Bearing Health Monitoring Using Relief-F-Based Feature Relevance Analysis and HMM

Abstract

1. Introduction

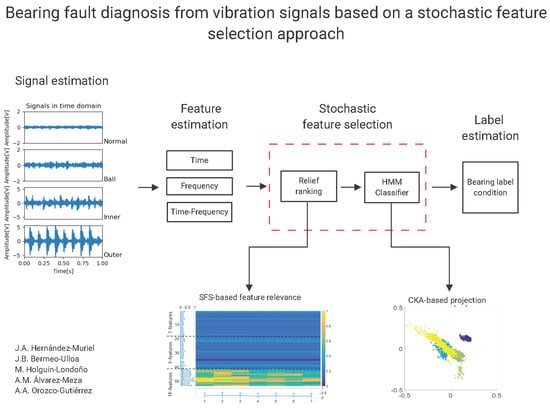

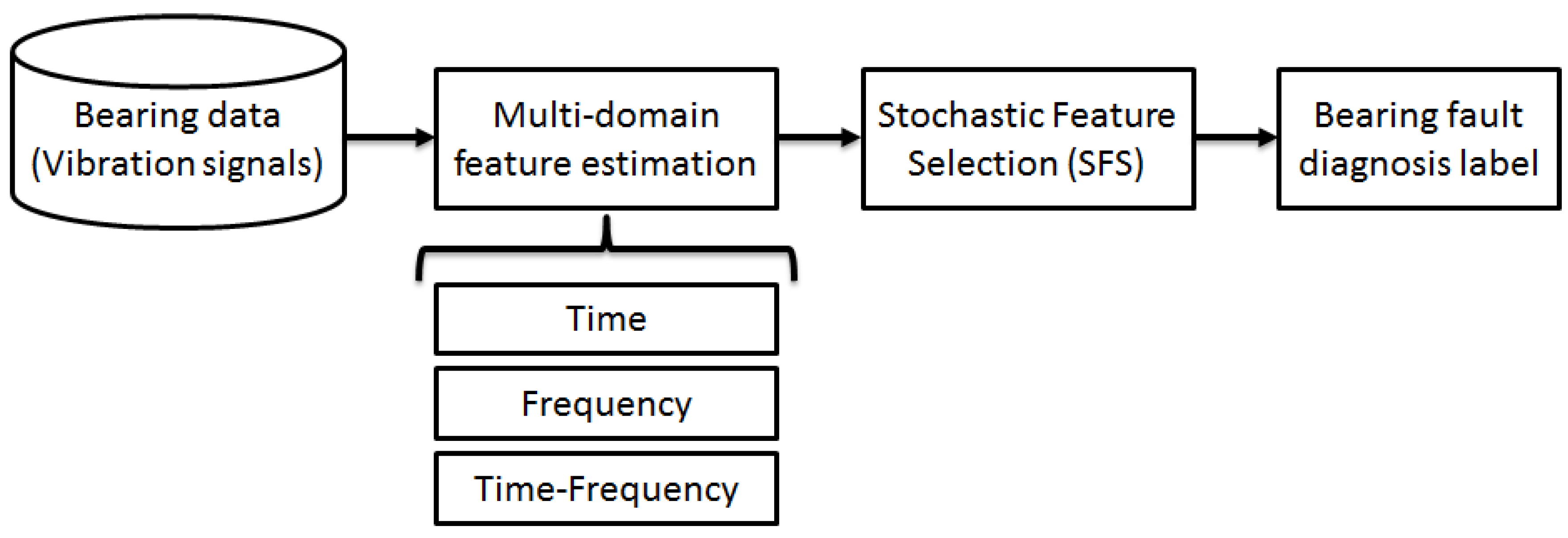

2. Stochastic Feature Selection

2.1. Multi-Domain Feature Estimation

2.2. Supervised Relevance Analysis under Stochastic Modeling

3. Experimental Setup

3.1. Database and Preprocessing

3.2. SFS Training

3.3. Method Comparison

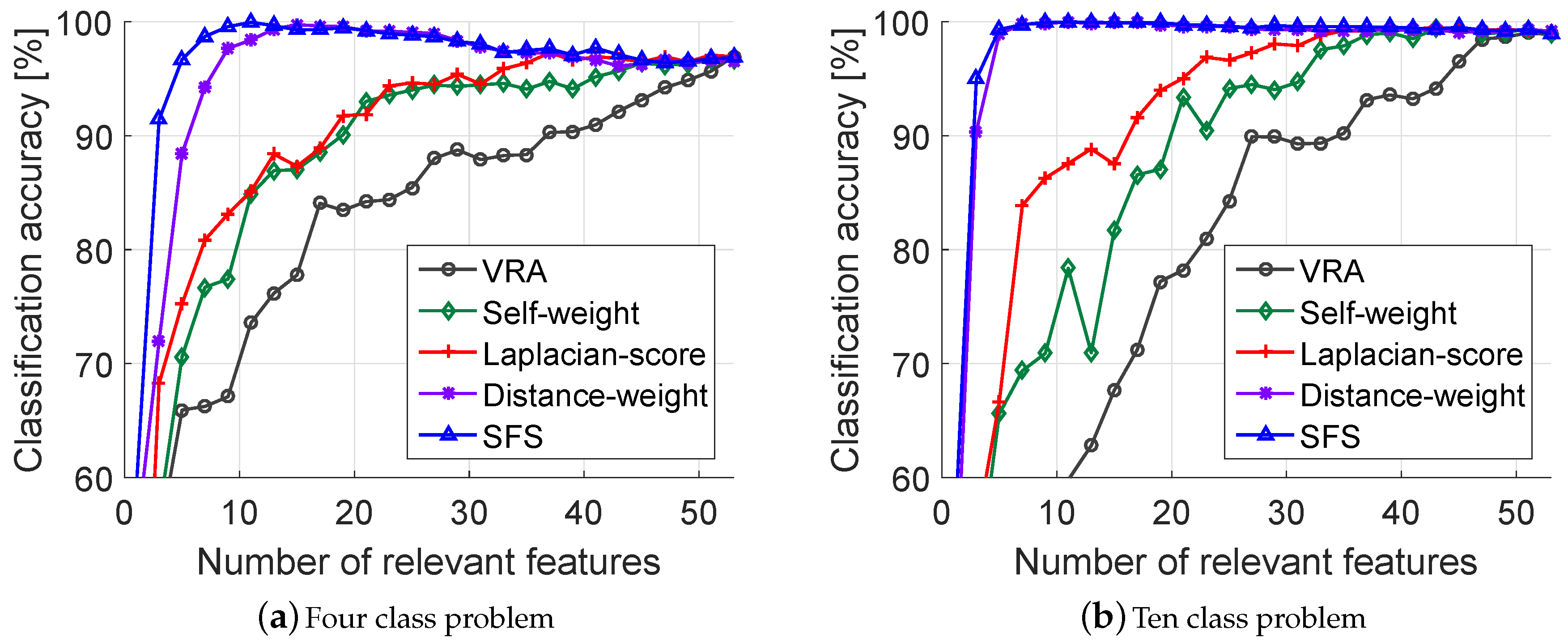

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Heng, A.; Zhang, S.; Tan, A.C.; Mathew, J. Rotating machinery prognostics: State of the art, challenges and opportunities. Mech. Syst. Signal Process. 2009, 23, 724–739. [Google Scholar] [CrossRef]

- Thorsen, O.V.; Dalva, M. A survey of faults on induction motors in offshore oil industry, petrochemical industry, gas terminals, and oil refineries. IEEE Trans. Ind. Appl. 1995, 31, 1186–1196. [Google Scholar] [CrossRef]

- Martinez-Rego, D.; Fontenla-Romero, O.; Alonso-Betanzos, A.; Principe, J.C. Fault detection via recurrence time statistics and one-class classification. Pattern Recognit. Lett. 2016, 84, 8–14. [Google Scholar] [CrossRef]

- Zhu, Y.; Gao, Z. Robust observer-based fault detection via evolutionary optimization with applications to wind turbine systems. In Proceedings of the 2014 IEEE 9th Conference on Industrial Electronics and Applications (ICIEA), Hangzhou, China, 9–11 June 2014; pp. 1627–1632. [Google Scholar]

- Gao, Z.; Cecati, C.; Ding, S.X. A survey of fault diagnosis and fault tolerant techniques Part I: Fault diagnosis with model-based and signal-based approaches. IEEE Trans. Ind. Electron. 2015, 62, 3757–3767. [Google Scholar] [CrossRef]

- Imani, M.; Braga-Neto, U.M. Optimal finite-horizon sensor selection for Boolean Kalman Filter. In Proceedings of the 2017 51st Asilomar Conference on Signals, Systems, and Computers, Pacific Grove, CA, USA, 29 October–1 November 2017; pp. 1481–1485. [Google Scholar]

- Shatnawi, Y.; Al-Khassaweneh, M. Fault diagnosis in internal combustion engines using extension neural network. IEEE Trans. Ind. Electron. 2014, 61, 1434–1443. [Google Scholar] [CrossRef]

- Lei, Y.; He, Z.; Zi, Y. Application of the EEMD method to rotor fault diagnosis of rotating machinery. Mech. Syst. Signal Process. 2009, 23, 1327–1338. [Google Scholar] [CrossRef]

- Baydar, N.; Ball, A. Detection of gear failures via vibration and acoustic signals using wavelet transform. Mech. Syst. Signal Process. 2003, 17, 787–804. [Google Scholar] [CrossRef]

- Jena, D.; Panigrahi, S. Automatic gear and bearing fault localization using vibration and acoustic signals. Appl. Acoust. 2015, 98, 20–33. [Google Scholar] [CrossRef]

- Holguín-Londoño, M.; Cardona-Morales, O.; Sierra-Alonso, E.F.; Mejia-Henao, J.D.; Orozco-Gutiérrez, Á.; Castellanos-Dominguez, G. Machine Fault Detection Based on Filter Bank Similarity Features Using Acoustic and Vibration Analysis. Math. Probl. Eng. 2016, 2016. [Google Scholar] [CrossRef]

- Janjarasjitt, S.; Ocak, H.; Loparo, K. Bearing condition diagnosis and prognosis using applied nonlinear dynamical analysis of machine vibration signal. J. Sound Vib. 2008, 317, 112–126. [Google Scholar] [CrossRef]

- Attoui, I.; Boutasseta, N.; Fergani, N.; Oudjani, B.; Deliou, A. Vibration-based bearing fault diagnosis by an integrated DWT-FFT approach and an adaptive neuro-fuzzy inference system. In Proceedings of the 2015 3rd International Conference on Control, Engineering & Information Technology (CEIT), Tlemcen, Algeria, 25–27 May 2015; pp. 1–6. [Google Scholar]

- Wang, Y.; Wei, Z.; Yang, J. Feature Trend Extraction and Adaptive Density Peaks Search for Intelligent Fault Diagnosis of Machines. IEEE Trans. Ind. Inform. 2019, 15, 105–115. [Google Scholar] [CrossRef]

- Jardine, A.K.; Lin, D.; Banjevic, D. A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mech. Syst. Signal Process. 2006, 20, 1483–1510. [Google Scholar] [CrossRef]

- Grądzki, R.; Kulesza, Z.; Bartoszewicz, B. Method of shaft crack detection based on squared gain of vibration amplitude. Nonlinear Dyn. 2019, 98, 671–690. [Google Scholar] [CrossRef]

- Lang, X.; Pennacchi, P.; Chatterton, S. A new method for the estimation of bearing health state and remaining useful life based on the moving average cross-correlation of power spectral density. Mech. Syst. Signal Process. 2020, 139, 106617. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, X.; He, Z.; Shen, Z. LMD method and multi-class RWSVM of fault diagnosis for rotating machinery using condition monitoring information. Sensors 2013, 13, 8679–8694. [Google Scholar] [CrossRef]

- Zaidi, S.S.H.; Aviyente, S.; Salman, M.; Shin, K.K.; Strangas, E.G. Prognosis of gear failures in dc starter motors using hidden Markov models. IEEE Trans. Ind. Electron. 2011, 58, 1695–1706. [Google Scholar] [CrossRef]

- Yan, R.; Liu, Y.; Gao, R.X. Permutation entropy: A nonlinear statistical measure for status characterization of rotary machines. Mech. Syst. Signal Process. 2012, 29, 474–484. [Google Scholar] [CrossRef]

- Zhang, L.; Xiong, G.; Liu, H.; Zou, H.; Guo, W. Bearing fault diagnosis using multi-scale entropy and adaptive neuro-fuzzy inference. Expert Syst. Appl. 2010, 37, 6077–6085. [Google Scholar] [CrossRef]

- Tiwari, R.; Gupta, V.K.; Kankar, P. Bearing fault diagnosis based on multi-scale permutation entropy and adaptive neuro fuzzy classifier. J. Vib. Control 2015, 21, 461–467. [Google Scholar] [CrossRef]

- Bandt, C.; Pompe, B. Permutation entropy: A natural complexity measure for time series. Phys. Rev. Lett. 2002, 88, 174102. [Google Scholar] [CrossRef]

- Aziz, W.; Arif, M. Multiscale permutation entropy of physiological time series. In Proceedings of the 9th International Multitopic Conference, Karachi, Pakistan, 23–25 December 2005; pp. 1–6. [Google Scholar]

- Zheng, J.; Pan, H.; Yang, S.; Cheng, J. Generalized composite multiscale permutation entropy and Laplacian score based rolling bearing fault diagnosis. Mech. Syst. Signal Process. 2018, 99, 229–243. [Google Scholar] [CrossRef]

- He, C.; Wu, T.; Liu, C.; Chen, T. A novel method of composite multiscale weighted permutation entropy and machine learning for fault complex system fault diagnosis. Measurement 2020, 158, 107748. [Google Scholar] [CrossRef]

- Zhang, X.; Liang, Y.; Zhou, J.; Zang, Y. A novel bearing fault diagnosis model integrated permutation entropy, ensemble empirical mode decomposition and optimized SVM. Measurement 2015, 69, 164–179. [Google Scholar] [CrossRef]

- Khamoudj, C.E.; Benbouzid-Si Tayeb, F.; Benatchba, K.; Benbouzid, M.; Djaafri, A. A Learning Variable Neighborhood Search Approach for Induction Machines Bearing Failures Detection and Diagnosis. Energies 2020, 13, 2953. [Google Scholar] [CrossRef]

- Imani, M.; Ghoreishi, S.F. Bayesian Optimization Objective-Based Experimental Design. In Proceedings of the 2020 American Control Conference (ACC 2020), Denver, CO, USA, 1–3 July 2020. [Google Scholar]

- Ghoreishi, S.F.; Imani, M. Bayesian Optimization for Efficient Design of Uncertain Coupled Multidisciplinary Systems. In Proceedings of the 2020 American Control Conference (ACC 2020), Denver, CO, USA, 1–3 July 2020. [Google Scholar]

- Zhou, H.; Chen, J.; Dong, G.; Wang, R. Detection and diagnosis of bearing faults using shift-invariant dictionary learning and hidden Markov model. Mech. Syst. Signal Process. 2016, 72, 65–79. [Google Scholar] [CrossRef]

- Shao, H.; Jiang, H.; Lin, Y.; Li, X. A novel method for intelligent fault diagnosis of rolling bearings using ensemble deep auto-encoders. Mech. Syst. Signal Process. 2018, 102, 278–297. [Google Scholar] [CrossRef]

- Haidong, S.; Hongkai, J.; Xingqiu, L.; Shuaipeng, W. Intelligent fault diagnosis of rolling bearing using deep wavelet auto-encoder with extreme learning machine. Knowl.-Based Syst. 2018, 140, 1–14. [Google Scholar] [CrossRef]

- Hoang, D.T.; Kang, H.J. Rolling element bearing fault diagnosis using convolutional neural network and vibration image. Cogn. Syst. Res. 2019, 53, 42–50. [Google Scholar] [CrossRef]

- Wang, Y.; Ning, D.; Feng, S. A Novel Capsule Network Based on Wide Convolution and Multi-Scale Convolution for Fault Diagnosis. Appl. Sci. 2020, 10. [Google Scholar] [CrossRef]

- Shen, C.; Xie, J.; Wang, D.; Jiang, X.; Shi, J.; Zhu, Z. Improved hierarchical adaptive deep belief network for bearing fault diagnosis. Appl. Sci. 2019, 9, 3374. [Google Scholar] [CrossRef]

- Li, J.; Li, X.; He, D.; Qu, Y. Unsupervised rotating machinery fault diagnosis method based on integrated SAE–DBN and a binary processor. J. Intell. Manuf. 2020, 1–18. [Google Scholar] [CrossRef]

- Tao, H.; Wang, P.; Chen, Y.; Stojanovic, V.; Yang, H. An unsupervised fault diagnosis method for rolling bearing using STFT and generative neural networks. J. Frankl. Inst. 2020. [Google Scholar] [CrossRef]

- Wang, S.; Xiang, J.; Zhong, Y.; Zhou, Y. Convolutional neural network-based hidden Markov models for rolling element bearing fault identification. Knowl. -Based Syst. 2018, 144, 65–76. [Google Scholar] [CrossRef]

- Cococcioni, M.; Lazzerini, B.; Volpi, S.L. Robust diagnosis of rolling element bearings based on classification techniques. IEEE Trans. Ind. Inform. 2013, 9, 2256–2263. [Google Scholar] [CrossRef]

- Prieto, M.D.; Cirrincione, G.; Espinosa, A.G.; Ortega, J.A.; Henao, H. Bearing fault detection by a novel condition-monitoring scheme based on statistical-time features and neural networks. IEEE Trans. Ind. Electron. 2013, 60, 3398–3407. [Google Scholar] [CrossRef]

- Malhi, A.; Gao, R.X. PCA-based feature selection scheme for machine defect classification. IEEE Trans. Instrum. Meas. 2004, 53, 1517–1525. [Google Scholar] [CrossRef]

- Shao, R.; Hu, W.; Wang, Y.; Qi, X. The fault feature extraction and classification of gear using principal component analysis and kernel principal component analysis based on the wavelet packet transform. Measurement 2014, 54, 118–132. [Google Scholar] [CrossRef]

- Liang, L.; Liu, F.; Li, M.; He, K.; Xu, G. Feature selection for machine fault diagnosis using clustering of non-negation matrix factorization. Measurement 2016, 94, 295–305. [Google Scholar] [CrossRef]

- Wei, Z.; Wang, Y.; He, S.; Bao, J. A novel intelligent method for bearing fault diagnosis based on affinity propagation clustering and adaptive feature selection. Knowl. -Based Syst. 2017, 116, 1–12. [Google Scholar] [CrossRef]

- Van, M.; Kang, H.J. Bearing-fault diagnosis using non-local means algorithm and empirical mode decomposition-based feature extraction and two-stage feature selection. IET Sci. Meas. Technol. 2015, 9, 671–680. [Google Scholar] [CrossRef]

- Brkovic, A.; Gajic, D.; Gligorijevic, J.; Savic-Gajic, I.; Georgieva, O.; Di Gennaro, S. Early fault detection and diagnosis in bearings for more efficient operation of rotating machinery. Energy 2016, 136, 63–71. [Google Scholar] [CrossRef]

- Patel, S.P.; Upadhyay, S. Euclidean distance based feature ranking and subset selection for bearing fault diagnosis. Expert Syst. Appl. 2020, 154, 113400. [Google Scholar] [CrossRef]

- Yan, X.; Jian, M. Intelligent fault diagnosis of rotating machinery using improved multiscale dispersion entropy and mRMR feature selectionn. Knowl.-Based Syst. 2019, 163, 450–471. [Google Scholar] [CrossRef]

- Hotait, H.; Chiementin, X.; Rasolofondraibe, L. AOC-OPTICS: Automatic Online Classification for Condition Monitoring of Rolling Bearing. Processes 2020, 8, 606. [Google Scholar] [CrossRef]

- Hernández-Muriel, J.A.; Álvarez-Meza, A.M.; Echeverry-Correa, J.D.; Orozco-Gutierrez, Á.Á.; Álvarez-López, M.A. Feature relevance estimation for vibration-based condition monitoring of an internal combustion engine. Tecno Lógicas 2017, 20, 159–174. [Google Scholar] [CrossRef]

- Li, C.; de Oliveira, J.V.; Cerrada, M.; Pacheco, F.; Cabrera, D.; Sanchez, V.; Zurita, G. Observer-biased bearing condition monitoring: From fault detection to multi-fault classification. Eng. Appl. Artif. Intell. 2016, 50, 287–301. [Google Scholar] [CrossRef]

- Chen, Y.; Pei, X.; Nie, S.; Kang, Y. Monitoring and diagnosis for the DC–DC converter using the magnetic near field waveform. IEEE Trans. Ind. Electron. 2011, 58, 1634–1647. [Google Scholar] [CrossRef]

- Nelwamondo, F.V.; Marwala, T. Faults detection using gaussian mixture models, mel-frequency cepstral coefficients and kurtosis. In Proceedings of the IEEE International Conference on Systems, Man and Cybernetics, Taipei, Taiwan, 8–11 October 2006; Volume 1, pp. 290–295. [Google Scholar]

- Sahidullah, M.; Saha, G. Design, analysis and experimental evaluation of block based transformation in MFCC computation for speaker recognition. Speech Commun. 2012, 54, 543–565. [Google Scholar] [CrossRef]

- Kononenko, I. Estimating attributes: Analysis and extensions of RELIEF. In Proceedings of the European Conference on Machine Learning, Catania, Italy, 6–8 April 1994; pp. 171–182. [Google Scholar]

- Robnik-Šikonja, M.; Kononenko, I. Theoretical and empirical analysis of ReliefF and RReliefF. Mach. Learn. 2003, 53, 23–69. [Google Scholar] [CrossRef]

- Cappé, O.; Moulines, E.; Rydén, T. Inference in hidden markov models. In Proceedings of the EUSFLAT Conference, Lisbon, Portugal, 20–24 July 2009; pp. 14–16. [Google Scholar]

- Yuwono, M.; Qin, Y.; Zhou, J.; Guo, Y.; Celler, B.G.; Su, S.W. Automatic bearing fault diagnosis using particle swarm clustering and Hidden Markov Model. Eng. Appl. Artif. Intell. 2016, 47, 88–100. [Google Scholar] [CrossRef]

- Murphy, K. Hidden Markov Model (hmm) Toolbox for Matlab. Available online: https://www.cs.ubc.ca/~murphyk/Software/HMM/hmm.html (accessed on 7 July 2020).

- Urbanowicz, R.J.; Meeker, M.; La Cava, W.; Olson, R.S.; Moore, J.H. Relief-based feature selection: Introduction and review. J. Biomed. Inform. 2018, 85, 189–203. [Google Scholar] [CrossRef] [PubMed]

- Khreich, W.; Granger, E.; Miri, A.; Sabourin, R. On the memory complexity of the forward–backward algorithm. Pattern Recognit. Lett. 2010, 31, 91–99. [Google Scholar] [CrossRef]

- Loparo, K.A. Bearing Data Center; Case Western Reserve University: Cleveland, OH, USA, 2003. [Google Scholar]

- Smith, W.A.; Randall, R.B. Rolling element bearing diagnostics using the Case Western Reserve University data: A benchmark study. Mech. Syst. Signal Process. 2015, 64, 100–131. [Google Scholar] [CrossRef]

- Nayana, B.; Geethanjali, P. Analysis of Statistical Time-Domain Features Effectiveness in Identification of Bearing Faults from Vibration Signal. IEEE Sens. J. 2017, 17, 5618–5625. [Google Scholar] [CrossRef]

- Ocak, H.; Loparo, K.A. Estimation of the running speed and bearing defect frequencies of an induction motor from vibration data. Mech. Syst. Signal Process. 2004, 18, 515–533. [Google Scholar] [CrossRef]

- Niebles, J.C.; Wang, H.; Fei-Fei, L. Unsupervised learning of human action categories using spatial-temporal words. Int. J. Comput. Vis. 2008, 79, 299–318. [Google Scholar] [CrossRef]

- Daza-Santacoloma, G.; Arias-Londono, J.D.; Godino-Llorente, J.I.; Sáenz-Lechón, N.; Osma-Ruíz, V.; Castellanos-Dominguez, G. Dynamic feature extraction: An application to voice pathology detection. Intell. Autom. Soft Comput. 2009, 15, 667–682. [Google Scholar]

- Yang, B.S.; Han, T.; An, J.L. ART–KOHONEN neural network for fault diagnosis of rotating machinery. Mech. Syst. Signal Process. 2004, 18, 645–657. [Google Scholar] [CrossRef]

- Alvarez Meza, A. Orozco-Gutierrez, G.C.D. Kernel-based relevance analysis with enhanced interpretability for detection of brain activity patterns. Front. Neurosci. 2017, 11, 550–564. [Google Scholar] [CrossRef]

- Jian, X.; Li, W.; Guo, X.; Wang, R. Fault Diagnosis of Motor Bearings Based on a One-Dimensional Fusion Neural Networkk. Sensors 2019, 19, 122. [Google Scholar] [CrossRef]

- William, P.E.; Hoffman, M.W. Identification of bearing faults using time domain zero-crossings. Mech. Syst. Signal Process. 2011, 25, 3078–3088. [Google Scholar] [CrossRef]

- Liu, Z.; Cao, H.; Chen, X.; He, Z.; Shen, Z. Multi-fault classification based on wavelet SVM with PSO algorithm to analyze vibration signals from rolling element bearings. Neurocomputing 2013, 99, 399–410. [Google Scholar] [CrossRef]

- Muruganatham, B.; Sanjith, M.; Krishnakumar, B.; Murty, S.S. Roller element bearing fault diagnosis using singular spectrum analysis. Mech. Syst. Signal Process. 2013, 35, 150–166. [Google Scholar] [CrossRef]

- Shen, C.; Wang, D.; Kong, F.; Peter, W.T. Fault diagnosis of rotating machinery based on the statistical parameters of wavelet packet paving and a generic support vector regressive classifier. Measurement 2013, 46, 1551–1564. [Google Scholar] [CrossRef]

- Berredjem, T.; Benidir, M. Bearing faults diagnosis using fuzzy expert system relying on an Improved Range Overlaps and Similarity method. Expert Syst. Appl. 2018, 108, 134–142. [Google Scholar] [CrossRef]

- Ocak, H.; Loparo, K.A. HMM-based fault detection and diagnosis scheme for rolling element bearings. J. Vib. Acoust. 2005, 127, 299–306. [Google Scholar] [CrossRef]

| Parameter | Estimation | Parameter | Estimation |

|---|---|---|---|

| Mean () | Skewness | ||

| Median | Max value | ||

| Standard deviation | Min value | ||

| Root mean square | Range | ||

| Peak () | Interquartile range | ||

| Shape factor | Kurtosis () | ||

| Crest factor | Speed kurtosis | ||

| Impulse factor | Acceleration kurtosis | ||

| Clearance factor | Acceleration kurtosis derivative |

| Parameter | Estimation | Parameter | Estimation |

|---|---|---|---|

| Mean frequency () | Standard deviation frequency | ||

| Central frequency () | Kurtosis | ||

| Root mean square frequency |

| C = 4 Problem | C = 10 Problem | ||||||

|---|---|---|---|---|---|---|---|

| Id | Bearing State | Id | Bearing State | Fault Diameter | Id | Bearing State | Fault Diameter |

| N | Normal | N | Normal | - | IR2 | Fault in inner race | 0.014″ |

| B | Fault in rolling element | B1 | Fault in rolling element | 0.007″ | IR3 | Fault in inner race | 0.021″ |

| IR | Fault in inner race | B2 | Fault in rolling element | 0.014″ | OR1 | Fault in outer race | 0.007″ |

| OR | Fault in outer race | B3 | Fault in rolling element | 0.021″ | OR2 | Fault in outer race | 0.014″ |

| IR1 | Fault in inner race | 0.007″ | OR3 | Fault in outer race | 0.021″ | ||

| Method | # Feat. | Best Acc. (%) | Best # Feat. | Acc (%) |

|---|---|---|---|---|

| No feature selection | 53 | - | - | |

| VRA | 53 | 51 | ||

| Self-weight | 53 | 41 | ||

| Laplacian Score | 37 | 33 | ||

| Distance-weight | 15 | 13 | ||

| SFS | 11 | 9 |

| Method | # Feat. | Best Acc. (%) | Best # Feat. | Acc (%) |

|---|---|---|---|---|

| No feature selection | 53 | - | - | |

| VRA | 51 | 47 | ||

| Self-weight | 43 | 37 | ||

| Laplacian Score | 43 | 33 | ||

| Distance-weight | 11 | 7 | ||

| SFS | 11 | 7 |

| Reference | (kHz) | Number of Classes | Labels | Feature Extraction | Feature Selection | Number of Features | Classifier | Accuracy (%) |

|---|---|---|---|---|---|---|---|---|

| William and Hoffman [72] | 12 | 4 | ZC | - | 10 | ANN | 97.13 | |

| Muruganatham et al. [74] | 12 | 4 | SSA | - | 10 | ANN | 96.53 | |

| Tiwari et al. [22] | 48 | 4 | MPE | - | 16 | ANFC | 97.50 | |

| Zhang et al. [27] | 12 | 4 | PE+EEMD | - | 12 | SVM+ICD | 97.75 | |

| Ocak and Loparo [77] | 12 | 3 | LPM | - | 30 | HMM | 99.67 | |

| Yuwono et al. [59] | 12 | 3 | WT+CL | - | 12 | HMM+SRCE | 95.08 | |

| Muruganatham et al. [74] | 12 | 4 | SSA | SV | 4 | ANN | 95.14 | |

| Shen et al. [75] | 12 | 4 | WPT+SP | DET | 30 | SVR | 100.00 | |

| Shen et al. [75] | 12 | 4 | WPT+SP | DET | 30 | SVR | 100.00 | |

| Van et al. [46] | - | 7 | TD+SP, FD+SP, EMD+SP | DET+PSO-KNN | 20 | KNN | 98.58 | |

| Van et al. [46] | - | 7 | TD+SP, FD+SP, EMD+SP | DET+PSO-KNN | 5 | PNN | 97.24 | |

| Van et al. [46] | - | 7 | TD+SP, FD+SP, EMD+SP | DET+PSO-KNN | 6 | SVM | 97.71 | |

| Brkovic et al. [47] | 12 | 4 | WT+SP | SM | 12 | QC | 100.00 | |

| Liang et al. [44] | 48 | 4 | TD+SP, FD+SP | NMF+ALS+SCD | 3 | KNN | 92.86 | |

| Zheng et al. [25] | 12 | 6 | GCMPE | LS | 2 | PSO-SVM | 98.89 | |

| Jian et al. [71] | 12 | 10 | ACNN-W | - | 10 | ACNN-W | 98.66 | |

| Toufik et al. [76] | 12 | 6 | FES | IRO | 11 | MMV | 96.08 | |

| SFS (our work) | 48 | 4 | TD+SP, FD+SP, TFD+SP | Relief-F | 9 | HMM | 99.56 | |

| SFS (our work) | 48 | 10 | TD+SP, FD+SP, TFD+SP | Relief-F | 7 | HMM | 99.74 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernández-Muriel, J.A.; Bermeo-Ulloa, J.B.; Holguin-Londoño, M.; Álvarez-Meza, A.M.; Orozco-Gutiérrez, Á.A. Bearing Health Monitoring Using Relief-F-Based Feature Relevance Analysis and HMM. Appl. Sci. 2020, 10, 5170. https://doi.org/10.3390/app10155170

Hernández-Muriel JA, Bermeo-Ulloa JB, Holguin-Londoño M, Álvarez-Meza AM, Orozco-Gutiérrez ÁA. Bearing Health Monitoring Using Relief-F-Based Feature Relevance Analysis and HMM. Applied Sciences. 2020; 10(15):5170. https://doi.org/10.3390/app10155170

Chicago/Turabian StyleHernández-Muriel, José Alberto, Jhon Bryan Bermeo-Ulloa, Mauricio Holguin-Londoño, Andrés Marino Álvarez-Meza, and Álvaro Angel Orozco-Gutiérrez. 2020. "Bearing Health Monitoring Using Relief-F-Based Feature Relevance Analysis and HMM" Applied Sciences 10, no. 15: 5170. https://doi.org/10.3390/app10155170

APA StyleHernández-Muriel, J. A., Bermeo-Ulloa, J. B., Holguin-Londoño, M., Álvarez-Meza, A. M., & Orozco-Gutiérrez, Á. A. (2020). Bearing Health Monitoring Using Relief-F-Based Feature Relevance Analysis and HMM. Applied Sciences, 10(15), 5170. https://doi.org/10.3390/app10155170