Characterization of Quinoa Seeds Milling Fractions and Their Effect on the Rheological Properties of Wheat Flour Dough

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Proximate Composition

2.3. Physical Properties of Quinoa Flour Fractions

2.3.1. Water Absorption Capacity

2.3.2. Water Retention Capacity

2.3.3. Swelling Capacity

2.3.4. Bulk Density

2.4. α-Amylase Activity

2.5. Mixolab Measurements

2.6. Design of Experiments and Statistics

3. Results and Discussion

3.1. Proximate Composition

3.2. Physical Properties

3.3. Fitting the Models

3.4. α-Amylase Activity

3.5. Dough Rheological Properties during Mixing Stage of the Mixolab

3.5.1. Water Absorption

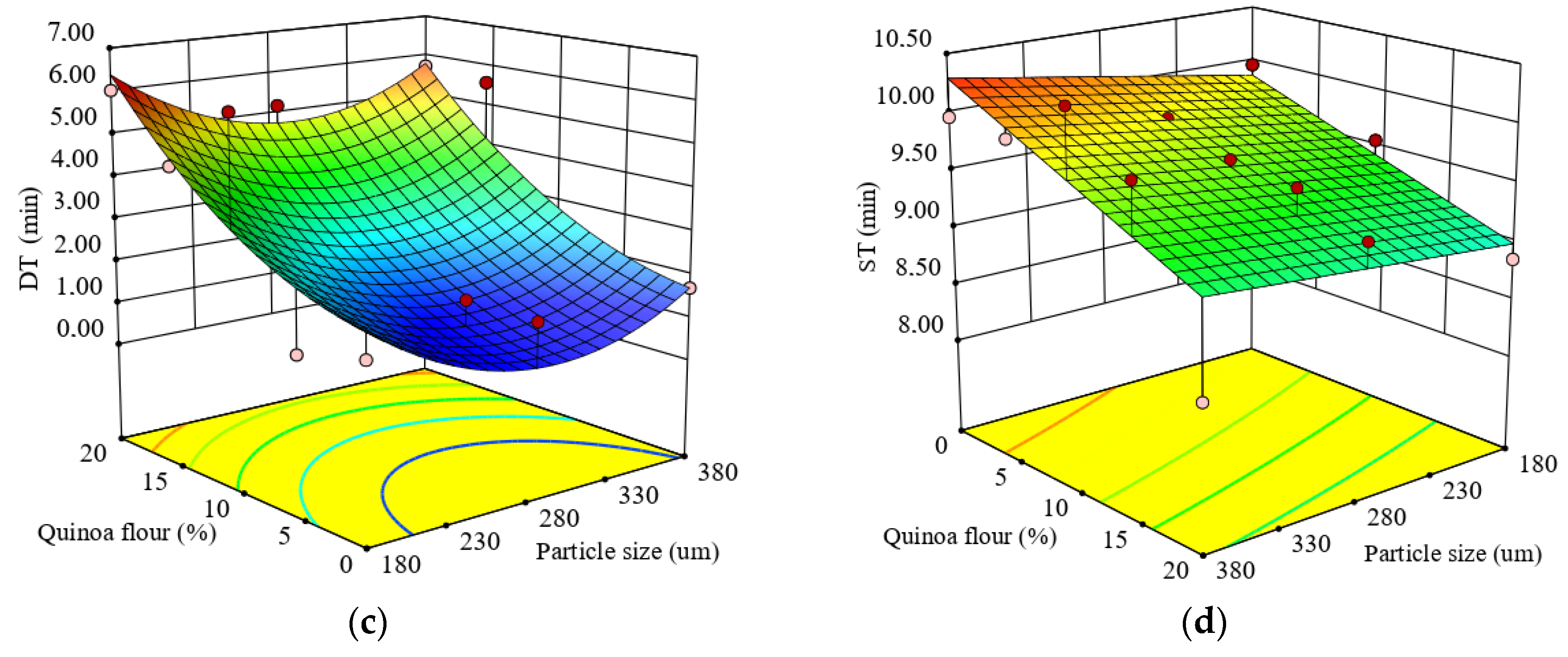

3.5.2. Dough Development Time

3.5.3. Dough Stability

3.6. Dough Rheological Properties during Heating

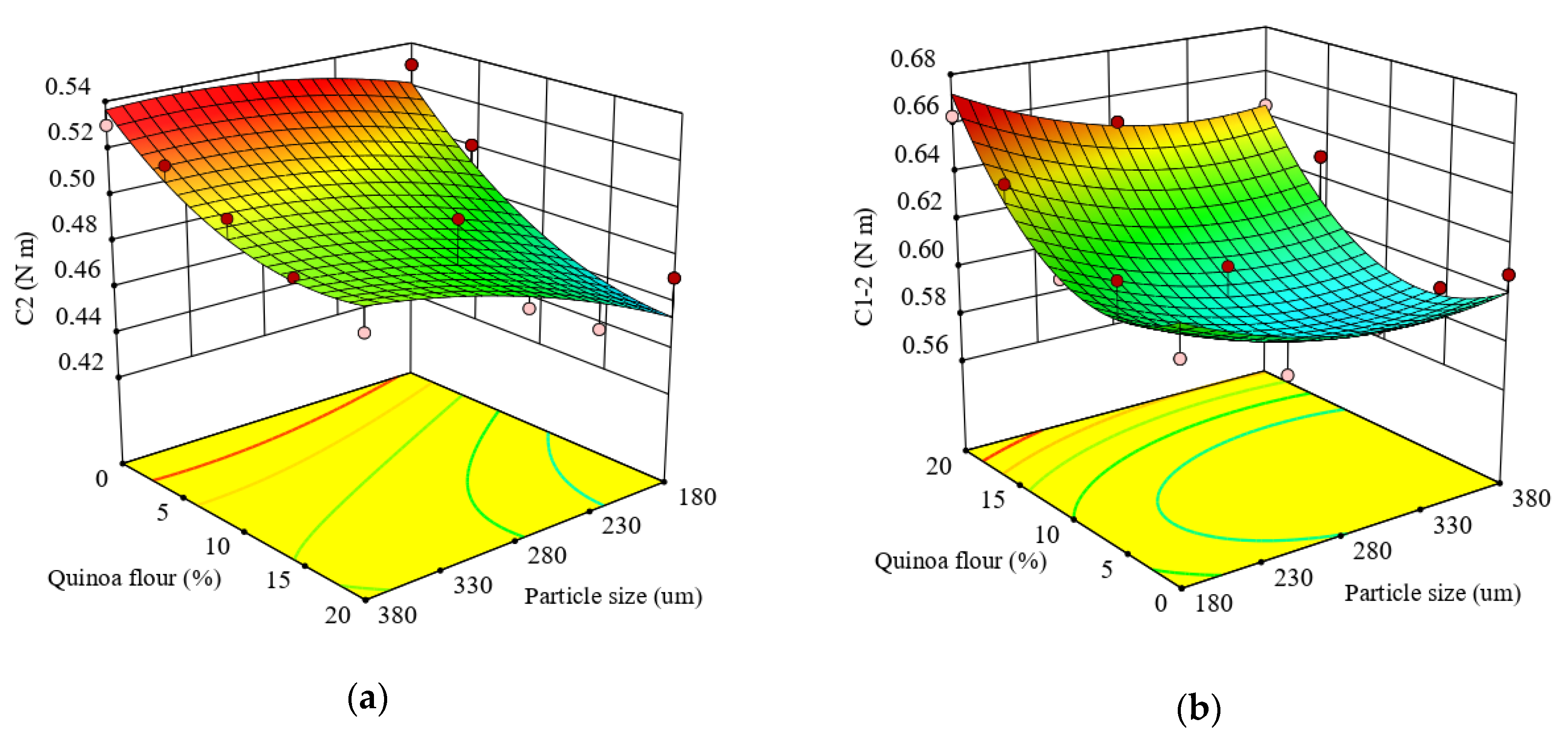

3.6.1. Protein Weakening

3.6.2. Starch Gelatinization

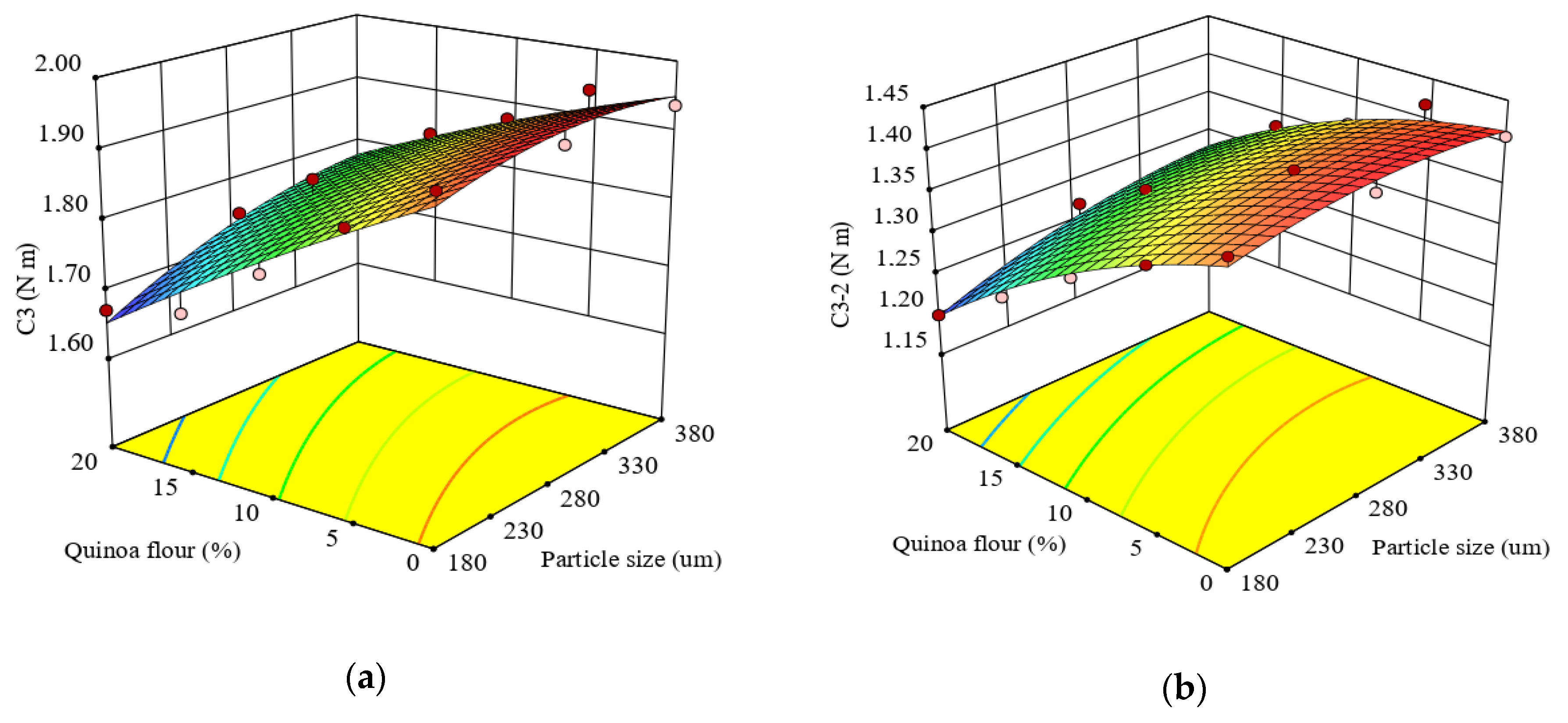

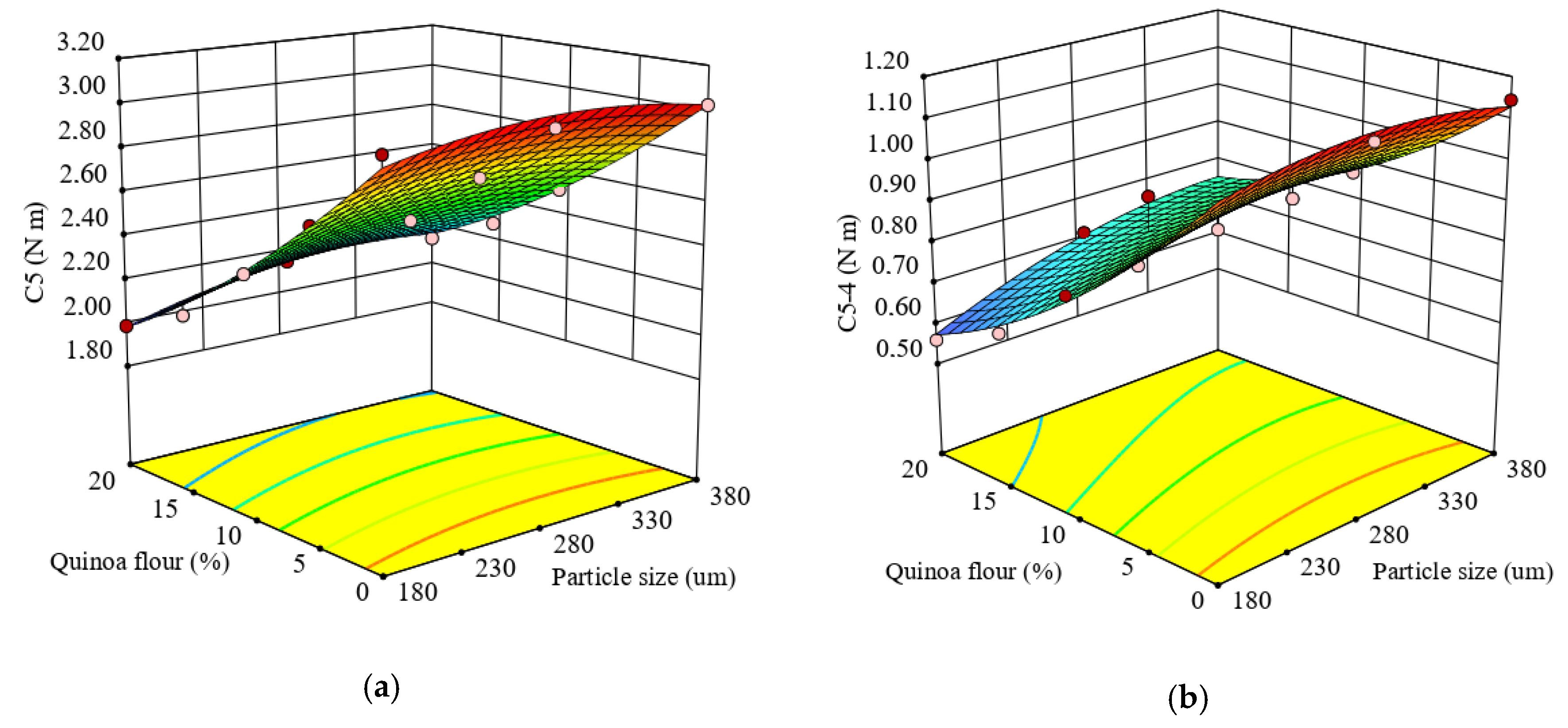

3.6.3. Hot Starch Stability Gel

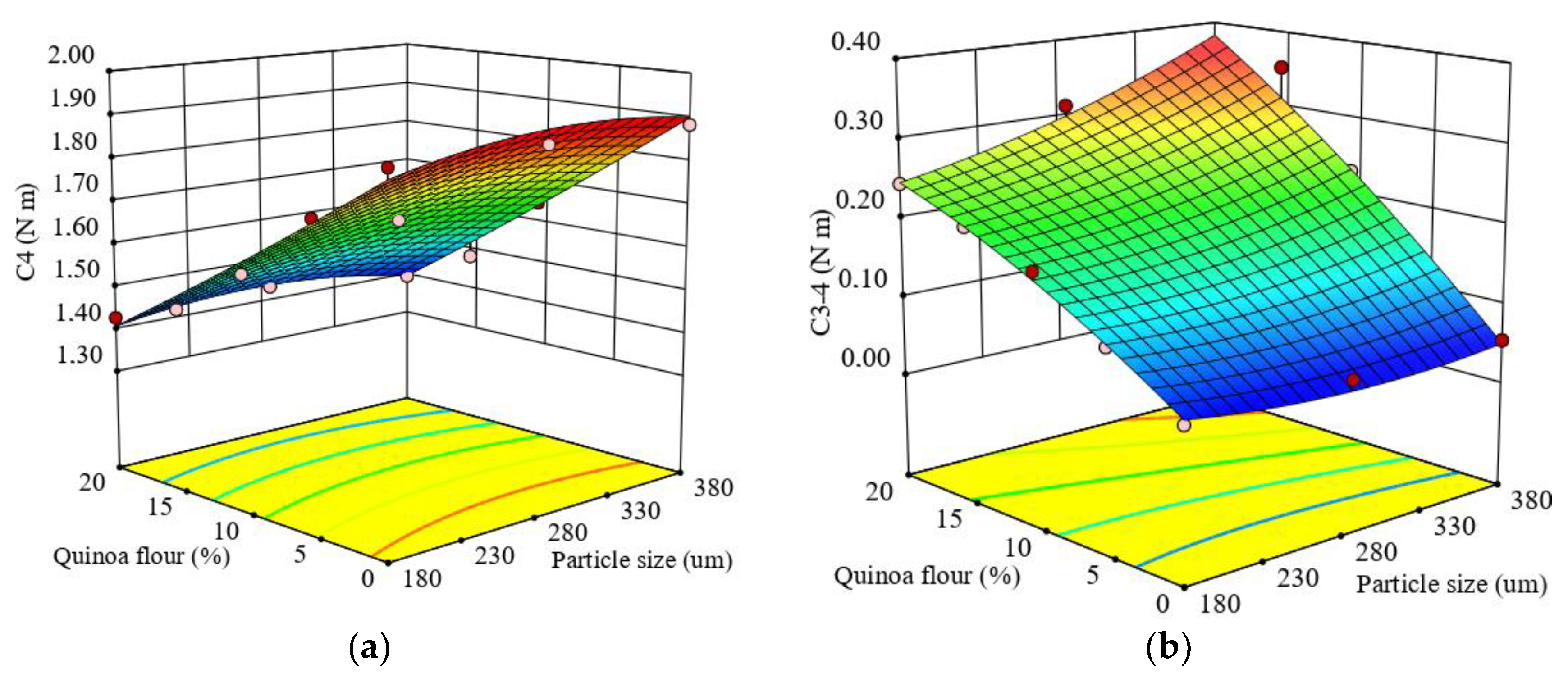

3.6.4. Starch Retrogradation

3.7. Optimization

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Martínez-Villaluenga, C.; Peñas, E.; Hernández-Ledesma, B. Pseudocereal grains: Nutritional value, health benefits and current applications for the development of gluten-free foods. Food Chem. Toxicol. 2020, 137, 111178. [Google Scholar] [CrossRef] [PubMed]

- Kahlon, T.S.; Avena-Bustillos, R.J.; Chiu, M.C.M. Sensory evaluation of gluten-free quinoa whole grain snacks. Heliyon 2016, 2, e00213. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Burgos, V.E.; López, E.P.; Goldner, M.C.; Del Castillo, V.C. Physicochemical characterization and consumer response to new Andean ingredients-based fresh pasta: Gnocchi. Int. J. Gastron. Food Sci. 2019, 16, 100142. [Google Scholar] [CrossRef]

- Solaesa, Á.G.; Villanueva, M.; Vela, A.J.; Ronda, F. Protein and lipid enrichment of quinoa (cv. Titicaca) by dry fractionation. Techno-functional, thermal and rheological properties of milling fractions. Food Hydrocoll. 2020, 105, 105770. [Google Scholar] [CrossRef]

- Pereira, E.; Encina-Zelada, C.; Barros, L.; Gonzales-Barron, U.; Cadavez, V.; Ferreira, I.C. Chemical and nutritional characterization of Chenopodium quinoa Willd (quinoa) grains: A good alternative to nutritious food. Food Chem. 2019, 280, 110–114. [Google Scholar] [CrossRef] [PubMed]

- Tanwar, B.; Goyal, A.; Irshaan, S.; Kumar, V.; Sihag, M.K.; Patel, A.; Kaur, I. Quinoa. In Whole Grains and their Bioactives: Composition and Health; Johnson, J., Walace, T., Eds.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2019; pp. 269–305. [Google Scholar] [CrossRef]

- Repo-Carrasco-Valencia, R.; Arana, J.V. Carbohydrates of Kernels. In Pseudocereals: Chemistry and Technology; Haros, M., Schoenlechner, R., Eds.; Wiley: Oxford, UK, 2017; pp. 28–48. [Google Scholar]

- James, L.E.A. Quinoa (Chenopodium quinoa Willd.): Composition, chemistry, nutritional, and functional properties. Adv. Food Nutr. Res. 2009, 58, 1–31. [Google Scholar] [CrossRef]

- Ahamed, N.T.; Singhal, R.S.; Kulkami, P.R.; Palb, M. Physicochemical and functional properties of Chenopodium quinoa starch. Carbohydr. Polym. 1996, 31, 99–103. [Google Scholar] [CrossRef]

- Lamothe, L.M.; Srichuwong, S.; Reuhs, B.L.; Hamaker, B.R. Quinoa (Chenopodium quinoa W.) and amaranth (Amaranthus caudatus L.) provide dietary fibres high in pectic substances and xyloglucans. Food Chem. 2015, 167, 490–496. [Google Scholar] [CrossRef]

- Nowak, V.; Du, J.; Charrondière, U.R. Assessment of the nutritional composition of quinoa (Chenopodium quinoa Willd.). Food Chem. 2016, 193, 47–54. [Google Scholar] [CrossRef]

- Rosero, O.; Marounek, M.; Břeňová, N. Phytase activity and comparison of chemical composition, phytic acid P content of four varieties of quinoa grain (Chenopodium quinoa Willd.). Acta Agronómica 2013, 62, 13–20. [Google Scholar]

- Rizzello, C.G.; Lorusso, A.; Montemurro, M.; Gobbetti, M. Use of sourdough made with quinoa (Chenopodium quinoa) flour and autochthonous selected lactic acid bacteria for enhancing the nutritional, textural and sensory features of white bread. Food Microbiol. 2016, 56, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Miranda, M.; Vega-Gálvez, A.; Quispe-Fuentes, I.; Rodríguez, M.J.; Maureira, H.; Martínez, E.A. Nutritional aspects of six quinoa (Chenopodium quinoa Willd.) ecotypes from three geographical areas of Chile. Chil. J. Agric. Res. 2012, 72, 175. [Google Scholar] [CrossRef]

- Joshi, D.C.; Sood, S.; Hosahatti, R.; Kant, L.; Pattanayak, A.; Kumar, A.; Yadav, D.; Stetter, M.G. From zero to hero: The past, present and future of grain amaranth breeding. Theor. Appl. Genet. 2018, 131, 1807–1823. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Li, X.; Chen, P.X.; Zhang, B.; Liu, R.; Hernandez, M.; Draves, J.; Marcone, M.F.; Tsao, R. Assessing the fatty acid, carotenoid, and tocopherol compositions of amaranth and quinoa seeds grown in Ontario and their overall contribution to nutritional quality. J. Agric. Food Chem. 2016, 64, 1103–1110. [Google Scholar] [CrossRef]

- Vera, E.P.; Alca, J.J.; Saravia, G.R.; Campioni, N.C.; Alpuy, I.J. Comparison of the lipid profile and tocopherol content of four Peruvian quinoa (Chenopodium quinoa Willd.) cultivars (‘Amarilla de Maranganí’, ‘Blanca de Juli’, INIA 415 ‘Roja Pasankalla’, INIA 420 ‘Negra Collana’) during germination. J. Cereal Sci. 2019, 88, 132–137. [Google Scholar] [CrossRef]

- Paucar-Menacho, L.M.; Dueñas, M.; Peñas, E.; Frias, J.; Martínez-Villaluenga, C. Effect of dry heat puffing on nutritional composition, fatty acid, amino acid and phenolic profiles of pseudocereals grains. Pol. J. Food Nutr. Sci. 2018, 68, 289–297. [Google Scholar] [CrossRef]

- Nascimento, A.C.; Mota, C.; Coelho, I.; Gueifão, S.; Santos, M.; Matos, A.S.; Gimenez, A.; Lobo, M.; Samman, N.; Castanheira, I. Characterisation of nutrient profile of quinoa (Chenopodium quinoa), amaranth (Amaranthus caudatus), and purple corn (Zea mays L.) consumed in the North of Argentina: Proximates, minerals and trace elements. Food Chem. 2014, 148, 420–426. [Google Scholar] [CrossRef]

- Vega-Gálvez, A.; Miranda, M.; Vergara, J.; Uribe, E.; Puente, L.; Martínez, E.A. Nutrition facts and functional potential of quinoa (Chenopodium quinoa Willd.), an ancient Andean grain: A review. J. Sci. Food Agric. 2010, 90, 2541–2547. [Google Scholar] [CrossRef]

- Han, Y.; Chi, J.; Zhang, M.; Zhang, R.; Fan, S.; Dong, L.; Huang, F.; Liu, L. Changes in saponins, phenolics and antioxidant activity of quinoa (Chenopodium quinoa Willd) during milling process. LWT Food Sci. Technol. 2019, 114, 108381. [Google Scholar] [CrossRef]

- Rocchetti, G.; Lucini, L.; Rodriguez, J.M.; Barba, F.J.; Giuberti, G. Gluten-free flours from cereals, pseudocereals and legumes: Phenolic fingerprints and in vitro antioxidant properties. Food Chem. 2019, 271, 157–164. [Google Scholar] [CrossRef]

- Gómez-Caravaca, A.M.; Segura-Carretero, A.; Fernández-Gutiérrez, A.; Caboni, M.F. Simultaneous determination of phenolic compounds and saponins in quinoa (Chenopodium quinoa Willd) by a liquid chromatography–diode array detection–electrospray ionization–time-of-flight mass spectrometry methodology. J. Agric. Food Chem. 2011, 59, 10815–10825. [Google Scholar] [CrossRef]

- Tamba-Berehoiu, R.M.; Turtoi, M.O.; Popa, C.N. Assessment of quinoa flours effect on wheat flour doughs rheology and bread quality. Ann. Univ. Dunarea Jos Galati. Fascicle Food Technol. 2019, 43, 173–188. [Google Scholar] [CrossRef]

- Codină, G.G.; Franciuc, S.G.; Todosi-Sănduleac, E. Studies on the influence of quinoa flour addition on bread quality. Food Environ. Saf. J. 2016, 15, 165–174. [Google Scholar]

- Wang, S.; Zhu, F. Formulation and Quality Attributes of Quinoa Food Products. Food Bioprocess Technol. 2016, 9, 49–68. [Google Scholar] [CrossRef]

- Sullivan, B.; Engebreston, W.E.; Anderson, M.L. The relation of particle size of certain flour characteristics. Cereal Chem. 1960, 37, 436–455. [Google Scholar]

- Ahmed, J.; Thomas, L.; Arfat, Y.A. Functional, rheological, microstructural and antioxidant properties of quinoa flour in dispersions as influenced by particle size. Food Res. Int. 2019, 116, 302–311. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, A.; Pasquier, P.; Marcotte, D. Influence of groundwater flow in fractured aquifers on standing column wells performance. Geothermics 2015, 58, 39–48. [Google Scholar] [CrossRef]

- Benito-Román, O.; Rodríguez-Perrino, M.; Sanz, M.T.; Melgosa, R.; Beltrán, S. Supercritical carbon dioxide extraction of quinoa oil: Study of the influence of process parameters on the extraction yield and oil quality. J. Supercrit. Fluids 2018, 139, 62–71. [Google Scholar] [CrossRef]

- Joubert, M.; Morel, M.H.; Lullien-Pellerin, V. Pasta color and viscoelasticity: Revisiting the role of particle size, ash, and protein content. Cereal Chem. 2018, 95, 386–398. [Google Scholar] [CrossRef]

- Tsatsaragkou, K.; Kara, T.; Ritzoulis, C.; Mandala, I.; Rosell, C.M. Improving carob flour performance for making gluten-free breads by particle size fractionation and jet milling. Food Bioprocess Technol. 2017, 10, 831–841. [Google Scholar] [CrossRef]

- Mironeasa, S.; Iuga, M.; Zaharia, D.; Mironeasa, C. Rheological analysis of wheat flour dough as influenced by grape peels of different particle sizes and addition levels. Food Bioprocess Technol. 2019, 12, 228–245. [Google Scholar] [CrossRef]

- Iuga, M.; Mironeasa, C.; Mironeasa, S. Oscillatory rheology and creep-recovery behaviour of grape seed-wheat flour dough: Effect of grape seed particle size, variety and addition level. Bull. UASVM Food Sci. Technol. 2019, 76, 40–51. [Google Scholar] [CrossRef]

- Mironeasa, S.; Iuga, M.; Zaharia, D.; Dabija, A.; Mironeasa, C. Influence of particle sizes and addition level of grape seeds on wheat flour dough rheological properties. In Proceedings of the International Multidisciplinary Scientific GeoConference Surveying Geology & Mining Ecology Management, Vienna, Austria, 27–29 November 2017; Volume 17, pp. 265–272. [Google Scholar] [CrossRef]

- Ahmed, J.; Al-Attar, H.; Arfat, Y.A. Effect of particle size on compositional, functional, pasting and rheological properties of commercial water chestnut flour. Food Hydrocoll. 2016, 52, 888–895. [Google Scholar] [CrossRef]

- Alonso-Miravalles, L.; O’Mahony, J.A. Composition, protein profile and rheological properties of pseudocereal-based protein-rich ingredients. Foods 2018, 7, 73. [Google Scholar] [CrossRef] [PubMed]

- Sosulski, F.; Humbert, E.S.; Bui, K.; Jones, J.D. Functional propreties of rapeseed flours, concentrates and isolate. J. Food Sci. 1976, 41, 49–1352. [Google Scholar] [CrossRef]

- Onipe, O.O.; Beswa, D.; Jideani, A.I.O. Effect of size reduction on colour, hydration and rheological properties of wheat bran. Food Sci. Technol. 2017, 37, 389–396. [Google Scholar] [CrossRef]

- Olapade, A.A.; Aworh, O.C.; Oluwole, O.B. Quality attributes of biscuit from acha (Digitaria exilis) flour supplemented with cowpea (Vigna unguiculata) flour. J. Food Sci. Technol. 2011, 2, 198–203. [Google Scholar] [CrossRef]

- Ikegwu, O.J.; Nwobasi, V.N.; Odoh, M.O.; Oledinma, N.U. Evaluation of the pasting and some functional properties of starch isolated from some improved cassava varieties in Nigeria. Afr. J. Biotechnol. 2009, 8, 2310–2315. [Google Scholar]

- ICC. International Association for Cereal Sciences and Technology, ICC Standard No. 173; ICC: Vienna, Austria, 2010. [Google Scholar]

- Coțovanu, I.; Stoenescu, G.; Mironeasa, S. Amaranth influence on wheat flour dough rheology: Optimal particle size and amount of flour replacement. J. Microbiol. Biotechnol. Food Sci. 2020, 10, 1–10. Available online: https://www.jmbfs.org/in-next-issue/ (accessed on 16 September 2020).

- Katina, K.; Heiniö, R.L.; Autio, K.; Poutanen, K. Optimization of sourdough process for improved sensory profile and texture of wheat bread. LWT Food Sci. Technol. 2006, 39, 1189–1202. [Google Scholar] [CrossRef]

- Mironeasa, S.; Mironeasa, C. Dough bread from refined wheat flour partially replaced by grape peels: Optimizing the rheological properties. J. Food Process Eng. 2009, 42, e13207. [Google Scholar] [CrossRef]

- Iuga, M.; Mironeasa, S. Grape seeds effect on refined wheat flour dough rheology: Optimal amount and particle size. Ukr. Food J. 2019, 8, 799–814. [Google Scholar] [CrossRef]

- Mironeasa, S.; Iuga, M.; Zaharia, D.; Mironeasa, C. Optimization of grape peels particle size and flour substitution in white wheat flour dough. Sci. Study Res. Chem. Eng. Biotechnol. Food Ind. 2019, 20, 29–42. [Google Scholar]

- Mironeasa, S.; Iuga, M.; Zaharia, D.; Mironeasa, C. Optimization of white wheat flour dough rheological properties with different levels of grape peels flour addition. Bull. UASVM Food Sci. Technol. 2019, 76, 27–39. [Google Scholar] [CrossRef]

- Drakos, A.; Kyriakakis, G.; Evageliou, V.; Protonotariou, S.; Mandala, I.; Ritzoulis, C. Influence of jet milling and particle size on the composition, physicochemical and mechanical properties of barley and rye flours. Food Chem. 2017, 215, 326–332. [Google Scholar] [CrossRef]

- Prasopsunwattana, N.; Omary, M.B.; Arndt, E.A.; Cooke, P.H.; Flores, R.A.; Yokoyama, W.; Toma, A.; Chongcham, S.; Lee, S.P. Particle size effects on the quality of flour tortillas enriched with whole grain waxy barley. Cereal Chem. 2009, 86, 439–451. [Google Scholar] [CrossRef]

- Offia-Olua, B.I. Chemical, functional and pasting properties of wheat (Triticum spp)-Walnut (Juglansregia) flour. Food Nutr. Sci. 2014, 5, 1591–1604. [Google Scholar] [CrossRef]

- Schuck, P.; Jeantet, R.; Dolivet, A. Analytical Methods Food Dairy Powders; Blackwell: Hoboken, NJ, USA, 2012. [Google Scholar]

- Sullivan, J.T. Evaluation of Forage Crops by Chemical Analysis. A Critique. Agron. J. 1962, 54, 511–515. [Google Scholar] [CrossRef]

- Ando, H.; Chen, Y.C.; Tang, H.; Shimizu, M.; Watanabe, K.; Mitsunaga, T. Food components in fractions of quinoa seed. Food Sci. Technol. Res. 2002, 8, 80–84. [Google Scholar] [CrossRef]

- D’Amico, S.; Jungkunz, S.; Balasz, G.; Foeste, M.; Jekle, M.; Tömösköszi, S.; Schoenlechner, R. Abrasive milling of quinoa: Study on the distribution of selected nutrients and proteins within the quinoa seed kernel. J. Cereal Sci. 2019, 86, 132–138. [Google Scholar] [CrossRef]

- Lindeboom, N.; Chang, P.R.; Falk, K.C.; Tyler, R.T. Characteristics of starch from eight quinoa lines. Cereal Chem. 2005, 82, 216–222. [Google Scholar] [CrossRef]

- Chauhan, G.S.; Eskin, N.A.M.; Tkachuk, R. Nutrients and antinutrients in quinoa seed. Cereal Chem. 1992, 69, 85–88. [Google Scholar]

- Herman, E.M.; Larkins, B.A. Protein storage bodies and vacuoles. Plant Cell 1999, 11, 601–613. [Google Scholar] [CrossRef] [PubMed]

- Koziol, M.J. Quinoa: A potential new oil crop. In New Crops; Janick, J., Simon, J.E., Eds.; Wiley: New York, NY, USA, 1993; pp. 328–336. [Google Scholar]

- Oshodi, H.N.; Ogungbenle, M.O.; Oladimeji, A.A. Chemical composition, nutritionally valuable minerals and functional properties of benniseed (Sesamum radiatum), pearl millet (Pennisetum typhoides) and quinoa (Chenopodium quinoa) flours. Int. J. Food Sci. Nutr. 1999, 50, 325–331. [Google Scholar] [CrossRef]

- Prego, I.; Maldonado, S.; Otegui, M. Seed structure and localization of reserves in Chenopodium quinoa. Ann. Bot. 1998, 82, 481–488. [Google Scholar] [CrossRef]

- Rodriguez-Sandoval, E.; Sandoval, G.; Cortes-Rodríguez, M. Effect of quinoa and potato flours on the thermomechanical and breadmaking properties of wheat flour. Braz. J. Chem. Eng. 2012, 29, 503–510. [Google Scholar] [CrossRef]

- Fekria, A.M.; Isam, A.M.A.; Suha, O.A.; Elfadil, E.B. Nutritional and functional characterization of defatted seed cake flour of two Sudanese groundnut (Arachis hypogaea) cultivars. Int. Food Res. J. 2012, 19, 629–637. [Google Scholar]

- Pérez, S.; Bertoft, E. The molecular structures of starch components and their contribution to the architecture of starch granules: A comprehensive review. Starch Stärke 2010, 62, 389–420. [Google Scholar] [CrossRef]

- Joardder, M.U.H.; Mourshed, M.; Masud, M.H. State of Bound Water: Measurement and Significance in Food Processing; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar] [CrossRef]

- Ogungbenle, H.N.; Oshodi, A.A.; Oladimeji, M.O. The proximate and effect of salt applications on some functional properties of quinoa (Chenopodium quinoa) flour. Pak. J. Nutr. 2009, 8, 49–52. [Google Scholar] [CrossRef][Green Version]

- Protonotariou, S.; Batzaki, C.; Yanniotis, S.; Mandala, I. Effect of jet milled whole wheat flour in biscuits properties. LWT- Food Sci. Technol. 2016, 74, 106–113. [Google Scholar] [CrossRef]

- Tang, Y.; Li, X.; Chen, P.X.; Zhang, B.; Hernandez, M.; Zhang, H.; Marcone, M.F.; Liu, R.; Tsao, R. Characterisation of fatty acid, carotenoid, tocopherol/tocotrienol compositions and antioxidant activities in seeds of three Chenopodium quinoa Willd genotypes. Food Chem. 2015, 174, 502–508. [Google Scholar] [CrossRef] [PubMed]

- Ratnawati, L.; Desnilasari, D.; Surahman, D.N.; Kumalasari, R. Evaluation of physicochemical, functional and pasting properties of soybean, mung bean and red kidney bean flour as ingredient in biscuit. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; Volume 251, p. 012026. [Google Scholar] [CrossRef]

- Struyf, N.; Verspreet, J.; Courtin, C.M. The effect of amylolytic activity and substrate availability on sugar release in non-yeasted dough. J. Cereal Sci. 2016, 69, 111–118. [Google Scholar] [CrossRef]

- Sundarram, A.; Murthy, T.P.K. α-amylase production and applications: A review. J. Appl. Environ. Microbiol. 2014, 2, 166–175. [Google Scholar] [CrossRef]

- Rao, B.D.; Anis, M.; Kalpana, K.; Sunooj, K.V.; Patiul, J.V.; Ganesh, T. Influence of milling methods and particle size hydration properties of sorghum flour and quality of sorghum biscuits. LWT Food Sci. Technol. 2016, 67, 8–13. [Google Scholar]

- Haros, C.M.; Sanz-Penella, J.M. Food uses of whole pseudocereals. In Pseudocereals: Chemistry and Technology; Haros, M., Schoenlechner, R., Eds.; Wiley: Oxford, UK, 2017; pp. 163–192. [Google Scholar]

- Carr, N.O.; Daniels, N.W.; Frazier, P.J. Lipid interactions in breadmaking. Crit. Rev. Food Sci. Nutr. 1992, 31, 237–258. [Google Scholar] [CrossRef]

- Mohammed, I.; Ahmed, A.R.; Senge, B. Effects of chickpea flour on wheat pasting properties and bread making quality. J. Food Sci. Technol. 2014, 51, 1902–1910. [Google Scholar] [CrossRef]

- Haros, C.M.; Schoenlechner, R. Pseudocereals: Chemistry and Technology; John Wiley & Sons: Hoboken, NJ, USA, 2017; pp. 163–192. [Google Scholar]

- Collar, C. Significance of heat-moisture treatment conditions on the pasting and gelling behaviour of various starch-rich cereal and pseudocereal flours. Food Sci. Technol. Int. 2017, 23, 623–636. [Google Scholar] [CrossRef]

- Liu, X.L.; Mu, T.H.; Sun, H.N.; Zhang, M.; Chen, J.W. Influence of potato flour on dough rheological properties and quality of steamed bread. J. Integr. Agric. 2016, 15, 2666–2676. [Google Scholar] [CrossRef]

- BeMiller, J.N. Starches: Molecular and granular structures and properties. In Carbohydrate Chemistry for Food Scientists, 3rd ed.; BeMiller, J.N., Ed.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 159–189. [Google Scholar]

| Run | Coded Values | Real Values | ||

|---|---|---|---|---|

| X1 | X2 | Particle Size (μm) | QF (%) | |

| 1 | 1.00 | −1.00 | 380 | 0 |

| 2 | 1.00 | −0.50 | 380 | 5 |

| 3 | −1.00 | 0.00 | 180 | 10 |

| 4 | 1.00 | 0.00 | 380 | 10 |

| 5 | −1.00 | 1.00 | 180 | 20 |

| 6 | −1.00 | 0.50 | 180 | 15 |

| 7 | 0.00 | 0.50 | 280 | 15 |

| 8 | −1.00 | −1.00 | 180 | 0 |

| 9 | 0.00 | 1.00 | 280 | 20 |

| 10 | 0.00 | −1.00 | 280 | 0 |

| 11 | −1.00 | −0.50 | 180 | 5 |

| 12 | 0.00 | −0.50 | 280 | 5 |

| 13 | 1.00 | 1.00 | 380 | 20 |

| 14 | 1.00 | 0.50 | 380 | 15 |

| 15 | 0.00 | 0.00 | 280 | 10 |

| Parameters | Particle Size | ||

|---|---|---|---|

| QL | QM | QS | |

| Chemical composition | |||

| Moisture (%) | 10.46 ± 0.05 a | 10.04 ± 0.01 a | 9.75 ± 0.50 a |

| Ash (%) | 1.75 ± 0.01 a | 3.20 ± 0.04 c | 2.53 ± 0.00 b |

| Protein (%) | 11.96 ± 0.08 a | 18.86 ± 0.05 c | 15.69 ± 0.19 b |

| Fat (%) | 6.44 ± 0.00 a | 6.41 ± 0.01 a | 6.36 ± 0.03a a |

| Carbohydrates (%) | 69.39 ± 0.94 c | 61.49 ± 0.09 a | 65.66 ± 0.65 b |

| Physical properties | |||

| WAC (%) | 2.50 ± 0.02 a | 2.92 ± 0.00 c | 2.75 ± 0.04 b |

| WRC (g/g) | 4.32 ± 0.04 a | 4.91 ± 0.10 b | 4.31 ± 0.04 a |

| SC (mL/g) | 5.26 ± 0.08 a | 5.55 ± 0.23 a | 6.21 ± 0.17 b |

| BD (g/mL) | 0.55 ± 0.00 c | 0.52 ± 0.01 b | 0.46 ± 0.00 a |

| Parameters | Values | |

|---|---|---|

| Optimized Sample | Control Sample | |

| FN (s) | 308.37 | 313.13 |

| WA (g/100 g) | 58.03 | 58.43 |

| DT (min) | 1.72 | 1.43 |

| ST (min) | 9.91 | 9.78 |

| C2 (N · m) | 0.49 | 0.51 |

| C1-2 (N · m) | 0.59 | 0.60 |

| C3 (N · m) | 1.86 | 1.92 |

| C3-2 (N · m) | 1.37 | 1.41 |

| C4 (N · m) | 1.69 | 1.89 |

| C3-4 (N · m) | 0.17 | 0.03 |

| C5 (N · m) | 2.58 | 3.02 |

| C5-4 (N · m) | 0.89 | 1.13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Coțovanu, I.; Batariuc, A.; Mironeasa, S. Characterization of Quinoa Seeds Milling Fractions and Their Effect on the Rheological Properties of Wheat Flour Dough. Appl. Sci. 2020, 10, 7225. https://doi.org/10.3390/app10207225

Coțovanu I, Batariuc A, Mironeasa S. Characterization of Quinoa Seeds Milling Fractions and Their Effect on the Rheological Properties of Wheat Flour Dough. Applied Sciences. 2020; 10(20):7225. https://doi.org/10.3390/app10207225

Chicago/Turabian StyleCoțovanu, Ionica, Ana Batariuc, and Silvia Mironeasa. 2020. "Characterization of Quinoa Seeds Milling Fractions and Their Effect on the Rheological Properties of Wheat Flour Dough" Applied Sciences 10, no. 20: 7225. https://doi.org/10.3390/app10207225

APA StyleCoțovanu, I., Batariuc, A., & Mironeasa, S. (2020). Characterization of Quinoa Seeds Milling Fractions and Their Effect on the Rheological Properties of Wheat Flour Dough. Applied Sciences, 10(20), 7225. https://doi.org/10.3390/app10207225