Design and Construction of a Low-Cost Test Bench for Testing Agricultural Spray Nozzles

Abstract

Featured Application

Abstract

1. Introduction

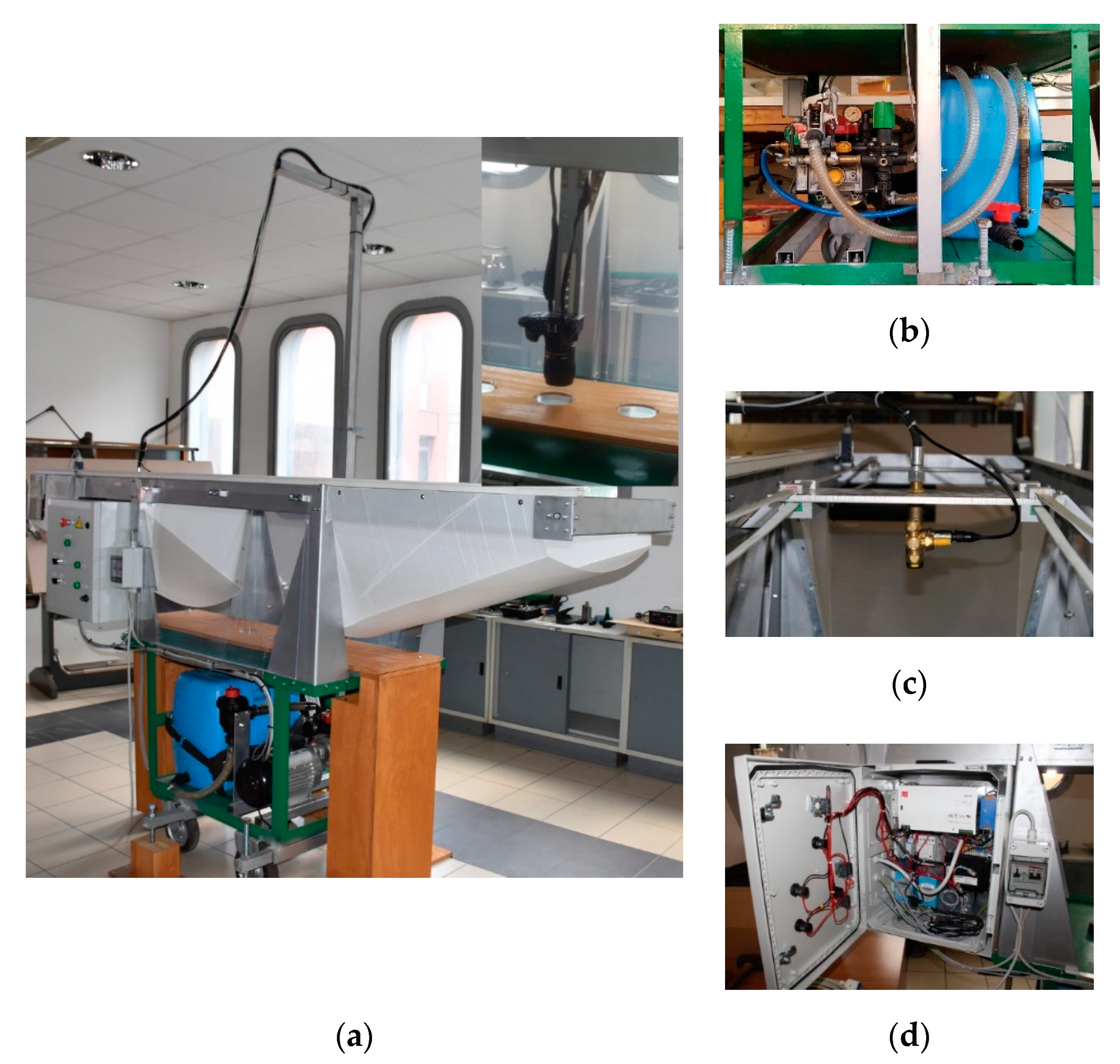

2. Materials and Methods

2.1. Test Bench Design Guidelines

2.2. Hydraulic Component Design

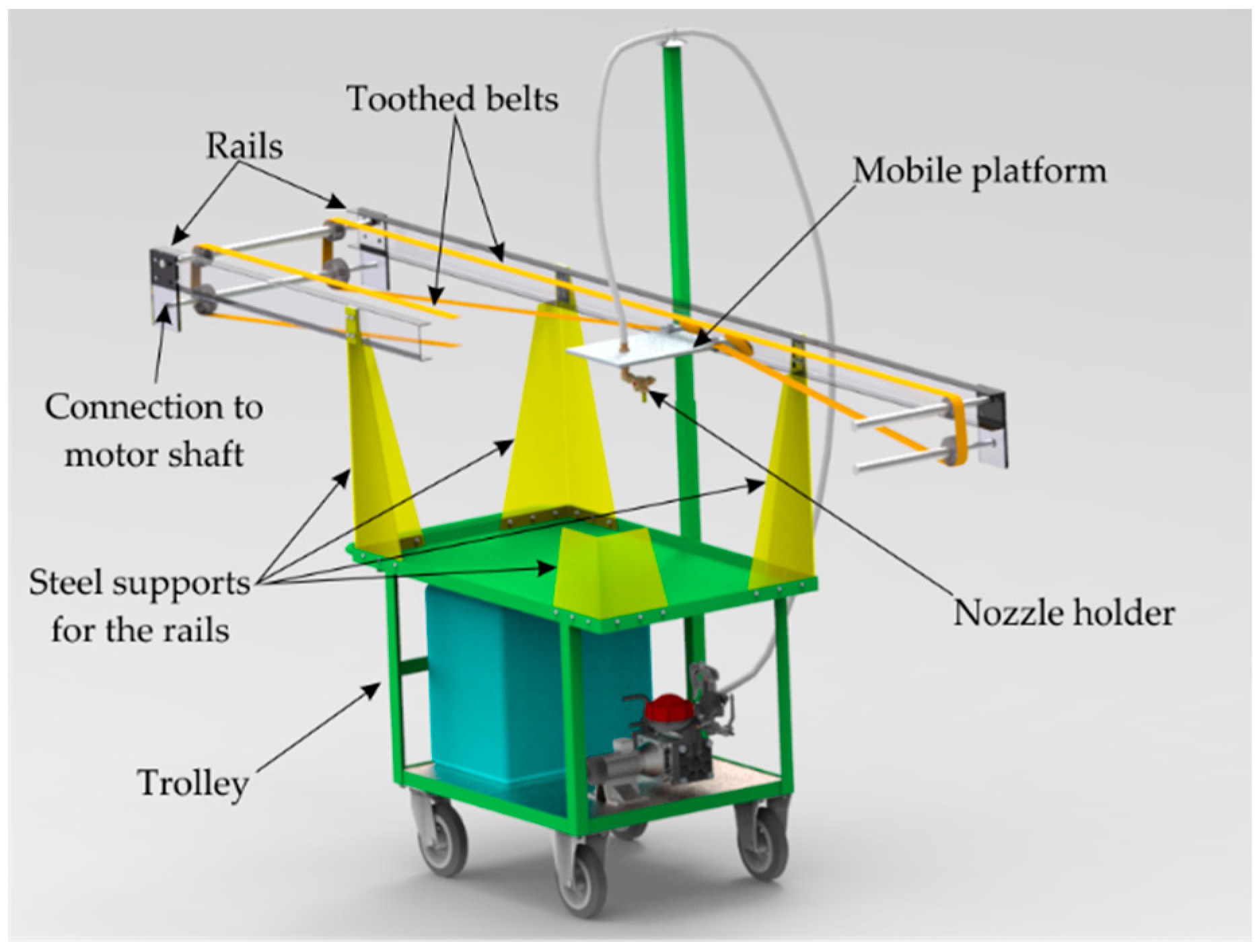

2.3. Mechanical Component Design

- possibility to control speed and position of the nozzle under test while spraying;

- mechanical insulation of the Petri dishes containing the drops from the pump and motors to avoid the transmission of vibration;

- general safety aspects due to the movement of the nozzle.

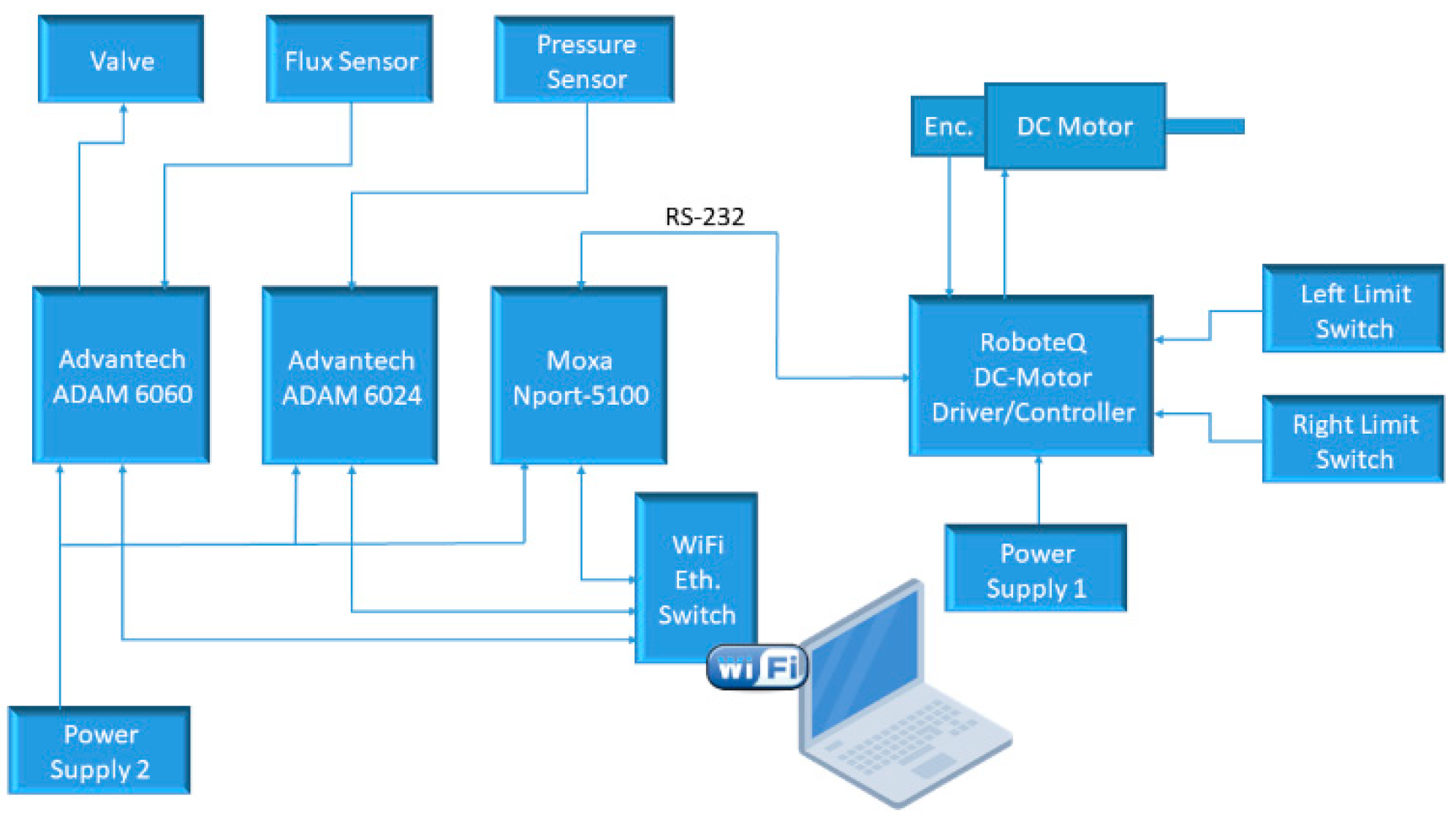

2.4. Control Subsystem Design

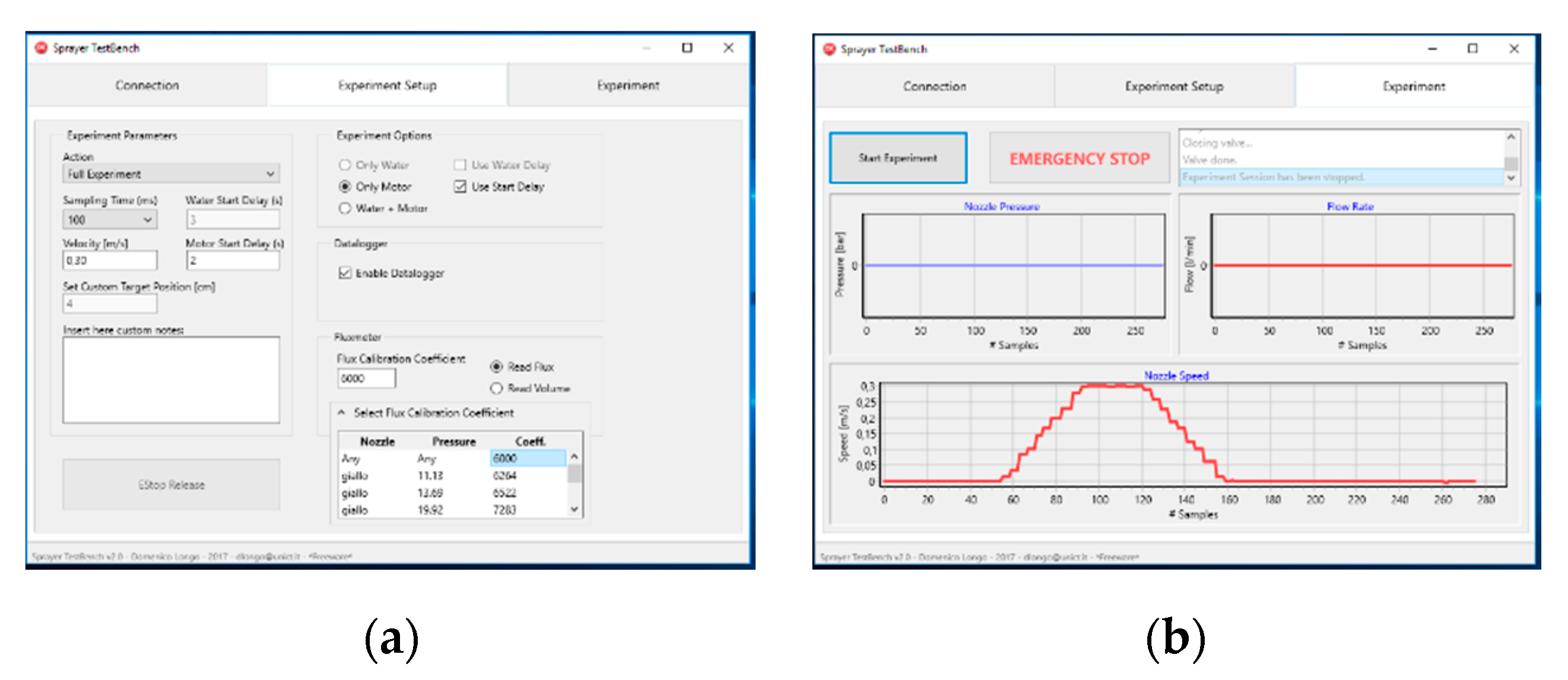

2.5. Software User Interface Design

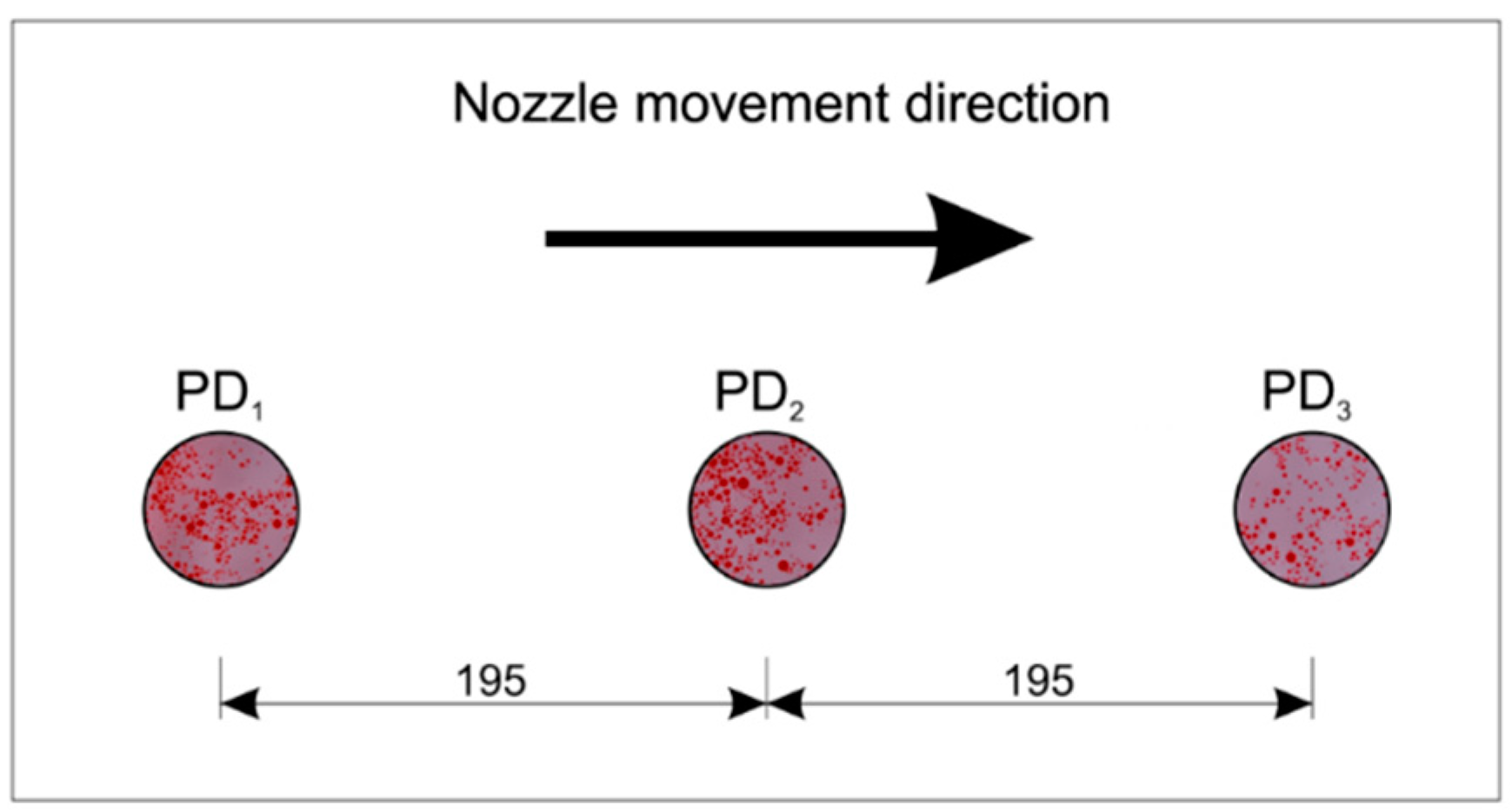

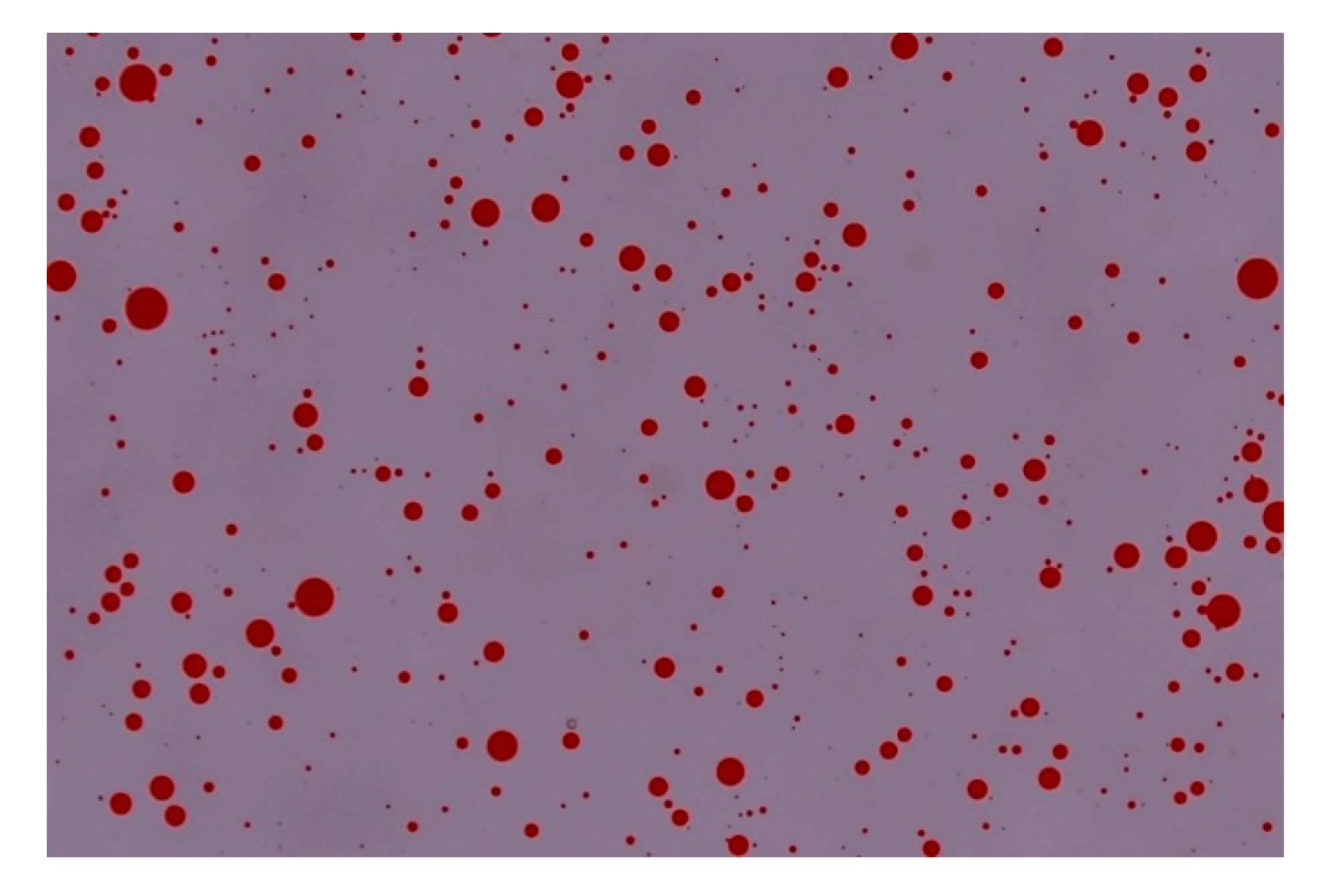

2.6. First Experimental Spraying Tests

- , as the arithmetic mean diameter;

- , as the surface mean diameter;

- , as the volume mean diameter;

- , as the Sauter mean diameter (SMD), i.e., diameter of a drop having the same volume to surface area ratio as the total volume of all the drops to the total surface area of all the drops;

- , , and , as volumetric diameters, below which smaller droplets constitute, respectively, 10%, 50%, and 90% of the total volume;

- relative span factor (RSF), a dimensionless parameter indicative of the uniformity of the drop size distribution, defined as:

- number mean diameter (NMD), which is the droplet diameter below which the droplet diameter for 50% of the number of drops are smaller;

- and , as percentages of total volume of droplets smaller than, respectively, 100 and 200 µm in diameter.

3. Results and Discussion

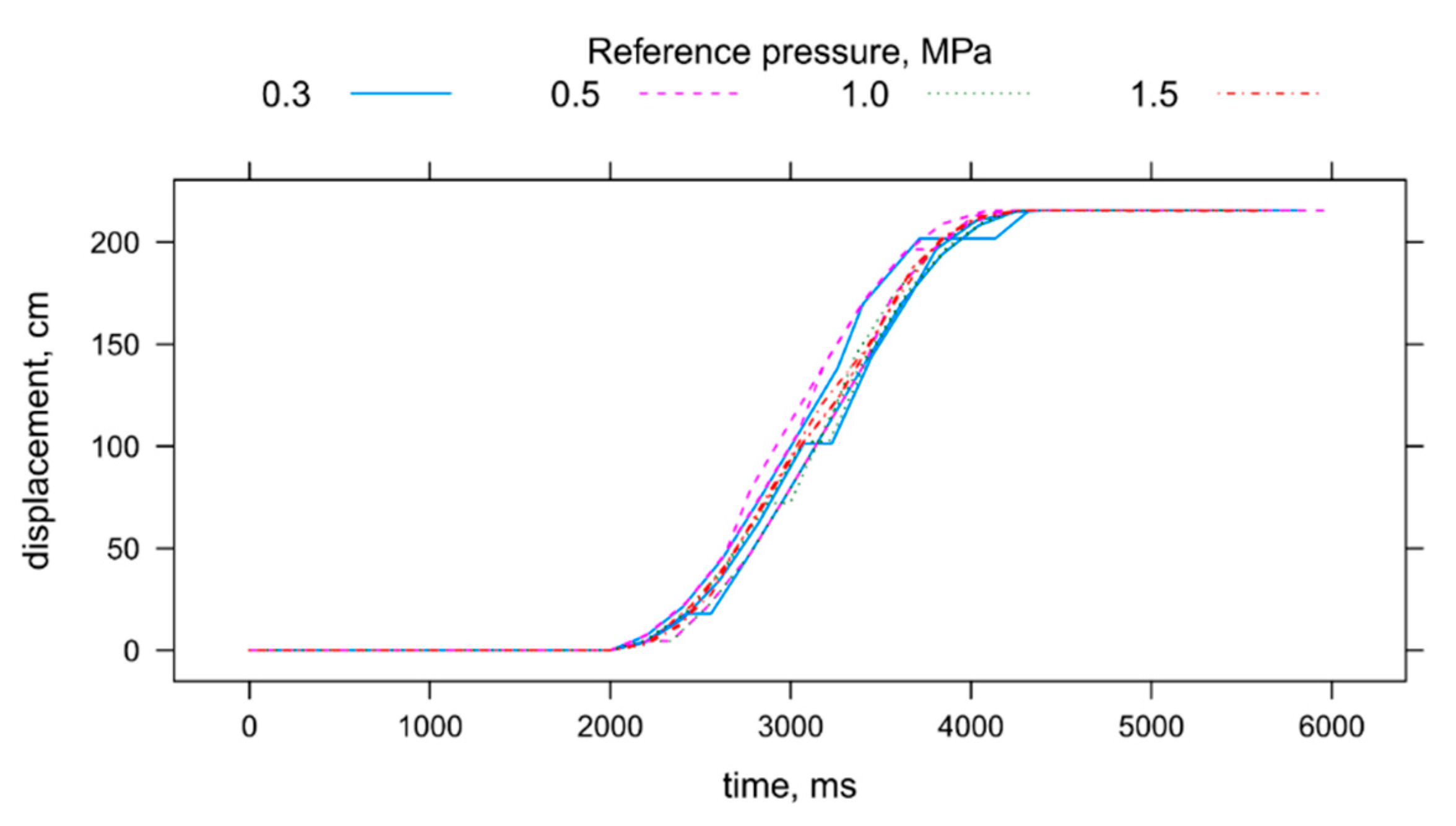

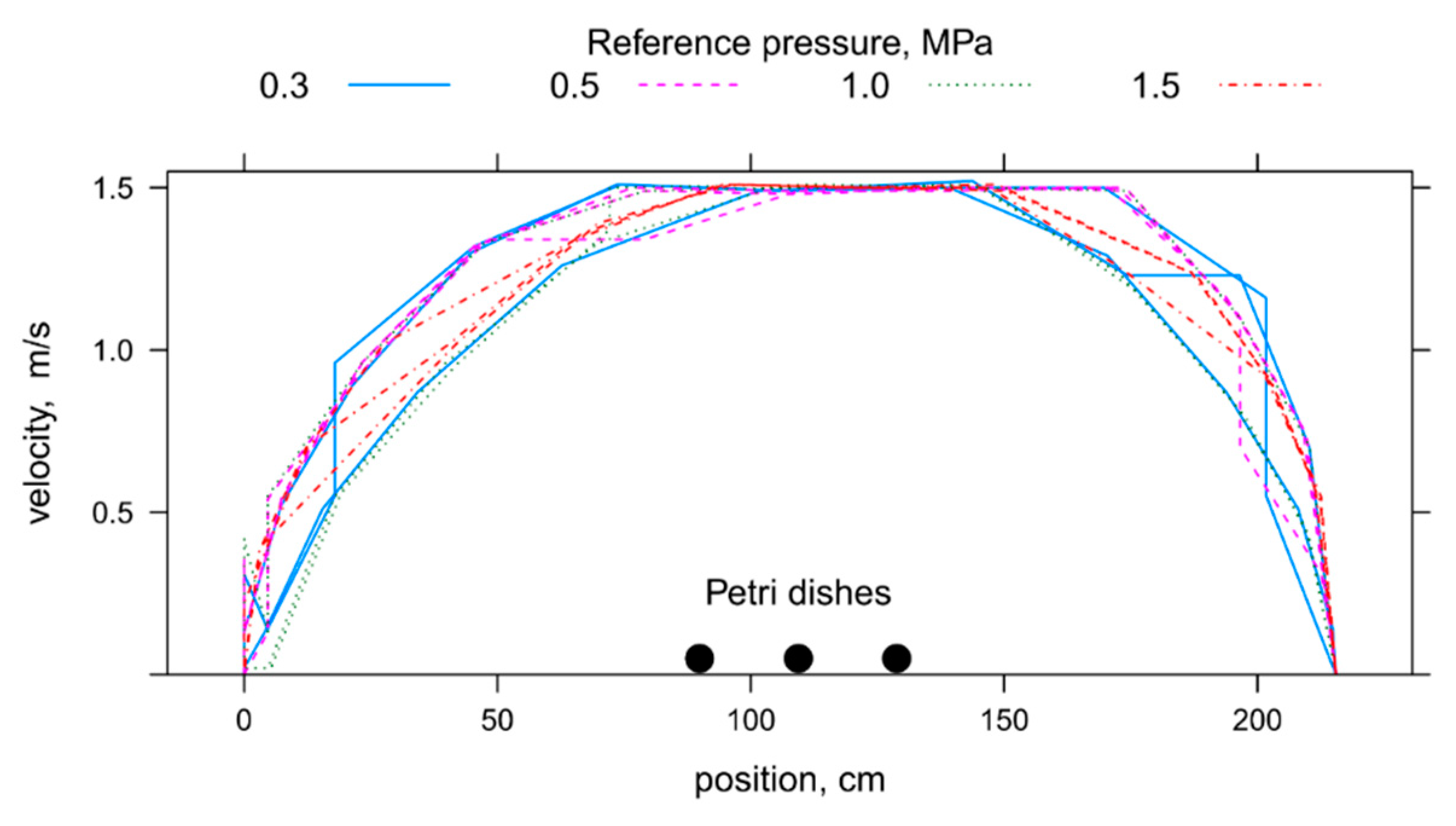

3.1. The Whole System Test

3.2. Mechanical Tests

3.3. Spraying Test Results

4. Conclusions

- The software interface to control the test bench and to set the test conditions is simple, and its organization in tabs (the first to set the test parameters; the second one to see graphically the evolution of the test variables) makes it easy to use the test bench.

- The hydraulic circuit allows for testing nozzles under work conditions similar to those present in commercial sprayers, using a standard diaphragm pump and standard manual pressure regulators.

- The electromechanic components allow for a fine and precise control of speed and position of the nozzle under test.

- The image acquisition system, based on a digital single-lens reflex camera, may be easily updated if higher resolutions are required. The actual system, with a scale factor of 188.0–189.0 pixel/mm, allows for detecting the drops whose diameter is greater than 10 µm, which can be considered suitable for similar applications.

- In measuring the single drop diameters, it is possible to devise the size diameter probability distribution function and all the usual spray drop parameters. The preliminary tests with the Albuz ATR80 orange hollow cone nozzles produced results in accordance with factory data sheets.

- Further tests that are aimed at comparing several nozzle types (hollow cone, fan, air induction) with the reference nozzles recommended by ISO/FDIS 25358:2018 [55] to define the boundaries/borders between the size classes may better assess the capabilities of the test bench.

Author Contributions

Funding

Conflicts of Interest

Abbreviation

| Symbol | |

| acceleration/deceleration value during transients, m/s2 | |

| trails section covered by the nozzle at constant acceleration/deceleration, m | |

| trails section covered by the nozzle at constant speed, m | |

| acceleration/deceleration time (transient time), s | |

| time while the nozzle moves at constant speed (steady state time), s | |

| desired constant nozzle speed, m/s | |

| area of droplet detected by ImageJ, pixel | |

| diameter of droplet i, pixel | |

| arithmetic mean diameter, µm | |

| surface mean diameter, µm | |

| volume mean diameter, µm | |

| Sauter mean diameter (SMD) or the diameter of a drop having the same volume to surface area ratio as the total volume of all the drops to the total surface area of all the drops, µm | |

| , | volumetric diameters below which smaller droplets constitute, respectively, 10% and 90% of the total volume, µm |

| volumetric median diameter (VMD), below which smaller droplets constitute 50% of the total volume, µm | |

| NMD | number mean diameter, the droplet diameter below which the droplet diameter for 50% of the number of drops are smaller, µm |

| RSF | relative span factor, a dimensionless parameter indicative of the uniformity of the drop size distribution |

| SMD | Sauter mean diameter, µm |

| VMD | volume median diameter, µm |

| , | proportion of total volume of droplets smaller than, respectively, 100 and 200 µm in diameter, % |

| Acronym | |

| AC | Alternated current |

| CSV | Comma separated value |

| CV | Coefficient of variation |

| DC | Direct current |

| DIA | Digital image analysis |

| DSLR | Digital single-lens reflex |

| GUI | Graphic user interface |

| IDE | Integrated development environment |

| IP | Internet protocol |

| LD | Laser diffraction |

| OAP | Optical array probes |

| OI | Optical imaging |

| PD | Petri dish |

| PDA | Phase Doppler anemometry |

| PDPA | Phase Doppler particle analyzers |

| PID | Proportional–integral–derivative |

| PMDC | Permanent magnets direct current |

| PPP | Plant protection products |

| PSU | Power supply unit |

| TCP | Transmission control protocol |

| TCP/IP | Transmission control protocol/Internet protocol |

References

- European Union. Directive 2009/128/EC of the European Parliament and of the Council of 21 October 2009 establishing a framework for Community action to achieve the sustainable use of pesticides. Off. J. L 2009, 309, 71–86. [Google Scholar]

- Cox, S. Information technology: The global key to precision agriculture and sustainability. Comput. Electron. Agric. 2002, 36, 93–111. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, M.; Wang, N. Precision agriculture—A worldwide overview. Comput. Electron. Agric. 2002, 36, 113–132. [Google Scholar] [CrossRef]

- Camilli, A.; Cugnasca, C.E.; Saraiva, A.M.; Hirakawa, A.R.; Corrȇa, P.L.P. From wireless sensors to field mapping: Anatomy of an application for precision agriculture. Comput. Electron. Agric. 2007, 58, 25–36. [Google Scholar] [CrossRef]

- Sankaran, S.; Mishra, A.; Ehsani, R.; Davis, C. A review of advanced techniques for detecting plant diseases. Comput. Electron. Agric. 2010, 72, 1–13. [Google Scholar] [CrossRef]

- Gil, E.; Arnó, J.; Llorens, J.; Sanz, R.; Llop, J.; Rosell-Polo, J.R.; Gallart, M.; Escolà, A. Advanced technologies for the improvement of spray application techniques in Spanish viticulture: An overview. Sensors 2014, 14, 691–708. [Google Scholar] [CrossRef]

- Jiao, L.; Dong, D.; Feng, H.; Zhao, X.; Chen, L. Monitoring spray drift in aerial spray application based on infrared thermal imaging technology. Comput. Electron. Agric. 2016, 121, 135–140. [Google Scholar] [CrossRef]

- Escolà, A.; Rosell-Polo, J.R.; Planas, S.; Gil, E.; Pomar, J.; Camp, F.; Llorens, J.; Solanelles, F. Variable rate sprayer. Part 1—orchard prototype: Design, implementation and validation. Comput. Electron. Agric. 2013, 95, 122–135. [Google Scholar] [CrossRef]

- Gil, E.; Llorens, J.; Llop, J.; Fàbregas, X.; Escolà, A.; Rosell-Polo, J.R. Variable rate sprayer. Part 2—Vineyard prototype: Design, implementation, and validation. Comput. Electron. Agric. 2013, 95, 136–150. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Cerruto, E. Spray deposition in “tendone” vineyards when using a pneumatic electrostatic sprayer. Crop Prot. 2015, 68, 1–11. [Google Scholar] [CrossRef]

- Oberti, R.; Marchi, M.; Tirelli, P.; Calcante, A.; Iriti, M.; Tona, E.; Hočevar, M.; Baur, J.; Pfaff, J.; Schütz, C.; et al. Selective spraying of grapevines for disease control using a modular agricultural robot. Biosyst. Eng. 2016, 146, 203–215. [Google Scholar] [CrossRef]

- Qin, W.C.; Qiu, B.J.; Xue, X.Y.; Chen, C.; Xu, Z.F.; Zhou, Q.Q. Droplet deposition and control effect of insecticides sprayed with an unmanned aerial vehicle against plant hoppers. Crop Prot. 2016, 85, 79–88. [Google Scholar] [CrossRef]

- Grella, M.; Gallart, M.; Marucco, P.; Balsari, P.; Gil, E. Ground deposition and airborne spray drift assessment in vineyard and orchard: The influence of environmental variables and sprayer settings. Sustainability 2017, 9, 728. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Cerruto, E.; Manetto, G. Foliar spray deposition in a “tendone” vineyard as affected by airflow rate, volume rate and vegetative development. Crop Prot. 2017, 91, 34–48. [Google Scholar] [CrossRef]

- Rao Mogili, U.M.; Deepak, B.B.V.L. Review on application of drone systems in precision agriculture. Procedia Comput. Sci. 2018, 133, 502–509. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Santoro, F.; Manetto, G.; Cerruto, E. Study of the correlation between foliar and patternator deposits in a “tendone” vineyard. Agric. Eng. Int. CIGR J. 2018, 20, 97–107. [Google Scholar]

- Gan-Mor, S.; Matthews, G.A. Recent developments in sprayers for application of biopesticides—An overview. Biosyst. Eng. 2003, 84, 119–125. [Google Scholar] [CrossRef]

- Blandini, G.; Emma, G.; Failla, S.; Manetto, G. A prototype for mechanical distribution of beneficials. Acta Hortic. 2008, 2, 1515–1522. [Google Scholar] [CrossRef]

- Pezzi, F.; Martelli, R.; Lanzoni, A.; Maini, S. Effects of mechanical distribution on survival and reproduction of Phytoseiulus persimilis and Amblyseius swirskii. Biosyst. Eng. 2015, 129, 11–19. [Google Scholar] [CrossRef]

- Lamichhane, J.R. Pesticide use and risk reduction in European farming systems with IPM: An introduction to the special issue. Crop Prot. 2017, 97. [Google Scholar] [CrossRef]

- Papa, R.; Manetto, G.; Cerruto, E.; Failla, S. Mechanical distribution of beneficial arthropods in greenhouse and open field: A review. J. Agric. Eng. 2018, 49, 81–91. [Google Scholar] [CrossRef]

- Lee, R.; den Uyl, R.; Runhaar, H. Assessment of policy instruments for pesticide use reduction in Europe; Learning from a systematic literature review. Crop Prot. 2019, 126, 104929. [Google Scholar] [CrossRef]

- Mantzoukas, S.; Eliopoulos, P.A. Endophytic entomopathogenic fungi: A valuable biological control tool against plant pests. Appl. Sci. 2020, 10, 360. [Google Scholar] [CrossRef]

- Hewitt, A.J. Droplet size and agricultural spraying, part I: Atomization, spray transport, deposition, drift, and droplet size measurement techniques. At. Sprays 1997, 7, 235–244. [Google Scholar] [CrossRef]

- Matthews, G.A. How was the pesticide applied? Crop Prot. 2004, 23, 651–653. [Google Scholar] [CrossRef]

- Nuyttens, D.; Baetens, K.; De Schampheleire, M.; Sonck, B. Effect of nozzle type, size and pressure on spray droplet characteristics. Biosyst. Eng. 2007, 97, 333–345. [Google Scholar] [CrossRef]

- Garcerá, C.; Román, C.; Moltó, E.; Abad, R.; Insa, J.A.; Torrent, X.; Chueca, P. Comparison between standard and drift reducing nozzles for pesticide application in citrus: Part II. Effects on canopy spray distribution, control efficacy of Aonidiella aurantii (Maskell), beneficial parasitoids and pesticide residues on fruit. Crop Prot. 2017, 94, 83–96. [Google Scholar] [CrossRef]

- Torrent, X.; Garcerá, C.; Moltó, E.; Chueca, P.; Abad, R.; Grafulla, C.; Planas, S. Comparison between standard and drift reducing nozzles for pesticide application in citrus: Part I. Effects on wind tunnel and field spray drift. Crop Prot. 2017, 96, 130–143. [Google Scholar] [CrossRef]

- Torrent, X.; Gregorio, E.; Douzals, J.P.; Tinet, C.; Rosell-Polo, J.R.; Planas, S. Assessment of spray drift potential reduction for hollow-cone nozzles: Part 1. Classification using indirect methods. Sci. Total Environ. 2019. [Google Scholar] [CrossRef]

- Berger-Preiß, E.; Boehnckey, A.; Könnecker, G.; Mangelsdorf, I.; Holthenrich, D.; Koch, W. Inhalational and dermal exposures during spray application of biocides. Int. J. Hyg. Environ. Health 2005, 208, 357–372. [Google Scholar] [CrossRef]

- Nuyttens, D.; Braekman, P.; Windey, S.; Sonck, B. Potential dermal pesticide exposure affected by greenhouse spray application technique. Pest Manag. Sci. 2009, 65, 781–790. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-Hermosilla, J.; Rincón, V.J.; Páez, F.; Agüera, F.; Carvajal, F. Field evaluation of a self-propelled sprayer and effects of the application rate on spray deposition and losses to the ground in greenhouse tomato crops. Pest Manag. Sci. 2011, 67, 942–947. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-Hermosilla, J.; Páez, F.; Rincón, V.J.; Carvajal, F. Evaluation of the effect of spray pressure in hand-held sprayers in a greenhouse tomato crop. Crop Prot. 2013, 54, 121–125. [Google Scholar] [CrossRef]

- Gil, E.; Balsari, P.; Gallart, M.; Llorens, J.; Marucco, P.; Andersen, P.G.; Fàbregas, X.; Llop, J. Determination of drift potential of different flat fan nozzles on a boom sprayer using a test bench. Crop Prot. 2014, 56, 58–68. [Google Scholar] [CrossRef]

- Cerruto, E.; Manetto, G.; Santoro, F.; Pascuzzi, S. Operator dermal exposure to pesticides in tomato and strawberry greenhouses from hand-held sprayers. Sustainability 2018, 10, 2273. [Google Scholar] [CrossRef]

- Rincón, V.J.; Páez, F.C.; Sánchez-Hermosilla, J. Potential dermal exposure to operators applying pesticide on greenhouse crops using low-cost equipment. Sci. Total Environ. 2018, 630, 1181–1187. [Google Scholar] [CrossRef]

- Lodwik, D.; Pietrzyk, J.; Malesa, W. Analysis of volume distribution and evaluation of the spraying spectrum in terms of spraying quality. Appl. Sci. 2020, 10, 2395. [Google Scholar] [CrossRef]

- Schick, R.J. Spray Technology Reference Guide: Understanding drop size. In Spraying Systems Bulletin no. 459C; Spraying Systems Co.: Wheaton, IL, USA, 2008; Available online: https://www.spray.com/literature_pdfs/B459C_Understanding_Drop_Size.pdf (accessed on 11 November 2019).

- Lad, N.; Aroussi, E.A.; Muhamad Said, M.F. Droplet size measurement for liquid spray using digital image analysis technique. J. Appl. Sci. 2011, 11, 1966–1972. [Google Scholar] [CrossRef][Green Version]

- De Cock, N.; Massinon, M.; Nuyttens, D.; Dekeyser, D.; Lebeau, F. Measurements of reference ISO nozzles by high-speed imaging. Crop Prot. 2016, 89, 105–115. [Google Scholar] [CrossRef]

- De Cock, N.; Massinon, M.; Ouled Taleb Salah, S.; Mercatoris, B.C.N.; Lebeau, F. Droplet size distribution measurements of ISO nozzles by shadowgraphy method. Commun. Appl. Biol. Sci. 2015, 80, 295–301. [Google Scholar]

- Hoffmann, W.C.; Hewitt, A.J. Comparison of three imaging systems for water-sensitive papers. Appl. Eng. Agric. 2005, 21, 961–964. [Google Scholar] [CrossRef]

- Marçal, A.R.S.; Cunha, M. Image processing of artificial targets for automatic evaluation of spray quality. Trans. ASABE 2008, 51, 811–821. [Google Scholar] [CrossRef]

- Zhu, H.; Salyani, M.; Fox, R.D. A portable scanning system for evaluation of spray deposit distribution. Comput. Electron. Agric. 2011, 76, 38–43. [Google Scholar] [CrossRef]

- Cunha, M.; Carvalho, C.; Marcal, A.R.S. Assessing the ability of image processing software to analyse spray quality on water-sensitive papers used as artificial targets. Biosyst. Eng. 2012, 111, 11–23. [Google Scholar] [CrossRef]

- Cerruto, E.; Aglieco, C.; Failla, S.; Manetto, G. Parameters influencing deposit estimation when using water sensitive papers. J. Agric. Eng. 2013, 44, 62–70. [Google Scholar] [CrossRef]

- Salyani, M.; Zhu, H.; Sweeb, R.D.; Pai, N. Assessment of spray distribution with water-sensitive paper. Agric. Eng. Int. CIGR J. 2013, 15, 101–111. [Google Scholar]

- Cerruto, E.; Failla, S.; Longo, D.; Manetto, G. Simulation of water sensitive papers for spray analysis. Agric. Eng. Int. CIGR J. 2016, 18, 22–29. [Google Scholar]

- Cerruto, E.; Manetto, G.; Longo, D.; Failla, S.; Papa, R. A model to estimate the spray deposit by simulated water sensitive papers. Crop Prot. 2019, 124, 104861. [Google Scholar] [CrossRef]

- ISO (International Organization for Standardization). ISO 5682-1, Equipment for Crop Protection—Spraying Equipment—Part 1: Test Methods for Sprayer Nozzles; ISO: Geneva, Switzerland, 2017. Available online: https://www.iso.org/standard/60053.html (accessed on 16 July 2020).

- Cerruto, E.; Manetto, G.; Longo, D.; Failla, S.; Schillaci, G. A laboratory system for nozzle spray analysis. Chem. Eng. Trans. 2017, 58, 751–756. [Google Scholar] [CrossRef]

- Ali, A.; Awan, A.; Khan, F.H.; Khan, M.A. Fabrication of Ultra Low Volume (ULV) pesticide sprayer test bench. Pak. J. Agric. Sci. 2011, 48, 135–140. [Google Scholar]

- Ziegler, G.; Nichols, N.B. Optimum settings for automatic controllers. Trans. ASME 1942, 64, 759–768. [Google Scholar] [CrossRef]

- Meshram, P.M.; Kanojiya, R.G. Tuning of PID controller using Ziegler-Nichols method for speed control of DC motor. In Proceedings of the IEEE-International Conference on Advances in Engineering, Science and Management (ICAESM-2012), Nagapattinam, Tamil Nadu, India, 30–31 March 2012; pp. 117–122. [Google Scholar]

- ISO (International Organization for Standardization). ISO/FDIS 25358:2018, Crop Protection Equipment—Droplet-Size Spectra from Atomizers—Measurement and Classification; ISO: Geneva, Switzerland, 2018. Available online: https://www.iso.org/standard/66412.html (accessed on 26 June 2020).

- Abramoff, M.D.; Magelhaes, P.J.; Ram, S.J. Image processing with Image. J. Biophot. Int. 2004, 11, 36–42. [Google Scholar]

- Sánchez-Hermosilla, J.; Medina, R. Adaptive threshold for droplet spot analysis using water-sensitive paper. Appl. Eng. Agric. 2011, 20, 547–551. [Google Scholar] [CrossRef]

- R Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2019; Available online: https://www.R-project.org (accessed on 1 May 2020).

| Measured Values | From Nozzle Data Sheets | ||

|---|---|---|---|

| Pressure, MPa | Flow Rate, L/min | Pressure, MPa | Flow Rate, L/min |

| 0.308 | 0.88 | ||

| 0.517 | 0.98 | 0.5 | 0.99 |

| 1.036 | 1.37 | 1.0 | 1.39 |

| 1.492 | 1.63 | 1.5 | 1.69 |

| 0.3 MPa | 0.5 MPa | 1.0 MPa | 1.5 MPa | |||||

|---|---|---|---|---|---|---|---|---|

| Parameter | Mean | Std Dev | Mean | Std Dev | Mean | Std Dev | Mean | Std Dev |

| (µm) | 81.7 | 7.1 | 69.7 | 2.4 | 56.6 | 4.9 | 54.6 | 4.4 |

| (µm) | 98.0 | 6.7 | 83.1 | 2.6 | 69.1 | 4.7 | 66.6 | 4.5 |

| (µm) | 113.1 | 6.4 | 95.8 | 3.5 | 82.0 | 4.1 | 79.0 | 4.6 |

| (µm) | 150.6 | 7.4 | 127.5 | 7.6 | 115.4 | 3.2 | 111.1 | 4.7 |

| (µm) | 97.1 | 10.9 | 79.6 | 4.0 | 69.9 | 3.4 | 66.2 | 4.1 |

| (µm) | 173.4 | 7.3 | 148.5 | 9.9 | 138.4 | 5.1 | 135.6 | 3.9 |

| (µm) | 264.4 | 11.0 | 236.5 | 9.0 | 227.3 | 4.4 | 219.0 | 6.2 |

| RSF | 0.97 | 0.08 | 1.06 | 0.06 | 1.14 | 0.04 | 1.13 | 0.03 |

| NMD (µm) | 68.3 | 10.2 | 61.4 | 5.2 | 45.3 | 6.1 | 44.2 | 5.7 |

| (%) | 11.6 | 3.3 | 22.0 | 4.4 | 25.8 | 2.6 | 28.7 | 2.9 |

| (%) | 65.8 | 3.3 | 77.7 | 4.0 | 81.3 | 1.4 | 84.0 | 1.8 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Longo, D.; Manetto, G.; Papa, R.; Cerruto, E. Design and Construction of a Low-Cost Test Bench for Testing Agricultural Spray Nozzles. Appl. Sci. 2020, 10, 5221. https://doi.org/10.3390/app10155221

Longo D, Manetto G, Papa R, Cerruto E. Design and Construction of a Low-Cost Test Bench for Testing Agricultural Spray Nozzles. Applied Sciences. 2020; 10(15):5221. https://doi.org/10.3390/app10155221

Chicago/Turabian StyleLongo, Domenico, Giuseppe Manetto, Rita Papa, and Emanuele Cerruto. 2020. "Design and Construction of a Low-Cost Test Bench for Testing Agricultural Spray Nozzles" Applied Sciences 10, no. 15: 5221. https://doi.org/10.3390/app10155221

APA StyleLongo, D., Manetto, G., Papa, R., & Cerruto, E. (2020). Design and Construction of a Low-Cost Test Bench for Testing Agricultural Spray Nozzles. Applied Sciences, 10(15), 5221. https://doi.org/10.3390/app10155221