Development of Driftwood Capture Trellis for Capturing Driftwood in Agricultural Drainage Ditches

Abstract

1. Introduction

2. Materials and Methods

2.1. Drainage Design Criteria

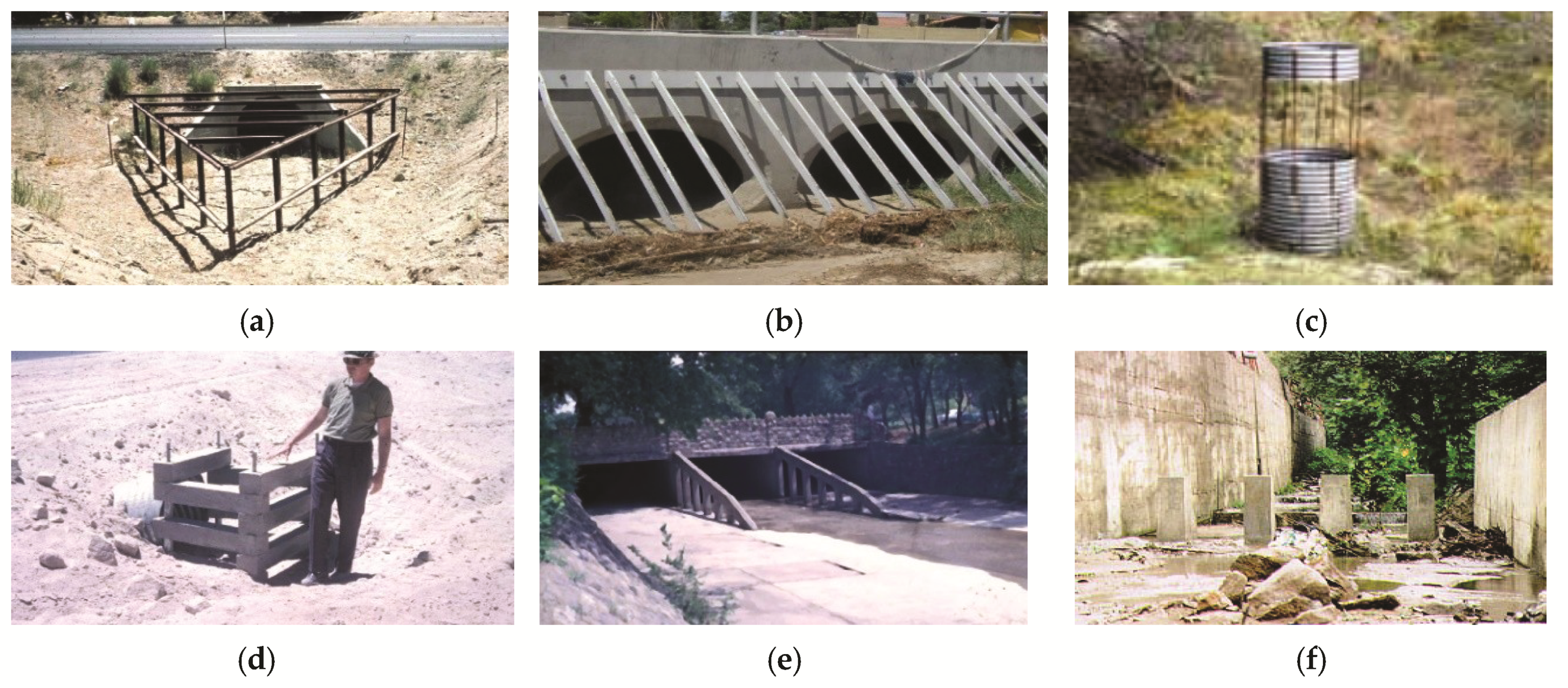

2.2. Definition of Driftwood in Agricultural Drainage Ditches

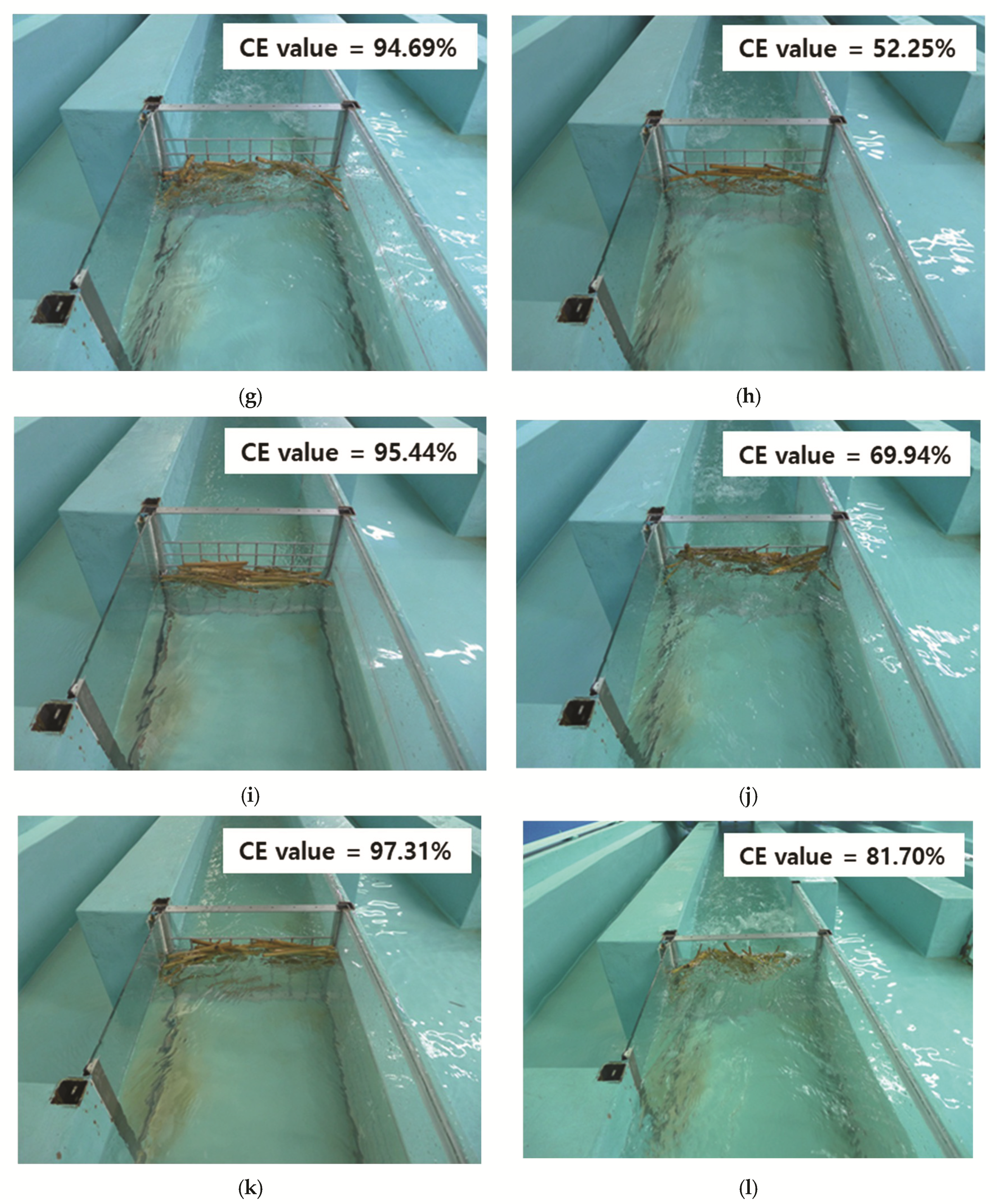

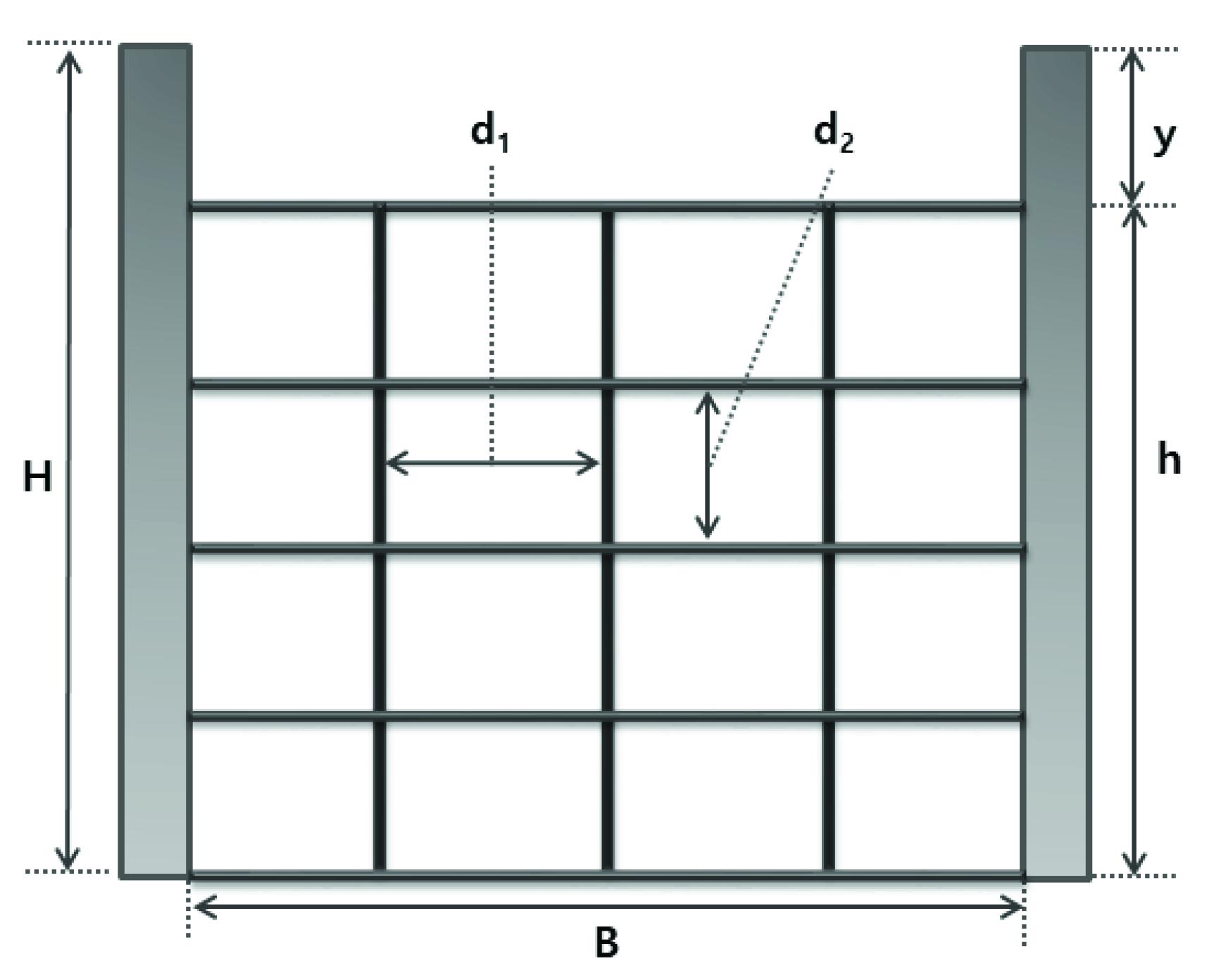

2.3. Development of Driftwood Capture Trellis for Agricultural Drainage Ditches

2.4. Manning Equation

2.5. Froude Number

3. Results

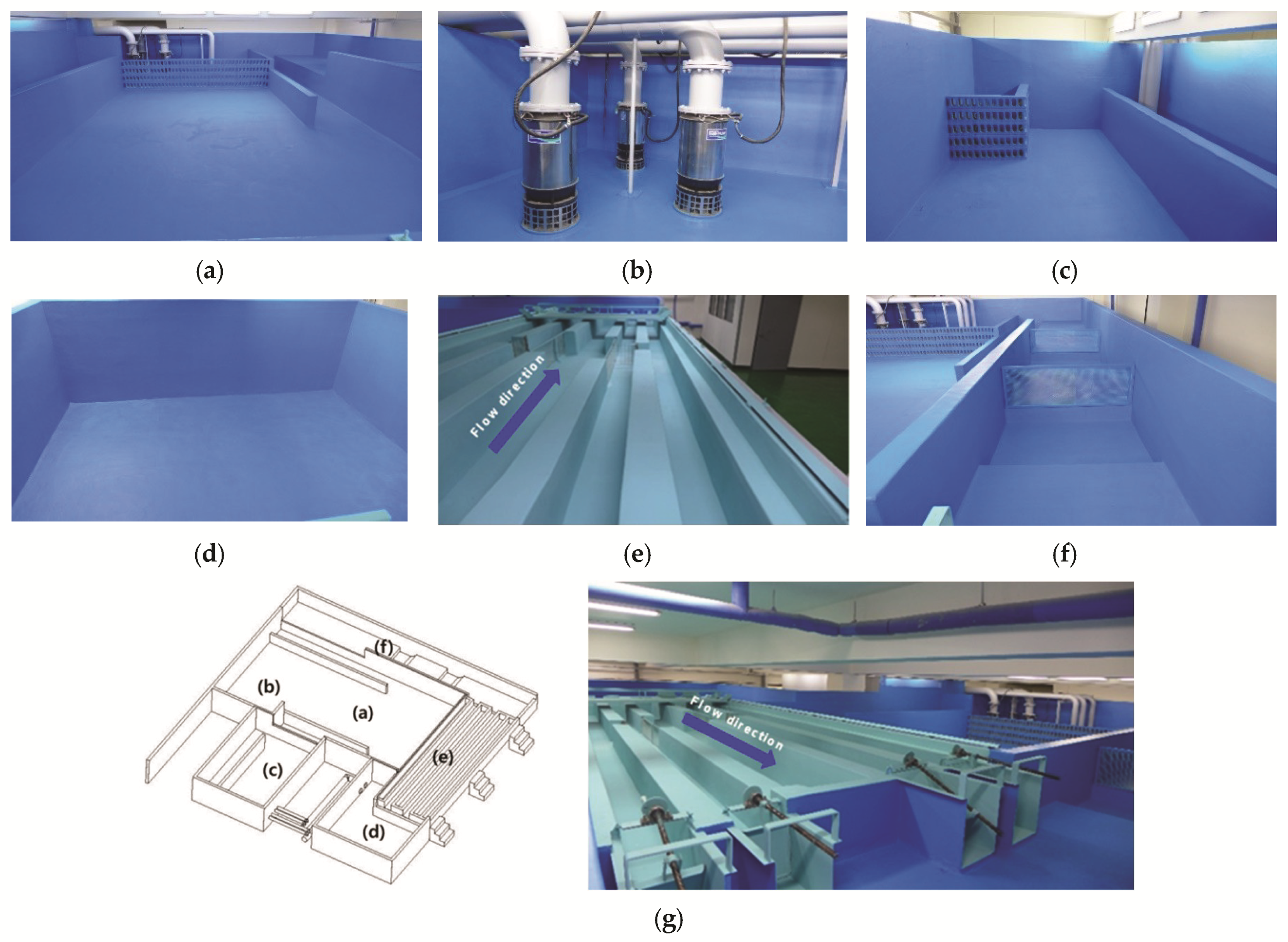

3.1. Characteristics of the Agricultural Drainage Ditches Hydraulic Lab

3.2. Experimental Conditions

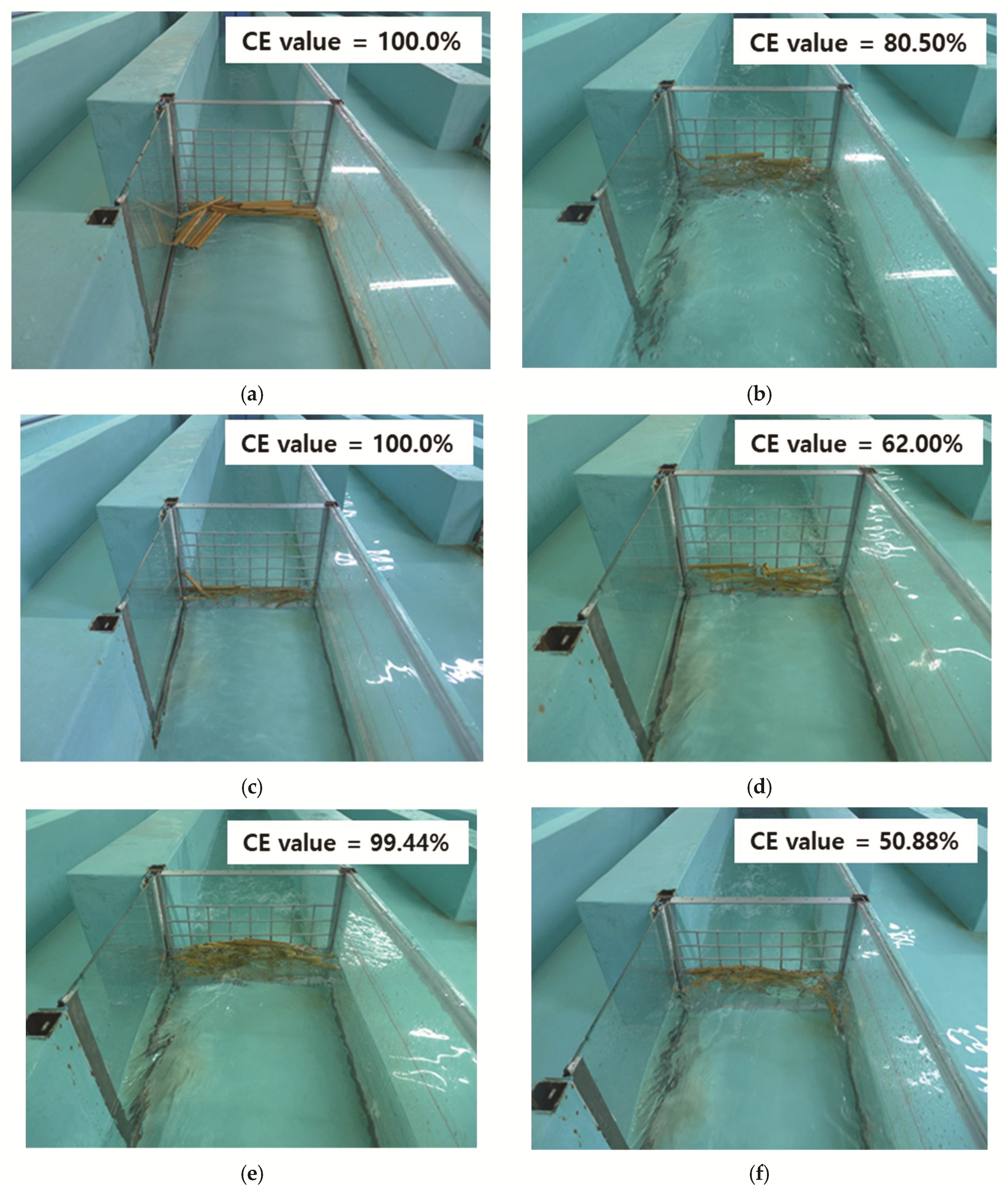

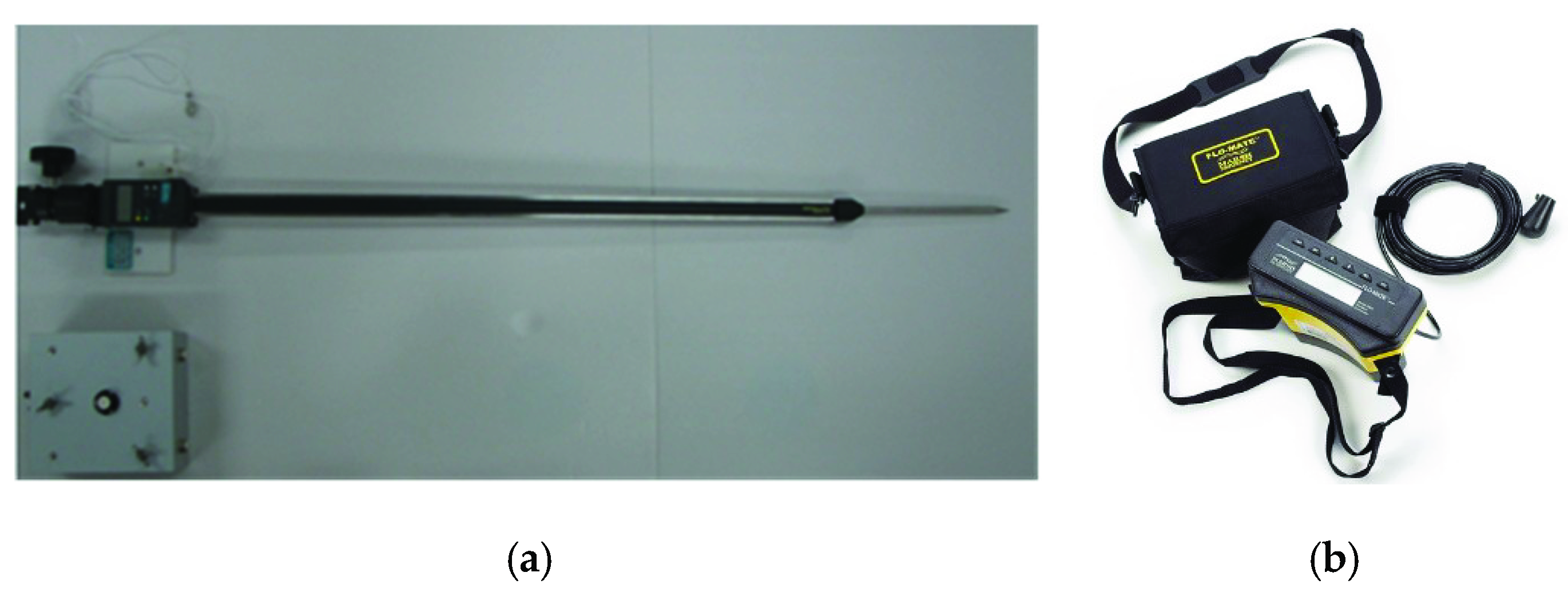

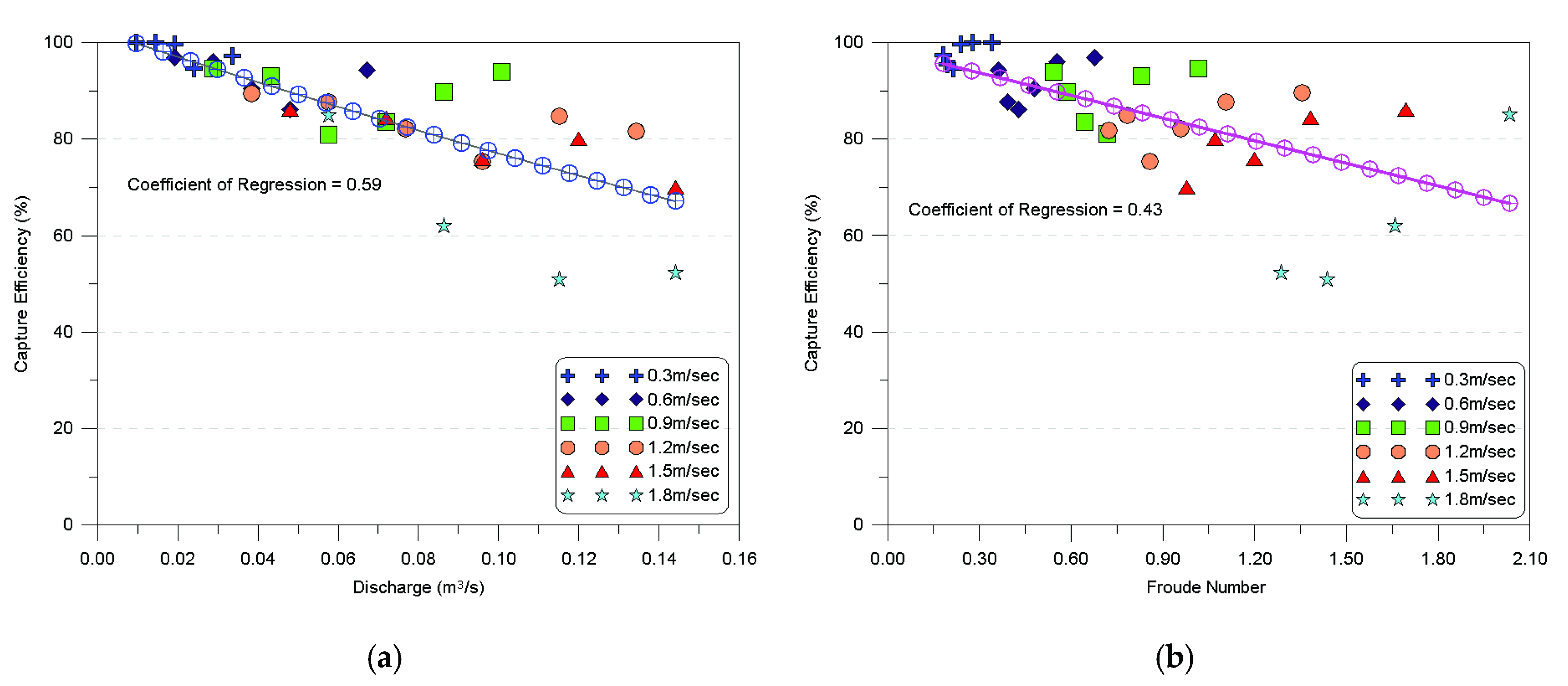

3.3. Driftwood Capture Efficiency of the Driftwood Capture Trellis

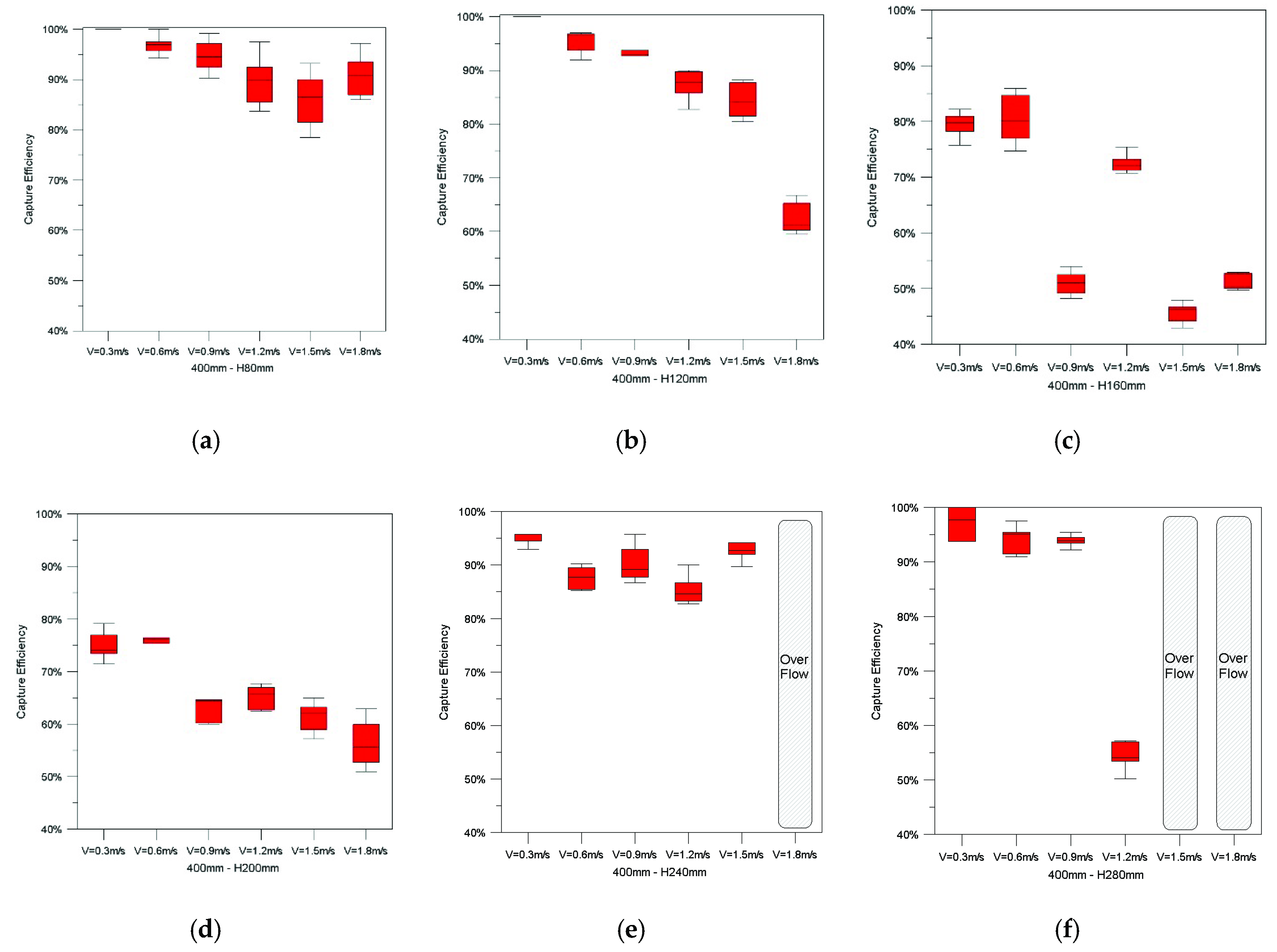

3.4. Hydraulic Performance Evaluation of the Driftwood Capture Trellis

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Chen, S.Y.; Xue, Z.C.; Li, M.; Zhu, X.P. Variable sets method for urban flood vulnerability assessment. Sci. China Technol. Sci. 2013, 56, 3129–3136. [Google Scholar] [CrossRef]

- Zhu, Z.; Chen, Z.; Chen, X.; He, P. Approach for evaluating inundation risks in urban drainage systems. Sci. Total Environ. 2016, 553, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Yin, J.; Yu, D.; Yin, Z.; Liu, M.; He, Q. Evaluating the impact and risk of pluvial flash flood on intra-urban road network: A case study in the city center of Shanghai, China. J. Hydrol. 2016, 537, 138–145. [Google Scholar] [CrossRef]

- Pachauri, R.K.; Allen, M.R.; Barros, V.R.; Broome, J.; Cramer, W.; Christ, R.; Church, J.A.; Clarke, L.; Dahe, Q.; Dasgupta, P.; et al. Climate Change 2014: Synthesis Report. Contribution of Working Groups I, II and III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Core Writing Team, Pachauri, R.K., Meyer, L.A., Eds.; IPCC: Geneva, Switzerland, 2014; p. 151. [Google Scholar]

- Du, J.K.; Qian, L.; Rui, H.Y.; Zuo, T.H.; Zheng, D.P.; Xu, Y.P.; Xu, C.Y. Assessing the effects of urbanization on annual runoff and flood events using an integrated hydrological modeling system for Qinhuai River basin. China. J. Hydrol. 2012, 464, 127–139. [Google Scholar] [CrossRef]

- Yin, J.; Yu, D.; Yin, Z.; Wang, J.; Xu, S. Modelling the anthropogenic impacts on fluvial flood risks in a coastal mega-city: A scenario-based case study in Shanghai, China. Landsc. Urban Plan. 2015, 136, 144–155. [Google Scholar] [CrossRef]

- Ministry of Land, Transport and Maritime Affairs. Urban Roadway Design Guideline, 1st ed.; Ministry of Land, Transport and Maritime Affairs: Goyangsi, Korea, 2012. [Google Scholar]

- Korea Expressway Corporation. Design Criteria for the Roads in Mountain Area, 1st ed.; Korea Expressway Corporation: Sejong-si, Korea, 2006. [Google Scholar]

- Ministry of Land, Infrastructure and Transport. Slope Drainage Design Guideline, 1st ed.; Ministry of Land, Infrastructure and Transport: Jinjusi, Korea, 2016. [Google Scholar]

- AASHTO. AASHTO Highway drainage guidelines. In Task Force on Hydrology and Hydraulics; American Association of State Highway and Transportation Officials: Washington, DC, USA, 1999. [Google Scholar]

- Park, M.S.; Jo, J.H.; Yun, D.K.; Han, K.H. A Study on the improvement of rural drainage system to cope with climate change. In Proceedings of the Korea Water Resources Association Conference, Daegu, Korea, 20 May 2011; Korea Water Resources Association: Daegu, Korea, 2011. [Google Scholar]

- Wong, T.S.W. Kinematic wave method for determination of road drainage inlet spacing. Adv. Water Resour. 1994, 17, 329–336. [Google Scholar] [CrossRef]

- Wong, T.S.W.; Moh, W.H. Effect of maximum flood width on road drainage inlet spacing. Water Sci. Technol. 1997, 36, 241–246. [Google Scholar] [CrossRef]

- Tu, M.-C.; Traver, R.G. Optimal Configuration of an Underdrain Delivery System for a Stormwater Infiltration Trench. J. Irrig. Drain. Eng. 2019, 145, 05019007. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, X.; Wang, L. An Analytical Solution of Partially Penetrating Hydraulic Fractures in a Box-Shaped Reservoir. Math. Probl. Eng. 2015, 2015, 726910. [Google Scholar] [CrossRef]

- Burgi, P.H.; Gober, D.E. Bicycle-Safe Grate Inlets Study: Hydraulic and Safety Characteristics of Three Selected Grate Inlets on Continuous Grades, 1st ed.; Federal Highway Administration, U.S. Department of Transportation: Washington, DC, USA, 1977. [Google Scholar]

- Pugh, C.A. Bicycle-Safe Grate Inlets Study: Hydraulic Characteristics of Slotted Drain Inlets, 4th ed.; Federal Highway Administration, U.S. Department of Transportation: Washington, DC, USA, 1980. [Google Scholar]

- Brown, S.A.; Stein, S.M.; Warner, J.C. Urban Drainage Design Manual: Hydraulic Engineering Circular No. 22, 1st ed.; Federal Highway Administration, U.S. Department of Transportation: Washington, DC, USA, 1996. [Google Scholar]

- Young-Il, K.; Jung-Cheol, B. Experimental investigation of effects of sediment concentration and bed slope on debris flow deposition in culvert. J. Korean Soc. Civ. Eng. 2011, 31, 467–474. [Google Scholar]

- Shin, H.J.; Won, C.H.; Choi, Y.H.; Kim, T.Y.; Choi, J.D. Study of installation of sediment trap drain channel to reduce soil erosion from storm water runoff. J. Korean Soc. Agric. Eng. 2010, 52, 95–100. [Google Scholar]

- Liu, J.; Nakatani, K.; Mizuyama, T. Effect assessment of debris flow mitigation works based on numerical simulation by using Kanako 2D. Landslides 2013, 10, 161–173. [Google Scholar] [CrossRef]

- Hye-Jin, K.; Gyeong-su, J. Varied flow analysis for linear drainage channels, Korea Water Resources Association. J. Korea Water Res. Assoc. 2008, 41, 773–784. [Google Scholar]

- Johnson, P.A.; Hey, R.D.; Horst, M.W.; Hess, A.J. Aggradation at Bridges. J. Hydraul. Eng. 2001, 127, 154–157. [Google Scholar] [CrossRef]

- Schmocker, L.; Hager, W.H. Probability of Drift Blockage at Bridge Decks. J. Hydraul. Eng. 2011, 137, 470–479. [Google Scholar] [CrossRef]

- Schmocker, L.; Hager, W.H. Scale Modeling of Wooden Debris Accumulation at a Debris Rack. J. Hydraul. Eng. 2013, 139, 827–836. [Google Scholar] [CrossRef]

- Chin, D.A. Hydraulic analysis and design of pipe culverts: USGS versus FHWA. J. Hydraul. Eng. 2013, 139, 886–893. [Google Scholar] [CrossRef]

- Dasika, B. New approach to design of culverts. J. Irrig. Drain. Eng. 1995, 121, 261–264. [Google Scholar] [CrossRef]

- Hager, W.H. Generalized culvert design diagram. J. Irrig. Drain. Eng. 1998, 124, 271–274. [Google Scholar] [CrossRef]

- Meselhe, E.A.; Hebert, K. Laboratory Measurements of Flow through Culverts. J. Hydraul. Eng. 2007, 133, 973–976. [Google Scholar] [CrossRef]

- Guven, A.; Hassan, M.; Sabir, S. Experimental investigation on discharge coefficient for a combined broad crested weir-box culvert structure. J. Hydrol. 2013, 500, 97–103. [Google Scholar] [CrossRef]

- Shrestha, B.B.; Nakagawa, H.; Kawaike, K.; Baba, Y.; Zhang, H. Driftwood deposition from debris flows at slit-check dams and fans. Nat. Haz. Earth Sys. Sci. 2012, 61, 577–602. [Google Scholar] [CrossRef]

- Lim, Y.H.; Chun, K.W.; Kim, M.S.; Yeom, J.J.; Lee, I.H. Capture effect of slit dam for debris flow and woody debris with hydraulic model experiment -Focusing on A and D type. In Proceedings of the 2008 Annual Summer Conference of the Korean Society of Forest Science, Jeonju-si, Korea, 21 August 2008; Korean Society of Forest Science: Jeonju-si, Korea, 2008. [Google Scholar]

- Geun-woo, J.; Young-hyeop, L.; Su-Yeon, N.; Su-Jin, J.; Yu-Seok, J.; Sang-yup, Y. Sediment and woody debris trap effect of h-type slit dam with model experiment. In Proceedings of the 2010 Annual Summer Conference of the Korean Society of Forest Science, Seoul, Korea, 14 September 2010; Korean Society of Forest Science: Seoul, Korea, 2010. [Google Scholar]

- Jin-hak, K.; Geun-woo, J.; Jung-il, S.; Joo-woong, Y.; Se-myung, K.; Yong-rae, K. Effects of float-board screen for catching drift woods and debris flows in urban areas. In Proceedings of the 2013 Conference of the Korean institute of Forest Recreation, Seoul, Korea, 11 April 2013; Korean Institute of Forest Recreation: Seoul, Korea, 2013. [Google Scholar]

- Douglas County. Storm Drainage Design and Technical Criteria Manual, 1st ed.; Douglas County: Englewood, CO, USA, 2008. [Google Scholar]

- Kim, S.J.; Kang, J.G.; Kim, J.T. An experimental study on debris reduction system for culvert. J. Korea Acad. Indust. Coop. Soc. 2017, 18, 696–706. [Google Scholar]

- Bradley, J.B.; Richards, D.L.; Bahner, C.D. Debris Control Structures: Evaluation and Countermeasures, 3rd ed.; U.S. Department of Transportation: Washington, DC, USA, 2005. [Google Scholar]

- Ministy of Agriculture, Forestry and Flsheries. Land Improvement Project Plan Design Standard Plan, 1st ed.; Ministy of Agriculture, Forestry and Flsheries: Tokyo, Japan, 2019. [Google Scholar]

- Ministry of Land, Infrastructure and Transport. Road Design Manual of Mountain Area, 1st ed.; Ministry of Land, Infrastructure and Transport: Sejong-si, Korea, 2007. [Google Scholar]

- Town of Castle Rock. Storm Drainage Design and Technical Criteria Manual, 1st ed.; Town of Castle Rock: Castle Rock, CO, USA, 2019. [Google Scholar]

- Department of Water Govement of Western Australia. Stormwater Management Manual for Western Australia, 1st ed.; Department of Water Govement of Western Australia: Perth, Australia, 2007. [Google Scholar]

- National Institute for Land and Infrastructure Management. Manual of Technical Standard for Designing Sabo Facilities against Debris Flow and Driftwood, 1st ed.; National Institute for Land and Infrastructure Management: Sabo, Japan, 2016. [Google Scholar]

- City of Toronto Technical Services Metro Hall. Design Criteria for Sewers and Watermains, 1st ed.; City of Toronto Technical Services Metro Hall: Toronto, ON, Canada, 2009. [Google Scholar]

| Debris Classification | Type |

|---|---|

| Light Floating Debris (LFD) | small twigs, wood chips, cloth |

| Medium Floating Debris (MFD) | twigs, big wood chips |

| Heavy Floating Debris (HFD) | log, timber |

| Floating Debris (FD1) | fluent substances, including clay, silt, sand, pebble, wood chips |

| Fine Detritus (FD2) | homogeneous silt, sand, and gravel without suspended solids deposited where flow is slow |

| Coarse Detritus (CD) | coarse gravel, rack fragments |

| Boulders (B) | boulder, large rock fragment in the event of a flood |

| Nation | Target Areas | Frequency |

|---|---|---|

| U.S. | All | 2 to 100 years |

| Canada | All | 2 to 100 years |

| Australia | All | 3 to 40 years |

| Japan | All | 20 to 50 years |

| Korea | Mountain Area | 20 to 50 years |

| Plain | 10 to 30 years | |

| Agricultural Land | 20 years |

| Diameter (mm) | Count | Ration (%) | Diameter (mm) | Count | Ration (%) |

|---|---|---|---|---|---|

| 1–2 | 16 | 4.6 | 12–13 | 6 | 1.7 |

| 2–3 | 46 | 13.1 | 13–14 | 5 | 1.4 |

| 3–4 | 65 | 18.5 | 14–15 | 6 | 1.7 |

| 4–5 | 59 | 16.8 | 15–16 | 2 | 0.6 |

| 5–6 | 44 | 12.6 | 16–17 | 1 | 0.3 |

| 6–7 | 34 | 9.7 | 17–18 | 3 | 0.9 |

| 7–8 | 16 | 4.6 | 18–19 | 2 | 0.6 |

| 8–9 | 16 | 4.6 | 19–20 | 1 | 0.3 |

| 9–10 | 9 | 2.6 | 20–25 | 4 | 1.1 |

| 10–11 | 7 | 2.0 | Sum | 350 | 100.0 |

| 11–12 | 8 | 2.3 |

| No. | Facilities | Dimension (Width × Depth × Height) | Capacity |

|---|---|---|---|

| (a) | Water Tank | 11,000 mm × 6850 mm × 700 mm | 52.8 m³ |

| (b) | Pump Facilities | 15 HP × 2ea, 10 HP × 1ea | 0.33 m³/s |

| (c) | Head Tank | 4000 mm × 6000 mm × 2000 mm | 48.0 m³ |

| (d) | Rectifying Tank | 5000 mm × 4000 mm × 700 mm | 14.0 m³ |

| (e) | Drainage | 4000 mm × 8750 mm × 400 mm | 1.4 m³ |

| (f) | Return Tank | 14,000 mm × 1500 mm × 200 mm | 4.2 m³ |

| Driftwood | Length (mm) | Diameter (mm) | Count | Effective Cross-Sectional Area (mm²) |

|---|---|---|---|---|

| 160 | 3 | 12 | 5760 |

| 5 | 12 | 9600 | ||

| 7 | 12 | 13,440 | ||

| 10 | 10 | 16,000 | ||

| 12 | 10 | 19,200 | ||

| Sum | 41 | 64,000 | ||

| Agricultural Drainage Ditches (Width(m)) | Driftwood Capture Trellis | Velocity (m/s) | Depth (m) | No. of Drops | No. of Driftwood Drops |

|---|---|---|---|---|---|

| 0.4 | 8 × 8 grid | 0.3 | 0.08 | 6 drops | 1 drop of driftwood = 41 pieces, ø3 mm ~ ø 12 mm in diameter |

| 0.6 | 0.12 | ||||

| 0.9 | 0.16 | ||||

| 1.2 | 0.2 | ||||

| 1.5 | 0.24 | ||||

| 1.8 | 0.28 | ||||

| Number of experiment runs | 216 | ||||

| Water Depth (mm) | Unit (%) | ||||||

|---|---|---|---|---|---|---|---|

| Velocity(m/s) | 80 | 120 | 160 | 200 | 240 | 280 | |

| 0.3 | 100.00 | 100.00 | 99.44 | 94.69 | 95.44 | 97.31 | |

| 0.6 | 96.81 | 95.94 | 90.44 | 86.13 | 87.63 | 94.31 | |

| 0.9 | 94.69 | 93.13 | 81.00 | 86.50 | 89.81 | 93.94 | |

| 1.2 | 89.50 | 87.75 | 82.19 | 75.31 | 84.81 | 81.70 | |

| 1.5 | 86.13 | 84.38 | 75.88 | 71.69 | 67.94 | overflow | |

| 1.8 | 80.50 | 62.00 | 50.88 | 52.25 | overflow | overflow | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Y.; Park, M. Development of Driftwood Capture Trellis for Capturing Driftwood in Agricultural Drainage Ditches. Appl. Sci. 2020, 10, 5805. https://doi.org/10.3390/app10175805

Song Y, Park M. Development of Driftwood Capture Trellis for Capturing Driftwood in Agricultural Drainage Ditches. Applied Sciences. 2020; 10(17):5805. https://doi.org/10.3390/app10175805

Chicago/Turabian StyleSong, Youngseok, and Moojong Park. 2020. "Development of Driftwood Capture Trellis for Capturing Driftwood in Agricultural Drainage Ditches" Applied Sciences 10, no. 17: 5805. https://doi.org/10.3390/app10175805

APA StyleSong, Y., & Park, M. (2020). Development of Driftwood Capture Trellis for Capturing Driftwood in Agricultural Drainage Ditches. Applied Sciences, 10(17), 5805. https://doi.org/10.3390/app10175805