1. Introduction

In Europe, there are approximately 448 airlines and 701 commercial airports that transported 606 million passengers during 2010 [

1]. Air traffic has increased by a factor of 2.4 since 2000, and it was expected by pre-COVID-19 forecast an average increasing of 4.3% per year over the next 20 years [

2]. Although the air transport sector has been strongly affected by the health crisis generated by the COVID-19, reducing the number of seats in 2020 by 50% [

3], and the recovery of the sector will unfortunately not be immediate but expected between 2023 and 2025 [

4], the long-term order forecast remains very important. For example, Boeing has a forecast of 48,400 aircraft by 2039 in October 2020, compared to 25,900 aircraft today [

5], and the Airbus backlog stands at 7441 commercial aircraft at September 2020 compared to 7133 at the same point in last year [

6], so efforts to optimize the sector’s costs, and reduce fuel consumption and pollutant and greenhouse emissions, are still worthwhile.

The cost of fuel is estimated at 32% of the operating cost of Airlines [

7]. Besides, commercial aviation is currently responsible for about 2% of global carbon emissions, and about 12% of all CO

2 emissions from the transport sector and, it is estimated that CO

2 emissions from commercial aircraft may triple by 2050, with air transport emissions reaching 25% of the total [

8]. On the other hand, passenger cars, pickup trucks, vans, motorcycles, and other two- and three-wheeled vehicles constitute about one-third of the world’s demand for petroleum. They generate about half of all transport-related greenhouse gas emissions, produce carbon monoxide, non-combusted hydrocarbons, sulphur oxides, nitrogen oxides, particles, and other air toxins [

8] and, a total of 2 billion vehicles are expected by 2030 [

9]. The European Union (EU) has a clear commitment to a gradual replacement of fossil fuels by renewable energies. In December 2018, the Renewable Energy Directive 2018/2001/EU entered into force, which sets a new binding target for renewable energy in the EU for 2030 of at least 32% to become the first climate-neutral continent by 2050 [

10].

In 2018, all airlines in the world with international routes began to officially report their emissions as part of the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA), adopted by the United Nations in 2016, which aims to halve total carbon emissions by 2050 [

11]. In June 2001, the Advisory Council for Aeronautics Research in Europe (ACARE) was created in Paris to develop and maintain a Strategic Research Agenda (SRA). This group consisted of the member states, the European Commission, and stakeholders from the aviation sector: the manufacturing industry, airlines, airports, service providers, regulators, research institutions, and academics. Among the goals defined for 2050 are a 75% reduction in CO

2 emissions per passenger and kilometer and a 90% reduction in NO

x emissions. Additionally, air vehicles must be designed and manufactured to be recyclable [

1].

Within this framework, and to meet current and future requirements, new innovative materials, design techniques, and manufacturing processes are being developed to increase efficiency and reduce consumption [

11]. The new families of Airbus aircraft are engineered to optimize fuel efficiency, the A320 and A350 aircraft save more than 20% in fuel consumption. The A350 includes more than 50% lightweight structural materials, and the A220′s primary structure includes aluminum-lithium on the fuselage, and titanium and hybrid materials on the wings [

12]. For its part, the Boeing 737 MAX family uses 20% less fuel than the aircraft it replaces, and it is as efficient as a hybrid electric car in terms of liters of fuel equivalent used per 100 km and passenger [

13]. The priorities defined in Boeing’s environmental policy are, firstly, the reduction of CO

2 emissions in all activities and, secondly, the optimization of fuel consumption [

11].

There are different working lines to optimize consumption and reduce the emission of pollutants: the development of new engine technologies [

9], the use of alternative technologies [

12], and the reduction of the aircraft’s weight, either by reducing their size or by replacing conventional heavy materials with new lightweight structural materials, or combinations of them while maintaining the same performance or improving it [

14]. The present work is framed in this last working line.

The consensus regarding the benefit of mass reduction is clear and has been outlined in many studies. For each 100 kg of vehicle mass reduction, there is a reduction in fuel consumption of 0.38 L/100 km, and a reduction of 8.7 g of CO

2 per km [

15]. Each kilogram of mass reduction produces a saving of 150,000 US dollars in fuel over the life of the engine [

16]. A 10% reduction in the mass of a vehicle results in a reduction of fuel consumption of 5–7% [

17]. One of the research and development lines currently open is based on the use of lightweight structural materials such as lightweight titanium, aluminum, and magnesium alloys, all with an excellent density/mechanical properties ratio [

18,

19,

20,

21,

22,

23], or plastic and polymer compounds [

21,

22]. For example, in the case of automotive vehicles, 40% of the total mass is in the car body; therefore, this is a key area for potential mass reduction [

24]. On the other hand, it is fundamental to bear in mind that the recyclability of the materials selected for the design is a must from the very beginning. Over the next 20 years, more than 12,000 aircraft are expected to reach the end of their lifetime. Airbus has established a method for dismantling and recycling its aircraft parts, achieving 90% recycling or reuse and safe and sustainable disposal when recycling is not possible. Since 2007, Airbus has recycled 117 aircraft worldwide with 92% reuse of the remaining parts and 100% recycled engines [

2,

25].

Aluminum and magnesium are two of the most abundant materials on earth, and they have been widely studied separately, but the number of studies in which a multimaterial combination of them is machined is very limited. From a structural point of view, their main characteristic is an excellent density/mechanical resistance ratio [

26]. This feature makes them very attractive when seeking to reduce mass to reduce fuel consumption and emissions while maintaining mechanical performance. In particular, aluminum alloys are the most commonly used lightweight structural materials and have been the subject of many scientific articles in recent years [

21,

22]. Moreover, Al and Mg alloys offer additional advantages such as their great capacity to be recycled [

27,

28] and their good machinability. However, they also present some common disadvantages such as lower mechanical resistance than other structural materials such as titanium or steel; lower working temperature; corrosion problems and worse weldability, among others [

29]. On the other hand, titanium has very good mechanical, chemical, and thermal properties that complement those of magnesium and aluminum. It has a relatively low density, 4500 kg/m

3 so that the overall properties of the multimaterials in which titanium is combined maintain a good ratio between mechanical properties and density [

29]. All this makes the study of possible combinations among these three light alloys in multimaterials, such as Mg-Al-Mg or Mg-Ti-Mg, very interesting for their potential applications in the reduction of the mass of vehicles and aircraft in a sustainable way.

Additionally, the current demands on high-performance parts make it difficult to design them using a single material. Therefore, it is often necessary to benefit from the properties of several materials to create a multimaterial or hybrid component with superior properties [

30]. It is also feasible to develop new alloys with the required properties, but the process is long, and the target is not always achieved. For example, in the case of gamma alloys, the first commercial flight using alloy 4822 engines in Low-Pressure Turbine Blades (LPTBs) was conducted in March 2012, but the first exploratory research into gamma alloys had begun 40 years earlier [

31]. Other interesting alloys under development included in recent studies are Ni-Al alloys with memory effect and superelasticity [

32] and gamma alloys [

31].

A topic of special interest within the hybrid components is the joining of dissimilar materials to create the multimaterial. The main joints are mechanical, through drilling and bolts or rivets [

33], and thermal, through different welding technologies. The machining of multimaterial or hybrid composites in a single operation is a challenging task because of the different characteristics of the materials resulting in different optimal machining conditions. This requires the use of compromise solutions between tool geometry and cutting parameters and frequently results in severe tool wear, increased cutting forces, poor hole quality or large burrs, worsening the difficulties in the interface between materials [

18,

33,

34,

35]. For instance, the most common defects in drilling titanium in hybrid compounds are errors in hole size, roundness, position, and the existence of burrs. Titanium chips evacuation can cause scratches at the interface between materials and in the materials during the chip outlet, and the surface quality is also influenced by the number of holes made by the tool because of the effect of wear [

33].

On the other hand, drilling plays a fundamental role in the assembly of parts in the aeronautical industry, and it is estimated to be used in 50% of the operations with chips removal. Therefore, it is frequently used in structural parts that require a subsequent assembly through bolts or rivets. The most frequent problems faced in the drilling process are high tool wear, poor surface quality, and out-of-tolerance diameter [

36]. Likewise, a significant factor in the drilling process, analyzed in several recent works, is the influence of the tool geometry and/or its coating on the final quality of the process [

7,

20,

33,

37,

38,

39].

The manufacturing of parts of responsibility for industries such as aerospace or automotive requires very strict manufacturing tolerances in terms of dimensional, geometrical, and physical-chemical properties to ensure reliable and predictable behavior in service [

40]. The usual range of roughness tolerances required in the aeronautical and aerospace sector in terms of arithmetical mean roughness,

Ra (μm) is 0.8 µm <

Ra < 1.6 µm [

41]. In the case of rivets, they are repaired by drilling a hole to a larger diameter and using either a larger diameter rivet or an ACRES

® sleeve or similar which allows the use of a bolt of the nominal design diameter [

42]. The metal sheets used in the aeronautical sector are mainly obtained by rolling, and their thickness most frequently varies from very thin sheets to sheet thicknesses of more than 6 mm [

43].

In addition, the advantages of residual compression stress (RCS) generated by different manufacturing processes and its effect on improving the fatigue behavior of materials have been analyzed in various papers. For example, Barry et al. [

44] carried out a study on the effect of shot peening on cast magnesium A8 parts. The researchers found that although the shot peening process significantly increases the surface roughness of the surfaces on which it is applied, the initiation of cracks on these surfaces is much lower than when it is not applied. The study concludes that the shot peening process increases fatigue life and delays the crack initiation, despite producing a significant increase in surface roughness. Besides, and within the study, it was achieved an increase of up to five times the working life and 30% of the fatigue resistance limit by applying shot peening to cast magnesium A8 parts. In UNS A92024-T3 aluminum alloys, studies have been carried out on the effect of compressive residual stress (CRS) generated by turning, concluding that the greater the residual compressive force generated, the greater the improvement in ultimate tensile strength (UTS) [

45].

In addition, the use of cutting fluids reduces the friction between the tool and the chip, lubricates the tool–piece interface, dissipates the heat, and helps to remove the chip adhered to the tool surface [

18,

29]. However, it causes environmental and health damage from the chemical additives it contains. To avoid this, there is a tendency towards almost dry cutting formulas such as minimum quantity lubrication (MQL) [

33,

46] and dry machining [

18,

19,

20,

40,

45], or new technologies such as cryogenic cooling [

47]. These options provide new solutions for alloys such as titanium in which tool wear occurs due to its low thermal conductivity and high chemical affinity. However, working with extremely low temperatures produces a workpiece hardening and an increase in the cutting forces. Therefore, several studies have been recently published seeking solutions to this problem. In one of the studies, an internal cryogenic cooling for the tool that maintains the standard working temperature on the workpiece is used, reducing the cutting force by 54% and the tool wear by 90% compared to traditional cooling [

48]. Other studies propose the use of an internal cryogenic cooling for the tool. In this direction, Pereira et al. [

49] study the use of a cryogenic cooling with MQL lubrication that employs CO

2 as internal coolant, and Damir et al. propose a hybrid system of cryogenic and MQL which clearly improves cutting forces, surface quality, and tool life [

50].

A requirement commonly used by manufacturers in the automotive and aerospace sectors as well as in numerous studies on light alloy machining is the Arithmetical Mean Roughness,

Ra (μm) [

18,

19,

20,

40,

46,

51,

52]. Therefore,

Ra (μm) is the response variable chosen in this study to determine the optimum thickness of Mg-Al-Mg hybrid component plates for drilled parts in the aeronautical industry. Besides, it is used to compare the results with those obtained, in previous works, for other combinations of materials, Mg-Ti-Mg, of identical geometry.

Furthermore, the research method that modifies a factor in each test is very time-consuming and does not provide knowledge of the interactions between parameters. The design of experiments (DoE) is an experiment-based modeling method that uses statistical techniques, such as analysis of variance (ANOVA) to process the data and find out about the factors of influence, the interaction between them, and their level of influence on the process [

18,

19,

20,

51,

53,

54,

55,

56].

This study is part of a larger research project that includes several structural lightweight materials, machining processes, and lubrication/cooling systems. Two experimental tests were carried out in 2017, the first allowed to determine the factors with the greatest influence on the turning process in Al-Mg multimaterial specimens [

19], the second studied the influence of the tool on the magnesium drilling process under different machining conditions on specimens [

20]. In 2018, this knowledge was applied for the selection of the drilling tool for Mg-Ti-Mg multimaterial components in the search for the best dry machining parameters [

18]. In 2019, a review of recent literature on hybrid composites was carried out which concluded that there is a clear scientific and automotive and aeronautical industry interest in the use of aluminum alloys being the single most commonly used material to form multimaterial combinations [

21]. Consequently, two experimental tests were carried out on Mg-Al-Mg multimaterial specimens to find the most significant factors in the process and the best machining conditions by applying sustainable cooling/lubrication techniques such as dry machining and cold compressed air. Besides, two different drill diameters were analyzed, finding slight differences depending on the diameter used, but the selection of influencing factors remained robust [

57,

58].

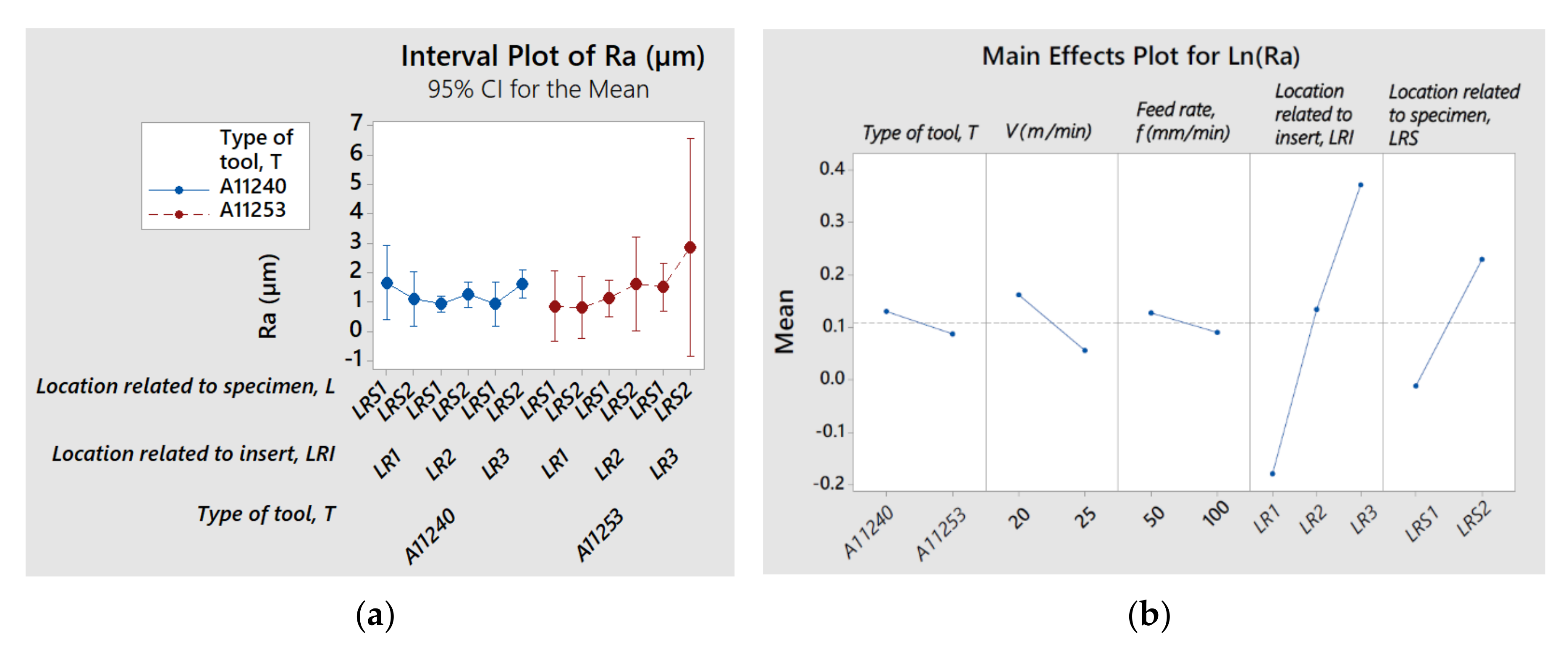

The novelty of this work is to carry out an analysis of magnesium-based multimaterial compounds focusing on the relationship between the thickness of the plates that form the compound and the multimaterial combination used. This analysis was carried out from a joint perspective and applying the previous knowledge acquired. Therefore, in addition to analyzing the data obtained in the individual experiment carried out for this study on a Mg-Al-Mg component, a comparative analysis was also carried out with the data obtained in a previous test framed in the same project and carried out on a Mg-Ti-Mg multimaterial combination [

18]. The data from both studies are comparable because they follow the same methodological structure based on Taguchi [

59], and designed for this purpose. The data from the previous study was reanalyzed following the perspective, objectives, and structure of the present study.

The study aims to establish the basis for correlating the surface quality obtained with the material combination of the hybrid magnesium-based components, the thicknesses of the plates that form them, and the cutting parameters in the repair and maintenance processes of drilled parts in the aeronautical industry so that the design requirements are guaranteed throughout their useful life. Furthermore, by carrying out tests with new materials, a complete table of materials, plate thicknesses, and the most suitable order of materials/drilling direction could be obtained, depending on the surface roughness required (as well as the cutting parameters under which this was achieved) so that it would serve as a guide in repair and maintenance operations to other researchers or workers in the topic. The ultimate goal is to use this new knowledge in applications involving the riveting of multimaterial plates made of light alloys in the aerospace industry.

An extensive review of recently published work on lightweight structural materials was conducted, in particular, those applied to the aeronautical and automotive sectors, in which sustainable manufacturing perspectives are applied. Moreover, following the Taguchi methodology on experimental design [

59], a series of tests were designed and conducted, and the results analyzed through an analysis of variance to determine the effect of the significant factors and their interactions on the response variable, specifically the arithmetical mean roughness,

Ra(µm).

Both types of specimens are geometrically identical and formed by hybrid magnesium-based compounds. Therefore, this comparative analysis can provide useful information to find potential constraints in the design of the current specimens and, subsequently, to redesign them so that future tests will provide more complete information on the process of repairing hybrid magnesium-based multimaterial by re-drilling.

From the analysis and comparison of both studies, the most favorable plate thicknesses found in the re-drilling process of the hybrid magnesium-based components are concluded, taking into account the materials that form the multimaterial. Besides, new thicknesses are proposed for the design of the specimens, and new tests will be carried out on both to verify the results, the current specimens, and the new specimens with the proposed thicknesses and settings.

2. Methodology and Materials

2.1. Methodology

This study is part of a research project that includes different lightweight structural materials, machining processes, and cooling/lubrication systems [

18,

19,

57,

58,

60]. The methodology used is similar to the one followed in previous works in which the bases that provided the initial knowledge for this work were established. In previous studies within the same project, and using a similar methodology to make the individual studies comparable, the influence factors on the turning of Mg-Al specimens were studied [

19], the influence of the tool on the drilling of magnesium alloy parts was investigated [

20], the best process parameters for re-drilling on titanium parts by dry machining were investigated to eliminate the use of lubricant/coolant fluids and thus make the process more sustainable and economical [

18], and the parameters with the most influence on the re-drilling of hybrid multimaterial Mg-Al-Mg compounds with various re-drilling diameters were investigated [

58,

60]. This methodology is based on the Taguchi methodology and the Montgomery guidelines [

59], to carry out a study in which the results can be compared with each other.

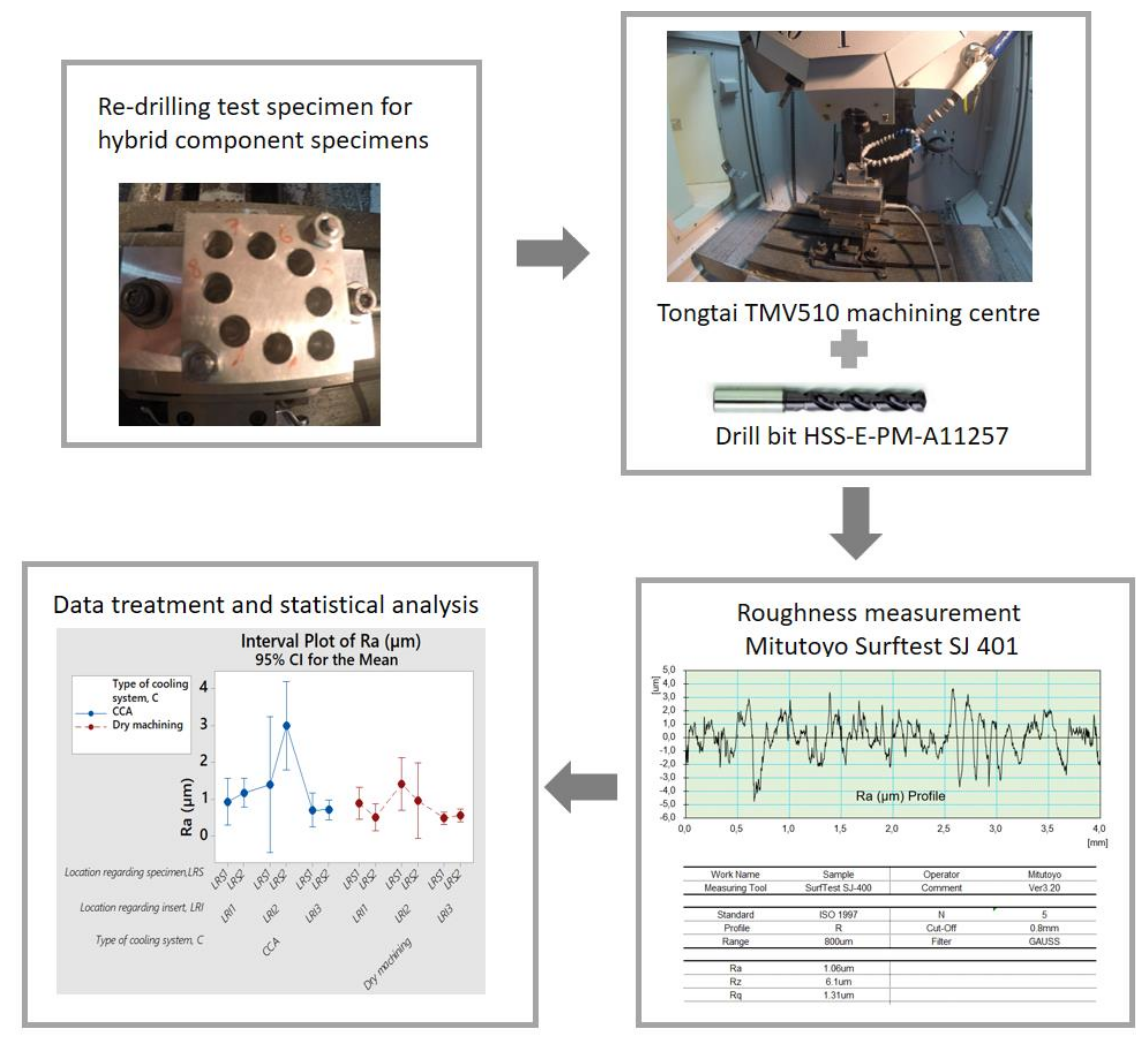

The methodology includes the following stages: pre-experimental planning in which the problem under study is defined, the identification of factors of influence, levels and ranges, and the choice of the response variable. Subsequently, the selection of the experimental design, its performance, and the statistical analysis of the results obtained takes place. Finally, after the discussion and the analysis of the results, the conclusions are drawn.

The problem under study is focused on repair and maintenance operations carried out by re-drilling on multimaterial or hybrid magnesium-based components, evaluating the cutting conditions and the sustainable cooling/lubrication techniques applied, and analyzing their influence on the results of the surface roughness obtained.

Since it is aimed at repair and maintenance operations, a single value of 0.5 mm was chosen for the depth of cut factor, d. Keeping the depth of cut at low values also helps to keep the cutting temperature low; being favorable to be far from the ignition temperatures of magnesium.

The type of cooling system, C, is a factor of great interest in the study of magnesium machining because of the special conditions that this material presents regarding ignition. For this reason, two levels were selected for the type of cooling, C, factor, the first level is Cold Compressed Air (CCA) and the second level is dry machining.

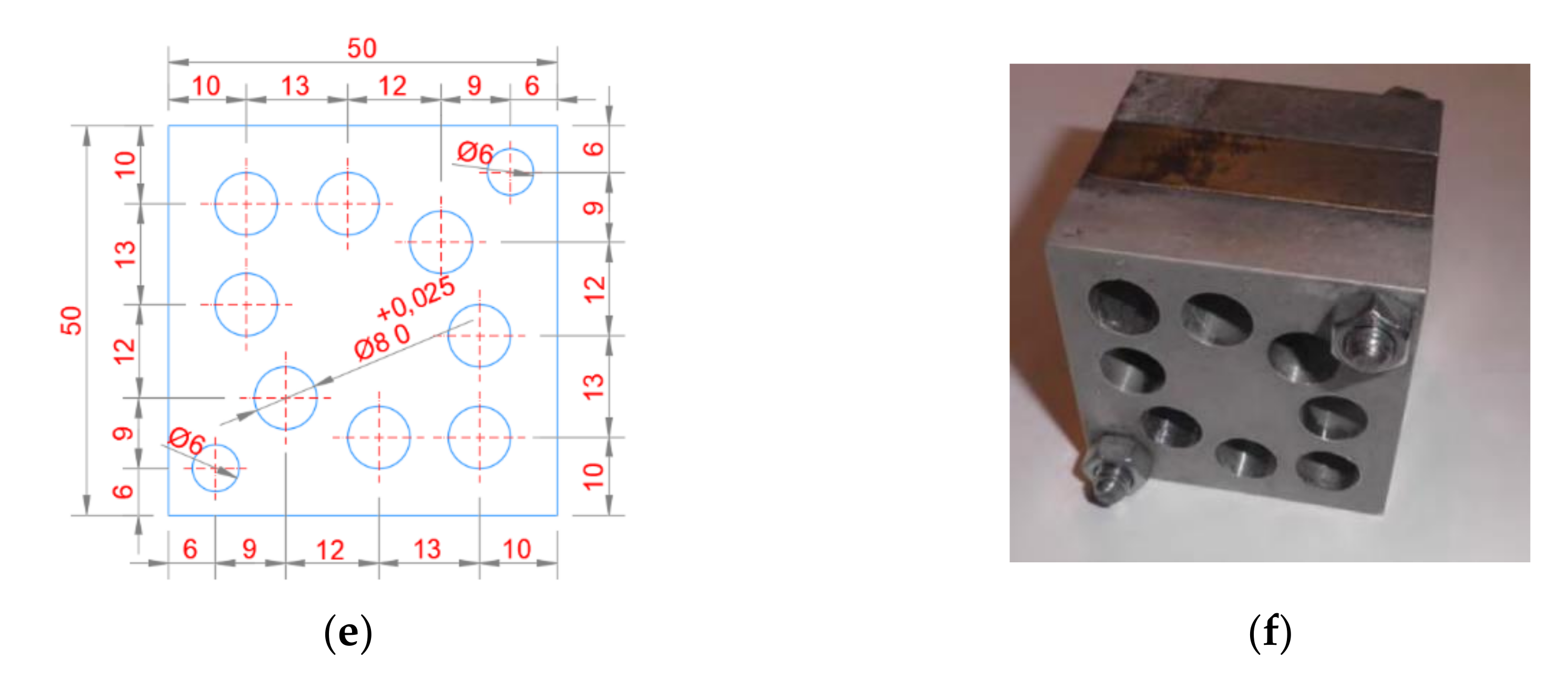

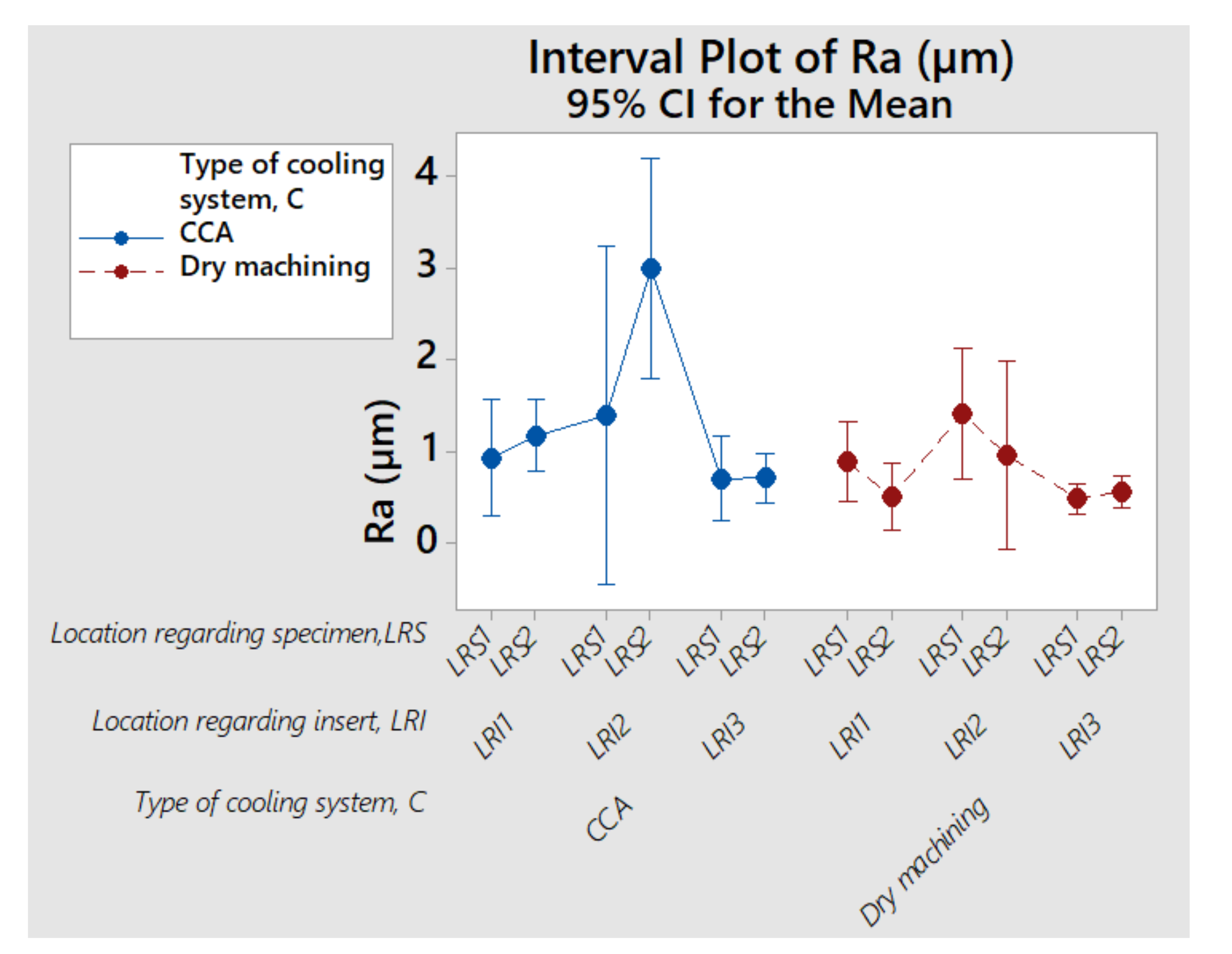

The cutting tool, which also has a great influence on the quality of the machining, was fixed on a 9 mm diameter high-performance twist drill. The test specimens consist of two magnesium plates with an aluminum plate in between. Chip evacuation was identified as a factor with potential influence, and, consequently, measurements of roughness were taken at the entrance and at the exit of each plate.

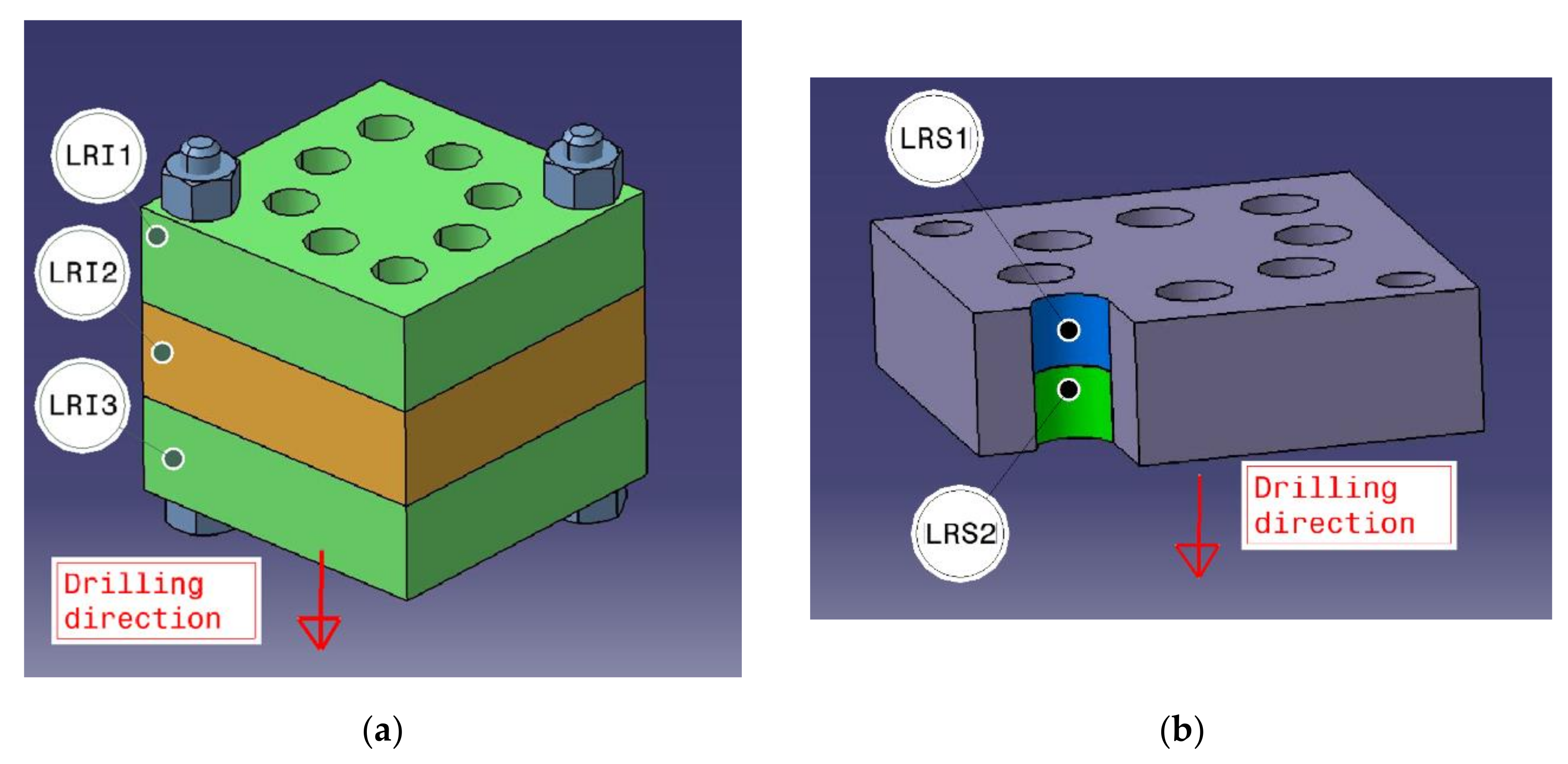

The following factors were established as factors of potential influence: the plate on which the measures are taken, Location Regarding Insert, LRI, and the position where the measures are taken on each plate, Location Regarding Specimen, LRS. The Location Regarding Insert factor has three levels depending on the plate LRI1: magnesium plate Mg1, LRI2: aluminum plate Al2 and LRI3: magnesium plate Mg3. The Location Regarding Specimen factor has two levels; depending on whether the measures are taken at the entrance of the hole, LRS1, or at the exit of the hole, LRS2.

For the feed per rev, f (mm/rev), and the spindle speed, N (r·min-1), both factors with potential influence, two levels were set based on the previous experience of researchers in the machining of this type of multimaterials, N, 500/1200 and, f, 0.05/0.1

Table 1 summarizes the factors used and the levels chosen for each factor.

The selected design was the product of a complete factorial 2

3 and a block of two factors (3 × 2). Roughness values were taken at the entrance and exit of each hole in each of the three plates that conform the multimaterial, with a total of eight experimental re-drillings, and six

Ra (μm) measurements per hole, providing a total of 48 measurements that can be seen in

Table 2. Roughness measurements were taken using a Mitutoyo Surftest SJ 401 which has a measurement range of 800 µm and a resolution of 0.000125 µm and using the ISO-1997 standard.

The areas where the roughness measurements are taken regarding the location of the plate within the hybrid compound,

LRI factor, are

LRI1 (Mg1),

LRI2 (Al2), and

LRI3 (Mg3), and the areas where roughness measurements are taken regarding its location within each hole,

LRS factor, are

LRS1 (entrance of the hole) and

LRS2 (exit of the hole).

Figure 1 shows a representation of the multimaterial component tested indicating the LRI factors on the left and the LRS factors on the right together with the drilling direction.

Afterwards, machining tests were carried out. Before performing the re-drilling tests, protocols were established both for the cutting parameters and the collection of the response variable data. Subsequently, test specimens, tools, CCA equipment, and the machining center were prepared, and the selected cutting conditions introduced. Then, the machining operations were carried out. Finally, photographs were taken, and videos recorded, for subsequent analysis.

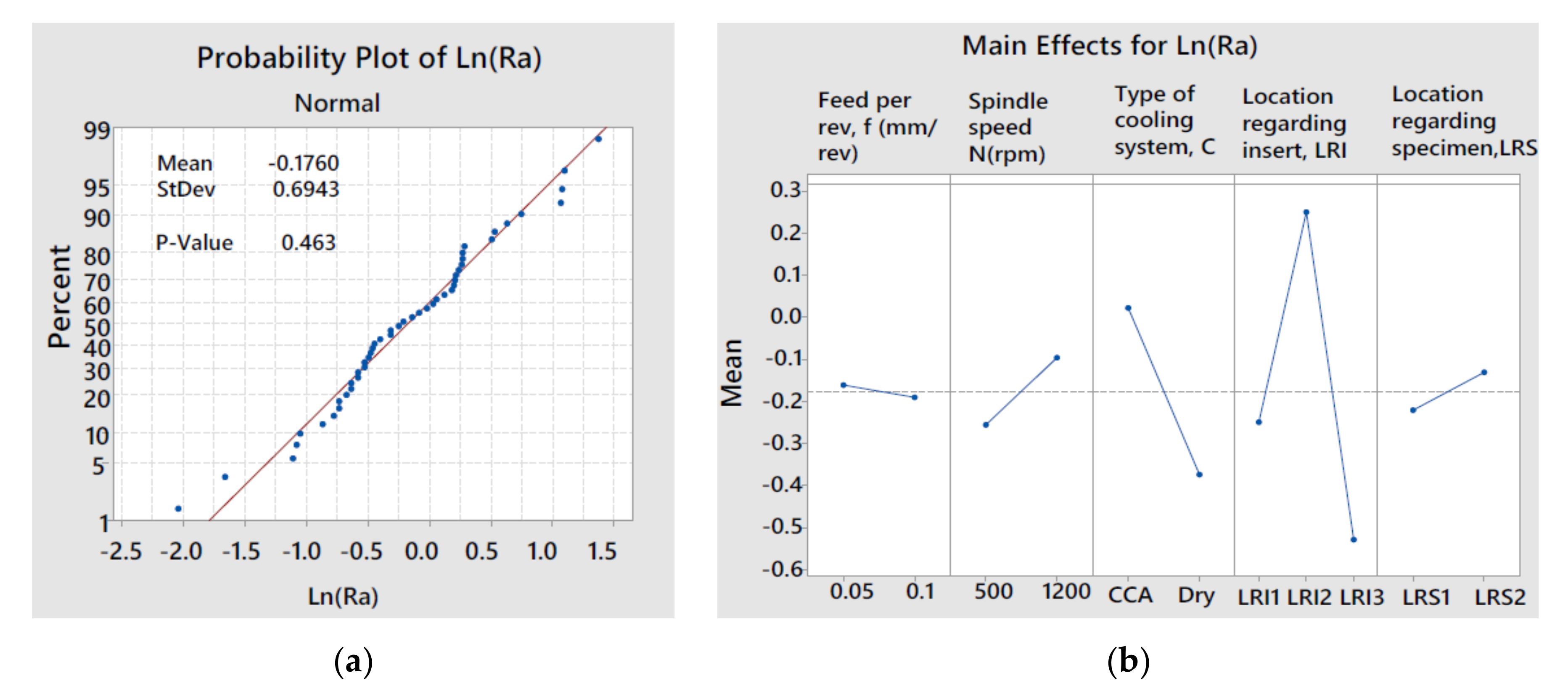

Subsequently, the response variable was measured. Specifically, the surface roughness was selected and analyzed as the Arithmetical Mean Roughness, Ra (µm). Once the data were collected, a statistical analysis was carried out. The variability of the Ra (µm) was modeled using Analysis of Variance (ANOVA), the factors, and interactions between them with an influence on surface roughness were identified. Finally, the results were statistically analyzed, and conclusions drawn.

2.2. Equipment, Tools, and Materials

The following equipment, tools, and materials were used to conduct the study:

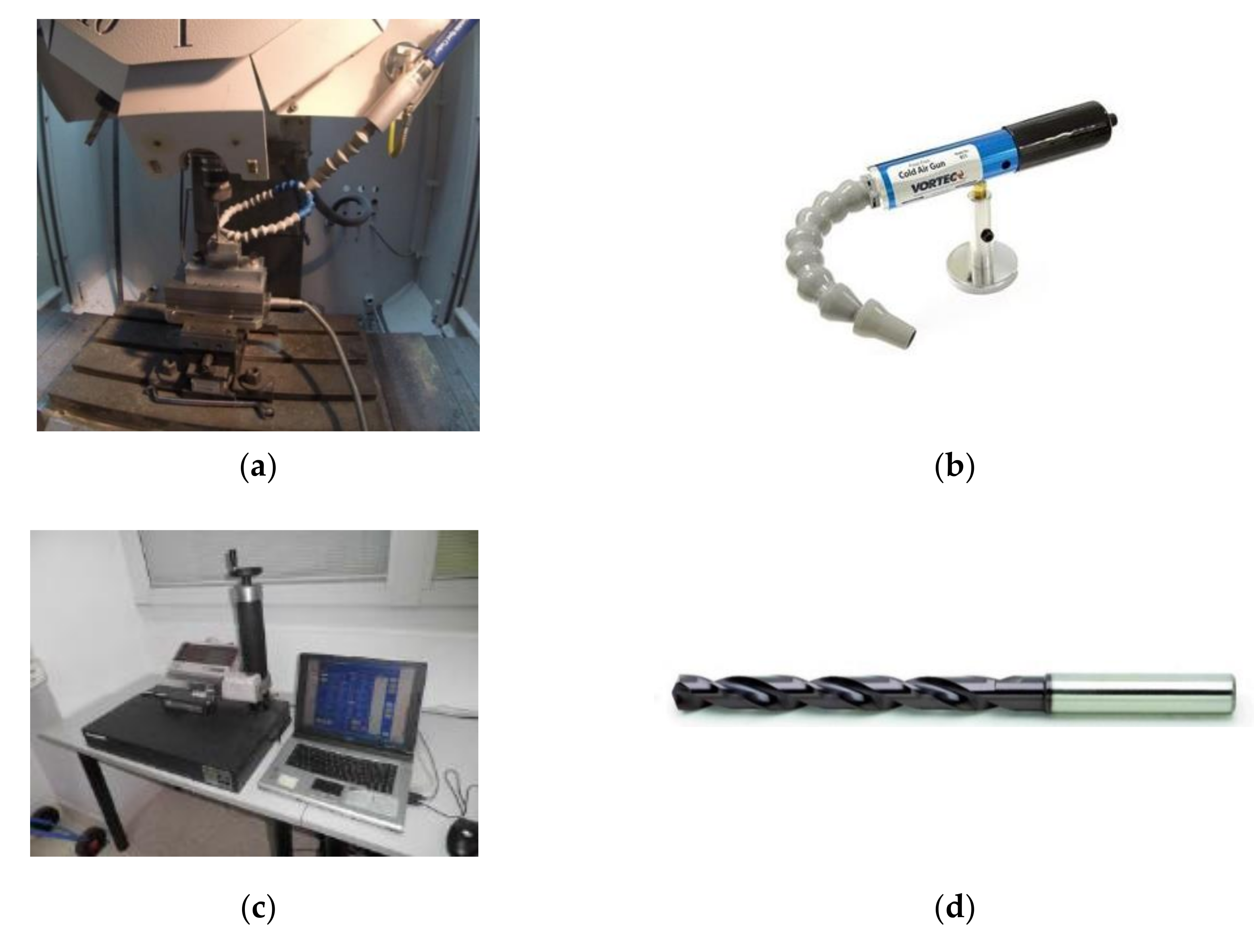

Tongtai TMV510 Machining center (Tongtai Machine and Tool Co, Luzhu Dist, Kaohsiung City, Taiwan) equipped with Fanuc series OI-MC numerical control (FANUC Iberia, Castelldefels, Barcelona, Spain) (

Figure 2a).

Cold Compressed Air system from Cold Air Gun Vortec (Vortec, Cincinnati, Ohio, U.S.). This equipment uses vortex tube technology and filtered compressed air to produce a compressed air of a working temperature of 8 °C. The equipment employs no moving parts, does not require electricity, just a compressed air source [

61]. (

Figure 2b).

Mitutoyo Surftest SJ 401 Roughness tester (Mitutoyo America Corporation, Aurora, IL, USA) (

Figure 2c).

A 9 mm diameter high performance twist drill with supplier reference HSS-E-PM-A1 1257. Supplier Garant (Hoffmann Iberia Quality Tools S.L., San Fernando de Henares, Madrid, Spain) (

Figure 2d).

Multimaterial or hybrid compound specimens for re-drilling. These specimens consist of three intercalated plates of magnesium/aluminum/magnesium alloys of 15 mm thickness. The combination of the different material layers is designed to allow the drill bit passing from one material to another during the machining of the hole. The operations performed aim to simulate the repair operations on hybrid components. For this reason, specimens used already have 8 mm pre-drilled holes, and the procedure consists of re-drilling them to a slightly larger diameter of 9 mm. The shape of each plate is a parallelepiped whose dimensions are 50 × 50 × 15 mm. The three parallelepipeds are mechanically fixed so that the surface roughness inside the machined holes can be dismantled and measured relatively easily (

Figure 2e). The chemical compositions of the magnesium and aluminum alloys used are available in

Table 3.

A schematic diagram of the experimental configuration for re-drilling tests on Mg-Al-Mg multimaterial specimens is shown in

Figure 3. The figure schematically shows the different stages of Taguchi-based research and the main materials employed. Predrilled specimens were tested using a machining center and cutting tool. Tests were carried out according to a predefined test plan in a Taguchi-based experimental design. Tests allow data collection of the response variable at each position predefined as potentially significant. Finally, this data is statistically analyzed using descriptive statistics and analysis of variance.