Performance-Related Assessment of the Potential Use of Sawing Sludge in Cementitious Fluidized Thermal Backfills

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

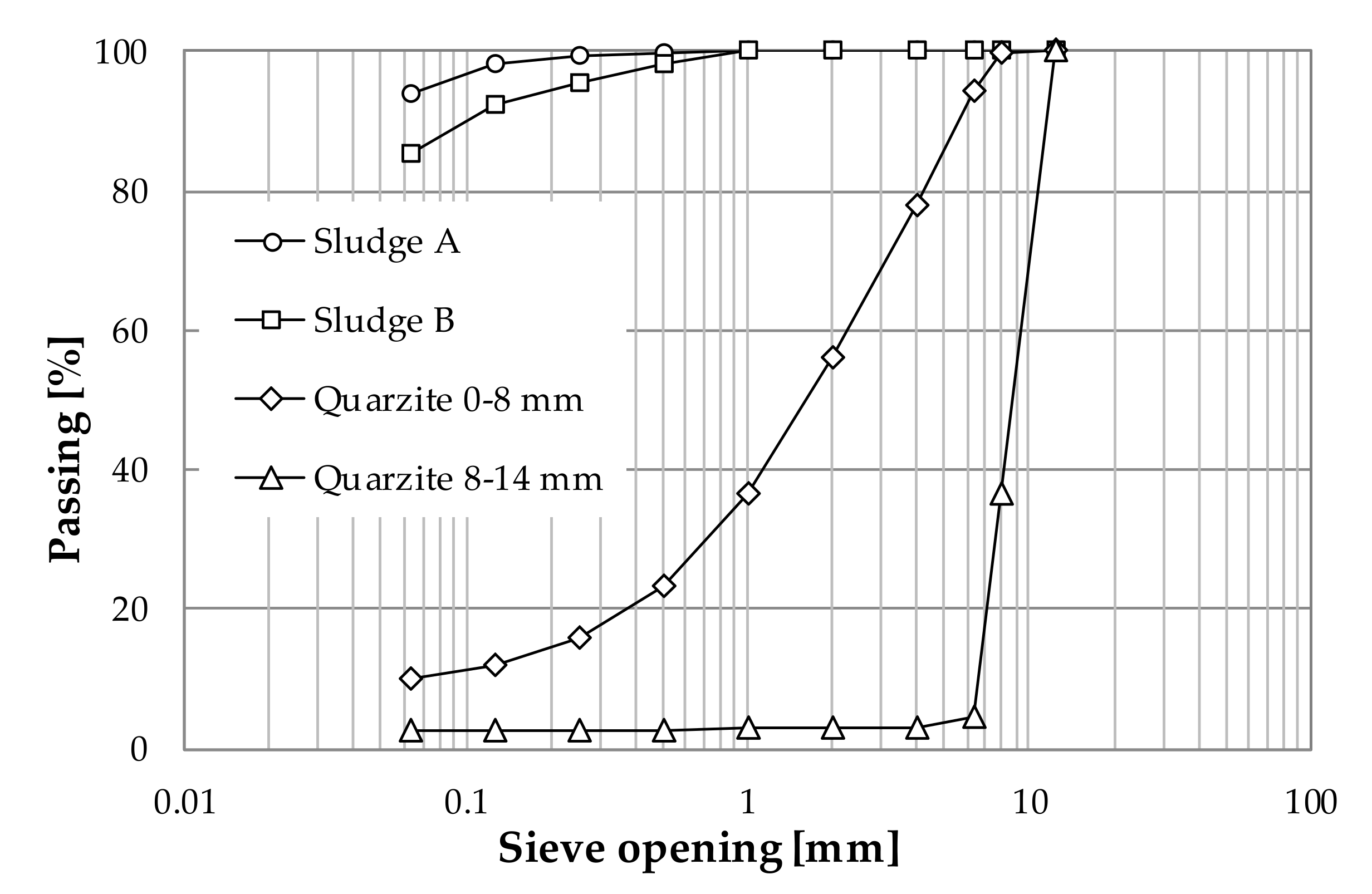

2.1. Constituent Materials

2.2. FTB Mixtures

2.3. Test Methods

3. Results and Discussion

3.1. Thermal Properties

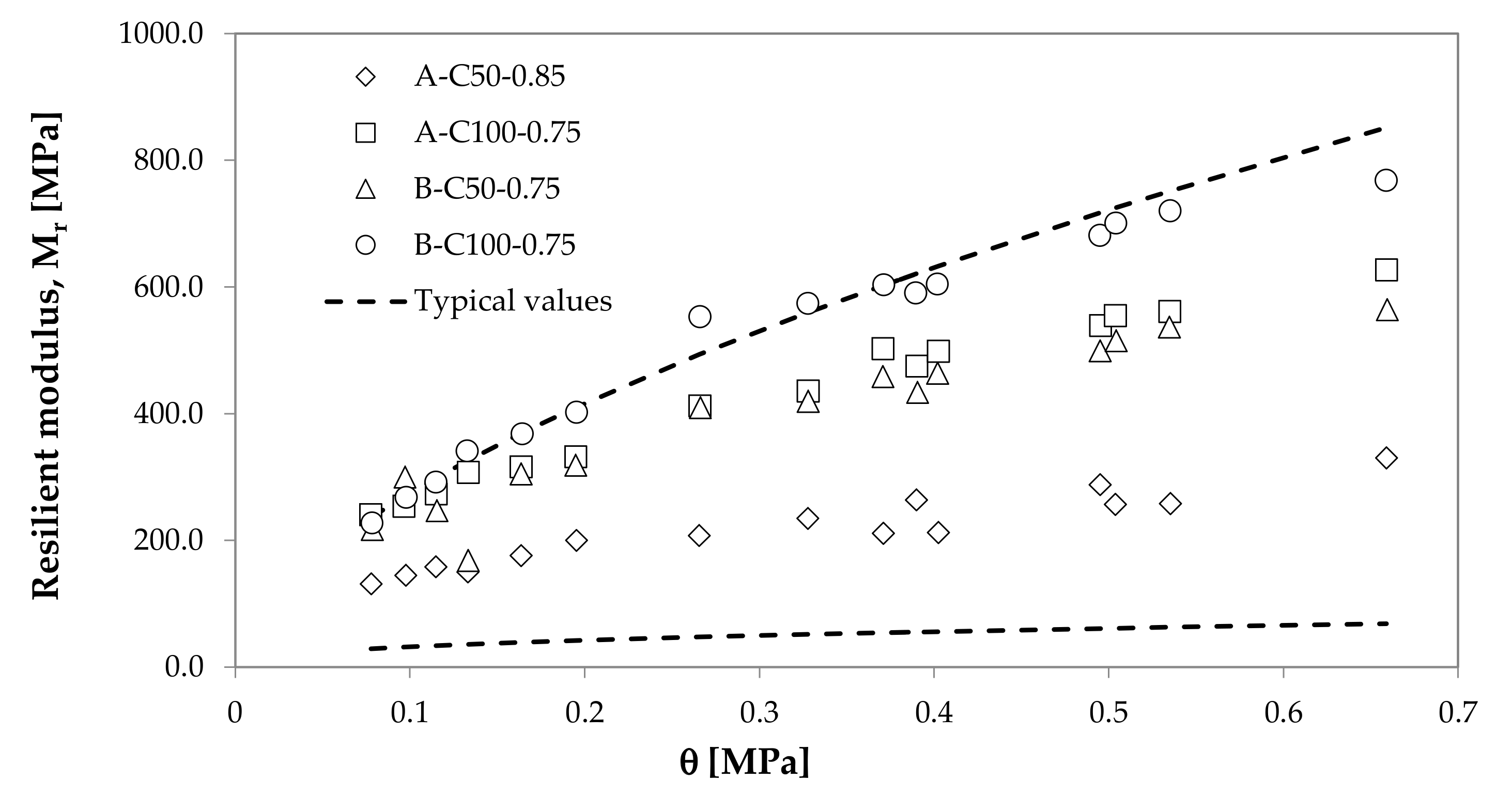

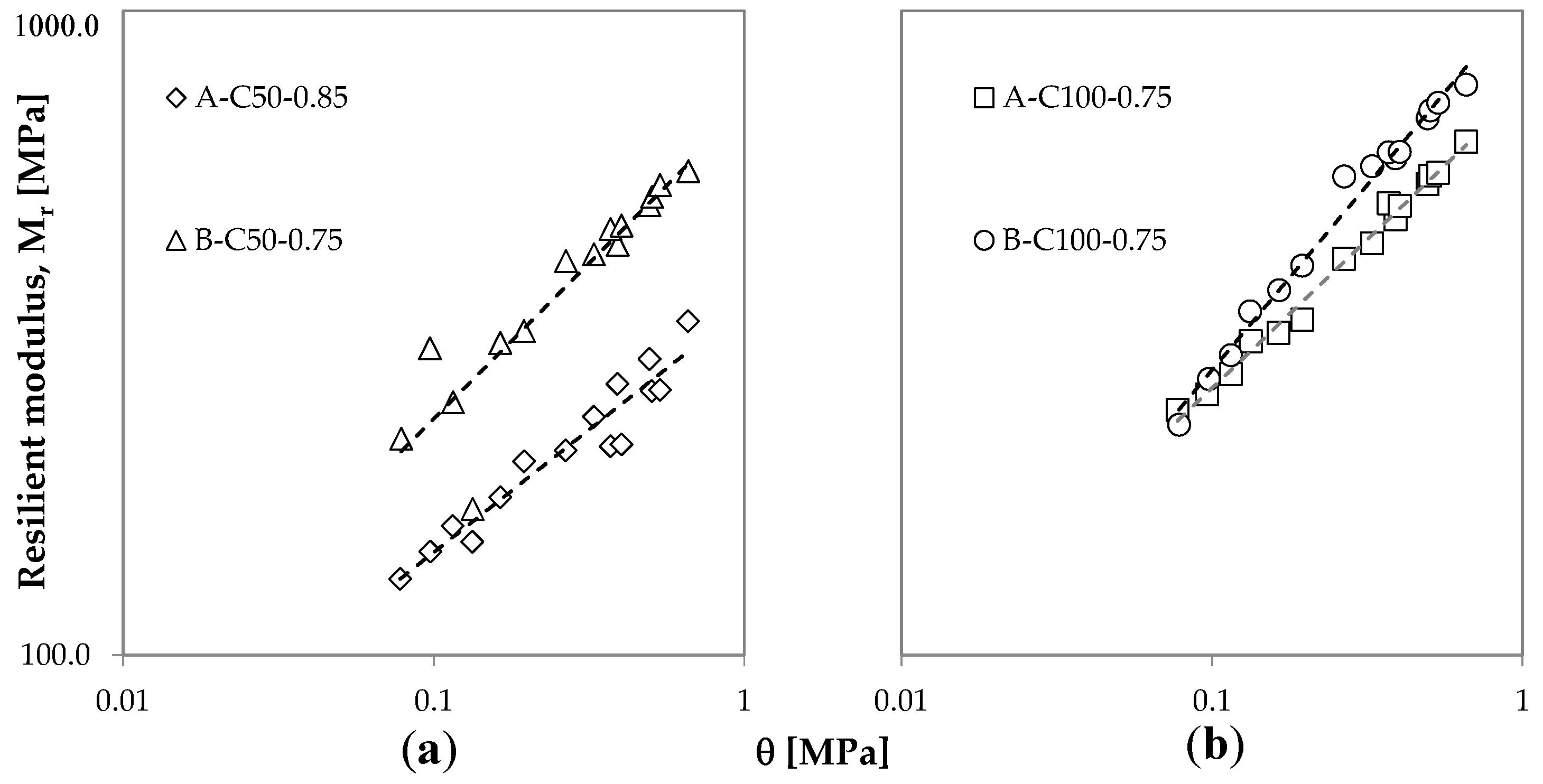

3.2. Mechanical Properties

3.3. Environmental Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gouda, O.E.; Osman, G.; Salem, W.; Arafa, S.H. Cyclic Loading of Underground Cables Including the Variations of Backfill Soil Thermal Resistivity and Specific Heat with Temperature Variation. IEEE Trans. Power Deliv. 2018, 33, 3122–3129. [Google Scholar] [CrossRef]

- Rerak, M.; Ocłoń, P. Thermal analysis of underground power cable system. J. Therm. Sci. 2017, 26, 465–471. [Google Scholar] [CrossRef]

- Ocłoń, P.; Cisek, P.; Pilarczyk, M.; Taler, D. Numerical simulation of heat dissipation processes in underground power cable system situated in thermal backfill and buried in a multilayered soil. Energy Convers. Manag. 2015, 95, 352–370. [Google Scholar] [CrossRef]

- Fu, C.-Z.; Si, W.-R.; Quan, L.; Yang, J. Numerical Study of Heat Transfer in Trefoil Buried Cable with Fluidized Thermal Backfill and Laying Parameter Optimization. Math. Probl. Eng. 2019, 2019, 1–13. [Google Scholar] [CrossRef]

- Gouda, O.E.; El Dein, A.Z. Improving underground power distribution capacity using artificial backfill materials. IET Gener. Transm. Distrib. 2015, 9, 2180–2187. [Google Scholar] [CrossRef]

- Ocłoń, P.; Cisek, P.; Taler, D.; Pilarczyk, M.; Szwarc, T. Optimizing of the underground power cable bedding using momentum-type particle swarm optimization method. Energy 2015, 92, 230–239. [Google Scholar] [CrossRef]

- Quan, L.; Fu, C.; Si, W.; Yang, J.; Wang, Q. Numerical study of heat transfer in underground power cable system. Energy Procedia 2019, 158, 5317–5322. [Google Scholar] [CrossRef]

- Williams, J.A.; Parmar, D.; Conroy, M.W. Controlled backfill optimization to achieve high ampacities on transmission cables. IEEE Trans. Power Deliv. 1994, 9, 544–552. [Google Scholar] [CrossRef]

- Rao, M.G.; Kolay, P.; Singh, D. Thermal characteristics of a class F fly ash. Cem. Concr. Res. 1998, 28, 841–846. [Google Scholar] [CrossRef]

- Kolay, P.K.; Singh, D. Application of Coal Ash in Fluidized Thermal Beds. J. Mater. Civ. Eng. 2002, 14, 441–444. [Google Scholar] [CrossRef]

- Célestin, J.C.H.; Fall, M. Thermal conductivity of cemented paste backfill material and factors affecting it. Int. J. Min. Reclam. Environ. 2009, 23, 274–290. [Google Scholar] [CrossRef]

- Bascom, E.C.R.; Patel, N.; Parmar, D. Thermal Environment Design Considerations for Ampacity of Buried Power Cables. In Proceedings of the IEEE Transmission & Distribution Conference, Chicago, IL, USA, 14–16 April 2014. [Google Scholar]

- Choorackal, E.A.; Riviera, P.P.; Dalmazzo, D.; Santagata, E.; Zichella, L.; Marini, P. Reuse of Recycled Asphalt Pavement and Mineral Sludges in Fluidized Thermal Backfills. In Proceedings of the 6th International Conference on Sustainable Solid Waste Management, Naxos Island, Greece, 13–16 June 2018. [Google Scholar]

- Choorackal, E.; Riviera, P.P.; Dalmazzo, D.; Santagata, E.; Zichella, L.; Marini, P. Performance-Related Characterization of Fluidized Thermal Backfills Containing Recycled Components. Waste Biomass Valoris. 2019, 11, 5393–5404. [Google Scholar] [CrossRef]

- Choorackal, E.; Riviera, P.P.; Santagata, E. Mix design and mechanical characterization of self-compacting cement-bound mixtures for paving applications. Constr. Build. Mater. 2019, 229, 116894. [Google Scholar] [CrossRef]

- Riviera, P.P.; Bertagnoli, G.; Choorackal, E.; Santagata, E. Controlled low-strength materials for pavement foundations in road tunnels: Feasibility study and recommendations. Mater. Struct. 2019, 52, 72. [Google Scholar] [CrossRef]

- Kim, K.-H.; Jeon, S.-E.; Kim, J.-K.; Yang, S. An experimental study on thermal conductivity of concrete. Cem. Concr. Res. 2003, 33, 363–371. [Google Scholar] [CrossRef]

- Uysal, H.; Demirboğa, R.; Şahin, R.; Gül, R. The effects of different cement dosages, slumps, and pumice aggregate ratios on the thermal conductivity and density of concrete. Cem. Concr. Res. 2004, 34, 845–848. [Google Scholar] [CrossRef]

- Damdelen, O. Influences of construction material type and water-cement ratio reduction on thermal transmittance of sustainable concrete mixes. Constr. Build. Mater. 2019, 196, 345–353. [Google Scholar] [CrossRef]

- Graziani, A.; Giovannelli, G. I Lapidei. Struttura del Settore e Tendenze Innovative; Centro Studi Osservatorio Fillea: Rome, Italy, 2015. [Google Scholar]

- Zichella, L.; Bellopede, R.; Spriano, S.; Marini, P. Preliminary investigations on stone cutting sludge processing for a future recovery. J. Clean. Prod. 2018, 178, 866–876. [Google Scholar] [CrossRef]

- Careddu, N.; Dino, G. Reuse of residual sludge from stone processing: Differences and similarities between sludge coming from carbonate and silicate stones—Italian experiences. Environ. Earth Sci. 2016, 75. [Google Scholar] [CrossRef]

- Chouhan, H.S.; Kalla, P.; Nagar, R.; Gautam, P.K. Influence of dimensional stone waste on mechanical and durability properties of mortar: A review. Constr. Build. Mater. 2019, 227, 116662. [Google Scholar] [CrossRef]

- Zichella, L.; Dino, G.A.; Bellopede, R.; Marini, P.; Padoan, E.; Passarella, I. Environmental impacts, management and potential recovery of residual sludge from the stone industry: The piedmont case. Resour. Policy 2020, 65, 101562. [Google Scholar] [CrossRef]

- Hamaie, H.D.A.; Khushefati, W.H. Granite Sludge Reuse in Mortar and Concrete. J. Appl. Sci. 2013, 13, 444–450. [Google Scholar] [CrossRef]

- Amin, M.N.; Khan, K.; Saleem, M.U.; Khurram, N.; Niazi, M.U.K. Aging and Curing Temperature Effects on Compressive Strength of Mortar Containing Lime Stone Quarry Dust and Industrial Granite Sludge. Materials 2017, 10, 642. [Google Scholar] [CrossRef] [PubMed]

- Mashaly, A.O.; Shalaby, B.N.; Rashwan, M. Performance of mortar and concrete incorporating granite sludge as cement replacement. Constr. Build. Mater. 2018, 169, 800–818. [Google Scholar] [CrossRef]

- Singh, S.; Khan, S.; Khandelwal, R.; Chugh, A.; Nagar, R. Performance of sustainable concrete containing granite cutting waste. J. Clean. Prod. 2016, 119, 86–98. [Google Scholar] [CrossRef]

- Singh, S.; Nande, N.; Bansal, P.; Nagar, R. Experimental Investigation of Sustainable Concrete Made with Granite Industry By-Product. J. Mater. Civ. Eng. 2017, 29, 04017017. [Google Scholar] [CrossRef]

- Da Silva, J.L.; Campos, D.B.D.C.; Lordsleem, A.C.; Povoas, Y.V. Influence of the partial substitution of fine aggregate by granite powder in mortar on the process of natural carbonation. Waste Manag. Res. 2019, 38, 254–262. [Google Scholar] [CrossRef]

- Santagata, E.; Baglieri, O.; Tsantilis, L.; Chiappinelli, G.; Riviera, P.P. Re-Use in Asphalt Pavements of Fillers from Natural Stone Sawmilling Sludge. In Proceedings of the AIIT International Congress on Transport Infrastructure and Systems (TIS 2017), Rome, Italy, 10–12 April 2017. [Google Scholar] [CrossRef]

- Aydin, E.; Arel, H.Ş. High-volume marble substitution in cement-paste: Towards a better sustainability. J. Clean. Prod. 2019, 237, 237. [Google Scholar] [CrossRef]

- EN 197-1. Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. Available online: https://standards.globalspec.com/std/1399038/EN%20197-1 (accessed on 4 November 2017).

- Khan, M. Factors affecting the thermal properties of concrete and applicability of its prediction models. Build. Environ. 2002, 37, 607–614. [Google Scholar] [CrossRef]

- Balkan, E.; Erkan, K.; Şalk, M. Thermal conductivity of major rock types in western and central Anatolia regions, Turkey. J. Geophys. Eng. 2017, 14, 909–919. [Google Scholar] [CrossRef]

- EN 933-1. Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method. Available online: https://standards.iteh.ai/catalog/standards/cen/100b983f-85a4-4a80-934c-e93c584dbdb4/en-933-1-2012 (accessed on 4 November 2017).

- EN 1097-6. Tests for Mechanical and Physical Properties of Aggregates—Part 6: Determination of Particle Density and Water Absorption. Available online: https://standards.iteh.ai/catalog/standards/cen/efd7df30-eac1-4445-90eb-9b2958fb2564/en-1097-6-2013 (accessed on 4 November 2017).

- EPA. EPA 3051A and EPA 6020A. 2007. Available online: https://www.epa.gov/sites/production/files/2015-07/documents/epa-6020a.pdf (accessed on 5 November 2017).

- EN 12457-2. Characterisation of waste—Leaching—Compliance Test for Leaching of Granular Waste Materials and Sludges—Part 2: One Stage Batch Test at a Liquid to Solid Ratio of 10 l/kg for Materials with Particle Size below 4 mm (without or with Size Reduction). Available online: https://standards.iteh.ai/catalog/standards/cen/db6fbdf3-1de7-457c-a506-46c4898e3f09/en-12457-2-2002 (accessed on 4 November 2017).

- Ali, S.E.; Ako, T.A. Lk+petrographic and physic-mechanical characteristics of quartzite from the wolframite mine in Zumba, northcentral Nigeria: Implication for their use as construction materials. J. Appl. Geol. Geophys. 2018, 6, 59–76. [Google Scholar] [CrossRef]

- Decreto Ministeriale 5 Febbraio 1998. Individuazione dei rifiuti non pericolosi sottoposti alle procedure semplificate di recupero ai sensi degli articoli 31 e 33 del decreto legislativo 5 febbraio 1997, n. 22, (GU Serie Generale n.88 del 16-04-1998—Suppl. Ordinario n. 72) (in Italian).

- Decreto Legislativo 3 Aprile 2006, n. 152. Norme in materia ambientale. (GU Serie Generale n.88 del 14-04-2006—Suppl. Ordinario n. 96).

- Decreto Ministeriale 5 Aprile 2006, n. 186. Regolamento recante modifiche al decreto ministeriale 5 febbraio 1998 “Individuazione dei rifiuti non pericolosi sottoposti alle procedure semplificate di recupero, ai sensi degli articoli 31 e 33 del decreto legislativo 5 febbraio 1997, n. 22” (GU Serie Generale n.115 del 19-05-2006) (in Italian).

- Funk, J.E.; Dinger, D.R. Predictive Process Control of Crowded Particulate Suspensions; Springer: New York, NY, USA, 1994. [Google Scholar]

- ASTM. Standard Test Method for Determination of Thermal Conductivity of Soil and Soft Rock by Thermal Needle Probe Procedure; ASTM D5334-14; ASTM: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Lekarp, F.; Isacsson, U.; Dawson, A. State of the Art. I: Resilient Response of Unbound Aggregates. J. Transp. Eng. 2000, 126, 66–75. [Google Scholar] [CrossRef]

- Riviera, P.P.; Bellopede, R.; Marini, P.; Bassani, M. Performance-based re-use of tunnel muck as granular material for subgrade and sub-base formation in road construction. Tunn. Undergr. Space Technol. 2014, 40, 160–173. [Google Scholar] [CrossRef]

- Pratibha, R.; Babu, G.L.S.; Latha, G.M. Stress–Strain Response of Unbound Granular Materials Under Static and Cyclic Loading. Indian Geotech. J. 2015, 45, 449–457. [Google Scholar] [CrossRef]

- Bilodeau, J.-P.; Ouellet-Plamondon, C.; Doré, G. Estimation of resilient modulus of unbound granular materials used as pavement base: Combined effect of grain-size distribution and aggregate source frictional properties. Mater. Struct. 2016, 49, 4363–4373. [Google Scholar] [CrossRef]

- Bassani, M.; Riviera, P.P.; Tefa, L.; Chiappinelli, G. Effects of quantity and plasticity of fine particles on the workability and resilient behaviour of aggregate-soil mixtures for granular pavement layers. Road Mater. Pavement Des. 2019, 1–20. [Google Scholar] [CrossRef]

- Taha, R.; Al-Harthy, A.; Al-Shamsi, K.; Al-Zubeidi, M. Cement Stabilization of Reclaimed Asphalt Pavement Aggregate for Road Bases and Subbases. J. Mater. Civ. Eng. 2002, 14, 239–245. [Google Scholar] [CrossRef]

- Santagata, E.; Chiappinelli, G.; Riviera, P.P.; Baglieri, O. Triaxial Testing for the Short Term Evaluation of Cold-Recycled Bituminous Mixtures. Road Mater. Pavement Des. 2010, 11, 123–147. [Google Scholar] [CrossRef]

- Fatemi, S.; Imaninasab, R. Performance evaluation of recycled asphalt mixtures by construction and demolition waste materials. Constr. Build. Mater. 2016, 120, 450–456. [Google Scholar] [CrossRef]

- Bassani, M.; Riviera, P.P.; Tefa, L. Short-Term and Long-Term Effects of Cement Kiln Dust Stabilization of Construction and Demolition Waste. J. Mater. Civ. Eng. 2017, 29, 04016286. [Google Scholar] [CrossRef]

- AASHTO. Standard Method of Test for Determining the Resilient Modulus of Soils and Aggregate Materials; AASHTO T 307-99; AASHTO: Washington, DC, USA, 2003. [Google Scholar]

- Lo-Shu, K.; Man-Qing, S.; Xing-Sheng, S.; Yun-Xiu, L. Research on several physico-mechanical properties of lightweight aggregate concrete. Int. J. Cem. Compos. Light. Concr. 1980, 2, 185–191. [Google Scholar] [CrossRef]

- Mengistu, A.G.; Van Rensburg, L.D.; Mavimbela, S.S. The effect of soil water and temperature on thermal properties of two soils developed from aeolian sands in South Africa. Catena 2017, 158, 184–193. [Google Scholar] [CrossRef]

- Huang, Y.H. Pavement Analysis and Design, 2nd ed.; Pearson Education Inc.: Upper Saddle River, NJ, USA, 2004. [Google Scholar]

- Poon, C.; Clark, A.; Peters, C.; Perry, R. Mechanisms of Metal Fixation and Leaching by Cement Based Fixation Processes. Waste Manag. Res. 1985, 3, 127–142. [Google Scholar] [CrossRef]

- Huang, M.; Feng, H.; Shen, D.-S.; Li, N.; Chen, Y.; Shentu, J. Leaching Behavior of Heavy Metals from Cement Pastes Using a Modified Toxicity Characteristic Leaching Procedure (TCLP). Bull. Environ. Contam. Toxicol. 2016, 96, 354–360. [Google Scholar] [CrossRef] [PubMed]

- Rojas, M.F.; De Rojas, M. Total and soluble chromium, nickel and cobalt content in the main materials used in the manufacturing of Spanish commercial cements. Cem. Concr. Res. 2002, 32, 435–440. [Google Scholar] [CrossRef]

- Potgieter, S.; Panichev, N.; Potgieter, J.; Panicheva, S. Determination of hexavalent chromium in South African cements and cement-related materials with electrothermal atomic absorption spectrometry. Cem. Concr. Res. 2003, 33, 1589–1593. [Google Scholar] [CrossRef]

- Laforest, G.; Duchesne, J. Immobilization of chromium (VI) evaluated by binding isotherms for ground granulated blast furnace slag and ordinary Portland cement. Cem. Concr. Res. 2005, 35, 2322–2332. [Google Scholar] [CrossRef]

- Estokova, A.; Palascakova, L.; Singovszka, E.; Holub, M. Analysis of the Chromium Concentrations in Cement Materials. Procedia Eng. 2012, 42, 123–130. [Google Scholar] [CrossRef]

- Estokova, A.; Palaščáková, L.; Kanuchova, M. Study on Cr (VI) Leaching from Cement and Cement Composites. Int. J. Environ. Res. Public Health 2018, 15, 824. [Google Scholar] [CrossRef]

| Sludge Type | Stone Type | Composition | Cutting Technology |

|---|---|---|---|

| A | Serizzo stone | Quartz, plagioclase, orthoclase, biotite, muscovite, epidote | Gangsaw |

| B | Mix of silicate stones (Beola, Granite, Serizzo, Luserna, Syenite) | Quartz, plagioclase, orthoclase, alkaline feldspar, biotite, muscovite, pyroxene, white mica, chlorite | Miscellaneous (gangsaw, diamond blade, diamond wire) |

| Fractions | SG |

|---|---|

| 0–8 mm | 2.79 |

| 8–14 mm | 2.72 |

| Sludge A | 2.67 |

| Sludge B | 2.74 |

| Sludge Type | Fractions [mm] | |||||

|---|---|---|---|---|---|---|

| >0.425 | 0.425 ÷ 0.212 | 0.212 ÷ 0.106 | 0.106 ÷ 0.075 | 0.075 ÷ 0.038 | <0.038 | |

| A | 5 | 10 | 25 | 9 | 11 | 43 |

| B | 35 | 45 | 35 | 8 | 22 | 52 |

| Sludge Type | Ba | Cu | Zn | Co | Ni | V | Cd | Crtot | CrVI | Pb | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 68 | 186 | 54.5 | 10.4 | 86.5 | 25.6 | <1 | 130 | <5 | 4.7 | 34.28 |

| B | 72 | 108 | 125 | 102 | 15 | 22 | <1 | 1836 | <5 | 26 | 11.84 |

| Threshold limits for reuse | - | 600 | 1000 | 250 | 500 | - | 15 | 800 | 15 | 1000 | - |

| Sludge Type | Ba | Cu | Zn | Co | Ni | V | Cd | Crtot | CrVI | Pb | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| [mg/L] | [mg/L] | [mg/L] | [g/L] | [g/L] | [g/L] | [g/L] | [g/L] | [g/L] | [g/L] | [mg/L] | |

| A | <0.01 | <0.001 | <0.001 | 4.49 | <1 | 5.48 | <1 | <1 | <0.01 | <1 | 0.03 |

| B | 0.02 | 0.01 | 0.01 | <1 | 10 | 3.36 | <1 | 2.45 | <0.01 | <1 | 4.48 |

| Threshold limits for reuse | 1 | 0.05 | 3 | 250 | 10 | 250 | 5 | 50 | - | 50 | - |

| Sludge Type | Fraction [%] | |

|---|---|---|

| Magnetic | Non-Magnetic | |

| A | 3.0 | 97.0 |

| B | 2.5 | 97.5 |

| FTB Mixture | Cement [kg/m3] | W/P [–] | Superplasticizer [%] | Composition of Aggregate Skeleton [%] | |||

|---|---|---|---|---|---|---|---|

| Sludge A | Sludge B | Quartzite 0–8 mm | Quartzite 8–14 mm | ||||

| A-C50-0.85 | 50 | 0.85 | 0.25 | 18 | - | 71 | 11 |

| A-C100-0.75 | 100 | 0.75 | 0.50 | 18 | - | 71 | 11 |

| B-C50-0.75 | 50 | 0.75 | 0.25 | - | 19 | 69 | 12 |

| B-C100-0.75 | 100 | 0.75 | 0.50 | . | 19 | 69 | 12 |

| FTB Mixture | Thermal Conductivity, k | |

|---|---|---|

| [W/(m∙K)] | ||

| 18 Days of Curing | Lab-Dried | |

| A-C50-0.85 | 0.97 | 0.51 |

| A-C100-0.75 | 1.57 | 1.04 |

| B-C50-0.75 | 1.16 | 0.84 |

| B-C100-0.75 | 1.70 | 1.15 |

| FTB Mixture | Ba | Cu | Zn | Co | Ni | V | Cd | Crtot | CrVI | Pb | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A-C50-0.85 | 24 | 11 | 11 | 9 | 4 | 9 | <1 | 63 | <5 | 2 | 5.120 |

| A-C100-0.75 | 27 | 13 | 12 | 10 | 6 | 10 | <1 | 13 | <5 | 2 | 6.993 |

| B-C50-0.75 | 29 | 9 | 10 | 2 | 7 | 7 | <1 | 11 | <5 | 1 | 4.045 |

| B-C100-0.75 | 26 | 15 | 17 | 3 | 11 | 13 | <1 | 17 | <5 | 2 | 3.990 |

| Threshold limits for reuse | - | 600 | 1500 | 250 | 500 | - | 15 | 800 | 15 | 1000 | - |

| FTB Mixture | Ba | Cu | Zn | Co | Ni | V | Cd | Crtot | CrVI | Pb | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| [mg/L] | [mg/L] | [mg/L] | [g/L] | [g/L] | [g/L] | [g/L] | [g/L] | [g/L] | [g/L] | [mg/L] | |

| A-C50-0.85 | <0.01 | <0.001 | <0.001 | <1 | <1 | 7.5 | <1 | 49.6 | 0.04 | <1 | 51.9 |

| A-C100-0.75 | <0.01 | <0.001 | <0.001 | 4 | <1 | <1 | <1 | 62.1 | 0.05 | <1 | 30.6 |

| B-C50-0.75 | <0.01 | <0.001 | <0.001 | <1 | <1 | 2.2 | <1 | 94.9 | 0.08 | <1 | 49.5 |

| B-C100-0.75 | 0.03 | <0.001 | <0.001 | <1 | <1 | <1 | <1 | 84.9 | 0.06 | <1 | 13.3 |

| Threshold limits for reuse | 1 | 0.05 | 3 | 250 | 10 | 250 | 5 | 50 | - | 50 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zichella, L.; Choorackal, E.; Airoldi, M.; Riviera, P.P.; Bellopede, R.; Santagata, E. Performance-Related Assessment of the Potential Use of Sawing Sludge in Cementitious Fluidized Thermal Backfills. Appl. Sci. 2020, 10, 8243. https://doi.org/10.3390/app10228243

Zichella L, Choorackal E, Airoldi M, Riviera PP, Bellopede R, Santagata E. Performance-Related Assessment of the Potential Use of Sawing Sludge in Cementitious Fluidized Thermal Backfills. Applied Sciences. 2020; 10(22):8243. https://doi.org/10.3390/app10228243

Chicago/Turabian StyleZichella, Lorena, Eldho Choorackal, Michela Airoldi, Pier Paolo Riviera, Rossana Bellopede, and Ezio Santagata. 2020. "Performance-Related Assessment of the Potential Use of Sawing Sludge in Cementitious Fluidized Thermal Backfills" Applied Sciences 10, no. 22: 8243. https://doi.org/10.3390/app10228243

APA StyleZichella, L., Choorackal, E., Airoldi, M., Riviera, P. P., Bellopede, R., & Santagata, E. (2020). Performance-Related Assessment of the Potential Use of Sawing Sludge in Cementitious Fluidized Thermal Backfills. Applied Sciences, 10(22), 8243. https://doi.org/10.3390/app10228243