Numerical Analysis of EOD Helmet under Blast Load Events Using Human Head Model

Abstract

1. Introduction

2. Numerical Model

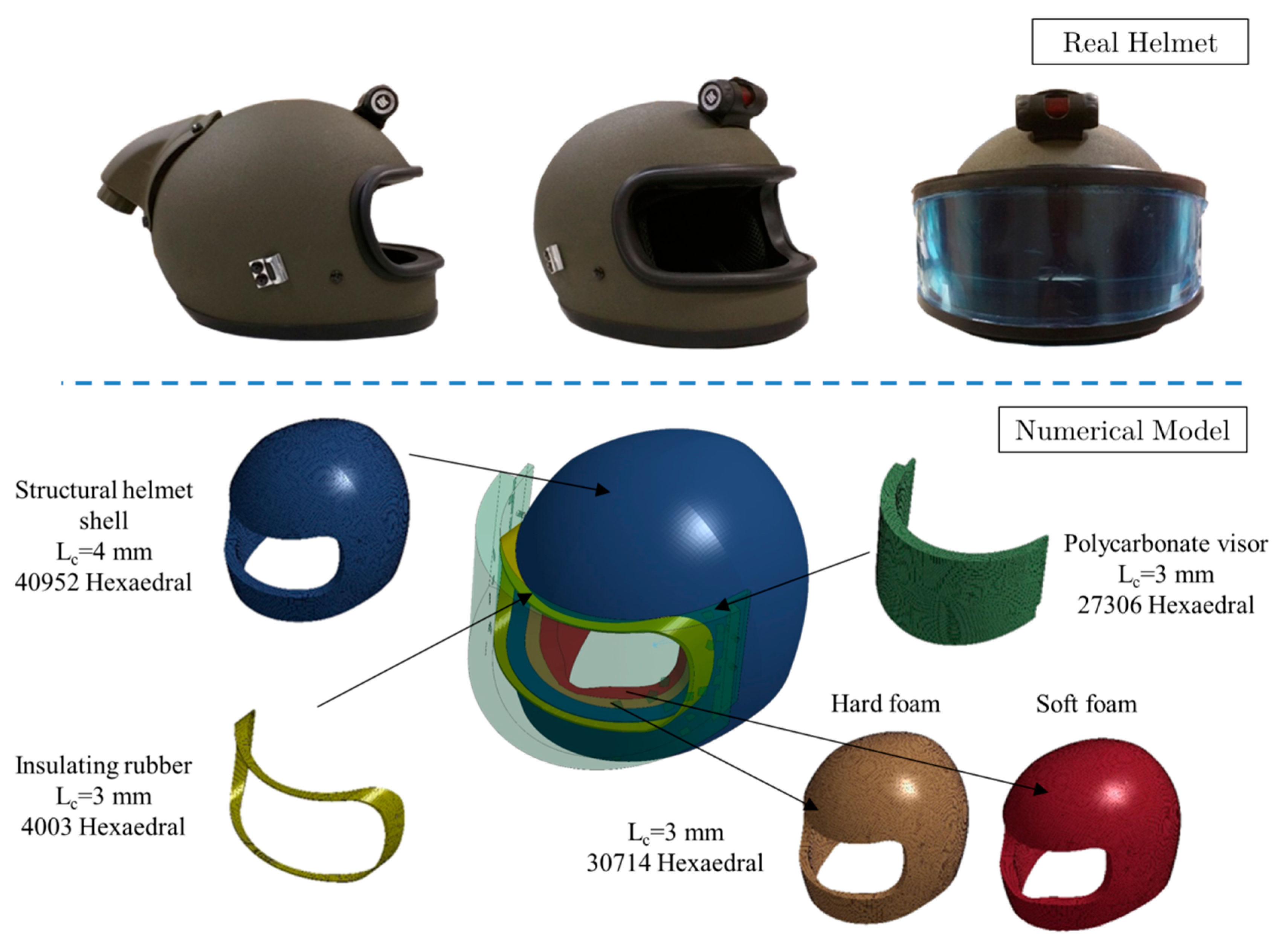

2.1. Helmet Assembly Model

- -

- Fiber breakage criterion is defined as

- -

- Matrix cracking criterion is defined as

- -

- Matrix compression failure criterion is defined as

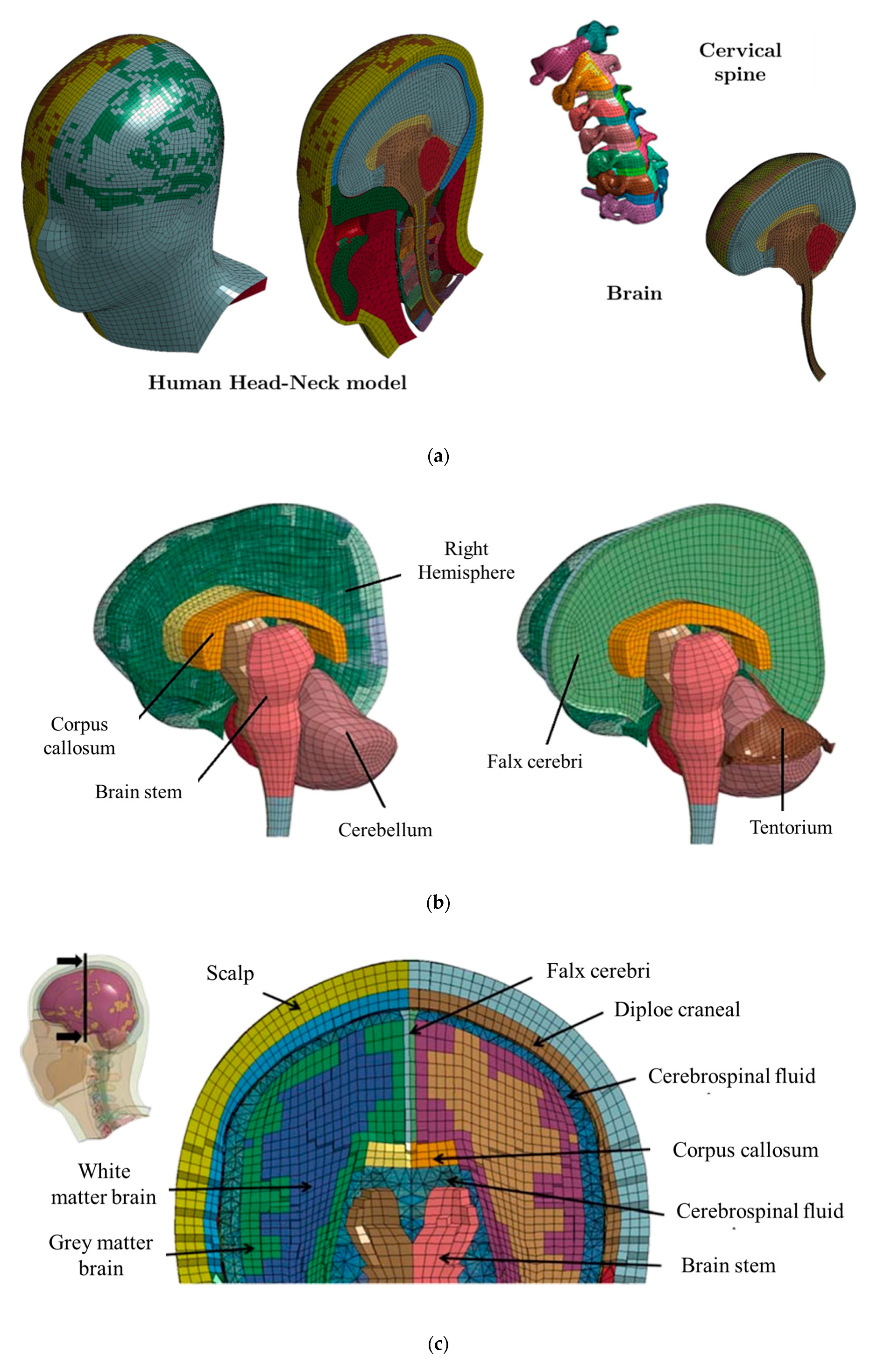

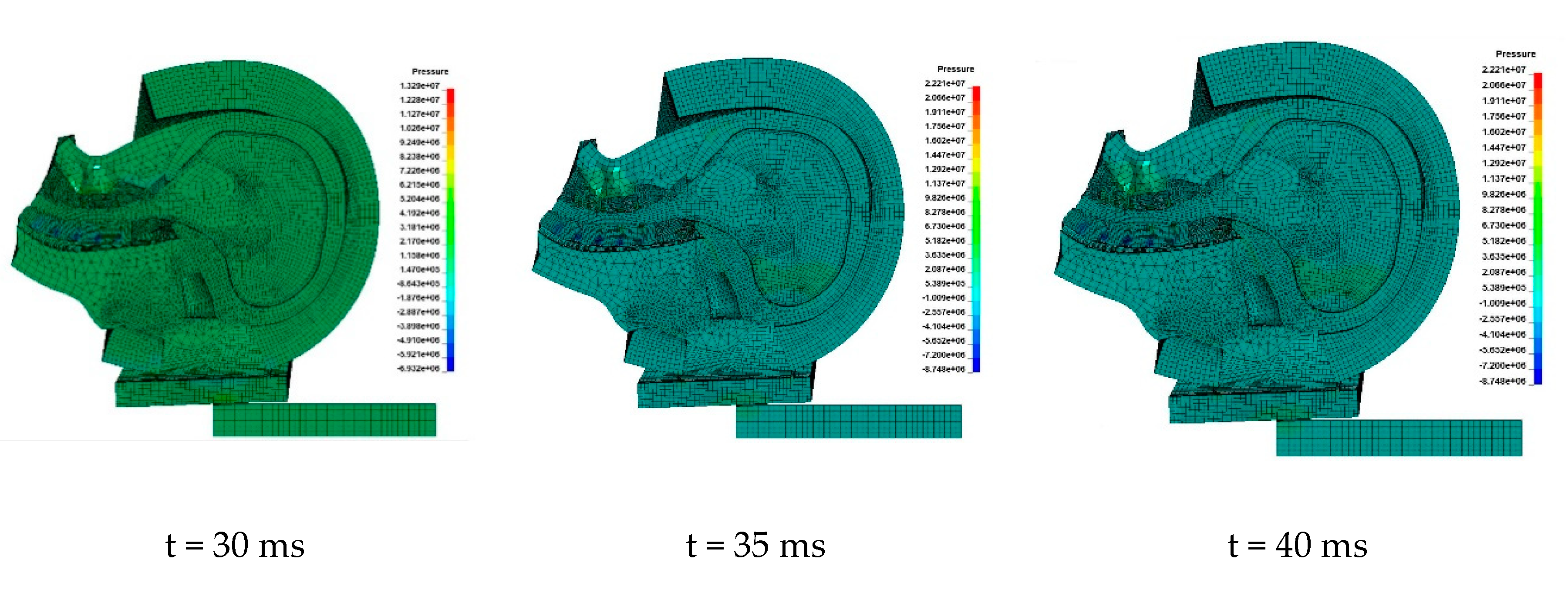

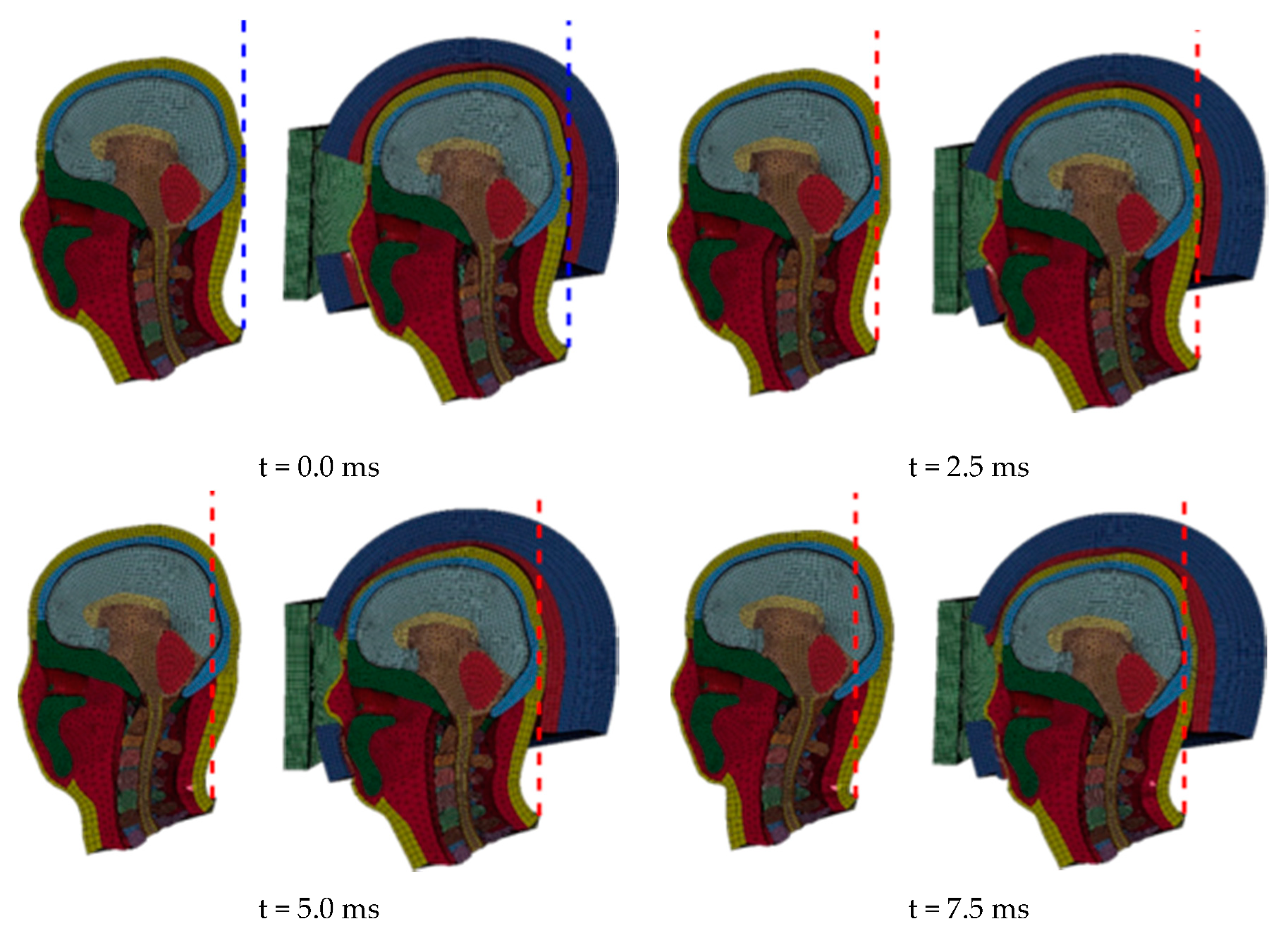

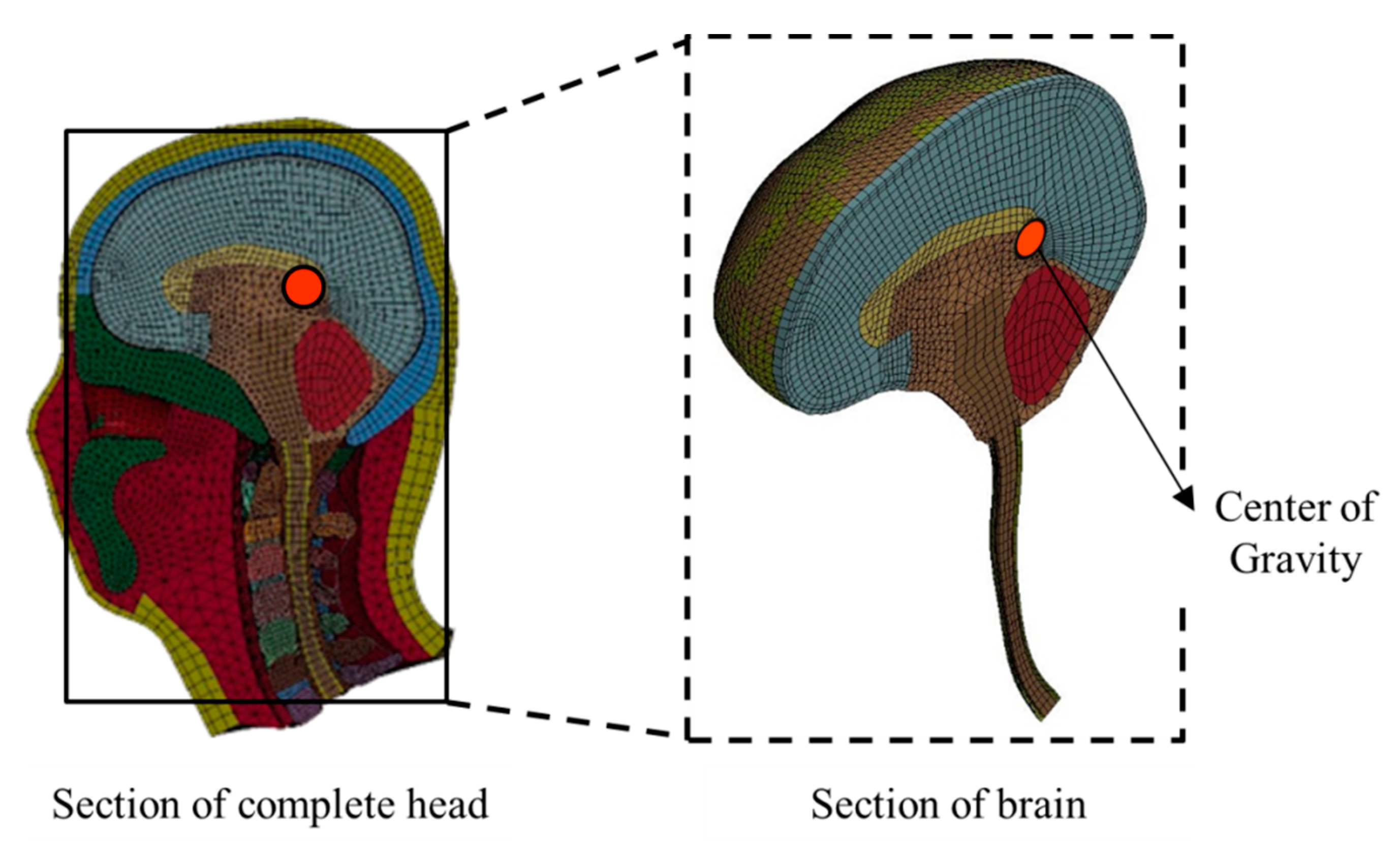

2.2. Head Assembly Model

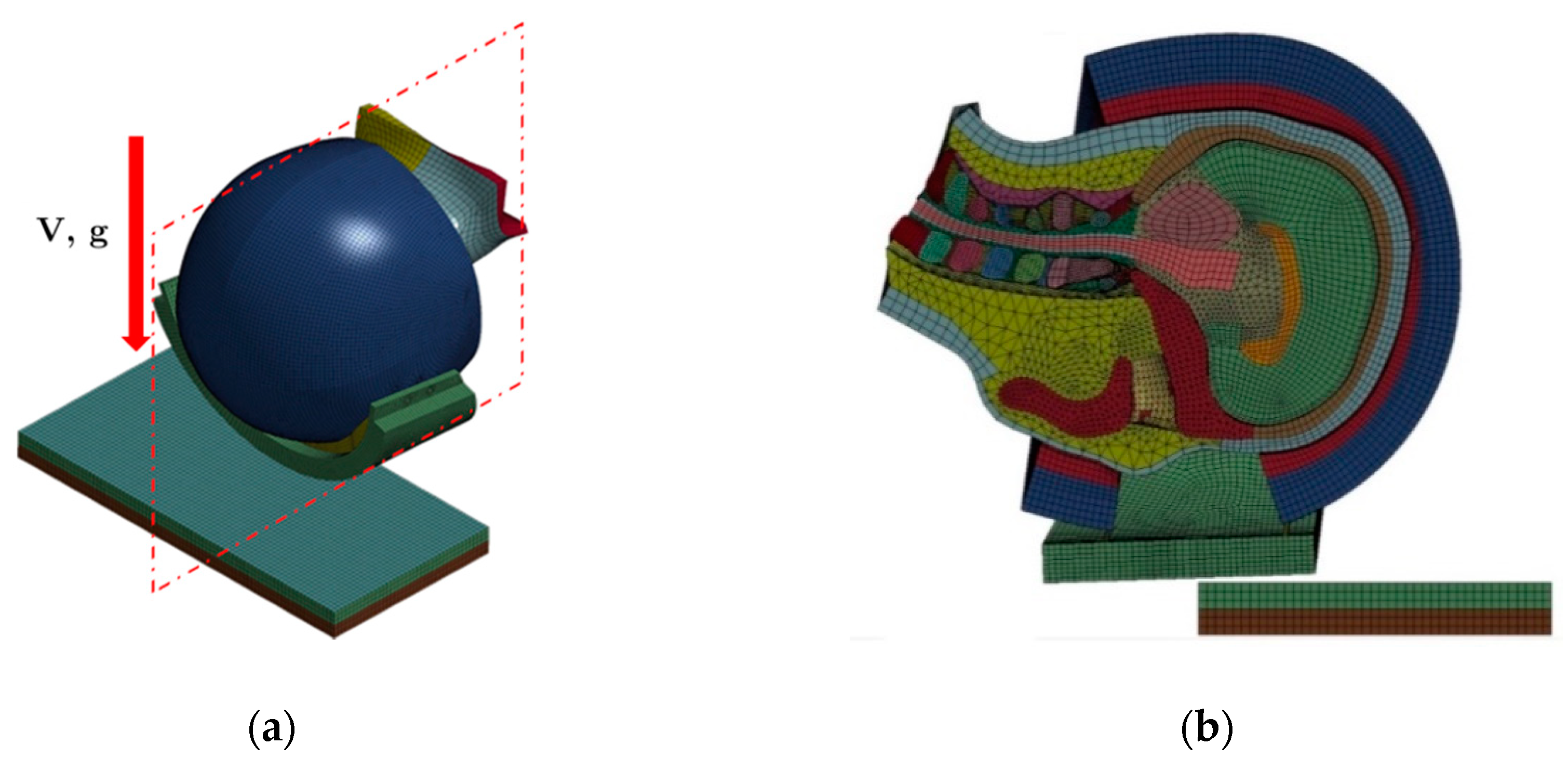

2.3. Boundary Conditions and Contact Interactions

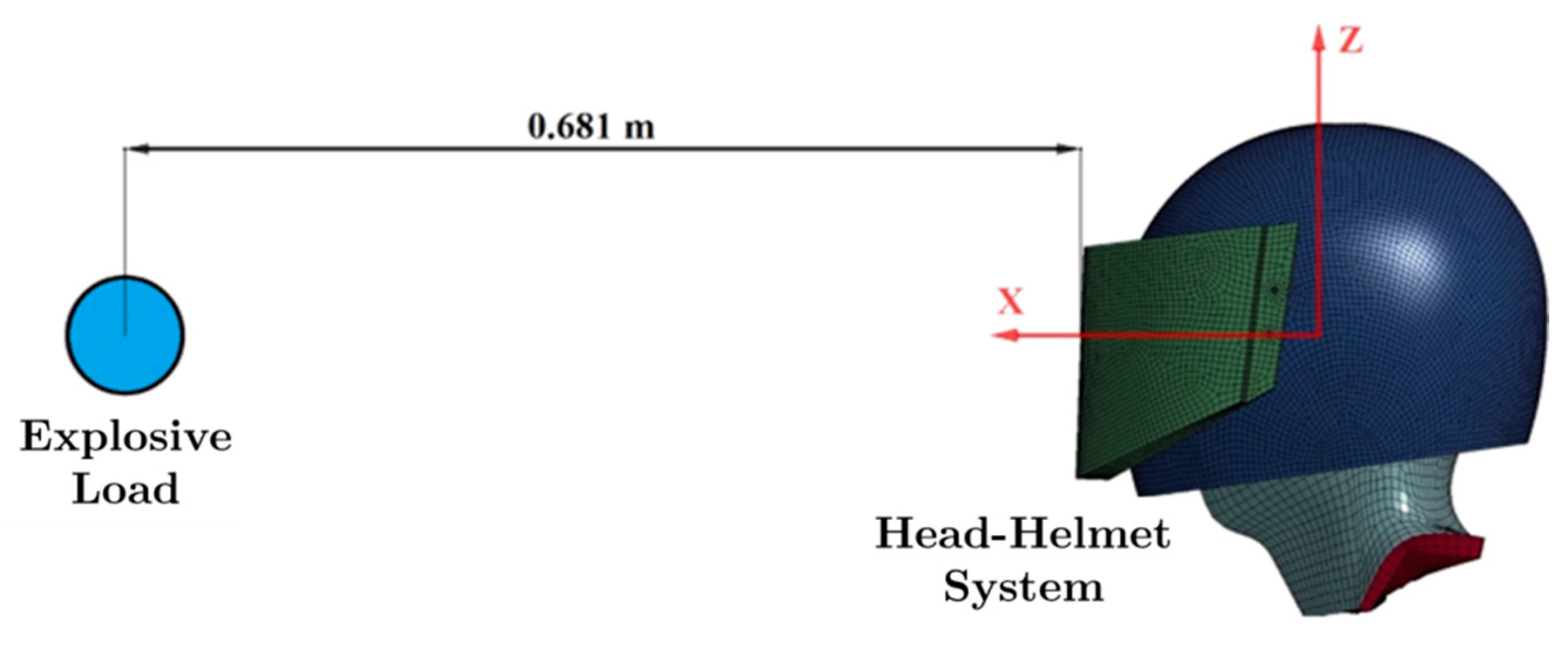

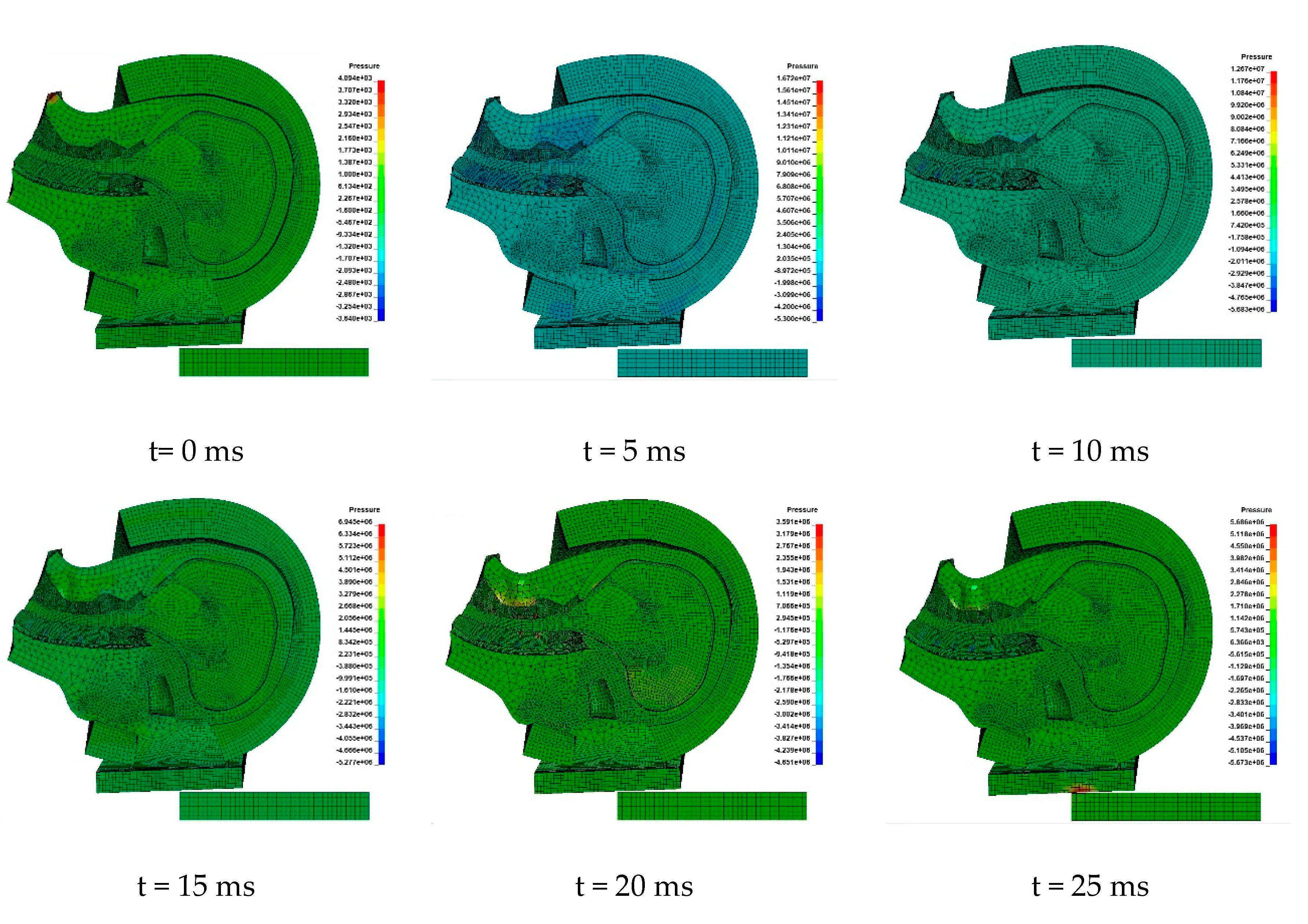

2.4. Blast Load Modelling

2.5. Model Check and Validation

3. Results and Discussion

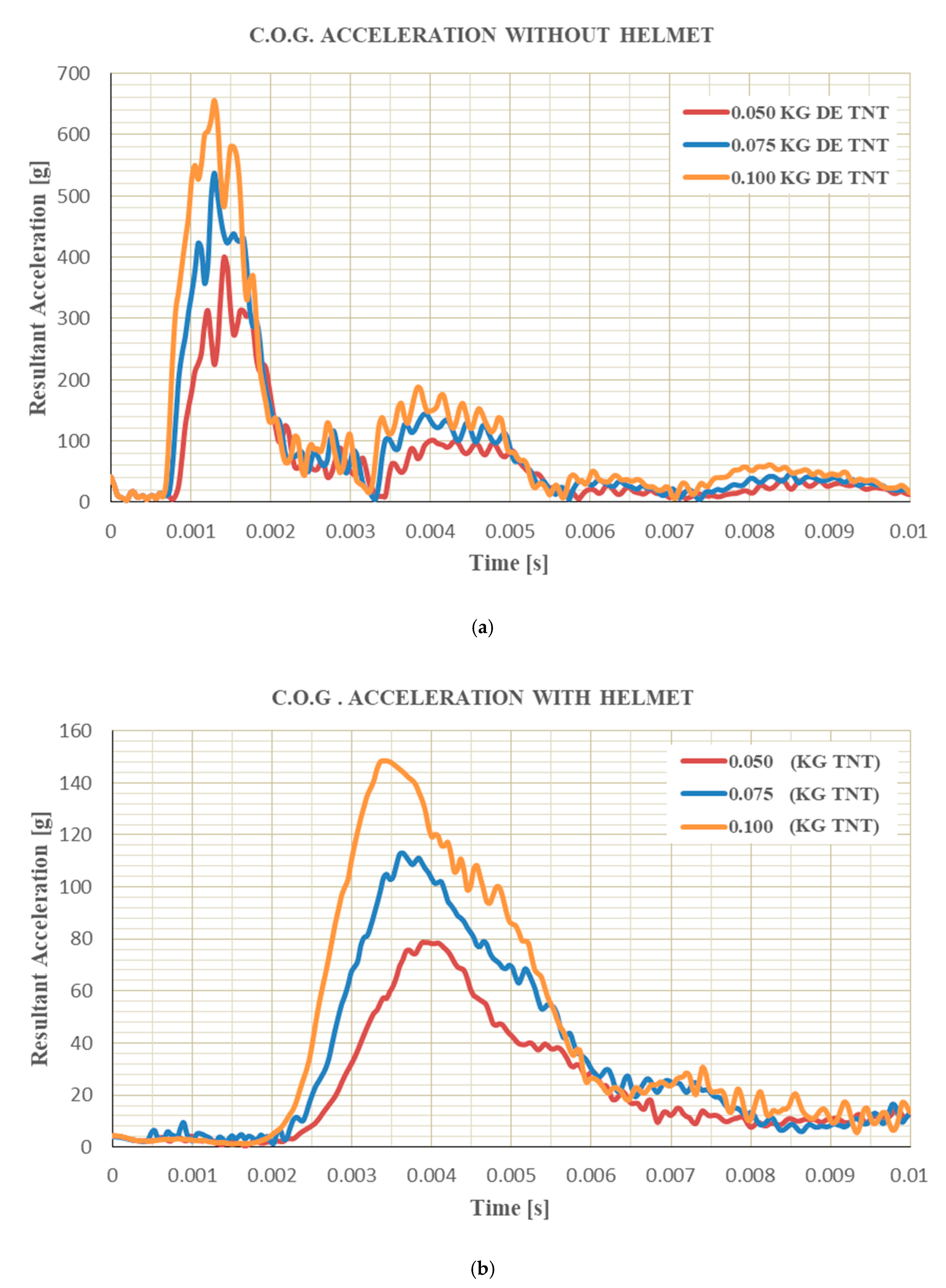

3.1. Brain Acceleration

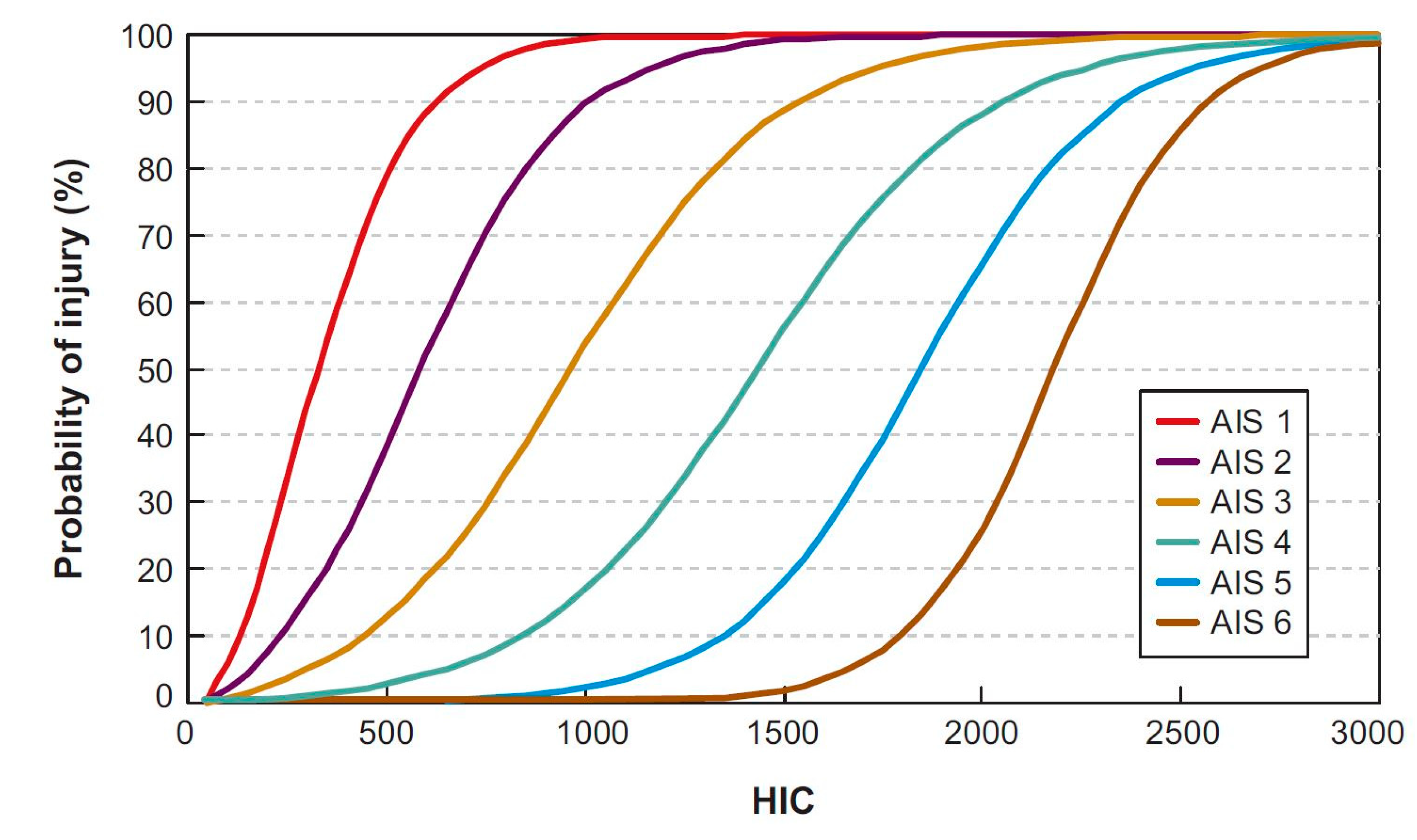

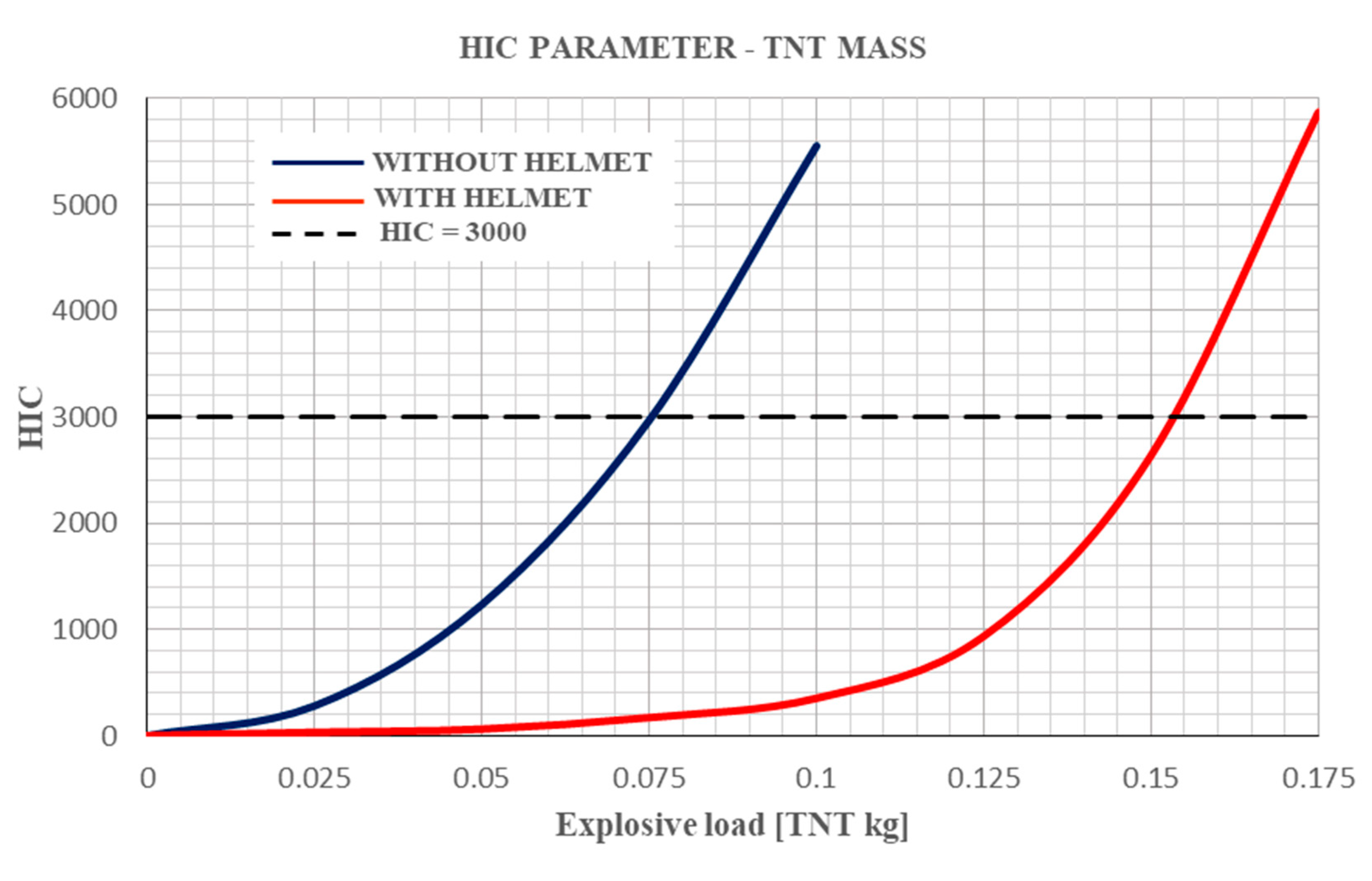

3.2. HIC and GSI Parameters

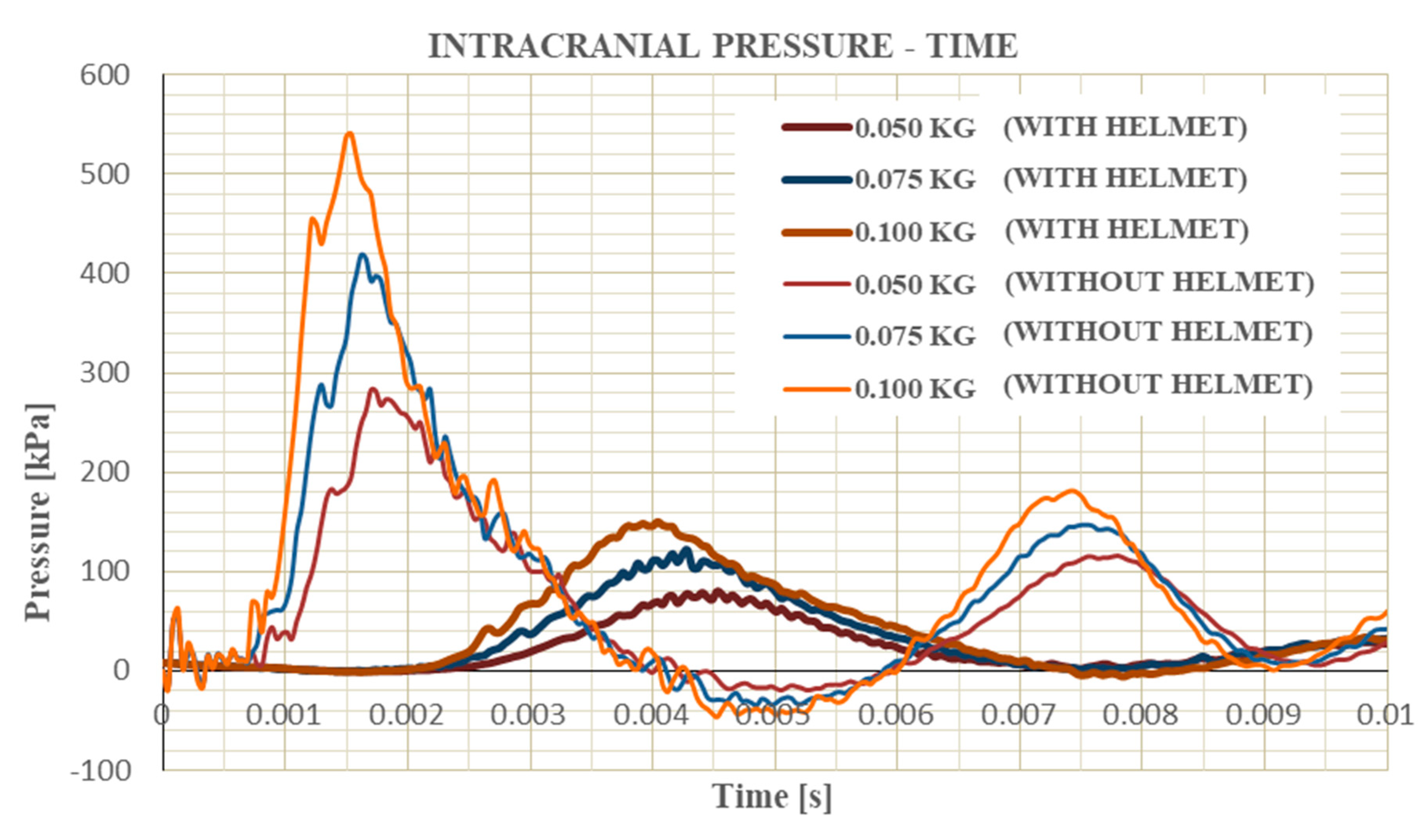

3.3. Intracranial Pressure (ICP)

- -

- If peak pressure is higher than 235 kPa, severe brain injuries like a concussion are likely to be.

- -

- If peak pressure is in the range 173–235 kPa, the injuries produced are of a mild nature, such as hemorrhage in the cerebral cortex.

- -

- Finally, if peak pressure is lower than 173 kPa, there are no brain injuries or they are likely to be very slight.

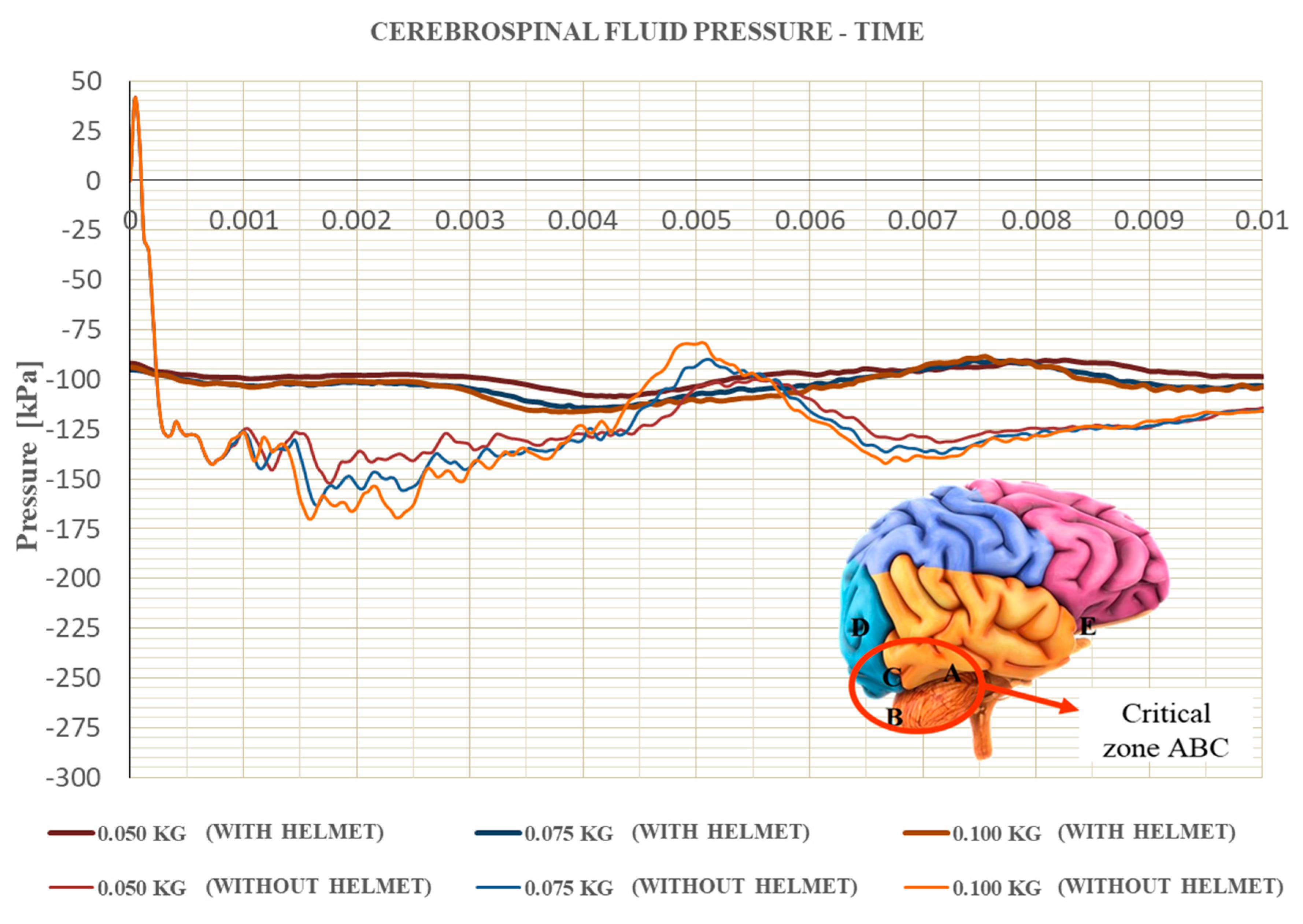

3.4. Cerebrospinal Fluid Pressure

- -

- For pressures, lower than −94 kPa, there is a 5% probability of subdural hematoma.

- -

- For pressures between −94 kPa and −134 kPa, the probability increases to 50%.

- -

- And, finally, when pressure is between −134 kPa and −177 kPa, the probability of subdural hematoma increases to 95%.

3.5. Cerebellum Strain

- -

- If cerebellum strain is higher than 0.14 (conservative criteria), a 25% probability of mTBI exists.

- -

- If the strains increase up to 0.19 (optimum criteria), the mTBI probability increases to 50%.

- -

- Finally, a mTBI probability of 80% is assumed if strains are higher than 0.24 (broad criteria).

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Townsend, M.T.; Alay, E.; Skotak, M.; Chandra, N. Effect of Tissue Material Properties in Blast Loading: Coupled Experimentation and Finite Element Simulation. Ann. Biomed. Eng. 2019, 47, 2019–2032. [Google Scholar] [CrossRef] [PubMed]

- NATO Standarization Agency. STANAG 2920 PPS—Ballistic Test Method for Personal Armour Materials and Combat Clothing, 2nd ed.; NATO: Brussels, Belgium, 2003. [Google Scholar]

- NIJ. NIJ Standard—0106.01; NIJ: Washington, DC, USA, 1981.

- Moore, D.F.; Jérusalem, A.; Nyein, M.; Noels, L.; Jaffee, M.S.; Radovitzky, R.A. Computational biology—Modeling of primary blast effects on the central nervous system. Neuroimage 2009, 47. [Google Scholar] [CrossRef] [PubMed]

- Grujicic, M.; Glomski, P.S.; He, T.; Arakere, G.; Bell, W.C.; Cheeseman, B.A. Material modeling and ballistic-resistance analysis of armor-grade composites reinforced with high-performance fibers. J. Mater. Eng. Perform. 2009, 18, 1169–1182. [Google Scholar] [CrossRef]

- Grujicic, M.; Arakere, A.; Pandurangan, B.; Grujicic, A.; Littlestone, A.; Barsoum, R. Computational investigation of shock-mitigation efficacy of polyurea when used in a combat helmet: A core sample analysis. Multidiscip. Model. Mater. Struct. 2012, 8, 297–331. [Google Scholar] [CrossRef]

- Panzer, M.B.; Bass, C.R.; Rafaels, K.A.; Shridharani, J.; Capehart, B.P. Primary blast survival and injury risk assessment for repeated blast exposures. J. Trauma Acute Care Surg. 2012, 72, 454–466. [Google Scholar] [CrossRef]

- Bass, C.R.; Panzer, M.B.; Rafaels, K.A.; Wood, G.; Shridharani, J.; Capehart, B. Brain injuries from blast. Ann. Biomed. Eng. 2012, 40, 185–202. [Google Scholar] [CrossRef]

- Zhang, L.; Makwana, R.; Sharma, S. Brain response to primary blast wave using validated finite element models of human head and advanced combat helmet. Front. Neurol. 2013, 4. [Google Scholar] [CrossRef]

- Rodríguez-Millán, M.; Tan, L.B.; Tse, K.M.; Lee, H.P.; Miguélez, M.H. Effect of full helmet systems on human head responses under blast loading. Mater. Des. 2017. [Google Scholar] [CrossRef]

- Sarvghad-Moghaddam, H.; Rezaei, A.; Ziejewski, M.; Karami, G. Evaluation of brain tissue responses because of the underwash overpressure of helmet and faceshield under blast loading. Int. J. Numer. Method. Biomed. Eng. 2017, 33. [Google Scholar] [CrossRef]

- Sarvghad-Moghaddam, H.; Jazi, M.S.; Rezaei, A.; Karami, G.; Ziejewski, M. Examination of the protective roles of helmet/faceshield and directionality for human head under blast waves. Comput. Methods Biomech. Biomed. Eng. 2015, 18, 1846–1855. [Google Scholar] [CrossRef]

- Singh, D.; Cronin, D.S. Efficacy of visor and helmet for blast protection assessed using a computational head model. Shock Waves 2017, 27, 905–918. [Google Scholar] [CrossRef]

- Li, J.; Ma, T.; Huang, C.; Huang, X.; Kang, Y.; Long, Z.; Liu, M. Protective Mechanism of Helmet Under Far-field Shock Wave. Int. J. Impact Eng. 2020, 143, 103617. [Google Scholar] [CrossRef]

- Tan, L.B.; Tse, K.M.; Tan, Y.H.; Sapingi, M.A.B.; Tan, V.B.C.; Lee, H.P. Face shield design against blast-induced head injuries. Int. J. Numer. Method. Biomed. Eng. 2017, 33. [Google Scholar] [CrossRef] [PubMed]

- Tse, K.M.; Bin Tan, L.; Ali Bin Sapingi, M.; Franklyn, M.; Lee, P.V.S.; Beng Chye Tan, V.; Pueh Lee, H. The role of a composite polycarbonate-aerogel face shield in protecting the human brain from blast-induced injury: A fluid–structure interaction (FSI) study. J. Sandw. Struct. Mater. 2019, 21, 2484–2511. [Google Scholar] [CrossRef]

- Bass, C.D.; Davis, M.; Rafaels, K.; Rountree, M.S.; Harris, R.M.; Sanderson, E.; Andrefsky, W.; Dimarco, G.; Zielinski, M. A Methodology for Assessing Blast Protection in Explosive Ordnance Disposal Bomb Suits. Int. J. Occup. Saf. Ergon. 2005, 11, 347–361. [Google Scholar] [CrossRef]

- Dionne, J.P.; Levine, J.; Makris, A. Acceleration-based methodology to assess the blast mitigation performance of explosive ordnance disposal helmets. Shock Waves 2018, 28, 5–18. [Google Scholar] [CrossRef]

- Sepulveda-Lopez, D.; Antona-Makoshi, J.; Rubio, I.; Rodríguez-Millán, M. Numerical Analysis of Bicycle Helmet under Blunt Behavior. Appl. Sci. 2020, 10, 3692. [Google Scholar] [CrossRef]

- Antona-Makoshi, J. Traumatic Brain Injuries: Animal Experiments and Numerical Simulations to Support the Development of a Brain Injury Criterion; Chalmers University of Technology: Gothenburg, Sweden, 2016; ISBN 978-91-628-9848-9. [Google Scholar]

- Van Hoof, J.; Cronin, D.S.; Worswick, M.J.; Williams, K.V.; Nandlall, D. Numerical Head and Composite Helmet Models to Predict Blunt Trauma. In Proceedings of the 19th International Symposium on Ballistics, Interlaken, Switzerland, 7–11 May 2001; pp. 7–11. [Google Scholar]

- Tan, L.B.; Tse, K.M.; Lee, H.P.; Tan, V.B.C.; Lim, S.P. Performance of an advanced combat helmet with different interior cushioning systems in ballistic impact: Experiments and finite element simulations. Int. J. Impact Eng. 2012, 50, 99–112. [Google Scholar] [CrossRef]

- Gower, H.L.; Cronin, D.S.; Plumtree, A. Ballistic impact response of laminated composite panels. Int. J. Impact Eng. 2008, 35, 1000–1008. [Google Scholar] [CrossRef]

- Shah, Q.H. Impact resistance of a rectangular polycarbonate armor plate subjected to single and multiple impacts. Int. J. Impact Eng. 2009, 36, 1128–1135. [Google Scholar] [CrossRef]

- Mark, J.E. Rubber elasticity. J. Chem. Educ. 1981, 58, 898. [Google Scholar] [CrossRef]

- Li, Y.Q.; Li, X.G.; Gao, X.L. Modeling of advanced combat helmet under ballistic impact. J. Appl. Mech. Trans. ASME 2015, 82. [Google Scholar] [CrossRef]

- Li, X.G.; Gao, X.L.; Kleiven, S. Behind helmet blunt trauma induced by ballistic impact: A computational model. Int. J. Impact Eng. 2016, 91, 56–67. [Google Scholar] [CrossRef]

- Rodríguez-Millán, M.; Ito, T.; Loya, J.A.; Olmedo, A.; Miguélez, M.H. Development of numerical model for ballistic resistance evaluation of combat helmet and experimental validation. Mater. Des. 2016, 110, 391–403. [Google Scholar] [CrossRef]

- Rubio, I.; Díaz-álvarez, A.; Bernier, R.; Rusinek, A.; Loya, J.A.; Miguelez, M.H.; Rodríguez-Millán, M. Postmortem analysis using different sensors and technologies on aramid composites samples after ballistic impact. Sensors 2020, 20, 2853. [Google Scholar] [CrossRef] [PubMed]

- Tham, C.Y.; Tan, V.B.C.; Lee, H.P. Ballistic impact of a KEVLAR® helmet: Experiment and simulations. Int. J. Impact Eng. 2008, 35, 304–318. [Google Scholar] [CrossRef]

- Rubio, I.; Rodríguez-Millán, M.; Marco, M.; Olmedo, A.; Loya, J.A. Ballistic performance of aramid composite combat helmet for protection against small projectiles. Compos. Struct. 2019, 226, 111153. [Google Scholar] [CrossRef]

- Palomar, M.; Belda, R.; Giner, E. Effect of different helmet shell configurations on the protection against head trauma. J. Strain Anal. Eng. Des. 2019, 54, 408–415. [Google Scholar] [CrossRef]

- Chang, F.-K.; Chang, K.-Y. A Progressive Damage Model for Laminated Composites Containing Stress Concentrations. J. Compos. Mater. 1987, 21, 834–855. [Google Scholar] [CrossRef]

- Chang, F.-K.; Chang, K.-Y. Post-Failure Analysis of Bolted Composite Joints in Tension or Shear-Out Mode Failure. J. Compos. Mater. 1987, 21, 809–833. [Google Scholar] [CrossRef]

- Moss, W.C.; King, M.J.; Blackman, E.G. Skull flexure from blast waves: A mechanism for brain injury with implications for helmet design. Phys. Rev. Lett. 2009, 103. [Google Scholar] [CrossRef] [PubMed]

- McElhaney, J.H. Handbook of Human Tolerance; Japan Automobile Research Institute: Ibaraki, Japan, 1976. [Google Scholar]

- Melvin, J.W.; Yoganandan, N. Biomechanics of Brain Injury: A Historical Perspective; Springer: New York, NY, USA, 2015; ISBN 978-14-939-1732-7. [Google Scholar]

- Jin, X.; Yang, K.H.; King, A.I. Mechanical properties of bovine pia-arachnoid complex in shear. J. Biomech. 2011, 44, 467–474. [Google Scholar] [CrossRef] [PubMed]

- Arbogast, K.B.; Margulies, S.S. Material characterization of the brainstem from oscillatory shear tests. J. Biomech. 1998, 31, 801–807. [Google Scholar] [CrossRef]

- Brolin, K.; Halldin, P. Development of a Finite Element Model of the Upper Cervical Spine and a Parameter Study of Ligament Characteristics. Spine 2004, 29, 376–385. [Google Scholar] [CrossRef]

- Yoganandan, N.; Kumaresan, S.; Pintar, F.A. Geometric and Mechanical Properties of Human Cervical Spine Ligaments. J. Biomech. Eng. 2000, 122, 623–629. [Google Scholar] [CrossRef]

- Tse, K.M.; Tan, L.B.; Yang, B.; Tan, V.B.C.; Lee, H.P. Effect of helmet liner systems and impact directions on severity of head injuries sustained in ballistic impacts: A finite element (FE) study. Med. Biol. Eng. Comput. 2017, 55, 641–662. [Google Scholar] [CrossRef]

- Nyein, M.K.; Jason, A.M.; Yu, L.; Pita, C.M.; Joannopoulos, J.D.; Moore, D.F.; Radovitzky, R.A. In silico investigation of intracranial blast mitigation with relevance to military traumatic brain injury. Proc. Natl. Acad. Sci. USA 2010, 107, 20703–20708. [Google Scholar] [CrossRef]

- Grujicic, M.; Arakere, G.; He, T. Material-modeling and structural-mechanics aspects of the traumatic brain injury problem. Multidiscip. Model. Mater. Struct. 2010, 6, 335–363. [Google Scholar] [CrossRef]

- Grujicic, M.; Bell, W.C.; Pandurangan, B.; Glomski, P.S. Fluid/Structure interaction computational investigation of blast-wave mitigation efficacy of the advanced combat helmet. J. Mater. Eng. Perform. 2011, 20, 877–893. [Google Scholar] [CrossRef]

- Grujicic, M.; Bell, W.C.; Pandurangan, B.; He, T. Blast-wave impact-mitigation capability of polyurea when used as helmet suspension-pad material. Mater. Des. 2010, 31, 4050–4065. [Google Scholar] [CrossRef]

- Jenson, D.; Unnikrishnan, V.U. Energy dissipation of nanocomposite based helmets for blast-induced traumatic brain injury mitigation. Compos. Struct. 2015, 121, 211–216. [Google Scholar] [CrossRef]

- Mott, D.R.; Young, T.R.; Schwer, D.A. Blast Loading on the Head Under a Military Helmet: Effect of Face Shield and Mandible Protection. In Proceedings of the 52nd Aerospace Sciences Meeting, National Harbor, MD, USA, 13–17 January 2014. [Google Scholar]

- NIJ. Public Safety Bomb Suit Standard NIJ Standard-0117.00; NIJ: Washington, DC, USA, 2016.

- Ganpule, S.; Gu, L.; Alai, A.; Chandra, N. Role of helmet in the mechanics of shock wave propagation under blast loading conditions. Comput. Methods Biomech. Biomed. Engin. 2012, 15, 1233–1244. [Google Scholar] [CrossRef] [PubMed]

- Gadd, C.W. Impact Acceleration Stress; National Academies Press: Washington, DC, USA, 1962; ISBN 978-0-309-34021-2. [Google Scholar]

- Hayes, W.C.; Erickson, M.S.; Power, E.D. Forensic Injury Biomechanics. Annu. Rev. Biomed. Eng. 2007, 9, 55–86. [Google Scholar] [CrossRef] [PubMed]

- Gennarelli, T.A.; Wodzin, E. AIS 2005: A contemporary injury scale. Injury 2006, 37, 1083–1091. [Google Scholar] [CrossRef]

- Ward, C.; Chan, M.; Nahum, A. Intracranial Pressure—A Brain Injury Criterion. SAE Trans. 1980, 89, 3867–3880. [Google Scholar]

- Deck, C.; Willinger, R. Improved head injury criteria based on head FE model. Int. J. Crashworthiness 2008, 13, 667–678. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, K.H.; King, A.I. A Proposed Injury Threshold for Mild Traumatic Brain Injury. J. Biomech. Eng. 2004, 126, 226–236. [Google Scholar] [CrossRef]

| Parts | Material Model LS-Dyna | Nº Elements | Element Type | Size | Material Properties | Source |

|---|---|---|---|---|---|---|

| Helmet Shell | *MAT_COMPOSITE_DAMAGE | 40,952 | Hexaedric solid |

| Table 2 | Van Hoof, J et al. Tan et al. Gower et al. [21,22,23] |

| Visor | *MAT_PLASTIC_KINEMATIC | 27,036 | Hexaedric solid |

| E = 1.5 GPa υ = 0.37 | Shah [24] |

| Insulating rubber | *MAT_ELASTIC | 4003 | Hexaedric solid |

| E = 5 GPa υ = 0.4 | Mark [25] |

| Hard foam | *MAT_LOW_DENSITY_FOAM | 30,714 | Hexaedric solid |

| Stress–strain curves | Zhang et al. Li et al. [9,26,27] |

| Soft foam | *MAT_LOW_DENSITY_FOAM | 30,714 | Hexaedric solid |

| Stress–strain curves | [9,26,27] |

| (kg/m3) | Density | 1230 |

| [GPa] | Young’s Modulus direction 11 | 18.5 |

| [GPa] | Young’s Modulus direction 22 | 18.5 |

| [GPa] | Young’s Modulus direction 33 | 6 |

| ν12 [–] | Poisson’s ratio plane 12 | 0.25 |

| ν13 [–] | Poisson’s ratio plane 13 | 0.33 |

| ν23 [–] | Poisson’s ratio plane 23 | 0.33 |

| [GPa] | Shear Modulus plane 12 | 0.77 |

| [GPa] | Shear Modulus plane 13 | 2.5 |

| [GPa] | Shear Modulus plane 23 | 2.5 |

| [GPa] | Tensile strength direction 11 | 0.555 |

| [GPa] | Tensile strength direction 22 | 0.555 |

| [GPa] | Shear Strength plane 12 | 0.588 |

| [GPa] | Compressive strength direction 22 | 1.086 |

| [GPa] | Normal tensile strength | 0.835 |

| [GPa] | Transverse shear strength | 1.06 |

| [GPa] | Transverse shear strength | 1.06 |

| Head Part | Material Model LS-Dyna | Material Properties | Source |

|---|---|---|---|

| Scalp and Neck Flesh | Fu Chang Foam | Stress–Strain curves at 3 Strain rates | Human cadaver Scalp in Compression, McElhaney [36] |

| Skull Tables | Piece-Wise Linear Plasticity | E = 6.48 GPa | Human Skull Tables in Shear, McElhaney [36] |

| Skull Diploe | Isotropic Elastic Plastic | E = 40 MPa | McElhaney [36] |

| Dura Mater | Elastic | E = 40 MPa | Human Dura in Tension Melvin [37] |

| Pia Mater | Elastic | E = 12.5 MPa | Bovine Pia-Arachnoid in Shear [38] |

| Cerebrospinal Fluid (CSF) | Elastic Fluid | K = 2.1 GPa υ = 0.4999 | McElhaney [36] |

| Brain | Brain Linear Viscoelastic | G0 = 1.6 kPa G1 = 0.9 kPa | Porcine Brain Tissue in Shear Arbogast & Margulies [39] |

| Falx and Tentorium | Elastic | E = 12.5 MPa | Jin et al. [38] |

| Vertebrae | Rigid | - | - |

| Intervertebral Discs and Facet Joints | Elastic | E = 10 MPa | Brolin et al. [40] |

| Neck Ligaments | Elastic | E = 43.8 MPa | Yoganandan [41] |

| Authors | Load [kg TNT] | Target Distance [m] | Comments |

|---|---|---|---|

| Zhang et al. [9] | 0.85 kg de TNT 1.50 kg de TNT 1.70 kg de TNT 5.40 kg de TNT | 1.06 m 1.45 m 1.85 m 2.80 m | Based on Bowen’s lung damage threshold curves |

| Rodríguez-Millán et al. [10] | 0.100 kg de TNT | 0.40 m | Configurations (with head): Helmet//Helmet + Mandible//Helmet + Visor//Helmet + Visor + Mandible |

| Nyeina et al. [43] | 3.160 gr de TNT | 0.12 m | Configurations: Head (only)//Head+Helmet//Head + Helmet + Visor |

| Grujicic et al. [44,45,46] | 0.0698 kg de TNT 0.3240 kg de TNT | 0.60 m 0.60 m | - overpressure of 5.2 atm ➔ Blast load lung injury threshold - overpressure of 18.6 atm ➔ 50% chance of death from lung injury |

| Jenson et al. [47] | 0.038 kg de TNT 0.093 kg de TNT 0.227 kg de TNT | 0.80 m 0.80 m 0.80 m | - |

| Mott et al. [48] | 1.500 kg de C-4 (2.010 kg de TNT aprox.) | 3.00 m | Configurations (with head): Helmet//Helmet + Mandible//Helmet + Visor//Helmet + Visor + Mandible |

| Case | TNT [kg] | Maximum Acceleration [m/s2–g] | Time amáx [ms] |

|---|---|---|---|

| Without Helmet | 0.050 | 3916.9–399.3 | 1.45 |

| 0.075 | 5267–536.92 | 1.37 | |

| 0.100 | 6430.1–655.5 | 1.29 | |

| With Helmet | 0.050 | 771.6–78.7 | 3.92 |

| 0.075 | 1109.3–113.1 | 3.68 | |

| 0.100 | 1456.9–148.5 | 3.43 |

| Case | TNT [kg] | HIC | GSI |

|---|---|---|---|

| Without Helmet | 0.050 | 1235.0 | 1537.5 |

| 0.075 | 2968.0 | 3620.2 | |

| 0.100 | 5552.0 | 6675.5 | |

| With Helmet | 0.050 | 61.9 | 75.9 |

| 0.075 | 170.3 | 199.2 | |

| 0.100 | 352.7 | 403.3 |

| Case | TNT (kg) | AIS ≥ 1 (%) | AIS ≥ 2 (%) | AIS ≥ 3 (%) | AIS ≥ 4 (%) | AIS ≥ 5 (%) | AIS 6 (%) |

|---|---|---|---|---|---|---|---|

| Without Helmet | 0.050 | 100 | 96 | 73 | 32 | 7 | 0 |

| 0.075 | 100 | 100 | 100 | 100 | 100 | 99 | |

| 0.100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| With Helmet | 0.050 | 2 | 1 | 0 | 0 | 0 | 0 |

| 0.075 | 16 | 6 | 2 | 0 | 0 | 0 | |

| 0.100 | 54 | 20 | 6 | 2 | 0 | 0 |

| Case | TNT [kg] | Intracranial Pressure Peak [kPa] | Time [ms] |

|---|---|---|---|

| Without Helmet | 0.050 | 282.8 | 1.74 |

| 0.075 | 418.6 | 1.66 | |

| 0.100 | 540.6 | 1.54 | |

| With Helmet | 0.050 | 80.2 | 4.40 |

| 0.075 | 121.7 | 4.28 | |

| 0.100 | 150.2 | 4.04 |

| Case | TNT [kg] | Cerebrospinal Fluid Press [kPa] | Time [ms] |

|---|---|---|---|

| Without Helmet | 0.050 | −151.73 | 1.78 |

| 0.075 | −163.30 | 1.66 | |

| 0.100 | −170.03 | 1.58 | |

| With Helmet | 0.050 | −108.64 | 4.28 |

| 0.075 | −114.39 | 4.12 | |

| 0.100 | −116.37 | 3.88 |

| 0.050 kg TNT | 0.075 kg TNT | 0.100 kg TNT | ||||

|---|---|---|---|---|---|---|

| Without Helmet |  |  |  | |||

| t = 2.02 ms | t = 2.14 ms | t = 2.14 ms | ||||

| With Helmet |  |  |  | |||

| T = 4.65 ms | T = 4.44 ms | T = 4.12 ms | ||||

| Cases | Without Helmet | With Helmet |

|---|---|---|

| 0.050 kg TNT |  |  |

| %Vol = 6.52 | %Vol = 0.01 | |

| 0.075 kg TNT |  |  |

| %Vol = 15.29 | %Vol = 0.11 | |

| 0.100 kg TNT |  |  |

| %Vol = 23.12 | %Vol = 1.07 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Valverde-Marcos, B.; Rubio, I.; Antona-Makoshi, J.; Chawla, A.; Loya, J.A.; Rodríguez-Millán, M. Numerical Analysis of EOD Helmet under Blast Load Events Using Human Head Model. Appl. Sci. 2020, 10, 8227. https://doi.org/10.3390/app10228227

Valverde-Marcos B, Rubio I, Antona-Makoshi J, Chawla A, Loya JA, Rodríguez-Millán M. Numerical Analysis of EOD Helmet under Blast Load Events Using Human Head Model. Applied Sciences. 2020; 10(22):8227. https://doi.org/10.3390/app10228227

Chicago/Turabian StyleValverde-Marcos, Borja, Ignacio Rubio, Jacobo Antona-Makoshi, Anoop Chawla, José Antonio Loya, and Marcos Rodríguez-Millán. 2020. "Numerical Analysis of EOD Helmet under Blast Load Events Using Human Head Model" Applied Sciences 10, no. 22: 8227. https://doi.org/10.3390/app10228227

APA StyleValverde-Marcos, B., Rubio, I., Antona-Makoshi, J., Chawla, A., Loya, J. A., & Rodríguez-Millán, M. (2020). Numerical Analysis of EOD Helmet under Blast Load Events Using Human Head Model. Applied Sciences, 10(22), 8227. https://doi.org/10.3390/app10228227