A Novel Method for Designing Motion Profiles Based on a Fuzzy Logic Algorithm Using the Hip Joint Angles of a Lower-Limb Exoskeleton Robot

Abstract

1. Introduction

2. Methods

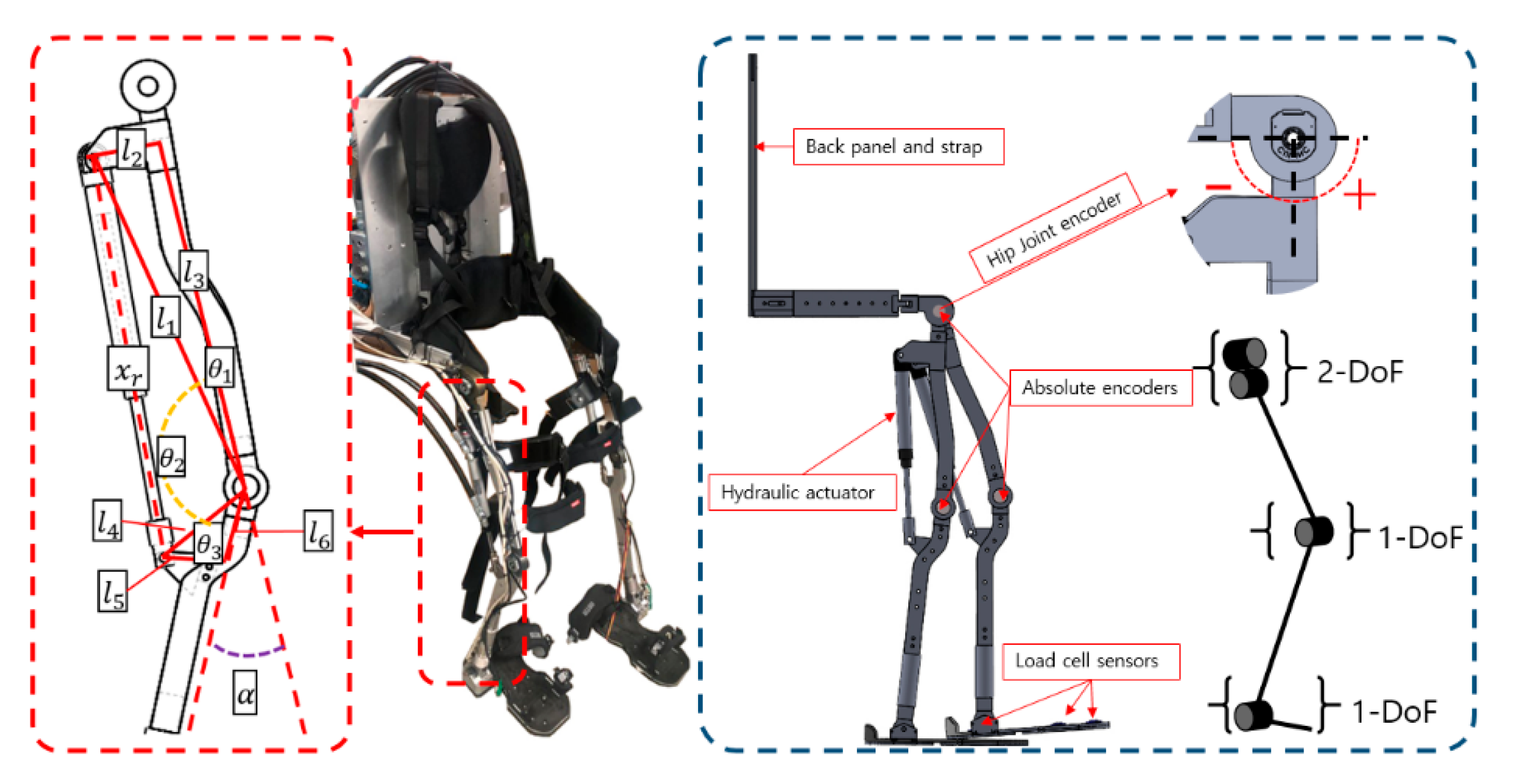

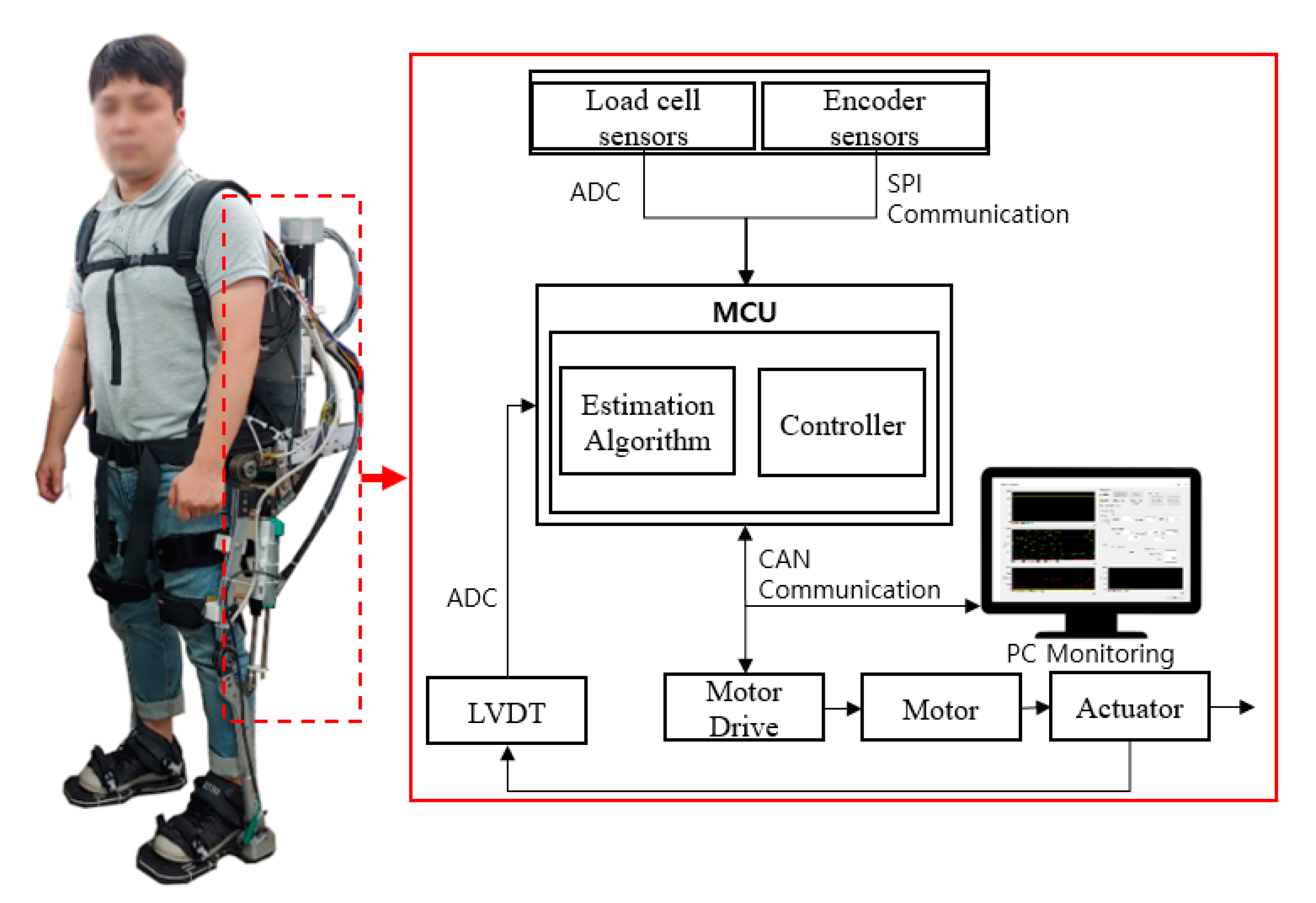

2.1. Design of an Exoskeleton Robot with an Electro-Hydarulic Actuator System

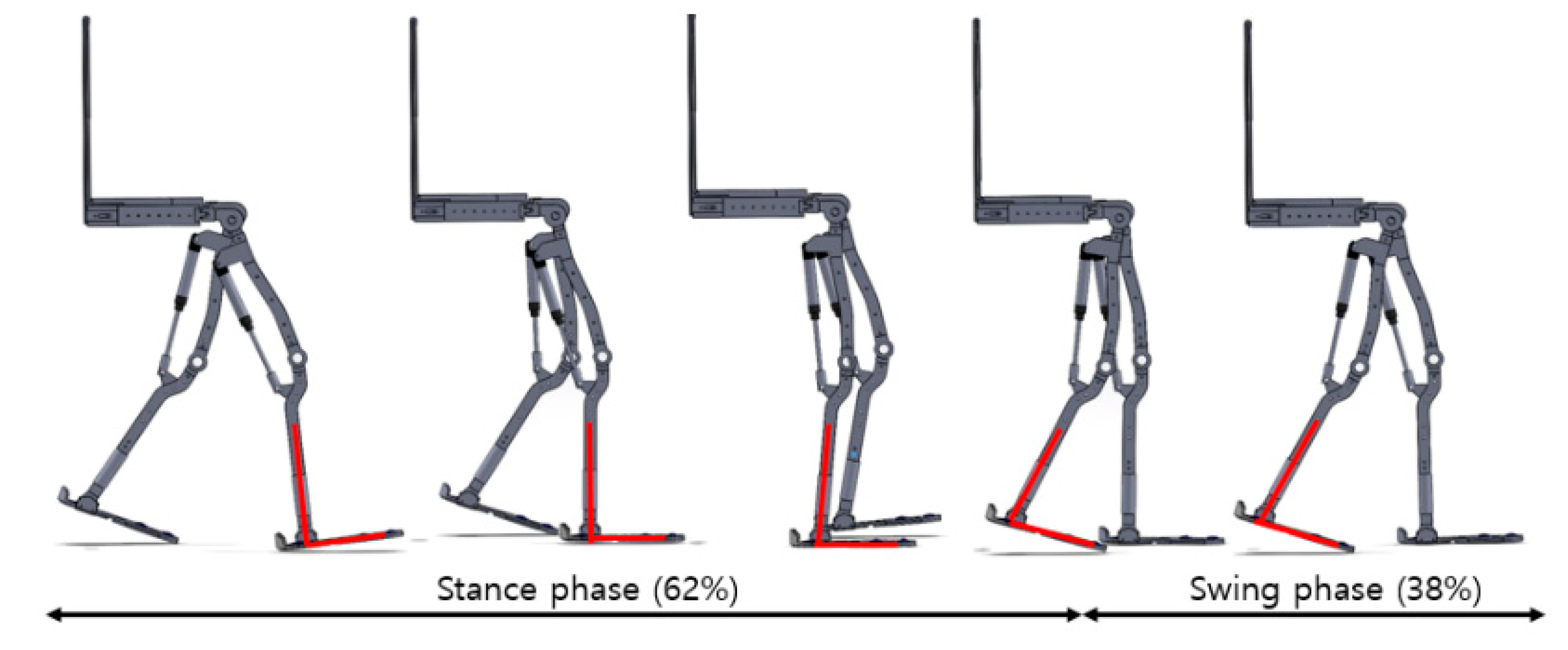

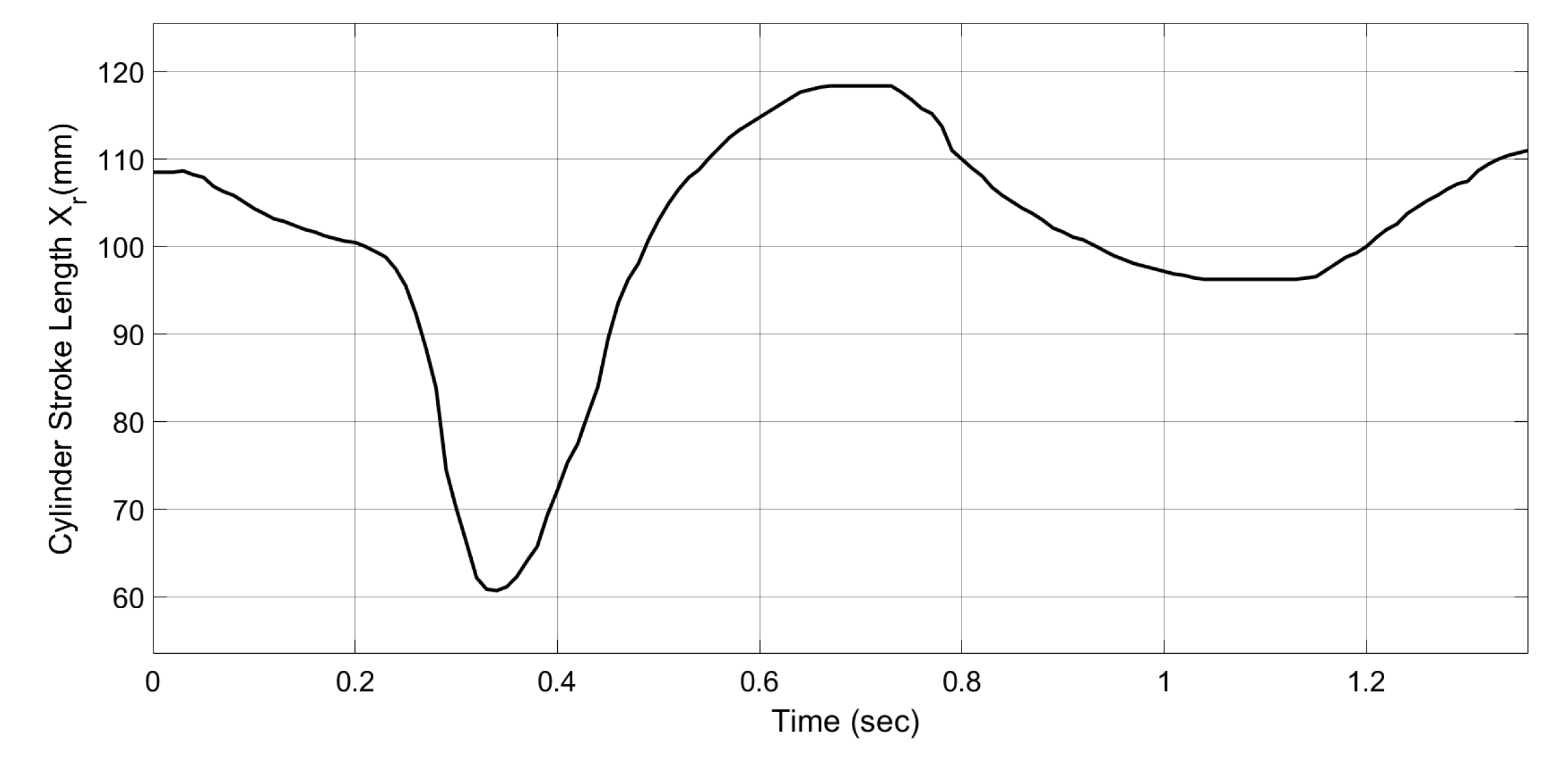

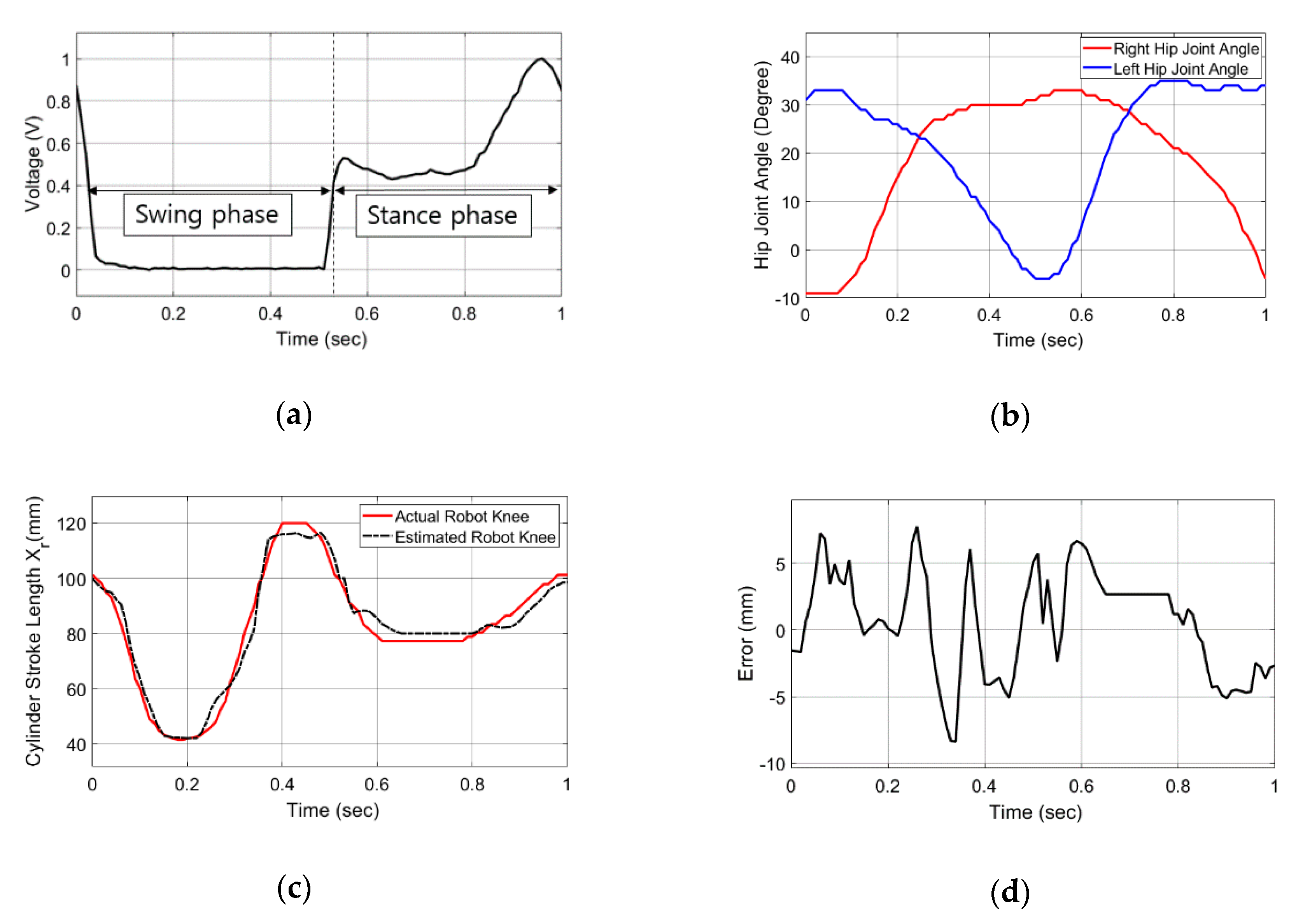

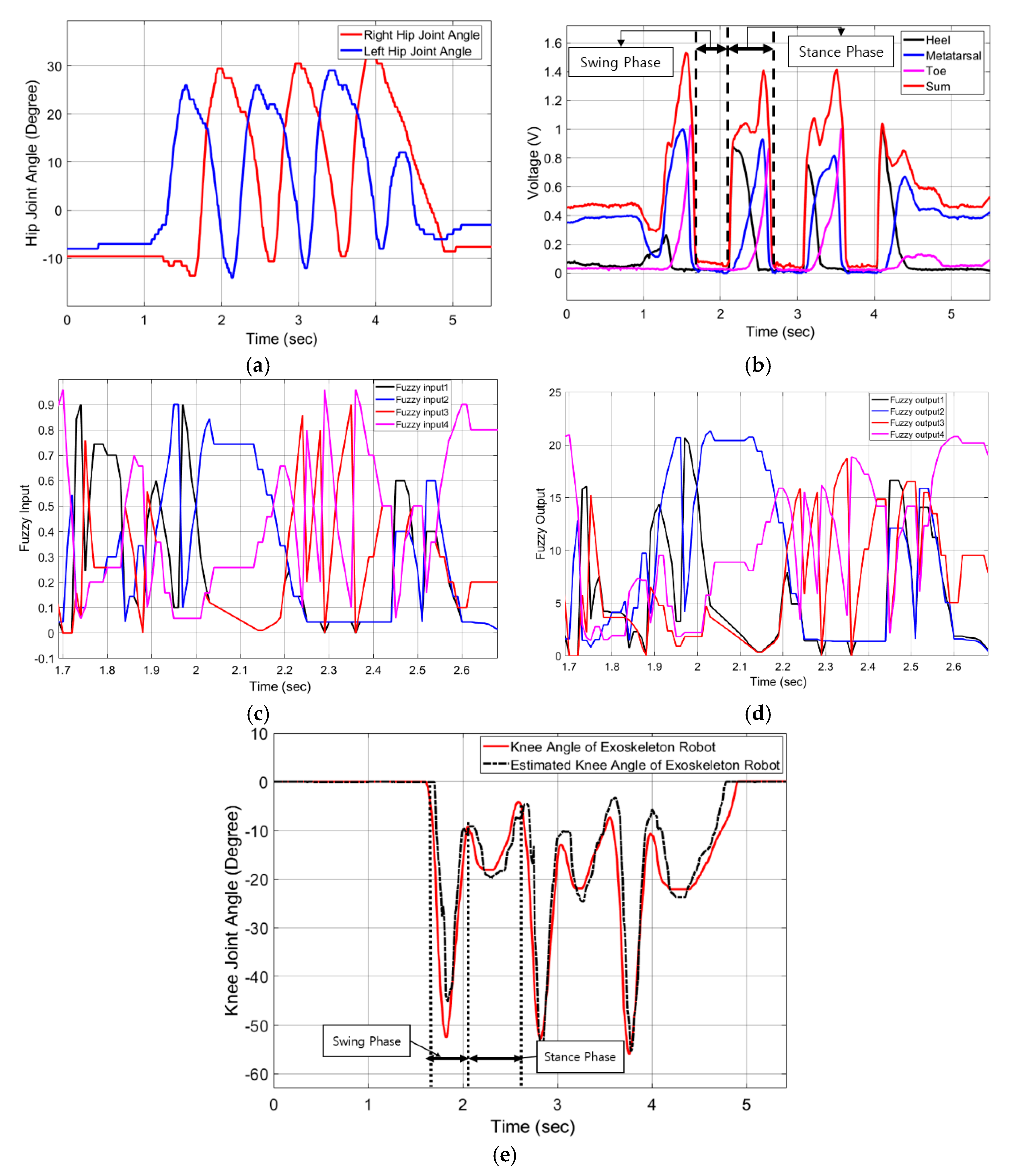

2.2. Design of a Real-Time Motion Profile for the Exoskeleton Robot’s Knee Joint Angle

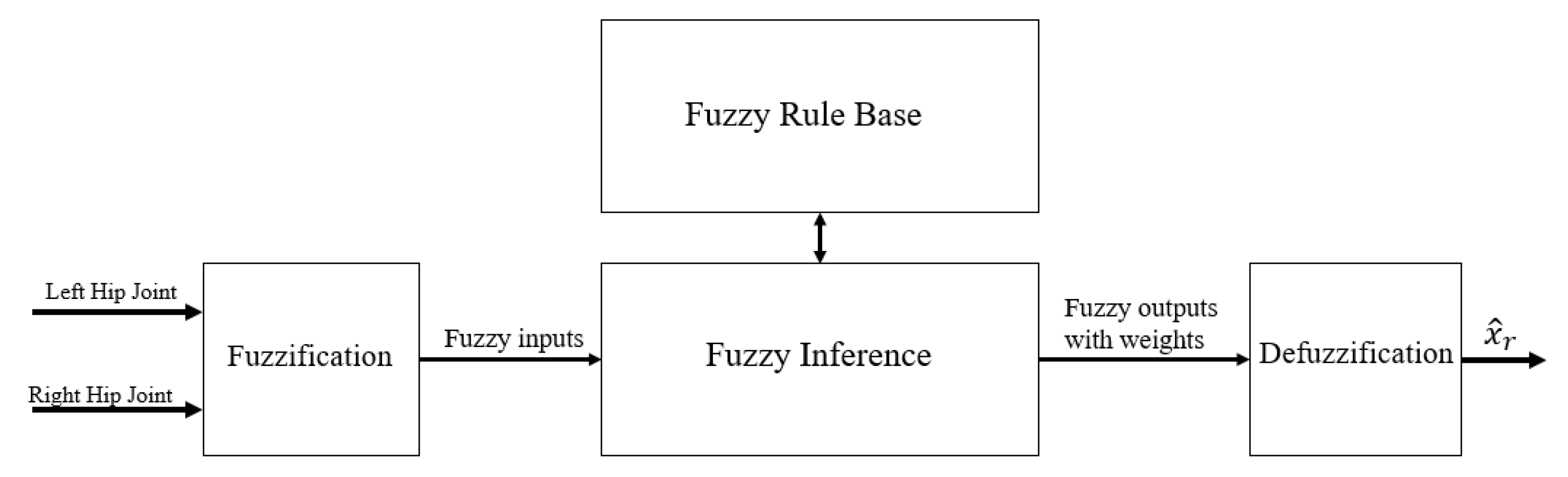

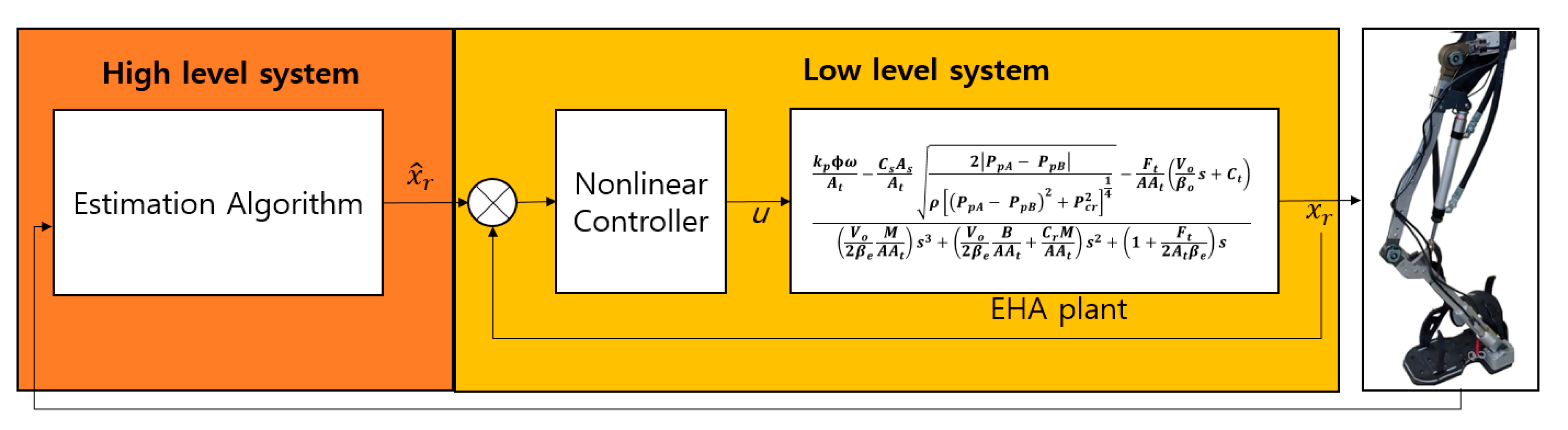

2.3. The Proposed Algorithm with a Controller

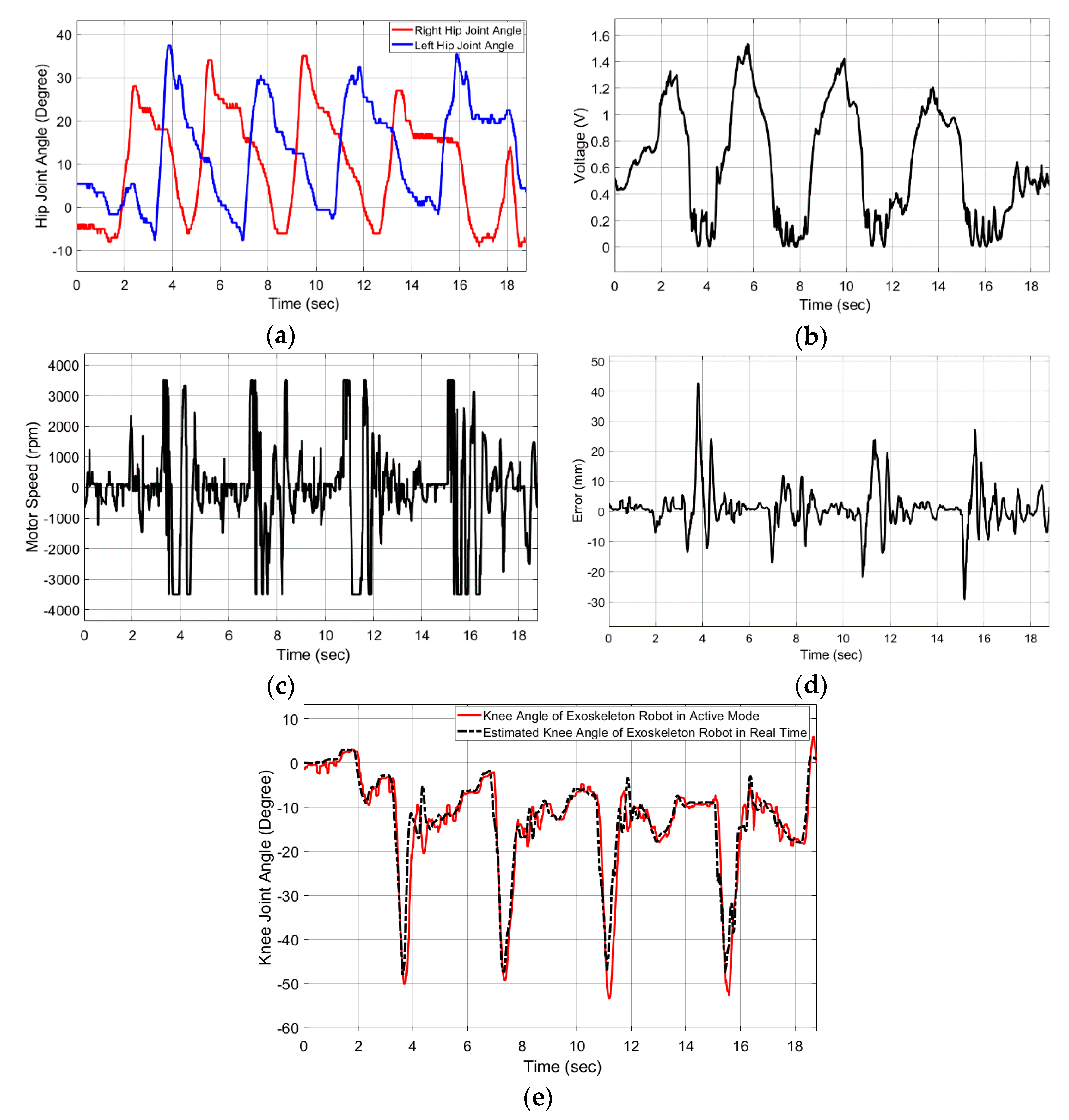

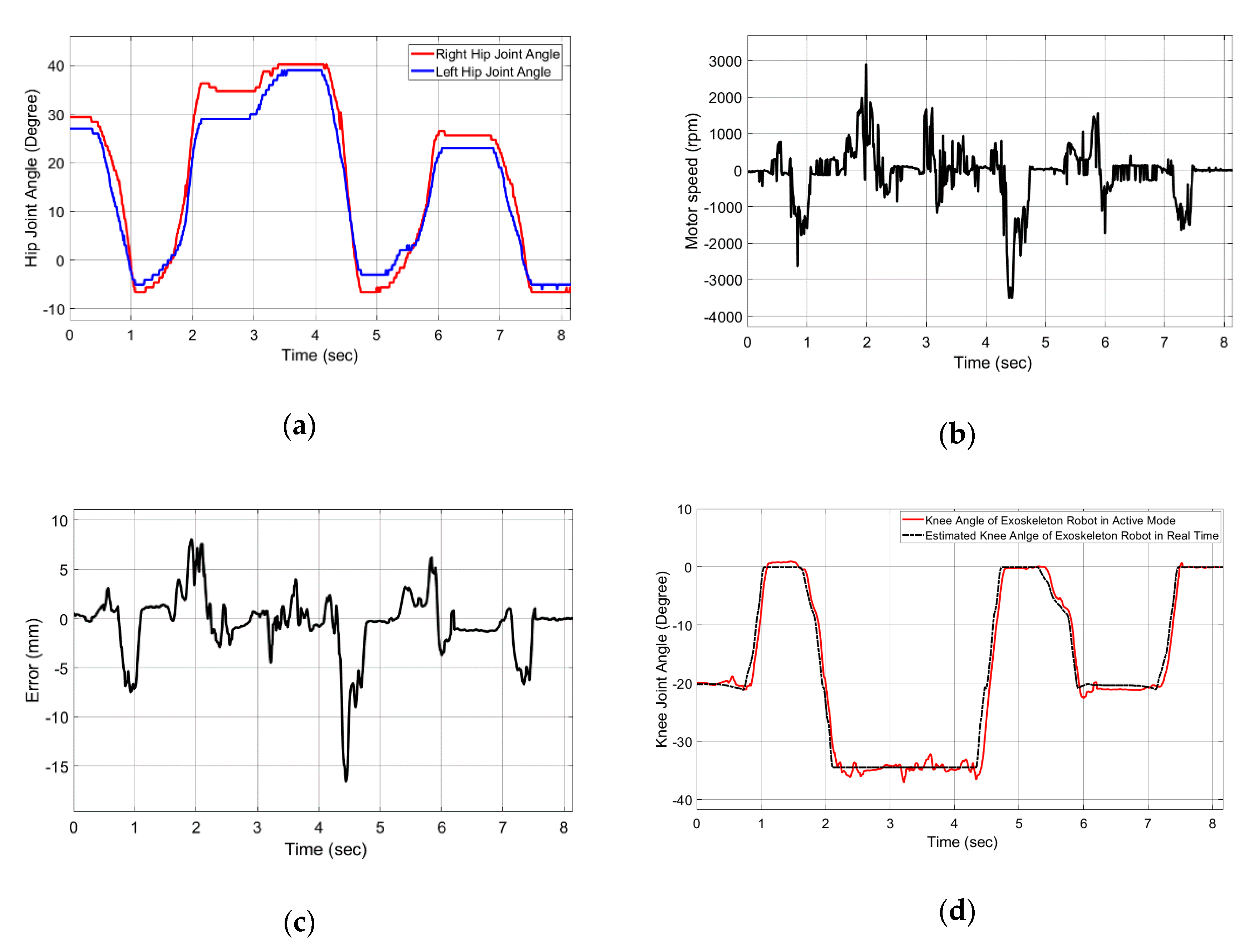

3. Experiment

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- UN Population Division. World Population Ageing 2015, Population Face Sheet. Available online: https://www.un.org/en/development/desa/population/publications/pdf/popfacts/PopFacts_2014-4Rev1.pdf (accessed on 16 September 2020).

- Rupal, B.S.; Rafique, S.; Singla, A.; Singla, E.; Isaksson, M.; Virk, G.S. Lower-limb exoskeletons. Int. J. Adv. Robot. Syst. 2017, 14. [Google Scholar] [CrossRef]

- Gilbert, K.E.; Callan, P.C. Hardiman I Prototype Project; General Electric Company: Schenectady, NY, USA, 1969. [Google Scholar]

- Ghan, J.; Steger, R.; Kazerooni, H. Control and system identification for the Berkeley lower extremity exoskeleton (BLEEX). Adv. Robot. 2006, 20, 989–1014. [Google Scholar] [CrossRef]

- Walsh, C.J.; Endo, K.; Herr, H. A quasi-passive leg exoskeleton for load-carrying augmentation. Int. J. Humanoid Robot. 2007, 4, 487–506. [Google Scholar] [CrossRef]

- Esquenazi, A.; Talaty, M.; Packel, A.; Saulino, M. The ReWalk Powered Exoskeleton to Restore Ambulatory Function to Individuals with Thoracic-Level Motor-Complete Spinal Cord Injury. Am. J. Phys. Med. Rehabil. 2012, 91, 911–921. [Google Scholar] [CrossRef] [PubMed]

- Yamamoto, K.; Hyodo, K.; Ishii, M.; Matsuo, T. Development of Power Assisting Suit for Assisting Nurse Labor. JSME Int. J. Ser. C 2002, 45, 703–711. [Google Scholar] [CrossRef]

- Kusuda, Y. In quest of mobility-Honda to develop walking assist devices. Ind. Robot. Int. J. 2009, 36, 537–539. [Google Scholar] [CrossRef]

- Song, B.; Lee, D.; Park, S.Y.; Baek, Y.S. Design and Performance of Nonlinear Control for an Electro-Hydraulic Actuator Considering a Wearable Robot. Processes 2019, 7, 389. [Google Scholar] [CrossRef]

- Ahn, K.-K.K.; Nam, D.N.C.; Jin, M. Adaptive Backstepping Control of an Electrohydraulic Actuator. IEEE/ASME Trans. Mechatron. 2013, 19, 987–995. [Google Scholar] [CrossRef]

- Lee, D.; Song, B.; Park, S.Y.; Baek, Y.S. Development and Control of an Electro-Hydraulic Actuator System for an Exoskeleton Robot. Appl. Sci. 2019, 9, 4295. [Google Scholar] [CrossRef]

- Michael, P.; Greene, B.S. Four Bar Linkage Knee Analysis. Orthot. Prosthet. 1983, 37, 15–24. [Google Scholar]

- Collo, A.; Bonnet, V.; Venture, G. A quasi-passive lower limb exoskeleton for partial body weight support. In Proceedings of the 6th IEEE International Conference on Biomedical Robotics and Biomechatronics (BioRob), Singapore, 26–29 June 2016; Institute of Electrical and Electronics Engineers (IEEE): Singapore, 2016; pp. 643–648. [Google Scholar]

- Perry, J.C.; Rosen, J.; Burns, S. Upper-Limb Powered Exoskeleton Design. IEEE/ASME Trans. Mechatron. 2007, 12, 408–417. [Google Scholar] [CrossRef]

- Reaz, M.B.I.; Hussain, M.S.; Mohd-Yasin, F.; Raez, M. Techniques of EMG signal analysis: Detection, processing, classification and applications. Boil. Proced. Online 2006, 8, 11–35. [Google Scholar] [CrossRef] [PubMed]

- Long, Y.; Du, Z.-J.; Wang, W.-D.; Dong, W. Human motion intent learning based motion assistance control for a wearable exoskeleton. Robot. Comput. Integr. Manuf. 2018, 49, 317–327. [Google Scholar] [CrossRef]

- Ding, S.; Ouyang, X.; Li, Z.; Yang, H. Proportion-based fuzzy gait phase detection using the smart insole. Sens. Actuators A Phys. 2018, 284, 96–102. [Google Scholar] [CrossRef]

- Huo, W.; Mohammed, S.; Amirat, Y.; Kong, K. Fast Gait Mode Detection and Assistive Torque Control of an Exoskeletal Robotic Orthosis for Walking Assistance. IEEE Trans. Robot. 2018, 34, 1–18. [Google Scholar] [CrossRef]

- Shim, M.; Han, J.I.; Choi, H.S.; Ha, S.M.; Kim, J.-H.; Baek, Y.S. Terrain Feature Estimation Method for a Lower Limb Exoskeleton Using Kinematic Analysis and Center of Pressure. Sensors 2019, 19, 4418. [Google Scholar] [CrossRef] [PubMed]

| Input2 | |||||||

|---|---|---|---|---|---|---|---|

| RN | RZR | RP | RPS | RPM | RPL | ||

| Input1 | LN | VL | L | M | H | VH | NA |

| LZR | L | VL | L | M | H | VH | |

| LP | M | L | VL | L | M | H | |

| LPS | H | M | L | VL | L | M | |

| LPM | VH | H | M | L | VL | L | |

| LPL | NA | VH | H | M | L | VL | |

| Input2 | |||||||

|---|---|---|---|---|---|---|---|

| RN | RZR | RP | RPS | RPM | RPL | ||

| Input1 | LN | VH | VH | VH | H | VH | NA |

| LZR | VH | VH | H | M | H | VH | |

| LP | VH | H | H | M | M | H | |

| LPS | H | M | M | M | M | M | |

| LPM | VH | H | M | M | M | M | |

| LPL | NA | VH | H | M | M | M | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, B.; Lee, D.; Park, S.Y.; Baek, Y.S. A Novel Method for Designing Motion Profiles Based on a Fuzzy Logic Algorithm Using the Hip Joint Angles of a Lower-Limb Exoskeleton Robot. Appl. Sci. 2020, 10, 6852. https://doi.org/10.3390/app10196852

Song B, Lee D, Park SY, Baek YS. A Novel Method for Designing Motion Profiles Based on a Fuzzy Logic Algorithm Using the Hip Joint Angles of a Lower-Limb Exoskeleton Robot. Applied Sciences. 2020; 10(19):6852. https://doi.org/10.3390/app10196852

Chicago/Turabian StyleSong, Buchun, Dongyoung Lee, Sang Yong Park, and Yoon Su Baek. 2020. "A Novel Method for Designing Motion Profiles Based on a Fuzzy Logic Algorithm Using the Hip Joint Angles of a Lower-Limb Exoskeleton Robot" Applied Sciences 10, no. 19: 6852. https://doi.org/10.3390/app10196852

APA StyleSong, B., Lee, D., Park, S. Y., & Baek, Y. S. (2020). A Novel Method for Designing Motion Profiles Based on a Fuzzy Logic Algorithm Using the Hip Joint Angles of a Lower-Limb Exoskeleton Robot. Applied Sciences, 10(19), 6852. https://doi.org/10.3390/app10196852