Study on Damage of 4H-SiC Single Crystal through Indentation and Scratch Testing in Micro–Nano Scales

Abstract

1. Introduction

2. Development of Analytical Model

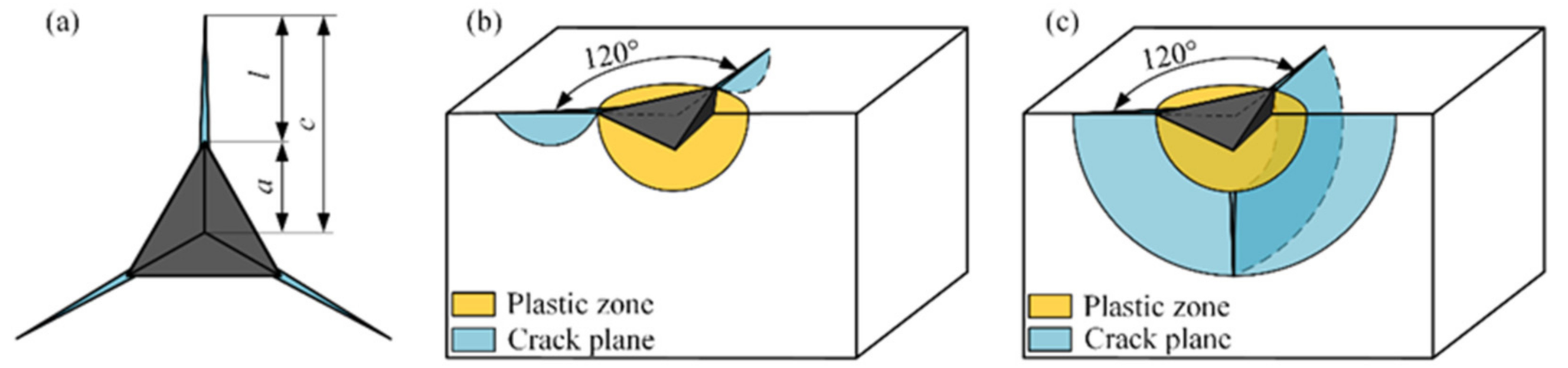

2.1. Indentation Crack System of Brittle Materials

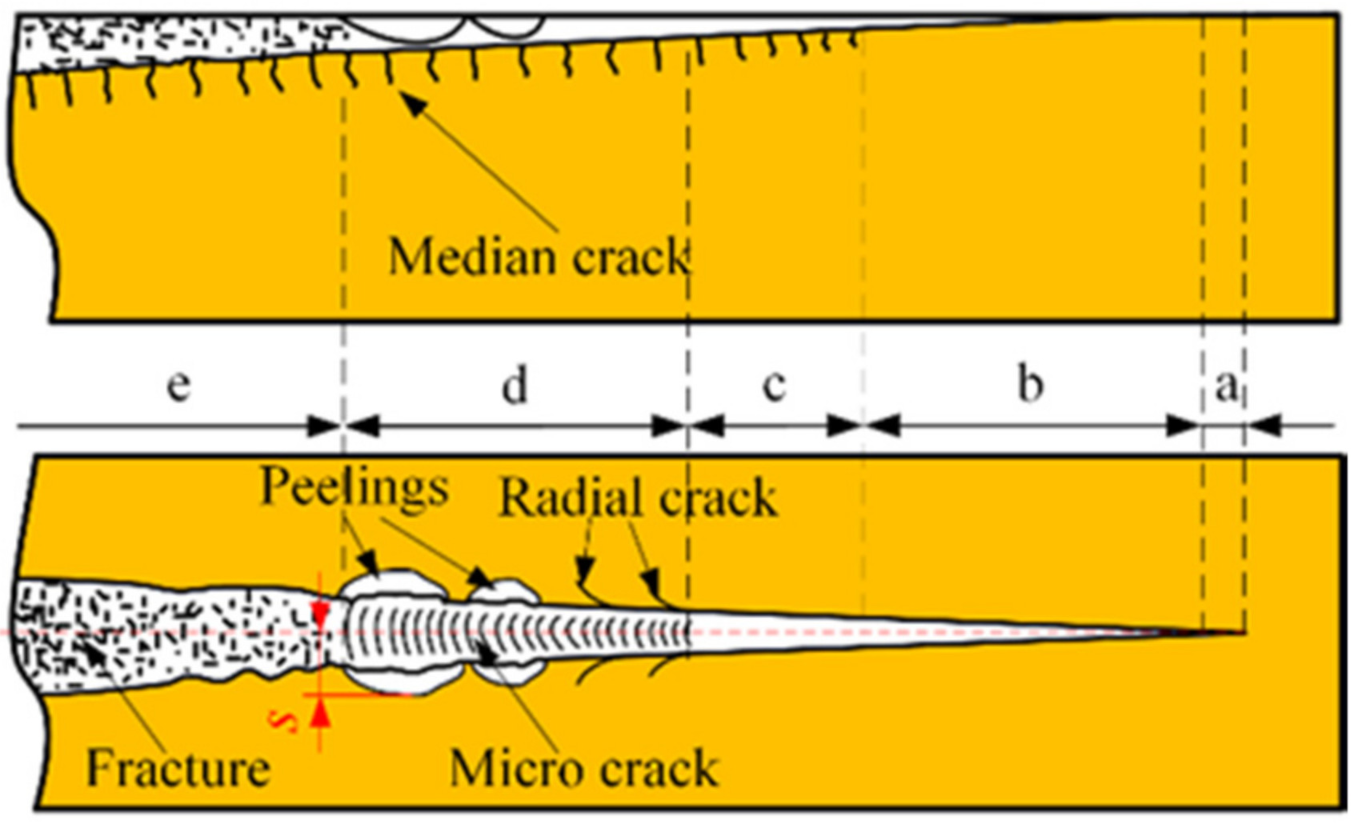

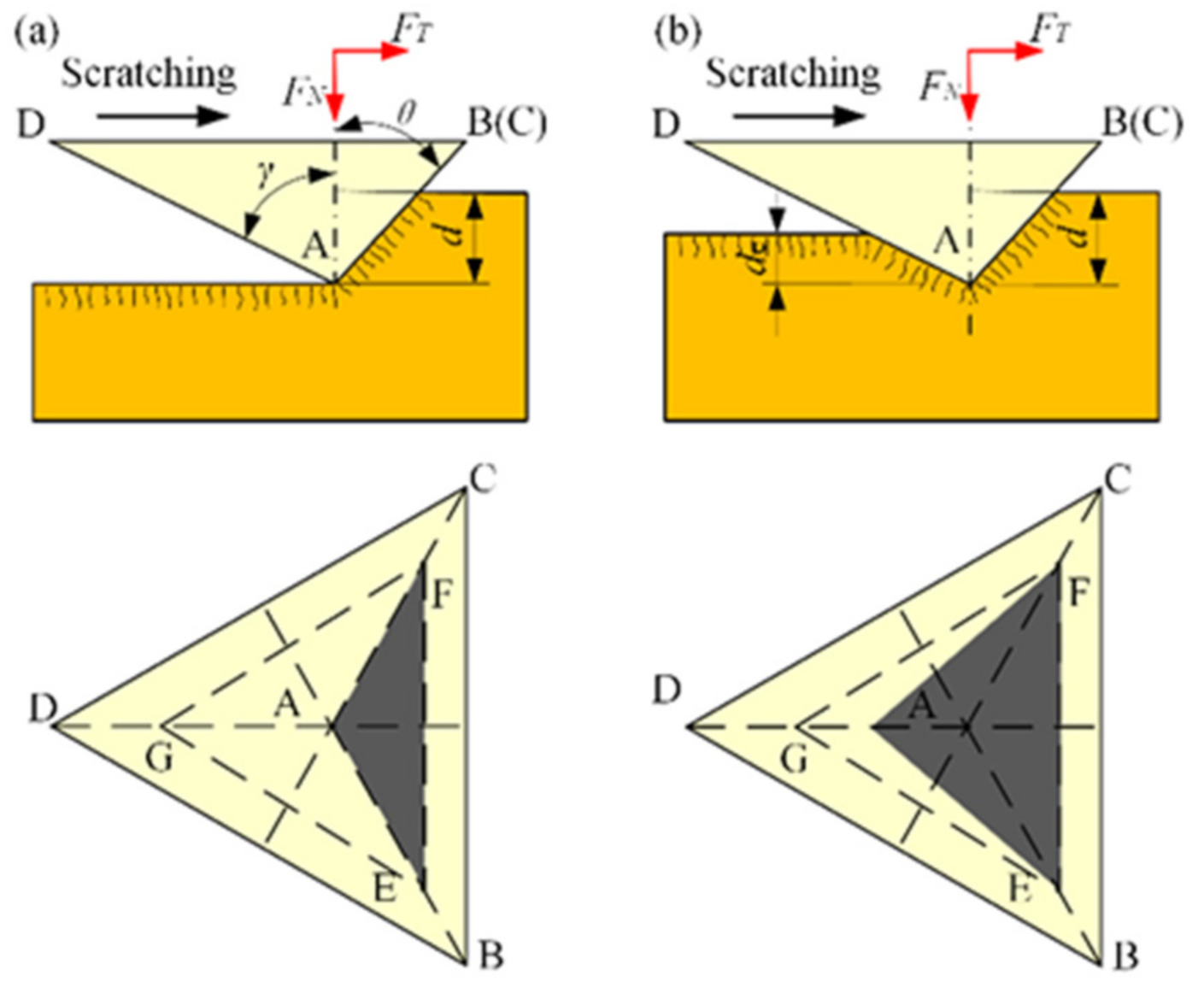

2.2. Scratch of Brittle Materials

2.3. Fracture Toughness Determination

2.4. Normal Force of Scratching

3. Experimental Procedure

3.1. Materials and Instruments

3.2. Indentation Test Procedure

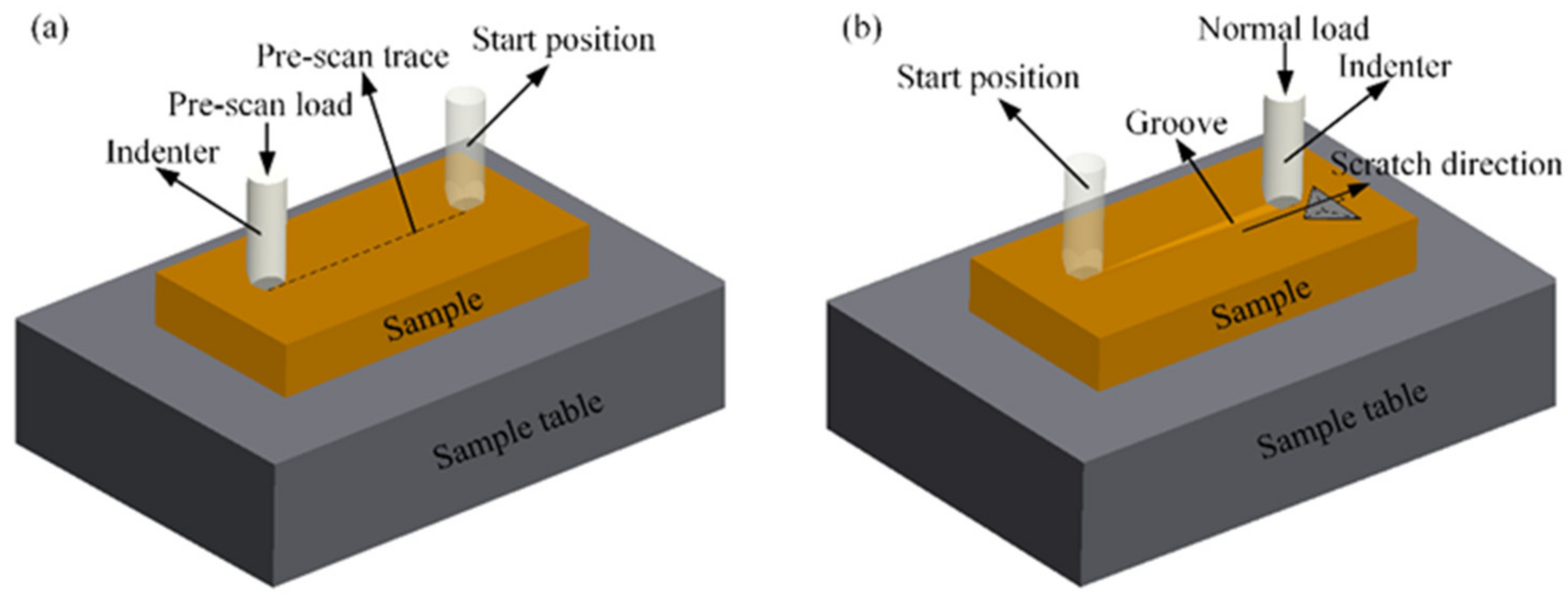

3.3. Scratch Test Procedure

4. Results

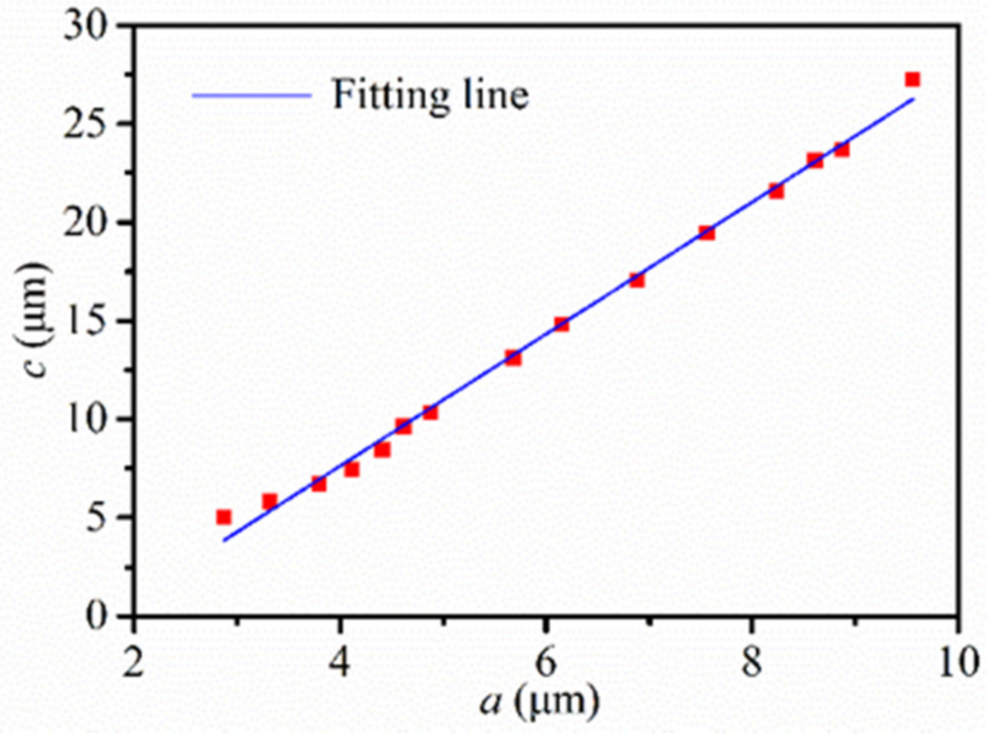

4.1. Indentation Results

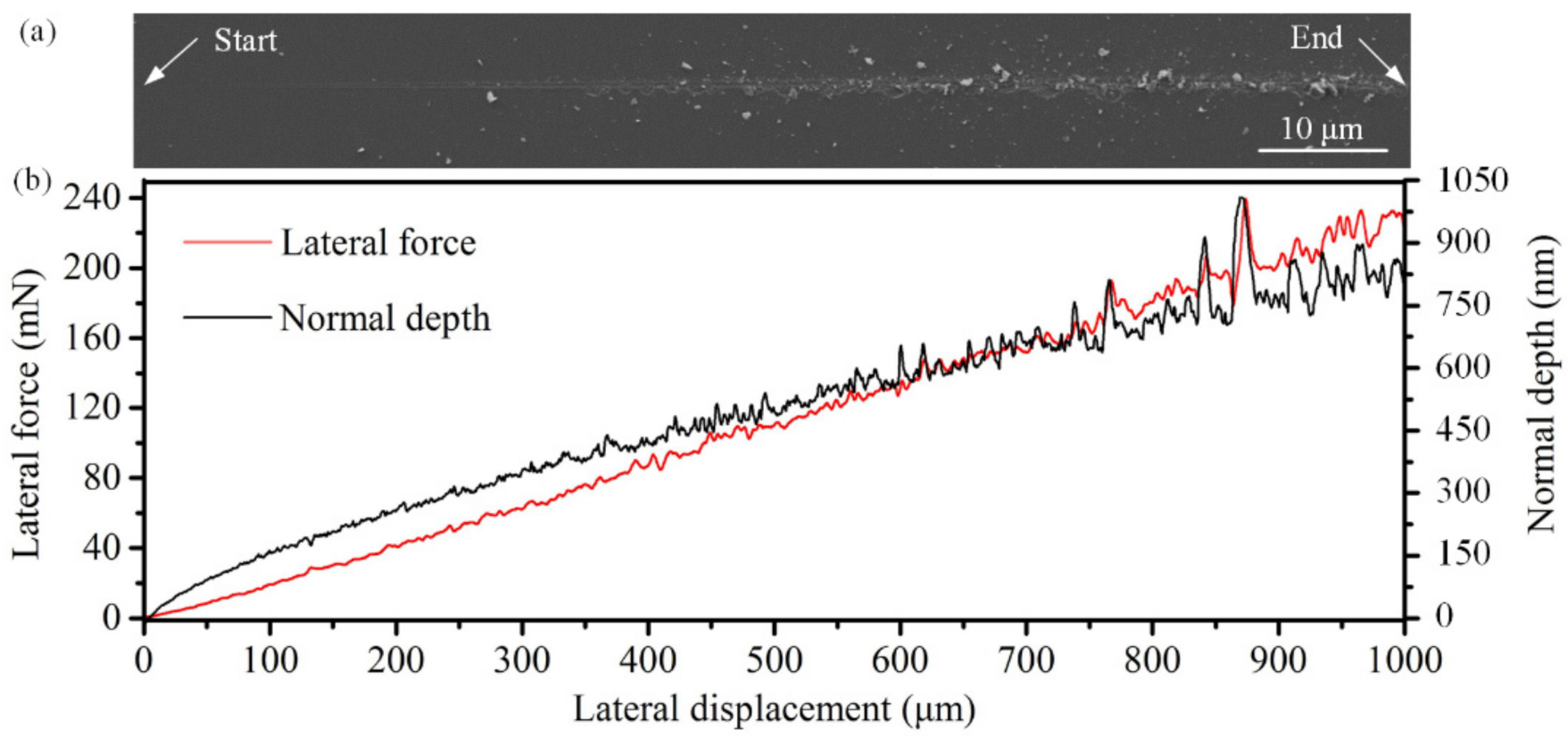

4.2. Scratch Results

5. Analysis and Discussion

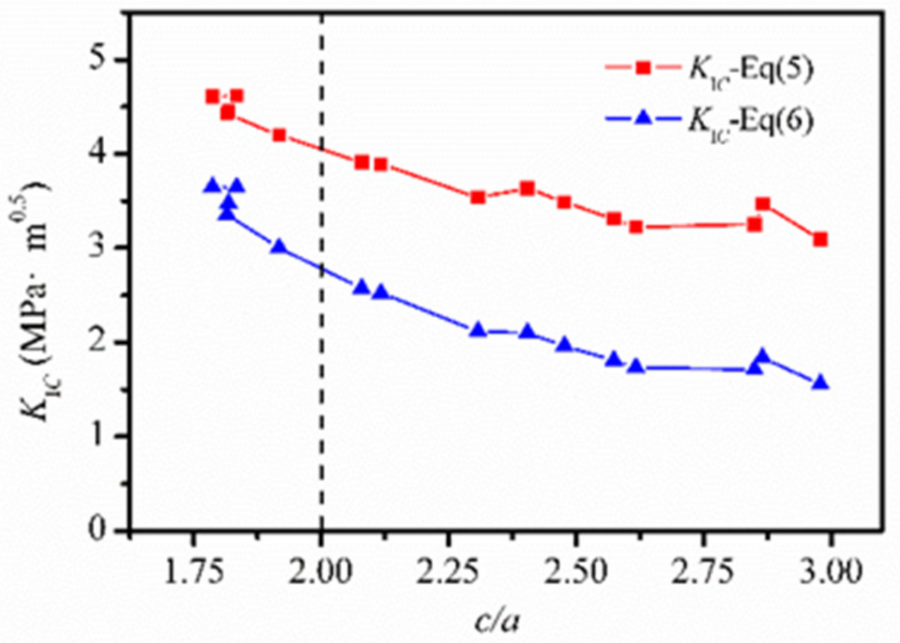

5.1. Determination of the Fracture Toughness

5.2. Critical Indentation Size

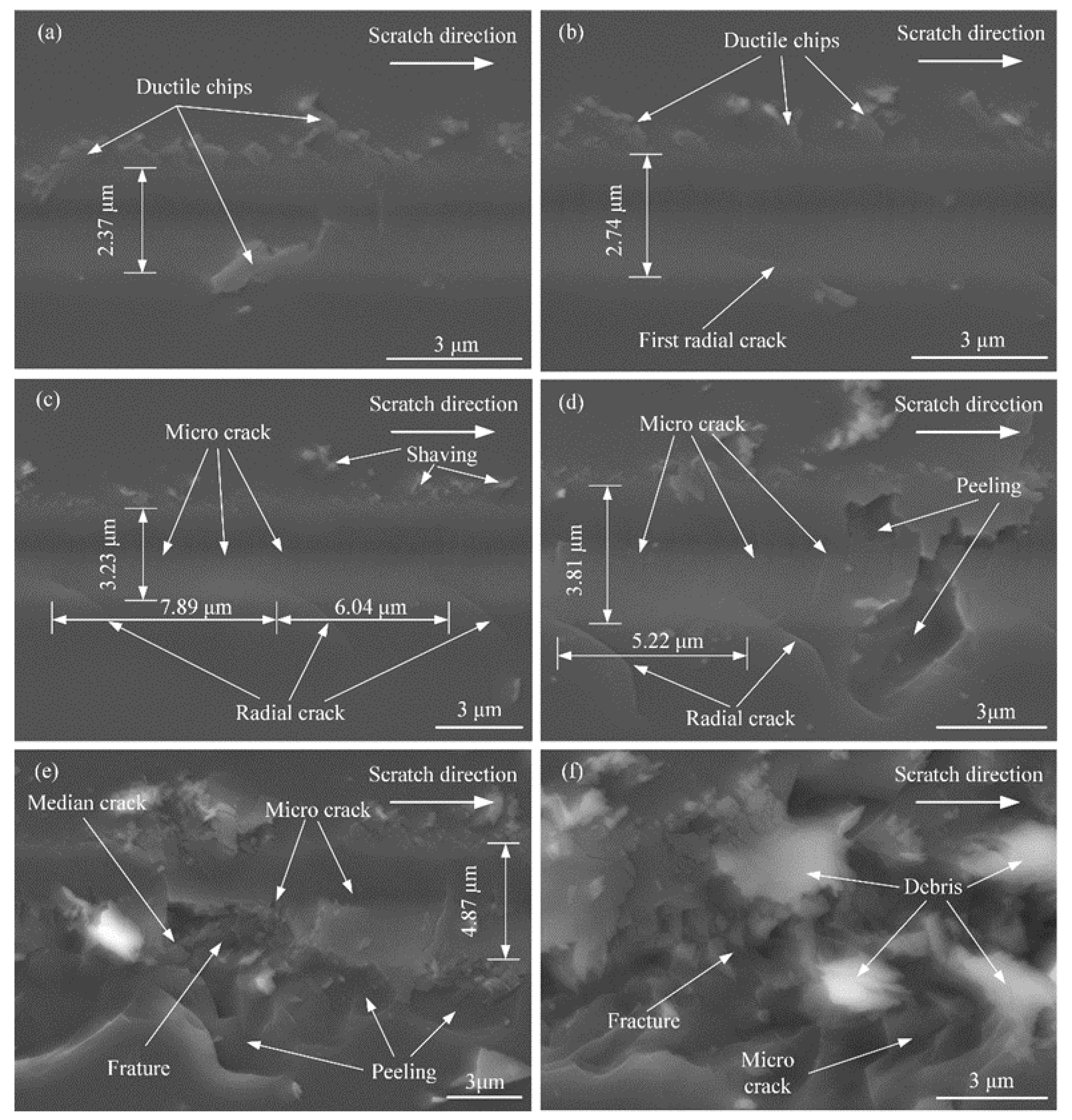

5.3. Material Removal Mechanism

5.4. Determination of Normal Force in Brittle Stage

6. Conclusions

- The fracture toughness of 4H-SiC single crystals was evaluated by a series of indentation tests in which the maximum normal force ranged from 0.4 to 3.3 N. The values of fracture toughness, calculated by both Lawn’s equation and Laugier’s equation, decreased with increasing c/a ratio. An appropriate value of c/a ratio is significant to calculate fracture toughness of 4H-SiC single crystals.

- According to the linear relationship between a and c, a critical condition with no cracks on the edge of the indentation was obtained through the fitting method, and the experimental fitting results agreed well with Lawn’s results.

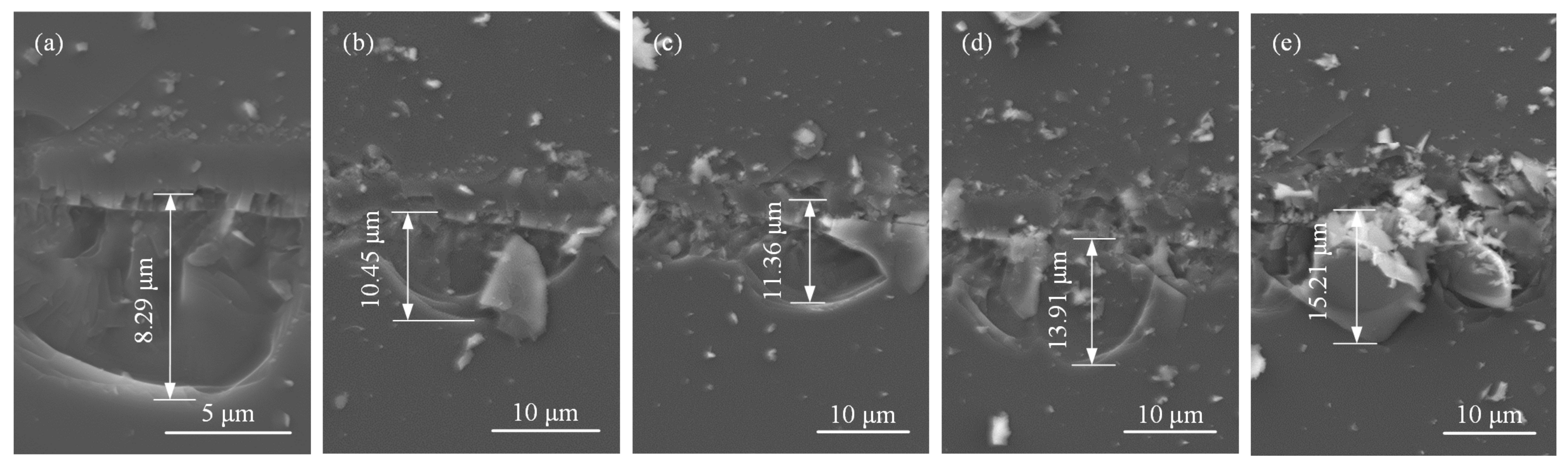

- The surface morphologies of the groove were analyzed by SEM. Plastic deformation was observed and characterized by the smooth groove without cracks and ductile chips on the edge of the groove in the initial stages of the scratch. With the increase in normal force, median cracks, radial cracks, and microcracks appeared in turn. With a sustained increase in normal force, the crack system was not able to continue extending stably, and the brittle fracture dominated the material removal.

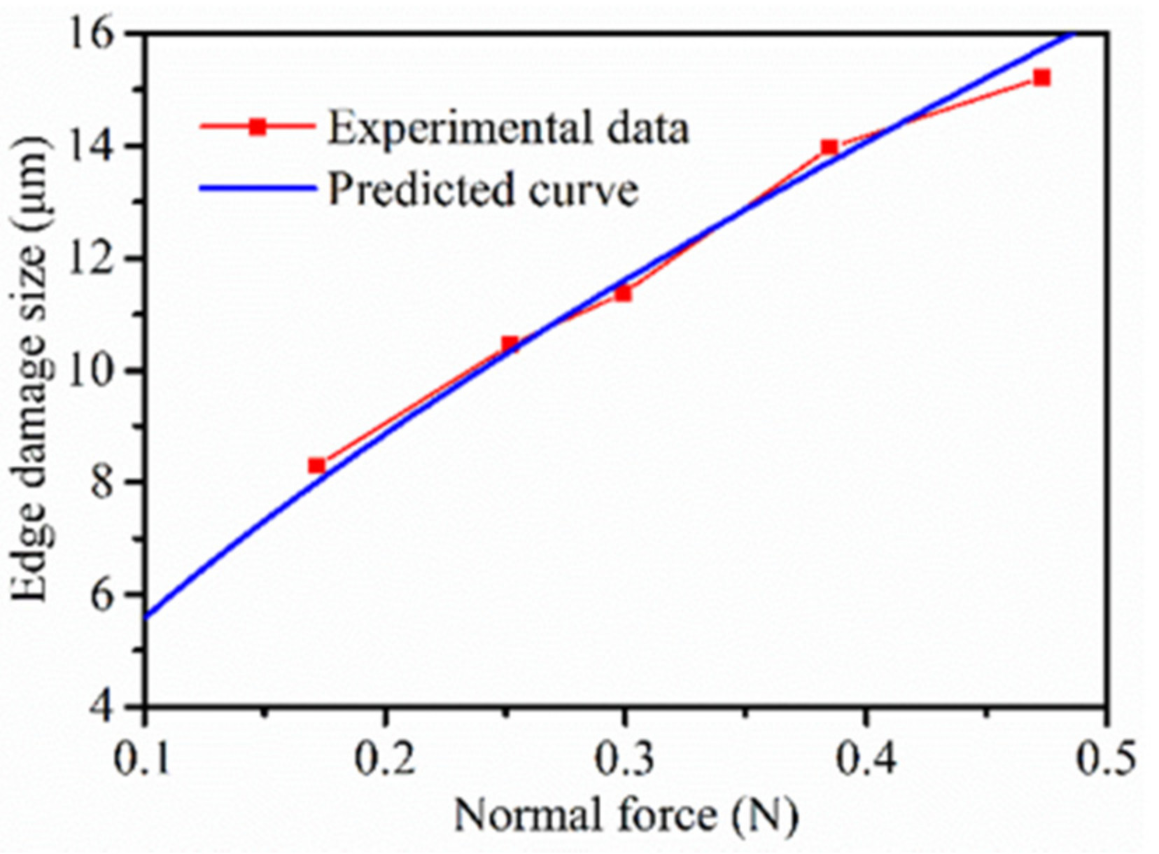

- The sizes of the edge damage of five characteristic positions generated relatively large peeling of the scratched groove, which were measured using SEM, and the experimental data highly agreed with the predicted curve.

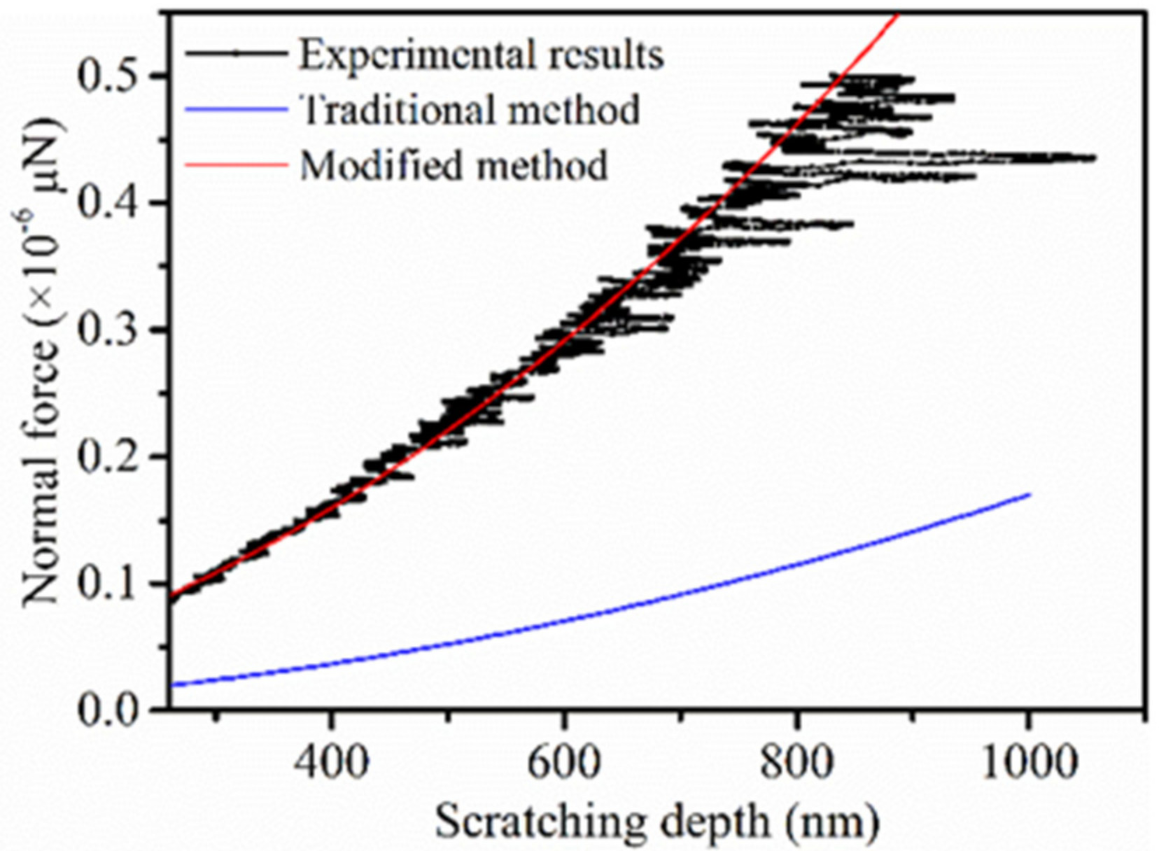

- A modified calculation model considered the previously proposed elastic recovery of normal force during the scratching process. Compared with the traditional calculation model, the modified predicted curve was closer to the experimental data. These results prove that the elastic recovery of 4H-SiC single crystals cannot be ignored during micro–nano machining.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kumar, P.; Srivastava, V.K. Tribological behaviour of C/C–SiC composites—A review. J. Adv. Ceram. 2016, 5, 1–12. [Google Scholar] [CrossRef]

- Guo, X.; Xun, Q.; Li, Z.; Du, S. Silicon Carbide Converters and MEMS Devices for High-temperature Power Electronics: A Critical Review. Micromachines 2019, 10, 406. [Google Scholar] [CrossRef] [PubMed]

- Shcherban, N.D. Review on synthesis, structure, physical and chemical properties and functional characteristics of porous silicon carbide. J. Ind. Eng. Chem. 2017, 50, 15–28. [Google Scholar] [CrossRef]

- She, X.; Huang, A.Q.; Lucia, O.; Ozpineci, B. Review of Silicon Carbide Power Devices and Their Applications. IEEE Trans. Ind. Electron. 2017, 64, 8193–8205. [Google Scholar] [CrossRef]

- Mohankumar, P.; Ajayan, J.; Yasodharan, R.; Devendran, P.; Sambasivam, R. A review of micromachined sensors for automotive applications. Measurement 2019, 140, 305–322. [Google Scholar] [CrossRef]

- Duan, W.; Yin, X.; Li, Q.; Schlier, L.; Greil, P.; Travitzky, N. A review of absorption properties in silicon-based polymer derived ceramics. J. Eur. Ceram. Soc. 2016, 36, 3681–3689. [Google Scholar] [CrossRef]

- Momohjimoh, I.; Hussein, M.A.; Al-Aqeeli, N. Recent Advances in the Processing and Properties of Alumina(-)CNT/SiC Nanocomposites. Nanomaterials 2019, 9, 86. [Google Scholar] [CrossRef]

- Eom, J.-H.; Kim, Y.-W.; Raju, S. Processing and properties of macroporous silicon carbide ceramics: A review. J. Asian Ceram. Soc. 2018, 1, 220–242. [Google Scholar] [CrossRef]

- Wang, P.; Ge, P.; Ge, M.; Bi, W.; Meng, J. Material removal mechanism and crack propagation in single scratch and double scratch tests of single-crystal silicon carbide by abrasives on wire saw. Ceram. Int. 2019, 45, 384–393. [Google Scholar] [CrossRef]

- Rao, X.; Zhang, F.; Luo, X.; Ding, F.; Cai, Y.; Sun, J.; Liu, H. Material removal mode and friction behaviour of RB-SiC ceramics during scratching at elevated temperatures. J. Eur. Ceram. Soc. 2019, 39, 3534–3545. [Google Scholar] [CrossRef]

- Yen, C.-Y.; Jian, S.-R.; Tseng, Y.-C.; Juang, J.-Y. The deformation behavior and fracture toughness of single crystal YSZ(111) by indentation. J. Alloys Compd. 2018, 735, 2423–2427. [Google Scholar] [CrossRef]

- Li, X.; Gao, Y.; Ge, P.; Zhang, L.; Bi, W.; Meng, J. Nucleation location and propagation direction of radial and median cracks for brittle material in scratching. Ceram. Int. 2019, 45, 7524–7536. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, X.; Zheng, L.; Xue, D. High-performance grinding of a 2-m scale silicon carbide mirror blank for the space-based telescope. Int. J. Adv. Manuf. Technol. 2016, 89, 463–473. [Google Scholar] [CrossRef]

- Zheng, G.; Xu, L.; Zou, X.; Liu, Y. Excitation of surface phonon polariton modes in gold gratings with silicon carbide substrate and their potential sensing applications. Appl. Surf. Sci. 2017, 396, 711–716. [Google Scholar] [CrossRef]

- Widmann, M.; Niethammer, M.; Makino, T.; Rendler, T.; Lasse, S.; Ohshima, T.; Ul Hassan, J.; Tien Son, N.; Lee, S.-Y.; Wrachtrup, J. Bright single photon sources in lateral silicon carbide light emitting diodes. Appl. Phys. Lett. 2018, 112, 231103. [Google Scholar] [CrossRef]

- Regnat, G.; Jeannin, P.-O.; Frey, D.; Ewanchuk, J.; Mollov, S.V.; Ferrieux, J.-P. Optimized Power Modules for Silicon Carbide MOSFET. IEEE Trans. Ind. Appl. 2018, 54, 1634–1644. [Google Scholar] [CrossRef]

- Kargarrazi, S.; Elahipanah, H.; Rodriguez, S.; Zetterling, C.-M. 500 °C, High Current Linear Voltage Regulator in 4H-SiC BJT Technology. IEEE Electron. Device Lett. 2018, 39, 548–551. [Google Scholar] [CrossRef]

- Shen, Y.; Jones, A.H.; Yuan, Y.; Zheng, J.; Peng, Y.; VanMil, B.; Olver, K.; Sampath, A.V.; Parker, C.; Opila, E.; et al. Near ultraviolet enhanced 4H-SiC Schottky diode. Appl. Phys. Lett. 2019, 115, 261101. [Google Scholar] [CrossRef]

- Datye, A.; Lin, H.-T. Energy analysis of spherical and Berkovich indentation contact damage in commercial polycrystalline silicon carbide. Ceram. Int. 2017, 43, 800–809. [Google Scholar] [CrossRef]

- Behner, T.; Heine, A.; Wickert, M. Dwell and penetration of tungsten heavy alloy long-rod penetrators impacting unconfined finite-thickness silicon carbide ceramic targets. Int. J. Impact Eng. 2016, 95, 54–60. [Google Scholar] [CrossRef]

- Shi, Y.; Sun, Y.; Liu, J.; Tang, J.; Li, J.; Ma, Z.; Cao, H.; Zhao, R.; Kou, Z.; Huang, K.; et al. UV nanosecond laser machining and characterization for SiC MEMS sensor application. Sens. Actuators A Phys. 2018, 276, 196–204. [Google Scholar] [CrossRef]

- Cook, E.; Tomaino-Iannucci, M.; Bernstein, J.; Weinberg, M.; Choy, J.; Hobart, K.; Luna, L.; Tadjer, M.; Myers-Ward, R.; Kub, F.; et al. A High-Mass, Eight-Fold Symmetric Silicon Carbide Mems Gyroscope. Solid State Sens. Actuators Microsyst. Workshop 2018, 364–365. [Google Scholar] [CrossRef]

- Okojie, R.S.; Lukco, D.; Nguyen, V.; Savrun, E. 4H-SiC Piezoresistive Pressure Sensors at 800 °C With Observed Sensitivity Recovery. IEEE Electron. Device Lett. 2015, 36, 174–176. [Google Scholar] [CrossRef]

- Lu, X.; Lee, J.Y.; Lin, Q. High-frequency and high-quality silicon carbide optomechanical microresonators. Sci. Rep. 2015, 5, 17005. [Google Scholar] [CrossRef] [PubMed]

- Cooper, O.; Wang, B.; Brown, C.L.; Tiralongo, J.; Iacopi, F. Toward Label-Free Biosensing With Silicon Carbide: A Review. IEEE Access 2016, 4, 477–497. [Google Scholar] [CrossRef]

- Phan, H.P.; Zhong, Y.; Nguyen, T.K.; Park, Y.; Dinh, T.; Song, E.; Vadivelu, R.K.; Masud, M.K.; Li, J.; Shiddiky, M.J.A.; et al. Long-Lived, Transferred Crystalline Silicon Carbide Nanomembranes for Implantable Flexible Electronics. ACS Nano 2019, 13, 11572–11581. [Google Scholar] [CrossRef] [PubMed]

- Chai, P.; Li, S.; Li, Y. Modeling and Experiment of the Critical Depth of Cut at the Ductile-Brittle Transition for a 4H-SiC Single Crystal. Micromachines 2019, 10, 382. [Google Scholar] [CrossRef]

- Chai, P.; Li, S.; Li, Y.; Liang, L.; Yin, X. Mechanical Behavior Investigation of 4H-SiC Single Crystal at the Micro-Nano Scale. Micromachines 2020, 11, 102. [Google Scholar] [CrossRef]

- Lawn, B.R.; Swain, M.V. Microfracture beneath point indentations in brittle solids. J. Mater. Sci. 1975, 10, 113–122. [Google Scholar] [CrossRef]

- Marshall, D.; Lawn, B.; Evans, A. Elastic/Plastic Indentation Damage in Ceramics: The Lateral Crack System. J. Am. Ceram. Soc. 1982, 65, 561–566. [Google Scholar] [CrossRef]

- John, C.; Lambropoulos, S.D.J.; Ruckman, J. Material removal mechanisms from grinding to polishing. Ceram. Trans. 1999, 102, 113–128. [Google Scholar]

- Wasmer, K.; Ballif, C.; Gassilloud, R.; Pouvreau, C.; Rabe, R.; Michler, J.; Breguet, J.M.; Solletti, J.M.; Karimi, A.; Schulz, D. Cleavage Fracture of Brittle Semiconductors from the Nanometre to the Centimetre Scale. Adv. Eng. Mater. 2005, 7, 309–317. [Google Scholar] [CrossRef]

- Le Houérou, V.; Sangleboeuf, J.-C.; Dériano, S.; Rouxel, T.; Duisit, G. Duisit. Surface damage of soda–lime–silica glasses: Indentation scratch behavior. J. Non-Cryst. Solids 2003, 63, 54–63. [Google Scholar] [CrossRef]

- Wang, L.; Gao, Y.; Li, X.; Pu, T.; Yin, Y. Analytical prediction of subsurface microcrack damage depth in diamond wire sawing silicon crystal. Mater. Sci. Semicond. Process. 2020, 112, 105015. [Google Scholar] [CrossRef]

- Lawn, B. Fracture of Brittle Solids, 2nd ed.; Cambridge University Press: Cambridge, UK, 1993. [Google Scholar] [CrossRef]

- Hervas, I.; Montagne, A.; Van Gorp, A.; Bentoumi, M.; Thuault, A.; Iost, A. Fracture toughness of glasses and hydroxyapatite: A comparative study of 7 methods by using Vickers indenter. Ceram. Int. 2016, 42, 12740–12750. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, X.; Giuliani, F.; Atkinson, A. Fracture Toughness of Porous Material of LSCF in Bulk and Film Forms. J. Am. Ceram. Soc. 2015, 98, 2183–2190. [Google Scholar] [CrossRef]

- Guo, H.; Jiang, C.B.; Yang, B.J.; Wang, J.Q. On the fracture toughness of bulk metallic glasses under Berkovich nanoindentation. J. Non-Cryst. Solids 2018, 481, 321–328. [Google Scholar] [CrossRef]

- Rao, X.; Zhang, F.; Luo, X.; Ding, F. Characterization of hardness, elastic modulus and fracture toughness of RB-SiC ceramics at elevated temperature by Vickers test. Mater. Sci. Eng. A 2019, 744, 426–435. [Google Scholar] [CrossRef]

- Ghidelli, M.; Sebastiani, M.; Johanns, K.E.; Pharr, G.M. Effects of indenter angle on micro-scale fracture toughness measurement by pillar splitting. J. Am. Ceram. Soc. 2017, 100, 5731–5738. [Google Scholar] [CrossRef]

- Bruns, S.; Petho, L.; Minnert, C.; Michler, J.; Durst, K. Fracture toughness determination of fused silica by cube corner indentation cracking and pillar splitting. Mater. Des. 2020, 186, 1–8. [Google Scholar] [CrossRef]

- Best, J.P.; Zechner, J.; Wheeler, J.M.; Schoeppner, R.; Morstein, M.; Michler, J. Small-scale fracture toughness of ceramic thin films: The effects of specimen geometry, ion beam notching and high temperature on chromium nitride toughness evaluation. Philos. Mag. 2016, 96, 3552–3569. [Google Scholar] [CrossRef]

- Ast, J.; Ghidelli, M.; Durst, K.; Göken, M.; Sebastiani, M.; Korsunsky, A.M. A review of experimental approaches to fracture toughness evaluation at the micro-scale. Mater. Des. 2019, 173, 107762. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, T. Determination of fracture toughness of brittle materials by indentation. Acta Mech. Solida Sin. 2015, 28, 221–234. [Google Scholar] [CrossRef]

- Zameer Abbas, S.; Ahmad Khalid, F.; Zaigham, H. Indentation fracture toughness behavior of FeCo-based bulk metallic glass intrinsic composites. J. Non-Cryst. Solids 2017, 457, 86–92. [Google Scholar] [CrossRef]

- Lawn, B.R.; Evans, A.G.; Marshall, D.B. Elastic/Plastic Indentation Damage in Ceramics: The Mediad/Radial Crack System. J. Am. Ceram. Soc. 1980, 63, 574–581. [Google Scholar] [CrossRef]

- Harding, D.S.; Oliver, W.C.; Pharr, G.M. Cracking During Nanoindentation and its Use in the Measurement of Fracture Toughness. MRS Proc. 1994, 356, 664–668. [Google Scholar] [CrossRef]

- Laugier, M.T. Palmqvist indentation toughness in WC-Co composites. J. Mater. Sci. Lett. 1987, 6, 897–900. [Google Scholar] [CrossRef]

- Garrido, M.A.; Giraldez, I.; Ceballos, L.; Rodriguez, J. On the possibility of estimating the fracture toughness of enamel. Dent. Mater. 2014, 30, 1224–1233. [Google Scholar] [CrossRef]

- Li, C.; Zhang, Q.; Zhang, Y.; Zhang, F.; Wang, X.; Dong, G. Nanoindentation and nanoscratch tests of YAG single crystals: An investigation into mechanical properties, surface formation characteristic, and theoretical model of edge-breaking size. Ceram. Int. 2020, 46, 3382–3393. [Google Scholar] [CrossRef]

- Gilles Orange, H.T.; Gilbert, F. Fracture Toughness of Pressureless Sintered Silicon Carbide: A Comparison of KIL Measurement Methods. Ceram. Int. 1987, 13, 159–165. [Google Scholar] [CrossRef]

- Henshall, J.L.; Rowcliffe, D.J.; Edington, J.W. Fracture Toughness of Single-Crystal Silicon Carbide. J. Am. Ceram. Soc. 1977, 60, 373–375. [Google Scholar] [CrossRef]

- Eswar Prasad, K.; Ramesh, K.T. Hardness and mechanical anisotropy of hexagonal SiC single crystal polytypes. J. Alloys Compd. 2019, 770, 158–165. [Google Scholar] [CrossRef]

| Applications | Properties | Instance and Reference |

|---|---|---|

| Optical material | High specific rigidity, high thermal stability | Space-based astronomy telescope [13], grating [14] |

| Device | Large band gap, high temperature, high frequency | Emitting diode [15], Metal-Oxide-Semiconductor Field-Effect Transistor (MOSFET) [16], Bipolar Junction Transistor (BJT) [17], Schottky diodes [18] |

| Composite and coating | High hardness, high strength, wear resistance | pistons, valve heads, bearings [19], armor [20] |

| Porous material | High porosity, less volume density, high mechanical strength | Water filtration, filters, polymer matrix composites [3,8] |

| Micro-Electro-Mechanical System (MEMS) | High temperature, corrosive environment, high radiation | Accelerometer [21], gyroscope [22], pressure sensors [23], resonator [24] |

| Biosensor | Biocompatibility, chemically inert | Biochemical detection systems [25], implantable flexible electronics [26] |

| Test Parameters | Units | Values |

|---|---|---|

| Prescan load | mN | 0.1 |

| Load range | mN | 0–500 |

| Scratch length | μm | 1000 |

| Scratch velocity | μm/s | 4 |

| Number | Fmax (N) | Average a (μm) | Average c (μm) | Standard Deviation of c | c/a |

|---|---|---|---|---|---|

| 1 | 0.4 | 2.87 | 5.01 | 0.31 | 1.75 |

| 2 | 0.5 | 3.32 | 5.81 | 0.51 | 1.75 |

| 3 | 0.6 | 3.80 | 6.72 | 0.53 | 1.77 |

| 4 | 0.7 | 4.12 | 7.47 | 0.65 | 1.82 |

| 5 | 0.8 | 4.41 | 8.46 | 0.66 | 1.92 |

| 6 | 0.9 | 4.62 | 9.61 | 0.75 | 2.08 |

| 7 | 1 | 4.88 | 10.33 | 0.69 | 2.12 |

| 8 | 1.3 | 5.68 | 13.11 | 0.68 | 2.31 |

| 9 | 1.6 | 6.15 | 14.79 | 0.91 | 2.40 |

| 10 | 1.9 | 6.89 | 17.06 | 0.82 | 2.48 |

| 11 | 2.2 | 7.56 | 19.46 | 0.77 | 2.57 |

| 12 | 2.5 | 8.24 | 21.56 | 0.79 | 2.62 |

| 13 | 2.8 | 8.61 | 24.54 | 0.85 | 2.85 |

| 14 | 3.1 | 8.87 | 25.42 | 1.32 | 2.87 |

| 15 | 3.4 | 9.56 | 28.49 | 2.39 | 2.98 |

| c/a ratio | KIC-Equation (5) (MPa∙m1/2) | KIC-Equation (6) (MPa∙m1/2) |

|---|---|---|

| 2.0 | 3.42 | 3.47 |

| 2.1 | 3.28 | 3.43 |

| 2.2 | 3.17 | 3.37 |

| 2.3 | 3.04 | 3.35 |

| 2.4 | 2.94 | 3.3 |

| 2.5 | 2.83 | 3.27 |

| Sample | Method | KIC (MPa∙m1/2) | Reference |

|---|---|---|---|

| α-SiC | Chevron notched beam (CVNB) | 3.03 | [51] |

| 6H-SiC (0001) | Single edge notched beam (SENB) | 3.3 | [52] |

| 4H-SiC (0001) | Indentation for Berkovich indenter | 3.33 | [53] |

| 4H-SiC (0001) | Indentation for Berkovich indenter | 3.42 | Present (Equation (5)) |

| 4H-SiC (0001) | Indentation for Berkovich indenter | 3.47 | Present (Equation (6)) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chai, P.; Li, S.; Li, Y.; Yin, X. Study on Damage of 4H-SiC Single Crystal through Indentation and Scratch Testing in Micro–Nano Scales. Appl. Sci. 2020, 10, 5944. https://doi.org/10.3390/app10175944

Chai P, Li S, Li Y, Yin X. Study on Damage of 4H-SiC Single Crystal through Indentation and Scratch Testing in Micro–Nano Scales. Applied Sciences. 2020; 10(17):5944. https://doi.org/10.3390/app10175944

Chicago/Turabian StyleChai, Peng, Shujuan Li, Yan Li, and Xincheng Yin. 2020. "Study on Damage of 4H-SiC Single Crystal through Indentation and Scratch Testing in Micro–Nano Scales" Applied Sciences 10, no. 17: 5944. https://doi.org/10.3390/app10175944

APA StyleChai, P., Li, S., Li, Y., & Yin, X. (2020). Study on Damage of 4H-SiC Single Crystal through Indentation and Scratch Testing in Micro–Nano Scales. Applied Sciences, 10(17), 5944. https://doi.org/10.3390/app10175944