A New Generation of Bio-Composite Thermoplastic Filaments for a More Sustainable Design of Parts Manufactured by FDM

Abstract

:1. Introduction

2. Materials and Methods

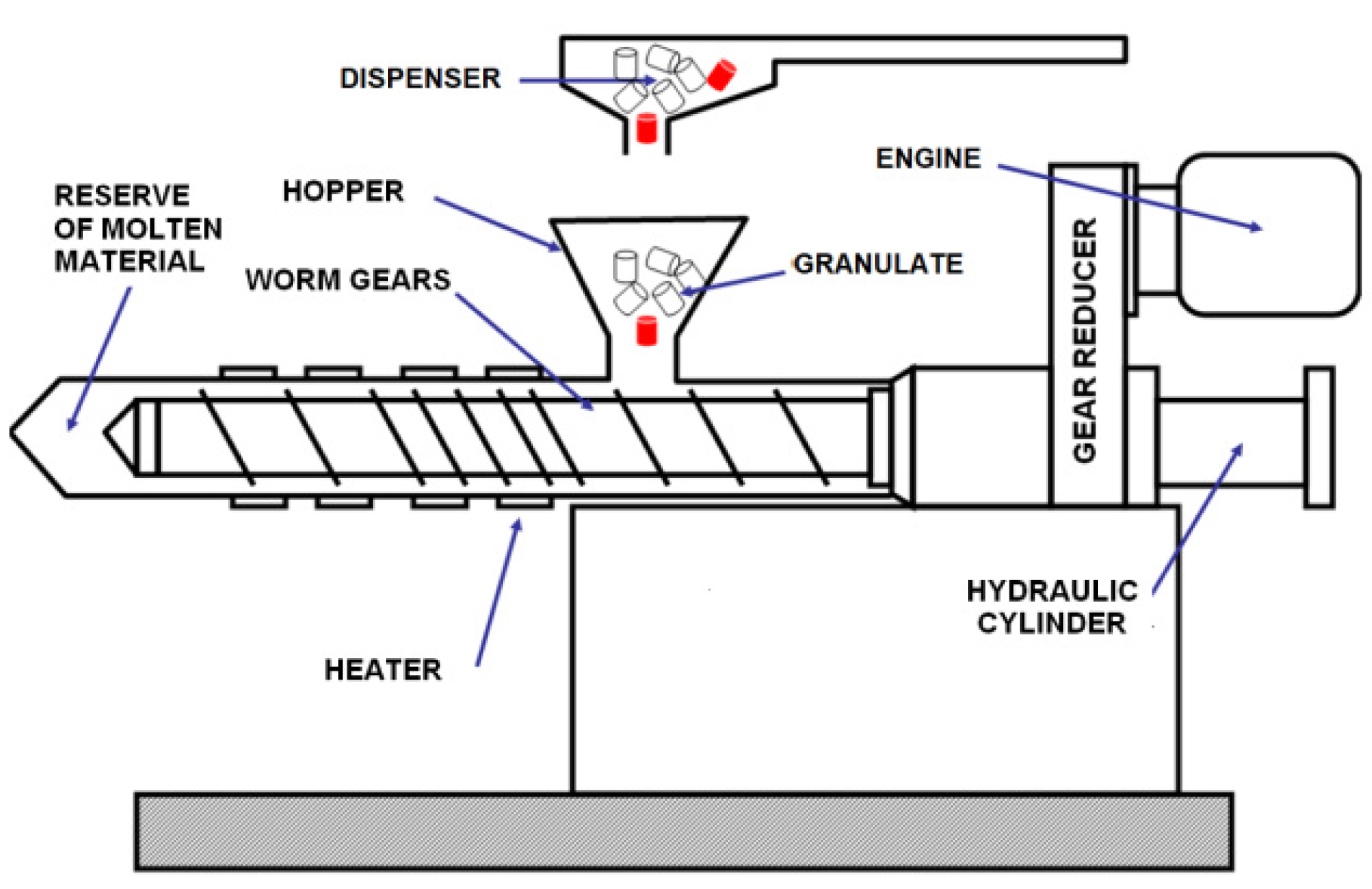

2.1. Bio-Plastic Compounds Fabrication

2.2. Performance Evaluation

- Manufacturing capability: this property was evaluated considering melting temperatures, filament surface roughness, density, and retraction behaviour, considered as longitudinal moulding shrinkage. In all the bio-composite materials, the melting temperature was evaluated by Differential scanning calorimetry (DSC), according to standard ISO 11357. The density was estimated at 23 °C, according to standard ISO 1183. The longitudinal moulding shrinkage was measured at 23 °C, according to standard ASTM D 995.

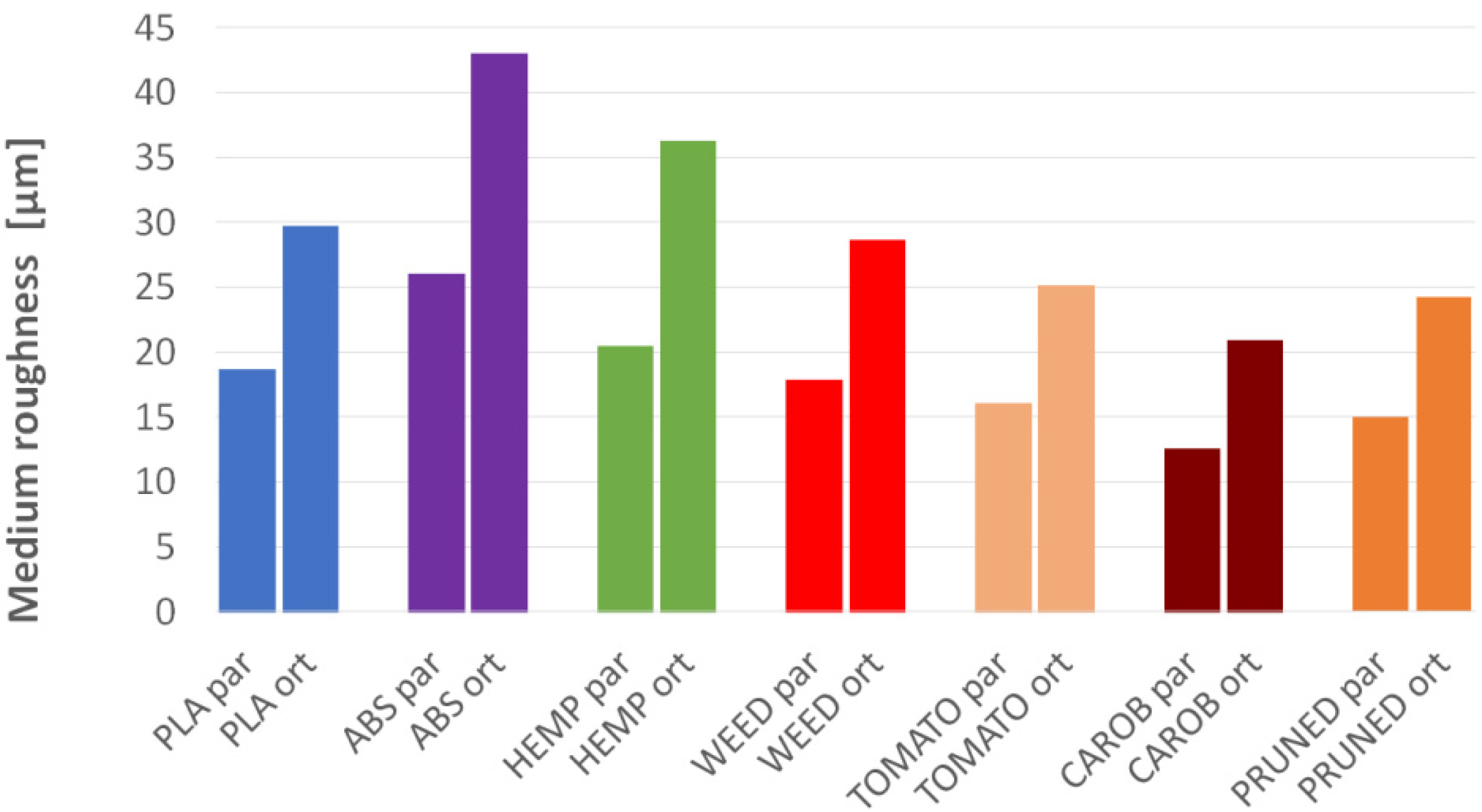

- Roughness: the average value of this characteristic was measured for an object printed with these new bio-composite materials and compared it with that of an object printed with pristine PLA and with Acrilonitrile-butadiene-stirene (ABS).

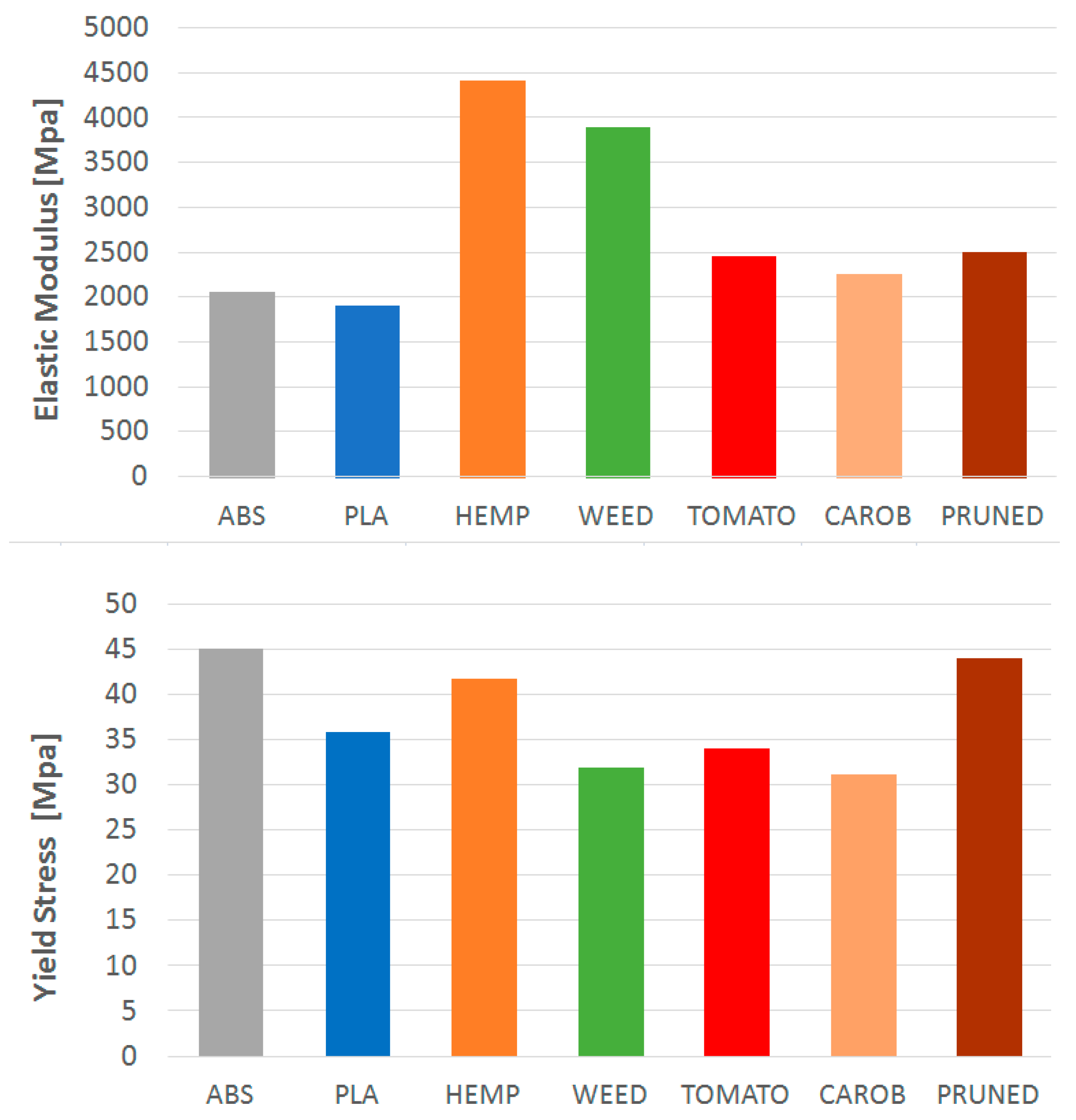

- Mechanical properties: the elastic modulus, the yield strength, the yield elongation, the ultimate stress, and the ultimate elongation were evaluated. The elastic modulus was evaluated at 23 °C by using a dynamic mechanical analyzer (DMA Q800, TA Instruments), according to standard ISO 527. The yield and elongation strength together with the ultimate stress and elongation were estimated by a static mechanical machine (Instron 5569), setting a displacement rate equal to 10 mm/min. All mechanical properties were tested at 23 °C, according to standard ISO 527.

3. Results and Discussion

3.1. Manufacturing Capability

3.2. Roughness

3.3. Mechanical Properties

- HEMP (Hempt fillers 20%): this material has excellent tensile strength, thanks to the high presence of silicon contained in the hemp shives. This is a result not obtainable even with hemp fiber or wood sawdust. The elastic modulus is more than double if compared to ABS (+115%) and PLA (+133%). Moreover, the yield strength remains almost constant in comparison with ABS, but it increases significantly when compared to PLA (+16%) (see Figure 5).

- WEED (Powder from hemp leaf fillers 20%): again, it results in a relevant increment of the elastic modulus. However, both yield stress and ultimate stress are smaller than ABS and PLA. In addition, this material undergoes a very high plastic deformation. This is due to cannabinoids, which give much plasticity to the material. The starting ABS or PLA have a percentage of elongation at break equal to about 3% [25]. Adding 20% of hemp leaf powder, this percentage reaches about 9%.

- TOMATO (Cherry tomatoes fillers 20%): the performances in terms of ultimate stress and ultimate elongation are very similar to pristine PLA and ABS. However, the TOMATO elastic modulus is about +20% higher than ABS and PLA. Moreover, ABS shows a higher yield stress (about +30%) compared to the TOMATO composite.

- CAROB (Carob flour fillers 20%): due to the high temperatures of the die, contained sugar becomes caramel, which gives the final material a noticeable elongation approaching the yield point. In fact, although most of its mechanical properties are similar to ABS and PLA, CAROB has a percentage of elongation at break which reaches more than a 20% value due to the addition of carob flour.

- PRUNED (Orange pruning fillers 20%): material has shown excellent resistance to plastic deformation and failure compared to PLA (+25% and +42%, respectively) while the elastic modulus is similar. In this case, its mechanical properties are very comparable to ABS with the exception of yield elongation that is closer to PLA values.

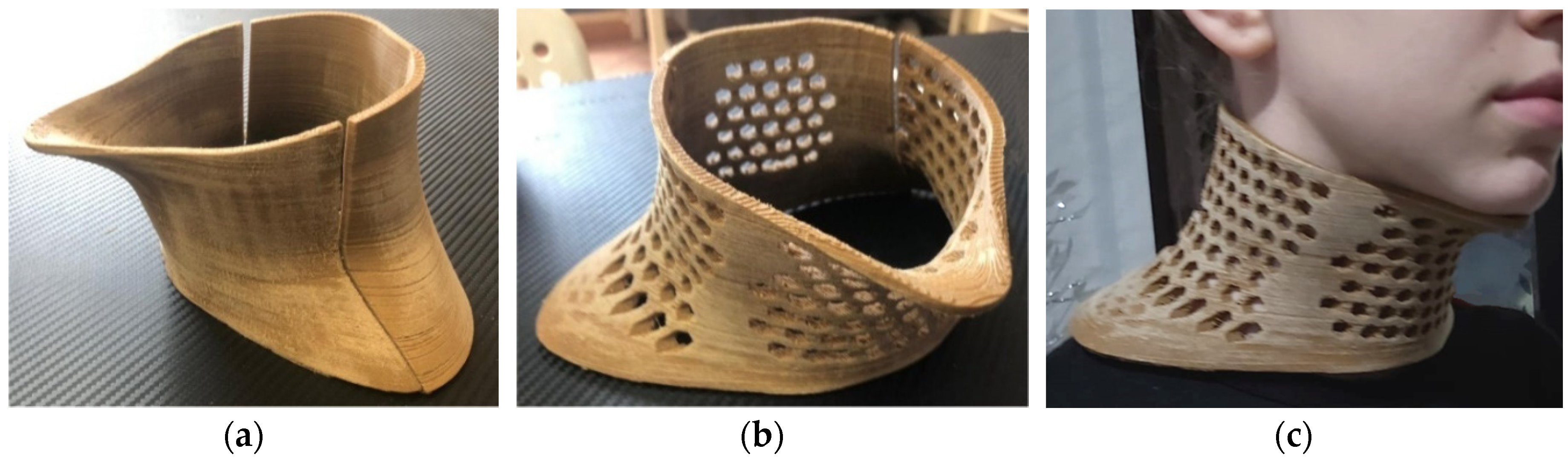

- HEMP: filler gives excellent surface touch properties, breathability, and wood effect (Figure 4c).

- WEED: this material has a characteristic natural green colour, which makes it very suitable for the production of domestic objects.

- TOMATO filler gives a vivid red colour.

- CAROB filler gives a characteristic reddish/brownish colour and a shiny appearance.

- PRUNED: this material has a characteristic brownish colour.

4. Applications to Biomedical Devices

4.1. Neck Orthosis

4.2. Laryngoscope

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Othmer, K. Encyclopedia of CHEMICAL Technology, Carbon and Graphite Fibers to Chlorocarbons and Chlorohydrocarbons-CSUB 1/SUB; John Wiley & Sons: Hoboken, NJ, USA, 1993. [Google Scholar]

- Kirchherr, J.; Piscicelli, L.; Bour, R.; Kostense-Smit, E.; Muller, J.; Huibrechtse-Truijens, A.; Hekkert, M. Barriers to the Circular Economy: Evidence From the European Union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef] [Green Version]

- European Commission. A European Strategy for Plastics in a Circular Economy; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- European Commission. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives; European Commission: Brussels, Belgium, 2008. [Google Scholar]

- Lavers, J.L.; Bond, A.L. Exceptional and rapid accumulation of anthropogenic debris on one of the world’s most remote and pristine islands. Proc. Natl. Acad. Sci. USA 2017, 114, 6052–6055. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gordon, S.; Burdfield-Steel, E. Avoiding Attack: The Evolutionary Ecology of Crypsis, Warning Signals and Mimicry. In Basic and Applied Ecology, 2nd ed.; Ruxton, G.D., Allen, W.L., Sherratt, T.N., Speed, M.P., Eds.; Oxford University Press: Oxford, UK, 2004; pp. 54–55. [Google Scholar]

- Teuten, E.L.; Saquing, J.M.; Knappe, D.R.U.; Barlaz, M.A.; Jonsson, S.; Björn, A.; Rowland, S.J.; Thompson, R.C.; Galloway, T.S.; Yamashita, R.; et al. Transport and release of chemicals from plastics to the environment and to wildlife. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2027–2045. [Google Scholar] [CrossRef] [PubMed]

- Hahladakis, J.N.; Velis, C.A.; Weber, R.; Iacovidou, E.; Purnell, P. An overview of chemical additives present in plastics: Migration, release, fate and environmental impact during their use, disposal and recycling. J. Hazard. Mater. 2018, 344, 179–199. [Google Scholar] [CrossRef] [PubMed]

- Stavropoulos, P.; Spetsieris, A.; Papacharalampopoulos, A. A Circular Economy based Decision Support System for the Assembly/Disassembly of Multi-Material Components. Procedia CIRP 2019, 85, 49–54. [Google Scholar] [CrossRef]

- Sauerwein, M.; Doubrovski, E.L.; Balkenende, R.; Bakker, C.; Doubrovski, Z. Exploring the potential of additive manufacturing for product design in a circular economy. J. Clean. Prod. 2019, 226, 1138–1149. [Google Scholar] [CrossRef]

- Bikas, H.; Stavropoulos, P.; Chryssolouris, G. Additive manufacturing methods and modelling approaches: A critical review. Int. J. Adv. Manuf. Technol. 2015, 83, 389–405. [Google Scholar] [CrossRef] [Green Version]

- Dong, Y.; Ghataura, A.; Takagi, H.; Haroosh, H.J.; Nakagaito, A.N.; Lau, K.-T. Polylactic acid (PLA) biocomposites reinforced with coir fibres: Evaluation of mechanical performance and multifunctional properties. Compos. Part A Appl. Sci. Manuf. 2014, 63, 76–84. [Google Scholar] [CrossRef] [Green Version]

- Bikas, H.; Lianos, A.K.; Stavropoulos, P. A design framework for additive manufacturing. Int. J. Adv. Manuf. Technol. 2019, 103, 3769–3783. [Google Scholar] [CrossRef] [Green Version]

- Speranza, D.; Citro, D.; Padula, F.; Motyl, B.; Marcolin, F.; Cali, M.; Martorelli, M. Additive Manufacturing Techniques for the Reconstruction of 3D Fetal Faces. Appl. Bionics Biomech. 2017, 2017, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Wong, K.; Kumta, S.M.; Sze, K.; Wong, C. Use of a patient-specific CAD/CAM surgical jig in extremity bone tumor resection and custom prosthetic reconstruction. Comput. Aided Surg. 2012, 17, 284–293. [Google Scholar] [CrossRef] [PubMed]

- Ambu, R.; Motta, A.; Calì, M. Design of a Customized Neck Orthosis for FDM Manufacturing with a New Sustainable Bio-composite. In Lecture Notes in Mechanical Engineering; Springer Science and Business Media LLC: Berlin, Germany, 2019; pp. 707–718. [Google Scholar]

- Oliveira, T.T.; Dos Reis, A.C. Fabrication of dental implants by the additive manufacturing method: A systematic review. J. Prosthet. Dent. 2019, 122, 270–274. [Google Scholar] [CrossRef] [PubMed]

- Ambu, R.; Morabito, A. Porous Scaffold Design Based on Minimal Surfaces: Development and Assessment of Variable Architectures. Symmetry 2018, 10, 361. [Google Scholar] [CrossRef] [Green Version]

- Alabort, E.; Barba, D.; Reed, R.C. Design of metallic bone by additive manufacturing. Scr. Mater. 2019, 164, 110–114. [Google Scholar] [CrossRef]

- Işmal, Ö.E.; Paul, R. Composite Textiles in High-Performance Apparel. In High-Performance Apparel; Elsevier BV: Amsterdam, The Netherlands, 2018; pp. 377–420. [Google Scholar]

- Kato, A.; Ikeda, Y.; Kohjiya, S. Carbon Black-Filled Natural Rubber Composites: Physical Chemistry and Reinforcing Mechanism. In Polymer Composites; Wiley: Hoboken, NJ, USA, 2012; pp. 515–543. [Google Scholar]

- Clyne, T.W.; Hull, D. An Introduction to Composite Materials; Cambridge University Press (CUP): Cambridge, UK, 2019. [Google Scholar]

- Gazzo, S.; Cuomo, M.; Boutin, C.; Contrafatto, L. Directional properties of fibre network materials evaluated by means of discrete homogenization. Eur. J. Mech.-A/Solids 2020, 82, 104009. [Google Scholar] [CrossRef]

- Superlab. Available online: http://www.superlab.it/laboratorio/caratterizzazioni-meccaniche/ (accessed on 17 August 2020).

- Bledzki, A.K.; Jaszkiewicz, A.; Scherzer, D. Mechanical properties of PLA composites with man-made cellulose and abaca fibres. Compos. Part A Appl. Sci. Manuf. 2009, 40, 404–412. [Google Scholar] [CrossRef]

- Corapi, D.; Morettini, G.; Pascoletti, G.; Zitelli, C. Characterization of a Polylactic acid (PLA) produced by Fused Deposition Modeling (FDM) technology. Procedia Struct. Integr. 2019, 24, 289–295. [Google Scholar] [CrossRef]

- Salim, M.A.; Termiti, Z.H.; Saad, A.M. Mechanical Properties on ABS/PLA Materials for Geospatial Imaging Printed Product using 3D Printer Technology. Ref. Modul. Mater. Sci. Mater. Eng. 2019. [Google Scholar] [CrossRef]

- Wu, W.; Geng, P.; Li, G.; Zhao, D.; Zhang, H.; Zhao, J. Influence of Layer Thickness and Raster Angle on the Mechanical Properties of 3D-Printed PEEK and a Comparative Mechanical Study between PEEK and ABS. Materials 2015, 8, 5834–5846. [Google Scholar] [CrossRef]

- Khan, B.A.; Warner, P.; Wang, H. Antibacterial Properties of Hemp and Other Natural Fibre Plants: A Review. BioResources 2014, 9, 3642–3659. [Google Scholar] [CrossRef] [Green Version]

- Lanzotti, V.; Grasso, M.; Staiano, G.; Martorelli, M. The impact of process parameters on mechanical properties of parts fabricated in PLA with an open-source 3-D printer. Rapid Prototyp. J. 2015, 21, 604–617. [Google Scholar] [CrossRef] [Green Version]

- Zanetti, E.M.; Aldieri, A.; Terzini, M.; Cali, M.; Franceschini, G.; Bignardi, C. Additively Manufactured Custom Load-Bearing Implantable Devices. Australas. Med. J. 2017, 10, 694. [Google Scholar] [CrossRef]

| Material | Relative Humidity | Shape | Particle Size (µm) |

|---|---|---|---|

| HEMP | 6% | Spherical-like | 130 |

| WEED | 4% | Spherical-like | 150 |

| TOMATO | 4% | Spherical | 100 |

| CAROB | 4% | Spherical | 130 |

| PRUNED | 4% | Spherical | 100 |

| Drying Granules | 10 h in a Vacuum Oven at 90 °C |

|---|---|

| Barrel temperature | 160–170 °C |

| Mold temperatures | 30 °C |

| Screw speed | 300 rpm |

| Injection speed | Slow |

| Material | Density (g/cm3) | Melting Temperature (°C) | Filament Surface Roughness (µm) | Molding Shrinkage (%) | Melt Volume Rate (cm3/10’) | Melt Flow Rate (g/10’) | Flexural Modulus (MPa) |

|---|---|---|---|---|---|---|---|

| PLA | 1.350 | 172.5 | 3.0 | 0.32 | 18.2 | 21.0 | 3200 |

| HEMP | 1.256 | 145.0 | 3.5 | 0.23 | 21.3 | 24.0 | 3833 |

| WEED | 1.265 | 150.5 | 3.2 | 0.28 | 76.0 | 86.9 | 3455 |

| TOMATO | 1.240 | 155.0 | 3.2 | 0.28 | 89.0 | 100.0 | 3220 |

| CAROB | 1.290 | 140.0 | 2.5 | 0.22 | 68.2 | 76.0 | 3560 |

| PRUNED | 1.220 | 150.0 | 2.8 | 0.27 | 110.0 | 124.0 | 3300 |

| Layer height (mm) | 0.25 |

| Infill ratio (%) | 50 |

| Nozzle diameter (mm) | 0.6 |

| Printing speed (mm/s) | 60 |

| Printing temperature (°C) | 200 |

| Material | Colour | Elastic Modulus (MPa) | Yield Stress (MPa) | Yield Elongation (%) | Ultimate Stress (MPa) | Ultimate Elongation (%) |

|---|---|---|---|---|---|---|

| ABS | 2060 | 45.1 | 1.0 | 38.0 | 3.0 | |

| PLA | 1900 | 35.9 | 2.0 | 26.4 | 3.8 | |

| HEMP | Wood | 4420 | 41.8 | 1.5 | 33.6 | 3.5 |

| WEED | Green | 3887 | 32.0 | 1.3 | 19.5 | 8.8 |

| TOMATO | Red | 2450 | 34.0 | 1.7 | 30.2 | 3.1 |

| CAROB | Reddish/Brownish | 2260 | 31.2 | 1.9 | 22.1 | 25 |

| PRUNED | Brownish | 2500 | 44.1 | 2.0 | 37.0 | 2.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Calì, M.; Pascoletti, G.; Gaeta, M.; Milazzo, G.; Ambu, R. A New Generation of Bio-Composite Thermoplastic Filaments for a More Sustainable Design of Parts Manufactured by FDM. Appl. Sci. 2020, 10, 5852. https://doi.org/10.3390/app10175852

Calì M, Pascoletti G, Gaeta M, Milazzo G, Ambu R. A New Generation of Bio-Composite Thermoplastic Filaments for a More Sustainable Design of Parts Manufactured by FDM. Applied Sciences. 2020; 10(17):5852. https://doi.org/10.3390/app10175852

Chicago/Turabian StyleCalì, Michele, Giulia Pascoletti, Massimiliano Gaeta, Giovanni Milazzo, and Rita Ambu. 2020. "A New Generation of Bio-Composite Thermoplastic Filaments for a More Sustainable Design of Parts Manufactured by FDM" Applied Sciences 10, no. 17: 5852. https://doi.org/10.3390/app10175852

APA StyleCalì, M., Pascoletti, G., Gaeta, M., Milazzo, G., & Ambu, R. (2020). A New Generation of Bio-Composite Thermoplastic Filaments for a More Sustainable Design of Parts Manufactured by FDM. Applied Sciences, 10(17), 5852. https://doi.org/10.3390/app10175852