Abrasion Behavior of Steel-Fiber-Reinforced Concrete in Hydraulic Structures

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Mixture Proportion

2.2. Casting

2.3. ASTM C1138 Test Method

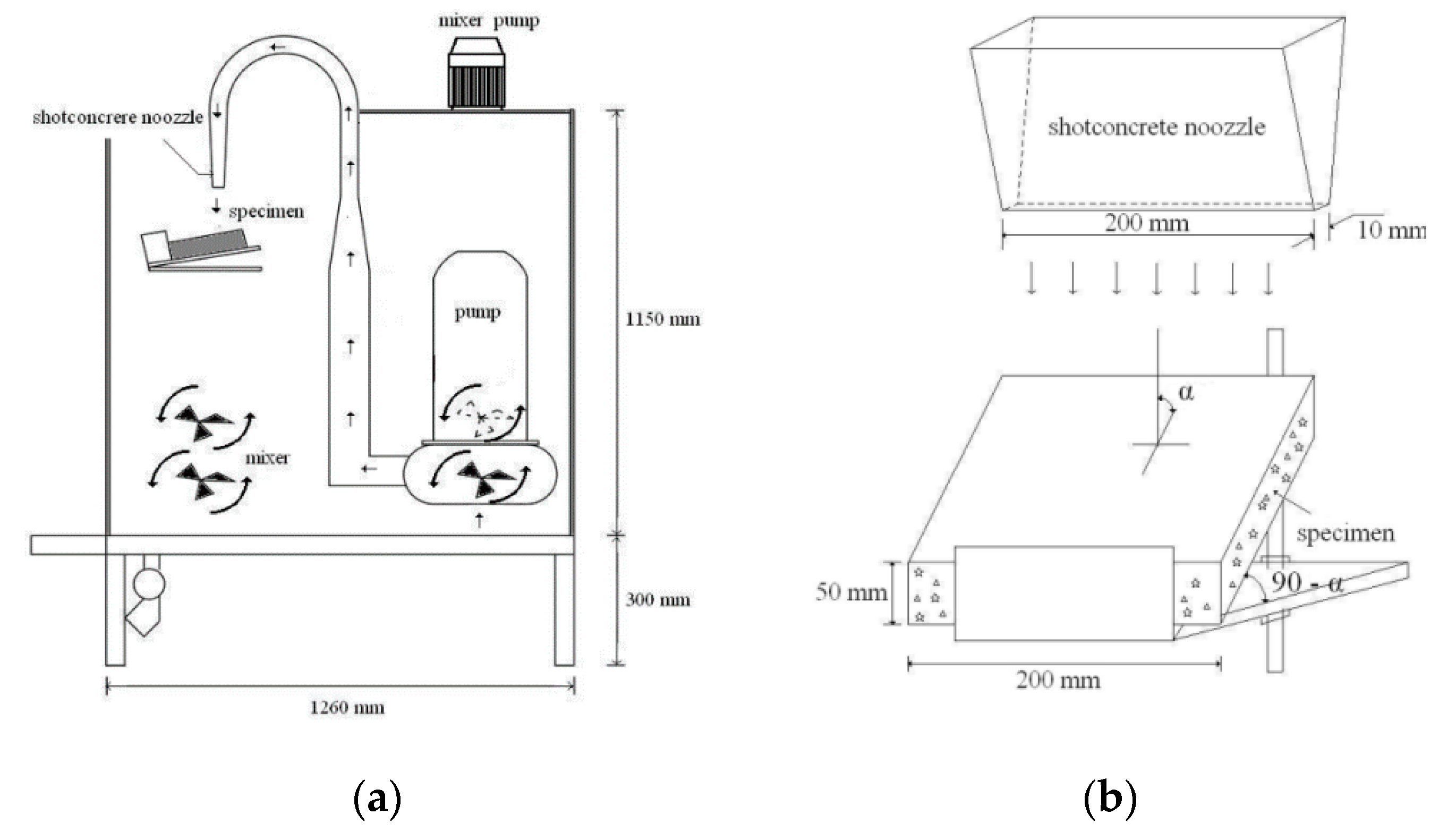

2.4. Waterborne Sand Test Method

3. Results and Discussion

3.1. Difference between Underwater Method and Abrasion Test on Waterborne Sand Impact

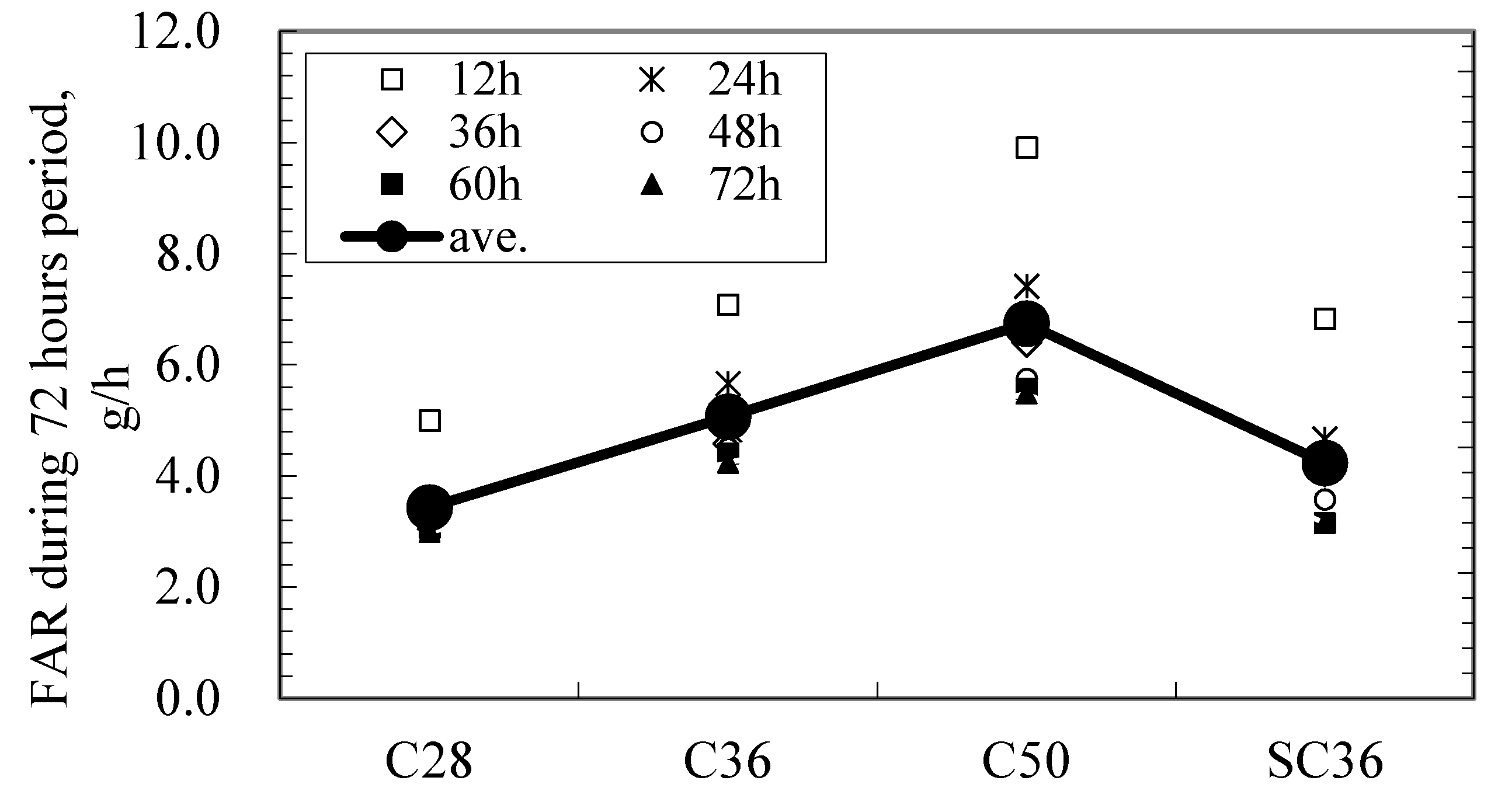

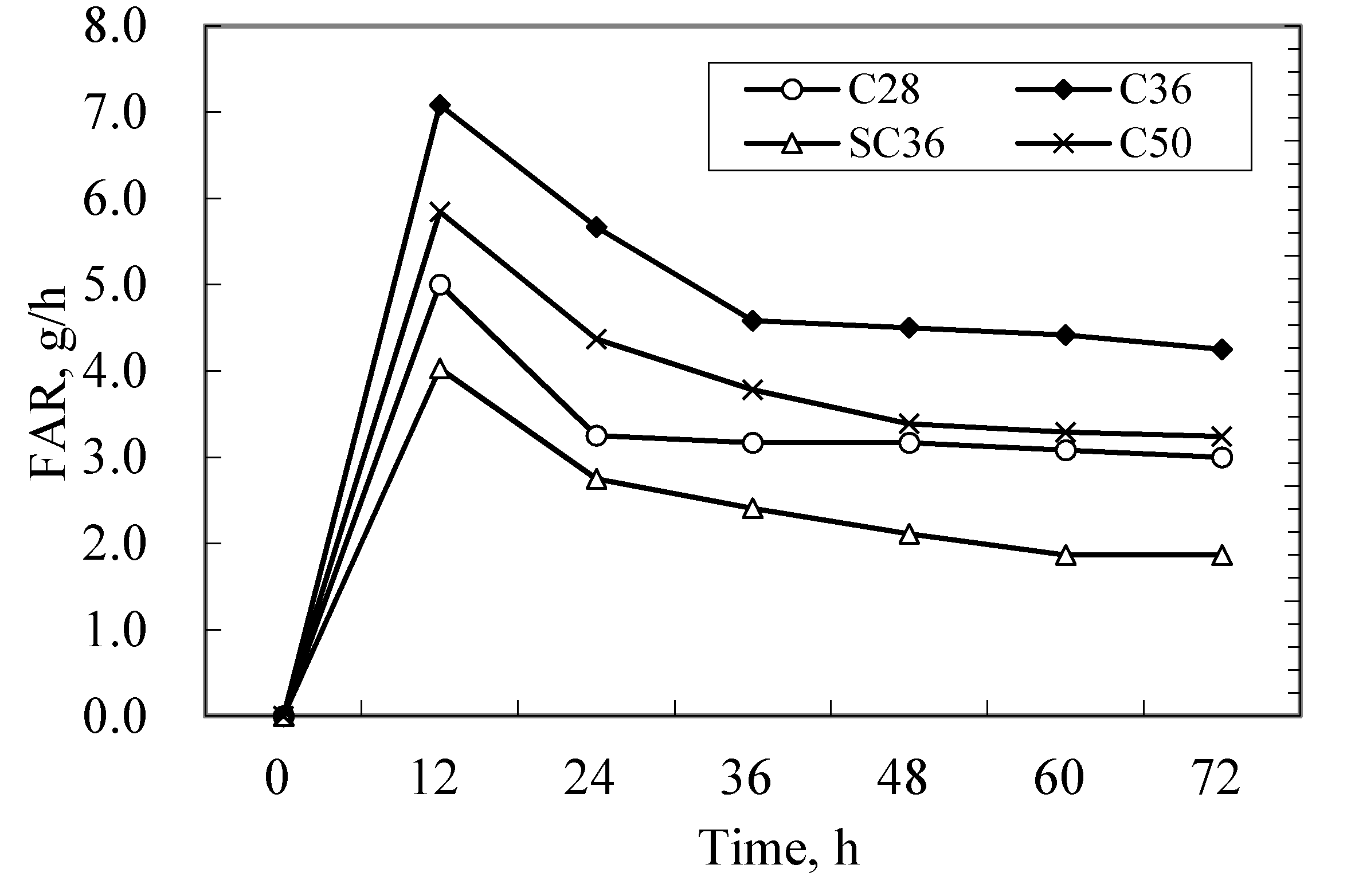

3.2. Abrasion Resistance of Concrete by Underwater Method

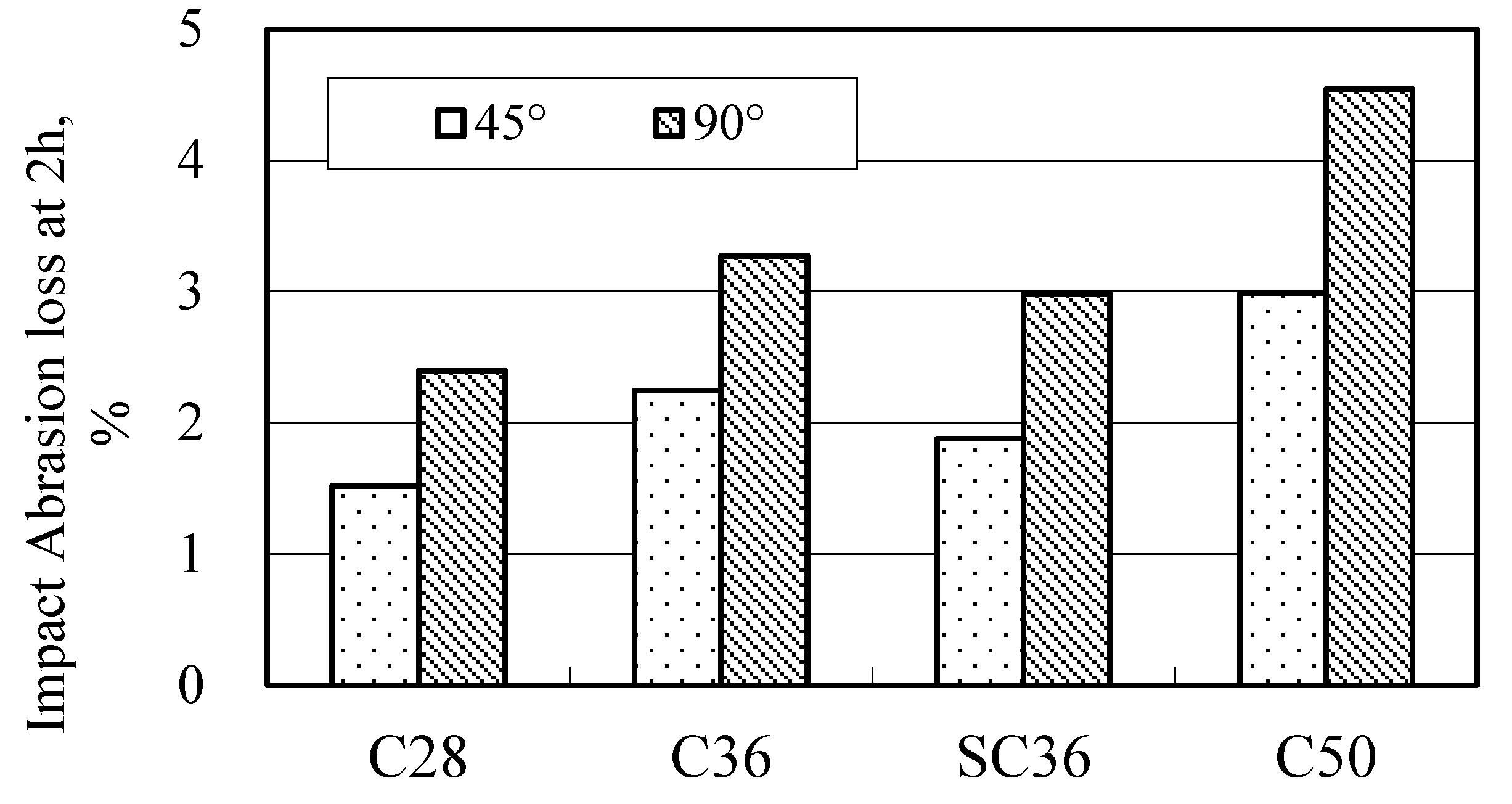

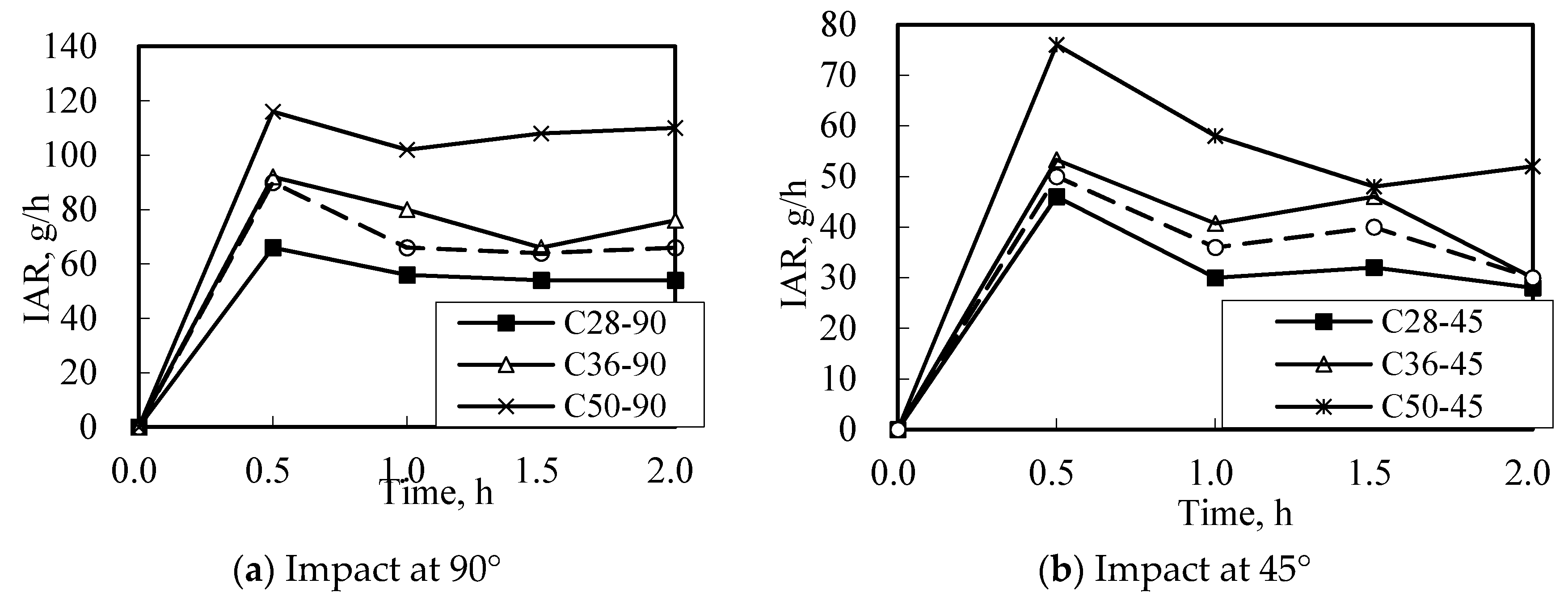

3.3. Impact Abrasion Resistance of Concrete by Waterborne Sand Flow

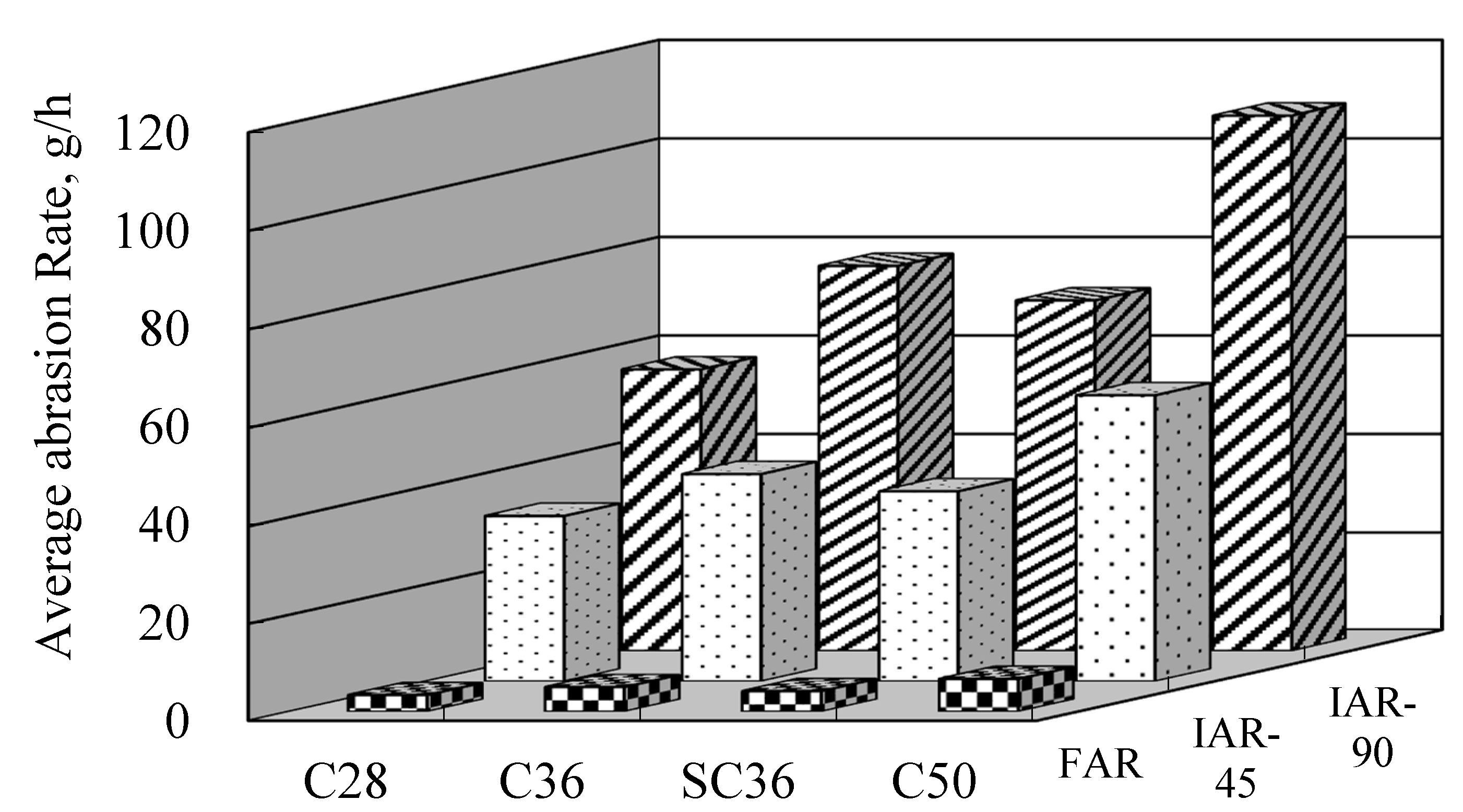

3.4. Comparing FAR with IAR

3.5. Correlations between Abrasion Rate and Compressive Strength

4. Conclusions

- Both the ASTM C1138 test and the waterborne sand flow impact test were successful in evaluating the relative performance in abrasion resistance of the concrete of hydraulic structures sited on a high-sand percentage river.

- For the ASTM C1138 underwater method, friction wear involved mainly abrasive action from the rolling water and steel balls. The principal resistances were shear strength and surface hardness.

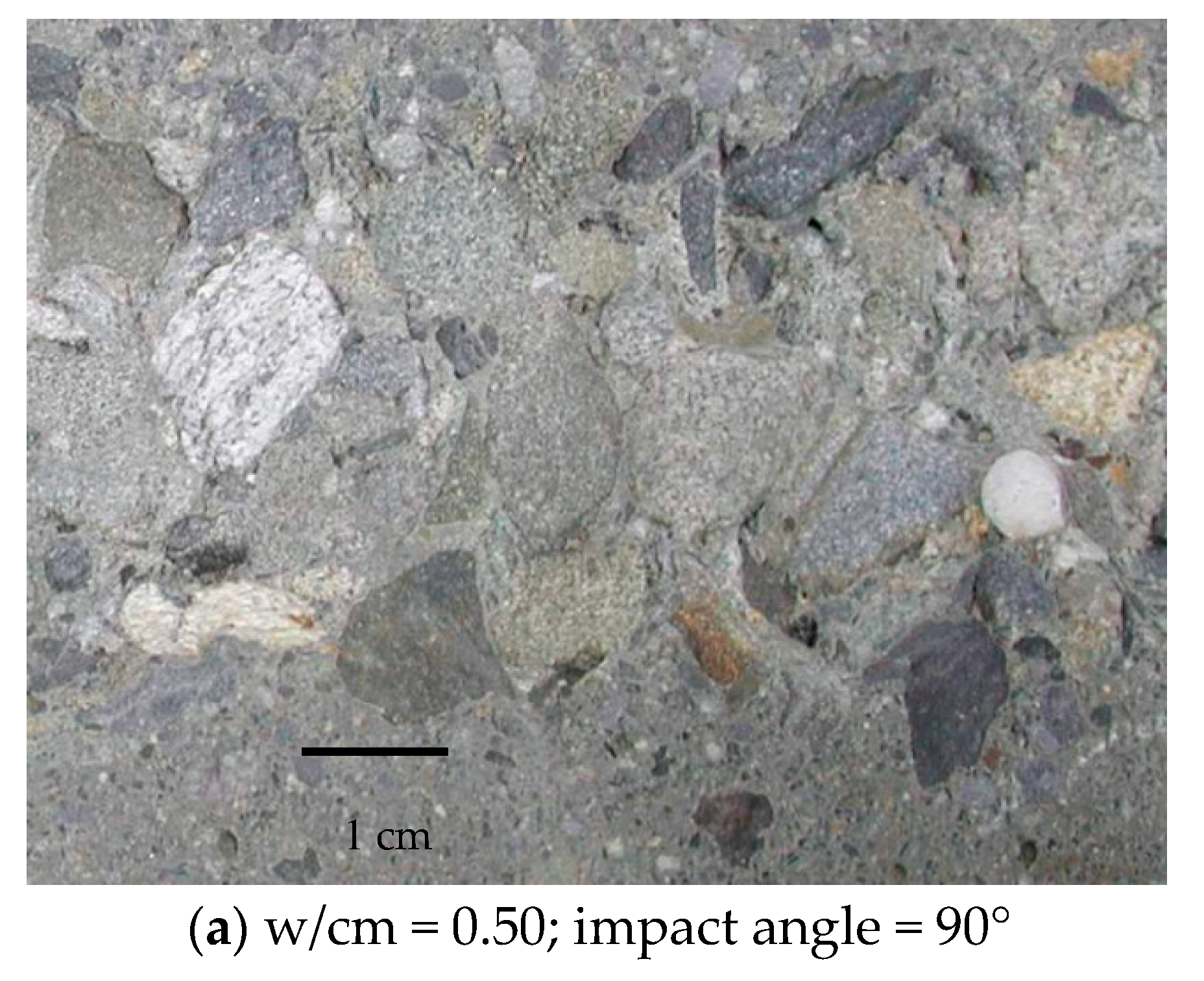

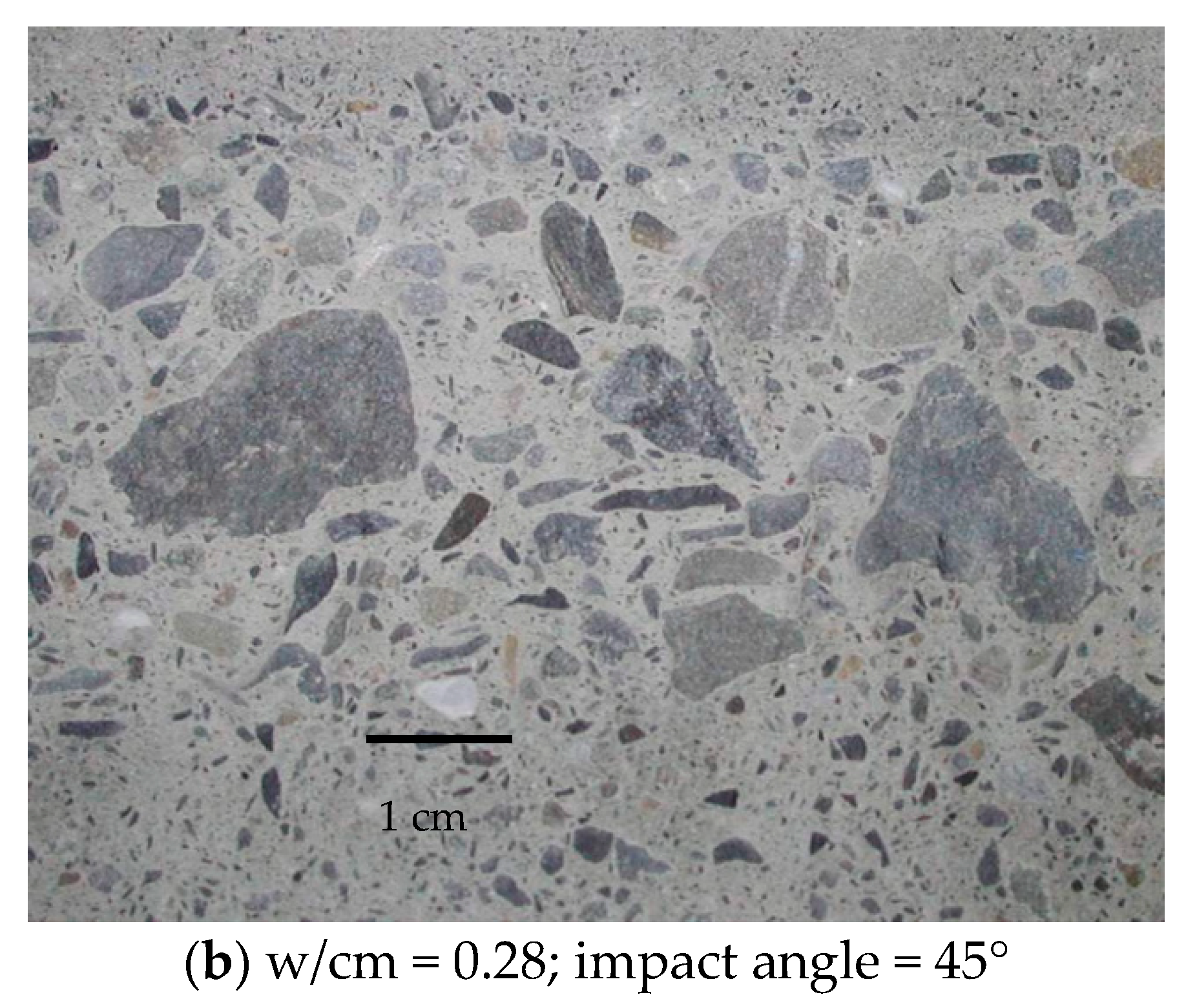

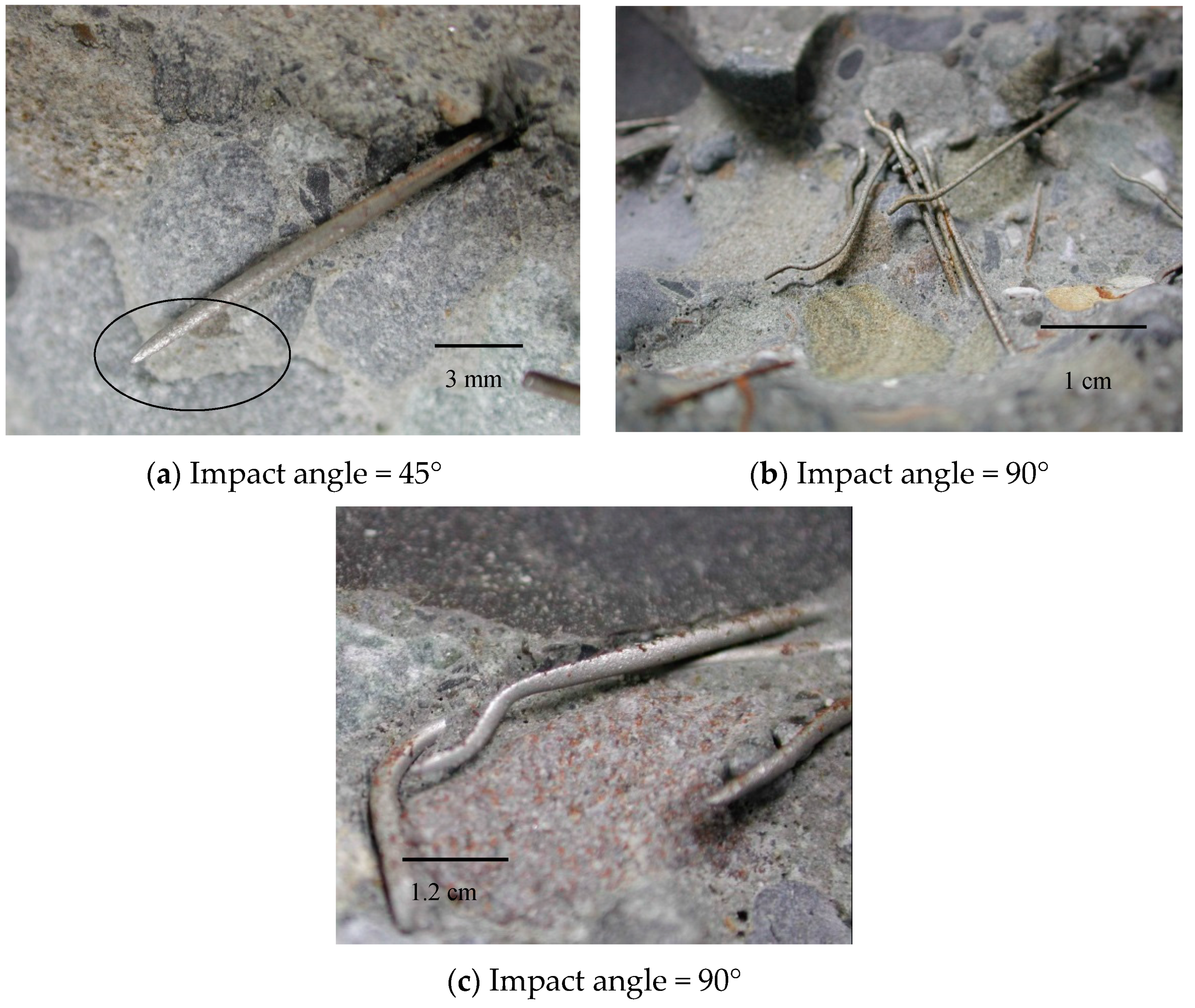

- For the concrete impacted by waterborne sand flow at 90°, the abrasive action mainly involved pre-abrasion peeling by water molecules and its associated hydraulic pressure, solid particle impact, edge effect, and prising. The principal resistances are tensile strength and the matrix/aggregate bond. For the concrete impacted at 45°, the aforementioned resistances applied, in addition to abrasion wear by waterborne sand flow and the principal resistances of shear strength and surface hardness.

- Concrete attacked by waterborne sand flow impact abrasion exhibited greater abrasion damage than that subjected to waterborne particle friction abrasion with the same abrasion time. The average IARs of the concrete were approximately 8–17 times the average FARs.

- In both the underwater and waterborne sand flow methods, the abrasion resistance of concrete without steel fibers increased as the w/cm ratio decreased, and the compressive strength of the concrete also increased. As the compressive strength decreased from 50 to 31 MPa, the average FAR, IAR-45°, and IAR-90° increased to 0.08, 0.80, and 1.53 per MPa, respectively, and they increased to only 0.04, 0.21, and 0.52 per MPa, respectively, as the compressive strength decreased from 91 to 50 MPa.

- Concrete containing steel fibers and silica fume exhibited improved abrasion resistance. For concrete subjected to friction abrasion and impacted at 45° and 90°, the improvements in friction and impact abrasion loss were nearly 17%, 8%, and 9%, respectively, relative to those of the reference mixture (C36).

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- ACI. Erosion of concrete in hydraulic structure. In ACI 201-03; American Concrete Institute: Farmington Hill, MI, USA, 2003. [Google Scholar]

- Chen, H.; Lin, G.W.; Shih, T.Y.; Horng, M.J.; Wu, S.J.; Chuang, B. Effects of topography, lithology, rainfall and earthquake on landslide and sediment discharge in mountain catchments of southeastern Taiwan. Geomorphology 2011, 3, 132–142. [Google Scholar] [CrossRef]

- Asieh, K.C.; Wu, S.J. The investigation of reservoirs sedimentation problems in Taiwan. In Proceedings of the 8th Conference on Water Power Engineering, Taipei, Taiwan, 8–9 July 1996; Chinese Institute of Civil and Hydraulic Engineering: Taipei City, Taiwan, 1996; pp. 537–544. [Google Scholar]

- Liu, Y.W. Abrasion-Erosion Resistance of High Performance Concrete Used as Overlay Material of Hydraulic Structures. Ph.D. Thesis, Department of Civil Engineering, University of Chung-Hsiung, Taichung, Taiwan, 2005. [Google Scholar]

- Holland, T.C.; Gutschow, R.A. Erosion resistance with silica-fume concrete. Concr. Int. 1987, 11, 32–40. [Google Scholar]

- Liu, Y.W.; Tsong, Y.; Hsu, T.H. Abrasion erosion of concrete by waterborne sand. Cem. Concr. Res. 2006, 36, 1814–1820. [Google Scholar] [CrossRef]

- Abid, S.R.; Shamkhi, M.S.; Mahdi, N.S.; Daek, Y.H. Hydro-abrasive resistance of engineered cementitious composites with PP and PVA fibers. Constr. Build. Mater. 2018, 187, 168–177. [Google Scholar] [CrossRef]

- Pyo, S.; Abate, S.Y.; Kim, H.K. Abrasion resistance of ultra high performance concrete incorporating coarser aggregate. Constr. Build. Mater. 2018, 165, 11–16. [Google Scholar] [CrossRef]

- Momber, A.W. Water jet Applications in Construction Engineering; AA Balkema: Rotterdam, The Netherlands, 1989. [Google Scholar]

- Cai, X.; He, Z.; Tang, S.; Chen, X. Abrasion erosion characteristics of concretemade with moderate heat Portland cement, fly ash and silica fume using sandblasting test. Construct. Build. Mater. 2016, 127, 804–814. [Google Scholar] [CrossRef]

- Huang, M.; Kang, Y.X.; Wang, Y.; Hu, D.; Li, C.C.; Chen, F. Effects of nozzle configuration on rock erosion under a supercritical carbon dioxide jet at various pressures and temperatures. Appl. Sci. 2017, 7, 606. [Google Scholar] [CrossRef]

- He, Z.; Chen, X.; Cai, X. Influence and mechanism of micro/nano-mineral admixtures on the abrasion resistance of concrete. Constr. Build. Mater. 2019, 197, 91–98. [Google Scholar] [CrossRef]

- Abid, S.R.; Hilo, A.; Ayoob, N.S.; Daek, Y.H. Underwater abrasion of steel fiberreinforced self-compacting concrete. Case Stud. Constr. Mater. 2019, 114, 1–17. [Google Scholar]

- ASTM. Standard test method for abrasion resistance of concrete (underwater method). In ASTM C1138-97; The American Society for Testing and Materials: Philadelphia, PA, USA, 1997. [Google Scholar]

- Lay, J. Analysis of Hardened Concrete and Mortar, Advanced Concrete Technology; Newman, J., Choo, B.S., Eds.; Butterworth-Heinemann: Oxford, UK, 2003; Volume 2, 4/12. [Google Scholar]

- Liu, T.C. Abrasion resistance of concrete. J. Am. Concr. Inst. 1981, 78, 341–350. [Google Scholar]

| Materials | SiO2 | Al2O3 | CaO | Fe2O3 | Na2O | K2O | SO3 | MgO |

|---|---|---|---|---|---|---|---|---|

| Cement | 20.9 | 5.6 | 63.9 | 3.1 | -- | -- | 2.5 | 2.9 |

| GGBFS | 33.7 | 13.7 | 42.1 | 1.2 | 0.29 | 0.3 | 1.87 | 6.53 |

| Silica fume | 93.2 | 0.1 | 0.9 | 0.04 | 0.6 | 2.0 | 0.005 | 0.5 |

| Fiber Shape | Coating | Diameter, mm | Length, mm | Tensile Strength, MPa | Specific Gravity |

|---|---|---|---|---|---|

| End-hooks | Brass | 0.75 mm | 30 | 1050 | 7.8 |

| Batch | w/cm | Quantities, kg/m3 | Slump, cm | Compressive Strength, MPa | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Water | Cement | GGBFS | SF | Steel Fiber | Sand | Gravel | SP | ||||

| C28 | 0.28 | 160 | 457 | 114 | 0 | 0 | 730 | 925 | 12.5 | 24 | 90.8 |

| C36 | 0.36 | 160 | 356 | 89 | 0 | 0 | 780 | 985 | 10.9 | 22 | 50.3 |

| C50 | 0.50 | 160 | 288 | 32 | 0 | 0 | 840 | 1055 | 0.5 | 21 | 30.4 |

| SC36 | 0.36 | 160 | 285 | 71 | 89 | 78 | 755 | 945 | 15 | 18 | 51.0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.-W.; Lin, Y.-Y.; Cho, S.-W. Abrasion Behavior of Steel-Fiber-Reinforced Concrete in Hydraulic Structures. Appl. Sci. 2020, 10, 5562. https://doi.org/10.3390/app10165562

Liu Y-W, Lin Y-Y, Cho S-W. Abrasion Behavior of Steel-Fiber-Reinforced Concrete in Hydraulic Structures. Applied Sciences. 2020; 10(16):5562. https://doi.org/10.3390/app10165562

Chicago/Turabian StyleLiu, Yu-Wen, Yu-Yuan Lin, and Shih-Wei Cho. 2020. "Abrasion Behavior of Steel-Fiber-Reinforced Concrete in Hydraulic Structures" Applied Sciences 10, no. 16: 5562. https://doi.org/10.3390/app10165562

APA StyleLiu, Y.-W., Lin, Y.-Y., & Cho, S.-W. (2020). Abrasion Behavior of Steel-Fiber-Reinforced Concrete in Hydraulic Structures. Applied Sciences, 10(16), 5562. https://doi.org/10.3390/app10165562