Printability of the Screen-Printed Strain Sensor with Carbon Black/Silver Paste for Sensitive Wearable Electronics

Abstract

1. Introduction

2. Experiments

2.1. Chemicals

2.2. Paste Formulation of CB/Ag Paste

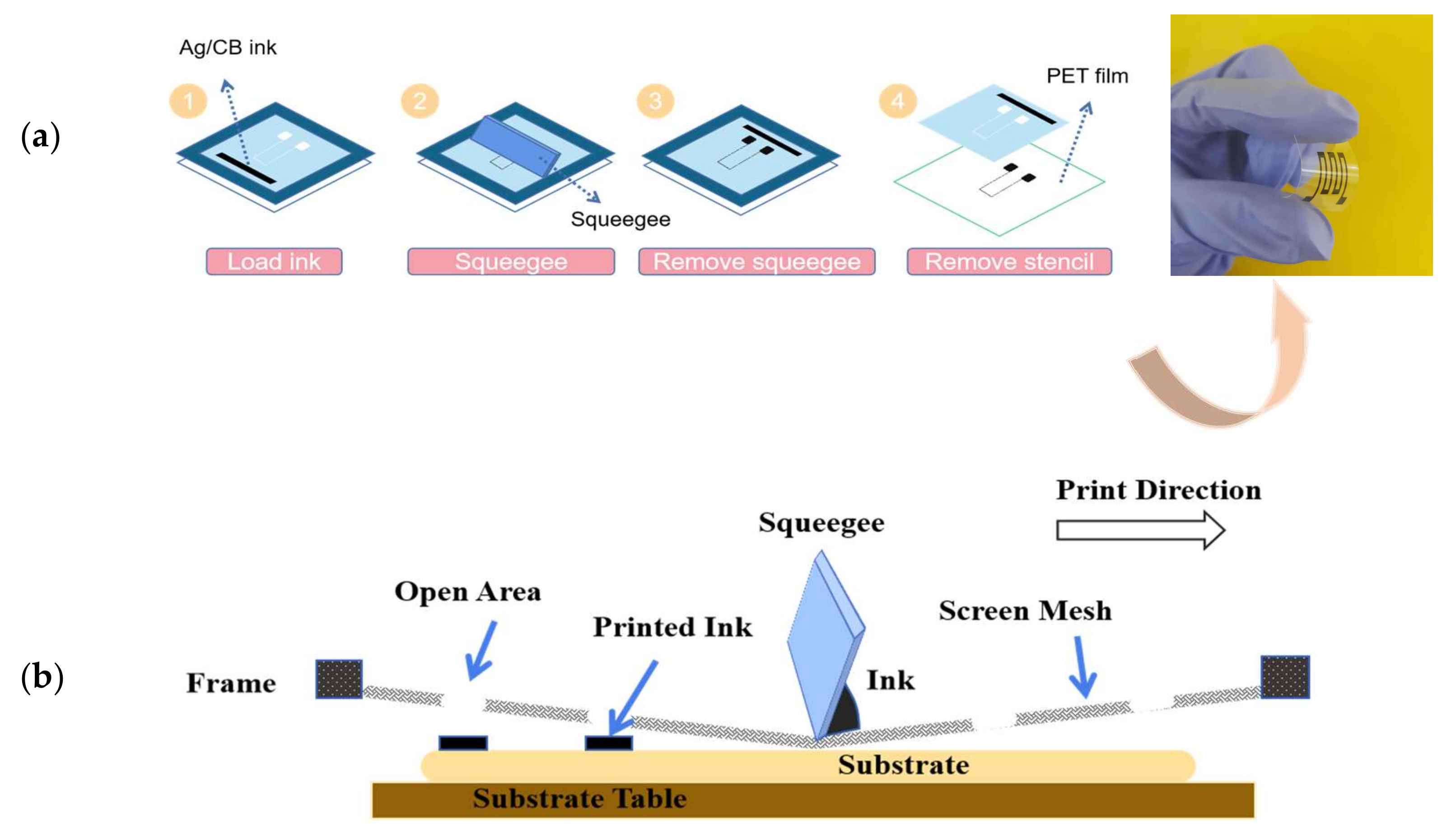

2.3. Fabrication of CB/Ag Strain Sensor

2.4. Characterization

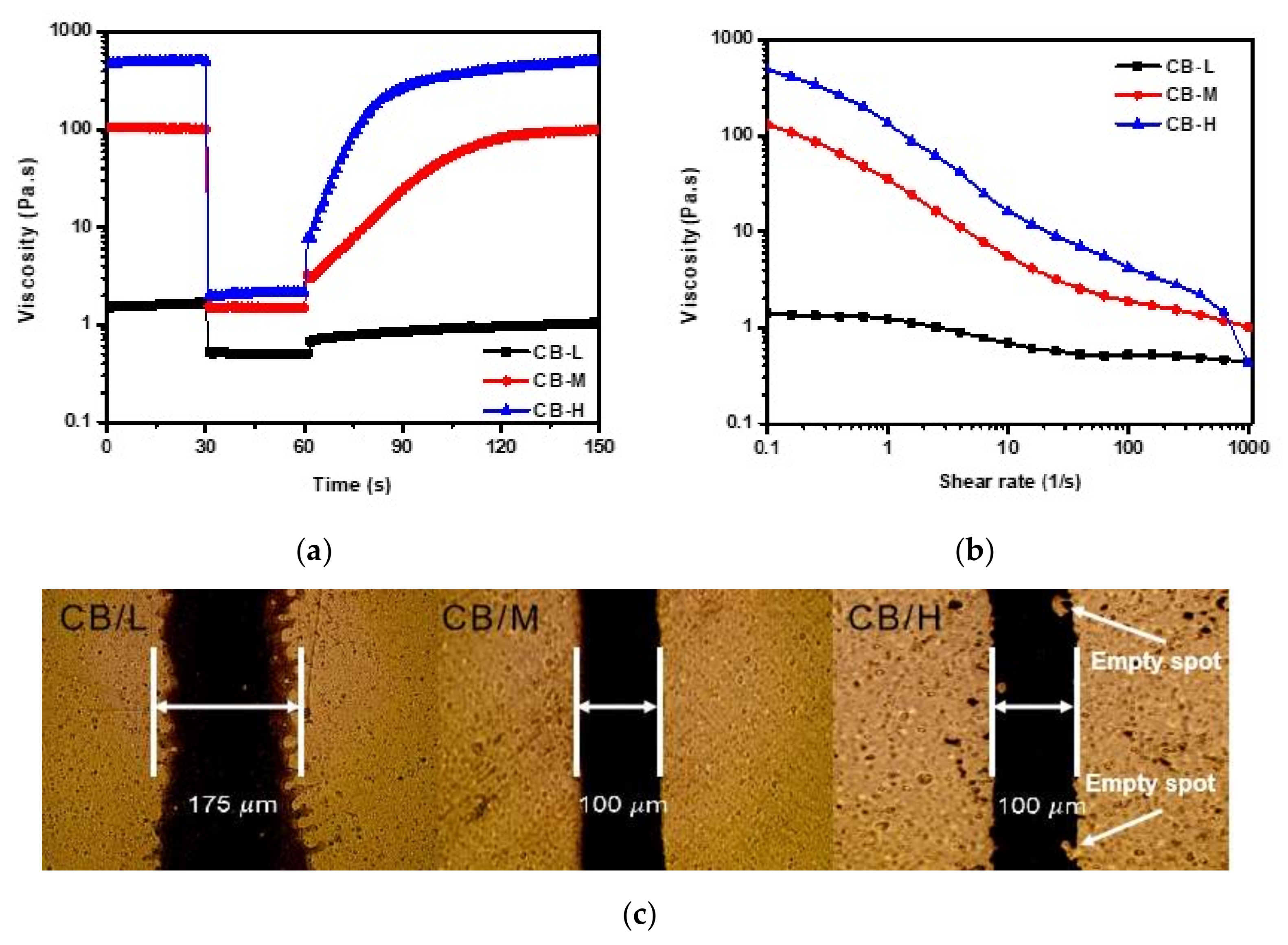

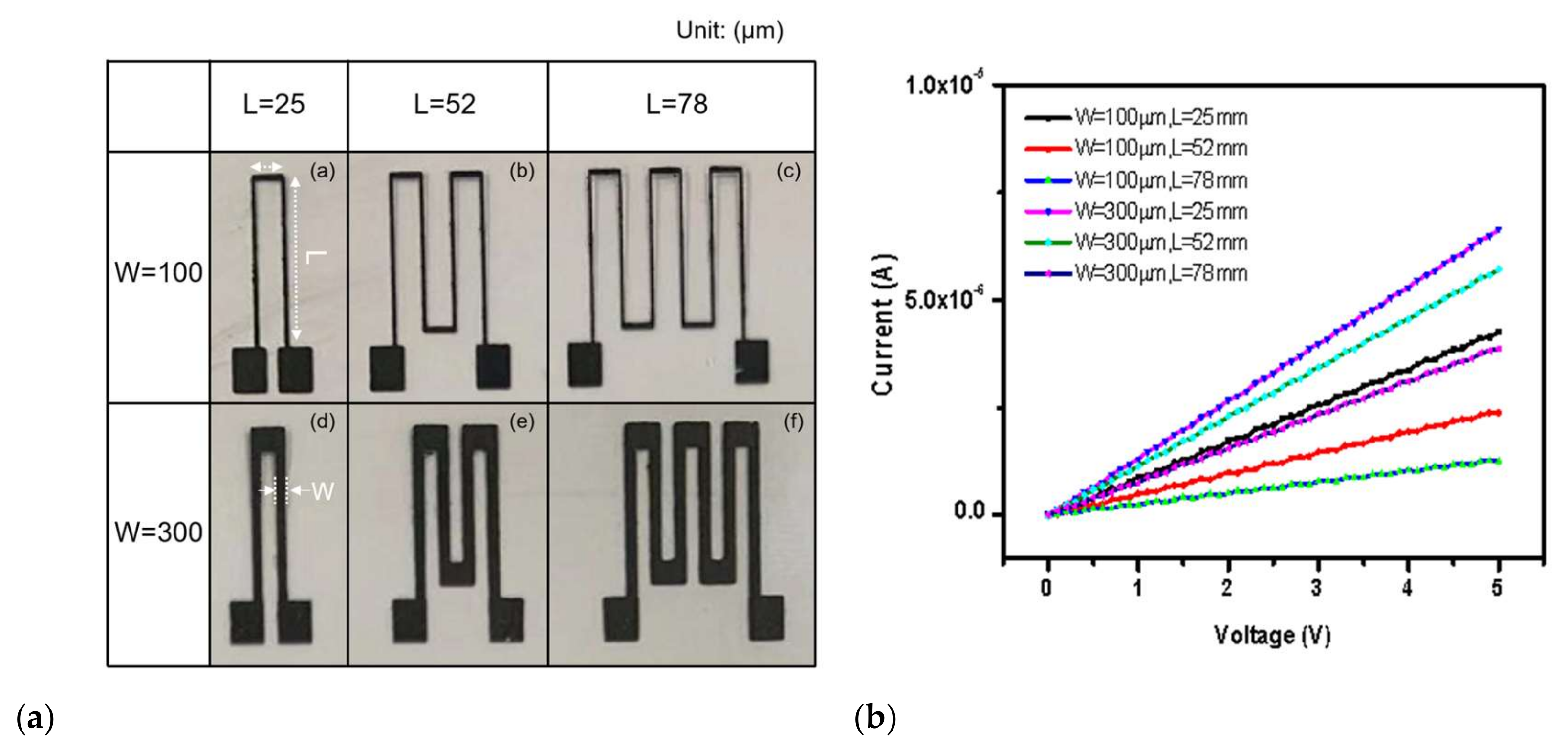

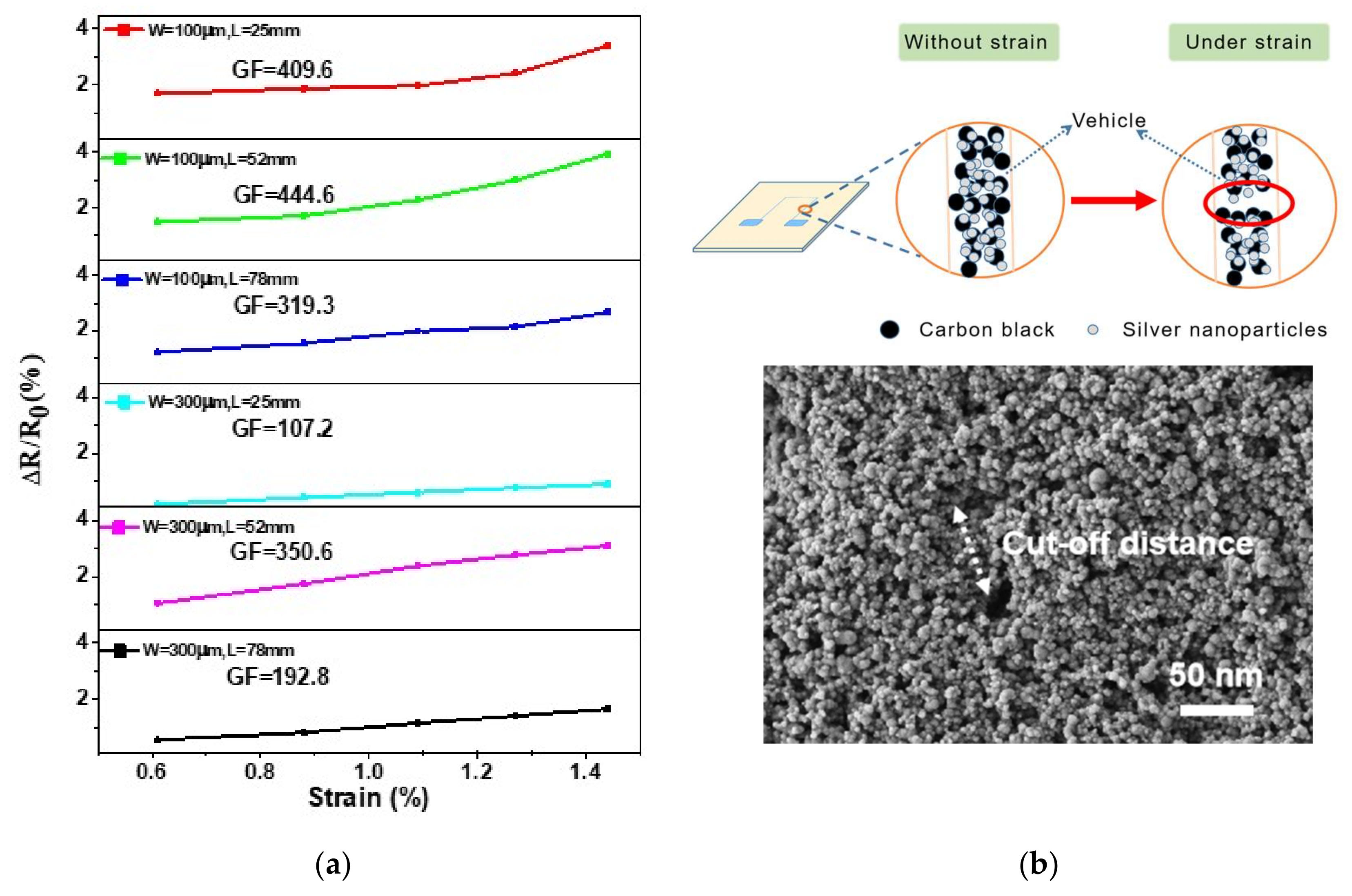

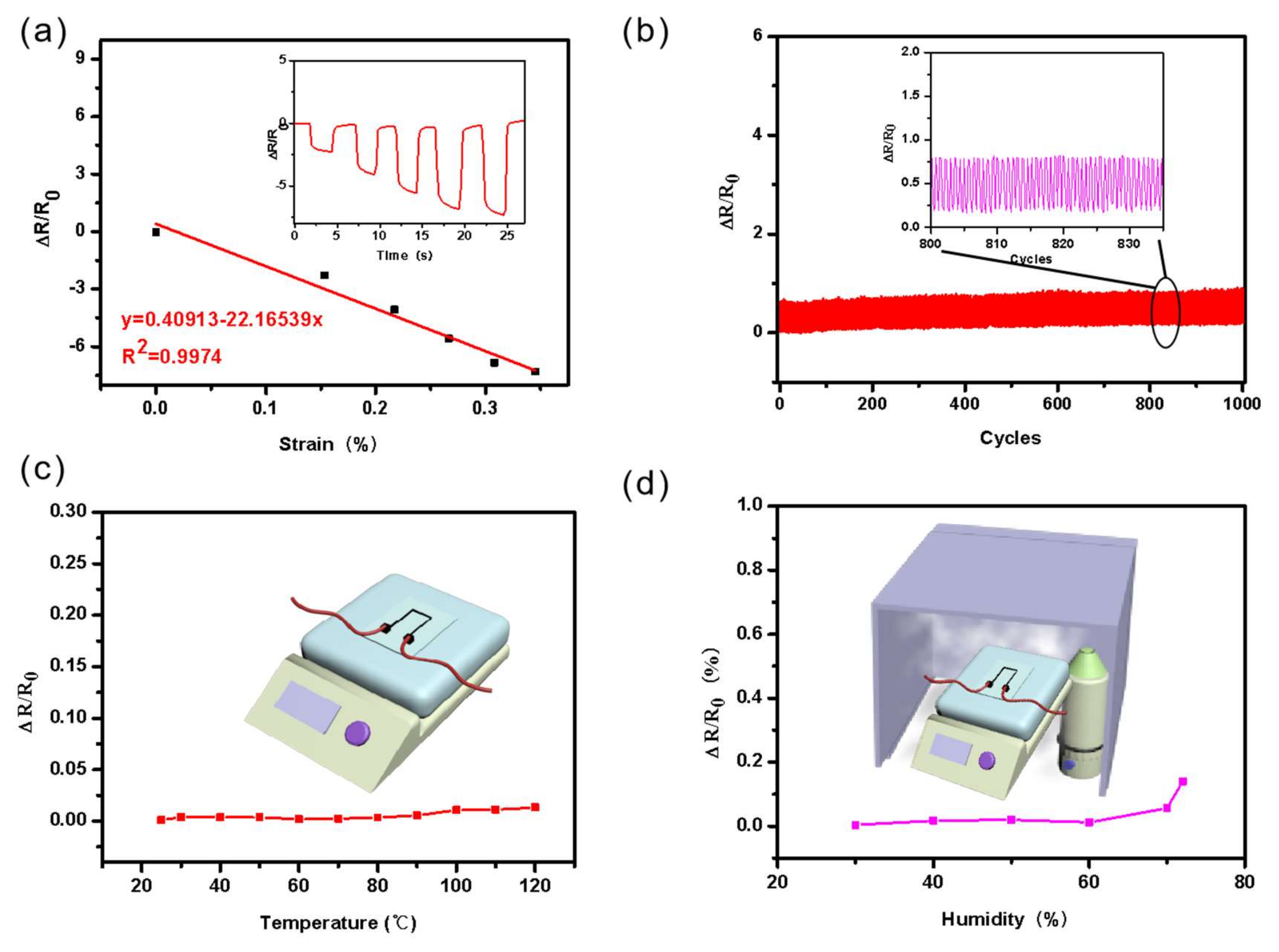

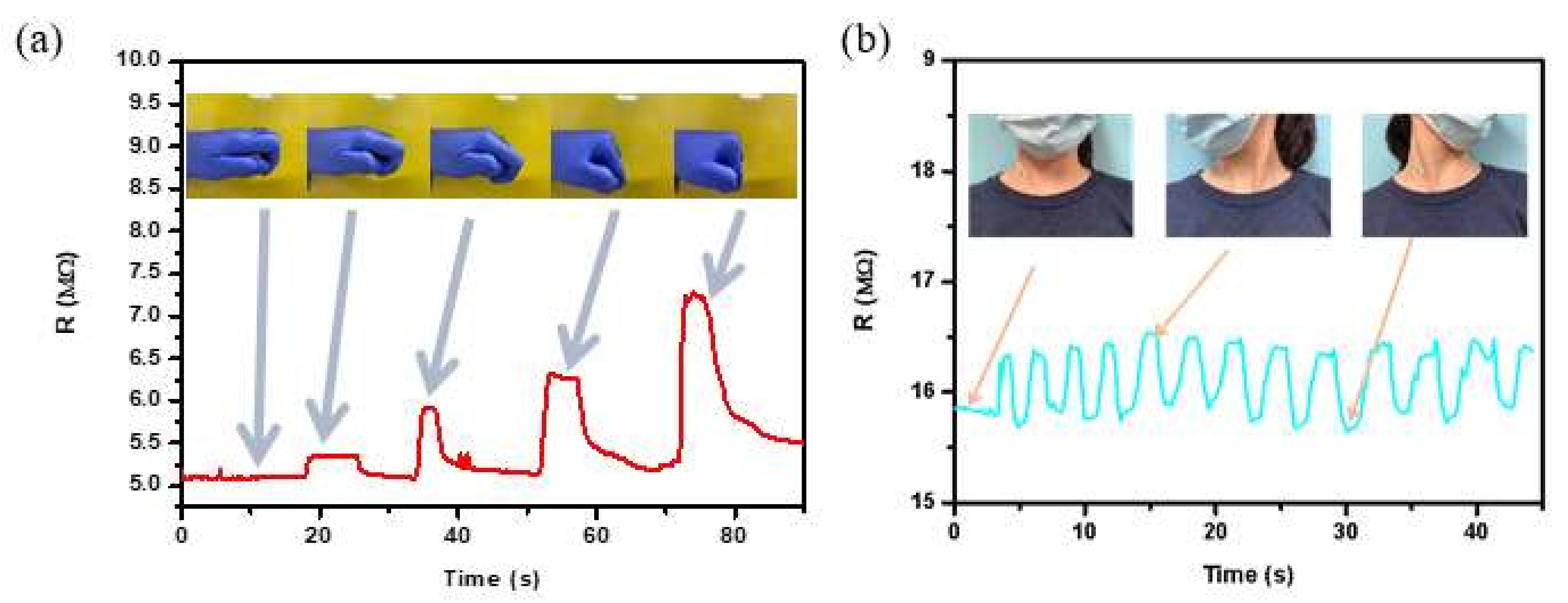

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Qi, X.; Li, X.; Jo, H.; Bhat, K.S.; Kim, S.; An, J.; Kang, J.W.; Lim, S. Mulberry paper-based graphene strain sensor for wearable electronics with high mechanical strength. Sens. Actuators A Phys. 2020, 301, 111697. [Google Scholar] [CrossRef]

- Amjadi, M.; Kyung, K.U.; Park, I.; Sitti, M. Stretchable, Skin-Mountable, and Wearable Strain Sensors and Their Potential Applications: A Review. Adv. Funct. Mater. 2016, 26, 1678–1698. [Google Scholar] [CrossRef]

- Patel, S.; Park, H.; Bonato, P.; Chan, L.; Rodgers, M. A review of wearable sensors and systems with application in rehabilitation. J. Neuroeng. Rehabil. 2012, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Zang, Y.; Zhang, F.; Di, C.A.; Zhu, D. Advances of flexible pressure sensors toward artificial intelligence and health care applications. Mater. Horiz. 2015, 2, 140–156. [Google Scholar] [CrossRef]

- Jayathilaka, W.A.D.M.; Qi, K.; Qin, Y.; Chinnappan, A.; Serrano-García, W.; Baskar, C.; Wang, H.; He, J.; Cui, S.; Thomas, S.W.; et al. Significance of Nanomaterials in Wearables: A Review on Wearable Actuators and Sensors. Adv. Mater. 2019, 31, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Pardo, D.A.; Jabbour, G.E.; Peyghambarian, N. Application of screen printing in the fabrication of organic light-emitting devices. Adv. Mater. 2000, 12, 1249–1252. [Google Scholar] [CrossRef]

- Liu, L.; Ye, X.; Wu, K.; Han, R.; Zhou, Z.; Cui, T. Humidity sensitivity of multi-walled carbon nanotube networks deposited by dielectrophoresis. Sensors 2009, 9, 1714–1721. [Google Scholar] [CrossRef]

- Ali, S.; Hassan, A.; Hassan, G.; Bae, J.; Lee, C.H. All-printed humidity sensor based on gmethyl-red/methyl-red composite with high sensitivity. Carbon N. Y. 2016, 105, 23–32. [Google Scholar] [CrossRef]

- Lee, J.; Cho, D.; Jeong, Y. A resistive-type sensor based on flexible multi-walled carbon nanotubes and polyacrylic acid composite films. Solid. State. Electron. 2013, 87, 80–84. [Google Scholar] [CrossRef]

- Yi, W.; Wang, Y.; Wang, G.; Tao, X. Investigation of carbon black/silicone elastomer/dimethylsilicone oil composites for flexible strain sensors. Polym. Test. 2012, 31, 677–684. [Google Scholar] [CrossRef]

- Moonen, P.F.; Yakimets, I.; Huskens, J. Fabrication of transistors on flexible substrates: From mass-printing to high-resolution alternative lithography strategies. Adv. Mater. 2012, 24, 5526–5541. [Google Scholar] [CrossRef] [PubMed]

- Zirkl, M.; Sawatdee, A.; Helbig, U.; Krause, M.; Scheipl, G.; Kraker, E.; Ersman, P.A.; Nilsson, D.; Platt, D.; Bodö, P.; et al. An all-printed ferroelectric active matrix sensor network based on only five functional materials forming a touchless control interface. Adv. Mater. 2011, 23, 2069–2074. [Google Scholar] [CrossRef] [PubMed]

- Bae, S.; Kim, H.; Lee, Y.; Xu, X.; Park, J.S.; Zheng, Y.; Balakrishnan, J.; Lei, T.; Ri Kim, H.; Il Song, Y.; et al. Roll-to-roll production of 30-inch graphene films for transparent electrodes. Nat. Nanotechnol. 2010, 5, 574–578. [Google Scholar] [CrossRef]

- Erath, D.; Filipović, A.; Retzlaff, M.; Goetz, A.K.; Clement, F.; Biro, D.; Preu, R. Advanced screen printing technique for high definition front side metallization of crystalline silicon solar cells. Sol. Energy Mater. Sol. Cells 2010, 94, 57–61. [Google Scholar] [CrossRef]

- Lee, T.M.; Choi, Y.J.; Nam, S.Y.; You, C.W.; Na, D.Y.; Choi, H.C.; Shin, D.Y.; Kim, K.Y.; Il Jung, K. Color filter patterned by screen printing. Thin Solid Films 2008, 516, 7875–7880. [Google Scholar] [CrossRef]

- Bao, Z.; Feng, Y.; Dodabalapur, A.; Raju, V.R.; Lovinger, A.J. High-Performance Plastic Transistors Fabricated by Printing Techniques. Chem. Mater. 1997, 9, 1299–1301. [Google Scholar] [CrossRef]

- Park, K.; Seo, D.; Lee, J. Conductivity of silver paste prepared from nanoparticles, Colloids Surfaces A Physicochem. Eng. Asp. 2008, 313–314, 351–354. [Google Scholar] [CrossRef]

- Faddoul, R.; Reverdy-bruas, N.; Blayo, A. Formulation and screen printing of water based conductive flake silver pastes.pdf. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2012, 177, 1053–1066. [Google Scholar] [CrossRef]

- Krebs, F.C.; Jørgensen, M.; Norrman, K.; Hagemann, O.; Alstrup, J.; Nielsen, T.D.; Fyenbo, J.; Larsen, K.; Kristensen, J. A complete process for production of flexible large area polymer solar cells entirely using screen printing-First public demonstration. Sol. Energy Mater. Sol. Cells 2009, 93, 422–441. [Google Scholar] [CrossRef]

- Hyun, W.J.; Secor, E.B.; Hersam, M.C.; Frisbie, C.D.; Francis, L.F. High-resolution patterning of graphene by screen printing with a silicon stencil for highly flexible printed electronics. Adv. Mater. 2015, 27, 109–115. [Google Scholar] [CrossRef]

- Cao, X.; Chen, H.; Gu, X.; Liu, B.; Wang, W.; Cao, Y.; Wu, F.; Zhou, C. Screen printing as a scalable and low-cost approach for rigid and flexible thin-film transistors using separated carbon nanotubes. ACS Nano 2014, 8, 12769–12776. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Liu, Q.; Chen, P. Flexible strain sensor based on carbon black/silver nanoparticles composite for humanmotion detection. Materials 2018, 11, 1836. [Google Scholar] [CrossRef] [PubMed]

- Song, H.; Zhang, J.; Chen, D.; Wang, K.; Niu, S.; Han, Z.; Ren, L. Superfast and high-sensitivity printable strain sensors with bioinspired micron-scale cracks. Nanoscale 2017, 9, 1166–1173. [Google Scholar] [CrossRef]

- Sorahan, T.; Harrington, J.M. A “lugged” analysis of lung cancer risks in UK carbon black production workers, 1951–2004. Am. J. Ind. Med. 2007, 50, 555–564. [Google Scholar] [CrossRef] [PubMed]

- Faddoul, R.; Reverdy-Bruas, N.; Bourel, J. Silver content effect on rheological and electrical properties of silver pastes. J. Mater. Sci. Mater. Electron. 2012, 23, 1415–1426. [Google Scholar] [CrossRef]

- Xiao, Y.; Jiang, S.; Li, Y.; Zhang, W. Highly sensitive printed crack-enhanced strain sensor as dual-directional bending detector. Smart Mater. Struct. 2020, 29, 045023. [Google Scholar] [CrossRef]

- Wu, X.; Han, Y.; Zhang, X.; Lu, C. Highly Sensitive, Stretchable, and Wash-Durable Strain Sensor Based on Ultrathin Conductive Layer@ Polyurethane Yarn for Tiny Motion Monitoring. ACS Appl. Mater. Interfaces 2016. [Google Scholar] [CrossRef]

- Mi, M.; Pissis, P.; Kraj, J. Study of the reinforcing mechanism and strain sensing in a carbon black filled elastomer. Compos. Part B Eng. 2015, 80, 20–26. [Google Scholar] [CrossRef]

- Guo, X.; Huang, Y.; Zhao, Y.; Mao, L.; Gao, L. Highly stretchable strain sensor based on SWCNTs/CB synergistic conductive network for Highly stretchable strain sensor based on SWCNTs/CB synergistic conductive network for wearable human-activity monitoring and recognition. Smart Mater. Struct. 2017, 26, 095017. [Google Scholar] [CrossRef]

- Koncar, V.; Lewandowski, M.; Dufour, C. Design and Development of a Flexible Strain Sensor for Textile Structures Based on a Conductive Polymer Composite. Sensors 2007, 7, 473–492. [Google Scholar]

- Zheng, Y.; Li, Y.; Li, Z.; Wang, Y.; Dai, K.; Zheng, G.; Liu, C. The effect of fi ller dimensionality on the electromechanical performance of polydimethylsiloxane based conductive nanocomposites for fl exible strain sensors. Compos. Sci. Technol. 2017, 139, 64–73. [Google Scholar] [CrossRef]

- Dubey, K.A.; Mondal, R.K.; Grover, V.; Bhardwaj, Y.K.; Tyagi, A.K. Physical Development of a novel strain sensor based on fluorocarbon–elastomeric nanocomposites: Effect of network density on the electromechanical properties. Sensors Actuators A. Phys. 2015, 221, 33–40. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, F.; Zhao, X.; Liu, M. High-Performance Strain Sensors Based on Spirally Structured Composites with Carbon Black, Chitin Nanocrystals, and Natural Rubber. ACS Sustain. Chem. Eng. 2018, 6, 10595–10605. [Google Scholar] [CrossRef]

- Schmid, P.; Orfert, M.; Vogt, M. Plasma deposition of Si-N and Si-O passivation layers on three-dimensional sensor devices. Surf. Coat. Technol. 1998, 98, 1510–1517. [Google Scholar] [CrossRef]

| 0.1 s−1 30 s | 200 s−1 60 s | 0.1 s−1 75 s | Recovery 75 s | 0.1 s−1 80 s | Recovery 80 s | 0.1 s−1 90 s | Recovery 90 s | 0.1 s−1 110 s | Recovery 110 s | 0.1 s−1 130 s | Recovery 130 s | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | 1.66 | 0.51 | 0.78 | 47.0% | 0.81 | 48.7% | 0.85 | 51.1% | 0.94 | 56.5% | 0.97 | 58.4% |

| M | 101.43 | 1.48 | 7.89 | 7.8% | 11.33 | 11.2% | 23.87 | 23.5% | 63.75 | 62.9% | 91.17 | 89.9% |

| H | 501.47 | 2.15 | 90.21 | 18.0% | 153.63 | 30.6% | 266.42 | 53.1% | 376.44 | 75.1% | 447.62 | 89.3% |

| Material | Strain | Gauge Factor | Year |

|---|---|---|---|

| CB/AgNPs composite | 0.61%−1.4% | 192.77–444.6 | this work |

| Carbon black/natural | 0.1% | 43.2 | 2016 [27] |

| thermoplastic elastomer (Evoprene)/carbon black | 10% | 31 | 2007 [30] |

| CB/PDMS | 10% | 15.75 | 2016 [31] |

| FCE/CB nanocomposites | 10% | 11.2 | 2015 [28] |

| ChNCs-CB/NR | 70% | 5 | 2018 [33] |

| CB/elastomer | 60% | 3 | 2015 [32] |

| SWCNTs/CB | 120% | 1.25 | 2017 [29] |

| PVC/CB | 0.14% | 741 | 2020 [26] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, X.; Ha, H.; Hwang, B.; Lim, S. Printability of the Screen-Printed Strain Sensor with Carbon Black/Silver Paste for Sensitive Wearable Electronics. Appl. Sci. 2020, 10, 6983. https://doi.org/10.3390/app10196983

Qi X, Ha H, Hwang B, Lim S. Printability of the Screen-Printed Strain Sensor with Carbon Black/Silver Paste for Sensitive Wearable Electronics. Applied Sciences. 2020; 10(19):6983. https://doi.org/10.3390/app10196983

Chicago/Turabian StyleQi, Xue, Heebo Ha, Byungil Hwang, and Sooman Lim. 2020. "Printability of the Screen-Printed Strain Sensor with Carbon Black/Silver Paste for Sensitive Wearable Electronics" Applied Sciences 10, no. 19: 6983. https://doi.org/10.3390/app10196983

APA StyleQi, X., Ha, H., Hwang, B., & Lim, S. (2020). Printability of the Screen-Printed Strain Sensor with Carbon Black/Silver Paste for Sensitive Wearable Electronics. Applied Sciences, 10(19), 6983. https://doi.org/10.3390/app10196983