Multidomain Simulation Model for Analysis of Geometric Variation and Productivity in Multi-Stage Assembly Systems

Abstract

1. Introduction

2. Methodologies and Techniques of the Research Work

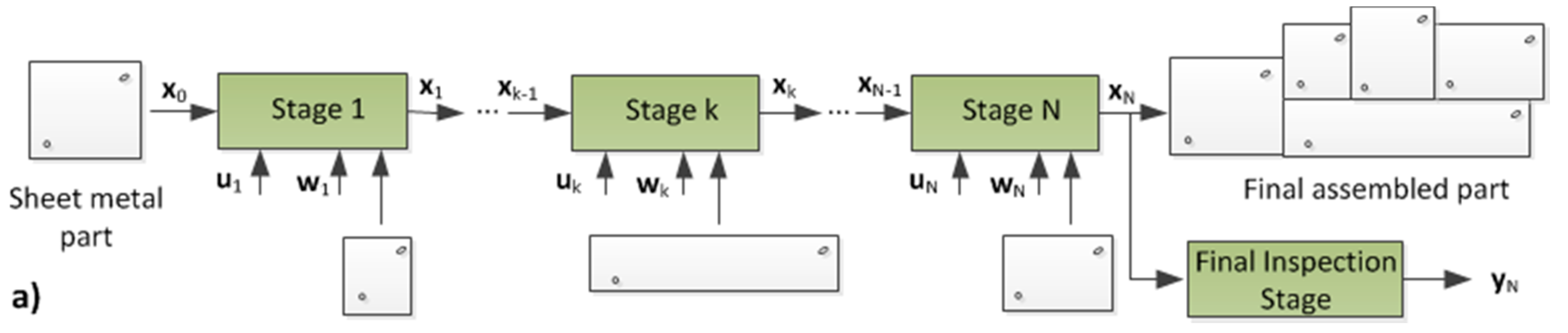

2.1. Error Propagation Modelling through SoV Model

2.2. Methodology Adopted to Define the Simulation Model

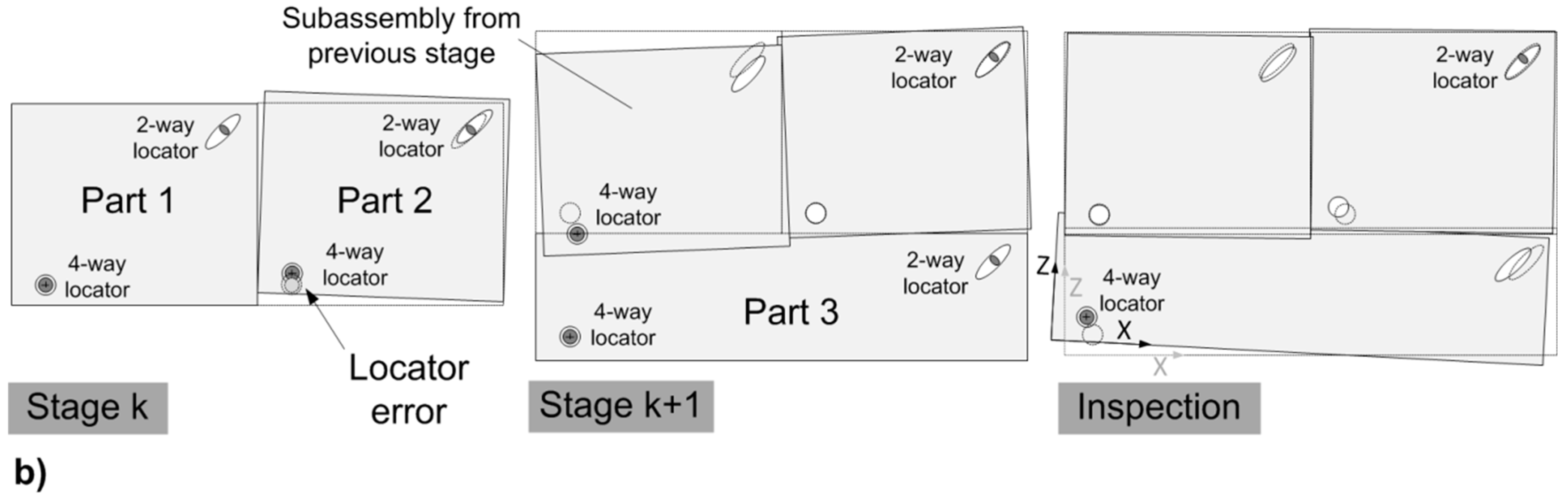

- Analysis of the functional and logical structure of the system to be simulated. The system must be analyzed in order to know the structural elements and their relationships that characterize it. This structure is usually described using a SysML block definition diagram (BDD), where the logical system components are represented by blocks and activity diagrams for process modelling.

- Definition of concepts and requirements for the simulation system model. For this, various aspects must be considered, such as the type of simulations (e.g., continuous dynamic or discrete events), the goals of the study (e.g., maximum defect index value, minimum throughput value, etc.), and the simulation alternatives for the prototype. For this task, SysML diagrams, such as BDD and requirement diagrams are used.

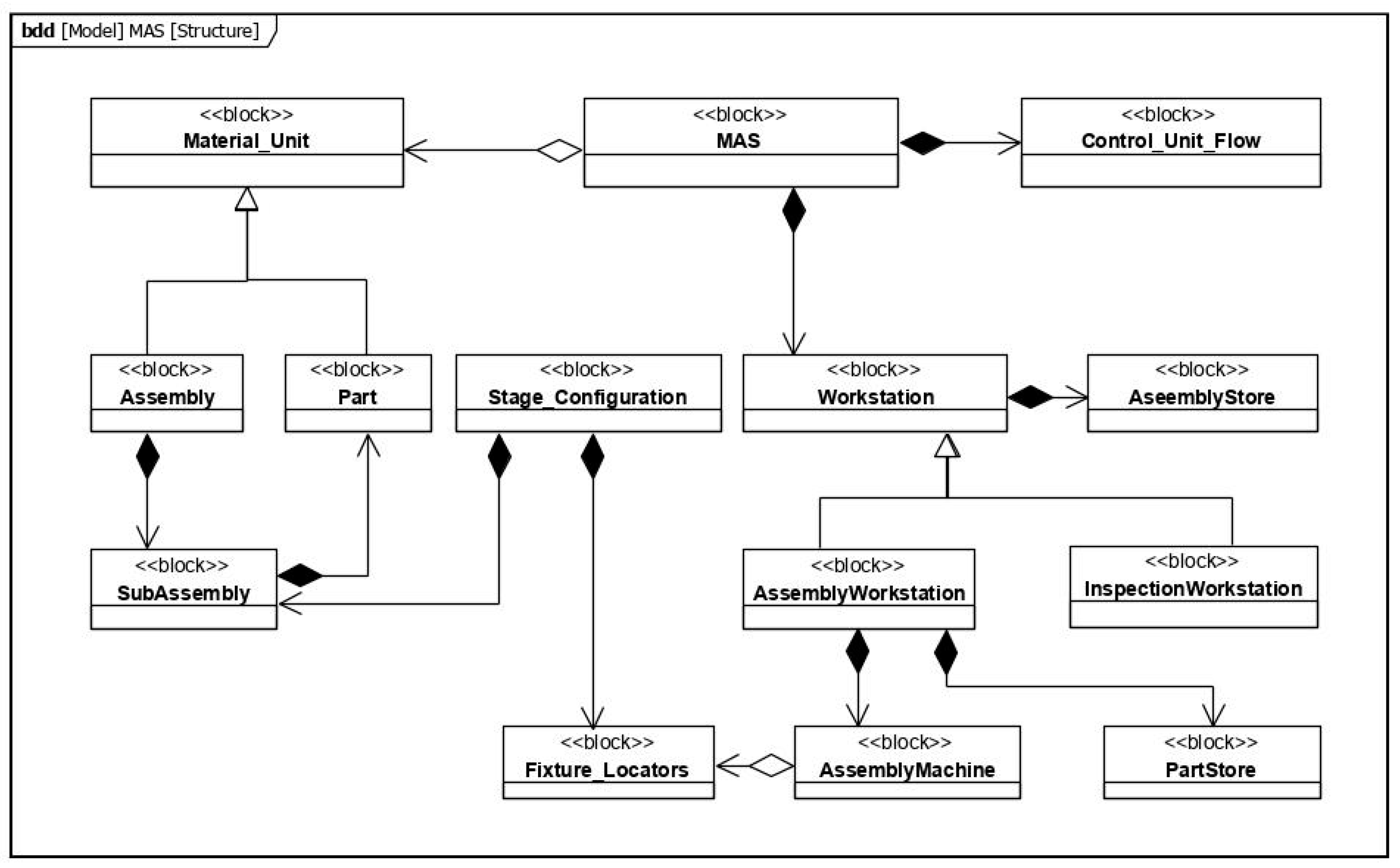

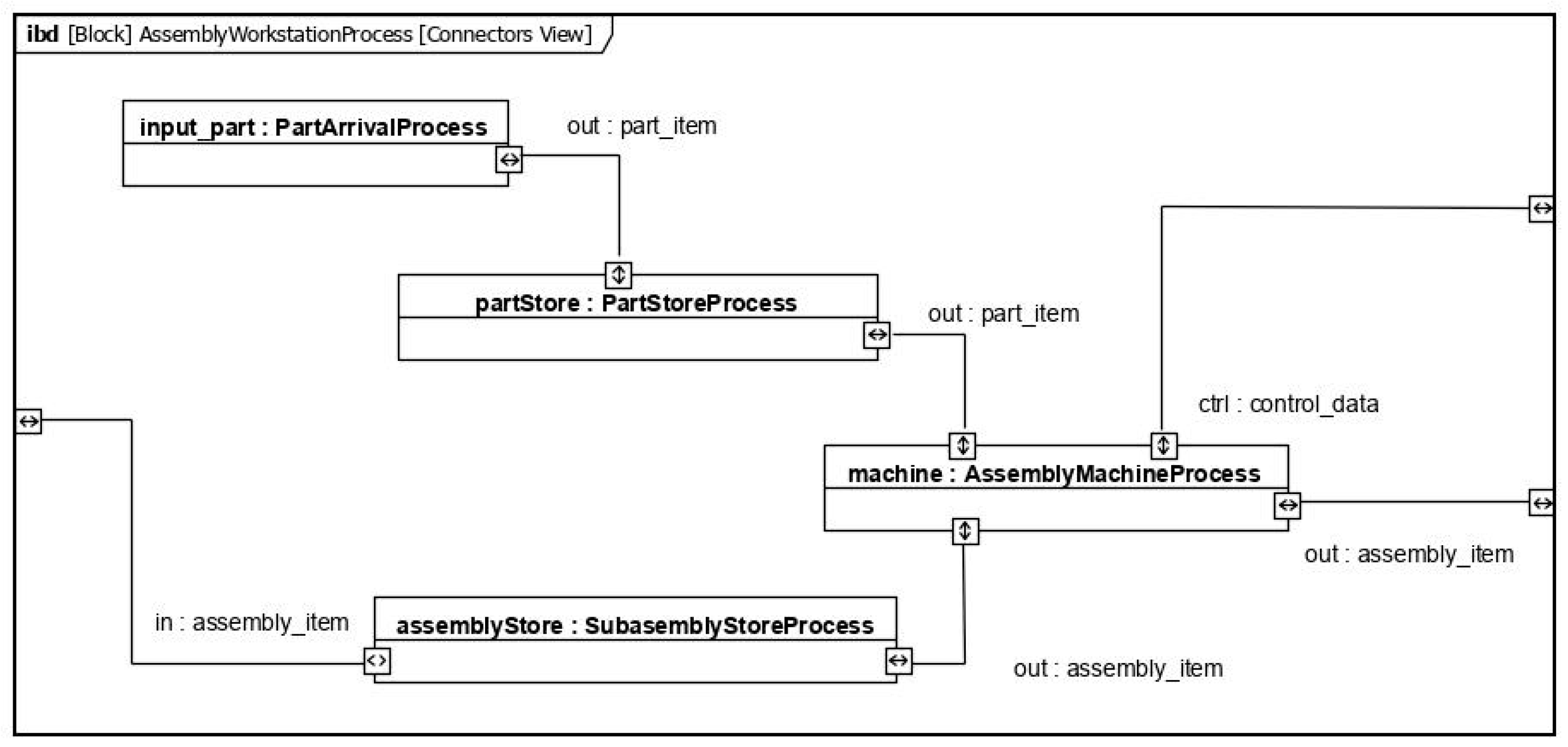

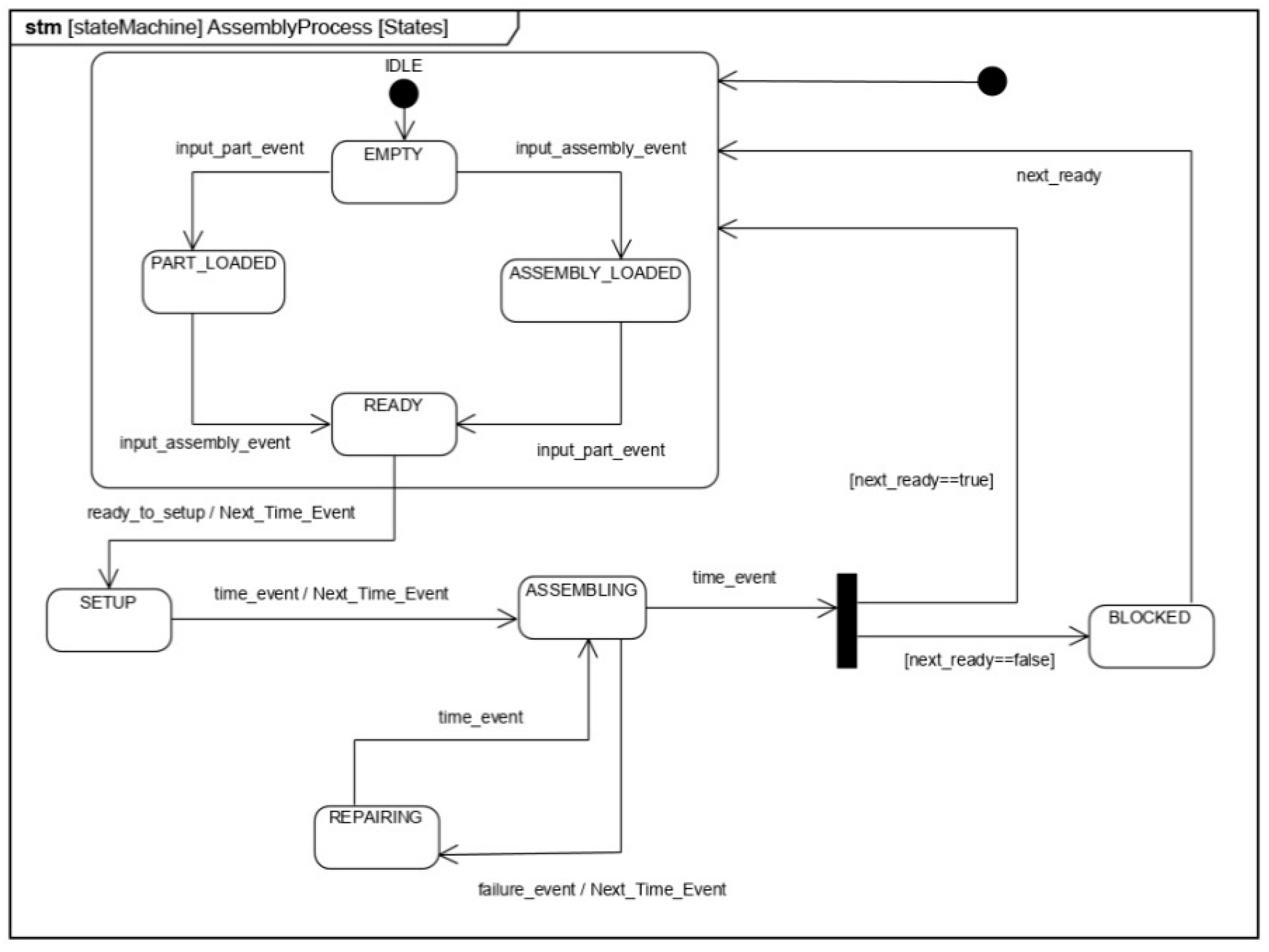

- Structural and behavioral modelling of the simulation system (the system of interest). Taking into account the results of the previous step, a viable solution is proposed for the objects structure of the simulation system and their prescribed behavior. Structure and behavior descriptions are decomposed to the level of abstraction required and they are described using SysML diagrams, such as BDDs, internal block diagrams (IBDs), parametric diagrams, activity diagrams, sequence diagrams, etc.

- Modelling the simulations. In this step, the simulation system is related to other relevant design information through: (a) defining a model context, where the elements of the simulation system are bound to the corresponding elements of the system to be analyzed in order to preserve the consistency among all models; (b) modelling the simulations, by defining the simulation runs to be performed; (c) abstracting the simulation by defining the measure of effectiveness from simulation; (d) using the abstracted simulation in the context of design optimization by relating them to stakeholder requirements and measures of effectiveness pointed out in the model of the system to be analyzed (Step 1).

- Transformation of SysML models into Modelica and validation of the meta-model through the use of the meta-model on a case study. To obtain an executable simulation model, the SysML description of the system must be implemented using a language with this capability, such as Modelica.

3. Modelling and Implementation of the Simulation Prototype

3.1. The Assembly System to Be Analysed and the Simulation System Requirements

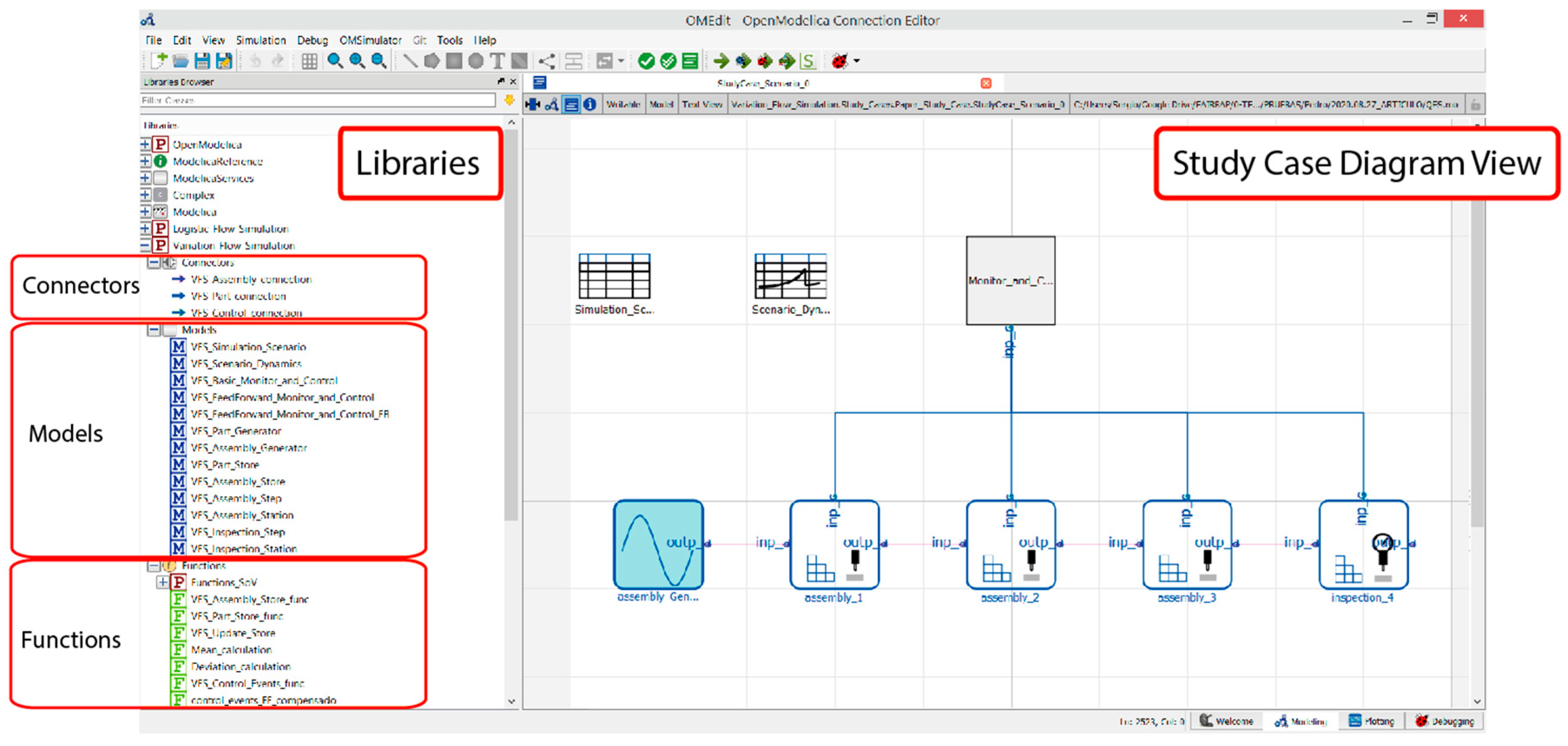

3.2. Proposed Simulation Meta-Model

3.3. Model Implementation Using Modelica

3.3.1. Logistic Flow Simulation

- Simulation_Scenario. This Modelica class contains the initial parameters that define the simulation scenario and corresponds to the Simulation_Scenario block of the SysML model. The main parameters are grouped into the following groups:

- ○

- Assembly_Plan: parameters to collect the sequence of assembly and/or inspection stages. For each stage, the following are indicated: the station in which it is carried out, the subassembly and built-in part, as well as the parameters to model the process time through a normal distribution (mean and a standard deviation).

- ○

- Assembly_Identification: parameters that identify each of the types of subassemblies used in the various stages, indicating the types of part included.

- ○

- Other parameters to model assembly orders’ arrival, part arrival, setup time, failure rate, storage capacity, etc.

- Scenario_Dynamics. Some initial parameters defined in Simulation_Scenario can be modelled with continuous functions or discrete changes, introducing a temporal variation. The Scenario_Dynamics class is used to model this dynamic behavior, for example, to consider a gradual increase in the processing time caused by the continuous degradation of the assembly station due to its use, or a punctual (sudden) change in the distribution of the arrival time of the parts due to a change of supplier.

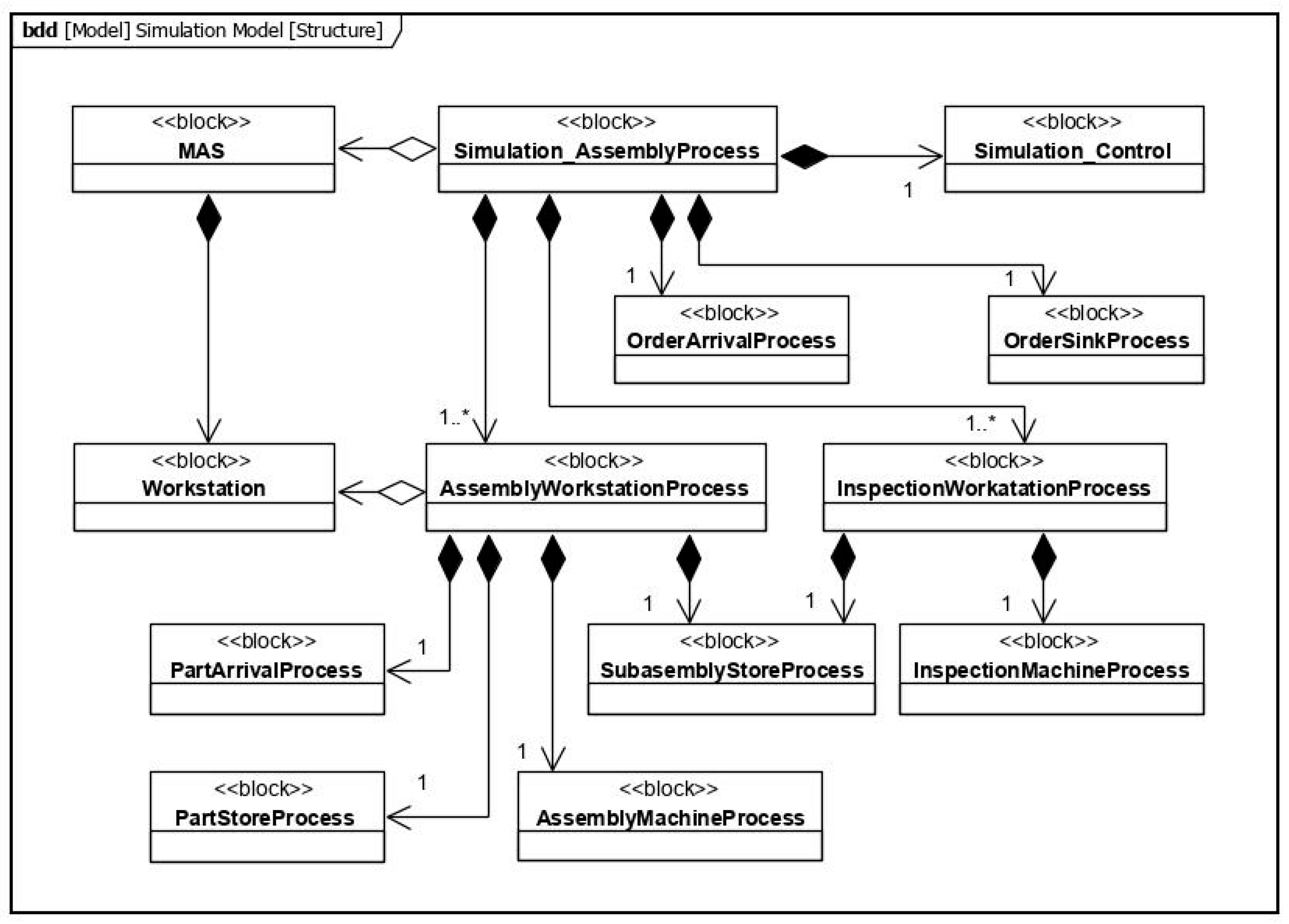

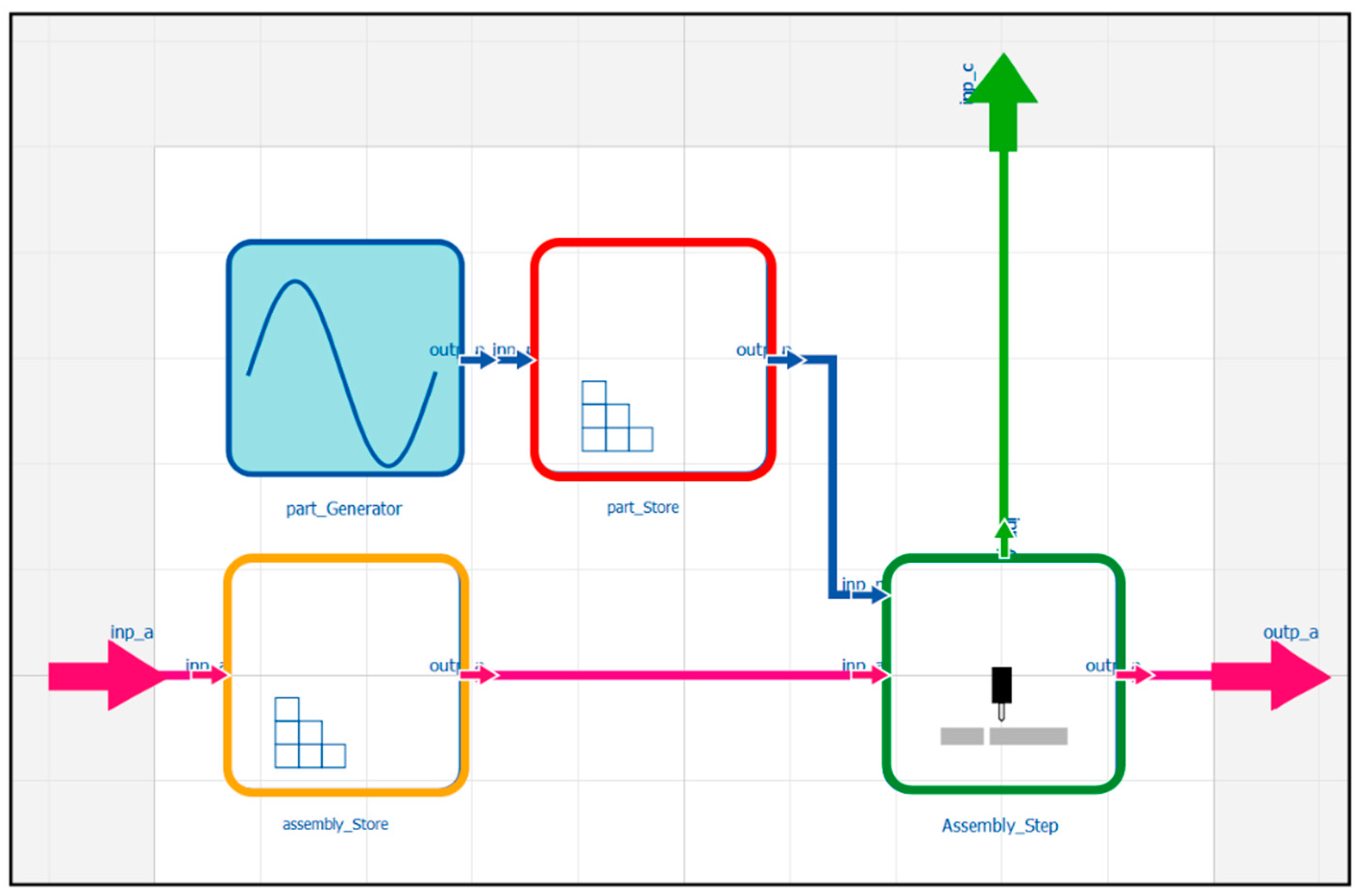

- Assembly_Station and Inspection_Station classes correspond to the WorkstationProcess block from the SysML model and represent an assembly and inspection workstation, respectively. As described in the SysML model, these complex blocks with a coupled DEVS behavior, in turn, are composed of single blocks which have a discrete behavior definition using an atomic DEVS formalism. All these single blocks use data from Simulation_Scenario and Scenario_Dynamics. In Figure 8, the internal structure of these Modelica classes is shown, mainly composed of the classes described below:

- ○

- Part_Generator and Assembly_Generator. These models define the process of generating the arrival of parts and assembly orders, respectively. These Modelica models correspond to PartArrivalProcess and AssemblyArrivalProcess blocks in the SysML model. Part_Generator is represented by a blue box in Figure 8.

- ○

- Part_Store and Assembly_Store. These blocks allow for storing input parts or assemblies for a WorkstationProcess. Actually, these stores use a First-In, First-Out strategy but they can be extended to include other delivery strategies. They are represented by red and yellow boxes, respectively, in Figure 8.

- ○

- Assembly_Step and Inspection_Step. These blocks correspond to the MachineProcess and InspectionProcess blocks from the SysML model and constitute the process itself characterized by an atomic DEVS formalism. Assembly_Step is represented by a green box in Figure 8.

- Monitor&Control. This Modelica class collects data from each WorkstationProcess, allowing it to execute a statistical analysis to estimate the productivity performance parameters. In addition, this is the basic class that can be specialized to carry out control actions, e.g., a change of the assembly processing order using a dispatching rule.

- Assembly_connection. This type of connection contains the data related to the assemblies’ flow. These data include the assembly order, the parts contained, and the types of these parts. Additionally, these connectors include Boolean variables to indicate the discrete external events linking the blocks that participate in the assemblies’ flow. This connector type is represented by a pink line in Figure 8.

- Part_connection. This type of connection contains the data related to the parts flow that are added in each assembly stage. In this case, these data include the part identification and its type. It also contains the variables to link the blocks that participate in the parts flow. This connector is represented by a blue line in Figure 8.

- Control_connection. This type of connection contains the data used to monitor and control the WorkstationProcess. These connections include data flowing from the WorkstationProcess to Monitor&Control block, such as workstation status, processing time, setup time, and so on. It also contains data that flows from the Monitor&Control block to WorkstationProcess to carry out control actions, such as maintenance stop, setup actions, etc. This connector is represented by a green line in Figure 8.

3.3.2. Variation Flow Simulation Using 2D-SoV

- VFS_Simulation_Scenario and VFS_Scenario_Dynamics extend the Simulation_Scenario and Scenario_Dynamics classes from the LFS library by incorporating the following parameters:

- ○

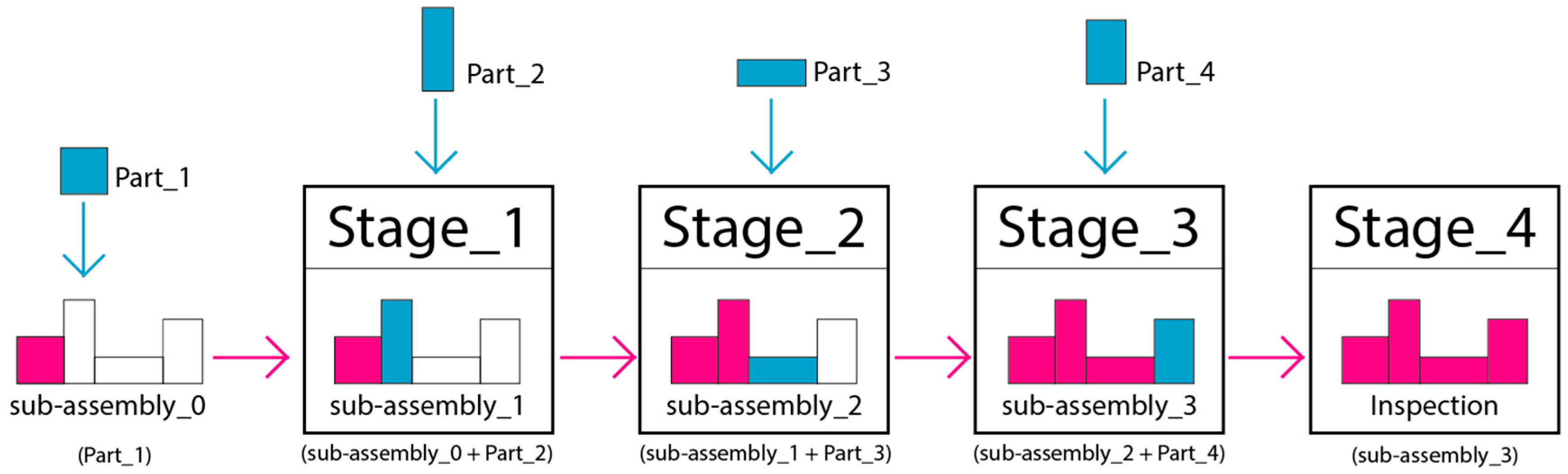

- Additional process plan data to specify the locating scheme for each assembly or inspection stage. As shown in Figure 1, each part or subassembly is located using a 4-way and a 2-way locator.

- ○

- Geometric data that define the nominal parts’ geometries and nominal locators’ positions and their respective variations modelled by a normal distribution with a mean and a standard deviation. These geometric variations can be modelled as a stable distribution or as a distribution whose parameters change progressively in time. For this, different VFS_Scenario_Dynamics extensions are used.

- ○

- Measurement of uncertainties at each stage with a measurement process (assembly stations with in-process measurement capability and inspection stations), modelled by a standard deviation. In-process measurements in assembly stations will present greater uncertainties than those obtained in the inspection stations.

- VFS_Assembly_Station and VFS_Inspection_Station extend the Assembly_Station and Inspection_Station classes from the LFS library to incorporate the necessary properties and functions for computing the DMV transformations in assembly stations and measured quality characteristics in inspection stations and assembly stations with in-process measurement, according to the SoV technique.

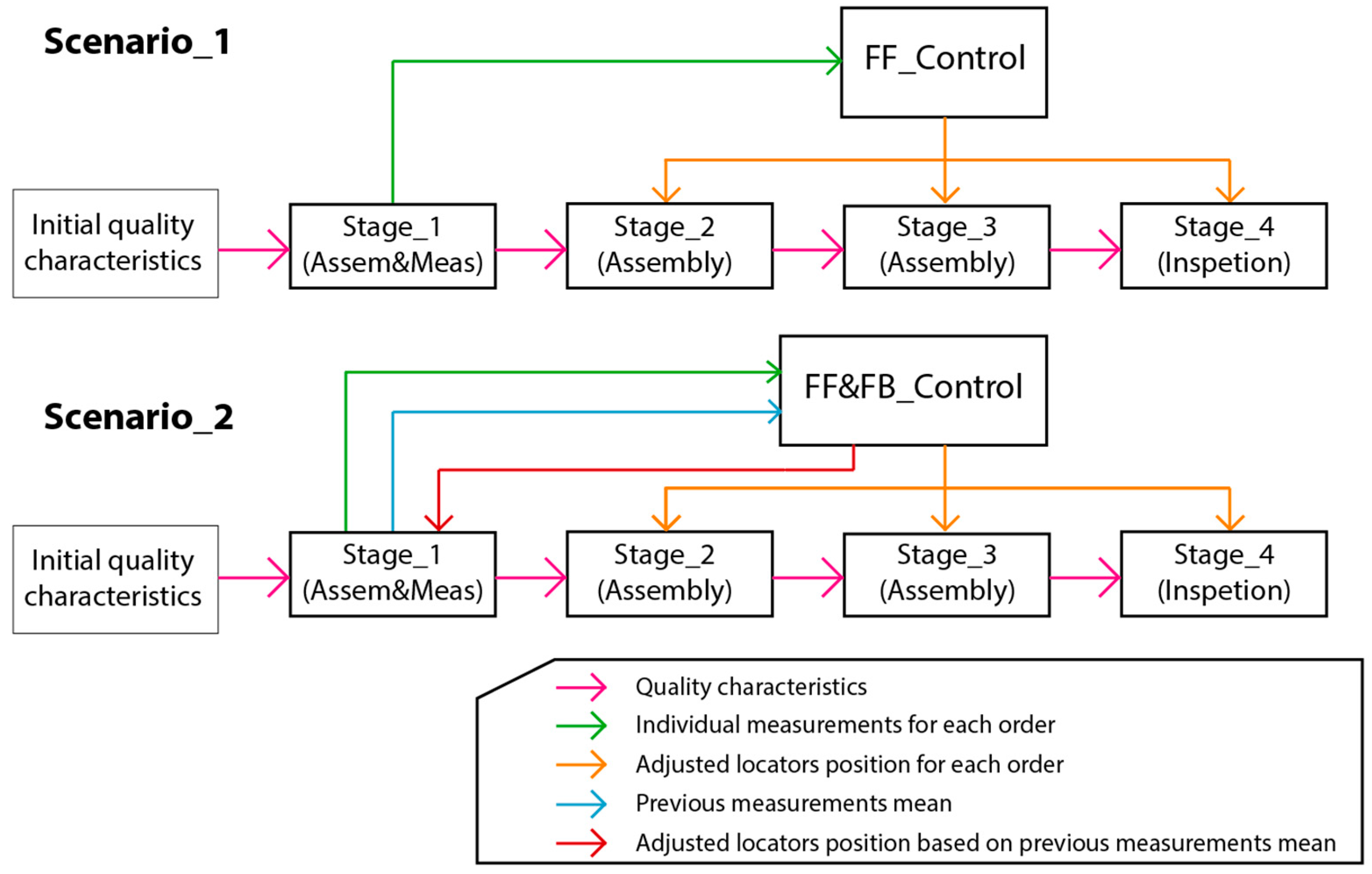

- VFS_FeedForward_Monitor&Control implements the technique proposed in [10]. This control logic, named feed-forward control, uses measurement data from an early stage to calculate the optimal position of locators placed at subsequent stages to minimize deviations in the final assembly. It is important to note that this calculation is carried out individually for each assembly order. To apply this logic, it must be also considered that the fixtures of subsequent stages have actuators to adjust the position of each locator. In feed-forward control, from the measurements at stage (i−1)

- VFS_FeedForward&Backward_Monitor&Control extends the previous control class to calculate the optimal position for the locators for all stages using a refined logic. Besides the feed-forward control logic, a backward control logic is added and an additional correction in the current stage is conducted using the deviation mean detected in previous processed assemblies at this stage. In backward control, in addition to the vector is computed to compensate the deviations at stage (i−1), taking into consideration the mean values for DMV . that are computed from the mean values of last measurements , by applying least squares to the expression

4. Case Study

4.1. Approach to the Case Study

- Scenario_0: No correction actions are applied. The VFS_Basic_Monitor&Control block monitors some of the variables of each stage and performs a statistical analysis of the final inspection of products carried out in Stage 4. Measurements of this final inspection are used to calculate the mean and the standard deviation of the geometric deviations obtained at each inspected point. In addition, the maximum geometric deviation and its corresponding inspection point is identified, as well as the number of products that do not meet specifications.

- Scenario_1: The in-process measuring capability of Stage_1 is used and, based on the measurement results, a VFS_FeedForward_Monitor&Control class calculates the optimal position of the locators in the subsequent stages for each assembly order to minimize the deviations obtained in the final inspection of each product. It must be also considered that the fixtures at Stages 2, 3, and 4 have actuators to adjust the position of each locator. For this reason, the setup times of these stages are modified to simulate the adjustment of the actuators.

- Scenario_2: the VFS_FeedForward&Backward_Monitor&Control block is used. In addition to the control actions considered in Scenario_1, corrections are calculated in the locators of Stage_1 using a statistical analysis of the measurements detected in the previous processed assemblies in Stage_1. For this reason, the setup time of Stage_1 is also modified to simulate the adjustment of the actuators.

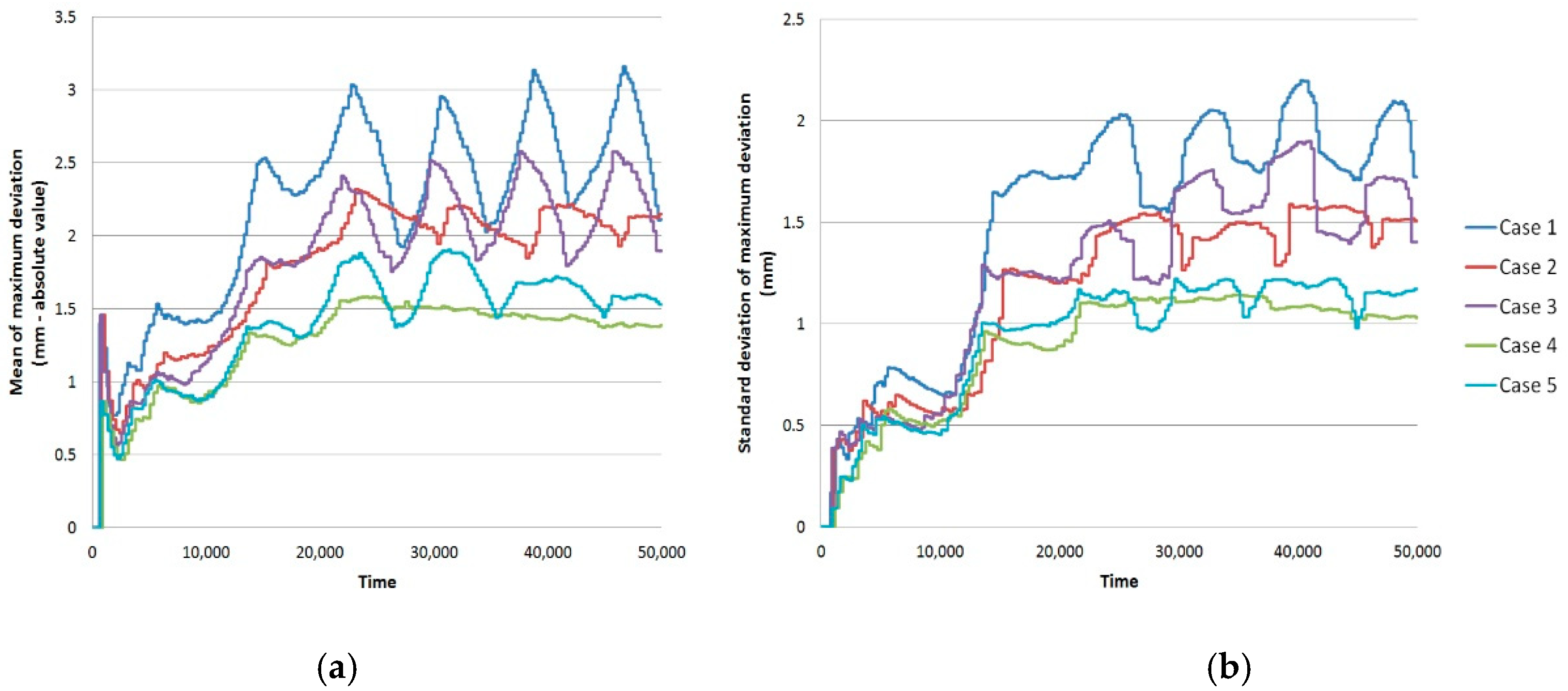

- Case 1: Simulation of Scenario_0.

- Case 2: Simulation of Scenario_1 using manual actuators.

- Case 3: Simulation of Scenario_1 using automatic actuators.

- Case 4: Simulation of Scenario_2 using manual actuators.

- Case 5: Simulation of Scenario_2 using automatic actuators.

- The processing time means for each stage in Case_1 are: 200 s, 220 s, 180 s, and 80 s, respectively. These time means are maintained in the rest of the cases, except in Stage_1 which includes an in-process measurement; its new time mean is 240 s. A 10 s standard deviation is defined for every process time.

- The setup time for each stage with actuators is 80 s for manual actuators and 20 s for automatic actuators.

- Initial part deviations are modelled as a normal distribution with 0 mean and 0.05 mm standard deviation at coordinates X and Z. In addition, another pair of random deviations at coordinates X and Z are generated to deduce a random orientation deviation.

- Initial locator deviations are modelled as a normal distribution with 0 mean and 0.02 mm standard deviation at coordinates X and Z. However, a bias of the positioners has been modelled by introducing a progressive increase in the mean parameter of the locator deviation distribution, following a quadratic function. This mean parameter is restored to 0 every 3000 s to simulate their adjustment, repair, or replacement.

- The measurement noise for the Stage_1 (assembly station with in-process measurement) is defined by a normal distribution with 0 mean and 0.03 mm standard deviation.

- The measurement noise for the inspection stage is defined by a normal distribution with 0 mean and 0.01 mm standard deviation.

4.2. Case Study Results

- Case 1 presents the highest throughput. However, this case also has the highest D.I.

- The introduction of the feed-forward control (Cases 2 and 3) allows for improvement of the quality of the finished products and to reduce the D.I.

- In Cases 4 and 5, a backward control is also incorporated, observing a greater improvement in the quality results and obtaining the minimum D.I.

- The consideration of manual and automatic actuators in locator positioning considerably reduces the number of finished products. This effect is greater in the cases with manual actuators (Cases 2 and 4).

- In the cases where manual actuators are considered (Cases 2 and 4), the improvement in quality is not enough to offset the reduction of throughput.

- In Case 3, the results show that, despite reducing the total number of products produced, the improvement in quality causes an increase in the number of finished products that meet specifications, obtaining the best result.

5. Discussion

- Validity of the meta-model. The correct construction, compilation, and simulation of the instances demonstrate the correct structuring and implementation of the meta-model. Moreover, it has been proven that the modular structure of the meta-model allows to build executable simulation models in a few minutes and in a very intuitive way.

- Multi-domain simulation approach. It has been proven that a multidomain global assessment is necessary to conduct an adequate analysis in MAS. For instance, according to the results in the best case scenario, the quality improvement increased the number of parts within specifications and the number of parts manufactured decreased with respect to other alternatives. Thus, an analysis to prioritize productivity would have provided a different alternative.

- Flexible simulation. The model instantiation supports the simulation of assembly lines with an interesting level of detail, allowing the introduction of various characteristics and behaviors of the process and obtaining realistic and reliable results. Moreover, the flexible and modular structure is aimed to facilitate the extension of the model to incorporate new block types, such as the consideration of new strategies (e.g., selective assembly) and logic control (e.g., based on establishment of optimal number and placement of inspection stations). For this reason, Modelica and the proposed libraries are a great potential resource for the analysis of assembly lines at the design stage.

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Colledani, M.; Tolio, T.; Fischer, A.; Iung, B.; Lanza, G.; Schmitt, R.; Váncza, J. Design and management of manufacturing systems for production quality. CIRP Ann. 2014, 63, 773–796. [Google Scholar] [CrossRef]

- Colledani, M.; Tolio, T.; Yemane, A. Production quality improvement during manufacturing systems ramp-up. CIRP J. Manuf. Sci. Technol. 2018, 23, 197–206. [Google Scholar] [CrossRef]

- Jionghua, J.; Shi, J. State space modeling of sheet metal assembly for dimensional control. ASME. J. Manuf. Sci. Eng. 1999, 121, 756–762. [Google Scholar] [CrossRef]

- Zhou, S.; Huang, Q.; Shi, J. State space modelling of dimensional variation propagation in multistage machining process using differential motion vectors. IEEE Trans. Robot. Autom. 2003, 19, 296–309. [Google Scholar] [CrossRef]

- Liu, J.; Jin, J.; Shi, J. State space modelling for 3-D variation propagation in rigid-body multistage assembly processes. IEEE Trans. Autom. Sci. Eng. 2009, 7, 274–290. [Google Scholar] [CrossRef]

- Liu, J.; Shi, J.; Hu, S.J. Quality-assured setup planning based on the Stream-of-Variation model for multi-stage machining processes. In Proceedings of the ASME 2006 International Manufacturing Science and Engineering Conference, Ypsilanti, MI, USA, 8–11 October 2006; Volume 47624. [Google Scholar] [CrossRef]

- Abellan-Nebot, J.V.; Liu, J.; Romero, F. Design of multi-station manufacturing processes by integrating the stream-of-variation model and shop-floor data. J. Manuf. Syst. 2011, 30, 70–82. [Google Scholar] [CrossRef]

- Liu, C.Q.; Ding, Y.; Chen, Y. Optimal coordinate sensor placements for estimating mean and variance components of variation sources. IIE Trans. 2005, 37, 877–889. [Google Scholar] [CrossRef]

- Barhak, J.; Djurdjanovic, D.; Spicer, P.; Katz, R. Integration of reconfigurable inspection with stream of variations methodology. Int. J. Mach. Tools Manuf. 2005, 45, 407–419. [Google Scholar] [CrossRef]

- Abellán-Nebot, J.V.; Penarrocha, I.; Sales-Setién, E.; Liu, J. Optimal inspection/actuator placement for robust dimensional compensation in multistage manufacturing processes. In Computational Methods and Production Engineering; Woodhead Publishing: Sawston, UK, 2017; pp. 31–50. [Google Scholar] [CrossRef]

- Abellan-Nebot, J.V.; Liu, J.; Romero, F. Quality prediction and compensation in multi-station machining processes using sensor-based fixtures. Robot. Comput. Integr. Manuf. 2012, 28, 208–219. [Google Scholar] [CrossRef]

- Djurdjanovic, D.; Ni, J. Online stochastic control of dimensional quality in multistation manufacturing systems. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2007, 221, 865–880. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A.Y.C. Digital twins and cyber–physical systems toward smart manufacturing and industry 4.0: Correlation and comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Ding, K.; Chan, F.T.; Zhang, X.; Zhou, G.; Zhang, F. Defining a digital twin-based cyber-physical production system for autonomous manufacturing in smart shop floors. Int. J. Prod. Res. 2019, 57, 6315–6334. [Google Scholar] [CrossRef]

- Shao, G.; Jain, S.; Laroque, C.; Lee, L.H.; Lendermann, P.; Rose, O. Digital twin for smart manufacturing: The simulation aspect. In Proceedings of the 2019 Winter Simulation Conference (WSC), National Harbor, MD, USA, 8–11 December 2019; pp. 2085–2098. [Google Scholar] [CrossRef]

- Fritzson, P. Principles of Object-Oriented Modeling and Simulation with Modelica 2.1; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar] [CrossRef]

- Ogata, K.; Yang, Y. Modern Control Engineering; Prentice Hall: Upper Saddle River, NJ, USA, 2002; Volume 4. [Google Scholar]

- Shi, J. Stream of Variation Modelling and Analysis for Multistage Manufacturing Processes; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar] [CrossRef]

- Friedenthal, S.; Moore, A.; Steiner, R. A Practical Guide to SysML: The Systems Modeling Language; Morgan Kaufmann: Burlington, MA, USA, 2014. [Google Scholar] [CrossRef]

- Papa, S.; Patalano, S.; Lanzotti, A.; Gerbino, S.; Choley, J.Y. Towards the integration of thermal physics and geometrical constraints for a 3D-multiphysical sketcher. In Proceedings of the 2015 IEEE International Symposium on Systems Engineering (ISSE), Rome, Italy, 28–30 September 2015; pp. 248–252. [Google Scholar] [CrossRef]

- Barbedienne, R.; Messaoud, Y.B.; Choley, J.Y.; Penas, O.; Ouslimani, A.; Rivière, A. SAMOS for Spatial Architecture based on Multi-physics and Organisation of Systems in conceptual design. In Proceedings of the 2015 IEEE International Symposium on Systems Engineering (ISSE), Rome, Italy, 28–30 September 2015; pp. 135–141. [Google Scholar] [CrossRef]

- Penas, O.; Plateaux, R.; Patalano, S.; Hammadi, M. Multi-scale approach from mechatronic to Cyber-Physical Systems for the design of manufacturing systems. Comput. Ind. 2017, 86, 52–69. [Google Scholar] [CrossRef]

- Cao, Y.; Liu, Y.; Paredis, C.J. System-level model integration of design and simulation for mechatronic systems based on SysML. Mechatronics 2011, 21, 1063–1075. [Google Scholar] [CrossRef]

- Johnson, T.; Kerzhner, A.; Paredis, C.J.; Burkhart, R. Integrating models and simulations of continuous dynamics into SysML. J. Comput. Inf. Sci. Eng. 2012, 12. [Google Scholar] [CrossRef]

- Eigner, M.; Gilz, T.; Zafirov, R. Interdisciplinary Product Development-Model Based Systems Engineering. 2012. Available online: https://www.plmportal.org/en/research-detail/interdisciplinary-product-development-model-based-systems-engineering.html (accessed on 4 September 2020).

- Kern, W.; Rusitschka, F.; Kopytynski, W.; Keckl, S.; Bauernhansl, T. Alternatives to assembly line production in the automotive industry. In Proceedings of the 23rd International Conference on Production Research, Manila, Philippines, 30 July–3 August 2015. [Google Scholar]

- Cellier, F.; Kofman, E. Continuous System Simulation; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar] [CrossRef]

- Noten, J.V.; Gadeyne, K.; Witters, M. Model-based Systems Engineering of Discrete Production Lines Using SysML: An Experience Report. Procedia CIRP 2017, 60, 157–162. [Google Scholar] [CrossRef]

- Mhenni, F.; Penas, O.; Hammadi, M.; Choley, J.Y.; Hehenberger, P. Systems engineering approach for the conjoint design of mechatronic products and their manufacturing systems. In Proceedings of the 2018 Annual IEEE International Systems Conference (SysCon), Vancouver, BC, Canada, 23–26 April 2018; pp. 1–8. [Google Scholar] [CrossRef]

- Plateaux, R.; Penas, O.; Mhenni, F.; Choley, J.Y.; Riviere, A. Introduction of the 3D Geometrical Constraints in Modelica. In Proceedings of the 7th International Modelica Conference, Como, Italy, 20–22 September 2009; pp. 526–530. [Google Scholar] [CrossRef]

- Warniez, A.; Penas, O.; Plateaux, R.; Soriano, T. SysML geometrical profile for integration of mechatronic systems. In Proceedings of the IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Besacon, France, 8–11 July 2014; pp. 709–714. [Google Scholar] [CrossRef]

- Tang, H.; Duan, J.; Lan, S.; Shui, H. A new geometric error modeling approach for multi-axis system based on stream of variation theory. Int. J. Mach. Tools Manuf. 2015, 92, 41–51. [Google Scholar] [CrossRef]

- Abellan-Nebot, J.V.; Liu, J.; Subirón, F.R.; Shi, J. State Space Modeling of Variation Propagation in Multistation Machining Processes Considering Machining-Induced Variations. J. Manuf. Sci. Eng. Trans. ASME 2012, 134, 021002. [Google Scholar] [CrossRef]

- Negri, E.; Fumagalli, L.; Cimino, C.; Macchi, M. FMU-supported simulation for CPS Digital Twin. Procedia Manuf. 2019, 28, 201–206. [Google Scholar] [CrossRef]

- Weyer, S.; Meyer, T.; Ohmer, M.; Gorecky, D.; Zühlke, D. Future Modeling and Simulation of CPS-based Factories: An Example from the Automotive Industry. IFAC PapersOnLine 2016, 49, 97–102. [Google Scholar] [CrossRef]

| Case 1 | Case 2 | Case 3 | Case 4 | Case 5 | |

|---|---|---|---|---|---|

| F.P. | 214 | 164 | 203 | 153 | 180 |

| Throughput | 15.41 | 11.81 | 14.61 | 11.01 | 12.96 |

| F.P.M.S. | 155 | 132 | 164 | 136 | 156 |

| D.I. | 27.57 | 19.51 | 19.21 | 11.11 | 13.33 |

| F.P.M.S.H. | 11.17 | 9.51 | 11.81 | 9.80 | 11.24 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benavent Nácher, S.; Rosado Castellano, P.; Romero Subirón, F.; Abellán-Nebot, J.V. Multidomain Simulation Model for Analysis of Geometric Variation and Productivity in Multi-Stage Assembly Systems. Appl. Sci. 2020, 10, 6606. https://doi.org/10.3390/app10186606

Benavent Nácher S, Rosado Castellano P, Romero Subirón F, Abellán-Nebot JV. Multidomain Simulation Model for Analysis of Geometric Variation and Productivity in Multi-Stage Assembly Systems. Applied Sciences. 2020; 10(18):6606. https://doi.org/10.3390/app10186606

Chicago/Turabian StyleBenavent Nácher, Sergio, Pedro Rosado Castellano, Fernando Romero Subirón, and José V. Abellán-Nebot. 2020. "Multidomain Simulation Model for Analysis of Geometric Variation and Productivity in Multi-Stage Assembly Systems" Applied Sciences 10, no. 18: 6606. https://doi.org/10.3390/app10186606

APA StyleBenavent Nácher, S., Rosado Castellano, P., Romero Subirón, F., & Abellán-Nebot, J. V. (2020). Multidomain Simulation Model for Analysis of Geometric Variation and Productivity in Multi-Stage Assembly Systems. Applied Sciences, 10(18), 6606. https://doi.org/10.3390/app10186606