Hybrid Impedance-Admittance Control for Upper Limb Exoskeleton Using Electromyography

Abstract

1. Introduction

2. Background

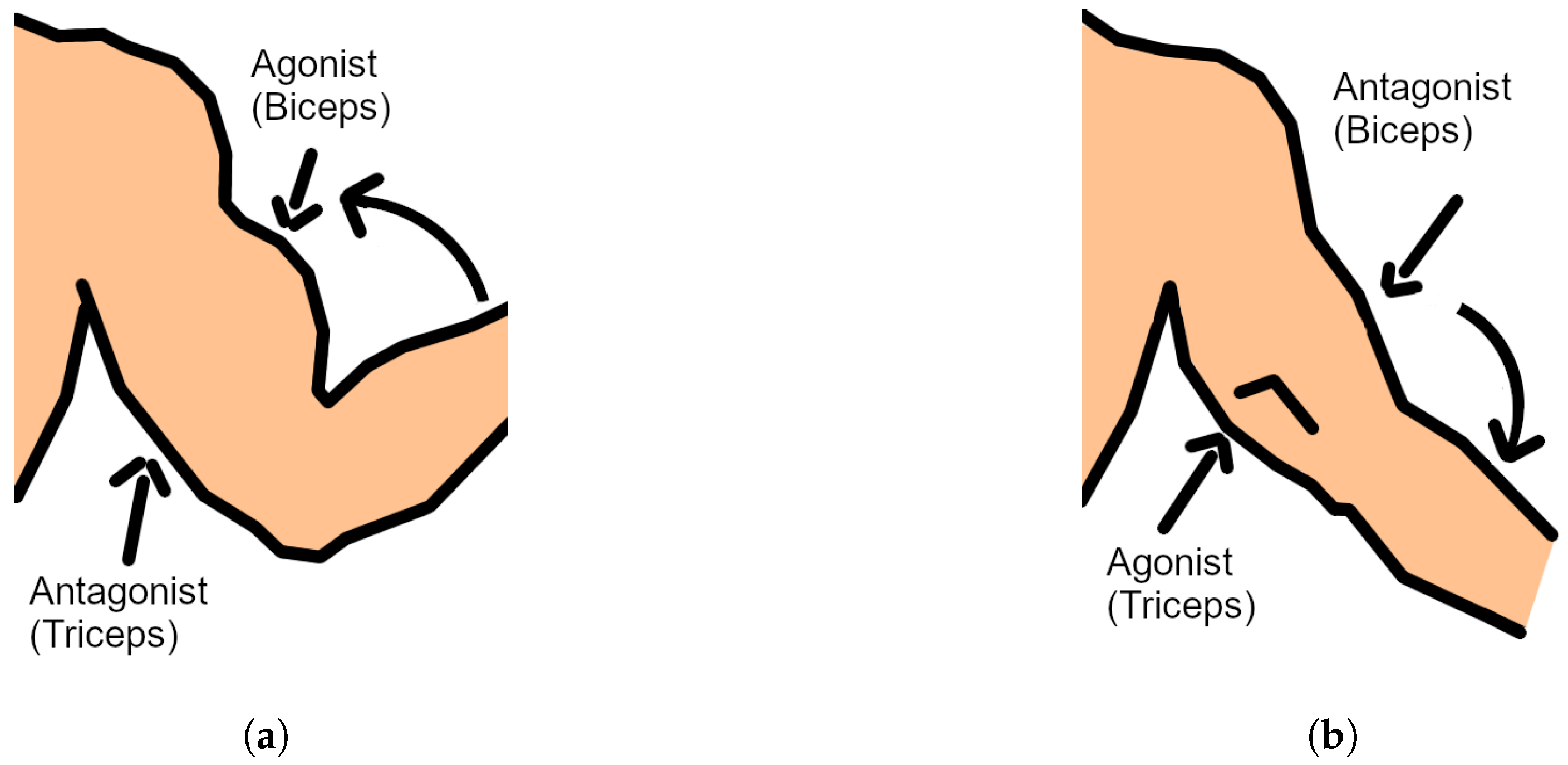

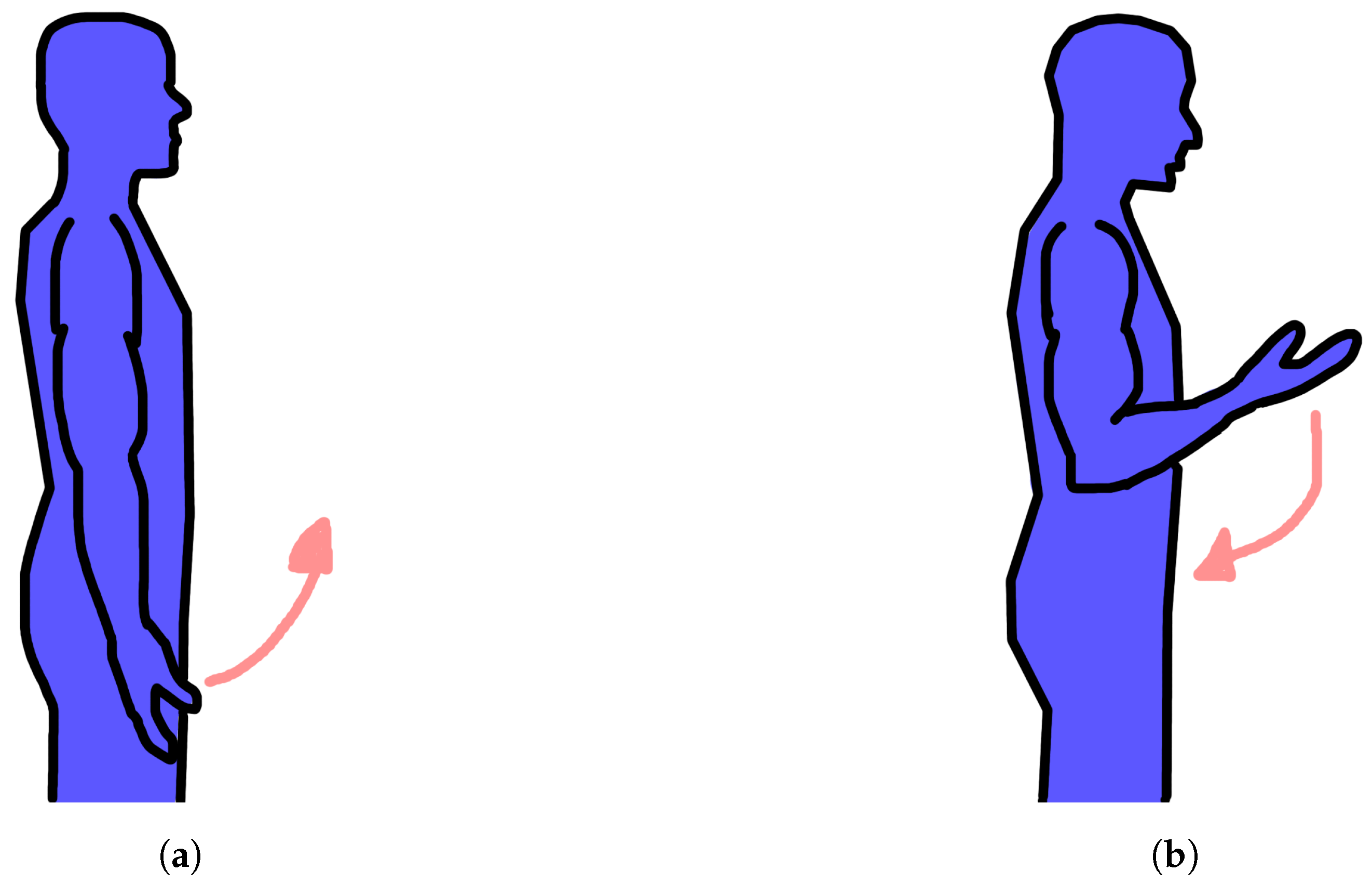

2.1. Fundamentals of Biomechanics

2.2. Electromyography

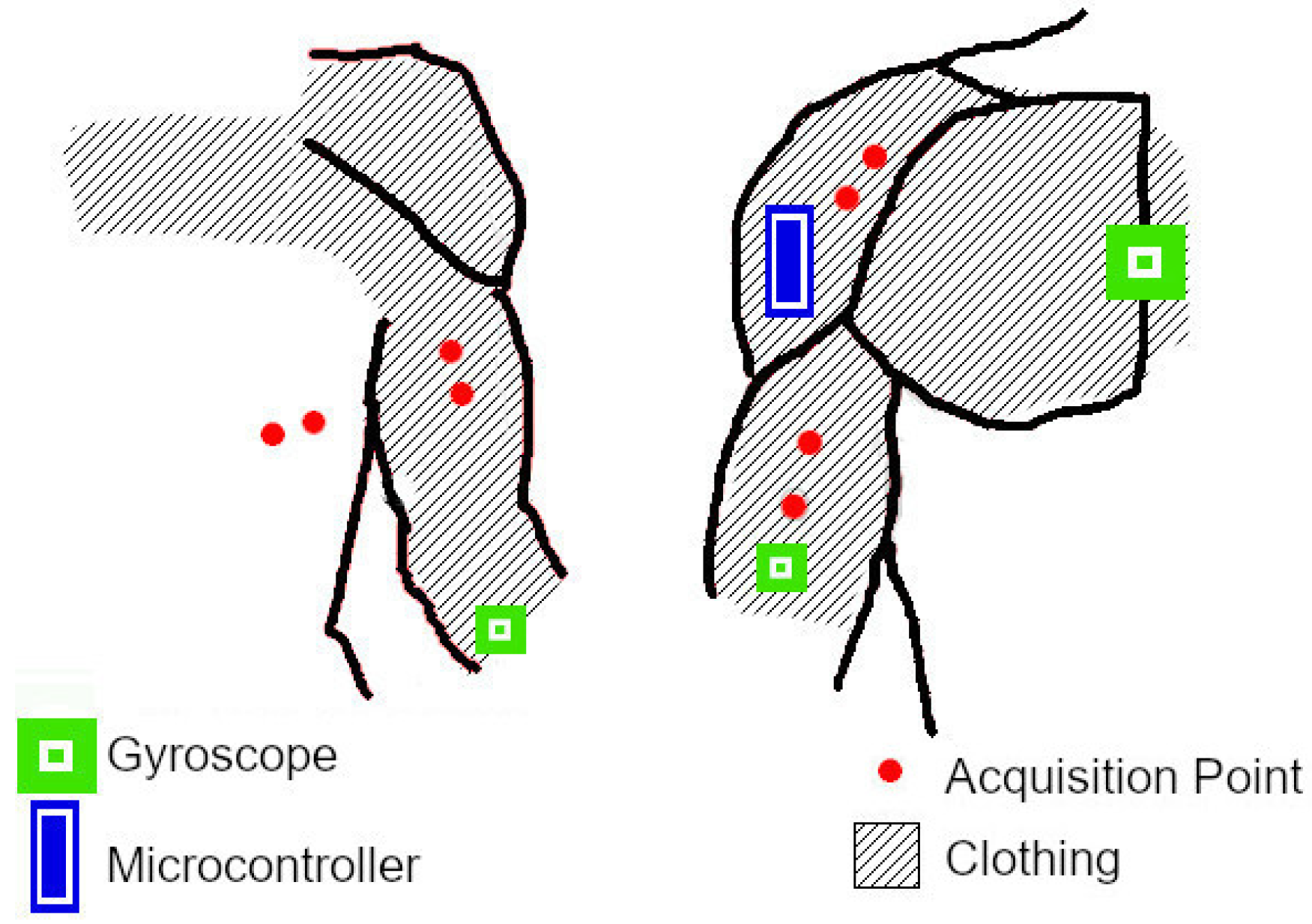

2.2.1. Positioning of Electrodes

2.2.2. Characteristics of the Electromyographic Signal

2.3. Bio-Inspired Controls

2.4. Related Work

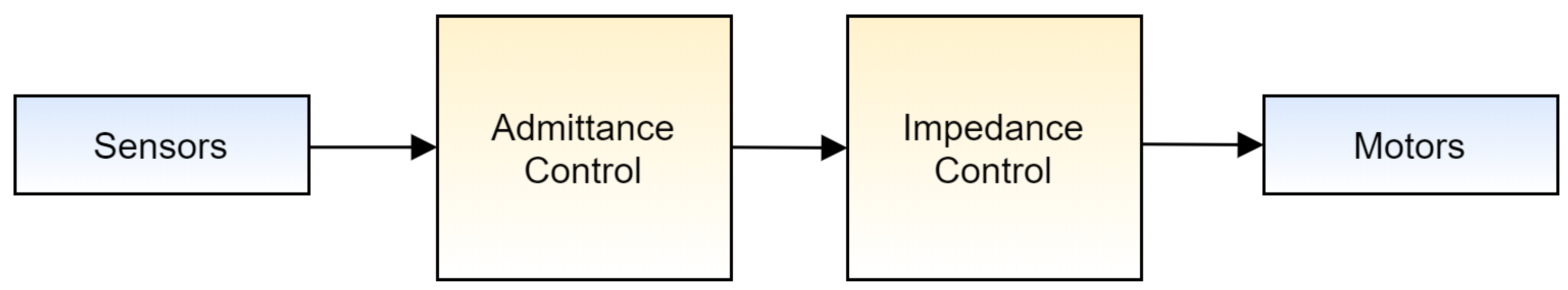

3. Control System

3.1. Admittance Control

3.2. Impedance Control

3.3. Integration

4. Materials and Methods

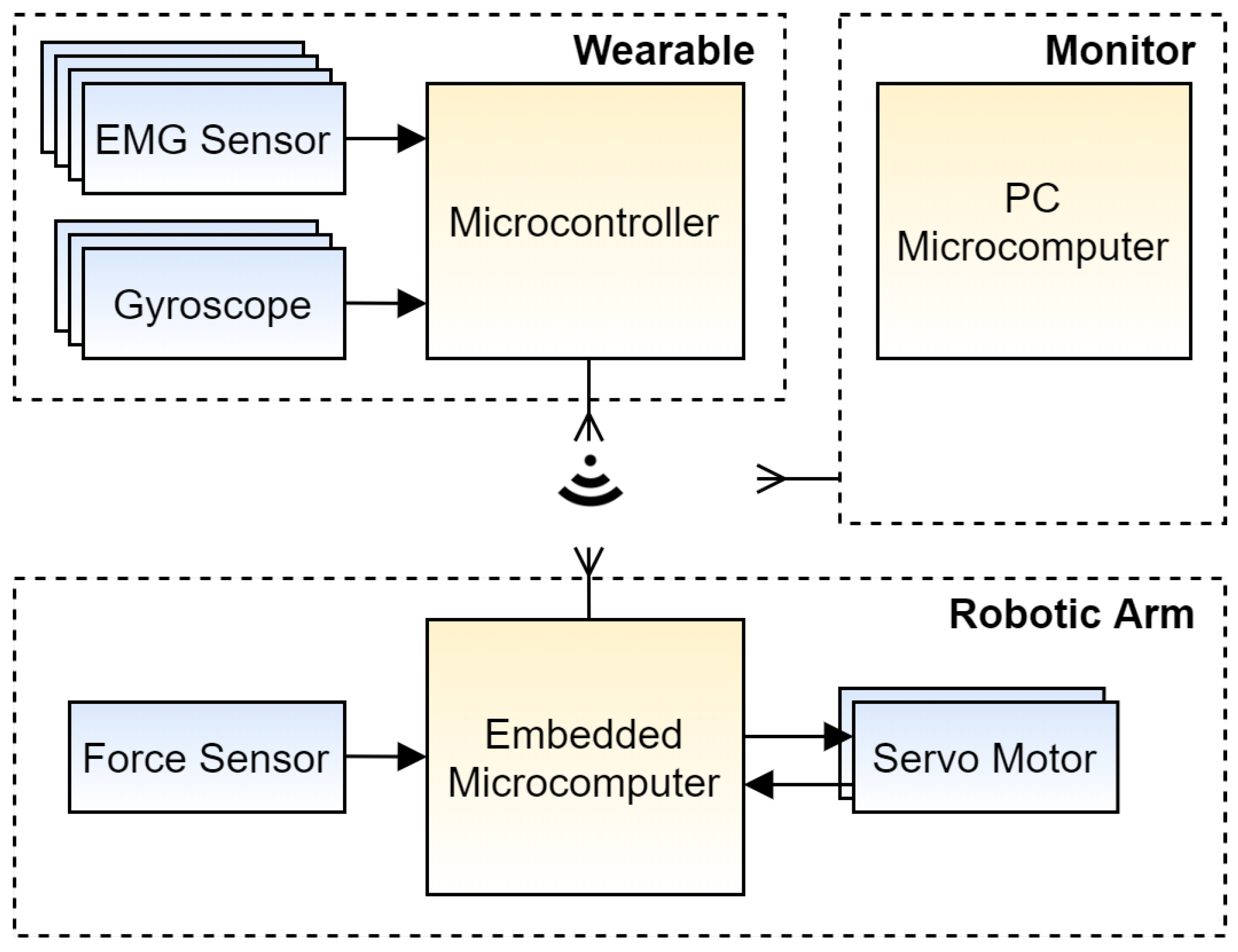

4.1. System Architecture

4.2. Materials

- EMG Sensor: MyoWare Muscle Sensor Development Kit, an Arduino-powered sensor kit from Advancer Technologies. The kit also includes circuitry boards to measure the filtered and rectified electrical activity of a muscle [36]. The MyoWare sensor has an input impedance of 110 G and can operate with an input voltage ranging from 2.9 to 5.7 V. It has a potentiometer with resistance ranging from 0.01 to 100 k to adjust the gain at the outputs. The sensor has two outputs that present the integrated and rectified electromyographic signal.

- Force Sensor: A 0.5" Force Sensitive Resistor (FSR) that senses applied force in the range from 100 g to 10 kg. It varies its resistance according to the pressure applied to the sensing area [37].

- Gyroscope: MPU-6050, a motion-tracking device that combines a 3-axis gyroscope, a 3-axis accelerometer, and a Digital Motion ProcessorTM in a small package [38].

- Servo Motor: Datan Analog S1213, an analog feedback servo providing a torque of 6.5 kg*cm with a speed of 0.21 s/60. This device provides feedback (potentiometer wiper) line that enables reading the servo’s position through an analog interface [39].

- Microcontroller: ESP32-DevKitC V1 from Espressif, a low-footprint development board which integrates a 32-bit microcontroller (ESP32) and a 2.4 GHz Wi-Fi circuitry, running C code on bare metal [40]. ESP is an acronym for Espressif.

- Embedded Microcomputer: Raspberry Pi 3 Model B, a single-board computer with wireless LAN and Bluetooth connectivity, running C code on Raspberry Pi OS [41].

- PC Microcomputer: A laptop computer with an Intel i5 4210U processor and 12 GB of RAM.

4.3. Methods

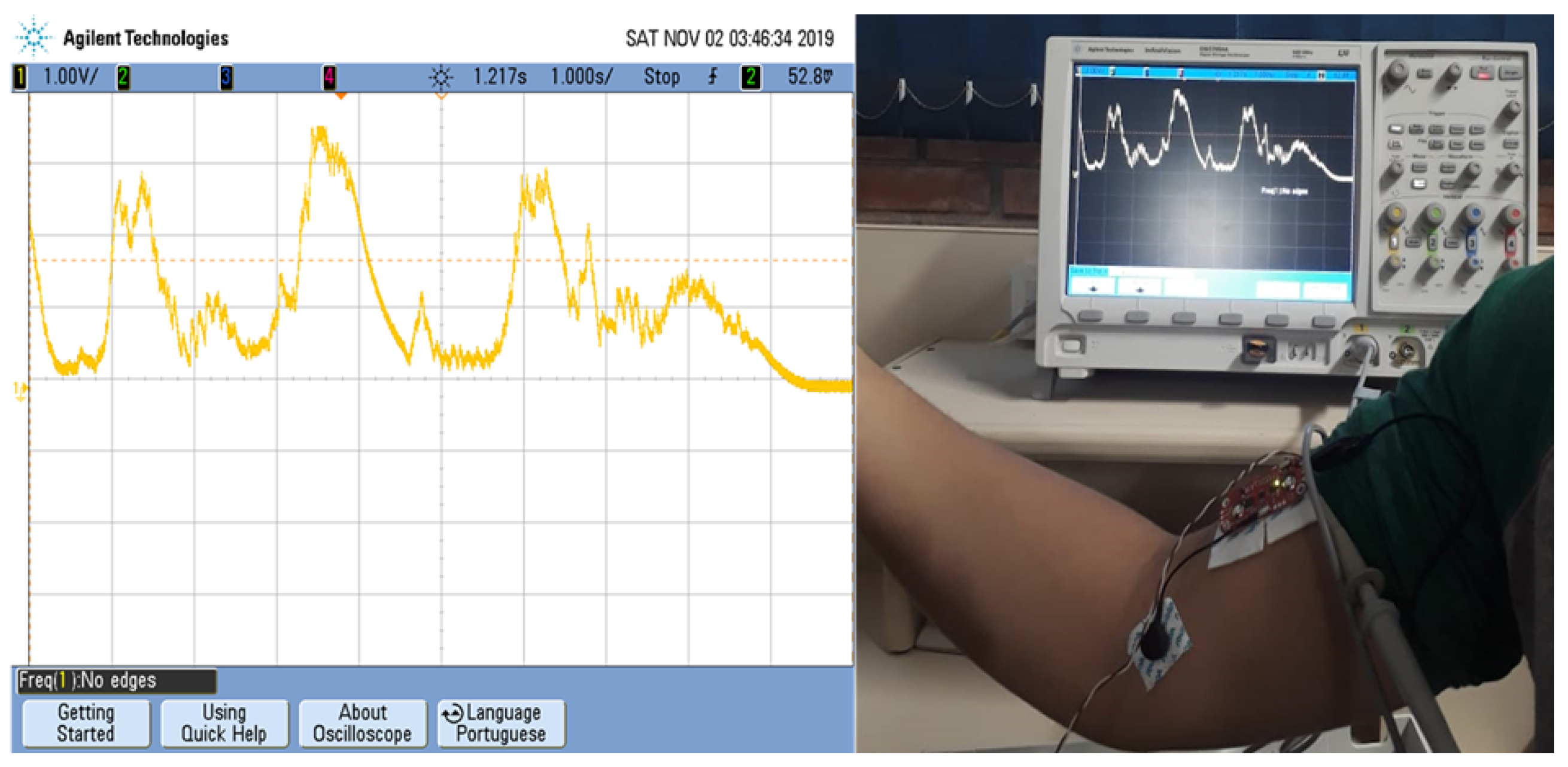

4.4. Signal Capture and Processing

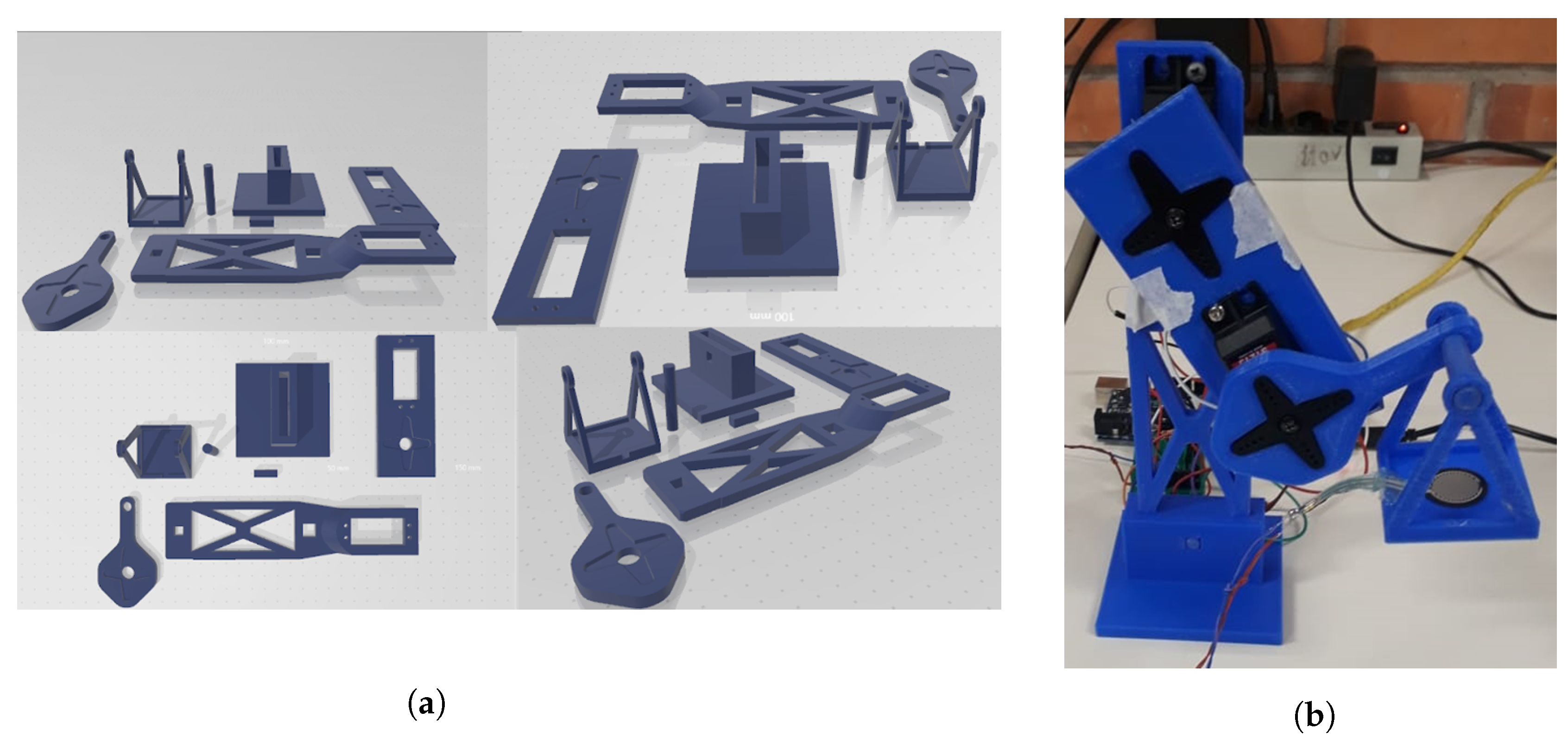

4.5. Proof of Concept

4.6. Calibration

4.6.1. Normalization

4.6.2. Control Coefficients

4.6.3. Influence of Structure Weight

4.7. Gyroscope Error

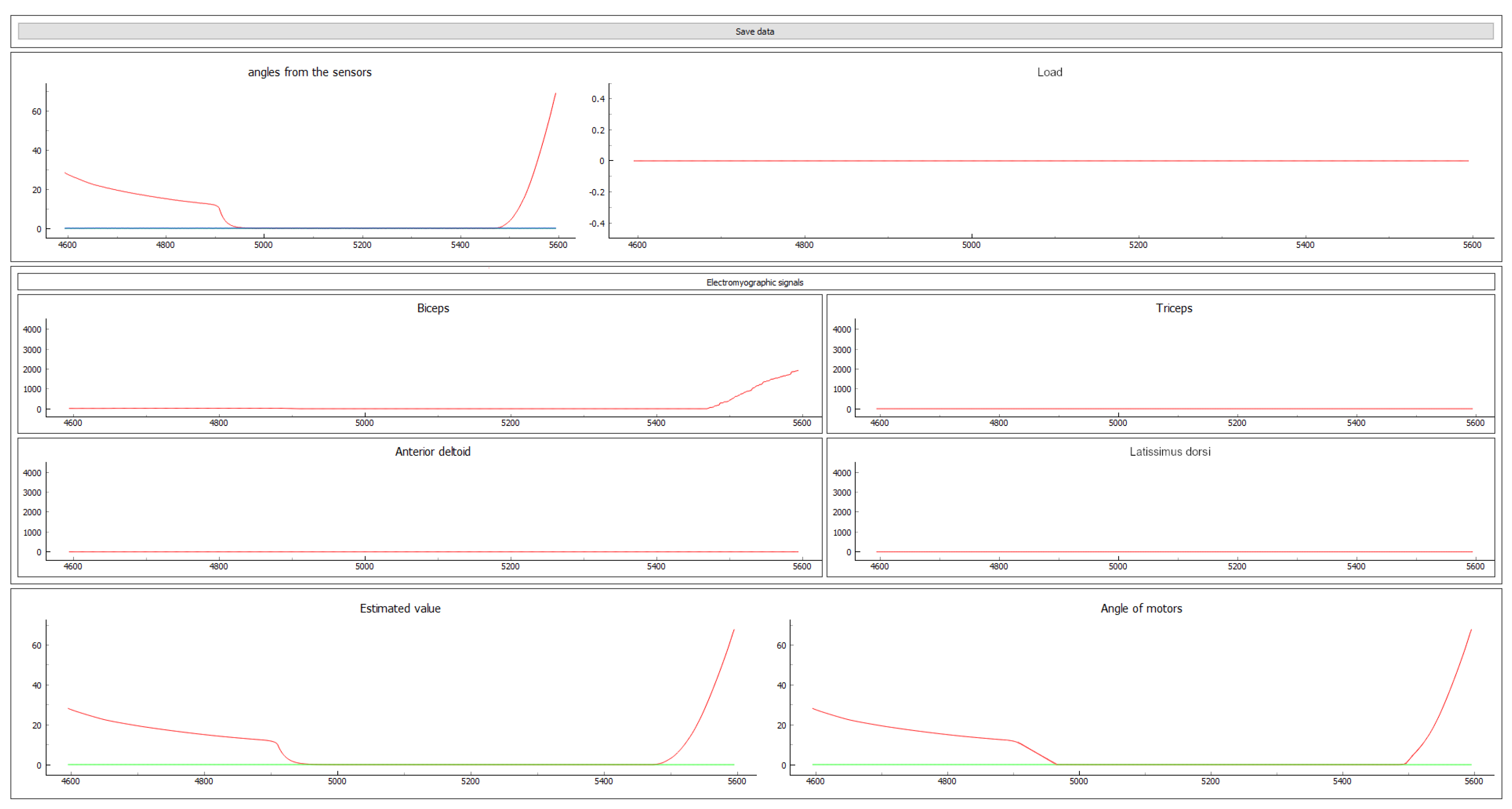

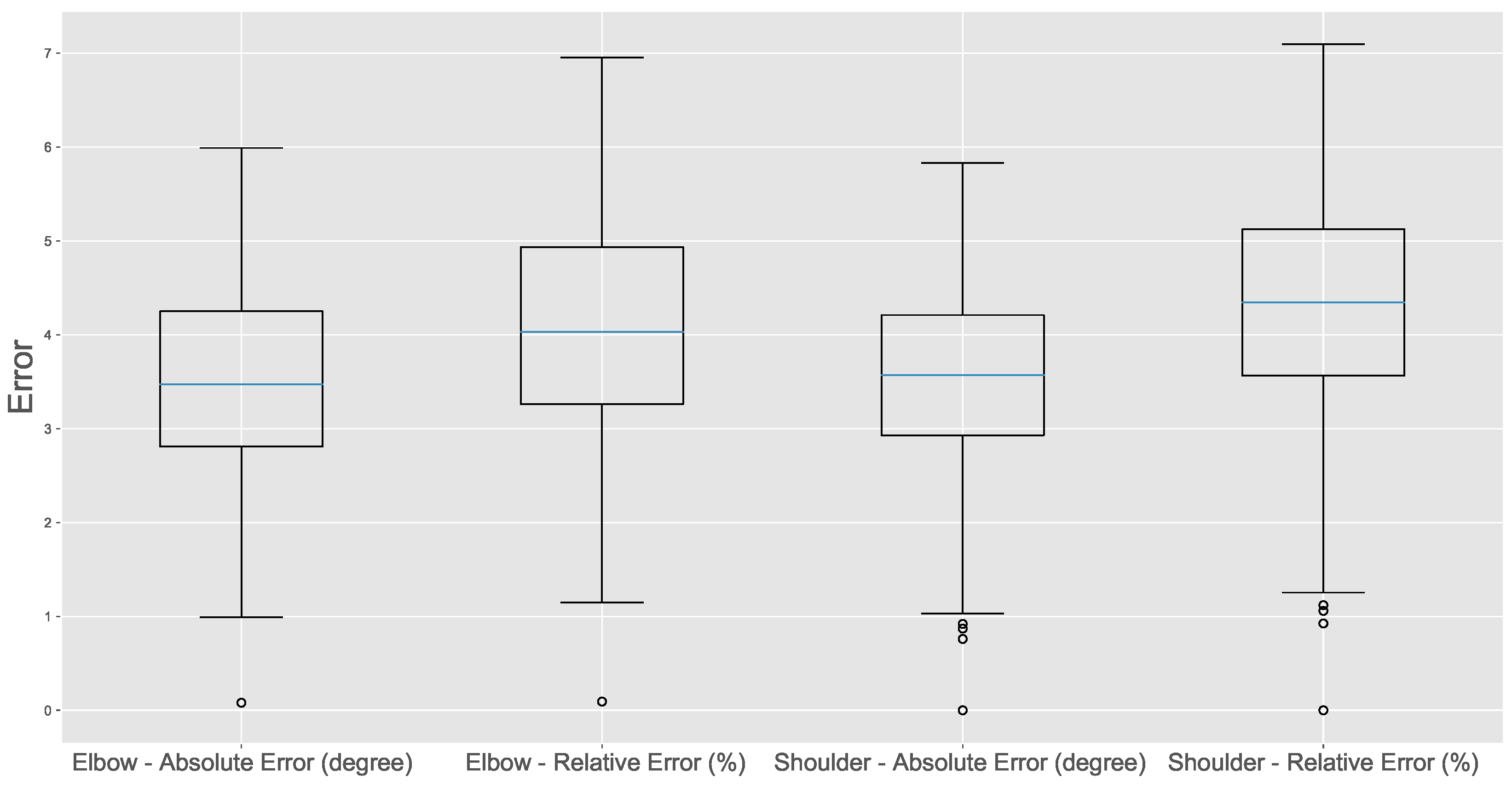

5. Experimental Results

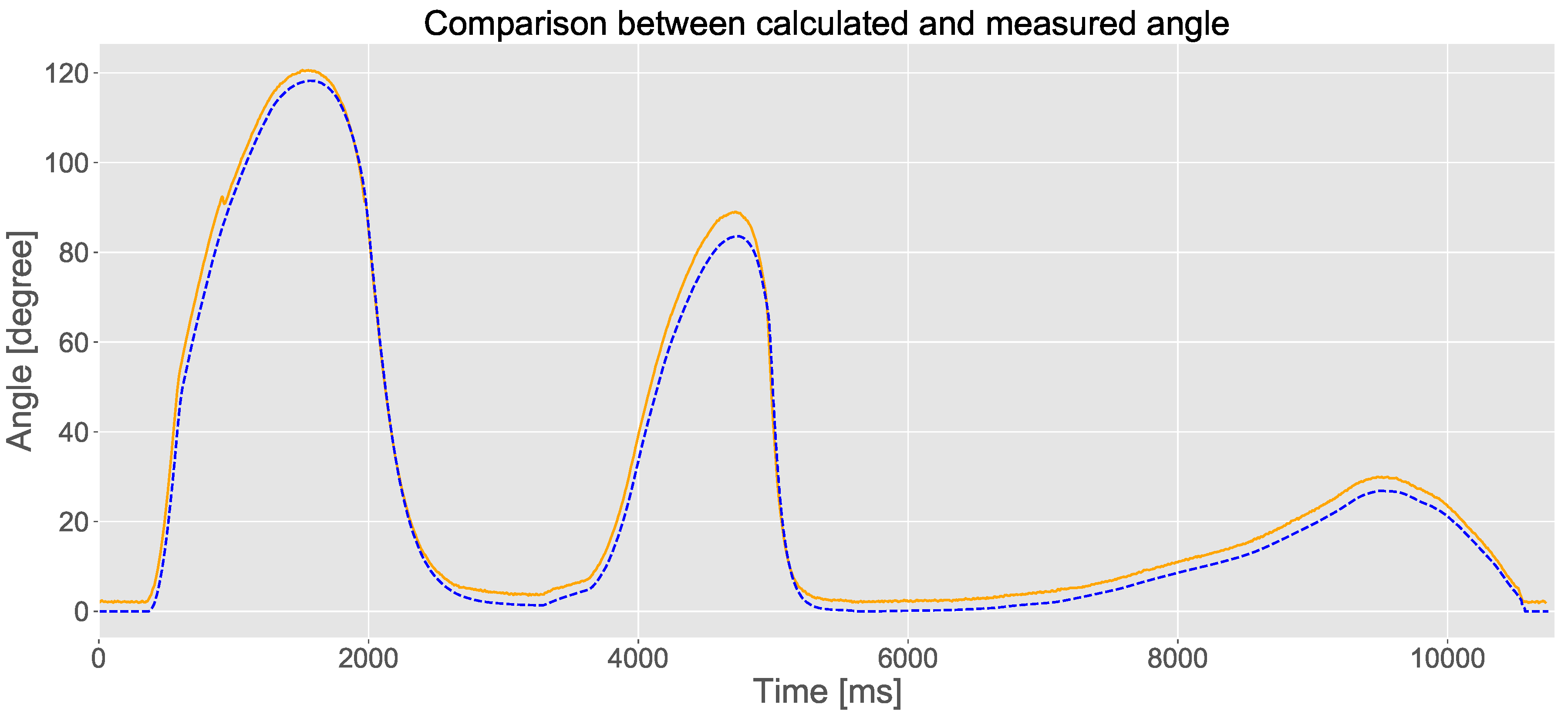

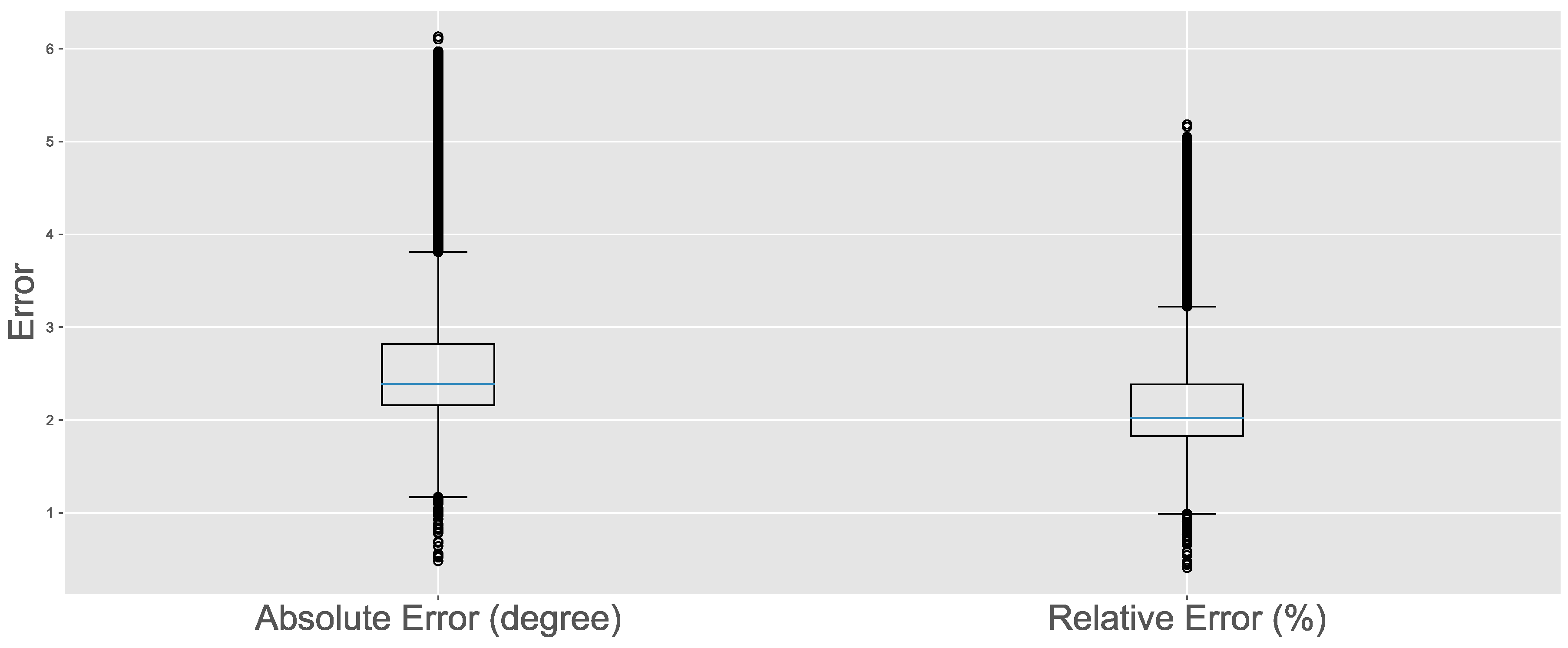

5.1. Experiment 1: One Degree and no Load

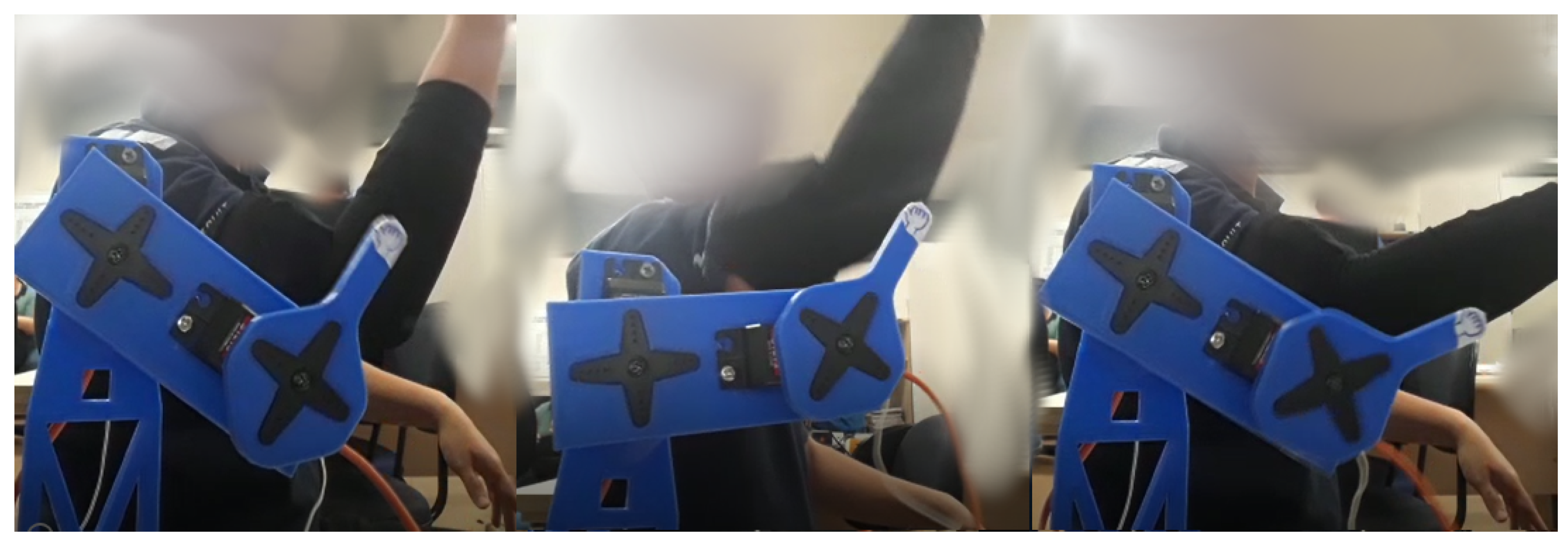

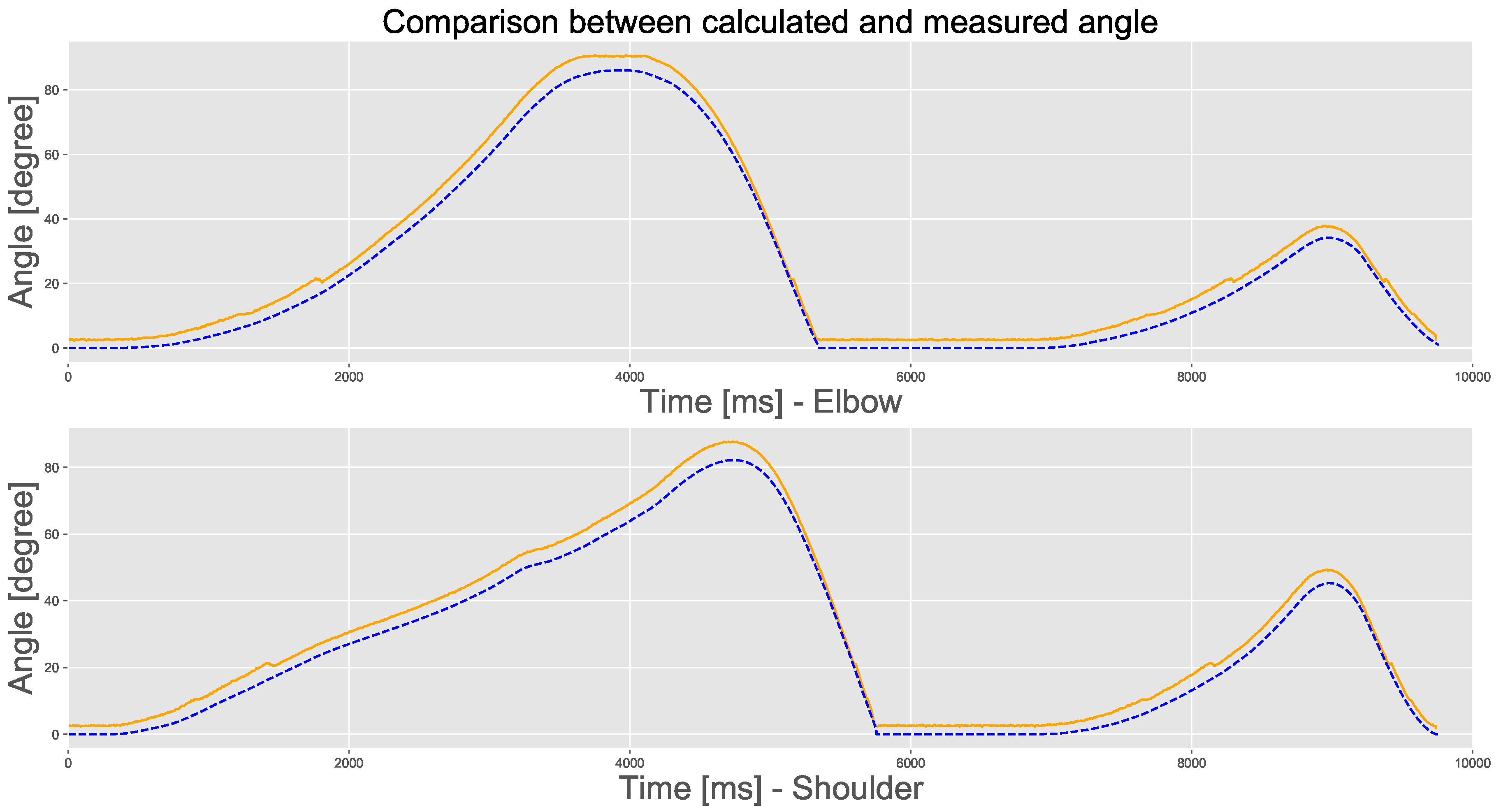

5.2. Experiment 2: Two Degrees and no Load

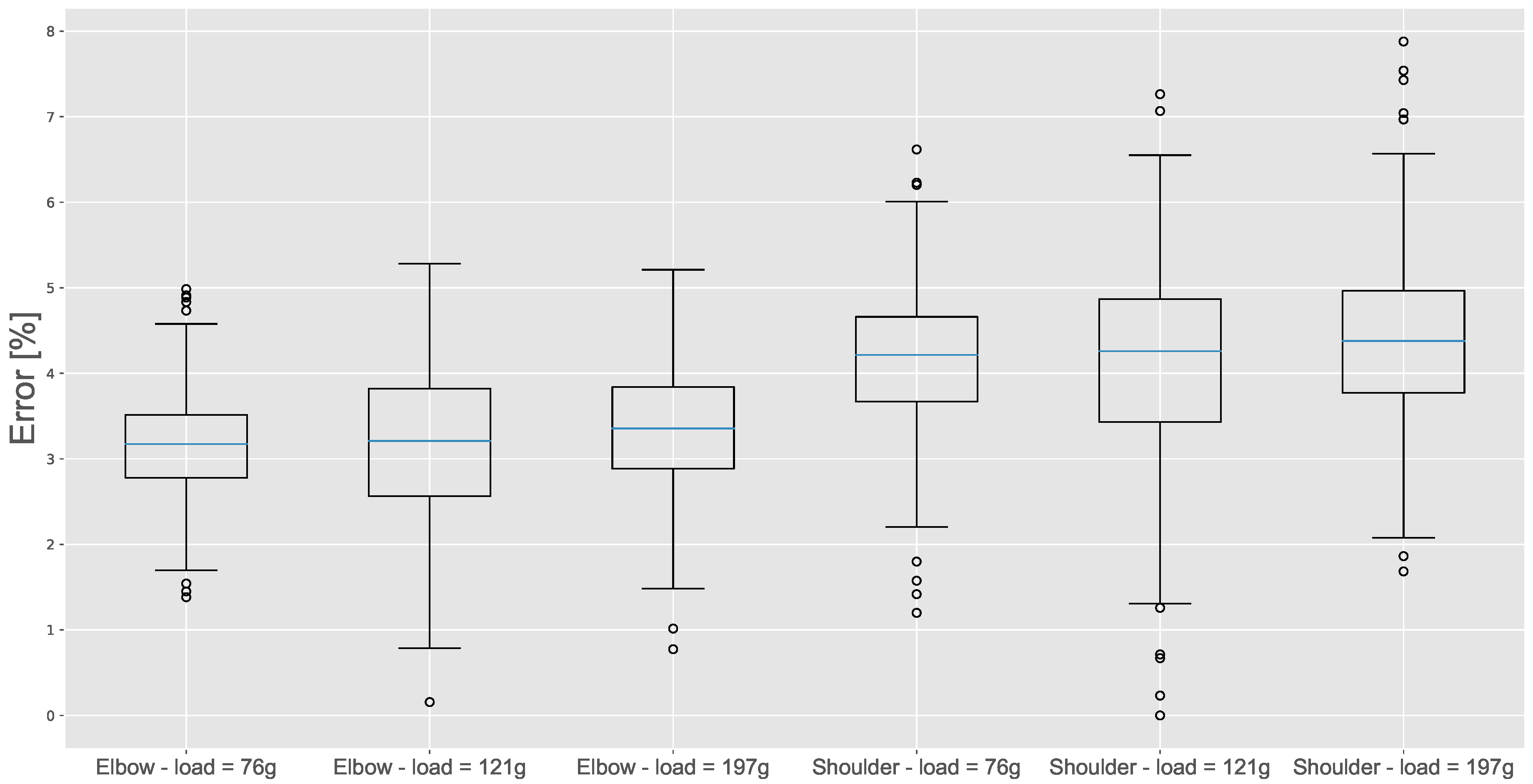

5.3. Experiment 3: Two Degrees and Variable Load

5.4. Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ADC | Analog-to-Digital |

| AI | Artificial Intelligence |

| BPNN | Back Propagation Neural Network |

| CMA | Contraction for Maximum Angle |

| CAD | Computer-aided Design |

| CVA | Cerebrovascular Accident |

| CMRR | Common-mode Rejection Ratio |

| DAC | Digital-to-Analog Converter |

| EMG | Electromyography |

| ESP | Espressif |

| FSR | Force Sensitive Resistor |

| LAN | Local Area Network |

| MQTT | Message Queuing Telemetry Transport |

| MVC | Maximum Voluntary Contraction |

| PC | Personal Computer |

| PLA | Polylactic Acid |

| POC | Proof of Concept |

| RAM | Random Access Memory |

| RMSE | Root Mean Square Error |

| sEMG | Surface Electromyography |

Symbols

| m | Mass read from the sensor |

| Mass of the system | |

| Damping coefficient | |

| Rigidity Of the system | |

| x | Real position |

| Reference position | |

| External force | |

| u | Input control |

| Position constant | |

| Speed constant | |

| Correction constant | |

| Electromyography constant | |

| Gravitational constant | |

| Normalized antagonist signal | |

| Normalized agonist signal | |

| Angle of anterior joint, | |

| Previously calculated angle | |

| Angle of the back joint | |

| Desired angle |

References

- Kim, H.J.; Noh, J.; Yang, W. Knee-Assistive Robotic Exoskeleton (KARE-1) Using a Conditionally Singular Mechanism for Industrial Field Applications. Appl. Sci. 2020, 10, 5141. [Google Scholar] [CrossRef]

- Rzyman, G.; Szkopek, J.; Redlarski, G.; Palkowski, A. Upper Limb Bionic Orthoses: General Overview and Forecasting Changes. Appl. Sci. 2020, 10, 5323. [Google Scholar] [CrossRef]

- Young, A.J.; Ferris, D.P. State of the Art and Future Directions for Lower Limb Robotic Exoskeletons. IEEE Trans. Neural Syst. Rehabil. Eng. 2017, 25, 171–182. [Google Scholar] [CrossRef] [PubMed]

- Lenzi, T.; De Rossi, S.M.M.; Vitiello, N.; Carrozza, M.C. Intention-Based EMG Control for Powered Exoskeletons. IEEE Trans. Biomed. Eng. 2012, 59, 2180–2190. [Google Scholar] [CrossRef] [PubMed]

- Siu, H.C.; Arenas, A.M.; Sun, T.; Stirling, L.A. Implementation of a Surface Electromyography-Based Upper Extremity Exoskeleton Controller Using Learning from Demonstration. Sensors 2018, 18, 467. [Google Scholar] [CrossRef]

- Vitiello, N.; Lenzi, T.; Roccella, S.; De Rossi, S.M.M.; Cattin, E.; Giovacchini, F.; Vecchi, F.; Carrozza, M.C. NEUROExos: A Powered Elbow Exoskeleton for Physical Rehabilitation. IEEE Trans. Robot. 2013, 29, 220–235. [Google Scholar] [CrossRef]

- Zhang, T.; Tran, M.; Huang, H. Admittance Shaping-Based Assistive Control of SEA-Driven Robotic Hip Exoskeleton. IEEE/ASME Trans. Mech. 2019, 24, 1508–1519. [Google Scholar] [CrossRef]

- Kiguchi, K.; Hayashi, Y. An EMG-Based Control for an Upper-Limb Power-Assist Exoskeleton Robot. IEEE Trans. Syst. Man Cybern. Part B 2012, 42, 1064–1071. [Google Scholar] [CrossRef]

- Wang, D.; Meng, Q.; Meng, Q.; Li, X.; Yu, H. Design and Development of a Portable Exoskeleton for Hand Rehabilitation. IEEE Trans. Neural Syst. Rehabil. Eng. 2018, 26, 2376–2386. [Google Scholar] [CrossRef]

- Waris, A.; Kamavuako, E.N. Effect of threshold values on the combination of EMG time domain features: Surface versus intramuscular EMG. Biomed. Signal Process. Control 2018, 45, 267–273. [Google Scholar] [CrossRef]

- Li, Z.; Wang, B.; Sun, F.; Yang, C.; Xie, Q.; Zhang, W. sEMG-Based Joint Force Control for an Upper-Limb Power-Assist Exoskeleton Robot. IEEE J. Biomed. Health Inform. 2014, 18, 1043–1050. [Google Scholar] [CrossRef] [PubMed]

- Cram, J.; Criswell, E. Cram’s Introduction to Surface Electromyography; G-Reference, Information and Interdisciplinary Subjects Series; Jones & Bartlett Learning: Burlington, MA, USA, 2010. [Google Scholar]

- Merletti, R.; Parker, P. Electromyography: Physiology, Engineering, and Non-Invasive Applications; IEEE Press Series on Biomedical Engineering; Wiley: Hoboken, NJ, USA, 2004. [Google Scholar]

- Nordin, M.; Frankel, V.H. Basic Biomechanics of the Musculoskeletal System, 4th North American ed.; LWW: Philadelphia, PA, USA, 2012. [Google Scholar]

- Kiguchi, K.; Rahman, M.H.; Sasaki, M.; Teramoto, K. Development of a 3DOF mobile exoskeleton robot for human upper-limb motion assist. Robot. Auton. Syst. 2008, 56, 678–691. [Google Scholar] [CrossRef]

- Tang, Z.; Yu, H.; Cang, S. Impact of Load Variation on Joint Angle Estimation From Surface EMG Signals. IEEE Trans. Neural Syst. Rehabil. Eng. 2016, 24, 1342–1350. [Google Scholar] [CrossRef] [PubMed]

- Guidotti, D.; Leofante, F.; Tacchella, A.; Castellini, C. Improving Reliability of Myocontrol Using Formal Verification. IEEE Trans. Neural Syst. Rehabil. Eng. 2019, 27, 564–571. [Google Scholar] [CrossRef] [PubMed]

- Ueda, J.; Ming, D.; Krishnamoorthy, V.; Shinohara, M.; Ogasawara, T. Individual Muscle Control Using an Exoskeleton Robot for Muscle Function Testing. IEEE Trans. Neural Syst. Rehabil. Eng. 2010, 18, 339–350. [Google Scholar] [CrossRef]

- Lu, L.; Wu, Q.; Chen, X.; Shao, Z.; Chen, B.; Wu, H. Development of a sEMG-based torque estimation control strategy for a soft elbow exoskeleton. Robot. Auton. Syst. 2019, 111, 88–98. [Google Scholar] [CrossRef]

- Chowdhury, R.; Reaz, M.B.I.; Mohd Ali, M.; A Bakar, A.A.; Chellappan, K.; Chang, T.G. Surface Electromyography Signal Processing and Classification Techniques. Sensors 2013, 13, 12431–12466. [Google Scholar] [CrossRef]

- Betthauser, J.L.; Hunt, C.L.; Osborn, L.E.; Masters, M.R.; Lévay, G.; Kaliki, R.R.; Thakor, N.V. Limb Position Tolerant Pattern Recognition for Myoelectric Prosthesis Control with Adaptive Sparse Representations From Extreme Learning. IEEE Trans. Biomed. Eng. 2018, 65, 770–778. [Google Scholar] [CrossRef]

- Al-Shuka, H.; Leonhardt, S.; Zhu, W.H.; Song, R.; Ding, C.; Li, Y. Active Impedance Control of Bioinspired Motion Robotic Manipulators: An Overview. Appl. Bionics Biomech. 2018. [Google Scholar] [CrossRef]

- Zhuang, Y.; Yao, S.; Ma, C.; Song, R. Admittance Control Based on EMG-Driven Musculoskeletal Model Improves the Human–Robot Synchronization. IEEE Trans. Ind. Inform. 2019, 15, 1211–1218. [Google Scholar] [CrossRef]

- Cafolla, D.; Wang, M.; Carbone, G.; Ceccarelli, M. LARMbot: A New Humanoid Robot with Parallel Mechanisms. CISM Int. Centre Mech. Sci. Courses Lectures 2016, 569, 275–283. [Google Scholar] [CrossRef]

- Cafolla, D.; Russo, M.; Carbone, G. CUBE, a Cable-driven Device for Limb Rehabilitation. J. Bionic Eng. 2019, 16, 492–502. [Google Scholar] [CrossRef]

- Hall, S. Basic Biomechanics; McGraw-Hill: New York, NY, USA, 2007. [Google Scholar]

- Barbero, M.; Merletti, R.; Rainoldi, A. Atlas of Muscle Innervation Zones: Understanding Surface Electromyography and Its Applications; Springer: Milan, Italy, 2012. [Google Scholar] [CrossRef]

- De Luca, C.J. The use of surface electromyography in biomechanics. J. Appl. Biomech. 1997, 13, 135–163. [Google Scholar] [CrossRef]

- Zeng, Y.; Yang, J.; Yin, Y. Gaussian Process-Integrated State Space Model for Continuous Joint Angle Prediction from EMG and Interactive Force in a Human-Exoskeleton System. Appl. Sci. 2019, 9, 1711. [Google Scholar] [CrossRef]

- Dietrich, A.M. Whole-Body Impedance Control of Wheeled Humanoid Robots. Ph.D. Thesis, Technische Universität München, Munich, Germany, 2015. [Google Scholar]

- Liang, C.; Hsiao, T. Admittance Control of Powered Exoskeletons Based on Joint Torque Estimation. IEEE Access 2020, 8, 94404–94414. [Google Scholar] [CrossRef]

- Li, Z.; Huang, Z.; He, W.; Su, C. Adaptive Impedance Control for an Upper Limb Robotic Exoskeleton Using Biological Signals. IEEE Trans. Ind. Electron. 2017, 64, 1664–1674. [Google Scholar] [CrossRef]

- Liu, J.; Ren, Y.; Xu, D.; Kang, S.H.; Zhang, L. EMG-Based Real-Time Linear-Nonlinear Cascade Regression Decoding of Shoulder, Elbow, and Wrist Movements in Able-Bodied Persons and Stroke Survivors. IEEE Trans. Biomed. Eng. 2020, 67, 1272–1281. [Google Scholar] [CrossRef]

- Lei, Z. An upper limb movement estimation from electromyography by using BP neural network. Biomed. Signal Process. Control 2019, 49, 434–439. [Google Scholar] [CrossRef]

- Weixing, W.; Qianqian, L.; Chao, L.; Shouqian, S. Effects of Proprioception and Visual Focus of Attention on Surface Electromyography Proportional Control. Appl. Sci. 2019, 9, 730. [Google Scholar] [CrossRef]

- Advancer Technologies. Sensor for Microcontroller Applications. Available online: https://github.com/AdvancerTechnologies/MyoWare_MuscleSensor/blob/master/Documents/AT-04-001.pdf (accessed on 27 August 2020).

- Interlink electronics. FSR 402 Data Sheet. Available online: https://www.interlinkelectronics.com/request-data-sheets (accessed on 27 August 2020).

- Inven Sense. MPU-6000 and MPU-6050 Product Specification Revision 3.4. Available online: https://invensense.tdk.com/wp-content/uploads/2015/02/MPU-6000-Datasheet1.pdf (accessed on 27 August 2020).

- ServoDataBase. Batan S1213 Servo. Available online: https://servodatabase.com/servo/batan/s1213 (accessed on 27 August 2020).

- Espressif Systems. ESP32 Series datasheet. Available online: https://www.espressif.com/sites/default/files/documentation/esp32_datasheet_en.pdf (accessed on 27 August 2020).

- Raspberry Pi Foundation. Datasheet Raspberry Pi Compute Module 3+. Available online: https://www.raspberrypi.org/documentation/hardware/computemodule/datasheets/rpi_DATA_CM3plus_1p0.pdf (accessed on 27 August 2020).

| Feature | [32] | [33] | [34] | [35] | This Work |

|---|---|---|---|---|---|

| Control technique | Shiftness-based impedance | Linear regression trained with EMG and limb position | BPNN trained wth EMG and limb position | BPNN trained with EMG and limb position | Impedance and admittance control |

| Body limb | Arm | Arm | Arm | Arm | Arm |

| Tested joints | Elbow and shoulder | Elbow, shoulder and wristle | Elbow | Elbow | Elbow and shoulder |

| Embedded implementation | No | No | Partial | No | Yes |

| Test | RMSE Elbow | RMSE Shoulder | NRMSE Elbow | NRMSE Shoulder |

|---|---|---|---|---|

| One degree—no load | 2.735 | - | 2.452% | - |

| Two degrees—no load | 3.609 | 3.642 | 4.190% | 4.433% |

| Two degrees—load = 76 g | 2.531 | 3.339 | 3.164% | 4.174% |

| Two degrees—load = 121 g | 2.431 | 3.109 | 3.198% | 4.091% |

| Two degrees—load = 197 g | 2.658 | 3.464 | 3.365% | 4.385% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

da Silva, L.D.L.; Pereira, T.F.; Leithardt, V.R.Q.; Seman, L.O.; Zeferino, C.A. Hybrid Impedance-Admittance Control for Upper Limb Exoskeleton Using Electromyography. Appl. Sci. 2020, 10, 7146. https://doi.org/10.3390/app10207146

da Silva LDL, Pereira TF, Leithardt VRQ, Seman LO, Zeferino CA. Hybrid Impedance-Admittance Control for Upper Limb Exoskeleton Using Electromyography. Applied Sciences. 2020; 10(20):7146. https://doi.org/10.3390/app10207146

Chicago/Turabian Styleda Silva, Lucas D. L., Thiago F. Pereira, Valderi R. Q. Leithardt, Laio O. Seman, and Cesar A. Zeferino. 2020. "Hybrid Impedance-Admittance Control for Upper Limb Exoskeleton Using Electromyography" Applied Sciences 10, no. 20: 7146. https://doi.org/10.3390/app10207146

APA Styleda Silva, L. D. L., Pereira, T. F., Leithardt, V. R. Q., Seman, L. O., & Zeferino, C. A. (2020). Hybrid Impedance-Admittance Control for Upper Limb Exoskeleton Using Electromyography. Applied Sciences, 10(20), 7146. https://doi.org/10.3390/app10207146