An Eco-Driving Algorithm for Interoperable Automatic Train Operation

Abstract

1. Introduction

- Level 0: this level is used when an ETCS equipped train runs on non-ETCS route. The on-board equipment monitors the maximum train speed and the driver has to observe the lineside signals.

- Level National Train Control (NTC): this level is meant for trains equipped with ETCS running on lines equipped with national Automatic Train Protection (ATP) systems instead of ERTMS. At this level, the train needs Specific Transmission Modules (STM) to interact with the national system and the ETCS system is used as an interface of the national ATP with the driver.

- Level 1: this level makes use of Eurobalises or Euroloops to perform a spot transmission of data from the track to the train. Eurobalises send the lineside signals aspect and the movement authority to the on-board train equipment. Using this information, the on-board computer calculates and monitors continuously the maximum speed and braking curves that the train must observe. Euroloops play the same role than Eurobalises but they can transmit the data continuously over a particular section of the track. At this level, lineside signals are needed.

- Level 2: this level makes uses of GSM-R to perform a continuous communication between both the train and trackside equipment. The lineside signal aspects and movement authority are displayed to the driver in the train cab. Out of the scope of ERTMS, other systems perform the train location using track circuits, axle counters, etc. At this level, lineside signals are optional.

- Level 3: as level 2, level 3 uses GSM-R to perform continuous communication between both the train and the track. The main difference with level 2 is that the train integrity supervision and train location functionalities are performed by the ERTMS system. Thus, the train positioning is transmitted continuously allowing a continuous determination of the position of the train route that has been cleared. Thus, the route clearance is not performed at fixed track sections, as it happens in level 2, reducing the minimum headway between trains and increasing the transport capacity.

- Type of point: departure, passing, or arrival.

- Position of the point.

- Time assigned.

2. Literature Review

2.1. Eco-Driving Approaches

2.2. Constraint Handling Mechanisms in Nature Inspired Algorithms

- The individual with the best value in the objective function is selected when two feasible solutions are compared.

- The feasible individual is selected when a feasible solution is compared with an infeasible solution.

- The solution with the lowest constraint violation is selected when two infeasible solutions are compared.

3. Problem Description

4. Differential Evolution Algorithm for the ATO over ERTMS Eco-Driving Problem

4.1. Differential Evolution Algorithm

4.2. Constraint-Handling Process

4.3. Simulation Model

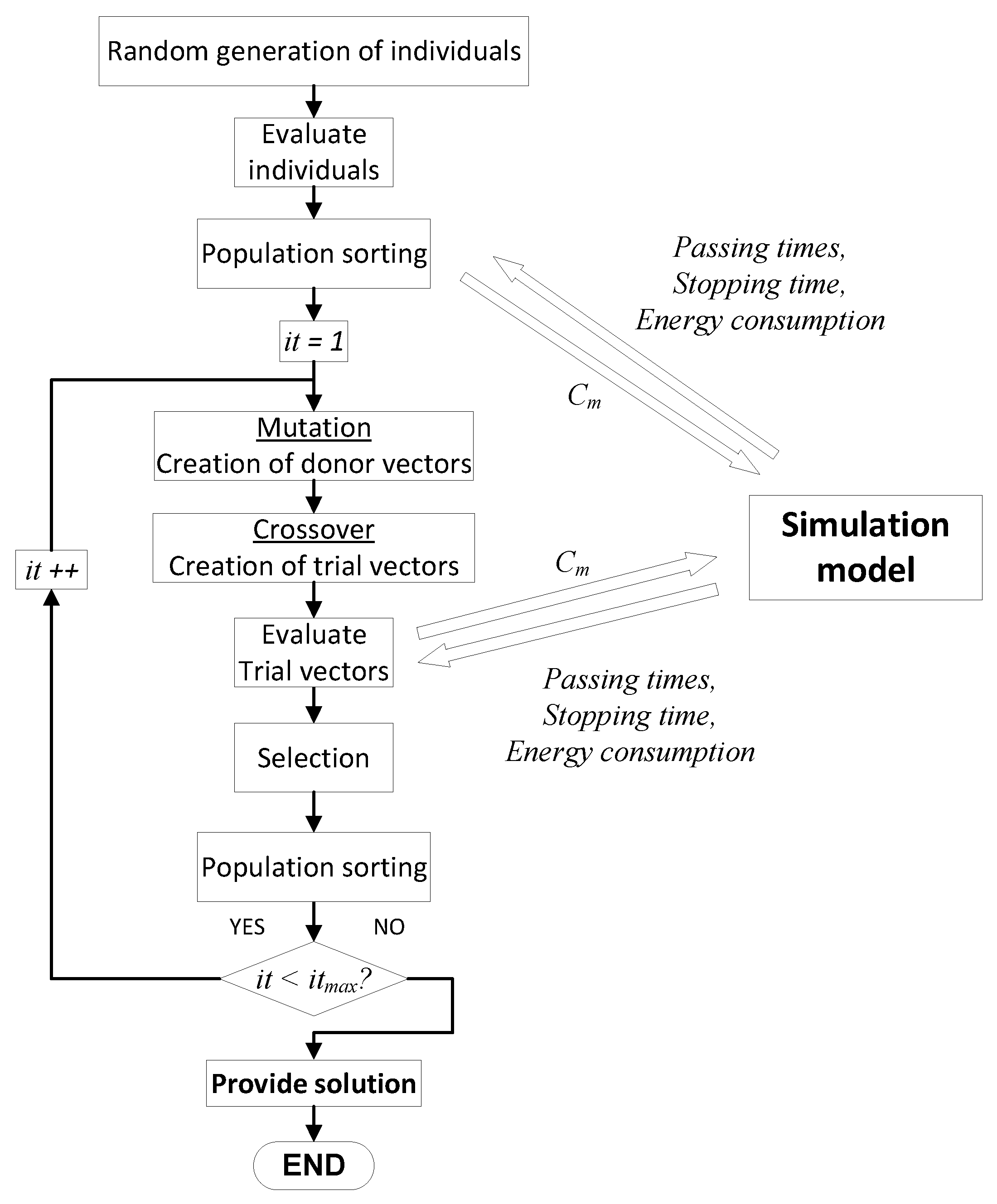

4.4. Optimization Method Flowchart

- The process starts generating a number of random individuals equals to the population size. Each individual is defined by a containing random values.

- These individuals are evaluated using the simulation model. The model receives the driving commands contained in the of the individual to evaluate and returns the energy consumption of the journey, the passing times at the intermediate target points, and the stopping time at the arrival. Using these results, the fitness of each individual is calculated.

- The population is sorted in increasing value of fitness to find the best individual in the population.

- The mutation process is applied to all the individuals in the population creating a donor vector for each individual in the population.

- Crossover is applied to the donor vectors to create a trial vector for each individual in the population.

- Donor vectors are evaluated using the simulation model, and the fitness value of each donor vector is calculated.

- The population is subjected to the selection process to create the population result of the iteration. Each individual is compared with its corresponding trial vector. If the individual presents lower fitness value, the individual survives in the new population and the trial vector is suppressed. Otherwise, the trial vector substitutes the individual in the new population.

- The new population is sorted in increasing value of fitness to find the best individual.

- If the iteration number is equal to the maximum number of iterations of the algorithm, the process finishes providing the best solution found. Otherwise, the number of iterations increases by one, and the process is repeated from step 4.

5. Case Study

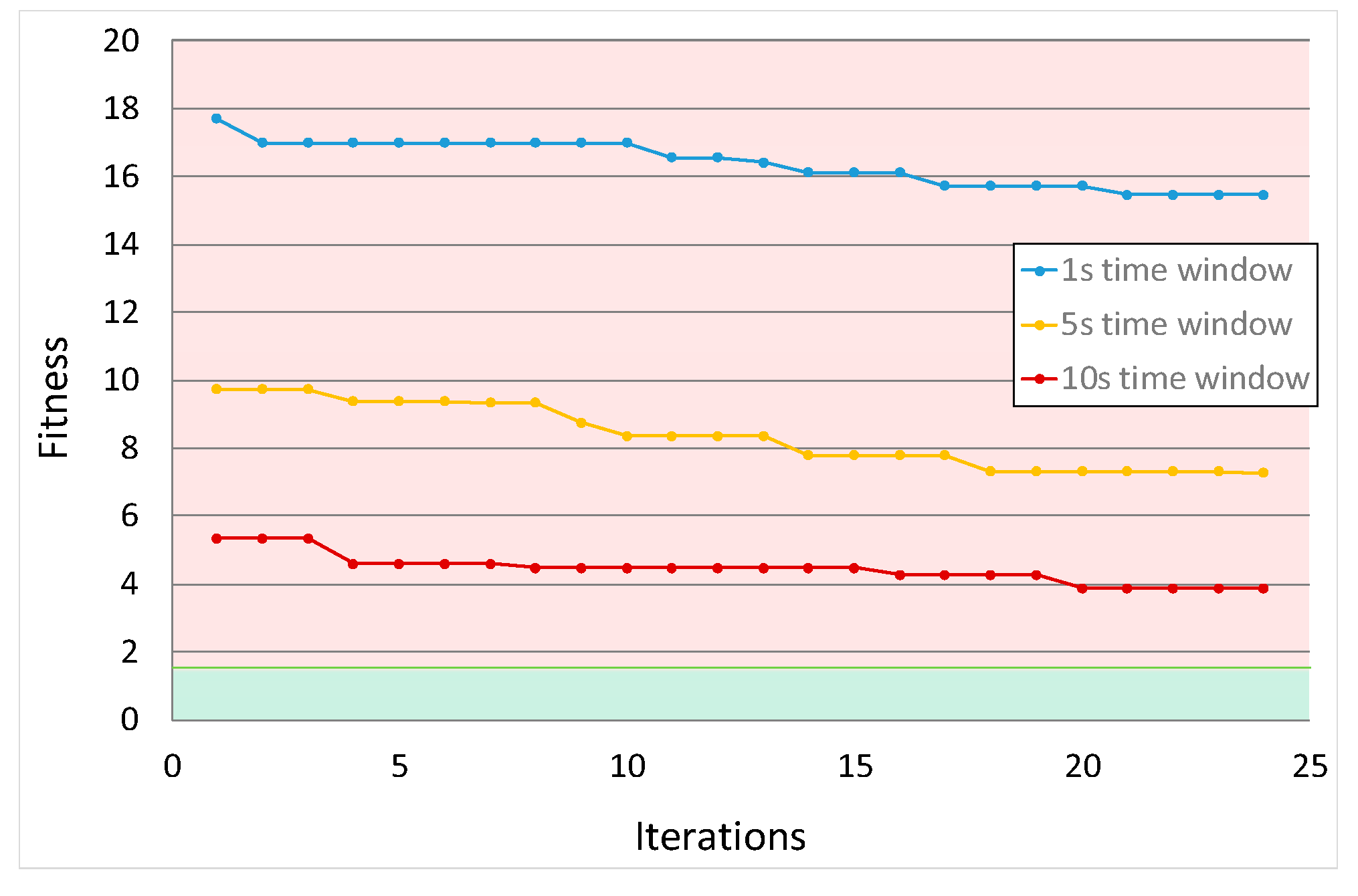

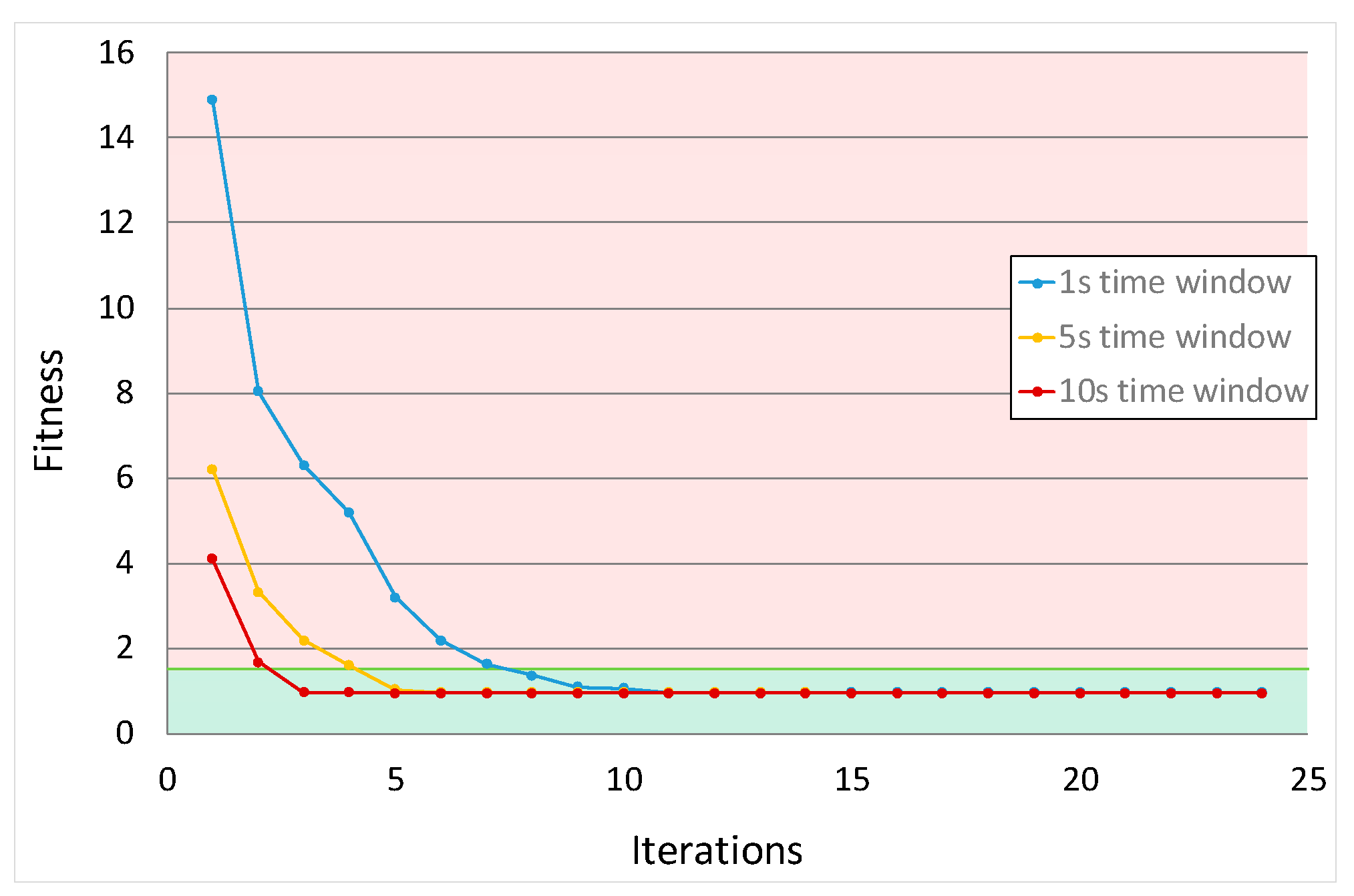

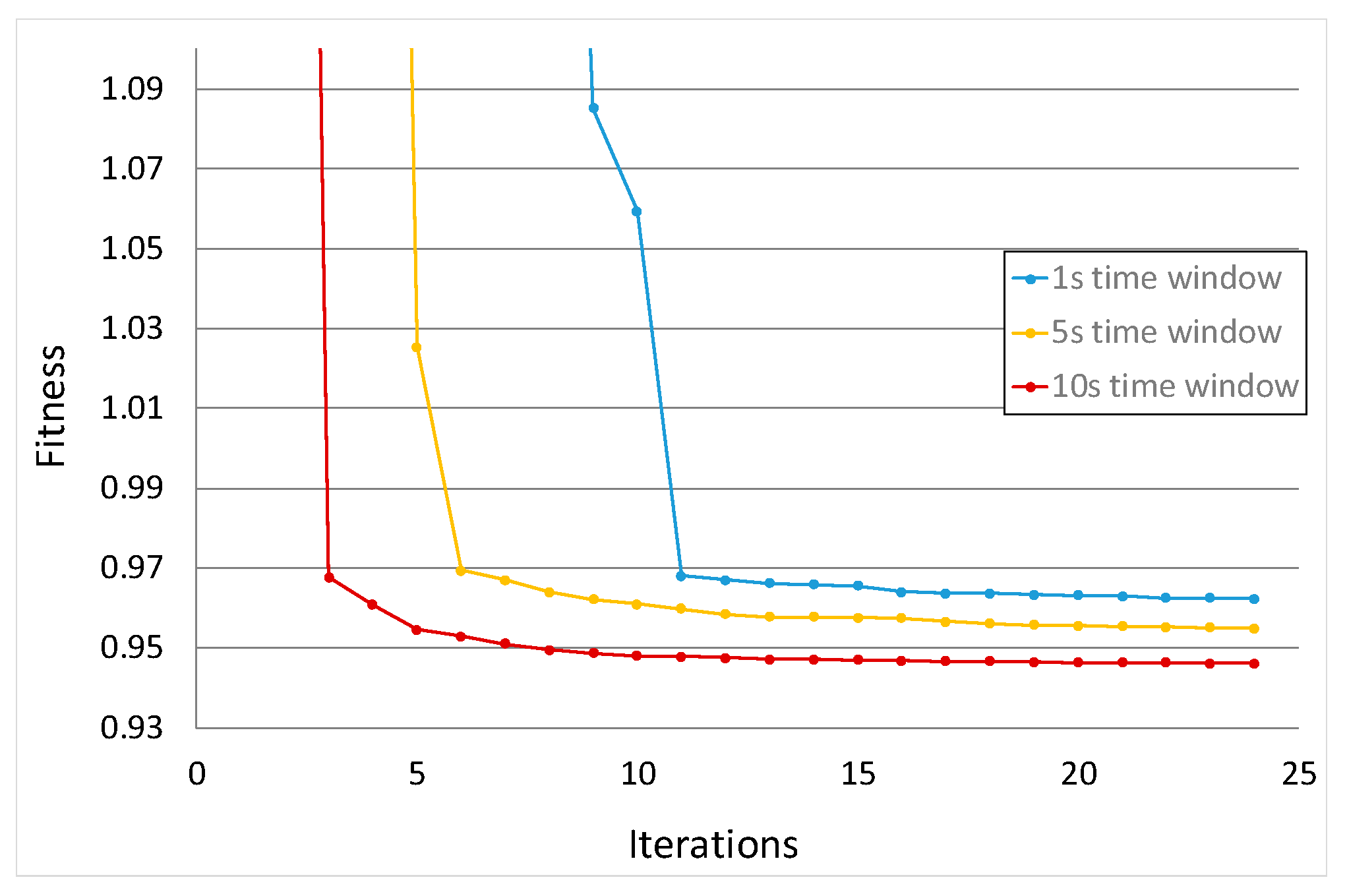

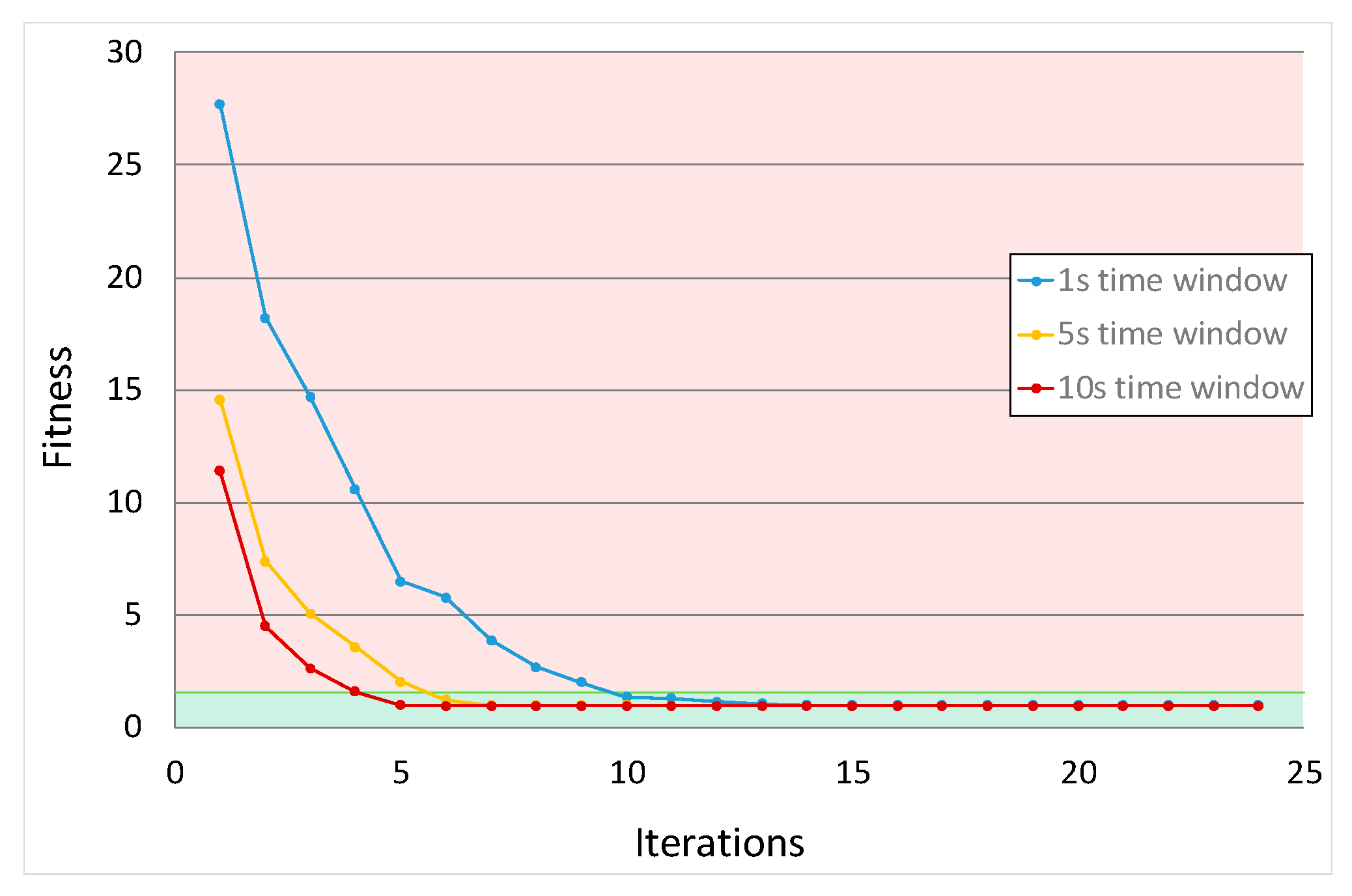

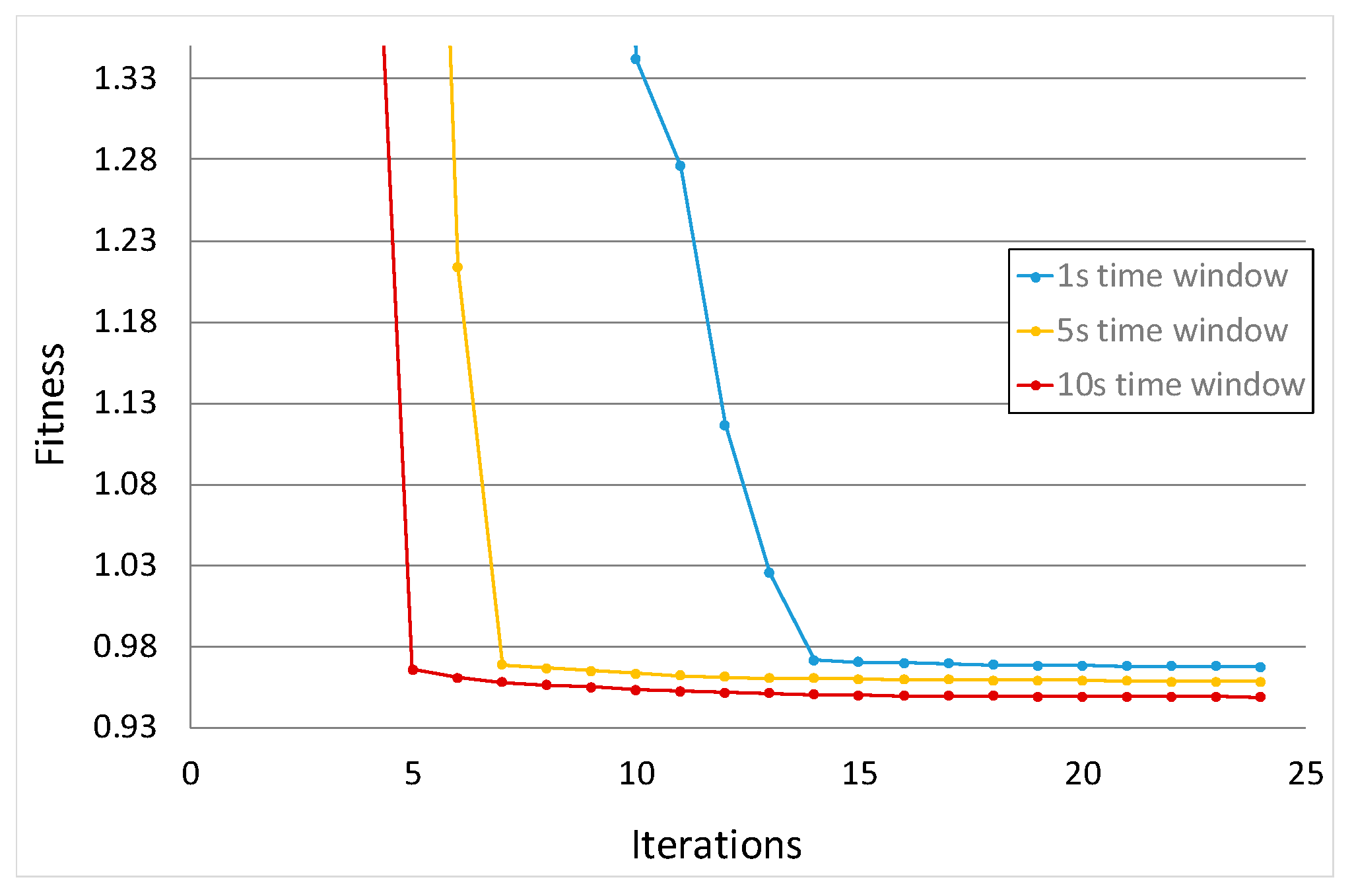

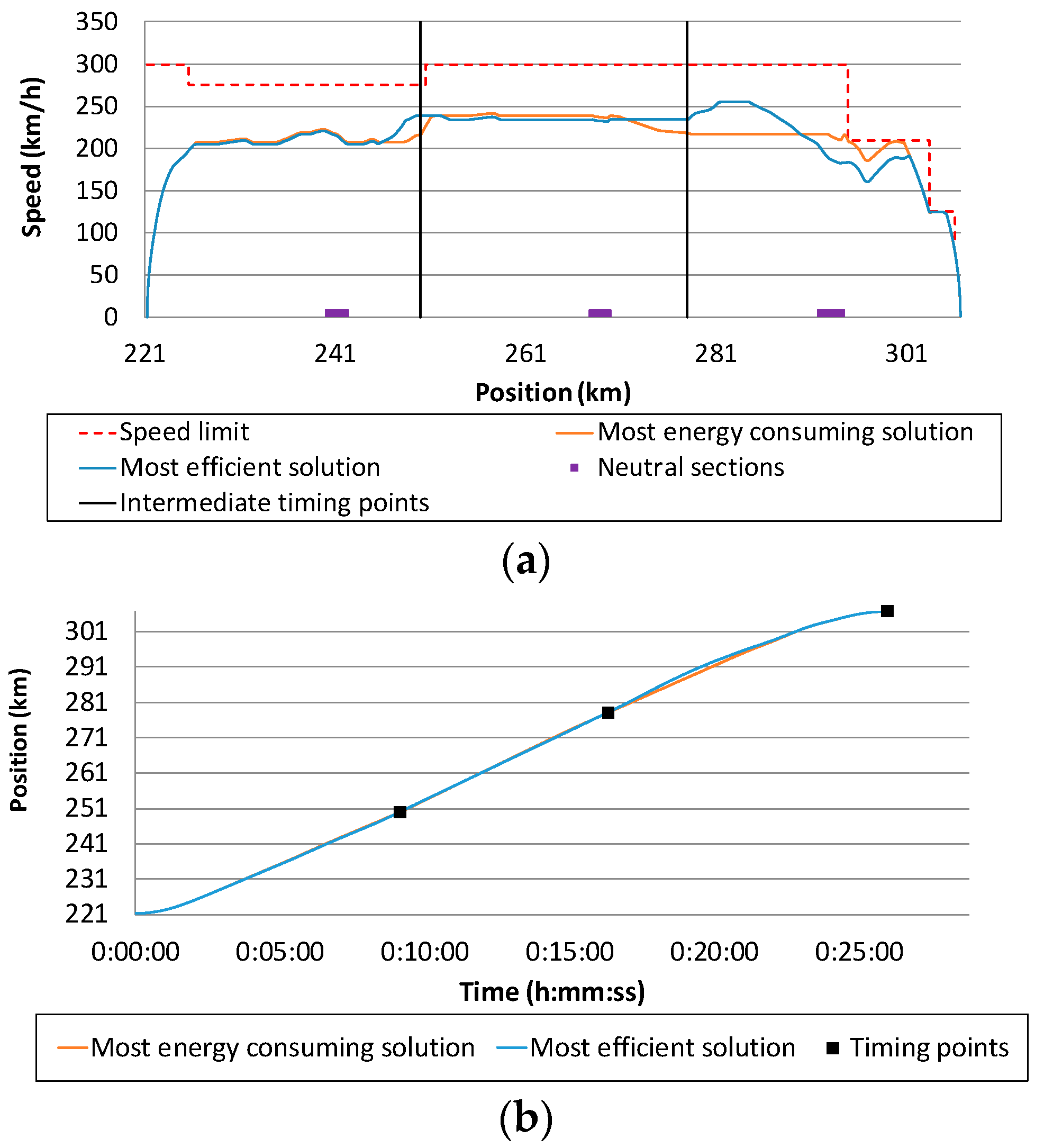

5.1. Benefits of the Proposed Optimisation Method Compared with Single Time Target Approaches

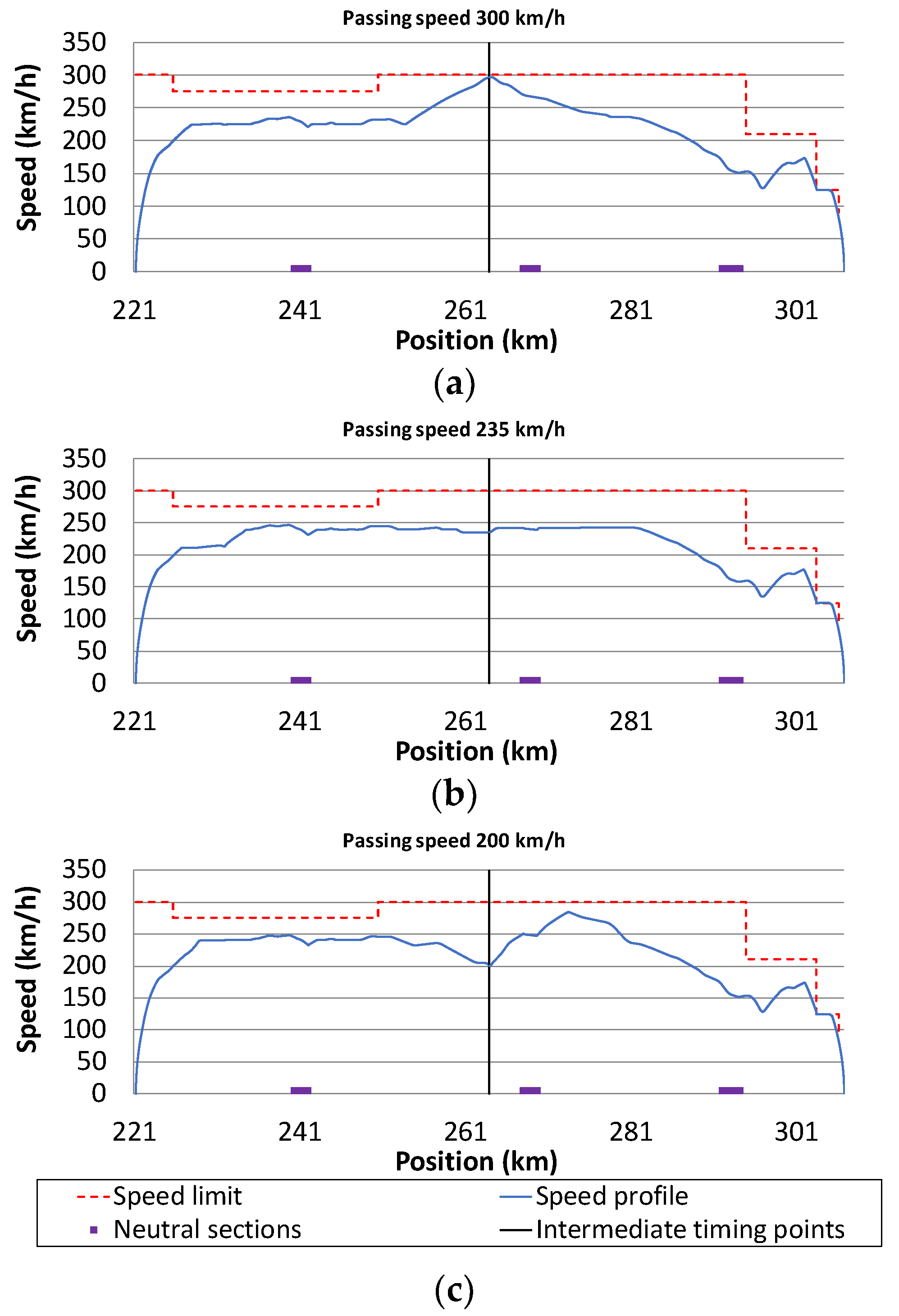

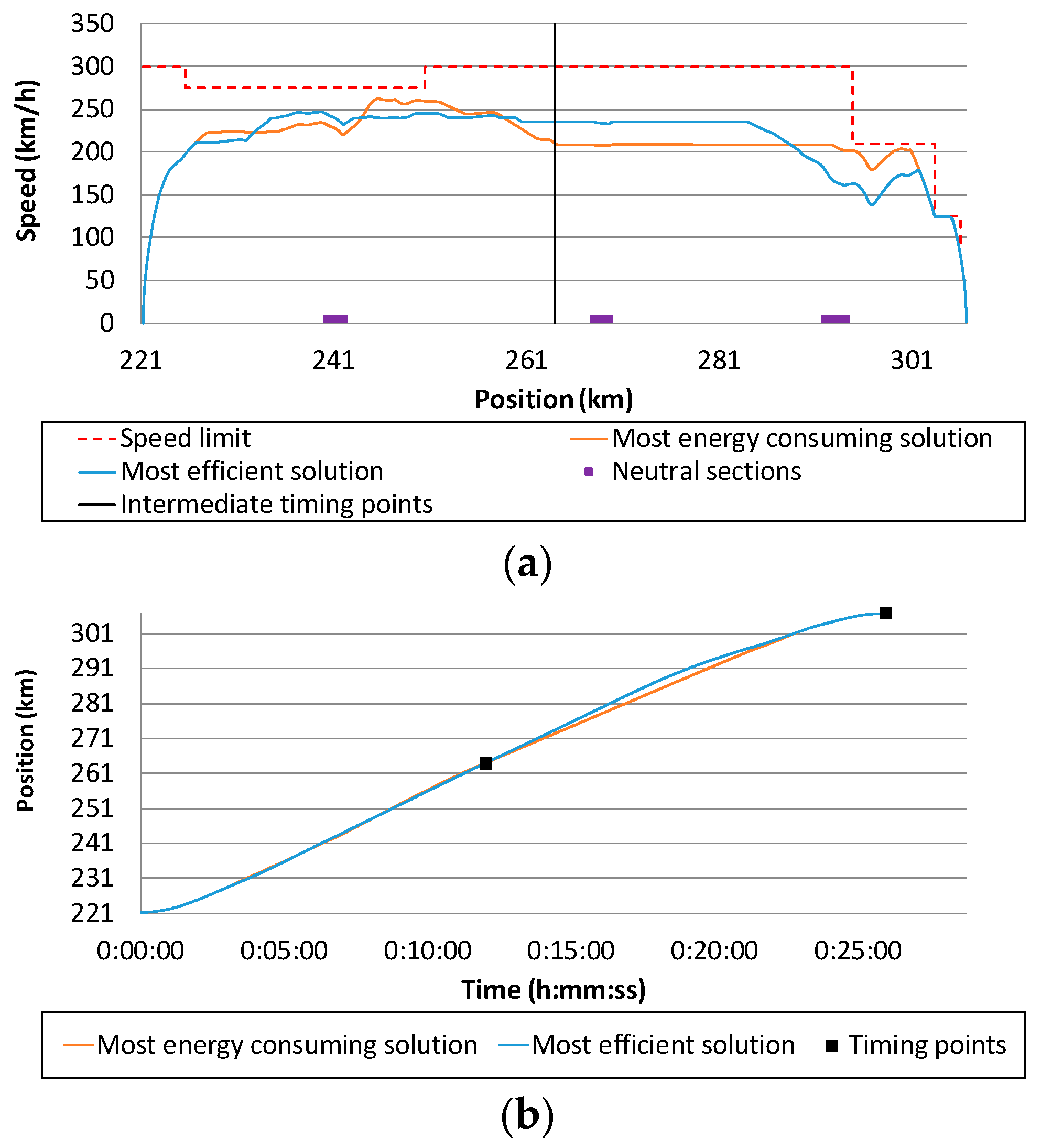

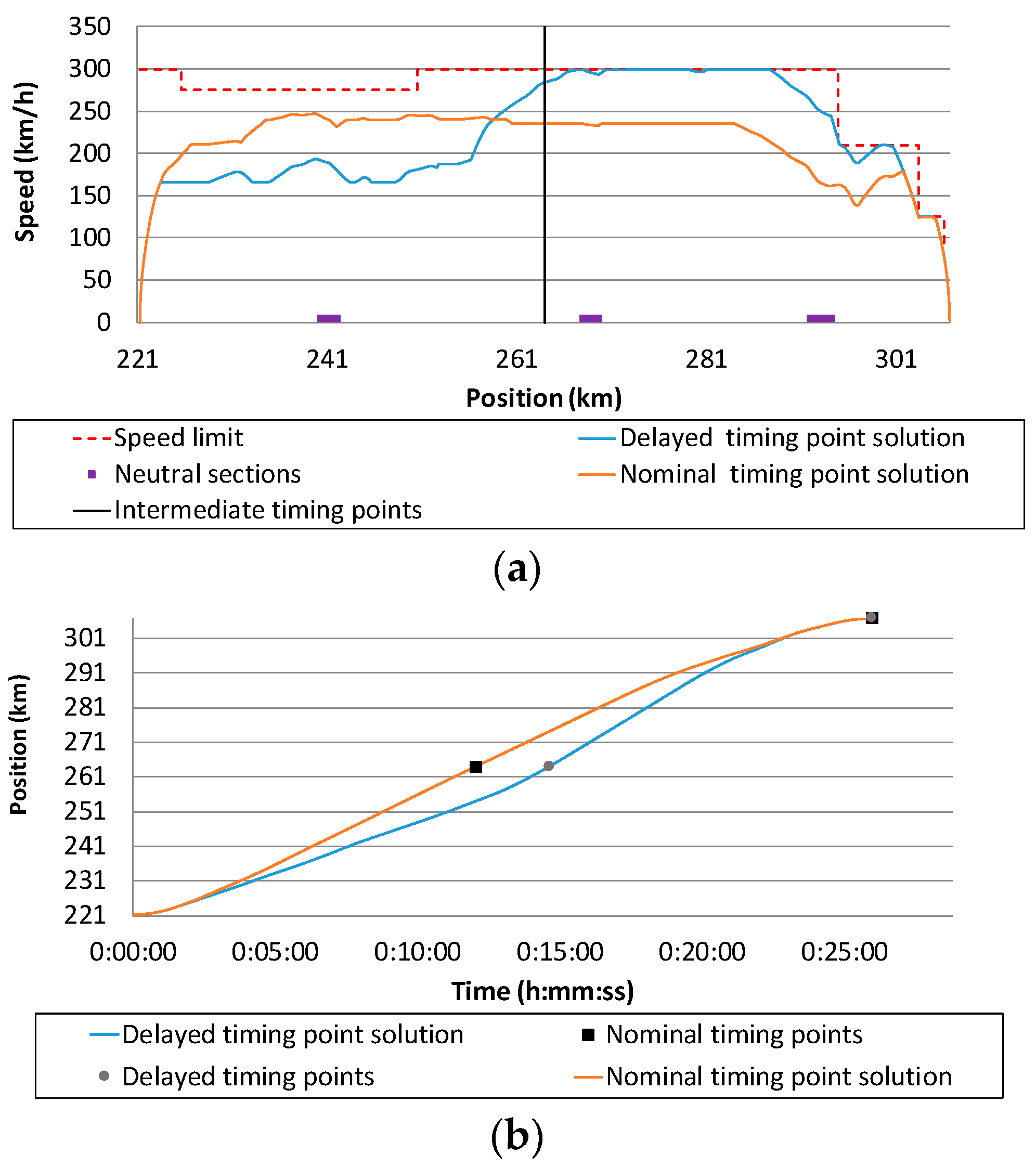

5.2. One Intermediate Timing Point

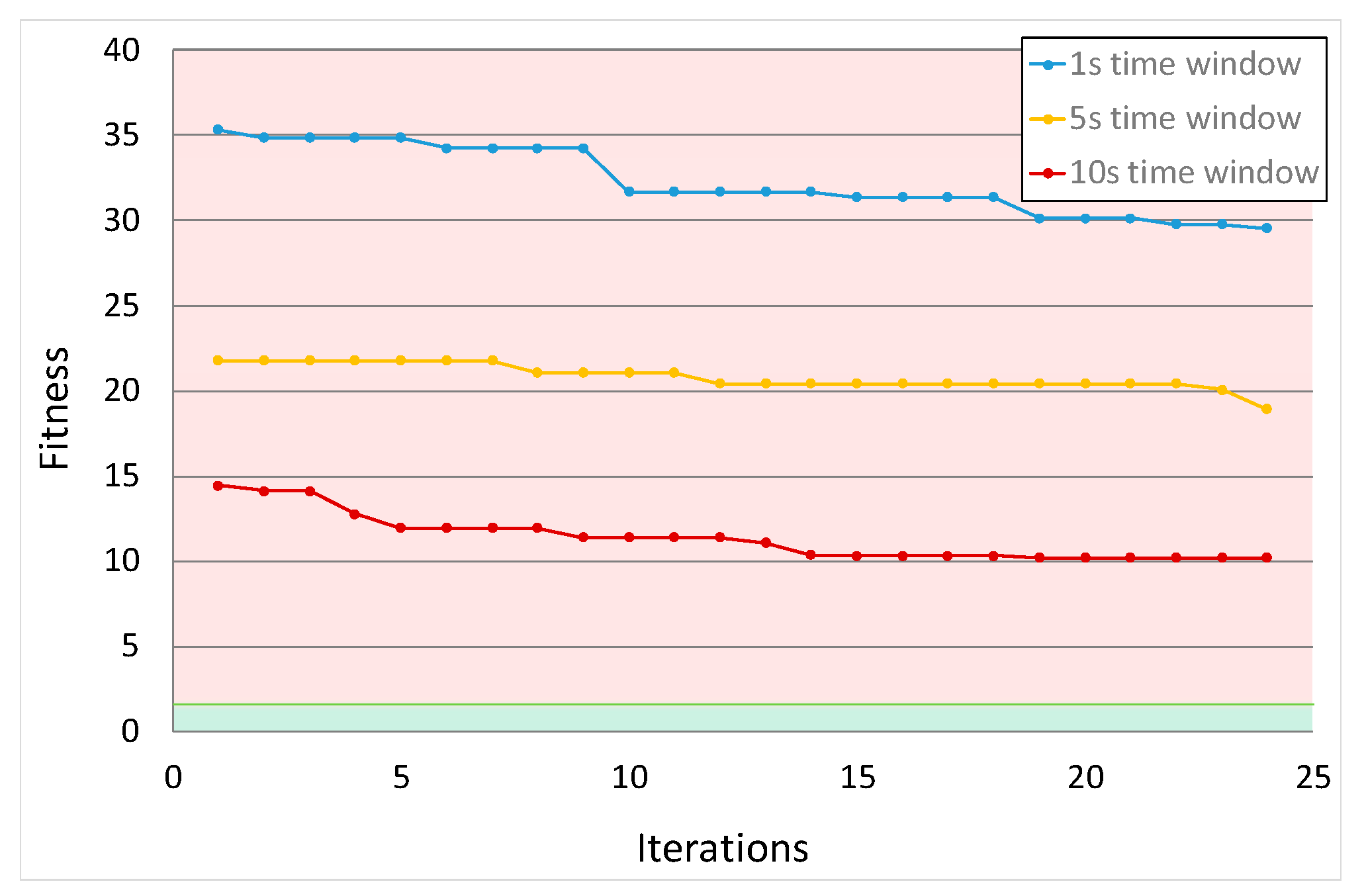

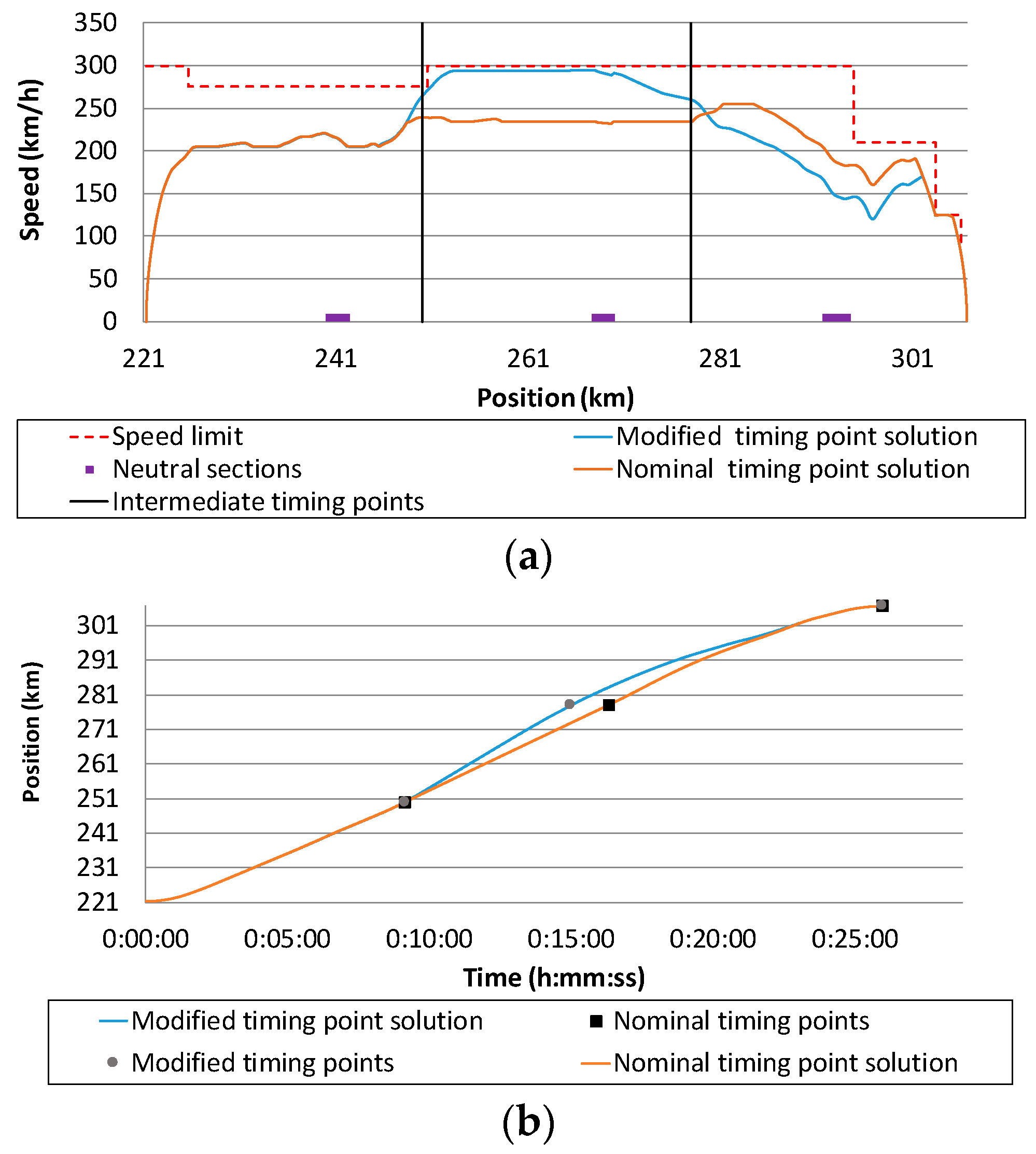

5.3. Two Intermediate Timing Points

5.4. Effect of the Target Times on the Energy Consumption

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Emery, D. Towards Automatic Train Operation for Long Distance Services: State-of-the Art and Challenges. In Proceedings of the 17th Swiss Transport Research Conference, Ascona, Switzerland, 17–19 May 2017. [Google Scholar]

- Council of the European Union. Council Directive 96/48/EC of 23 July 1996 on the Interoperability of the Trans-European High-Speed Rail System; European Union: Brussels, Belgium, 1996; pp. 6–24. [Google Scholar]

- Colla, I.; Consilvio, A.; Olmi, A.; Romano, A.; Sciutto, M. High Density—HD Using ERTMS: The Italian Solution for the Railway Traffic Management. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I CPS Europe), Palermo, Italy, 12–15 June 2018; pp. 1–6. [Google Scholar]

- TEN-T—ATO Project. ATO over ERTMS Operatinal Requirements; European Commission: Brussels, Belgium, 2016. [Google Scholar]

- ARCC Project. Automated Rail Cargo Consortium: Rail Freight Automation Research Activities to Boost Levels of Quality, Efficiency and Cost Effectiveness in All Areas of Rail Freight Operations; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- FR8RAIL III. Smart Data for Rail Freight Transport; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- X2Rail-1. Start-Up Activities for Advanced Signalling and Automation Systems; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- X2Rail-2. Enhancing Railway Signalling Systems Based on Train Satellite Positioning, On-board Safe Train Integrity, Formal Methods Approach and Standard Interfaces, Enhancing Traffic Management System Functions; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- X2Rail-3. Advanced Signalling, Automation and Communication System (IP2 and IP5)—Prototyping the future by Means of Capacity Increase, Autonomy and Flexible Communication; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- X2Rail-4. Advanced Signalling and Automation System—Completion of Activities for Enhanced Automation Systems, Train Integrity, Traffic Management Evolution and Smart Object Controllers; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Burton, A.D. Automatic train operation (ATO) specification for Thameslink. Electr. Railw. Lond. Engl. 2001 2009, 54, 188–190. [Google Scholar]

- Rio Tinto Launches the Autonomous Heavy Freight Rail Operation. Available online: http://sts.hitachirail.com/en/news/rio-tinto-launches-autonomous-heavy-freight-rail-operation (accessed on 26 October 2020).

- Villalba, M. Pioneering ATO over ETCS Level 2. Railw. Gaz. Int. 2016, 172, 107–109. [Google Scholar]

- Bienfait, B.; Zoetardt, P.; Barnard, B. Automatic Train Operation: The Mandatory Improvement for ETCS Applications. In Proceedings of the IRSE’s International Technical Conference ASPECT, London, UK, 10–12 September 2012. [Google Scholar]

- Matsuoka, K.; Kondo, M. Energy Saving Technologies for Railway Traction Motors. IEEJ Trans. Electr. Electron. Eng. 2014, 5, 278–284. [Google Scholar] [CrossRef]

- Bombardier. Aeroefficient Optimised Train Shaping; Bombardier: Hennigsdorf, Germany, 2010. [Google Scholar]

- Beusen, B.; Degraeuwe, B.; Debeuf, P. Energy savings in light rail through the optimization of heating and ventilation. Transp. Res. Part Transp. Environ. 2013, 23, 50–54. [Google Scholar] [CrossRef]

- Das, S.; Abraham, A.; Chakraborty, U.K.; Konar, A. Differential Evolution Using a Neighborhood-Based Mutation Operator. IEEE Trans. Evol. Comput. 2009, 13, 526–553. [Google Scholar] [CrossRef]

- Li, Z.; Liang, J.J.; He, X.; Shang, Z. Differential evolution with dynamic constraint-handling mechanism. In Proceedings of the IEEE Congress on Evolutionary Computation, Barcelona, 18–23 July 2010; pp. 1–8. [Google Scholar] [CrossRef]

- Cao, C.; Feng, Z. Optimal capacity allocation under random passenger demands in the high-speed rail network. Eng. Appl. Artif. Intell. 2020, 88, 103363. [Google Scholar] [CrossRef]

- Abril, M.; Salido, M.A.; Barber, F. Distributed search in railway scheduling problems. Eng. Appl. Artif. Intell. 2008, 21, 744–755. [Google Scholar] [CrossRef]

- Peña-Alcaraz, M.; Fernandez, A.; Cucala, A.P.; Ramos, A.; Pecharromán, R.R. Optimal underground timetable design based on power flow for maximizing the use of regenerative-braking energy. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2011, 226, 397–408. [Google Scholar] [CrossRef]

- Yang, X.; Li, X.; Ning, B.; Tang, T. A Survey on Energy-Efficient Train Operation for Urban Rail Transit. IEEE Trans. Intell. Transp. Syst. 2016, 17, 2–13. [Google Scholar] [CrossRef]

- Ichikawa, K. Application of Optimization Theory for Bounded State Variable Problems to the Operation of Train. Bull. JSME 1968, 11, 857–865. [Google Scholar] [CrossRef]

- Howlett, P. Existence of an Optimal Strategy for the Control of a Train; School of Mathematics Report; South Australian Inst. Technol.: Adelaide, SA, Australia, 1987. [Google Scholar]

- Howlett, P. An optimal strategy for the control of a train. J. Aust. Math. Soc. Ser. B 1990, 31, 454–471. [Google Scholar] [CrossRef]

- Khmelnitsky, E. On an optimal control problem of train operation. IEEE Trans. Autom. Control 2000, 45, 1257–1266. [Google Scholar] [CrossRef]

- Liu, R.; Golovitcher, I.M. Energy-efficient operation of rail vehicles. Transp. Res. Part Policy Pract. 2003, 37, 917–932. [Google Scholar] [CrossRef]

- Howlett, P.G.; Pudney, P.J.; Vu, X. Local energy minimization in optimal train control. Automatica 2009, 45, 2692–2698. [Google Scholar] [CrossRef]

- Albrecht, A.R.; Howlett, P.G.; Pudney, P.J.; Vu, X. Energy-efficient train control: From local convexity to global optimization and uniqueness. Automatica 2013, 49, 3072–3078. [Google Scholar] [CrossRef]

- Su, S.; Li, X.; Tang, T.; Gao, Z. A Subway Train Timetable Optimization Approach Based on Energy-Efficient Operation Strategy. IEEE Trans. Intell. Transp. Syst. 2013, 14, 883–893. [Google Scholar] [CrossRef]

- Miyatake, M.; Matsuda, K. Energy Saving Speed and Charge/Discharge Control of a Railway Vehicle with On-board Energy Storage by Means of an Optimization Model. IEEJ Trans. Electr. Electron. Eng. 2009, 4, 771–778. [Google Scholar] [CrossRef]

- Miyatake, M.; Ko, H. Optimization of Train Speed Profile for Minimum Energy Consumption. IEEJ Trans. Electr. Electron. Eng. 2010, 5, 263–269. [Google Scholar] [CrossRef]

- Su, S.; Wang, X.; Cao, Y.; Yin, J. An Energy-Efficient Train Operation Approach by Integrating the Metro Timetabling and Eco-Driving. IEEE Trans. Intell. Transp. Syst. 2020, 21, 4252–4268. [Google Scholar] [CrossRef]

- Rodrigo, E.; Tapia, S.; Mera, J.; Soler, M. Optimizing Electric Rail Energy Consumption Using the Lagrange Multiplier Technique. J. Transp. Eng. 2013, 139, 321–329. [Google Scholar] [CrossRef]

- Wang, Y.; De Schutter, B.; van den Boom, T.J.J.; Ning, B. Optimal trajectory planning for trains—A pseudospectral method and a mixed integer linear programming approach. Transp. Res. Part C Emerg. Technol. 2013, 29, 97–114. [Google Scholar] [CrossRef]

- Wang, Y.; De Schutter, B.; van den Boom, T.J.J.; Ning, B. Optimal trajectory planning for trains under fixed and moving signaling systems using mixed integer linear programming. Control Eng. Pract. 2014, 22, 44–56. [Google Scholar] [CrossRef]

- Howlett, P.G.; Milroy, I.P.; Pudney, P.J. Energy-efficient train control. Control Eng. Pract. 1994, 2, 193–200. [Google Scholar] [CrossRef]

- Domínguez, M.; Fernández, A.; Cucala, A.P.; Lukaszewicz, P. Optimal design of metro automatic train operation speed profiles for reducing energy consumption. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2011, 225, 463–474. [Google Scholar] [CrossRef]

- Scheepmaker, G.M.; Willeboordse, H.Y.; Hoogenraad, J.H.; Luijt, R.S.; Goverde, R.M.P. Comparing train driving strategies on multiple key performance indicators. J. Rail Transp. Plan. Manag. 2020, 13, 100163. [Google Scholar] [CrossRef]

- Li, K.; Gao, Z. An improved equation model for the train movement. Simul. Model. Pract. Theory 2007, 15, 1156–1162. [Google Scholar] [CrossRef]

- Figueira, G.; Almada-Lobo, B. Hybrid simulation–optimization methods: A taxonomy and discussion. Simul. Model. Pract. Theory 2014, 46, 118–134. [Google Scholar] [CrossRef]

- De Cuadra, F.; Fernandez, A.; de Juan, J.; Herrero, M.A. Energy-Saving Automatic Optimisation of Train Speed Commands Using Direct Search Techniques; Wessex Institute of Technology: Southampton, UK, 1996; Volume 10. [Google Scholar]

- Zhao, N.; Roberts, C.; Hillmansen, S.; Tian, Z.; Weston, P.; Chen, L. An integrated metro operation optimization to minimize energy consumption. Transp. Res. Part C Emerg. Technol. 2017, 75, 168–182. [Google Scholar] [CrossRef]

- Tian, Z.; Weston, P.; Zhao, N.; Hillmansen, S.; Roberts, C.; Chen, L. System energy optimisation strategies for metros with regeneration. Transp. Res. Part C Emerg. Technol. 2017, 75, 120–135. [Google Scholar] [CrossRef]

- Acikbas, S.; Soylemez, M.T. Coasting point optimisation for mass rail transit lines using artificial neural networks and genetic algorithms. IET Electr. Power Appl. 2008, 2, 172–182. [Google Scholar] [CrossRef]

- Yin, J.; Su, S.; Xun, J.; Tang, T.; Liu, R. Data-driven approaches for modeling train control models: Comparison and case studies. ISA Trans. 2019. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.S.; Sim, S.S. Optimising train movements through coast control using genetic algorithms. Electr. Power Appl. IEE Proc. 1997, 144, 65–73. [Google Scholar] [CrossRef]

- Wong, K.K.; Ho, T.K. Coast control for mass rapid transit railways with searching methods. IEE Proc. Electr. Power Appl. 2004, 151, 365–376. [Google Scholar] [CrossRef]

- Bocharnikov, Y.V.; Tobias, A.M.; Roberts, C. Reduction of Train and Net Energy Consumption Using Genetic Algorithms for Trajectory Optimisation. In Proceedings of the IET Conference on Railway Traction Systems (RTS 2010), Birmingham, UK, 13–15 April 2010; pp. 1–5. [Google Scholar]

- Lechelle, S.A.; Mouneimne, Z.S. OptiDrive: A Practical Approach for the Calculation of Energy-Optimised Operating Speed Profiles. In Proceedings of the IET Conference on Railway Traction Systems, Birmingham, UK, 13–15 April 2010; p. 23. [Google Scholar]

- Li, X.; Lo, H.K. An energy-efficient scheduling and speed control approach for metro rail operations. Transp. Res. Part B Methodol. 2014, 64, 73–89. [Google Scholar] [CrossRef]

- Bocharnikov, Y.V.; Tobias, A.M.; Roberts, C.; Hillmansen, S.; Goodman, C.J. Optimal driving strategy for traction energy saving on DC suburban railways. IET Electr. Power Appl. 2007, 1, 675–682. [Google Scholar] [CrossRef]

- Cucala, A.P.; Fernández, A.; Sicre, C.; Domínguez, M. Fuzzy optimal schedule of high speed train operation to minimize energy consumption with uncertain delays and driver’s behavioral response. Eng. Appl. Artif. Intell. 2012, 25, 1548–1557. [Google Scholar] [CrossRef]

- Sicre, C.; Cucala, A.P.; Fernández-Cardador, A. Real time regulation of efficient driving of high speed trains based on a genetic algorithm and a fuzzy model of manual driving. Eng. Appl. Artif. Intell. 2014, 29, 79–92. [Google Scholar] [CrossRef]

- Lu, S.; Hillmansen, S.; Ho, T.K.; Roberts, C. Single-Train Trajectory Optimization. IEEE Trans. Intell. Transp. Syst. 2013, 14, 743–750. [Google Scholar] [CrossRef]

- Kim, Y.-G.; Jeon, C.-S.; Kim, S.-W.; Park, T.-W. Operating speed pattern optimization of railway vehicles with differential evolution algorithm. Int. J. Automot. Technol. 2013, 14, 903–911. [Google Scholar] [CrossRef]

- Ke, B.-R.; Lin, C.-L.; Yang, C.-C. Optimisation of train energy-efficient operation for mass rapid transit systems. IET Intell. Transp. Syst. 2012, 6, 58–66. [Google Scholar] [CrossRef]

- Xie, T.; Wang, S.; Zhao, X.; Zhang, Q. Optimization of Train Energy-Efficient Operation Using Simulated Annealing Algorithm. In Proceedings of the International Conference on Intelligent Computing for Sustainable Energy and Environment, Shanghai, China, 12–13 September 2012; Li, K., Li, S., Li, D., Niu, Q., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 351–359, ISBN 978-3-642-37104-2. [Google Scholar]

- Domínguez, M.; Fernández-Cardador, A.; Cucala, A.P.; Gonsalves, T.; Fernández, A. Multi objective particle swarm optimization algorithm for the design of efficient ATO speed profiles in metro lines. Eng. Appl. Artif. Intell. 2014, 29, 43–53. [Google Scholar] [CrossRef]

- Fernandez-Rodriguez, A.; Fernandez-Cardador, A.; Cucala, A.P.; Dominguez, M.; Gonsalves, T. Design of Robust and Energy-Efficient ATO Speed Profiles of Metropolitan Lines Considering Train Load Variations and Delays. IEEE Trans. Intell. Transp. Syst. 2015, 16, 2061–2071. [Google Scholar] [CrossRef]

- Carvajal-Carreño, W.; Cucala, A.P.; Fernández-Cardador, A. Optimal design of energy-efficient ATO CBTC driving for metro lines based on NSGA-II with fuzzy parameters. Eng. Appl. Artif. Intell. 2014, 36, 164–177. [Google Scholar] [CrossRef]

- Fernández-Rodríguez, A.; Fernández-Cardador, A.; Cucala, A.P. Balancing energy consumption and risk of delay in high speed trains: A three-objective real-time eco-driving algorithm with fuzzy parameters. Transp. Res. Part C Emerg. Technol. 2018, 95, 652–678. [Google Scholar] [CrossRef]

- Pudney, P.; Howlett, P.G.; Albrecht, A.; Coleman, D.; Vu, X.; Koelewijn, J. Optimal Driving Strategies with Intermediate Timing Points. Ph.D. Thesis, International Heavy Haul Association, Calgary, UK, 2011. [Google Scholar]

- Albrecht, T.; Binder, A.; Gassel, C. Applications of real-time speed control in rail-bound public transportation systems. IET Intell. Transp. Syst. 2013, 7, 305–314. [Google Scholar] [CrossRef]

- Quaglietta, E.; Pellegrini, P.; Goverde, R.M.P.; Albrecht, T.; Jaekel, B.; Marlière, G.; Rodriguez, J.; Dollevoet, T.; Ambrogio, B.; Carcasole, D.; et al. The ON-TIME real-time railway traffic management framework: A proof-of-concept using a scalable standardised data communication architecture. Transp. Res. Part C Emerg. Technol. 2016, 63, 23–50. [Google Scholar] [CrossRef]

- Albrecht, A.R.; Howlett, P.G.; Pudney, P.J.; Vu, X.; Zhou, P. Energy-efficient train control: The two-train separation problem on level track. J. Rail Transp. Plan. Manag. 2015, 5, 163–182. [Google Scholar] [CrossRef]

- Albrecht, A.; Howlett, P.; Pudney, P.; Vu, X.; Zhou, P. The two-train separation problem on non-level track—Driving strategies that minimize total required tractive energy subject to prescribed section clearance times. Transp. Res. Part B Methodol. 2018, 111, 135–167. [Google Scholar] [CrossRef]

- Wang, P.; Goverde, R.M.P. Multi-train trajectory optimization for energy efficiency and delay recovery on single-track railway lines. Transp. Res. Part B Methodol. 2017, 105, 340–361. [Google Scholar] [CrossRef]

- Wang, P.; Goverde, R.M.P. Multiple-phase train trajectory optimization with signalling and operational constraints. Transp. Res. Part C Emerg. Technol. 2016, 69, 255–275. [Google Scholar] [CrossRef]

- Wang, P.; Goverde, R.M.P. Two-Train Trajectory Optimization with a Green-Wave Policy. Transp. Res. Rec. J. Transp. Res. Board 2016, 2546, 112–120. [Google Scholar] [CrossRef]

- Coello Coello, C.A. Theoretical and numerical constraint-handling techniques used with evolutionary algorithms: A survey of the state of the art. Comput. Methods Appl. Mech. Eng. 2002, 191, 1245–1287. [Google Scholar] [CrossRef]

- Mezura-Montes, E.; Coello Coello, C.A. Constraint-handling in nature-inspired numerical optimization: Past, present and future. Swarm Evol. Comput. 2011, 1, 173–194. [Google Scholar] [CrossRef]

- Baeck, T.; Fogel, D.B.; Michalewicz, Z. Handbook of Evolutionary Computation; CRC Press: Boca Raton, FL, USA, 1997; ISBN 978-1-4200-5038-7. [Google Scholar]

- Powell, D.; Skolnick, M.M. Using Genetic Algorithms in Engineering Design Optimization with Non-Linear Constraints. In Proceedings of the 5th International Conference on Genetic Algorithms, Urbana-Champaign, IL, USA, 17–21 July 1993; Morgan Kaufmann Publishers Inc.: San Francisco, CA, USA, 1993; pp. 424–431. [Google Scholar]

- Deb, K. An efficient constraint handling method for genetic algorithms. Comput. Methods Appl. Mech. Eng. 2000, 186, 311–338. [Google Scholar] [CrossRef]

- Brest, J.; Zumer, V.; Maucec, M.S. Self-Adaptive Differential Evolution Algorithm in Constrained Real-Parameter Optimization. In Proceedings of the 2006 IEEE International Conference on Evolutionary Computation, Vancouver, BC, Canada, 16–21 July 2006; pp. 215–222. [Google Scholar]

- Zielinski, K.; Laur, R. Constrained Single-Objective Optimization Using Differential Evolution. In Proceedings of the 2006 IEEE International Conference on Evolutionary Computation, Vancouver, BC, Canada, 16–21 July 2006; pp. 223–230. [Google Scholar]

- Mezura-Montes, E.; Velázquez-Reyes, J.; Coello Coello, C.A. Promising Infeasibility and Multiple Offspring Incorporated to Differential Evolution for Constrained Optimization. In Proceedings of the 7th Annual Conference on Genetic and Evolutionary Computation, Washington, DC, USA, 25–28 June 2005; ACM: New York, NY, USA, 2005; pp. 225–232. [Google Scholar]

- Kim, D.G.; Husbands, P. Landscape Changes and the Performance of Mapping Based Constraint Handling Methods. In Parallel Problem Solving from Nature—PPSN V; Eiben, A.E., Bäck, T., Schoenauer, M., Schwefel, H.-P., Eds.; Springer: Berlin/Heidelberg, Germany, 1998; pp. 221–229. [Google Scholar]

- Kim, D.G.; Husbands, P. Mapping Based Constraint Handling for Evolutionary Search; Thurston’s Circle Packing and Grid Generation. In Adaptive Computing in Design and Manufacture; Parmee, I.C., Ed.; Springer: London, UK, 1998; pp. 161–173. [Google Scholar]

- Sicre, C.; Cucala, A.P.; Fernández, A.; Lukaszewicz, P. Modeling and optimizing energy-efficient manual driving on high-speed lines. IEEJ Trans. Electr. Electron. Eng. 2012, 7, 633–640. [Google Scholar] [CrossRef]

- Storn, R.; Price, K. Differential Evolution—A Simple and Efficient Heuristic for global Optimization over Continuous Spaces. J. Glob. Optim. 1997, 11, 341–359. [Google Scholar] [CrossRef]

- Das, S.; Suganthan, P.N. Differential Evolution: A Survey of the State-of-the-Art. IEEE Trans. Evol. Comput. 2011, 15, 4–31. [Google Scholar] [CrossRef]

- Das, S.; Mullick, S.S.; Suganthan, P.N. Recent advances in differential evolution—An updated survey. Swarm Evol. Comput. 2016, 27, 1–30. [Google Scholar] [CrossRef]

- Fernández-Rodríguez, A.; Fernández-Cardador, A.; Cucala, A.P. Real time eco-driving of high speed trains by simulation-based dynamic multi-objective optimization. Simul. Model. Pract. Theory 2018, 84, 50–68. [Google Scholar] [CrossRef]

- Wong, K.K.; Ho, T.K. Dynamic coast control of train movement with genetic algorithm. Intern J. Syst. Sci. 2004, 35, 835–846. [Google Scholar] [CrossRef]

- Wong, K.K.; Ho, T.K. Coast Control of Train Movement with Genetic Algorithm. In Proceedings of the the 2003 Congress on Evolutionary Computation, CEC ’03, Canberra, Australia, 8–12 December 2003; IEEE: New York, NY, USA, 2003; Volume 2, pp. 1280–1287. [Google Scholar]

- Yang, L.; Li, K.; Gao, Z.; Li, X. Optimizing trains movement on a railway network. Omega 2012, 40, 619–633. [Google Scholar] [CrossRef]

| Population Size | Scaling Factor ( ) | Crossover Rate ( ) | Number of Sections in ( ) | Number of Iterations |

|---|---|---|---|---|

| 80 | 0.5 | 0.9 | 4 | 24 |

| Population Size | Elite Group Size | Number of Crossover | Number of Mutations | Number of Sections in Cm ( ) | Number of Iterations |

|---|---|---|---|---|---|

| 120 | 40 | 26 | 52 | 4 | 24 |

| Location of Timing Point | Target Time |

|---|---|

| 264 km | 00:12:03 |

| 306.7 km | 00:26:00 |

| Passing Speed (km/h) | Passing Time | Arrival Time | Energy Consumption (MWh) | Difference with Minimum Consumption |

|---|---|---|---|---|

| 300 | 00:12:03 | 00:26:00 | 0.955 | 0.13 % |

| 235 | 00:12:03 | 00:26:00 | 0.954 | 0.00 % |

| 200 | 00:12:03 | 00:26:00 | 0.959 | 0.54 % |

| Location of Timing Point | Target Time |

|---|---|

| 250 km | 00:09:10 |

| 278 km | 00:16:20 |

| 306.7 km | 00:26:00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernández-Rodríguez, A.; Cucala, A.P.; Fernández-Cardador, A. An Eco-Driving Algorithm for Interoperable Automatic Train Operation. Appl. Sci. 2020, 10, 7705. https://doi.org/10.3390/app10217705

Fernández-Rodríguez A, Cucala AP, Fernández-Cardador A. An Eco-Driving Algorithm for Interoperable Automatic Train Operation. Applied Sciences. 2020; 10(21):7705. https://doi.org/10.3390/app10217705

Chicago/Turabian StyleFernández-Rodríguez, Adrián, Asunción P. Cucala, and Antonio Fernández-Cardador. 2020. "An Eco-Driving Algorithm for Interoperable Automatic Train Operation" Applied Sciences 10, no. 21: 7705. https://doi.org/10.3390/app10217705

APA StyleFernández-Rodríguez, A., Cucala, A. P., & Fernández-Cardador, A. (2020). An Eco-Driving Algorithm for Interoperable Automatic Train Operation. Applied Sciences, 10(21), 7705. https://doi.org/10.3390/app10217705