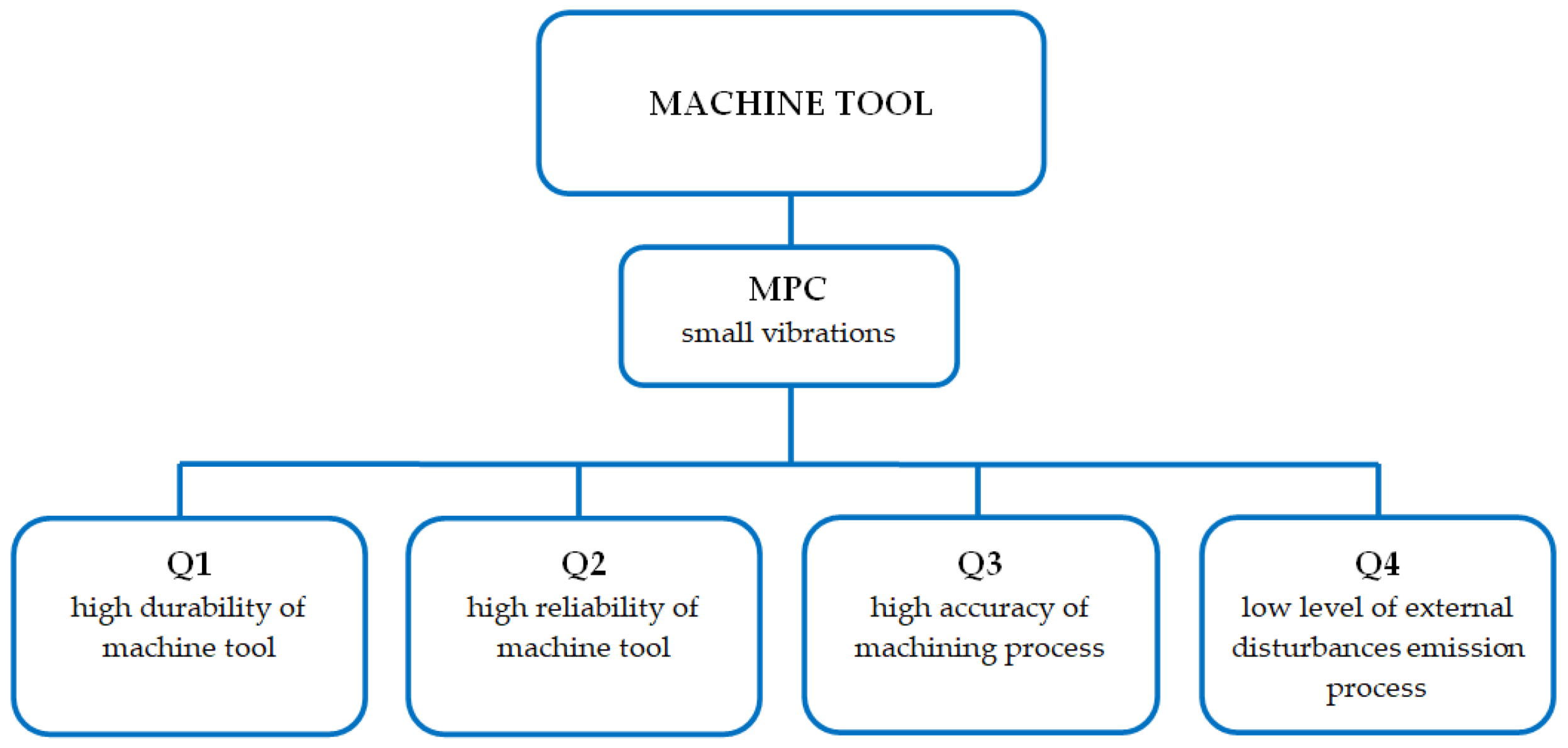

The Design Development of the Sliding Table Saw Towards Improving Its Dynamic Properties

Abstract

1. Introduction

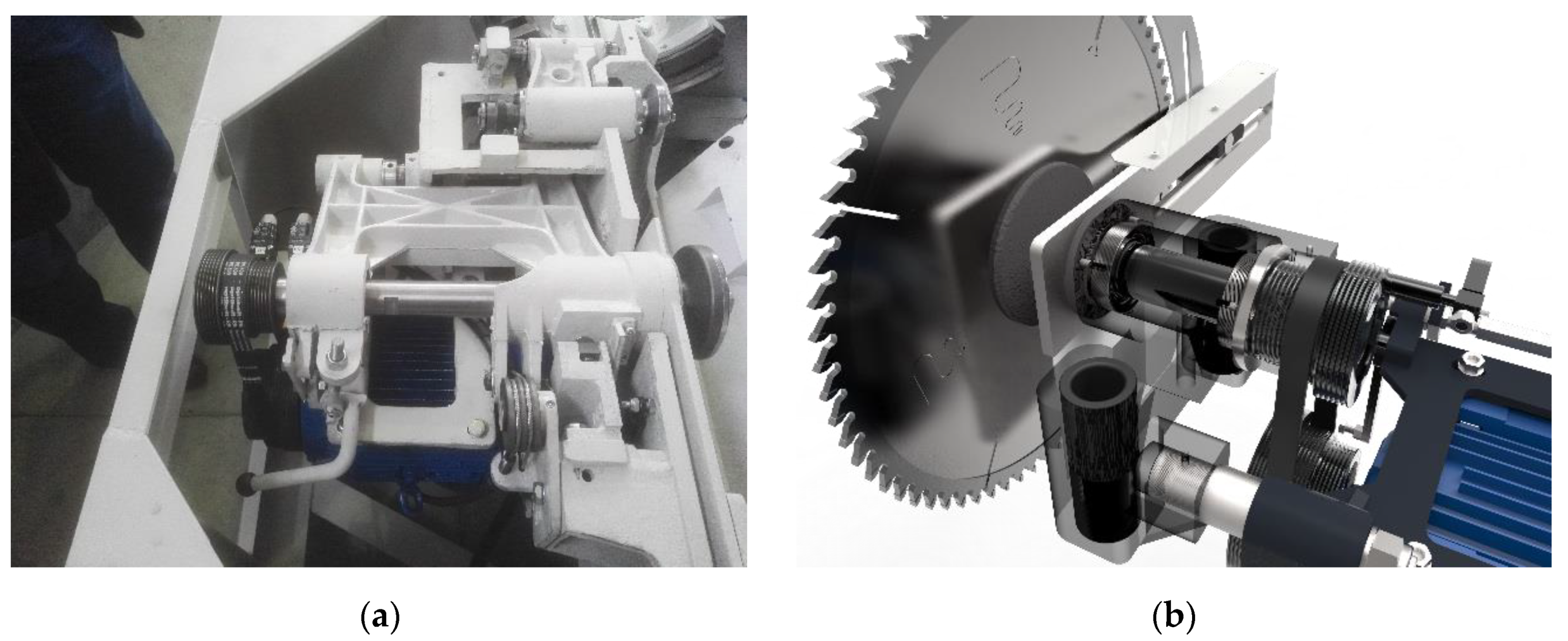

2. Spindle and Main Driving System

2.1. Design Variants of Main Spindles

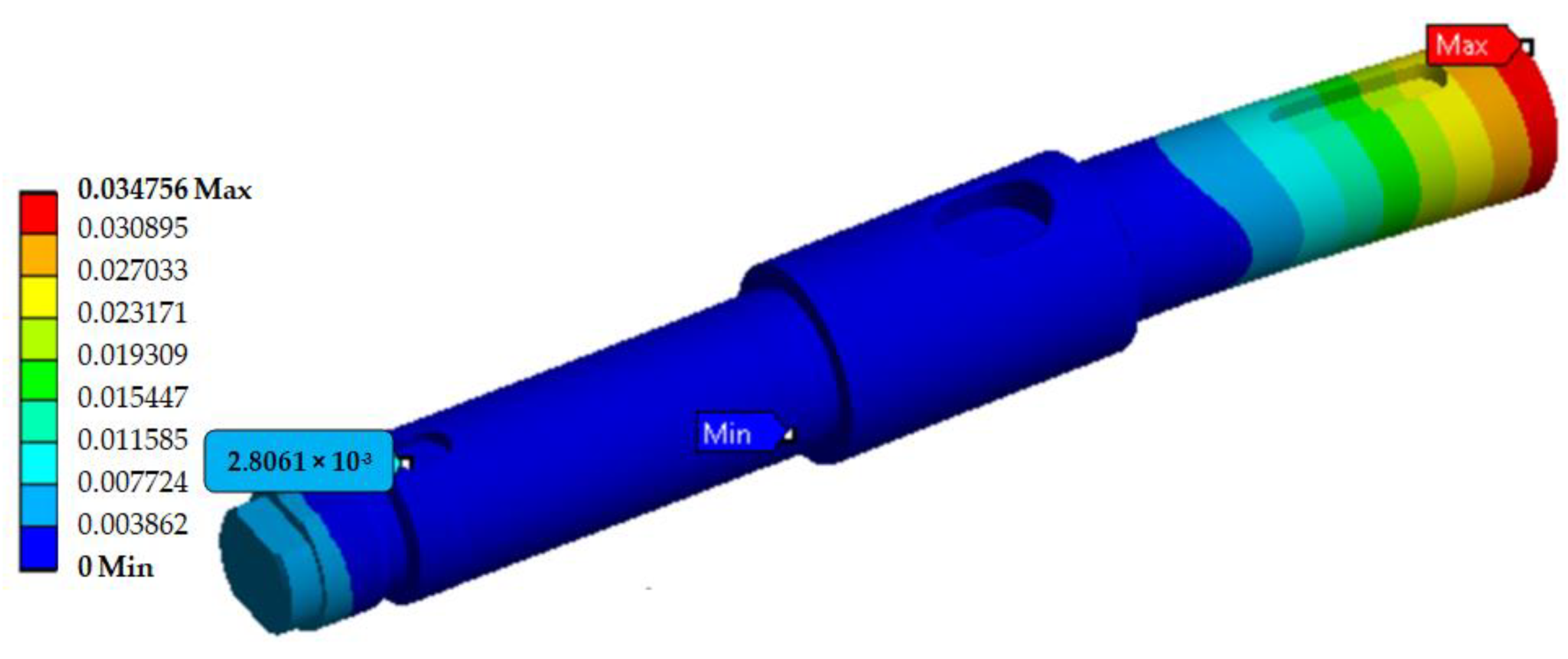

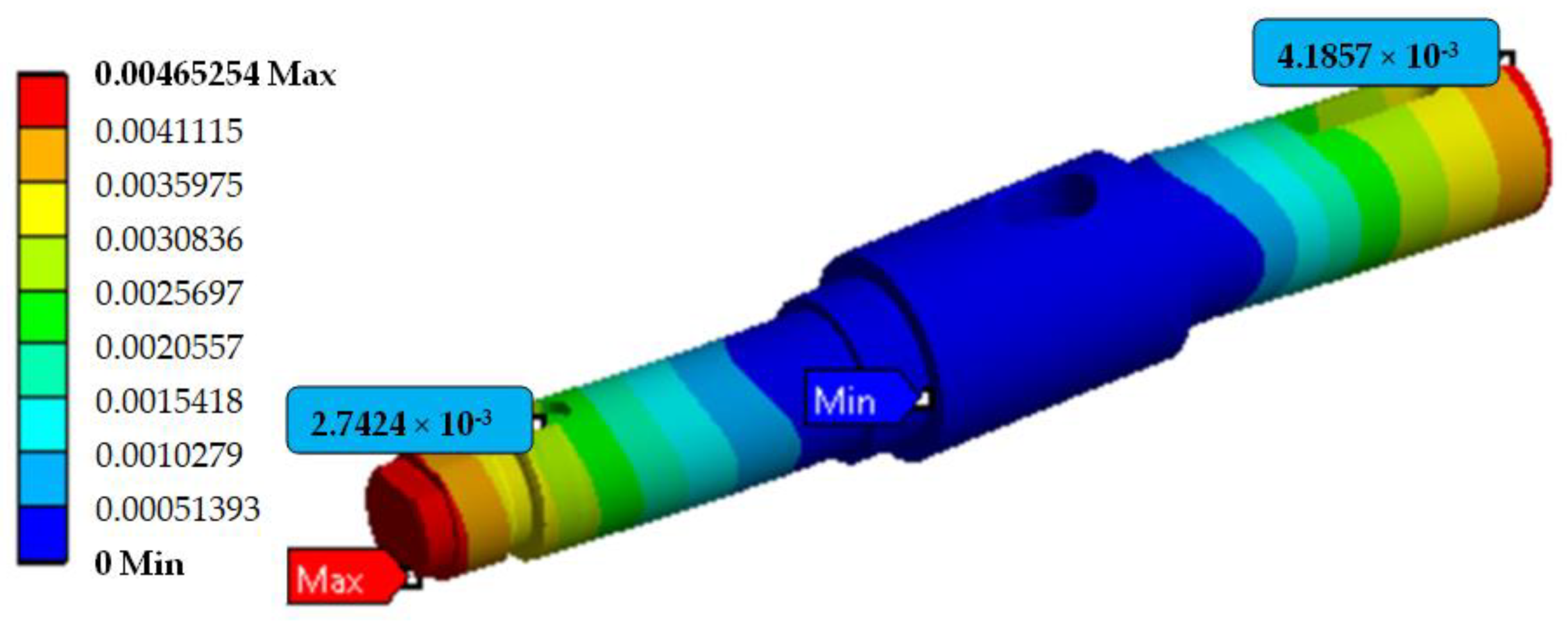

2.2. Static and Dynamical Properties of Spindles

3. Dynamic Properties of the Machine Tool

3.1. Dynamic Properties of the Main Driving System

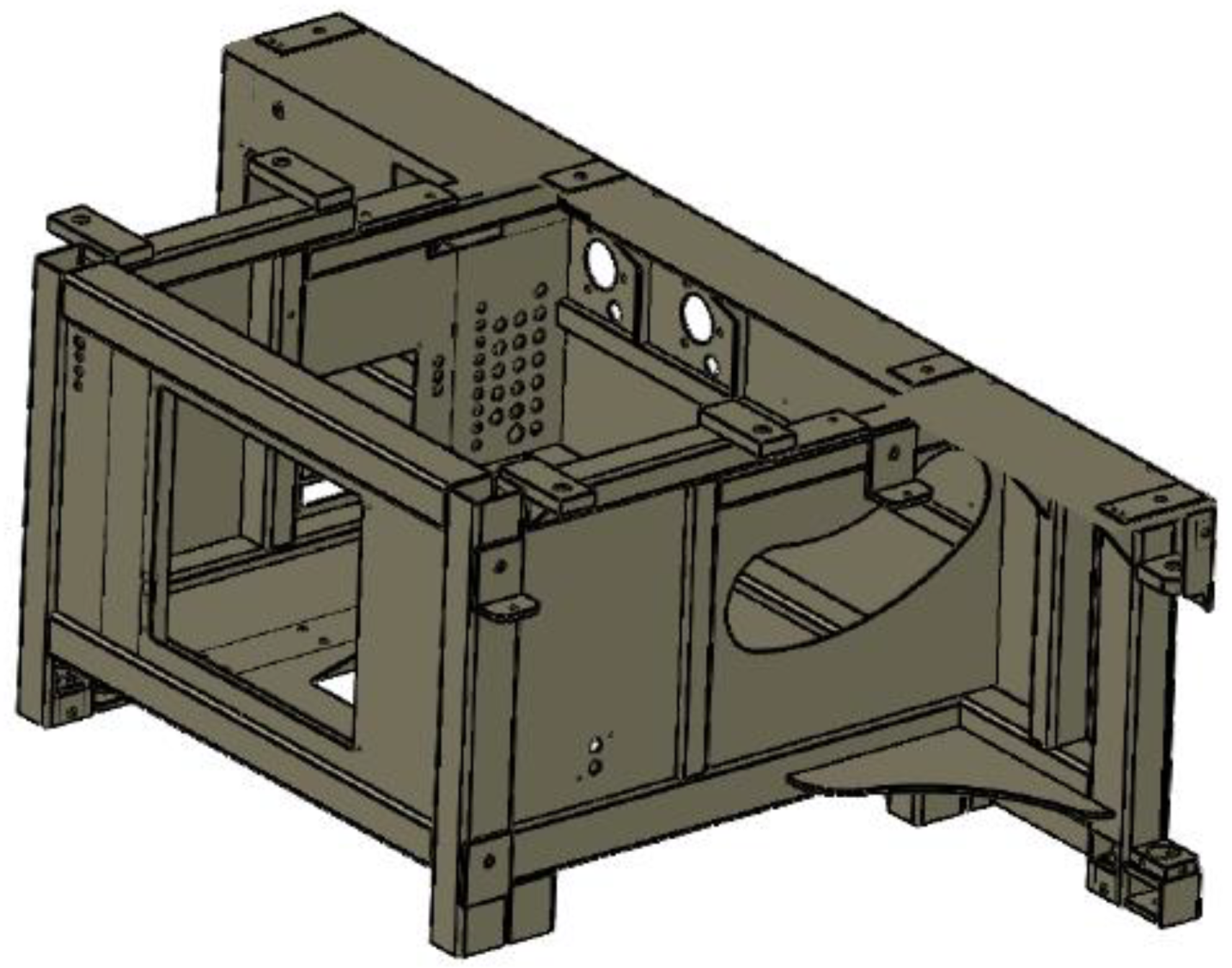

3.2. Dynamic Properties of the Machine Tool Body

4. Conclusions

- In modern design solutions of sliding table saws, the main circular saw blades are clamped by means of collars on spindles with a short support spacing with a ratio of the supports spacing L to the inner diameter of the front bearing d of about 3. It ought to be emphasized, that excessive increase in the diameter of the front bearing d and simultaneous striving for the optimum support spacing is not possible with the sliding table saws, as every manufacturer aims for the smallest possible dimensions of the cutting unit.

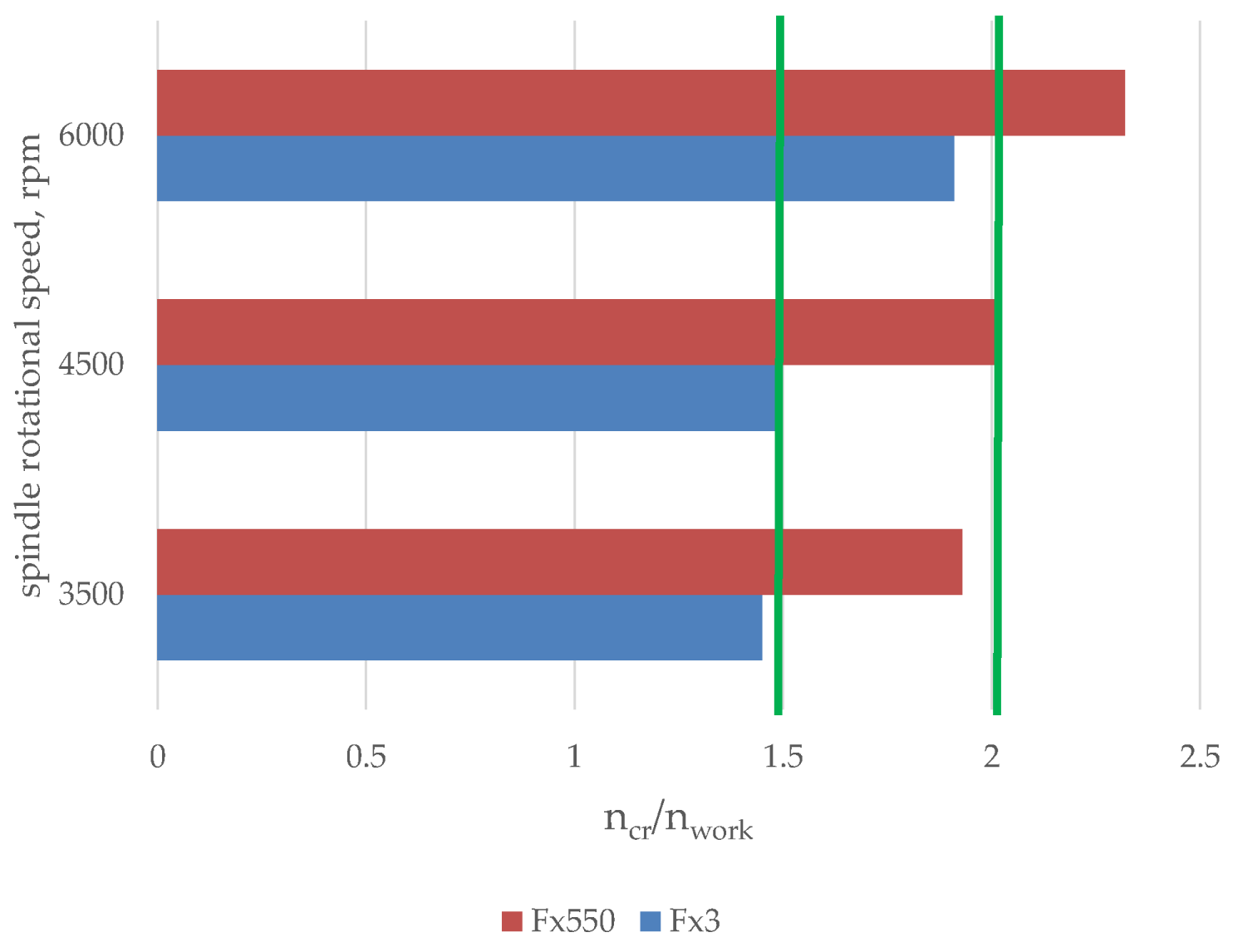

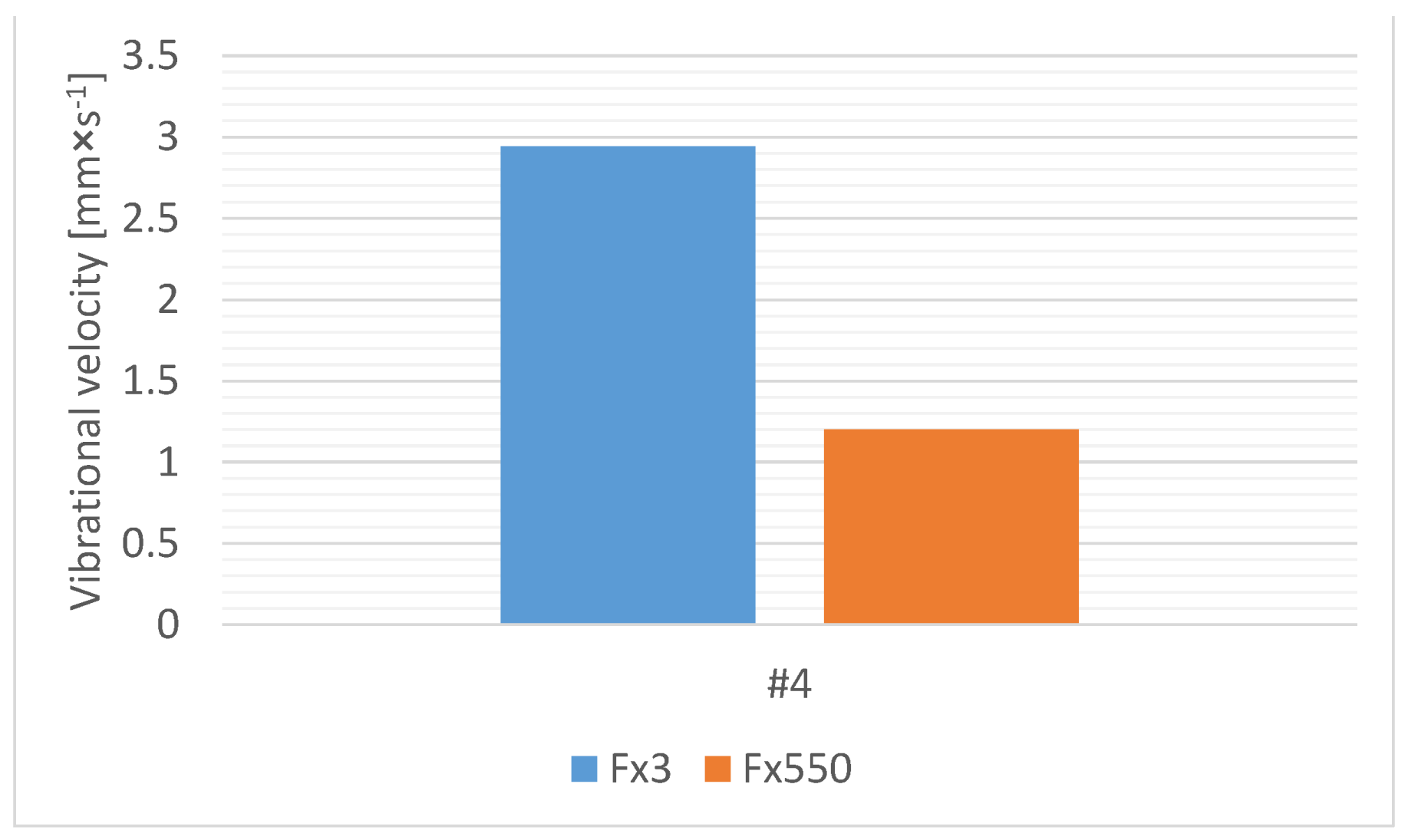

- To evaluate the dynamic properties (behavior) of the spindle it is useful to determine their critical values of rotational speeds. The maximum deformations determined in static structural linear analyses showed that in the case of the Fx550 saw spindle they are 10× smaller in comparison with the spindle of the Fx3 saw, which made it possible to estimate critical speeds, which satisfied the inequality presented in Equation (2).

- The use of only rational imitation in the spindle design on the basis of the other sliding table saws produced does not lead to the expected effect in the form of correct spindle operation, and this mainly concerns the possible exceeding of the tool’s lateral runout value.

- The errors on sawn surfaces caused by the tool’s lateral runout value can be more apparent especially in case of top wood composite boards (MDF, HDF, LVL, plywood or particle boards) in the sawn package.

- An application in a new machine frame body of steel sections connected with special lockers instead of the solution which based on a set of bent body parts between flat steel plates resulted in lower noise values of around 5 dB during idling.

- If the noise of the machine tool is decreased and simultaneously vibrations are at lower level, hence, it could be expected higher accuracy of sawing which is especially important in furniture production.

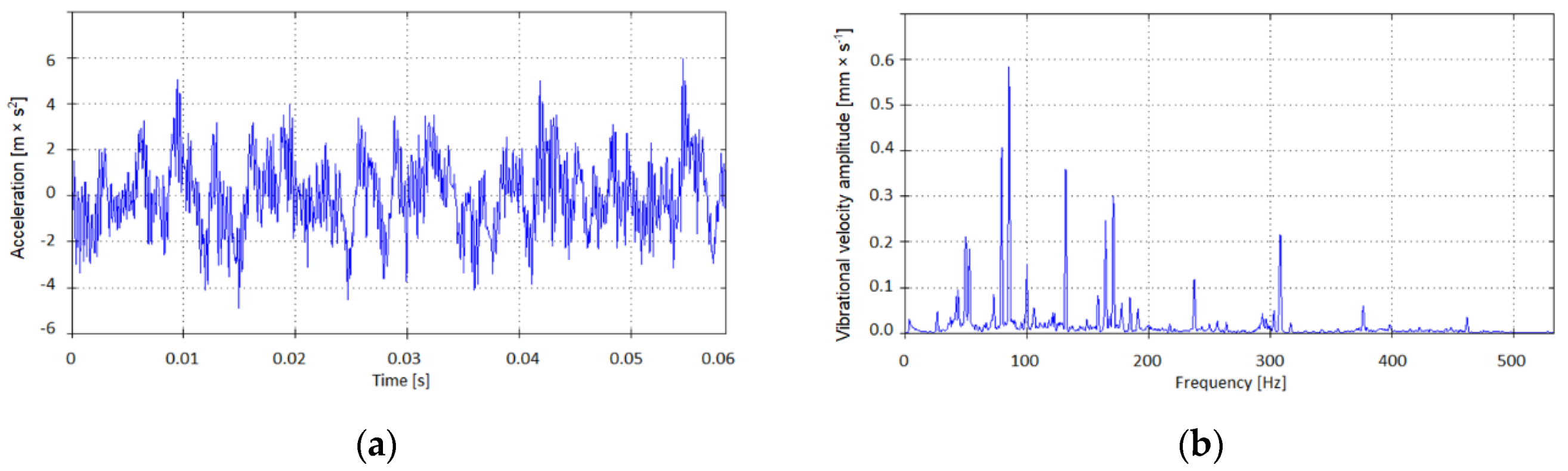

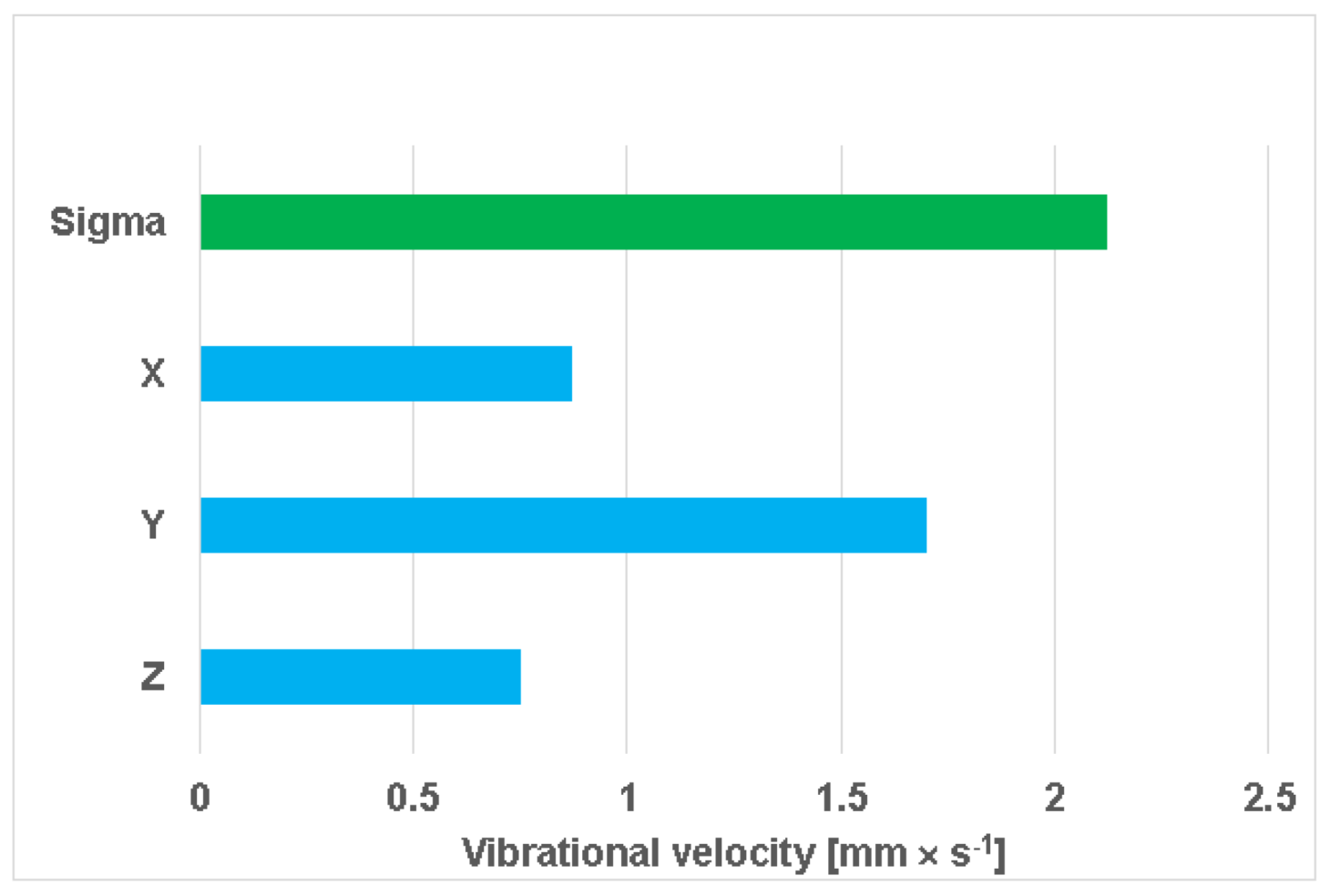

- Experimental values of vibrational velocities (RMS or peak value of vibrational velocities) on basis of a few diagnosis standards allowed us to classify the examined main spindle system of the sliding table saw Fx550 as good or admissible design solution from the point of its dynamics.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Goli, G.; Curti, R.; Marcon, B.; Scippa, A.; Campatelli, G.; Furferi, R.; Denaud, L. Specific cutting forces of isotropic and orthotropic engineered wood products by round shape machining. Materials 2018, 11, 2575. [Google Scholar] [CrossRef] [PubMed]

- Salca, E.-A.; Bekhta, P.; Seblii, Y. The effect of veneer densification temperature and wood species on the plywood properties made from alternate layers of densified and non-densified veneers. Forests 2020, 11, 700. [Google Scholar] [CrossRef]

- Mirski, R.; Derkowski, A.; Dziurka, D.; Dukarska, D.; Czarnecki, R. Effects of a chipboard structure on its physical and mechanical properties. Materials 2019, 12, 3777. [Google Scholar] [CrossRef] [PubMed]

- Hernandez-Vazquez, J.-M.; Garitaonandia, I.; Fernandes, M.H.; Muñoa, J.; López de Lacalle, L.N. A consistent procedure using response surface methodology to identify stiffness properties of connections in machine tools. Materials 2018, 11, 1220. [Google Scholar] [CrossRef]

- Orlowski, K.A.; Wasielewski, R. Study washboarding phenomenon in frame sawing machines. Holz als-Roh Werkst. 2006, 64, 37–44. [Google Scholar] [CrossRef]

- Mohammadpanah, A.; Hutton, S.G. Flutter instability speeds of guided splined disks. An experimental and analytical investigation. J. Shock Vib. 2015, 2015, 942141. [Google Scholar] [CrossRef]

- Mohammadpanah, A.; Hutton, S.G. Maximum operation speed of splined saws. Wood Mater. Sci. Eng. 2016, 11, 142–146. [Google Scholar] [CrossRef]

- Svoreň, J.; Hrčková, M. Woodworking Machines, Part I; Technical University in Zvolen: Zvolen, Slovak Republic, 2015. [Google Scholar]

- Mohammadpanah, A.; Hutton, S.G. Dynamic response of guided spline circular saws vs. collared circular saws, subjected to external loads. Wood Mater. Sci. Eng. 2019. [Google Scholar] [CrossRef]

- Hu, W.-Y.; Qi, Y.-J.; Zhang, Z.-H.; Qi, X.-J. Study on noise of precision panel saw. J. For. Res. 2003, 14, 335–338. [Google Scholar]

- Cempel, C. Diagnostyka Wibroakustyczna Maszyn; Politechnika Poznańska: Poznań, Poland, 1985. (In Polish) [Google Scholar]

- Szulewski, P.; Śniegulska-Grądzka, D. Systems of Automatic Vibration Monitoring in Machine Tools. Mechanik 2017, 90, 170–175. [Google Scholar] [CrossRef]

- Nasir, V.; Cool, J. A review on wood machining: Characterization, optimization, and monitoring of the sawing process. Wood Mater. Sci. Eng. 2020, 15, 1–16. [Google Scholar] [CrossRef]

- Kvietková, M.; Gaff, M.; Gašparík, M.; Kminiak, R.; Kriš, A. Effect of number of saw blade teeth on noise level and wear of blade edges during cutting of wood. Bioresources 2015, 10, 1657–1666. [Google Scholar] [CrossRef]

- Kminiak, R.; Gašparík, M.; Kvietková, M. The dependence of surface quality on tool wear of circular saw blades during transversal sawing of beech wood. Bioresources 2015, 10, 7123–7135. [Google Scholar] [CrossRef]

- Krilek, J.; Kováč, J.; Kučera, M. Wood crosscutting process analysis for circular saws. Bioresources 2014, 9, 1417–1429. [Google Scholar] [CrossRef]

- Hlásková, L.; Kopecký, Z.; Novák, V. Influence of wood modification on cutting force, specific cutting resistance and fracture parameters during the sawing process using circular sawing machine. Eur. J. Wood Wood Prod. 2020, 78, 1173–1182. [Google Scholar] [CrossRef]

- Mandic, M.; Svrzic, S.; Danon, G. The comparative analysis of two methods for the power consumption measurement in circular saw cutting of laminated particle board. Wood Res. 2015, 60, 125–136. [Google Scholar]

- Aguilera, A. Surface roughness evaluation in medium density fibreboard rip sawing. Eur. J. Wood Wood Prod. 2011, 69, 489–493. [Google Scholar] [CrossRef]

- Aguilera, A.; Barros, J.L. Surface roughness assessment on medium density fibreboard rip sawing using acoustic signals. Eur. J. Wood Wood Prod. 2012, 70, 369–372. [Google Scholar] [CrossRef]

- Barcenas, C.H.; Delclos, G.L.; El-Zein, R.; Tortolero-Luna, G.; Whitehead, L.W.; Spitz, M.R. Wood dust exposure is a potential risk factor for lung cancer. Am. J. Ind. Med. 2005, 47, 349–357. [Google Scholar] [CrossRef]

- Barański, J.; Jewartowski, M.; Wajs, J.; Orlowski, K.; Pikała, T. Experimental examination and modification of chip suction system in circular sawing machine. Drv. Ind. 2018, 69, 223–230. [Google Scholar] [CrossRef]

- Nasir, V.; Cool, J. Characterization, optimization, and acoustic emission monitoring of airborne dust emission during wood sawing. Int. J. Adv. Manuf. Technol. 2020, 109, 2365–2375. [Google Scholar] [CrossRef]

- Yokochi, H.; Nakashima, H.; Kimura, S. Vibration of circular saws during cutting I. Effect of slots on vibration. Mokuzai Gakkaishi 1993, 39, 1246–1252. [Google Scholar]

- Nishio, S.; Marui, E. Effect of slots on the lateral vibration of a circular saw blade during sawing. Mokuzai Gakkaishi 1995, 41, 722–730. [Google Scholar]

- Nishio, S. Stable sawblade. In Proceedings of the 17th International Wood Machining Seminar; Scholz, F., Ed.; Retru-Verlag e.K.: Weyarn, Germany, 2005; pp. 418–420. [Google Scholar]

- Droba, A.; Javorek, L.; Svoreň, J.; Pauliny, D. New design of circular saw blade body and its influence on critical rotational speed. Drewno 2015, 58, 147–157. [Google Scholar]

- Svoreň, J. The analysis of the effect of the number of teeth of the circular saw blade on the critical rotation speed. Acta Fac. Tech. (Zvolen–Slovakia) 2012, 17, 109–117. [Google Scholar]

- Orlowski, K.A.; Sandak, J.; Tanaka, C. The critical rotational speed of a circular saw: Simple measurement method and its practical implementations. J. Wood Sci. 2007, 53, 388–393. [Google Scholar] [CrossRef]

- Stakhiev, Y.M. Research on circular saws disc problems: Several of results. Holz als Roh-Werkst 2003, 61, 13–22. [Google Scholar] [CrossRef]

- Dietrych, J. System i konstrukcja, (In Polish, System and Design); Wydawnictwa Naukowo-Techniczne: Warszawa, Poland, 1978. [Google Scholar]

- Cempel, C. Vibroacoustic condition monitoring. In Ellis Horwood Series in Mechanical Engineering; Haddad, S.D., Ed.; Ellis Horwood Ltd.: New York, NY, USA, 1991. [Google Scholar]

- Wrotny, L.T. Projektowanie Obrabiarek. Zagadnienia Ogólne i Przykłady Obliczeń, (In Polish: Designing Machine Tools. General Issues and Examples of Calculations); Wydawnictwa Naukowo-Techniczne: Warszawa, Poland, 1986. [Google Scholar]

- Orlowski, K.A.; Duchnicz, K.; Dudek, P. Analiza wpływu cech konstrukcyjnych wrzeciona pilarki formatowej na jego obroty krytyczne. Mechanik 2016, 89, 1112–1113. [Google Scholar]

- Orlowski, K.A.; Dudek, P. Analysis of the design development of the sliding table saw spindles. Mechanik 2017, 90, 849–851. [Google Scholar] [CrossRef][Green Version]

- Wasielewski, R.; Orlowski, K.A. The effect of the power transmission method of the spindle on the position of the circular saw teeth. In Proceedings of the 18th International Wood Machining Seminar, Vancouver, BC, Canada, 7–9 May 2007; pp. 97–103. [Google Scholar]

- Altendorf F45. Available online: https://www.altendorf.com/en/f-45.html (accessed on 20 October 2020).

- Pikała, T. (Rema, S.A., Reszel, Poland). Personal communication, 2017.

- Rema Fx550. Available online: https://rema-sa.pl/produkty/pilarka-formatowa-rema-fx550 (accessed on 27 August 2020).

- UNICA 400 and UNICA 500. Available online: https://wtp.hoechsmann.com/en/lexikon/20024/unica_500 (accessed on 20 October 2020).

- K 700 S. Available online: https://www.felder-group.com/pl-pl/produkty/pily-formatowe-c1947/pila-formatowa-k-700-s-p64674 (accessed on 11 September 2020).

- PF 400S. Available online: http://rojek.cz/pdf/PF300L_350_400S_New.pdf (accessed on 11 September 2020).

- Černoch, S. Strojnĕ Technická Přiručka 1; SNTL-Státní nakladatelství technické literatury: Praha, Czechoslovakia, 1968. [Google Scholar]

- SKF Belt Calculator. Available online: https://www.skfptp.com/Publications/Publications# (accessed on 11 September 2020).

- SKF. Available online: https://www.skf.com/my/products/super-precision-bearings/principles/bearing-selection-process/bearing-execution/system-rigidity (accessed on 2 September 2020).

- Orlowski, K.; Duchnicz, K. The effect of a belt position in the spindle driving system on critical rotational speeds. Ann. WULS-SGGW For. Wood Technol. 2016, 95, 303–307. [Google Scholar]

- Orlowski, K.A.; Blacharski, W.; Pikała, T. Empirical assessment of the main driving system of the circular sawing machine. Trieskove Beztrieskove Obrabanie Dreva 2016, 10, 145–151. [Google Scholar]

- ISO-7960: Airborne Noise Emitted by Machine Tools—Operating Conditions for Woodworking Machines; ISO: Geneva, Switzerland, 1995.

| RMS of Vibrational Velocities, vΣ mm·s−1 | Peak Value of Vibrational Velocities, vmax mm·s−1 | |

|---|---|---|

| Experimental Results | 2.08 | 3.27 |

| Standards | Diagnosis | Range RMS of vibrational velocities for diagnosis, mm·s−1 or *range peak value of vibrational velocities, mm·s−1 |

| IRD Mechanalysis | Admissible | 2–4 |

| VCI Ltd. | Good | 1.27–2.54 |

| Blake | Admissible | *2.20–6.00 |

| Łączkowski | Good | *2.50–6.30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Orlowski, K.A.; Dudek, P.; Chuchala, D.; Blacharski, W.; Przybylinski, T. The Design Development of the Sliding Table Saw Towards Improving Its Dynamic Properties. Appl. Sci. 2020, 10, 7386. https://doi.org/10.3390/app10207386

Orlowski KA, Dudek P, Chuchala D, Blacharski W, Przybylinski T. The Design Development of the Sliding Table Saw Towards Improving Its Dynamic Properties. Applied Sciences. 2020; 10(20):7386. https://doi.org/10.3390/app10207386

Chicago/Turabian StyleOrlowski, Kazimierz A., Przemyslaw Dudek, Daniel Chuchala, Wojciech Blacharski, and Tomasz Przybylinski. 2020. "The Design Development of the Sliding Table Saw Towards Improving Its Dynamic Properties" Applied Sciences 10, no. 20: 7386. https://doi.org/10.3390/app10207386

APA StyleOrlowski, K. A., Dudek, P., Chuchala, D., Blacharski, W., & Przybylinski, T. (2020). The Design Development of the Sliding Table Saw Towards Improving Its Dynamic Properties. Applied Sciences, 10(20), 7386. https://doi.org/10.3390/app10207386