Using Waste in Producing Bio-Composite Mycelium Bricks

Abstract

1. Introduction

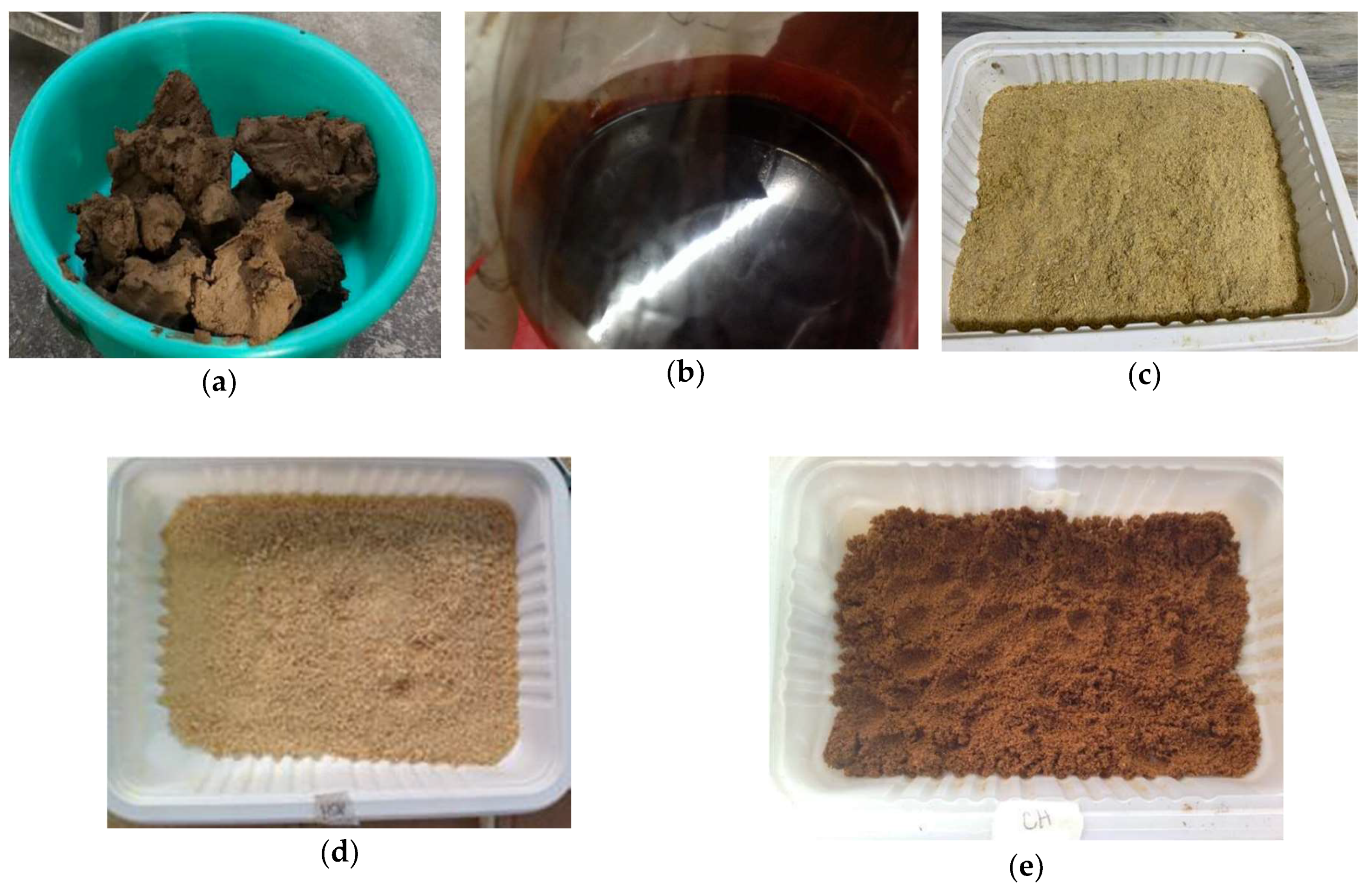

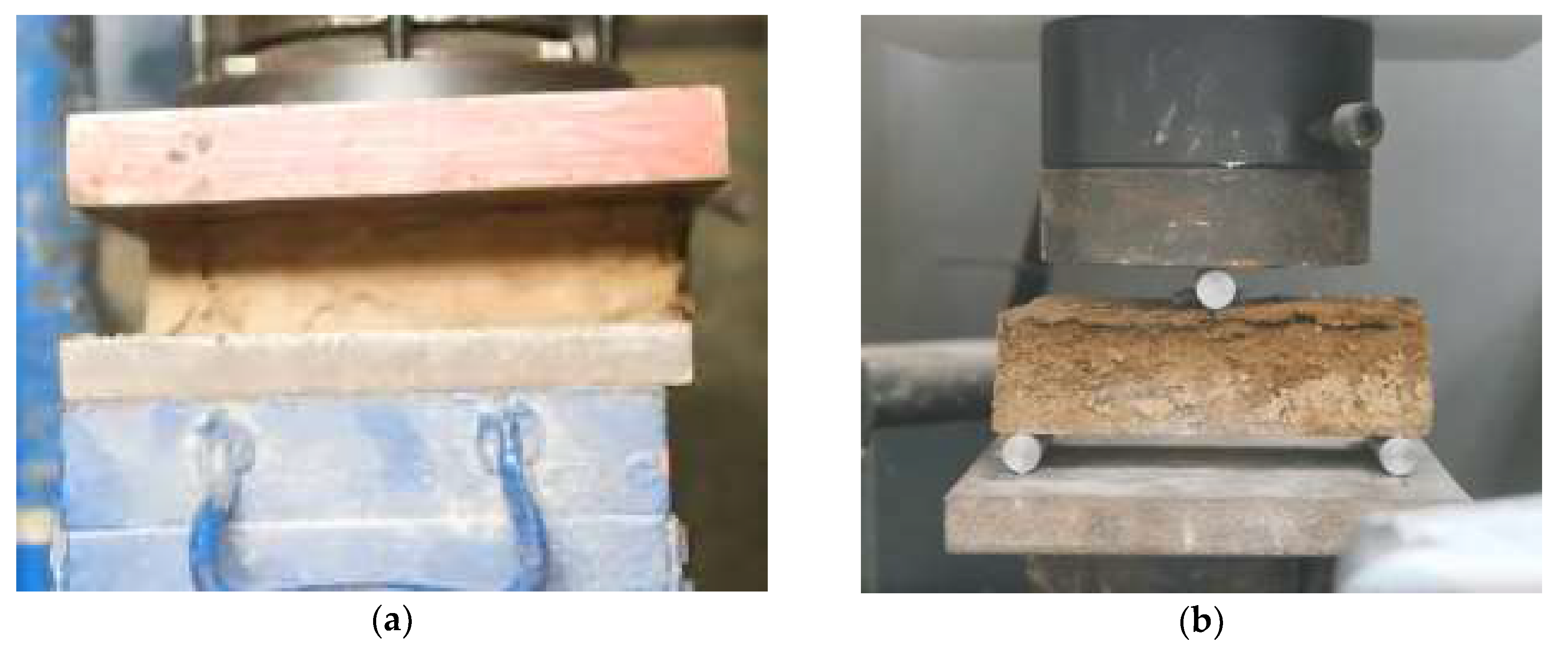

2. Materials and Method

3. Results and Discussion

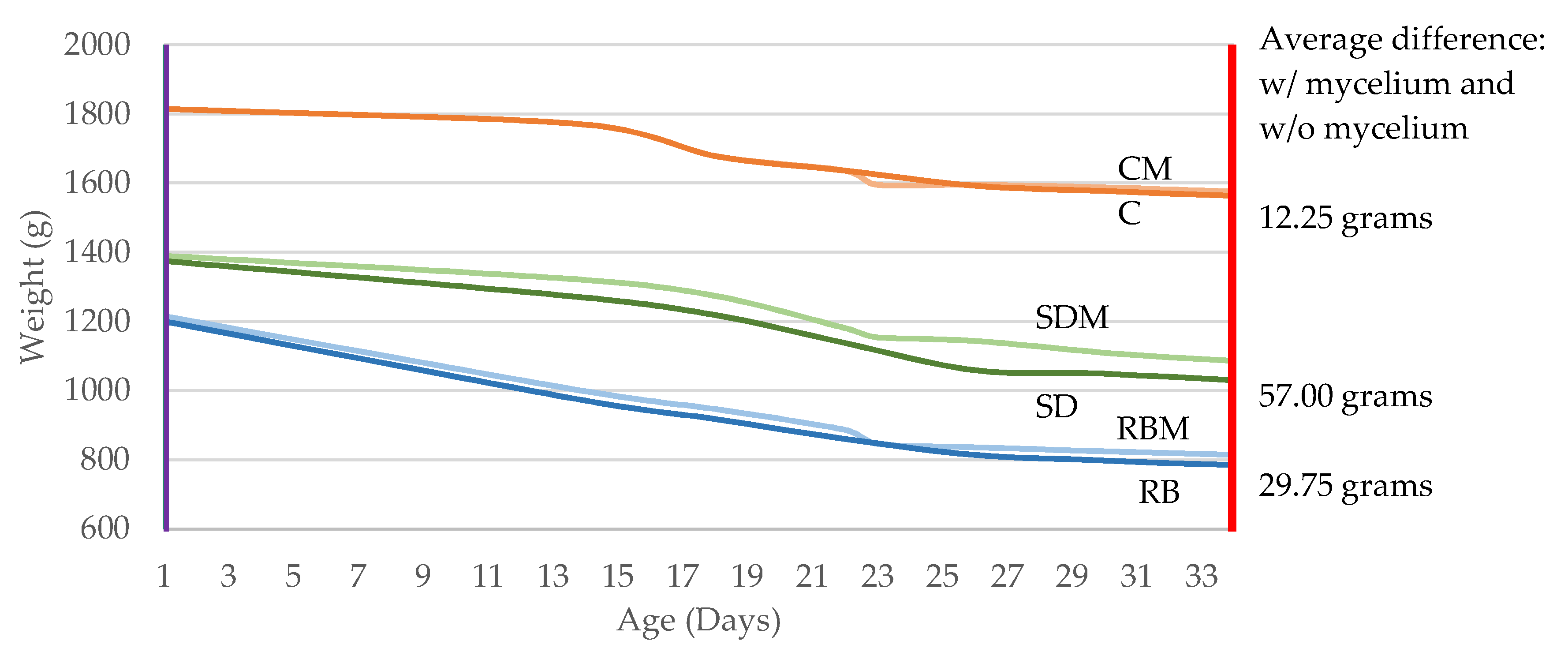

3.1. Weight against Age

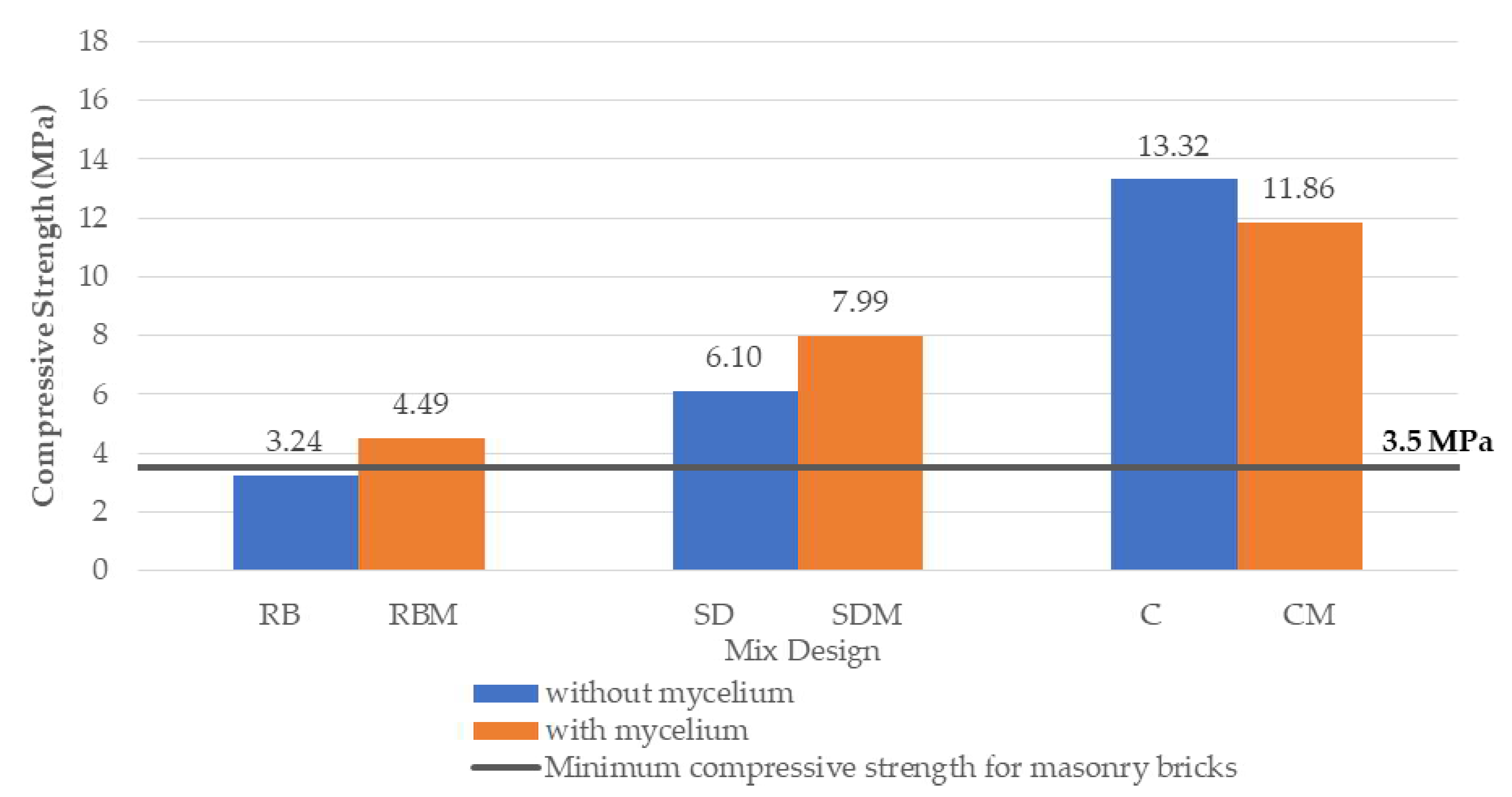

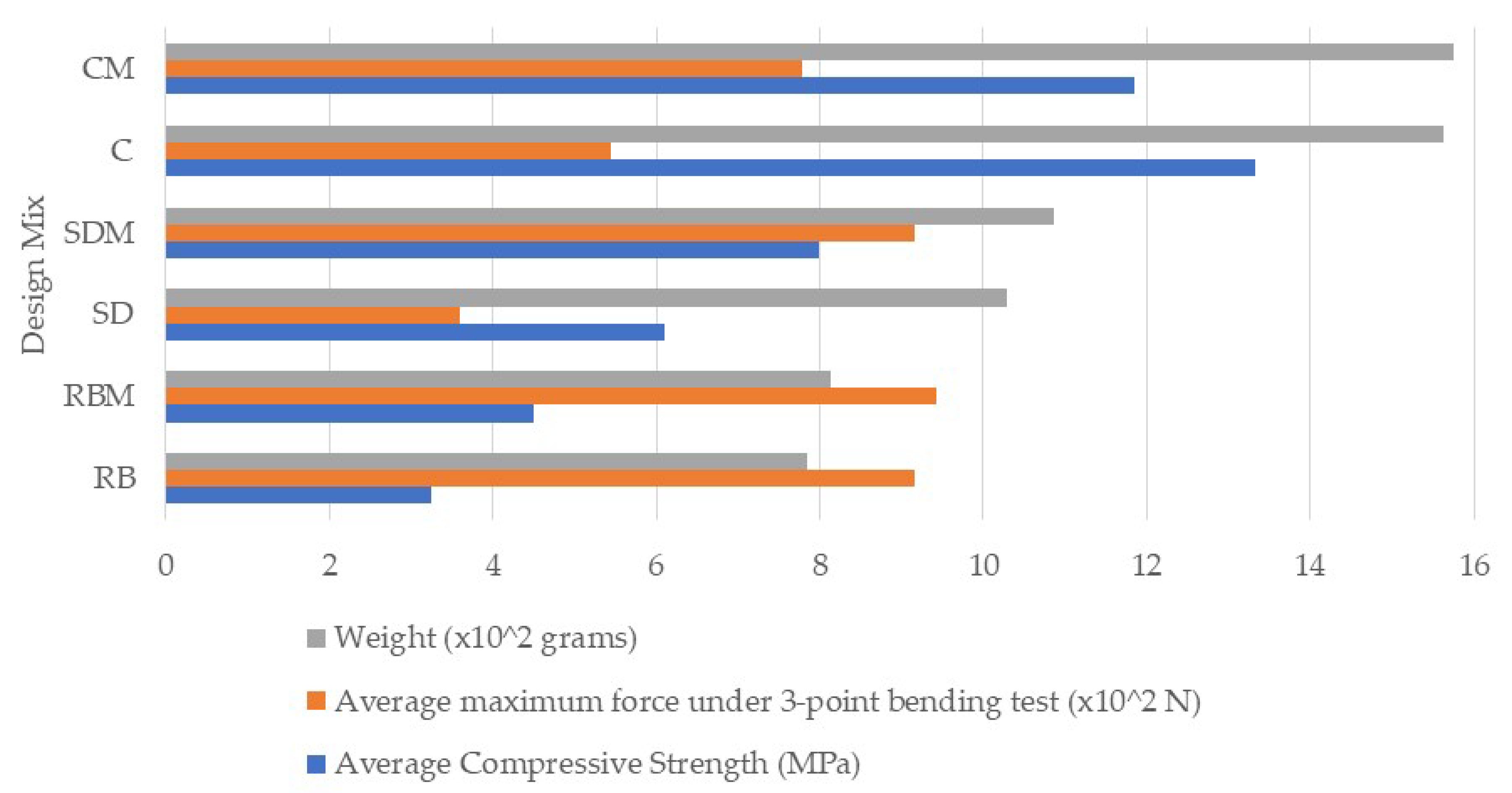

3.2. Compressive Strength

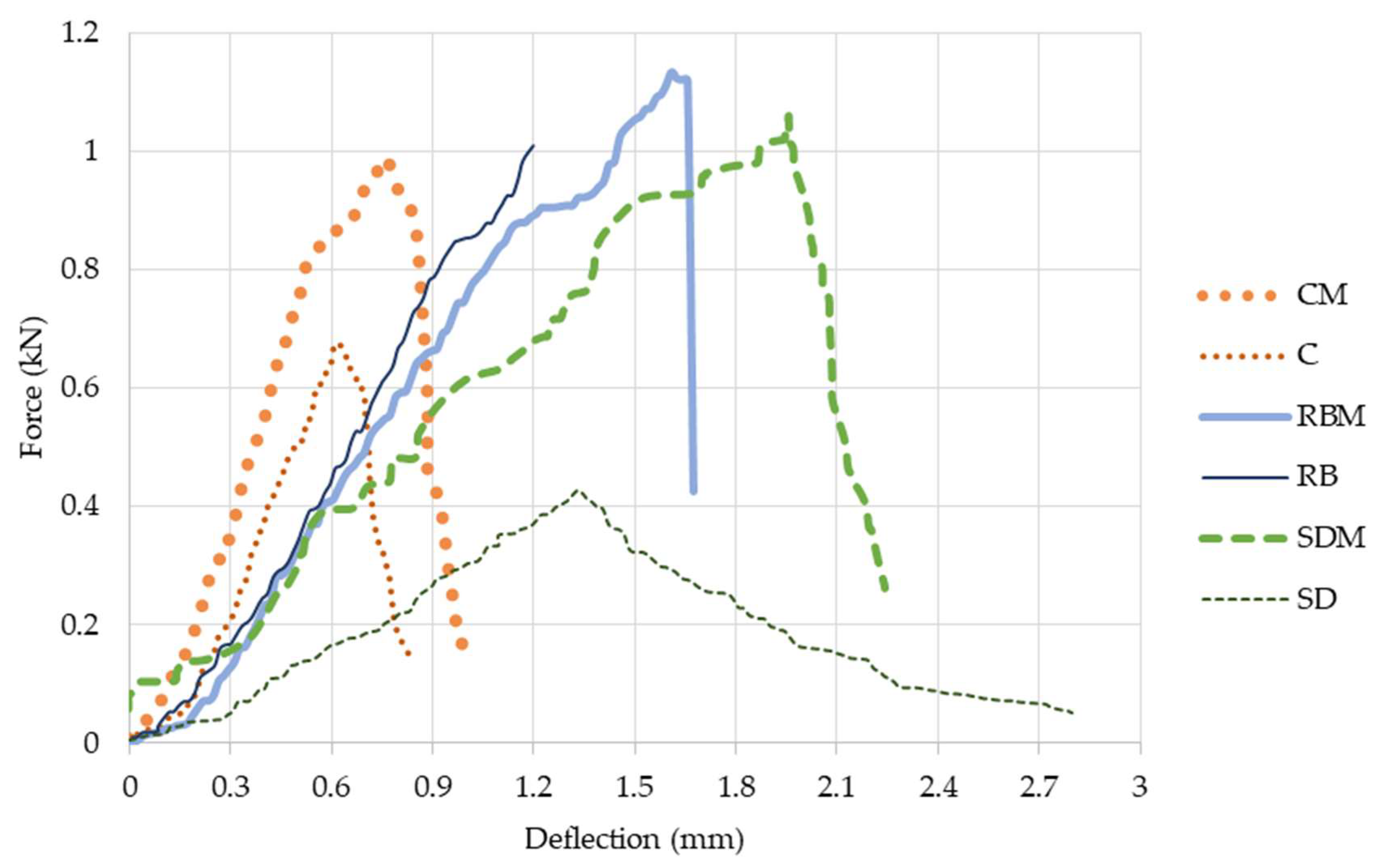

3.3. Flexural Strength

- - Flexural Strength (MPa)

- P - Recorded Maximum Load (N)

- L - Length of the brick (m)

- b - Width of the brick (m)

- d - Height of the brick (m)

3.4. Compressive Strength, Flexural Strength, and Weight

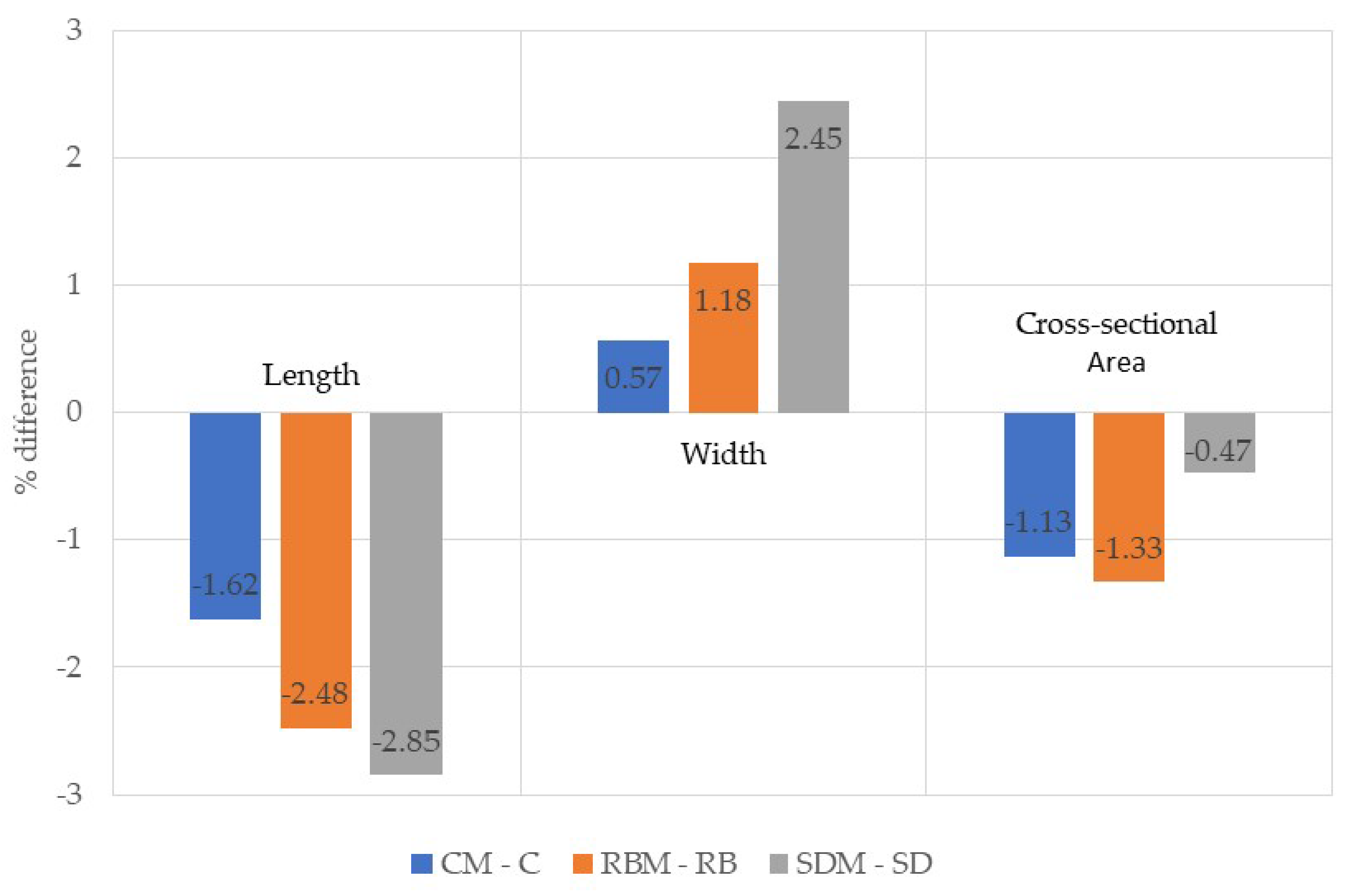

3.5. Dimensional Stability

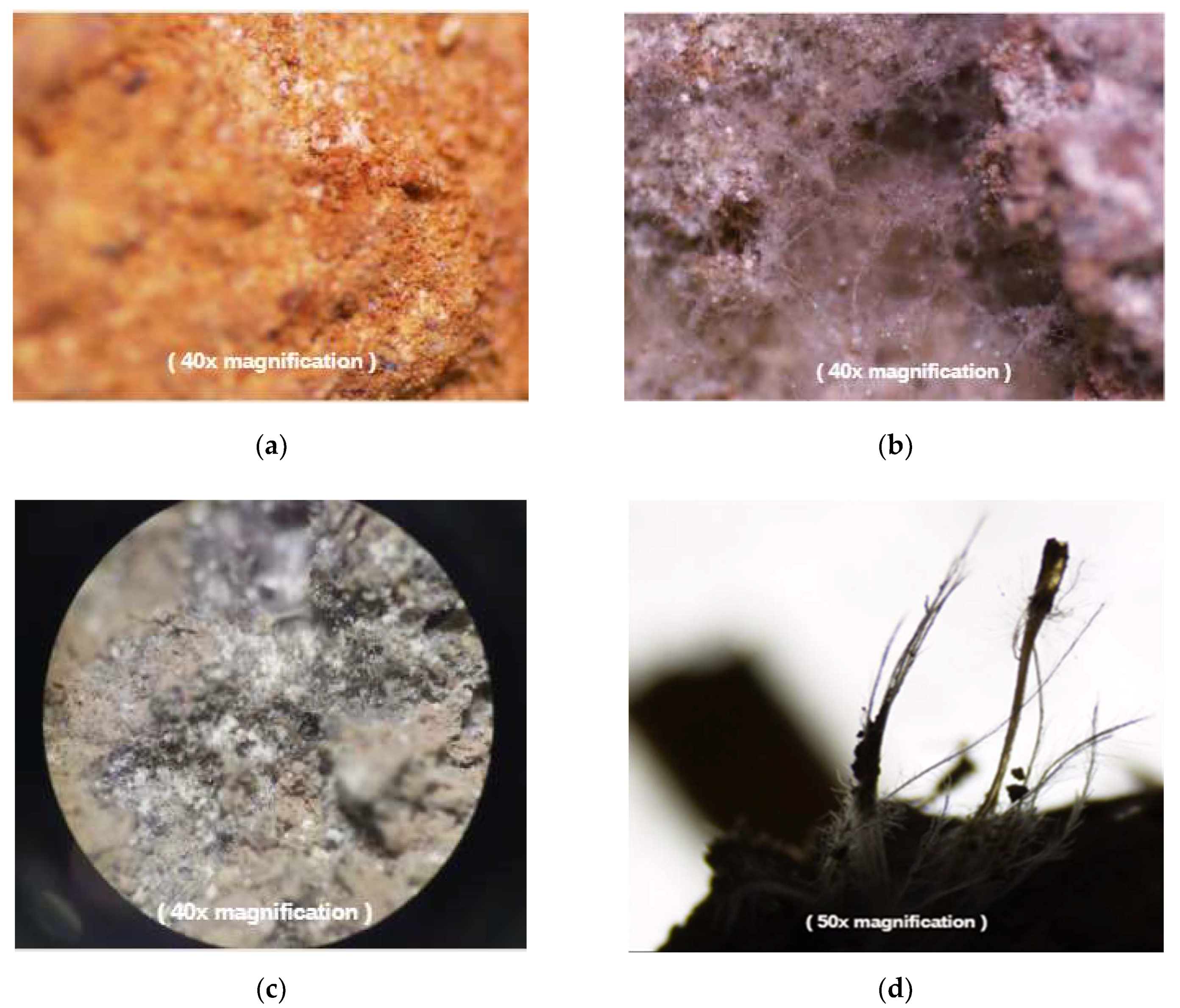

3.6. Images

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Abhijith, R.; Ashok, A.; Reejeesh, C.R. Sustainable packaging applications from mycelium to substitute polystyrene: A review. Mater. Todays Proc. 2018, 5, 2139–2145. [Google Scholar] [CrossRef]

- Leiva, F.; Saenz-Diez, J.; Martinez, E.; Jimenez, E.; Blanco, J. Environmental impact of Agaricus bisporus mycelium production. Agric. Syst. 2015, 138, 38–45. [Google Scholar] [CrossRef]

- Jiang, L.; Walczyk, D.; Mclntyre, G.; Bucinell, R.; Tudryn, G. Manufacturing of biocomposite sandwich structures using mycelium-bound cores and preforms. J. Manuf. Process. 2017, 28, 50–59. [Google Scholar] [CrossRef]

- Jones, M.; Huynh, T.; Dekiwadia, C.; Daver, F.; John, S. Mycelium Composites: A Review of Engineering Characteristics and Growth Kinetics. J. Bionanosci. 2017, 11, 241–257. [Google Scholar] [CrossRef]

- Attias, N.; Danai, O.; Abitbol, T.; Tarazi, E.; Ezov, N.; Pereman, I.; Grobman, Y.J. Mycelium bio-composites in industrial design and architecture: Comparative review and experimental analysis. J. Clean. Prod. 2020, 246, 119037. [Google Scholar] [CrossRef]

- Elsacker, E.; Vandelook, S.; Van Wylick, A.; Ruytinx, J.; De Laet, L.; Peteers, E. A comprehensive framework for the production of mycelium-based lignocellulosic composites. Sci. Total Environ. 2020, 725, 138431. [Google Scholar] [CrossRef] [PubMed]

- Dahy, H. Biocomposite materials based on annual natural fibers and biopolymers—Design, fabrication and customized applications in architecture. Constr. Build. Mater. 2017, 147, 212–220. [Google Scholar] [CrossRef]

- Gruber, P.; Imhof, B. Patterns of growth—Biomimetics and architectural design. Buildings 2017, 7, 32. [Google Scholar] [CrossRef]

- Kuznetsova, I.; Zaitsev, B.; Krasnopolskaya, L.; Teplykh, A.; Semyonov, A.; Avtonomova, A.; Ziangirova, M.; Smirnov, A.; Kolesov, V. Influence of humidity on the acoustic properties of mushroom mycelium films used as sensitive layers for acoustic sensors. Sensors 2020, 20, 2711. [Google Scholar] [CrossRef] [PubMed]

- Huarachi, D.A.R.; Goncalves, G.; de Francisco, A.C.; Canteri, M.H.G.; Piekarski, C.M. Life Cycle assessment of traditional and alternative bricks: A review. Environ. Impact Assess. Rev. 2020, 80, 1066335. [Google Scholar] [CrossRef]

- Zurbano, L.; Bellere, A.; Savilla, L. Mycelial Growth, Fruiting Body Production and Proximate Composition of Pleurotus djamor on Different Substrate. CLSU Int. J. Sci. Technol. 2017, 2, 7–13. [Google Scholar] [CrossRef]

- Indian Standard Common Burnt Clay Building Bricks—Specification; IS Bureau of Indian Standards: New Delhi, India, 2007; pp. 1–3.

- Ongpeng, J.; Oreta, A.; Hirose, S. Monitoring damage using acoustic emission source location and computational geometry in reinforced concrete beams. Appl. Sci. 2018, 8, 189. [Google Scholar] [CrossRef]

- Ongpeng, J.; Oreta, A.; Hirose, S. Damage progression in concrete using acoustic emission test through convex hull visualization. ACI Materials 2016, 113, 737–744. [Google Scholar] [CrossRef]

- Ongpeng, J.; Oreta, A.; Hirose, S. Investigation on the sensitivity of ultrasonic test applied to reinforced concrete beams using neural network. Appl. Sci. 2018, 8, 405. [Google Scholar] [CrossRef]

- Ongpeng, J.; Oreta, A.; Hirose, S. Contact and non-contact ultrasonic nondestructive test in reinforced concrete beam. Adv. Civ. Eng. 2018, 5783175. [Google Scholar]

| Specimen Mix Design | C:X:CH by Mass | Added Water (mL) | Mycelium Serum | Number of Specimens for Compressive Tests | Number of Specimens for Flexural Tests |

|---|---|---|---|---|---|

| Rice Bran bricks (RB) | 5:2:1 | 350 | Without | 4 | 4 |

| Rice Bran with mycelium bricks (RBM) | 5:2:1 | 350 | With | 4 | 4 |

| Sawdust bricks (SD) | 5:3:1 | 450 | Without | 4 | 4 |

| Sawdust with mycelium bricks (SDM) | 5:3:1 | 450 | With | 4 | 4 |

| Clay Bricks (C) | 5:0:0 | Variable | Without | 4 | 4 |

| Clay with mycelium bricks (CM) | 5:0:0 | Variable | With | 4 | 4 |

| Specimen Mix Design | Average Maximum Midpoint Displacement (mm) | Average (MPa) |

|---|---|---|

| Rice Bran bricks (RB) | 0.967 | 1.013 |

| Rice Bran with mycelium bricks (RBM) | 1.977 | 0.916 |

| Sawdust bricks (SD) | 2.937 | 0.473 |

| Sawdust with mycelium bricks (SDM) | 2.764 | 0.962 |

| Clay Bricks (C) | 0.870 | 0.629 |

| Clay with mycelium bricks (CM) | 1.202 | 0.878 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maximino C. Ongpeng, J.; Inciong, E.; Sendo, V.; Soliman, C.; Siggaoat, A. Using Waste in Producing Bio-Composite Mycelium Bricks. Appl. Sci. 2020, 10, 5303. https://doi.org/10.3390/app10155303

Maximino C. Ongpeng J, Inciong E, Sendo V, Soliman C, Siggaoat A. Using Waste in Producing Bio-Composite Mycelium Bricks. Applied Sciences. 2020; 10(15):5303. https://doi.org/10.3390/app10155303

Chicago/Turabian StyleMaximino C. Ongpeng, Jason, Edward Inciong, Vince Sendo, Crizia Soliman, and Adrian Siggaoat. 2020. "Using Waste in Producing Bio-Composite Mycelium Bricks" Applied Sciences 10, no. 15: 5303. https://doi.org/10.3390/app10155303

APA StyleMaximino C. Ongpeng, J., Inciong, E., Sendo, V., Soliman, C., & Siggaoat, A. (2020). Using Waste in Producing Bio-Composite Mycelium Bricks. Applied Sciences, 10(15), 5303. https://doi.org/10.3390/app10155303