4.1. Verification of Moisture Transport Analysis

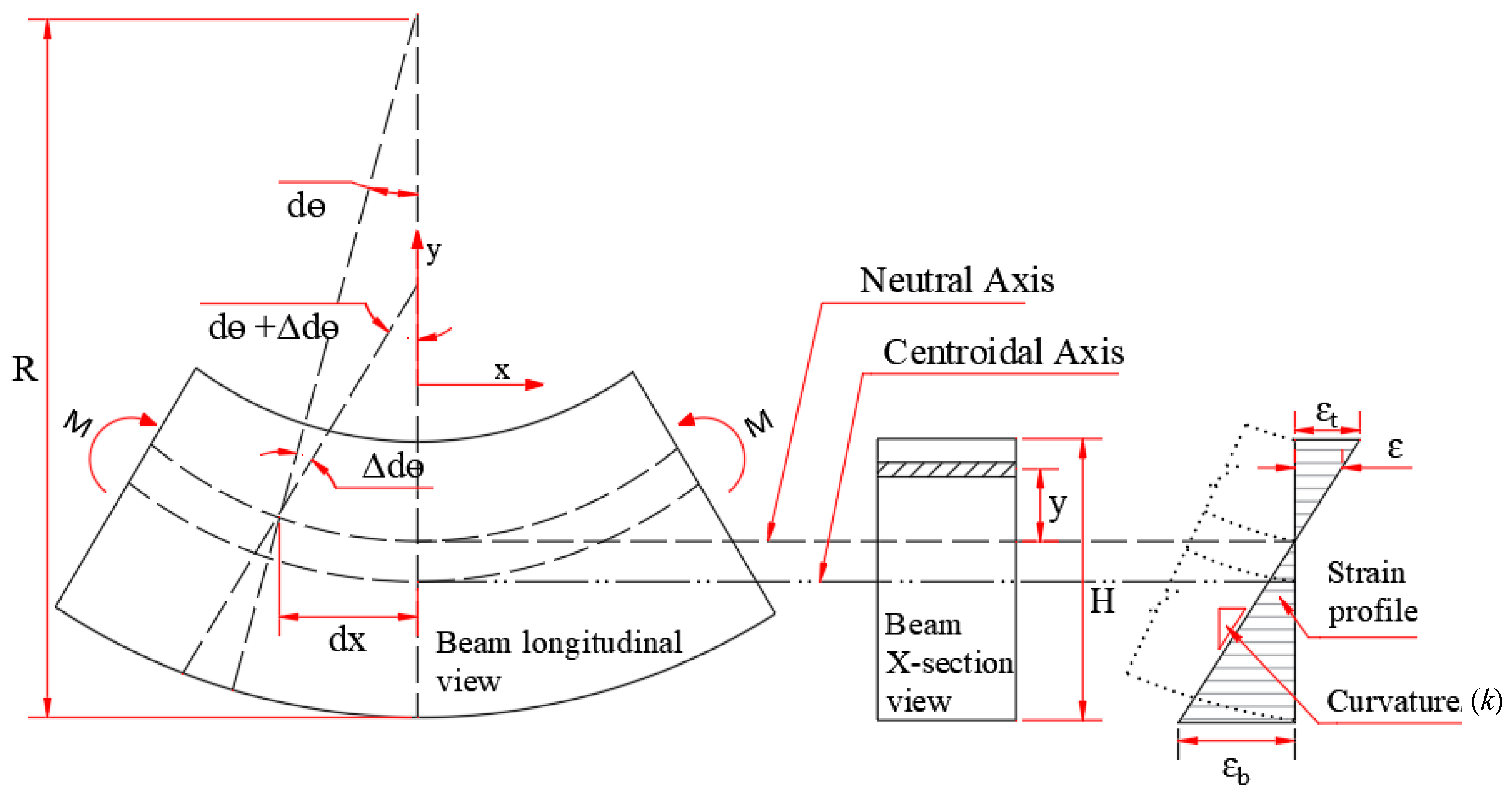

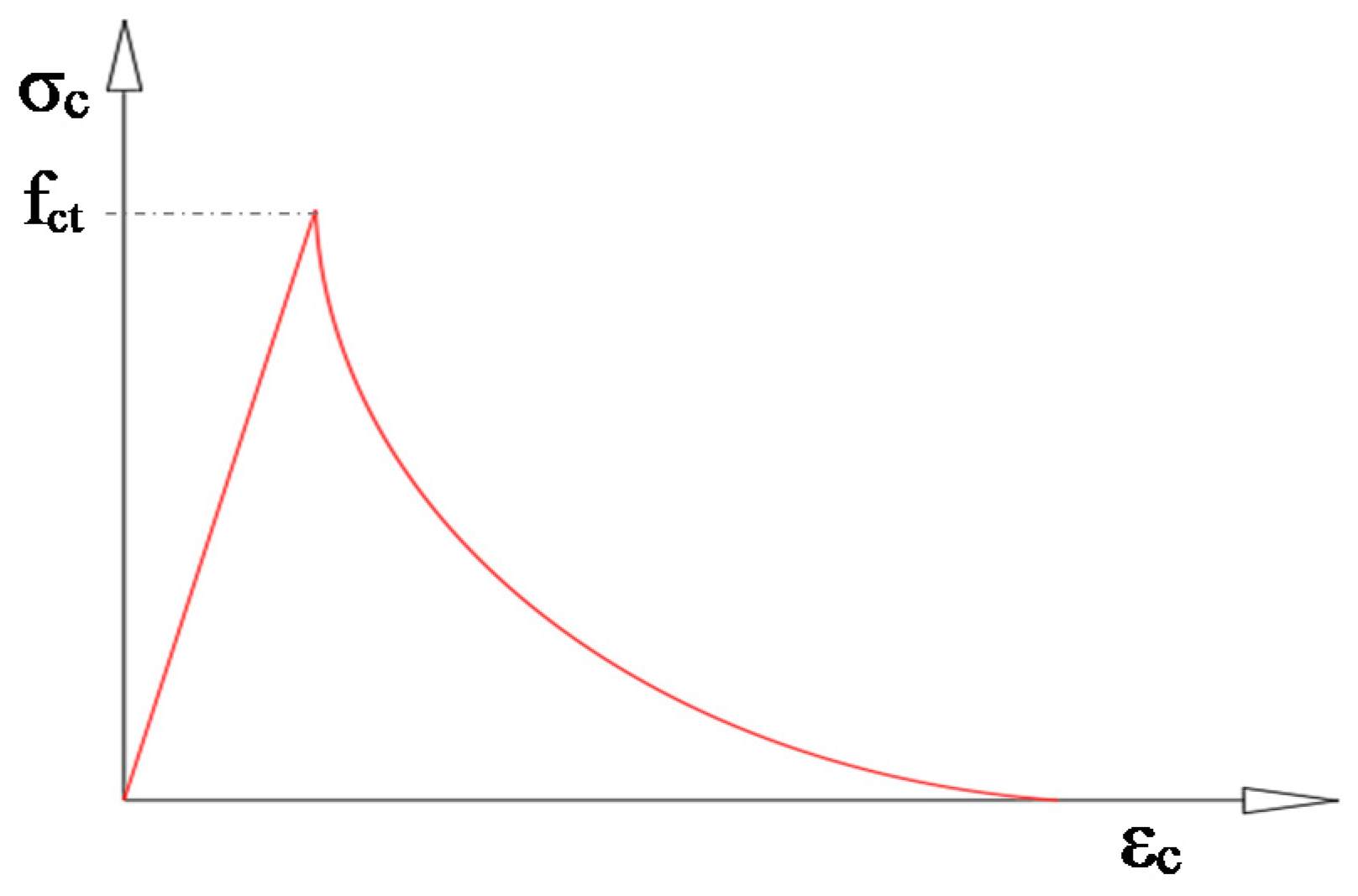

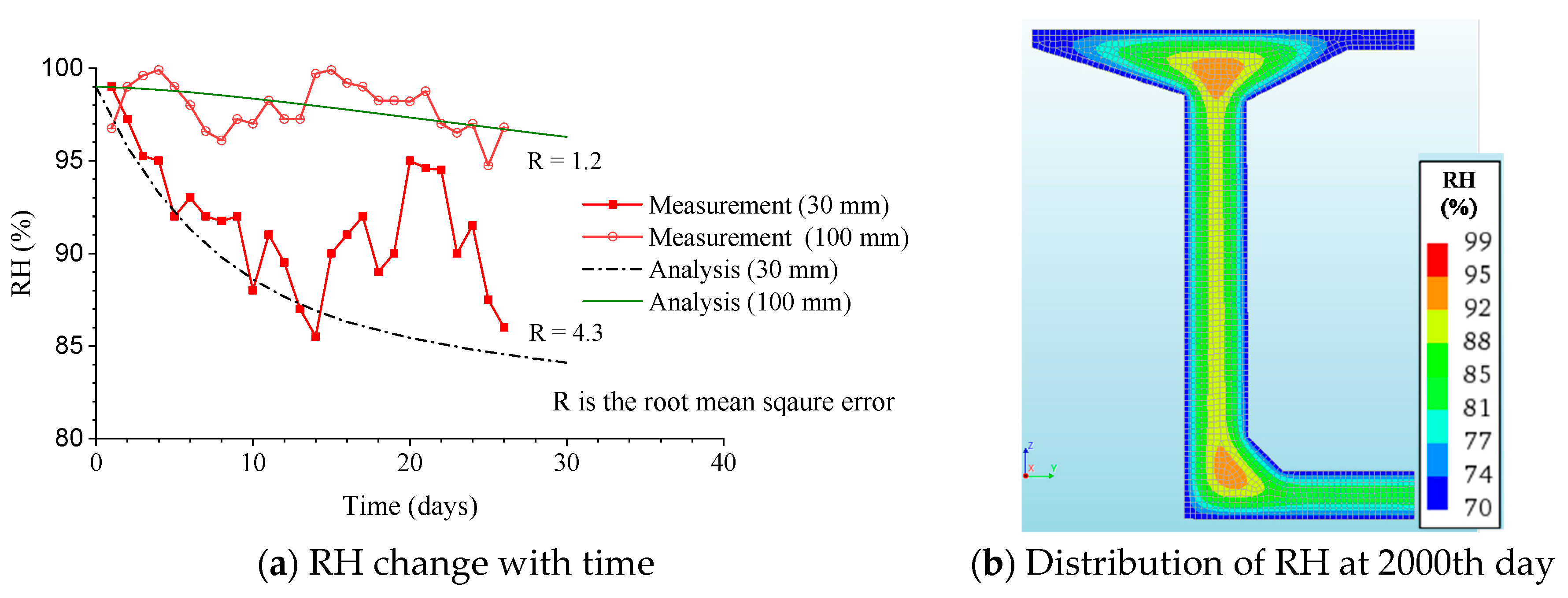

In this section, the analysis is performed to validate the numerical model for the moisture analysis and to calibrate the important parameters for the analysis such as the diffusion coefficient of concrete and the moisture loss at the surface of the member (the evaporation rate). Huang et al. [

2] performed a parametric moisture analysis and verified the analytical results using experimental data measured at the Yuji River Bridge located in Chongqing, China. They measured the RH inside the top slab of the box girder section with digital sensors with an accuracy of ±2%. The sensors were placed on the top slab of midspan section (

Figure 3b) at depths of 0, 30, and 100 mm from the top slab surface. The bridge is a cantilever bridge with a free span length of 115 m. The bridge girder has a height of 14.98 m at the fixed end and 4.5 m at the other end. The top slab is 11 m wide. The girder has bottom slab and web thickness of 0.77 m and 0.9 m, respectively, at mid-span. An initial prestressing force of 3375 kN and 4312 kN is applied using 18 and 23 diameter 15.2 tendons at the top and bottom slab, respectively. Modulus of elasticity of the concrete was reported to be 34.5 GPa [

2].

In this study, these measurements were used to calibrate and verify the concrete parameters for the moisture transport analysis. A half-section of the bridge with dimensions identical to the mid-span cantilever section of the Yuji River Bridge was modeled. The boundary condition was assigned such that moisture loss was allowed on all surfaces in contact with air, including the internal side of the box girder. The evaporation rate was calibrated to fit the experimental data. The atmospheric RH was assumed to be 70%. For the sake of simplicity, the diffusion coefficient of the concrete was assumed as constant and was calculated based on the atmospheric RH value.

Figure 3a shows a comparison of the RH changes with time based on analysis and measurement at depths of 30 and 100 mm. The diffusion coefficient of the concrete calculated for the assumed atmospheric RH value and the evaporation rate at the surface with a value of 3 × 10

−9 m/s gave the best results. The figure shows that the results are in reasonably good agreement with the measured values as reported by Huang et al. [

2]. The moisture distribution at the half-section of the bridge at 2000 days is presented in

Figure 3b. It can be seen that the moisture content varies across the section according to the thickness of the members and exposure conditions. Hence, the shrinkage strain varies along the depth from the surface, resulting in additional curvature and deflection.

4.2. Calculation of Long-Term Deflection of Short-Span PSC Beam (Case A)

The first combined analysis was performed for a short-span PSC beam selected from a series of tests performed by Espion and Halluex between 1981 and 1986 at the University of Brussel [

23]. The beam had a rectangular section of 0.34 × 0.4 m and a length of 8 m. The beam was prestressed with five strands (diameter 12.7 mm) with an effective area of 93 mm

2. A prestressing stress of 1320 MPa was applied at 14 days. The dimensions and reinforcement details are shown in

Figure 4.

In view of the symmetry of the section, a half-span of the beam was modeled to save computation time. Espion and Halluex reported that the compressive strength of the concrete at the time of prestressing was 32.4 MPa [

23]. Accordingly, based on MC2010 [

13], the material properties of concrete were assumed as follows: Young’s modulus

= 32 GPa, mean compressive strength

= 33 MPa, uniaxial tensile strength

= 2.56 MPa, and unit weight

= 2350 kg/m

3. For the prestressing and non-prestressing reinforcing bars, it was assumed that the elastic modulus

was 200 GPa, and the unit weight

was 7850 kg/m

3.

Two quarter-point loads () of 16.5 kN and 63.75 kN were each applied to the beam for 28 days and 84 days, respectively. The tests were performed in a laboratory with an average RH and temperature of 60% and 20 °C, respectively. As the beam was kept in the laboratory during the test, the same evaporation rate (3 × 10−9 m/s) was assigned to all surfaces. Due to the absence of experimental data, the same evaporation rate with the case in 4.1, 3 × 10−9, is assumed. The moisture diffusion coefficient of the concrete was also assumed to be constant and was calculated for a constant RH value of 60%. The hydro-shrinkage constant was calibrated to fit the experimental data.

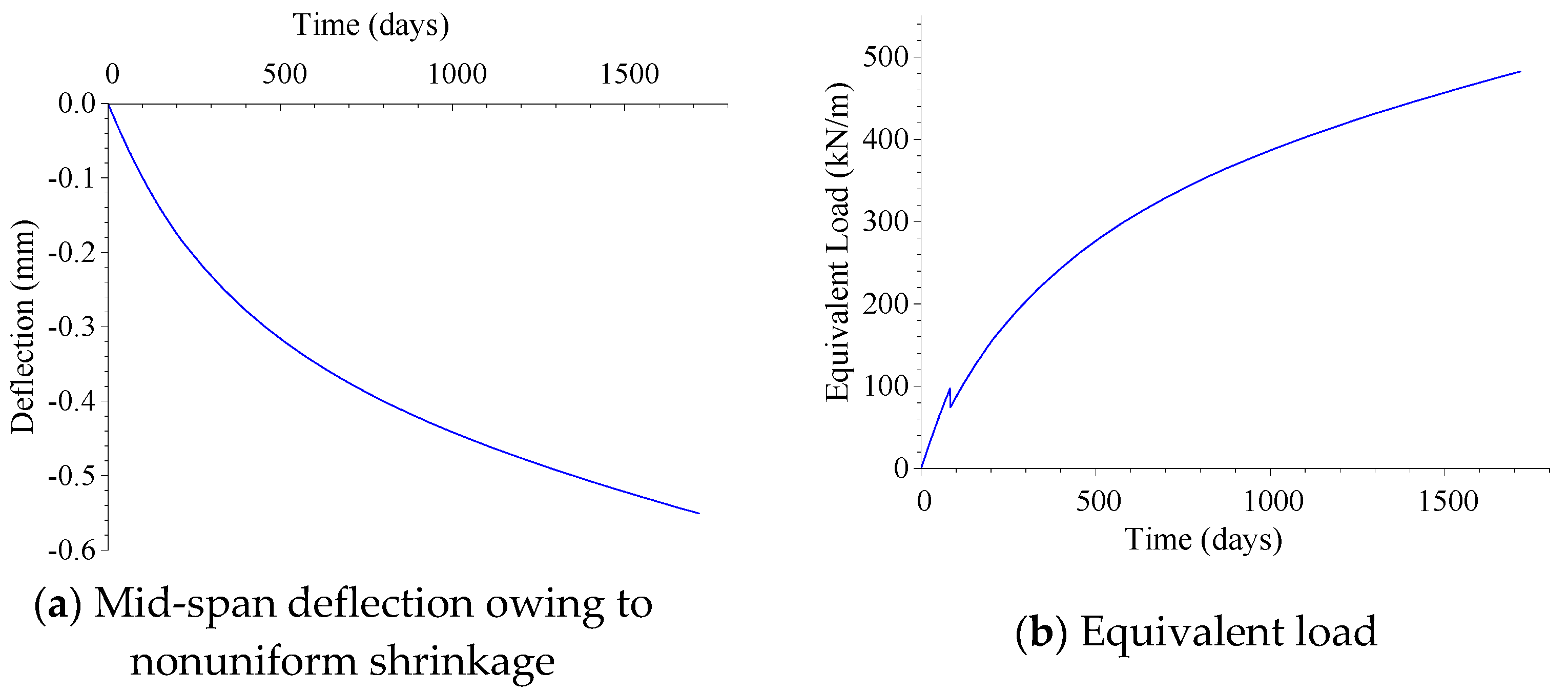

The resulting distribution of the RH across the beam section at different times is presented in

Figure 5. Because the evaporation rate was assumed to be the same on all surfaces and the section is symmetrical, the RH values at the top and bottom surfaces are similar. This means that the deflection owing to nonuniform shrinkage is induced owing to the presence of a relatively larger area of reinforcement at the bottom section, as shown in

Figure 4. The prestressing and reinforcing bars are mostly located under the neutral axis of the beam section, which restricts the shrinkage strain at the bottom of the beam. Hence, the actual unrestricted strain of the top face of the beam becomes larger than that of the bottom face. As a result, a downward deflection is induced. The resulting deflection has a very small value, i.e., only 0.56 mm at the 1700th day, as shown in

Figure 6a.

Figure 6b shows the equivalent load calculated for the nonuniform shrinkage deflection in

Figure 6a. The equivalent load at 84 days decreases as shown in

Figure 6b because it is adjusted by a load adjusting factor

of 0.85 on the 84th day, i.e., the onset of cracking, which can be estimated from the structural analysis using

Model-2. It should be noted that the negative deflection in

Figure 6a indicates a downward deflection, whereas in

Figure 6b, the positive equivalent load indicates the downward distributed load.

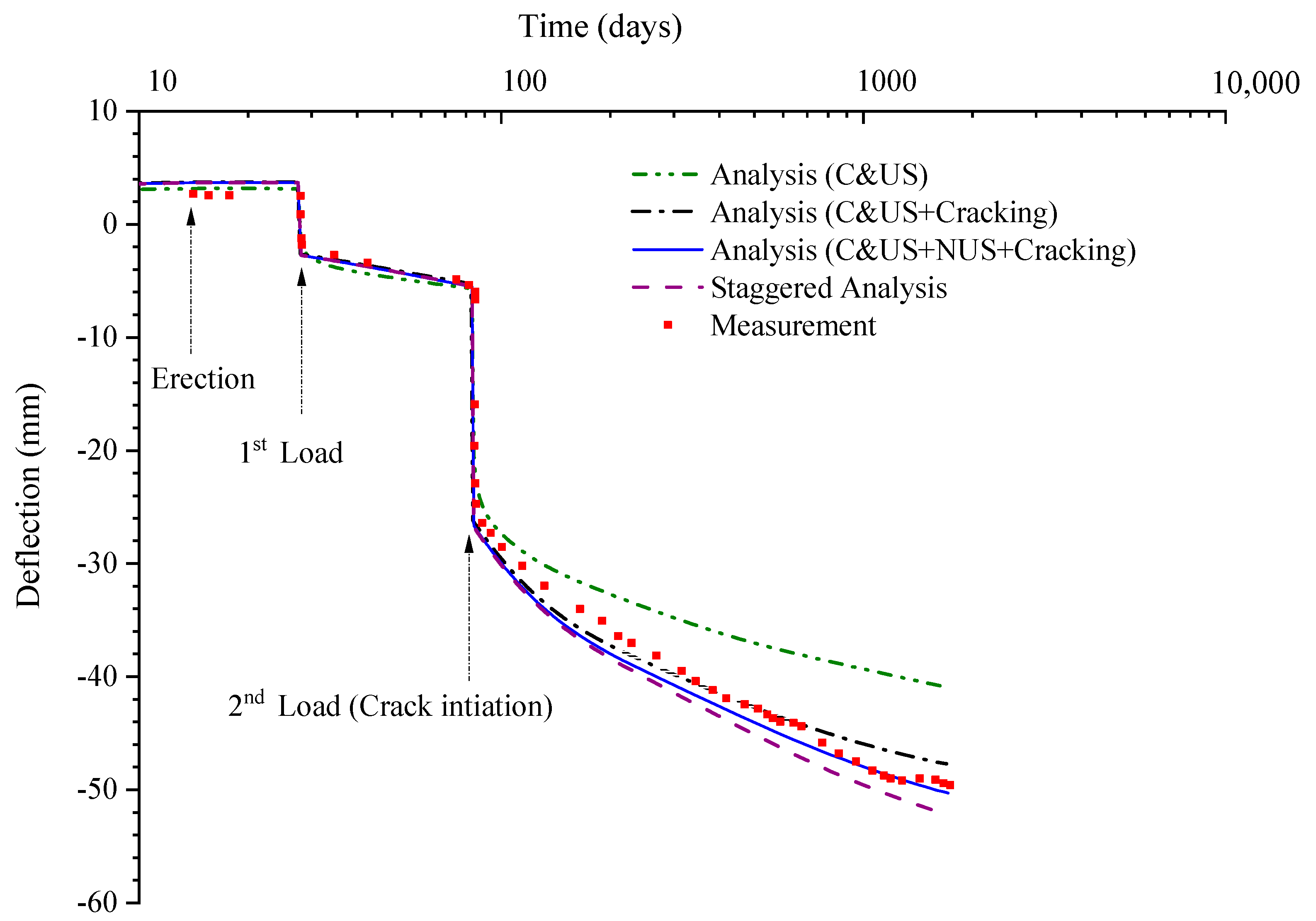

Figure 7 shows the change in the mid-span deflection with time. Four different approaches were used to calculate the deflection. The first used a built-in MC2010 model for the creep and uniform shrinkage (

C&US) without considering cracking, as shown by the green line in

Figure 7. The second considered creep and uniform shrinkage together with the stiffness reduction of concrete from cracking (

C&US + Cracking), as shown by the black line in

Figure 7. The third considered the effect of non-uniform shrinkage by using an equivalent load in addition to the combined effects of creep, uniform shrinkage, and cracking (

C&US + NUS + Cracking), as shown by the blue line in

Figure 7. The fourth approach was a staggered analysis shown by the purple line in

Figure 7. The staggered analysis combined the potential flow and structural analyses provided by DIANA FEA [

15,

16]; the moisture analysis was directly linked to the subsequent nonlinear structural analysis. The hydro-shrinkage constant for the best fit to the measured deflection data was found to be 8 × 10

−4.

The results in

Figure 7 show that the analysis result from using the built-in MC2010 model code without considering cracking and nonuniform shrinkage (

C&US) starts to diverge from the experimental data and other numerical results at the application of the second load (which induces cracks), and exhibits considerable differences from the measured data at later stages. On the contrary, the analyses considering cracking provide values closer to the measured data (shown with red square dots). The stiffness degradation of the beam owing to the cracking of the concrete significantly increased the long-term deflection. In addition, cracks grow and propagate owing to the creep and nonuniform shrinkage. To demonstrate the effects of creep and nonuniform shrinkage on the crack propagation, an additional crack analysis was performed without considering the creep.

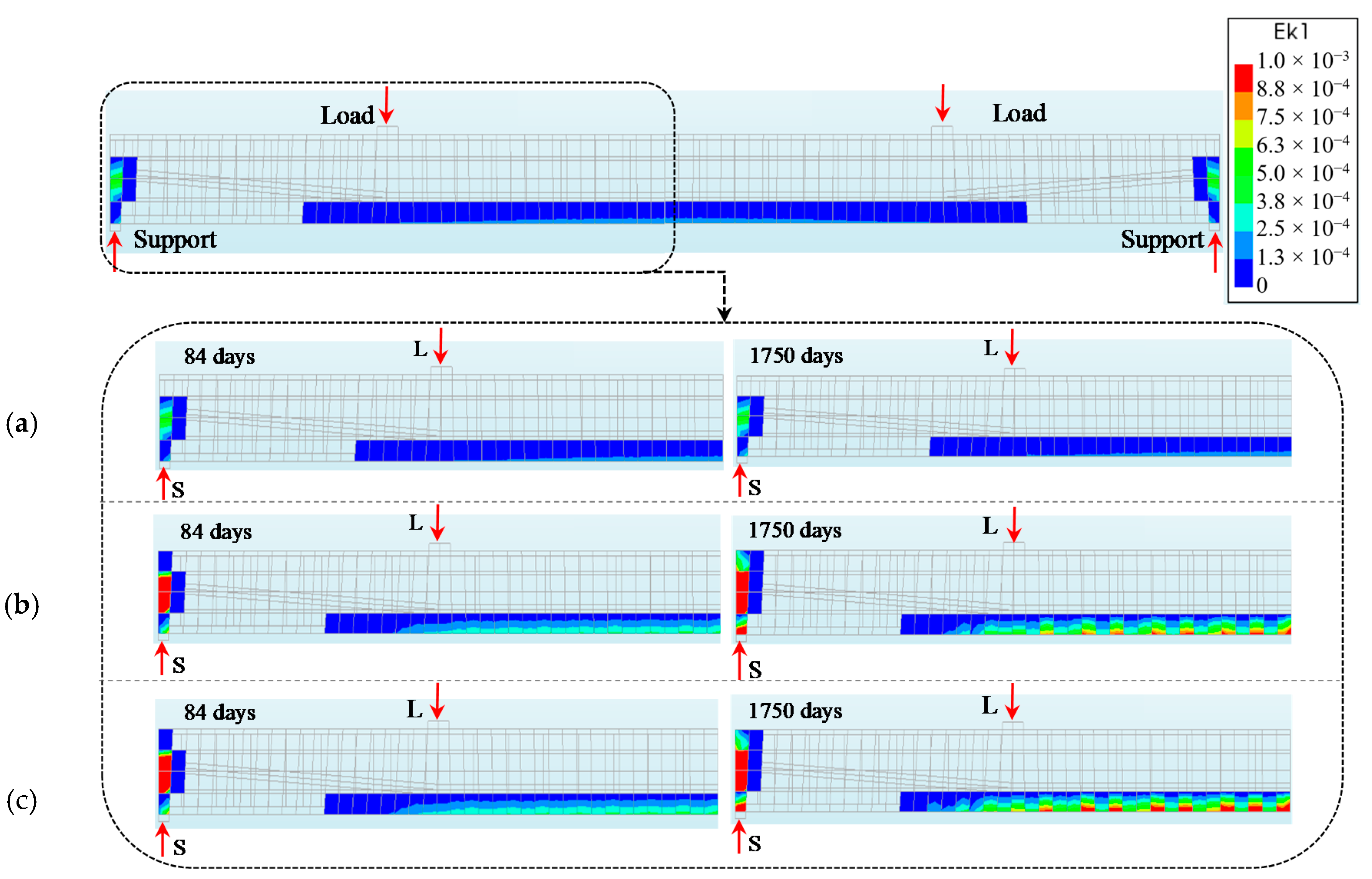

Figure 8 shows the crack strain at the bottom of the beam when the second load was applied (84th day) and at the end of the analysis period (1750th day). In the analysis considering neither creep nor nonuniform shrinkage, the crack strain does not show any change after the application of the second load. In contrast, under the influence of creep and nonuniform shrinkage, the crack strain not only increases but also extends to a wider region. This further reduces the stiffness of the beam. In addition, the nonuniform shrinkage contributes to the increase in deflection. The final deflection owing to the non-uniform shrinkage alone is only 0.56 mm from the moisture transport analysis as shown in

Figure 6a but grows to 2.4 mm on the 1700th day, when the resulting equivalent load is added to the other loads in

Model-2. This is also owing to the combined actions of the cracking and creep. Consequently, the analysis using the equivalent load for nonuniform shrinkage in combination with creep, uniform shrinkage, and cracking (

C&US+NUS+Cracking) provides the results closest to the measured data.

As depicted in

Figure 7, the staggered analysis also gives results close to the measured data (and the results of the equivalent load analysis (

C&US+NUS+Cracking)). However, the stress distributions in the staggered analysis and equivalent load analysis are not identical. In the staggered approach, additional tensile stress is developed because the differential drying shrinkage is restrained by the surrounding concrete and reinforcements; i.e., the stress is in the opposite direction of the shrinkage strain. In contrast, in the equivalent load analysis, stress is induced in the same direction as the flexural strain induced by the equivalent load. In this case, however, the reinforcement ratio is larger in the lower part of the section. Hence the shrinkage strain at the bottom is more restrained than that at the top. Thus, higher compressive strain occurs at the top than at the bottom, and the tensile strain and stress occurs at the bottom. This is same in the equivalent load analysis. There must be some differences in the amplitude of strain and stress in the staggered analysis and equivalent load analysis. However, the restraint to the shrinkage strain is small due to relatively small reinforcement ratio. Therefore, tensile stress is compared to the total stress in the beam faces including the self-weight, prestressing force, and applied loads, the stress difference between the staggered analysis and equivalent load analysis is very small and does not make a significant difference. The difference in the tensile stress between the staggered analysis and the equivalent load approach was less than 0.2 MPa and that in the deflection was less than 1.9 mm at the end of the analysis period.

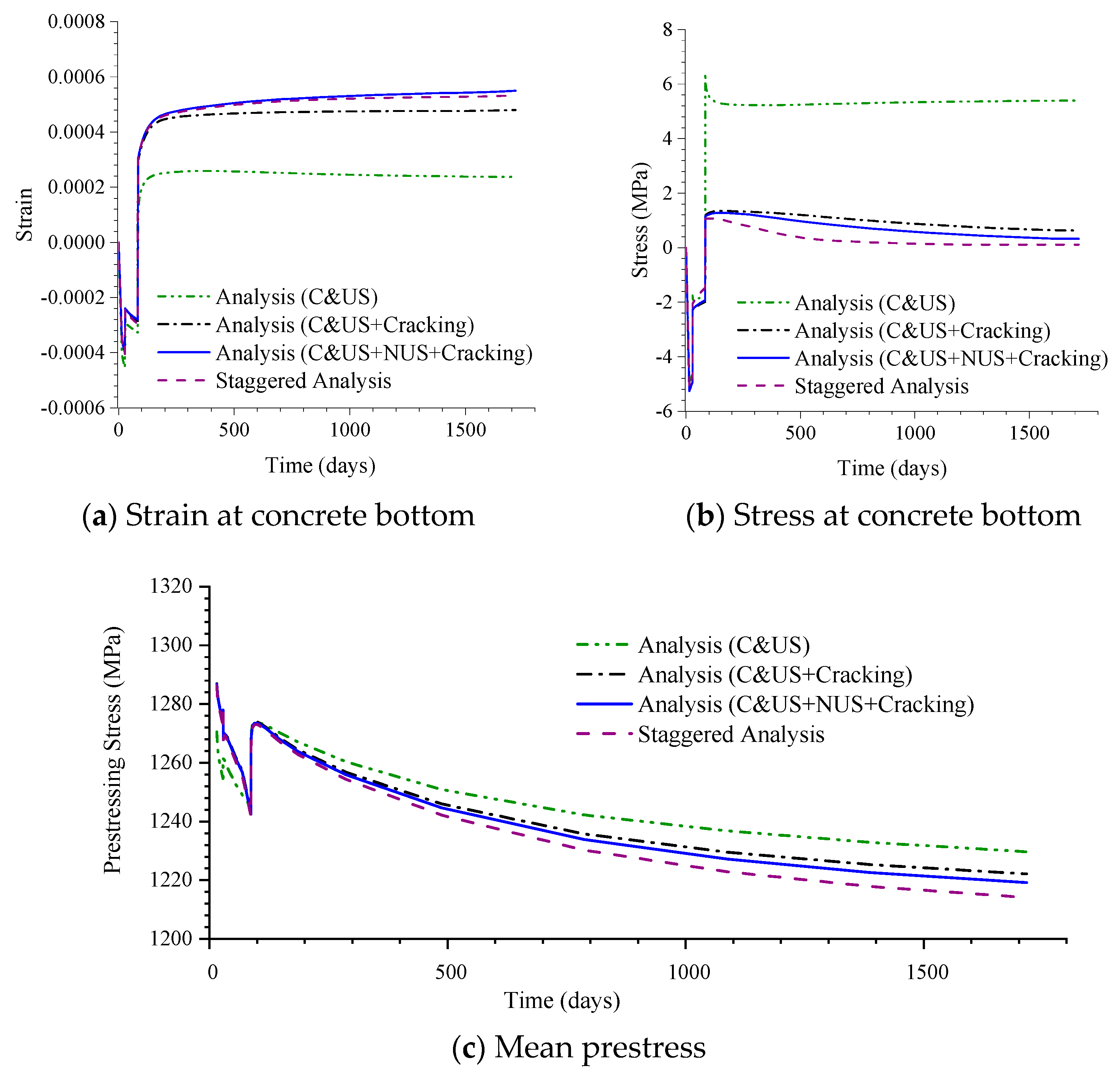

Figure 9 shows the variations of the strain and stress of the concrete bottom and mean prestress at the mid-span section with time. As shown in

Figure 9a, in all analyses, the tensile strain occurs at the bottom after 84 days. The tensile strains from the staggered analysis and equivalent load analysis (

C&US+NUS+Cracking) are the largest owing to the non-uniform shrinkage. However, as shown in

Figure 9b, the tensile stresses are smaller in the analyses considering cracking because the cracks relieve stress. The tensile stresses from the staggered analysis are the smallest owing to the larger deflection and larger crack strain. In addition, as shown in

Figure 9c, the staggered analysis gives the lowest prestress. This suggests that the total shrinkage strain (uniform plus non-uniform shrinkage) is larger at the center of the prestressing tendons in the staggered analysis than in the equivalent load analysis.

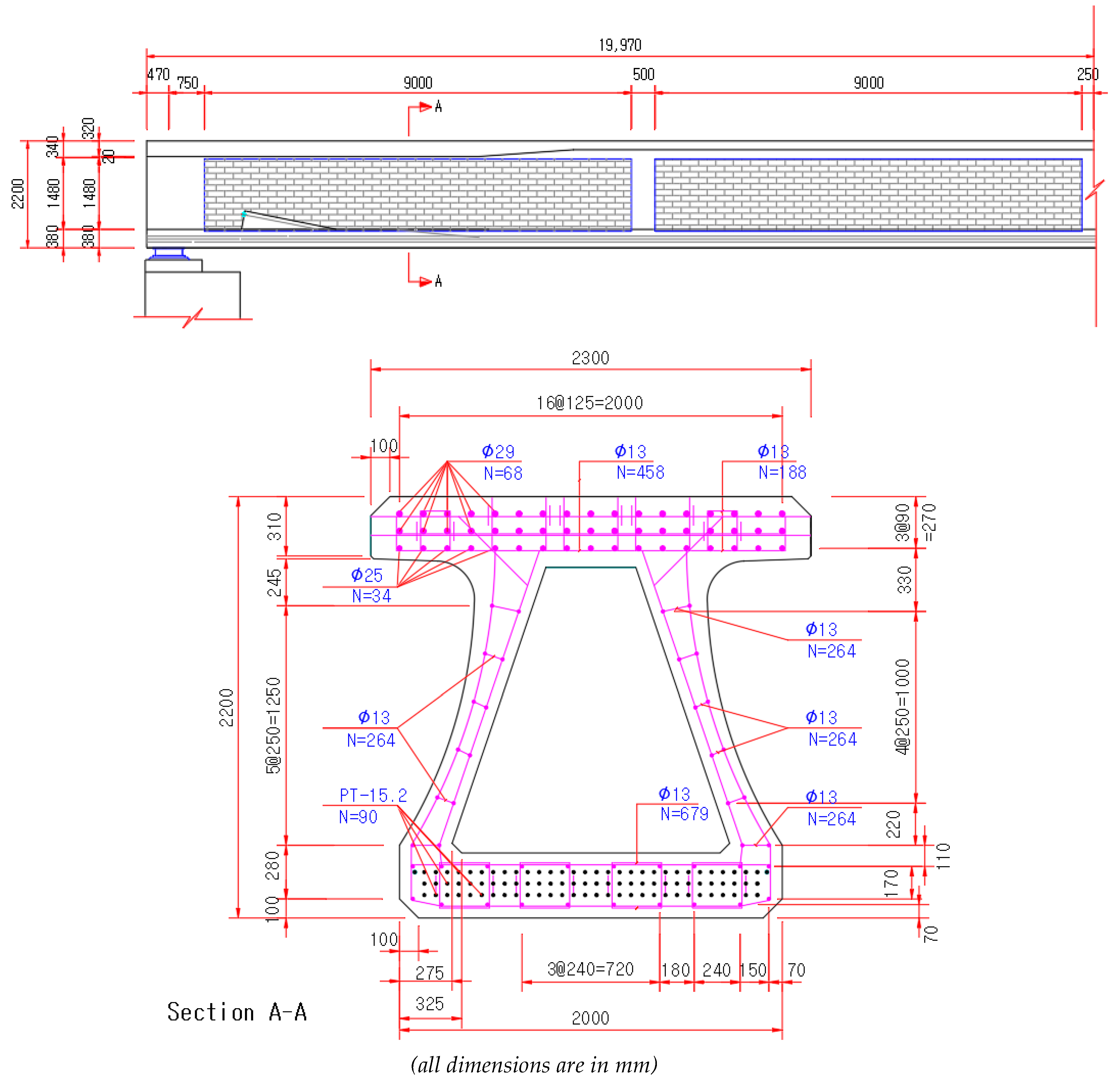

4.3. Calculation of Long-Term Deflection of Medium-Span PSC Box Girder (Case B)

The second example analysis was performed for a 40-m span precast PSC box girder bridge for railways located in Osong, South Korea. It was erected at the end of 2017. The girder has a total height of 2.2 m. The thickness of the bottom slab is 0.34 m, and that of the top slab is 0.37 m. The details of the shape and dimensions of the girder are shown in

Figure 10.

The compressive strength of the concrete cylinder was 50 MPa. The modulus of elasticity and the tensile strength of the concrete were calculated as 41.6 GPa and 4.1 MPa, respectively, according to MC2010 [

13]. The moduli of both the non-prestressing and prestressing rebar were set to 200 GPa.

The prestressing force was applied using ninety 15.2-mm diameter bars in three layers. The yield strength of each bar was 1600 MPa with an allowable stress of 1502 MPa. The design applied stress was assumed to be 87% of the allowable stress, i.e., 1308 MPa. In the model, an effective stress of 1250 MPa was applied while assuming an immediate loss of 4% owing to the combined effects of the elastic shortening, friction, and anchorage slip.

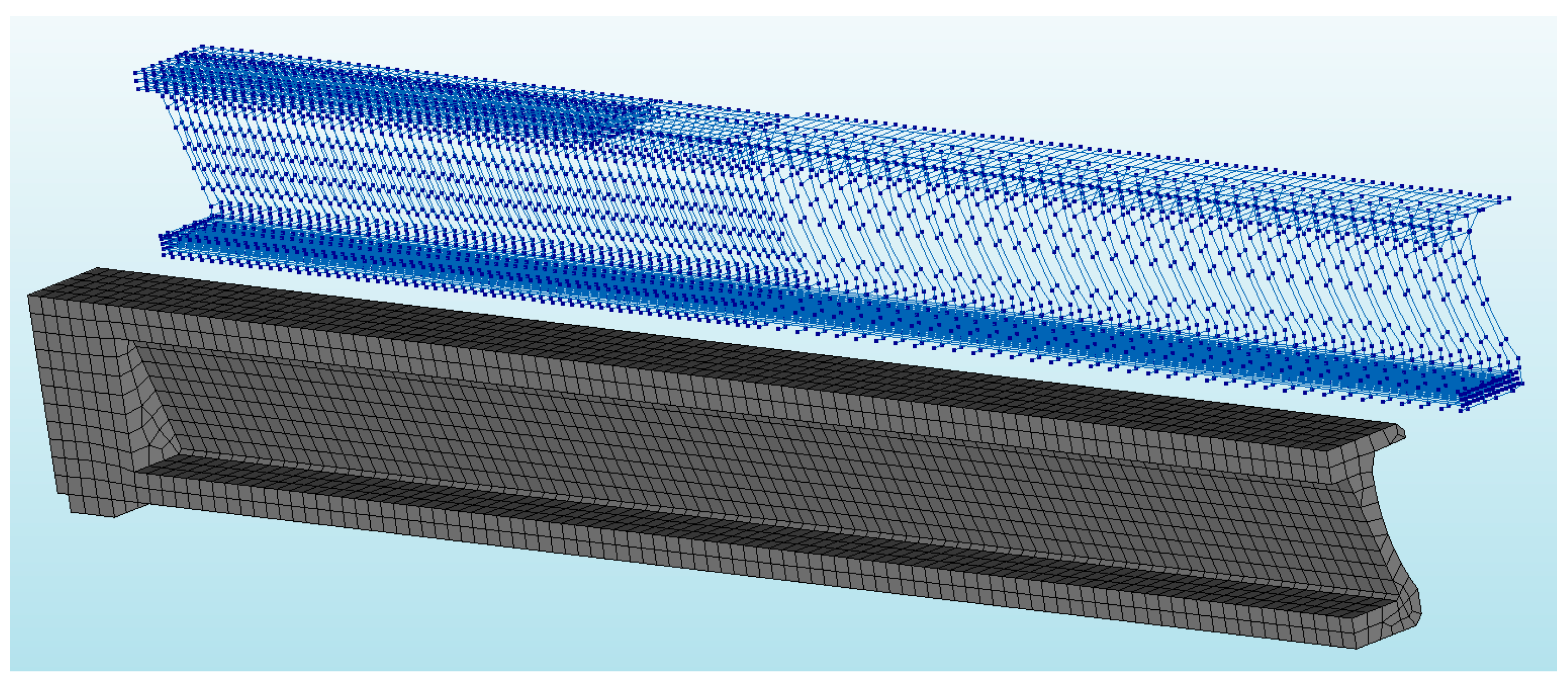

The half-span and half-section of the bridge were modeled in DIANA FEA while using the advantages of symmetry. A total of 3817 quadratic hexahedron elements were used for the half concrete girder section. The prestressing and longitudinal reinforcing bars were modeled using 45 and 41 bar elements, respectively. In addition, for the transverse bar and stirrups, 2423 bar elements were used.

Figure 11 shows the 3D FE model for the medium-span PSC box girder.

The daily average temperature at the site was lowest at −4 °C in January and highest at 24 °C in July. The annual average RH was approximately 68.5%. Accordingly, the average atmospheric RH was set to 68.5% in the moisture transport analysis. The moisture diffusion coefficient of the concrete was calculated for a constant RH value of 69%. The evaporation rate was assumed to be 3 × 10−9 m/s for the top and outer side faces of the girder. To account for the different environmental exposure conditions such as sunlight, the evaporation rate through the bottom and inner faces of the box girder was set to 50% of that of the top and the outer side faces. The hydro-shrinkage constant value was calibrated for the best fit to the measured data.

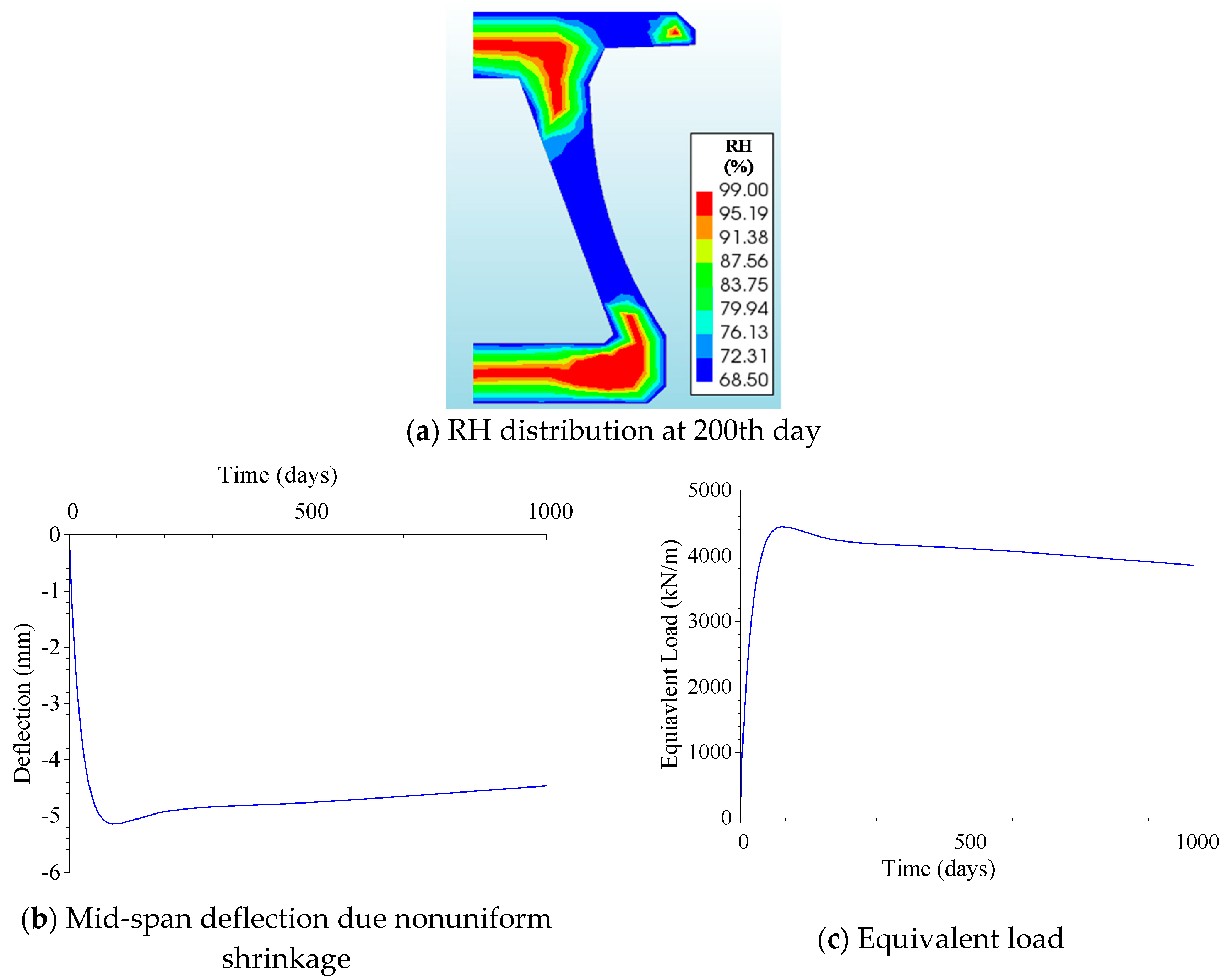

Figure 12a shows the results from the moisture distribution analysis on the 200th day. The lower web section of the girder, which is thinner, dried out faster.

Figure 12b shows the variation in the mid-span deflection owing to the nonuniform shrinkage strain. It rises to a peak value of 5.1 mm after 120 days and then slowly decreases to 4.5 mm on the 1000th day, as the moisture level gradually equilibrates with the atmosphere. As the girder is almost prismatic, the resulting equivalent load has the same profile as the deflection-time curve (see

Figure 12c).

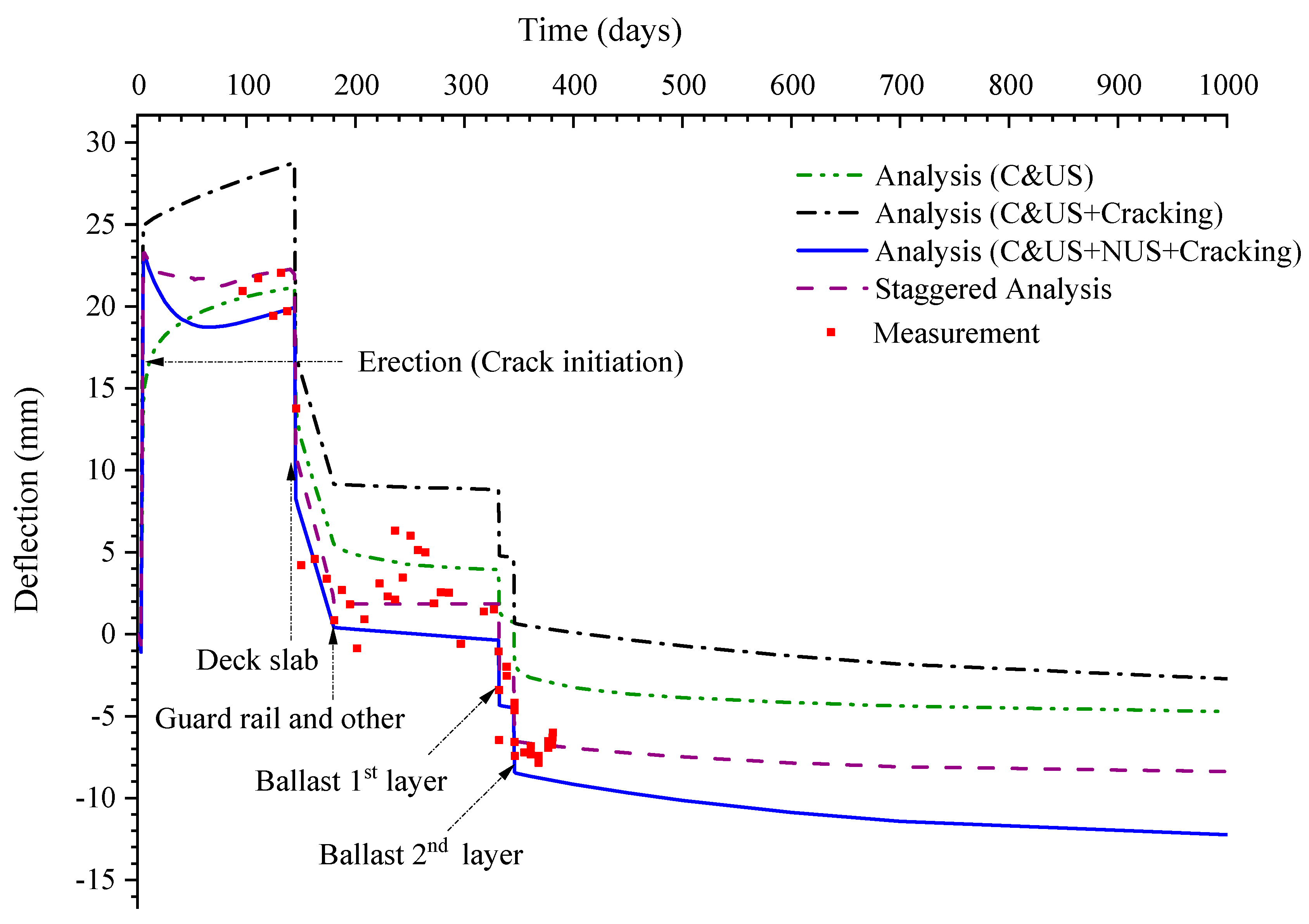

In the structural analysis using Model-2, the loads were applied according to the construction history of the bridge. The self-weight and prestressing force were applied on the 5th day. The deck slab was placed on the 150th day, and other permanent loads (excluding the railway track) were added between the 145th and 180th days. The first and second layers of the ballast were installed on the 332nd and 346th days, respectively. The load adjusting factor for the equivalent load (0.75) was applied after crack initiation on the 5th day.

The deflection of the girder was measured for 380 days [

24]. The variations in the mid-span deflection with time by different analysis methods are presented in

Figure 13. The hydro-shrinkage constant for the best fit of the results of the equivalent load analysis (

C&US+NUS+Cracking) was found to be 3 × 10

−3. The higher hydro-shrinkage constant value (relative to that for the short-span PSC beam (case A)) is attributed to the higher environmental RH as pointed out by Alvarado [

22], and the use of ground-granulated blast furnace slag as a concrete binder.

As can be seen in

Figure 13, the staggered analysis and combined analysis using the equivalent load for nonuniform shrinkage (

C&US+NUS+Cracking) gave the results closest to the measured data up to 380 days. In contrast, the analysis using the built-in MC2010 model for creep and uniform shrinkage (

C&US) without considering cracking and the analysis considering creep and uniform shrinkage together with a stiffness reduction of the concrete by cracking (

C&US+Cracking) failed to predict the long-term deflection. The cracking initiates in the support area, when the self-weight and the prestressing force is applied on the 5th day (see

Figure 14). The analysis without considering cracking (

C&US) results in a lower upward deflection (camber) at the erection relative to the other analyses. The analysis considering cracking but not nonuniform shrinkage (

C&US+Cracking) overestimates the upward deflection. The nonuniform shrinkage has a more significant contribution to the downward deflection throughout the analysis period than that in the short-span PSC beam case (case A) owing to the larger girder section. The final deflection owing to nonuniform shrinkage alone is only 4.5 mm in the moisture transport analysis but is raised to 9.5 mm in the combined analysis (

C&US+ NUS+Cracking) and to 5.7 mm in the staggered analysis, owing to the combined action of cracking and creep as discussed in

Section 4.2.

The difference between the results of the staggered analysis and those of the equivalent load analysis (

C&US + NUS + Cracking) is larger than that in the short-span PSC beam (case A) described in

Section 4.2. The difference was 0.7 MPa in the compressive stress values and 3.8 mm the deflection values at the end of the analysis period. Additionally, unlikely to be the case in 4.2, the upward deflection by the staggered analysis is larger than that by the equivalent load analysis, and the final deflection by the staggered analysis is smaller. This is because there are more reinforcing bars that are uniformly distributed in the top and bottom flanges in this PSC box girder than in the short-span PSC beam. That is, restraint to shrinkage strain is higher, and the downward or upward deflection is more restrained by the well-distributed reinforcements with higher reinforcement ratio. Therefore, smaller additional tensile strain due to nonuniform shrinkage occurs at the bottom of the girder in the staggered analysis than that in the equivalent load analysis. Additional tensile stress is induced at the top flange and additional compressive stress is induced at the bottom of the girder. This stress distribution is opposite to that in the equivalent load analysis. Consequently, larger upward deflection is obtained in the staggered analysis (as compared to the equivalent load analysis) as shown in

Figure 13. This suggests that the section shape, dimensions, and reinforcement details considerably affect the nonuniform shrinkage induced deflection of the PSC girder.

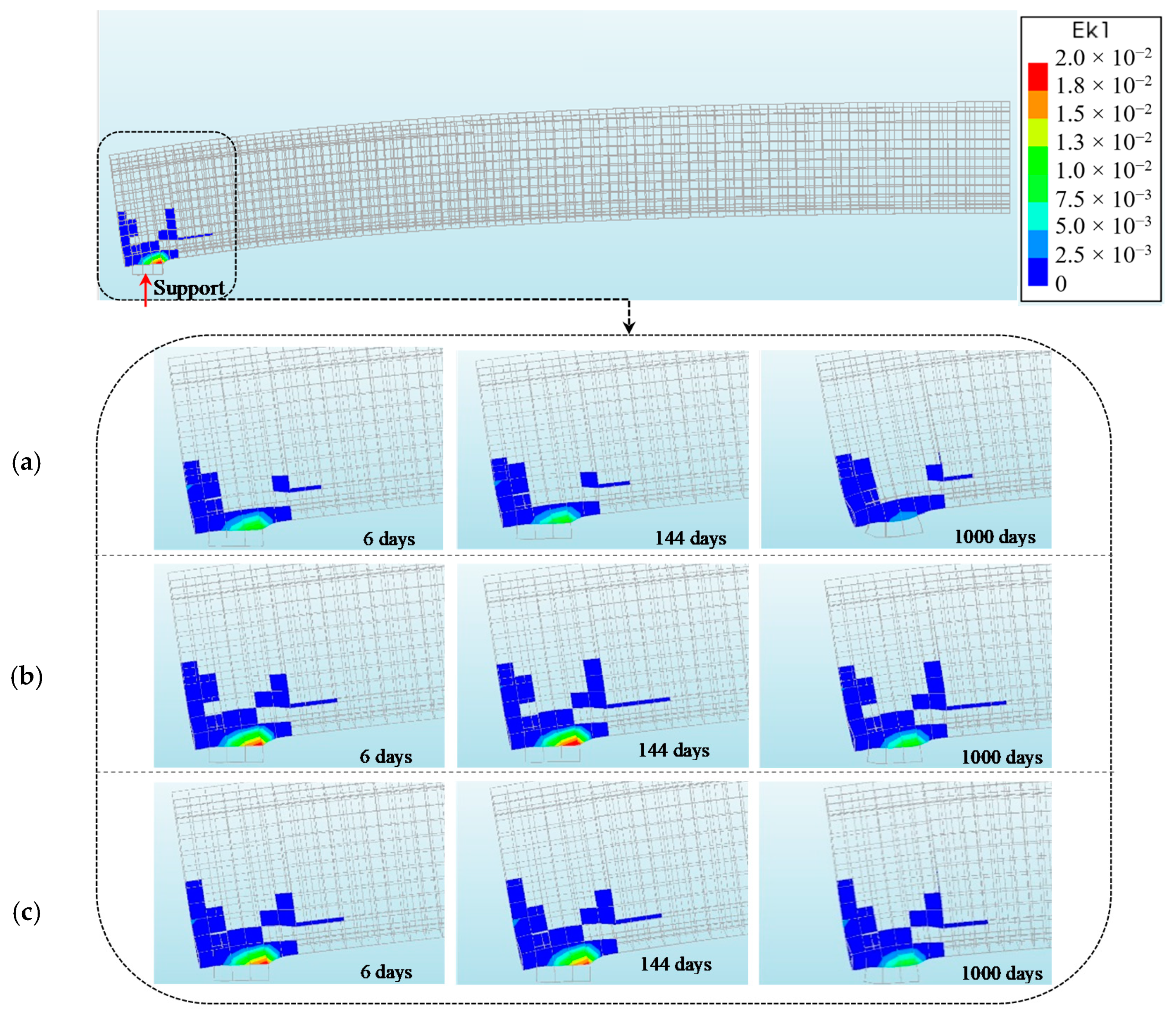

Shear cracking is visible at erection but only in the support area. The other section remains uncracked for the entire analysis period, as shown in

Figure 14. Thus, the significance of the stiffness reduction owing to cracking is minimal at later stages.

Figure 15 shows the stress and strain at the bottom concrete and the mean prestress at the mid-span section of the girder. As shown in the figure, the girder section remains in compression at the mid-span section throughout the analysis period. The compressive strain in the staggered analysis is the largest because of the compressive shrinkage strain at the bottom, whereas the equivalent load induces a tensile stress and strain at the bottom unlike in the staggered analysis, as explained earlier in

Section 4.2. Thus, the equivalent load analysis yields the smallest compressive stress and strain, as shown in

Figure 15a,b. As the prestress loss is a multiple of strain changes and the elastic modulus of the prestressing tendon, it follows the same curve as that of the compressive strain of the concrete (see

Figure 15c). Due to creep, the compressive strain at the bottom increases with increasing deflection as shown in

Figure 15a, but, as can be found in

Figure 15b, the stress at the bottom concrete becomes almost constant after 346 days in the analyses without considering nonuniform shrinkage. Since creep does not develop stress, the stress change after all fixed loads are imposed is mainly due to non-uniform shrinkage. In the equivalent load analysis, the additional tensile stress at the bottom due to the nonuniform shrinkage is reducing slowly as the moisture distribution is converging to equilibrium state with the environment RH, and thus, the compressive stress is increasing slowly. Whereas, in the staggered analysis, the compressive stress at the bottom increases due to restraint.

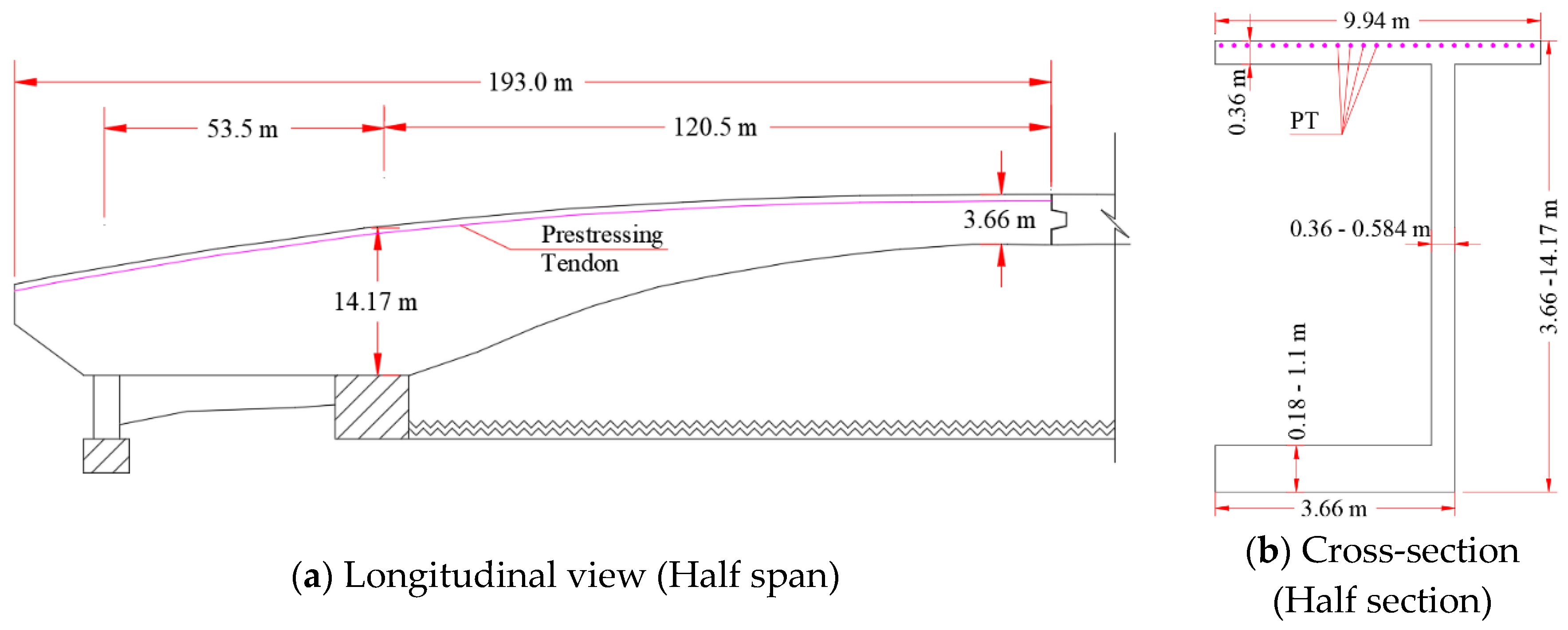

4.4. Long-Term Deflection of Long-Span Cantilever PSC Bridge (Koror–Babeldaob Bridge) (Case C)

The third example analysis was conducted for a long-span PSC bridge. The Koror–Babeldaob Bridge, with a main span of 241 m, was built in 1977 using a cantilever method. It collapsed in 1996, three months after remedial prestressing. The final mid-span deflection in design was expected to be in the range of 0.53 to 0.65 m. However, after 18 years, it reached 1.39 m and continued to increase until it collapsed on September 26, 1996 [

25]. The main span of the bridge comprised a pair of large cantilevers connected with a sliding hinge to allow relative longitudinal movements [

26].

The specified compressive strength of the concrete was 35 MPa. In the design, the allowable tensile stress was set to zero [

26]. The 28-day elastic modulus of the concrete in the initial design was assumed as 28.3 GPa according to AASHTO [

10]; however, various studies have reported that the actual value was in the range of 19.6 to 22 GPa [

26,

27]. The average unit weight of the concrete was reported as 23.5 kN/m

3. In the model, the elastic moduli of both the non-prestressing and prestressing bars were set as 200 GPa, whereas that of concrete was assumed to be 22 GPa in the user-defined material. The uniaxial tensile strength of the concrete was calculated as 3.2 MPa, according to MC2010 [

13]. The detailed dimensions of the bridge girder are shown in

Figure 16. In the area where the bridge was built, the annual average temperature was approximately 28 °C, and the annual average RH was approximately 82% [

26].

Using high-strength threaded bars with a diameter of 32 mm and strength of 1050 MPa, the prestress of 735 MPa, 70% of the tensile strength of the bar, was applied. The same bars were used to provide vertical prestress for the webs with spacing varying from 300 to 3000 mm and the horizontal transverse prestress of the top slab, with a typical spacing of 560 mm [

25]. The average thickness of the concrete pavement at the top slab was 75 mm.

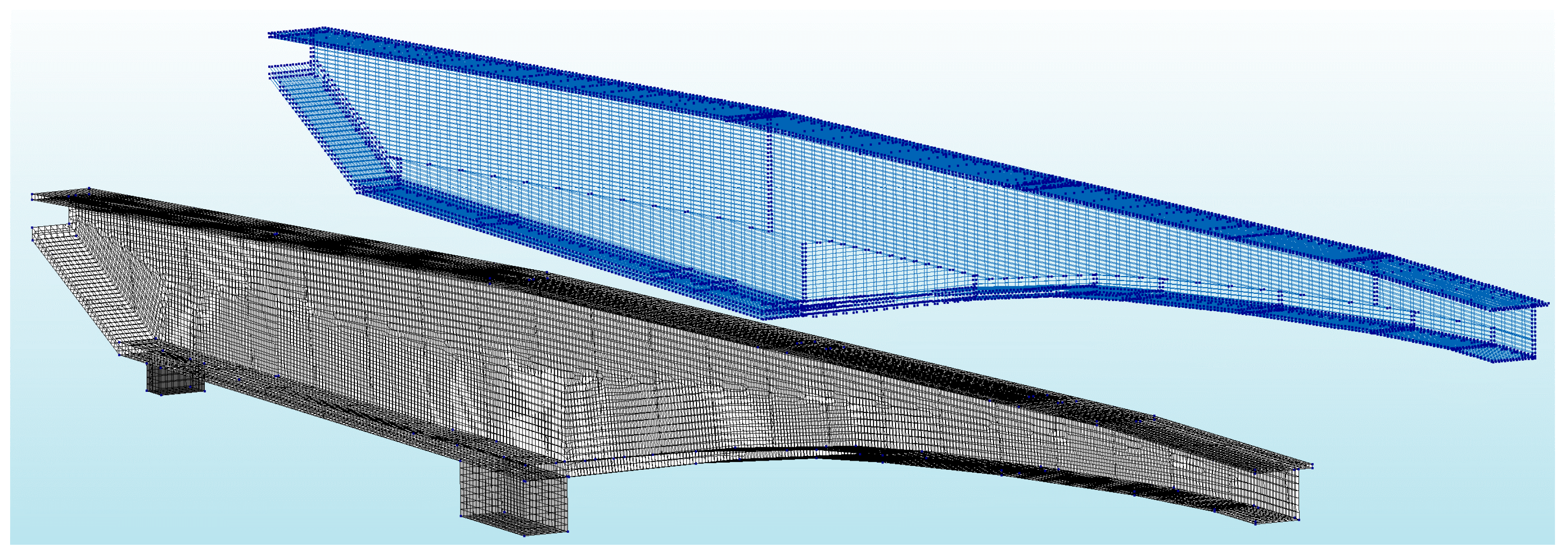

The half-span of the bridge was modeled with half-section using DIANA FEA with the advantage of symmetry. A total of 17,432 quadratic hexahedron elements were used for the girder, and 158, 344, and 121 bar elements were used to model the longitudinal, lateral, and vertical prestressing bars, respectively. In addition, 1373 bar elements were used to model the non-prestressing reinforcing bars for the half-concrete girder section excluding the supports.

Figure 17 shows the 3D FE model for the Koror–Babeldaob Bridge.

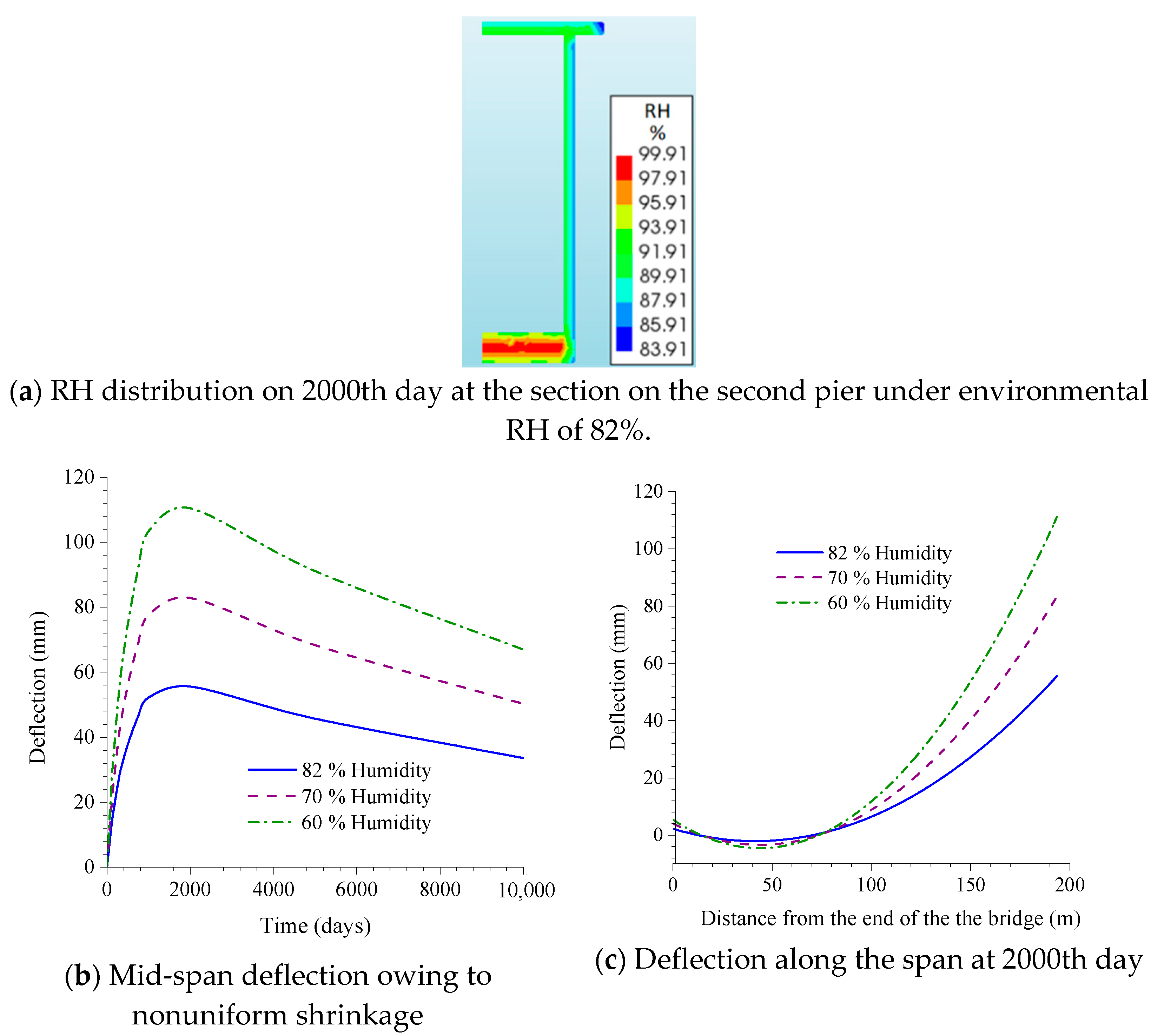

To study the effect of the environmental RH on the deflection owing to the non-uniform shrinkage, in the moisture transport analysis using Model-1, the average atmospheric RH was set as 60% and 70%, in addition to the reported value of 82%. The evaporation rate was assumed to be 3 × 10−9 m/s, and the hydro-shrinkage constant value was calibrated for the best fit to the measured data. The moisture diffusion coefficient was calculated for an RH value of 82%.

The analysis result in

Figure 18 shows that the deflection owing to the non-uniform shrinkage is upward owing to the cantilever arrangement of the bridge and rises up to 55.5 m on the 2000th day when exposed to 82% RH. After that, as the RH inside the concrete approaches equilibrium with the atmospheric RH, the deflection slowly decreases to a final value of 33.5 m at the end of the analysis period. As the atmospheric RH decreases, the resulting deflection (in this case, the camber) caused by the nonuniform shrinkage increases, as shown in

Figure 18.

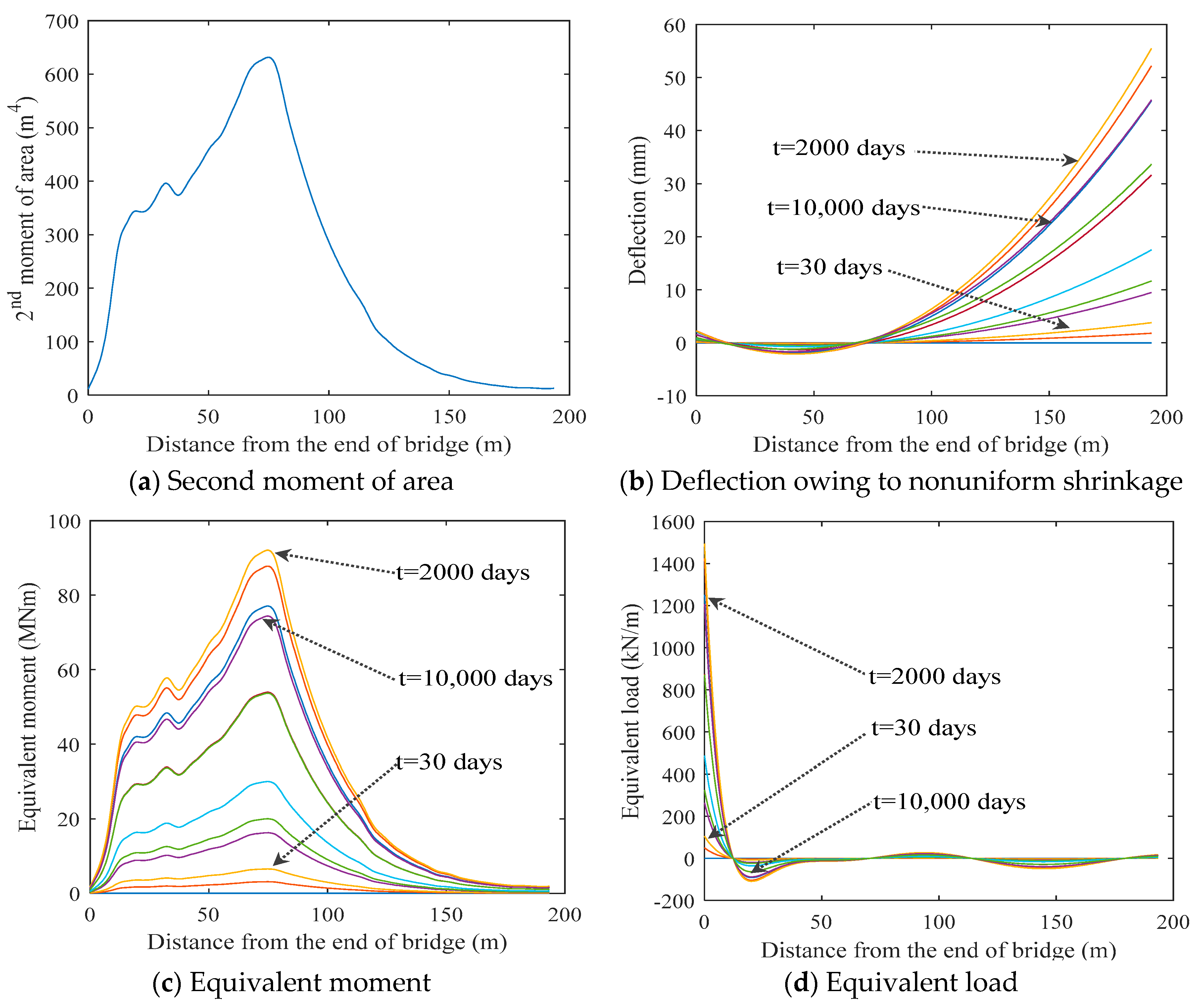

As the bridge is non-prismatic, the second moment of area of its section is calculated at every meter along the length of the bridge, as shown in

Figure 19a. The deflection owing to the non-uniform shrinkage is extracted every 0.5 m at the top slab and is formulated as a function of the length of the bridge. From this data, the moment and equivalent load are derived, as shown in

Figure 19c,d.

In the structural analysis using Model-2, because the bridge was built using a segmental construction method, the self-weight and prestressing load were gradually applied for 220 days. Other permanent loads, such as the weight of the pavement and guardrail load, were applied 20 days after the completion of the segmental construction. The total analysis period was 10,000 days. The load adjusting factor for the equivalent load was calculated as 0.8 and was applied on the 14th day.

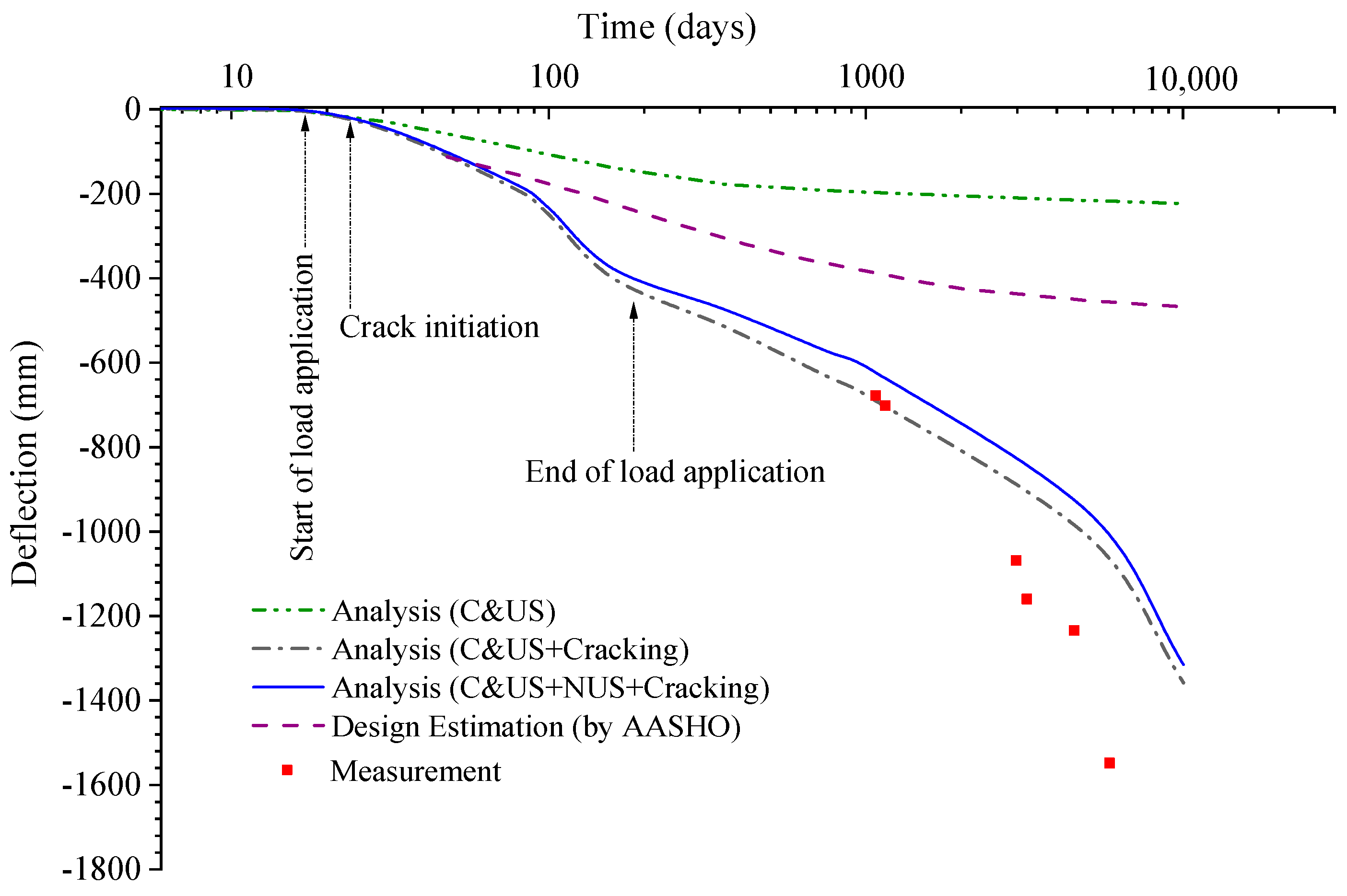

In

Figure 20, the analysis results are compared against the measured data (shown by the red squares) and the original design calculation (shown with the purple line). The original estimation of the deflection was calculated using a simplified approach based on the American Association of State Highway Officials design guidelines [

26]. In this approach, the creep and shrinkage are assumed to start after the completion of bridge construction. Accordingly, the elastic deflection owing to all permanent loads is calculated first, and the long-term deflection is estimated by multiplying the elastic deflection by the assumed creep coefficient. The total elastic deflection after an assumed 10% prestress loss was 370 mm, and multiplying this by a creep coefficient of 1.3 gave the final long-term deflection as 481 mm.

Figure 20 shows the results for the deflection calculation using different methods. As shown, the analyses considering cracking provide results that are very close to the measured data. The relatively steeper slope in the period from the 30th to 220th day in the analyses considering cracking is caused by the gradual increment of permanent loads during this period. In contrast, the results from the analysis using the built-in MC2010 model show a long-term deflection under 250 mm, which is the lowest value and is too far away from the measured data. This indicates that a design and analytic approach that does not consider cracking (even a current one) cannot correctly predict an excessive deflection in a case where the stiffness degradation owing to cracking is the main cause of the excessive deflection.

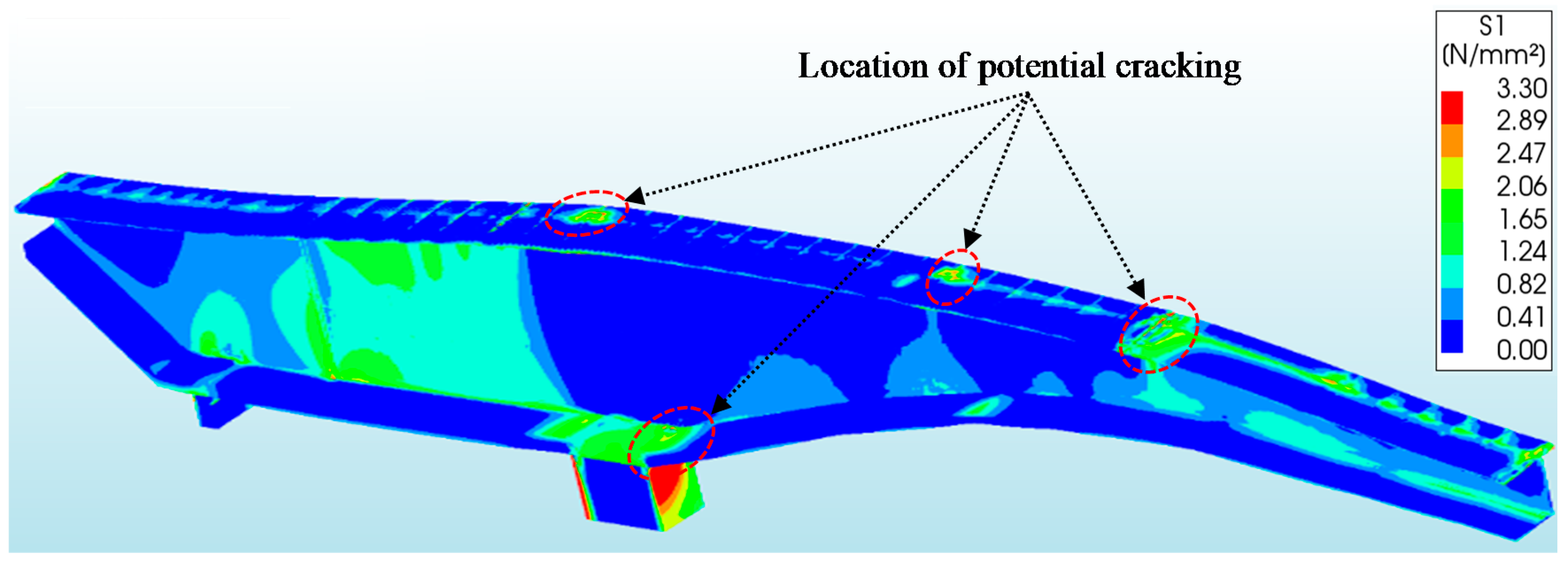

The cracking starts at the face of the second pier and at a location 66 m away from that point, as shown in

Figure 21. The principal stress exceeds the tensile strength of concrete, i.e., 3.2 MPa. This is in good agreement with the report by Tang [

26], i.e., cracking and failure occur near the same location.

The nonuniform shrinkage induced deflection is upward, and thus, the final deflection from the equivalent load analysis (C&US+NUS+Cracking) is less than that from the analysis without considering the non-uniform shrinkage (C&US+Cracking). However, it is worth noting that the nonuniform shrinkage induces a considerable amount of additional deflection in long-span PSC bridges. It is expected that this additional deflection induces more cracks, further reducing the stiffness of the girder, and consequently, enhances the long-term deflection.