Heat Transfer Analysis in a Single Spool Gas Turbine by Using Calculated-Estimated Coefficients with the Finite Element Method

Abstract

Featured Application

Abstract

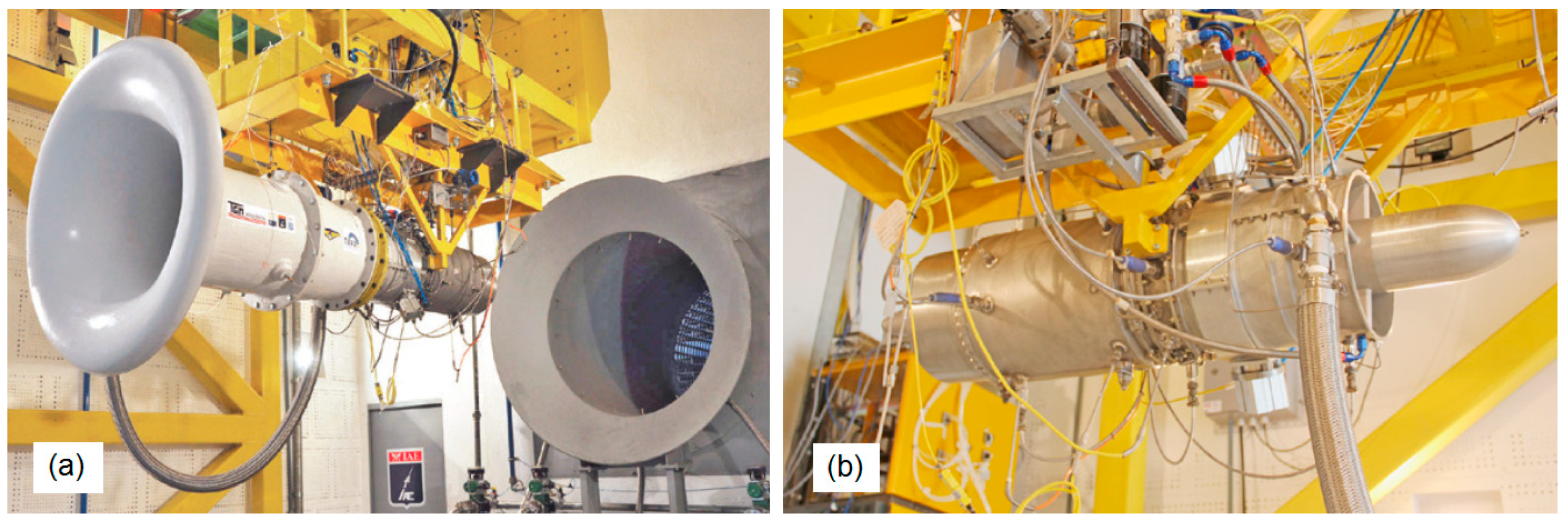

1. Introduction

Literature Review

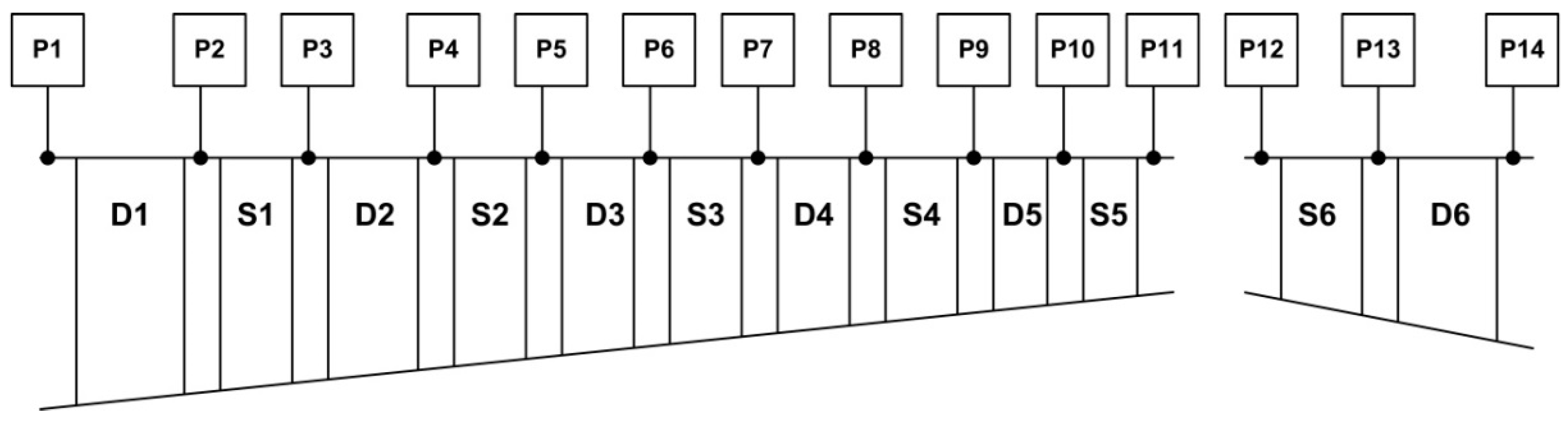

2. Convective Heat Transfer Coefficients

2.1. Stator Vanes and Disc Blades

2.2. Compressor and Turbine Discs

2.2.1. Convective Cooling

2.2.2. Impingement Cooling

2.2.3. Heat Transfer Coefficient without Cooling Flow

2.3. Turbine Annular Passage: Inner and Outer Walls

2.4. Heat Transfer on the Combustor Annular Passage

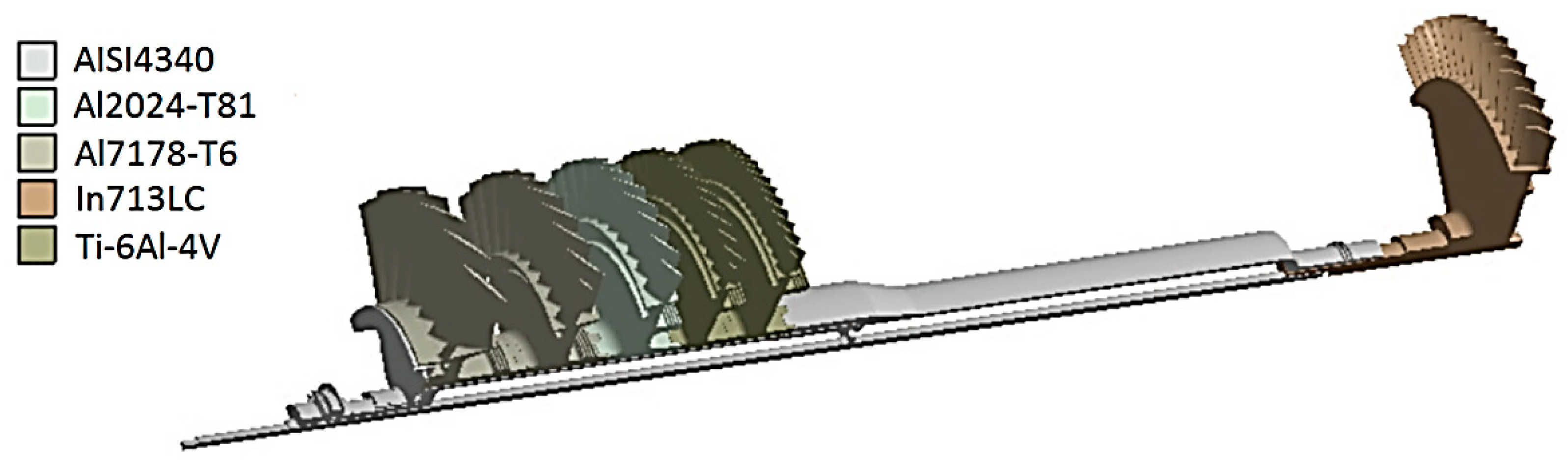

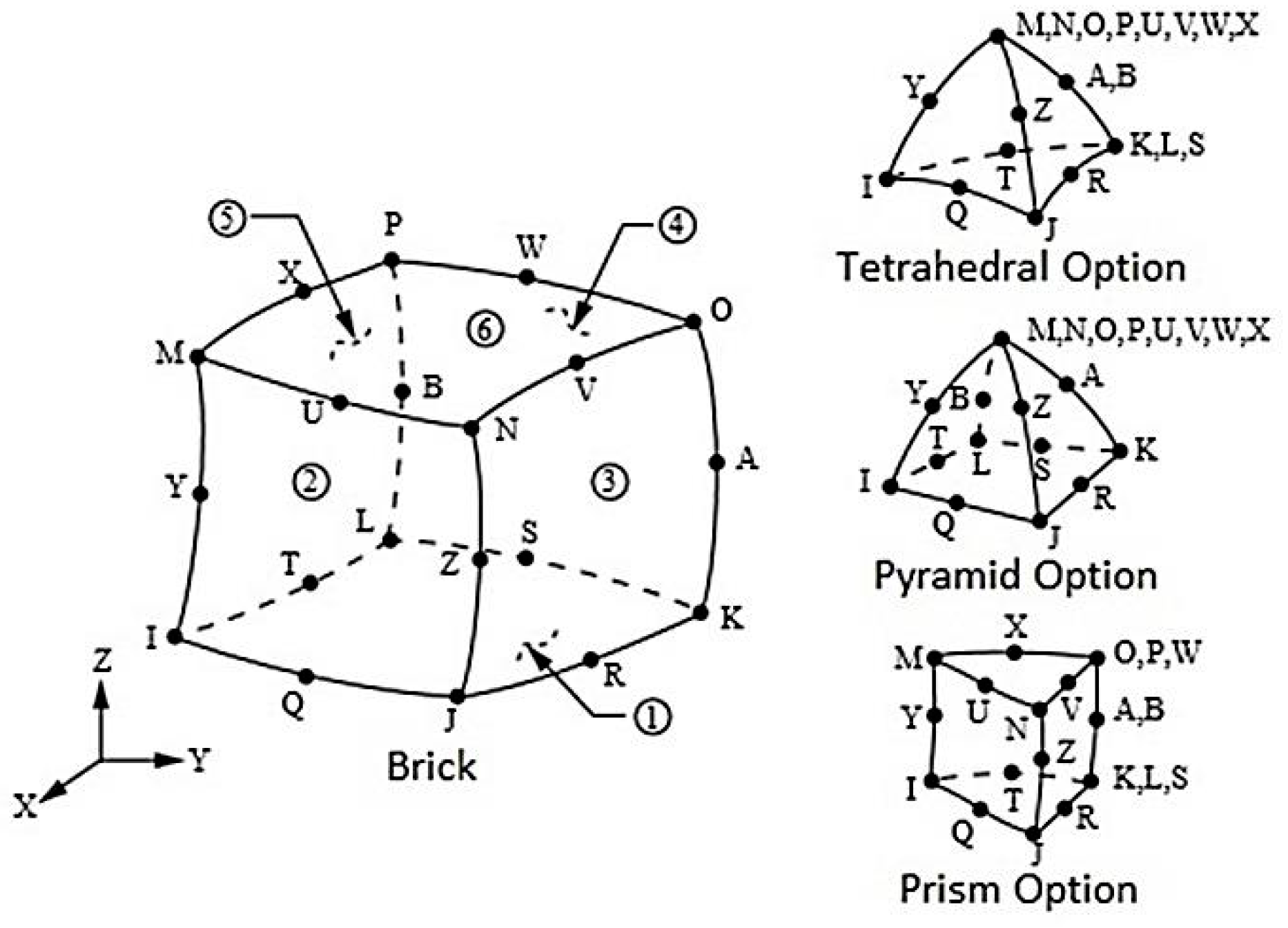

3. Materials and Boundary Conditions

4. Results and Discussion

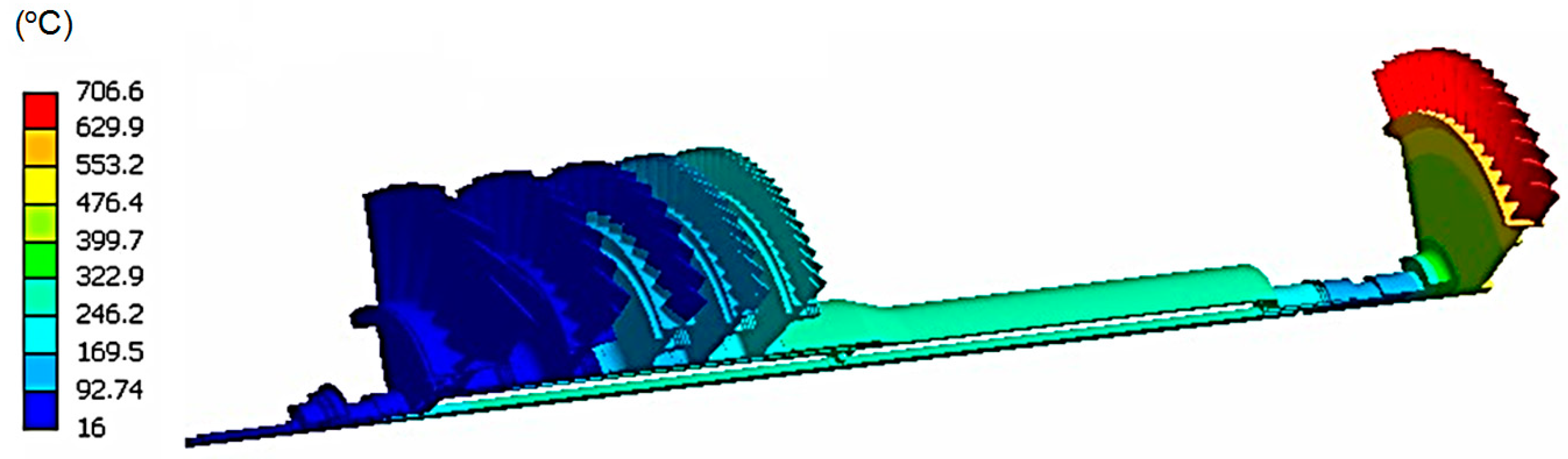

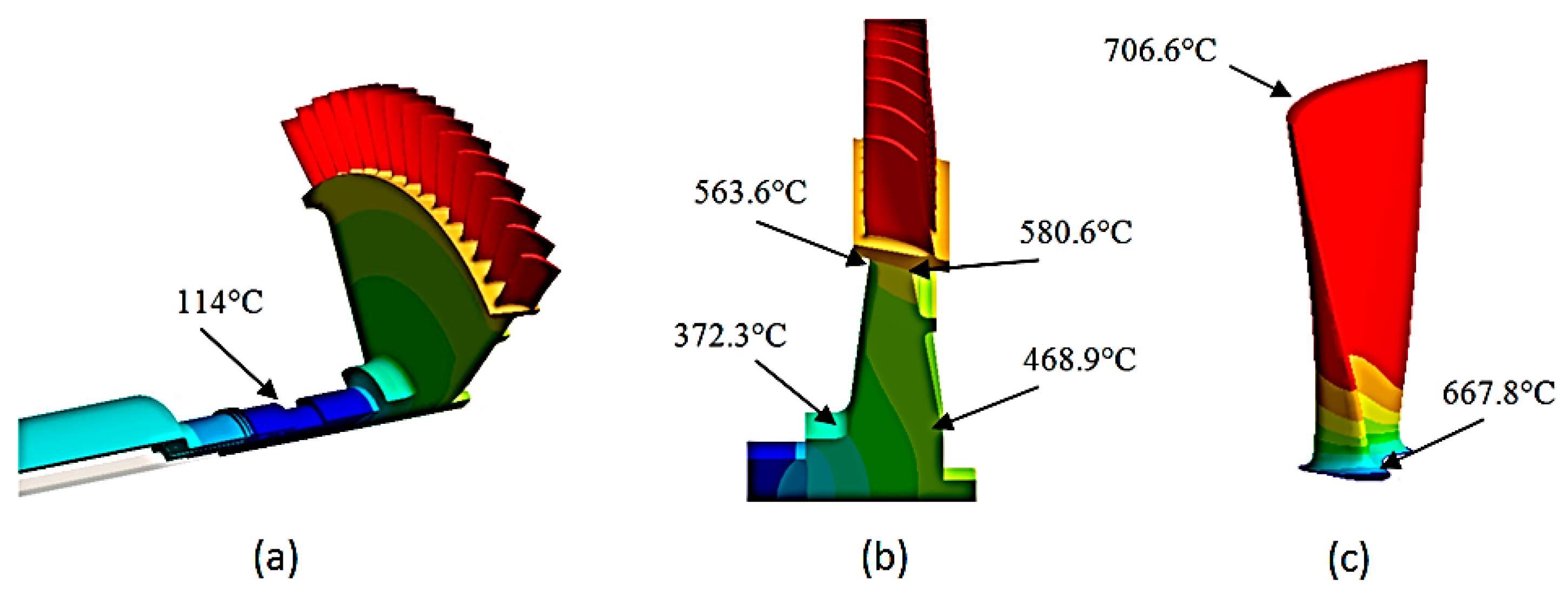

4.1. Temperature Distribution over the Rotating Assembly

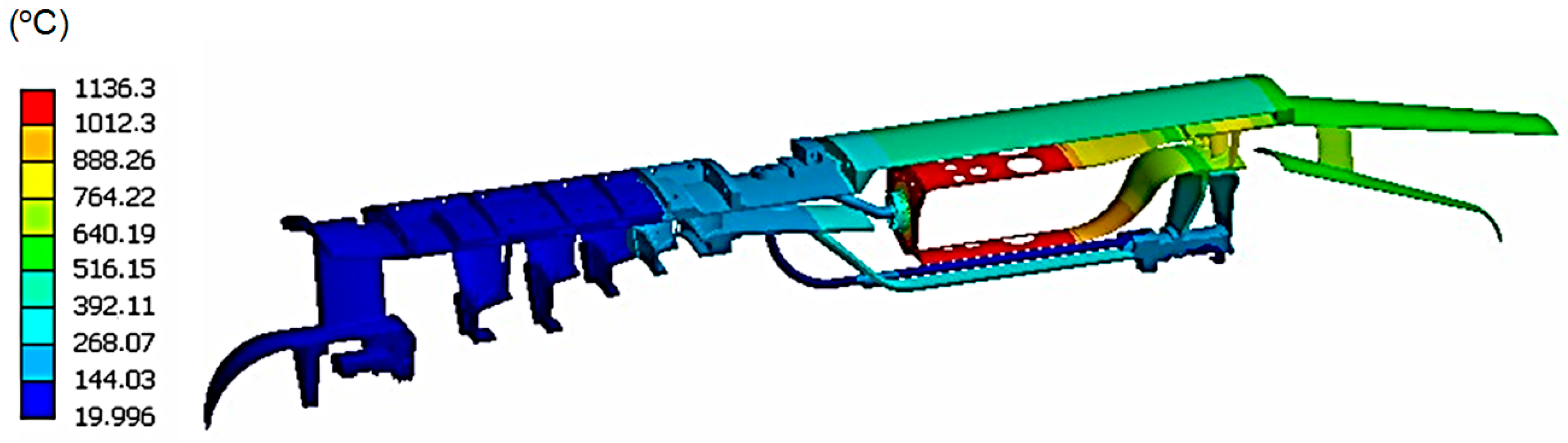

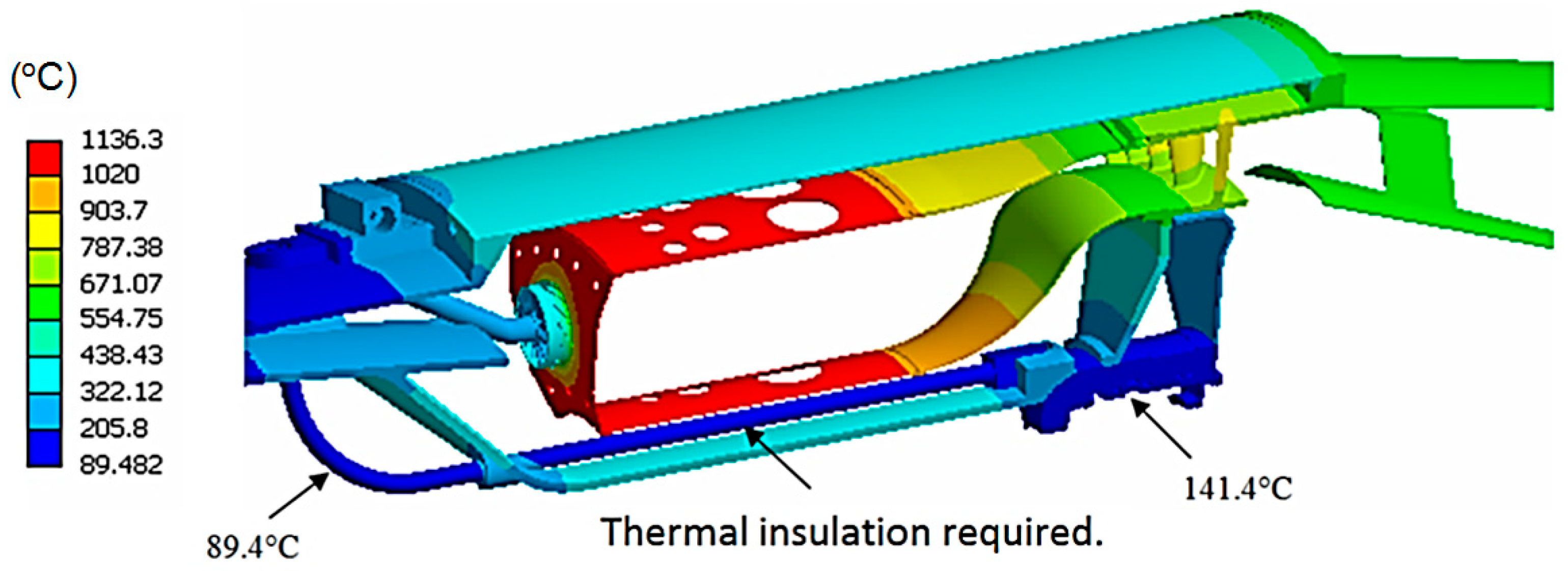

4.2. Temperature Distribution over the Static Assembly

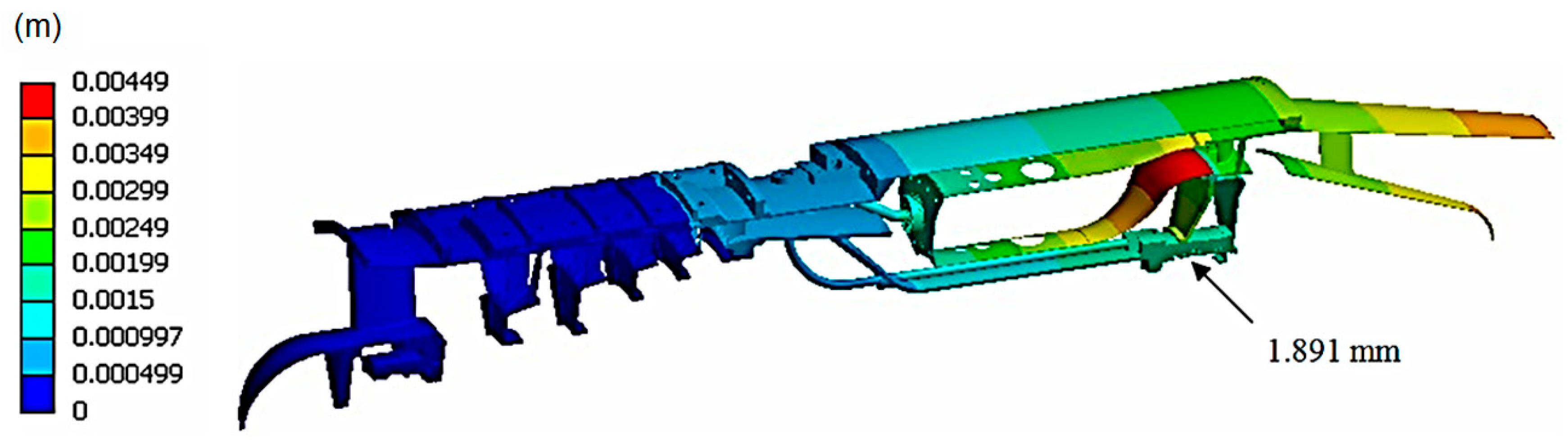

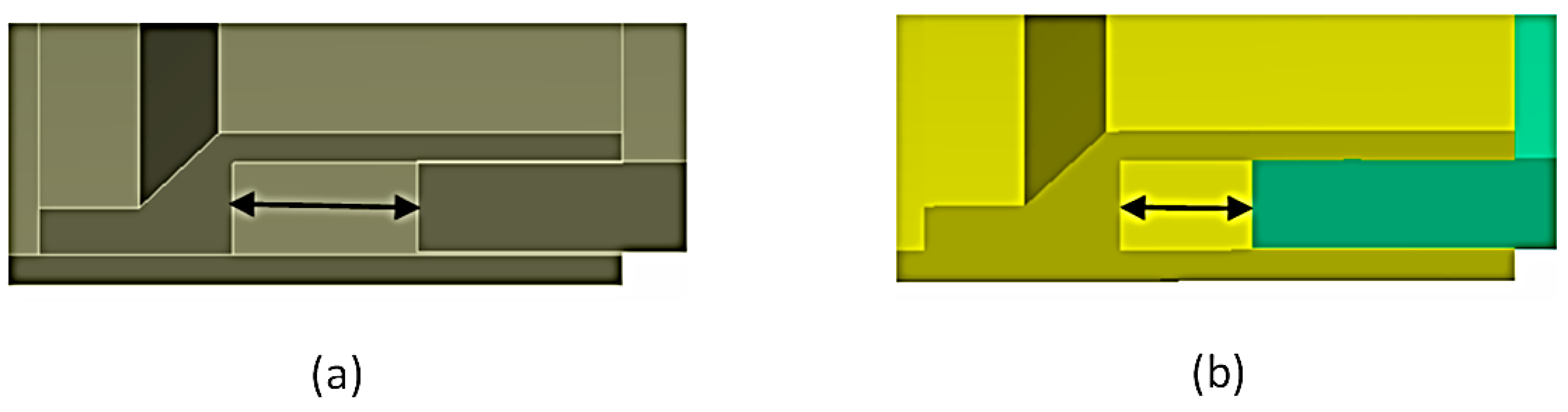

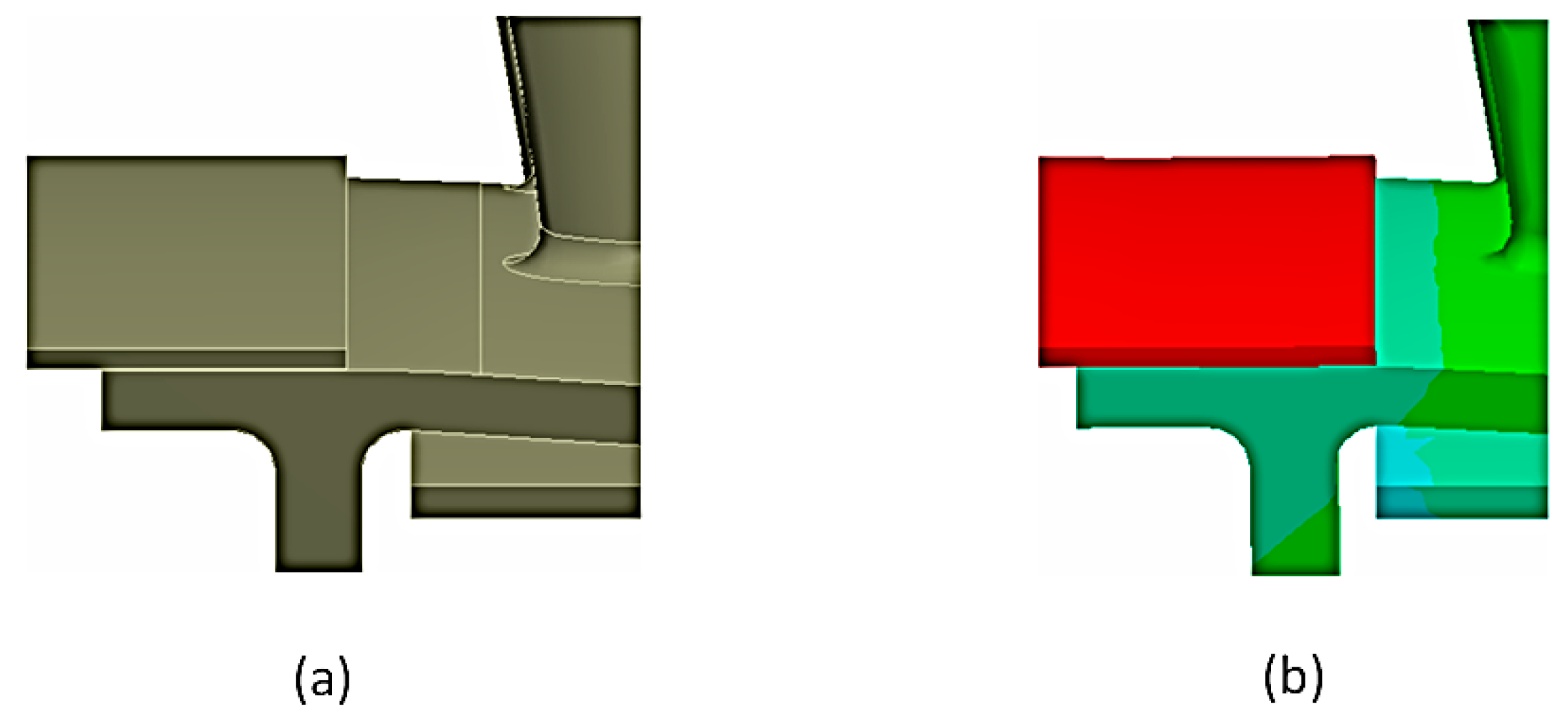

4.3. Thermal Expansion Behavior over the Rotating and Static Assemblies

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Creci, G.; Menezes, J.C.; Barbosa, J.R.; Corra, J.A. Rotordynamic Analysis of a 5-Kilonewton Thrust Gas Turbine by Considering Bearing Dynamics. J. Propuls. Power 2011, 27, 330–336. [Google Scholar] [CrossRef]

- Creci Filho, G. Influência da Dinâmica dos Mancais na Resposta Vibratória de uma Turbina Aeronáutica de 5kN de Empuxo. Ph.D. Thesis, Instituto Tecnológico de Aeronáutica, São José dos Campos, Brazil, 2012; p. 307. Available online: http://www.bdita.bibl.ita.br/tesesdigitais/lista_resumo.php?num_tese=62130 (accessed on 20 November 2020).

- Creci, G.; Balastrero, J.O.; Domingues, S.; Torres, L.V.; Menezes, J.C. Influence of the Radial Clearance of a Squeeze Film Damper on the Vibratory Behavior of a Single Spool Gas Turbine Designed for Unmanned Aerial Vehicle Applications. Shock. Vib. 2017, 2017, 4312943. [Google Scholar] [CrossRef]

- Leme, A.D.S.; Creci, G.; De Jesus, E.R.B.; Rodrigues, T.C.; Menezes, J.C. Finite Element Analysis to Verify the Structural Integrity of an Aeronautical Gas Turbine Disc Made from Inconel 713LC Superalloy. Adv. Eng. Forum 2019, 32, 15–26. [Google Scholar] [CrossRef]

- Mazur, Z.; Luna-Ramírez, A.; Juárez-Islas, J.; Campos-Amezcua, A. Failure analysis of a gas turbine blade made of Inconel 738LC alloy. Eng. Fail. Anal. 2005, 12, 474–486. [Google Scholar] [CrossRef]

- Sadowski, T.; Golewski, P. Multidisciplinary analysis of the operational temperature increase of turbine blades in combustion engines by application of the ceramic thermal barrier coatings (TBC). Comput. Mater. Sci. 2011, 50, 1326–1335. [Google Scholar] [CrossRef]

- Kim, K.M.; Park, J.S.; Lee, D.H.; Lee, T.W.; Cho, H.H. Analysis of conjugated heat transfer, stress and failure in a gas turbine blade with circular cooling passages. Eng. Fail. Anal. 2011, 18, 1212–1222. [Google Scholar] [CrossRef]

- El-Batsh, H.M.; Nada, S.A.; Abdo, S.N.; El-Tayesh, A.A. Effect of Secondary Flows on Heat Transfer of a Gas Turbine Blade. Int. J. Rotating Mach. 2013, 2013, 797841. Available online: https://www.hindawi.com/journals/ijrm/2013/797841/ (accessed on 20 November 2020). [CrossRef]

- Fu, C.-Z.; Si, W.; Quan, L.; Yang, J. Numerical Study of Convection and Radiation Heat Transfer in Pipe Cable. Math. Probl. Eng. 2018, 2018, 5475136. [Google Scholar] [CrossRef]

- Bade, M.; Clark, N.N.; Robinson, M.C.; Famouri, P. Parametric Investigation of Combustion and Heat Transfer Characteristics of Oscillating Linear Engine Alternator. J. Combust. 2018, 2018, 2907572. [Google Scholar] [CrossRef]

- Dou, H.-S.; Jiang, G.; Zhang, L.-T. A Numerical Study of Natural Convection Heat Transfer in Fin Ribbed Radiator. Math. Probl. Eng. 2015, 2015, 989260. [Google Scholar] [CrossRef]

- Jedsadaratanachai, W.; Boonloi, A. Numerical Study on Turbulent Forced Convection and Heat Transfer Characteristic in a Circular Tube with V-Orifice. Model. Simul. Eng. 2017, 2017, 3816739. [Google Scholar] [CrossRef]

- Badreddine, H.; Sato, Y.; Berger, M.; Ničeno, B. A Three-Dimensional, Immersed Boundary, Finite Volume Method for the Simulation of Incompressible Heat Transfer Flows around Complex Geometries. Int. J. Chem. Eng. 2017, 2017, 1726519. [Google Scholar] [CrossRef]

- Devaraj, C.; Muthuswamy, E.; Kandasamy, S. Numerical Investigation of Laminar Natural Convection in Inclined Square Enclosure with the Influence of Discrete Heat Source. J. Appl. Math. 2015, 2015, 985218. [Google Scholar] [CrossRef]

- Schlichting, H. Boundary Layer Theory, 6th ed.; McGraw-Hill: New York, NY, USA, 1968; Available online: https://books.google.com.br/books?id=6IZTAAAAMAAJ (accessed on 20 November 2020).

- Colladay, R. Turbine Design and Application; NASA SP 290, Turbine Cooling; National Aeronautics and Space Administration, Lewis Research Center: Cleveland, OH, USA, 1975; Volume 3, pp. 59–101.

- White, F.M. Viscous Fluid Flow; McGraw-Hill: New York, NY, USA, 1974; Available online: https://books.google.com.br/books?isbn=007124493X (accessed on 20 November 2020).

- Evans, D.M. Calculation of Temperature Distribution in Multistage Axial Gas Turbine Rotor Assemblies When Blades Are Uncooled. J. Eng. Power 1973, 95, 309–318. [Google Scholar] [CrossRef]

- Lefebvre, A.H. Gas Turbine Combustion, 2nd ed.; Taylor & Francis Ltd.: Ann Arbor, MI, USA, 1999; Available online: https://books.google.com.br/books?isbn=1560326735 (accessed on 20 November 2020).

- MATWEB: Material Property Data. 2018. Available online: http://www.matweb.com/ (accessed on 20 November 2020).

- Zienkiewicz, O.C. The Finite Element Method; McGraw-Hill Company: London, UK, 1977; Available online: https://books.google.com/books?isbn=0070840725 (accessed on 20 November 2020).

- Moaveni, S. Finite Element Analysis: Theory and Application with Ansys; Prentice Hall: Upper Saddle River, NJ, USA, 1999; Available online: https://books.google.com/books?isbn=0137850980 (accessed on 20 November 2020).

- Ansys® Academic Research Documentation Manual, Release 18.2, Help System, Guide. ANSYS, Inc. Available online: https://www.ansys.com/ (accessed on 20 November 2020).

| Metallic Alloys | Composition |

|---|---|

| AISI4340 | C (0.37–0.43%); Cr (0.70–0.90%); Fe (95.195–96.33%) as remainder; Mn (0.60–0.80%); Mo (0.20–0.30%); Ni (1.65–2.0%); P (<=0.035%); Si (0.15–0.30%); S (<=0.040%). |

| Al2024-T81 | Al (90.7–94.7%) as remainder; Cr (<=0.10%); Cu (3.8–4.9%); Fe (<=0.50%); Mg (1.2–1.8%); Mn (0.30–0.90%); Si (<=0.50%); Ti (<=0.15%); Zn (<=0.25%). |

| Al7178-T6 | Al (85.3–89.5%) as remainder; Cr (0.18–0.28%); Cu (1.6–2.4%); Fe (<=0.50%); Mg (2.4–3.1%); Mn (<=0.30%); Si (<=0.40%); Ti (<=0.20%); Zn (6.3–7.3%). |

| In713LC | Al (6.1%); B (1.012%); C (0.12%); Cr (12.5%); Ni (77.368%) as remainder; Nb/Cb (2.0%); Ti (0.80%); Zr (0.10%). |

| Ti-6Al-4V | Al (5.5–6.75%); C (<=0.080%); H (<=0.015%); Fe (<=0.40%); N (<=0.030%); O (<=0.20%); Ti (87.725–91%) as remainder; V (3.5–4.5%). |

| Property | AISI4340 | Al2024-T81 | Al7178-T6 | In713LC | TI-6Al-4V |

|---|---|---|---|---|---|

| Young modulus | 205 GPa | 72.4 GPa | 71.7 GPa | 190 GPa | 113.8 GPa |

| Density | |||||

| Yield strength | 862 MPa | 450 MPa | 540 MPa | 750 MPa | 873 MPa |

| Poisson’s ratio | |||||

| Fatigue strength | ) | ) | ) | ) | ) |

| Thermal conductivity | |||||

| Specific heat | |||||

| Thermal expansion coefficient |

| Total Pressure (Pa) | Static Pressure (Pa) | Total Pressure (Pa) | Static Pressure (Pa) | ||

|---|---|---|---|---|---|

| P1 | 101,325.0 | 85,810.4 | P8 | 494,712.9 | 415,134.8 |

| P2 | 159,589.4 | 131,760.6 | P9 | 474,924.4 | 444,226.1 |

| P3 | 153,205.8 | 132,186.7 | P10 | 633,281.3 | 556,937.3 |

| P4 | 243,236.0 | 185,535.1 | P11 | 607,950.0 | 580,379.0 |

| P5 | 233,506.6 | 208,730.9 | P12 | 476,227.5 | 442,810.9 |

| P6 | 357,671.4 | 286,118.7 | P13 | 460,006.8 | 265,130.2 |

| P7 | 343,364.6 | 315,009.4 | P14 | 223,318.8 | 171,831.4 |

| Local | Local | ||||

|---|---|---|---|---|---|

| Turbine blade convex surface | 1265 | 706 | Compressor stator 4 blade surface | 2297 | 162 |

| Turbine blade concave surface | 975 | 706 | Compressor stator 4 blade platform | 837 | 162 |

| Turbine blade tip surface | 840 | 711 | Compressor stator 4 frontal surface | 744 | 154 |

| Turbine blade platform | 839 | 699 | Compressor stator 4 back surface | 1111 | 169 |

| Turbine disc frontal surface | 397 | 295 | Compressor stator 5 blade surface | 2561 | 206 |

| Turbine disc back surface | 794 | 541 | Compressor stator 5 blade platform | 909 | 206 |

| Compressor disc 1 blade surface | 1302 | 16 | Compressor stator 5 frontal surface | 933 | 200 |

| Compressor disc 1 blade platform | 375 | 16 | Compressor top surface 1st of 13 | 349 | 16 |

| Compressor disc 1 blade tip surface | 349 | 16 | Compressor top surface 2nd of 13 | 370 | 23 |

| Compressor disc 1 frontal surface | 319 | 15 | Compressor top surface 3rd of 13 | 417 | 37 |

| Compressor disc 1 back surface | 407 | 44 | Compressor top surface 4th of 13 | 443 | 44 |

| Compressor disc 2 blade surface | 1461 | 45 | Compressor top surface 5th of 13 | 480 | 55 |

| Compressor disc 2 blade platform | 464 | 45 | Compressor top surface 6th of 13 | 538 | 77 |

| Compressor disc 2 blade tip surface | 443 | 45 | Compressor top surface 7th of 13 | 558 | 88 |

| Compressor disc 2 frontal surface | 428 | 44 | Compressor top surface 8th of 13 | 608 | 100 |

| Compressor disc 2 back surface | 560 | 84 | Compressor top surface 9th of 13 | 682 | 125 |

| Compressor disc 3 blade surface | 1879 | 89 | Compressor top surface 10th of 13 | 705 | 137 |

| Compressor disc 3 blade platform | 575 | 89 | Compressor top surface 11th of 13 | 762 | 150 |

| Compressor disc 3 blade tip surface | 558 | 89 | Compressor top surface 12th of 13 | 820 | 173 |

| Compressor disc 3 frontal surface | 568 | 84 | Compressor top surface 13th of 13 | 889 | 205 |

| Compressor disc 3 back surface | 742 | 131 | Cover surface around compressor | 50 | 20 |

| Compressor disc 4 blade surface | 2575 | 137 | Rear bearing seal | 300 | 130 |

| Compressor disc 4 blade platform | 723 | 137 | Front bearing seal | 650 | 45 |

| Compressor disc 4 blade tip surface | 705 | 137 | Front bearing stop | 450 | 40 |

| Compressor disc 4 frontal surface | 744 | 131 | Spring of front bearing | 500 | 25 |

| Compressor disc 4 back surface | 944 | 179 | Surface with oil at rear bearing | 2850 | 95 |

| Compressor disc 5 blade surface | 3410 | 185 | Oil duct near front bearing | 1200 | 100 |

| Compressor disc 5 blade platform | 841 | 185 | Aerofoil and oil duct | 2561 | 206 |

| Compressor disc 5 blade tip surface | 823 | 185 | Static rear part of oil duct | 200 | 206 |

| Compressor disc 5 frontal surface | 933 | 179 | Front bearing oil duct | 1200 | 70 |

| Compressor disc 5 back surface | 1111 | 218 | Frontal thermal shield | 300 | 300 |

| Turbine stator blade surface | 1250 | 830 | Back thermal shield | 400 | 310 |

| Turbine stator blade platform | 850 | 830 | Outlet exhaustion duct | 50 | 20 |

| Turbine stator top surface high | 1250 | 830 | Exhaustion duct top surface | 820 | 650 |

| Turbine stator top surface low | 100 | 300 | Exhaustion duct inferior surface | 820 | 650 |

| Turbine stator frontal surface | 500 | 350 | Exhaustion duct support | 1000 | 650 |

| Turbine stator back surface | 300 | 300 | Exhaustion duct inner surface | 200 | 541 |

| Compressor stator 1 blade surface | 1077 | 30 | Combustion chamber surface 1st of 6 | 560 | 1700 |

| Compressor stator 1 blade platform | 415 | 30 | Combustion chamber surface 2nd of 6 | 560 | 1200 |

| Compressor stator 1 frontal surface | 319 | 30 | Combustion chamber surface 3rd of 6 | 560 | 900 |

| Compressor stator 1 back surface | 560 | 30 | Combustion chamber surface 4th of 6 | 920 | 300 |

| Compressor stator 2 blade surface | 1439 | 65 | Combustion chamber surface 5th of 6 | 400 | 300 |

| Compressor stator 2 blade platform | 539 | 65 | Combustion chamber surface 6th of 6 | 600 | 300 |

| Compressor stator 2 frontal surface | 429 | 58 | Combustion chamber inner top | 900 | 300 |

| Compressor stator 2 back surface | 742 | 72 | Cover around combustion chamber | 50 | 20 |

| Compressor stator 3 blade surface | 1795 | 112 | Shaft end at rear bearing | 250 | 300 |

| Compressor stator 3 blade platform | 676 | 112 | Shaft exterior surface | 400 | 300 |

| Compressor stator 3 frontal surface | 568 | 104 | Shaft interior surface | 400 | 260 |

| Compressor stator 3 back surface | 944 | 120 | Static rear part inner shaft | 900 | 300 |

| Static interior back part | 150 | 250 | Static front part inner shaft | 400 | 300 |

| Static interior platform part | 200 | 206 | Swiler | 500 | 250 |

| Local | Emissivity/Radiation | ||||

| Combustion chamber interior high | 0.6 | 1700 | |||

| Combustion chamber interior medium | 0.6 | 1200 | |||

| Combustion chamber interior low | 0.6 | 900 | |||

| Static part around combustion chamber | 0.6 | 980 | |||

| Static part below combustion chamber | 0.6 | 1100 | |||

| Static part around turbine disc | 0.6 | 600 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Creci, G.; de Mendoça, M.T.; Menezes, J.C.; Barbosa, J.R. Heat Transfer Analysis in a Single Spool Gas Turbine by Using Calculated-Estimated Coefficients with the Finite Element Method. Appl. Sci. 2020, 10, 8328. https://doi.org/10.3390/app10238328

Creci G, de Mendoça MT, Menezes JC, Barbosa JR. Heat Transfer Analysis in a Single Spool Gas Turbine by Using Calculated-Estimated Coefficients with the Finite Element Method. Applied Sciences. 2020; 10(23):8328. https://doi.org/10.3390/app10238328

Chicago/Turabian StyleCreci, Geraldo, Márcio Teixeira de Mendoça, João Carlos Menezes, and João Roberto Barbosa. 2020. "Heat Transfer Analysis in a Single Spool Gas Turbine by Using Calculated-Estimated Coefficients with the Finite Element Method" Applied Sciences 10, no. 23: 8328. https://doi.org/10.3390/app10238328

APA StyleCreci, G., de Mendoça, M. T., Menezes, J. C., & Barbosa, J. R. (2020). Heat Transfer Analysis in a Single Spool Gas Turbine by Using Calculated-Estimated Coefficients with the Finite Element Method. Applied Sciences, 10(23), 8328. https://doi.org/10.3390/app10238328