriging surrogate model. Aerospace Sci. Technol. 2020, 104, 105957. [Google Scholar] [CrossRef]

- Viana, F.A.C.; Haftka, R.T. Cross validation can estimate how well prediction variance correlates with error. AIAA J. 2009, 47, 2266–2270. [Google Scholar] [CrossRef][Green Version]

- Zhang, F.; Cheng, L.; Wu, M.Y.; Xu, X.Y.; Wang, P.C.; Liu, Z.B. Performance analysis of two-stage thermoelectric generator model based on Latin hypercube sampling. Energy Convers. Manag. 2020, 221, 113159. [Google Scholar] [CrossRef]

- Mark, C. Status of the James Webb space telescope (JWST). In Space Telescopes and Instrumentation 2008: Optical, Infrared, and Millimeter; International Society for Optics and Photonics: Bellingham, DC, USA, 2008; Volume 7010, p. 70100L.

- Pierre, Y.B. The Design and Construction of Large Optical Telescopes; Springer: Berlin, Germany, 2003; pp. 146–155. [Google Scholar]

- Liang, T.; Lu, H. A novel method based on Multi-Island Genetic Algorithm improved variational mode decomposition and multi-features for fault diagnosis of rolling bearing. Entropy 2020, 22, 995. [Google Scholar] [CrossRef]

| Variable | Initial Value | Optimization Result |

|---|---|---|

| l1 | 50 mm | 52.5 mm |

| t1 | 3 mm | 3.9 mm |

| t2 | 4 mm | 3.5 mm |

| h1 | 5 mm | 4.5 mm |

| h2 | 5 mm | 4.5 mm |

| p | 15 mm | 12 mm |

| Variable | Initial Value | Optimization Result |

|---|---|---|

| h | 5 mm | 7.5 mm |

| d1 | 15 | 9.4 mm |

| d2 | 10 | 8.7 mm |

| l2 | 80 | 65 mm |

| Output Response | ||||||

|---|---|---|---|---|---|---|

| Surrogate | RBF | PRS | KRG | RBF | PRS | KRG |

| 20 | 0 | 0 | 1 | 1 | 0 | 0 |

| 25 | 0 | 0 | 1 | 1 | 0 | 0 |

| 30 | 0.25 | 0.55 | 0.20 | 1 | 0 | 0 |

| 35 | 0 | 1 | 0 | 0.82 | 0.18 | 0 |

| 40 | 0 | 0.29 | 0.71 | 0.78 | 0.22 | 0 |

| 45 | 1 | 0 | 0 | 0.69 | 0.31 | 0 |

| 50 | 0.69 | 0.31 | 0 | 0.65 | 0.35 | 0 |

| 55 | 0.47 | 0 | 0.53 | 0.33 | 0.33 | 0.24 |

| Surrogate | MS | PRS | RBFNN | KRG |

|---|---|---|---|---|

| 0.92 | 0.87 | 0.90 | 0.90 | |

| 0.91 | 0.85 | 0.85 | 0.64 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, S.; Dong, J.; Xu, S.; Lu, Z.; Xu, B. Design of a Segmented Mirror with a Global Radius of Curvature Actuation System: Contributions of Multiple Surrogates. Appl. Sci. 2020, 10, 8375. https://doi.org/10.3390/app10238375

Wu S, Dong J, Xu S, Lu Z, Xu B. Design of a Segmented Mirror with a Global Radius of Curvature Actuation System: Contributions of Multiple Surrogates. Applied Sciences. 2020; 10(23):8375. https://doi.org/10.3390/app10238375

Chicago/Turabian StyleWu, Songhang, Jihong Dong, Shuyan Xu, Zhirong Lu, and Boqian Xu. 2020. "Design of a Segmented Mirror with a Global Radius of Curvature Actuation System: Contributions of Multiple Surrogates" Applied Sciences 10, no. 23: 8375. https://doi.org/10.3390/app10238375

APA StyleWu, S., Dong, J., Xu, S., Lu, Z., & Xu, B. (2020). Design of a Segmented Mirror with a Global Radius of Curvature Actuation System: Contributions of Multiple Surrogates. Applied Sciences, 10(23), 8375. https://doi.org/10.3390/app10238375