Optimized Scheme for Accelerating the Slagging Reaction and Slag–Metal–Gas Emulsification in a Basic Oxygen Furnace

Abstract

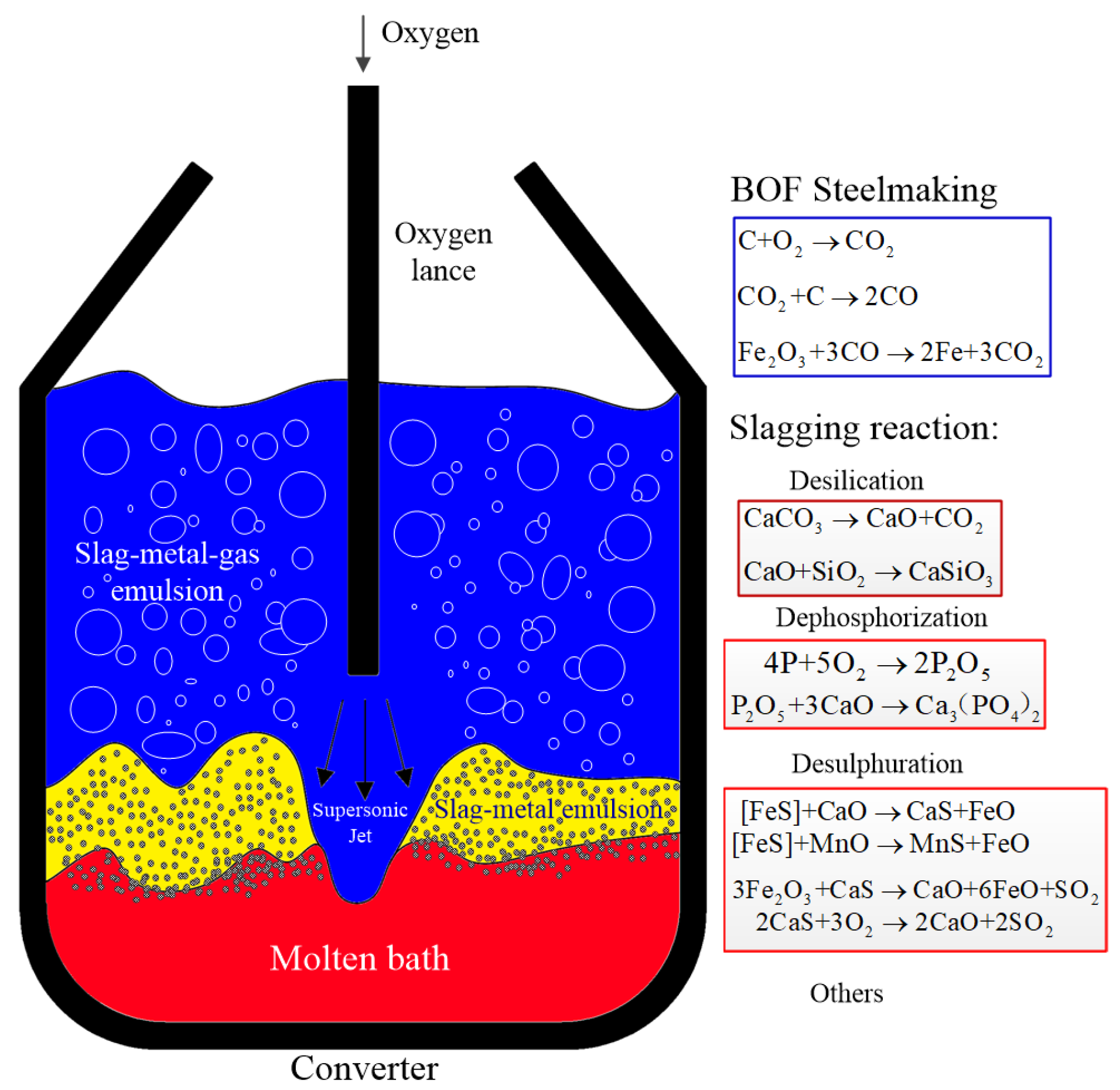

1. Introduction

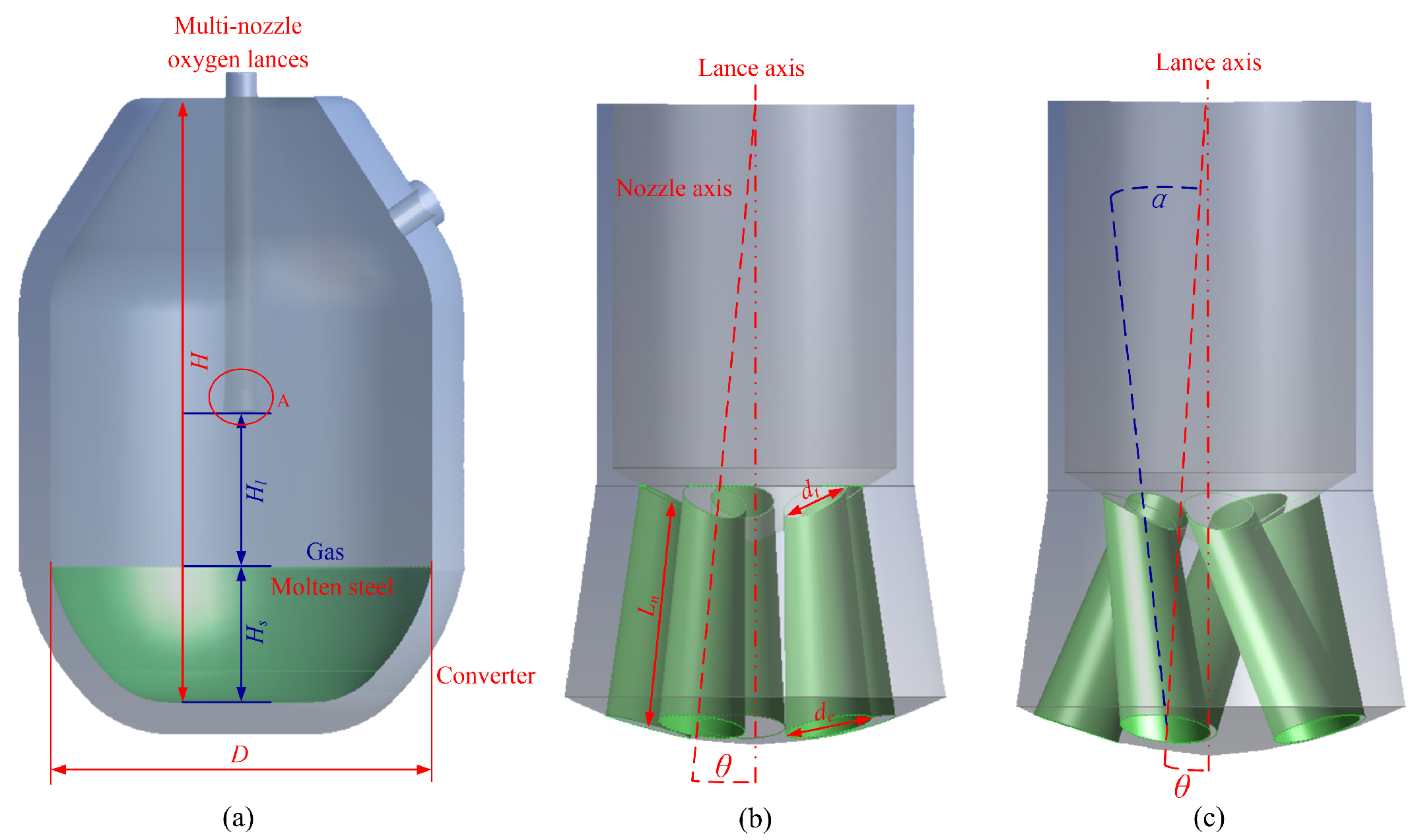

2. Oxygen Blow and Stirring Dynamics Model

2.1. Numerical Model of BOF Process

2.2. Governing Equation and Turbulence Model

2.3. Multiphase Flow Coupling Model

2.4. Solution Methods and Boundary Conditions

2.5. Grid-Independence Test

3. Numerical Calculation and Discussion

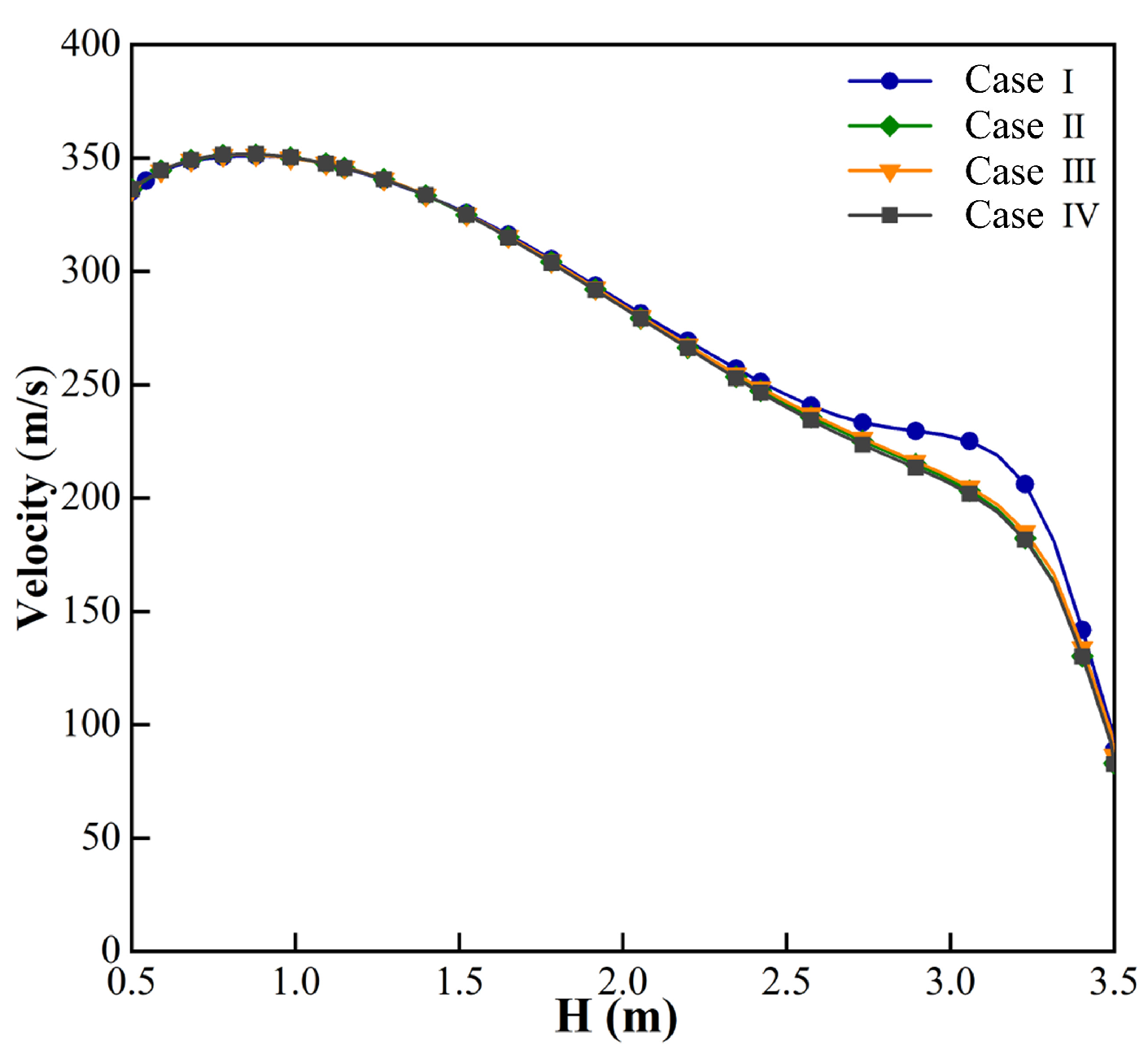

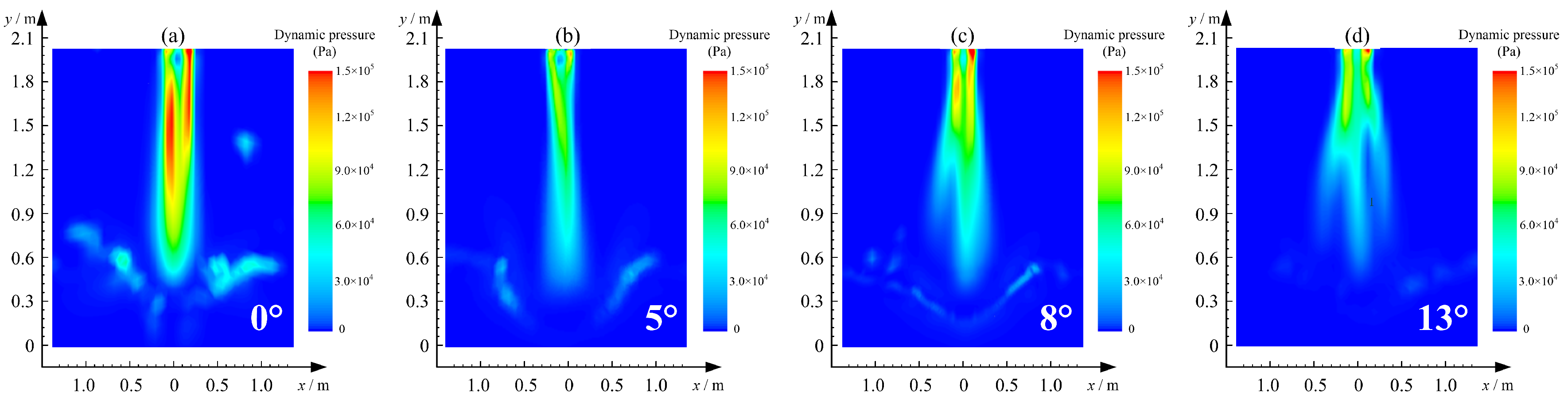

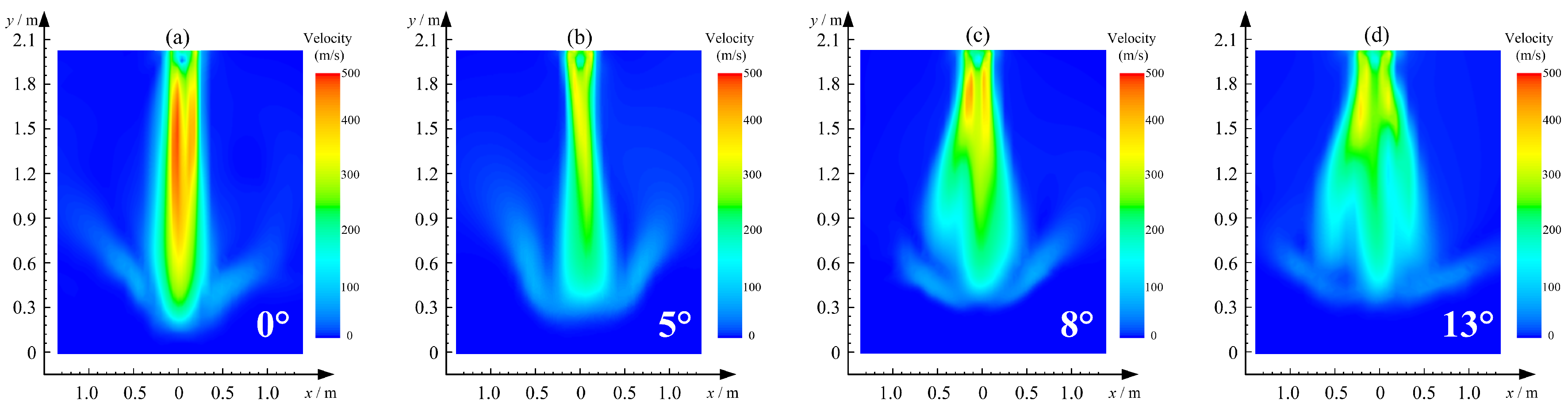

3.1. Analysis of Supersonic Coherent Jets with Multi-Nozzle Oxygen Lance

- The dynamic pressure and velocity of the conventional oxygen lance are the largest, and the impact depth is considerable. However, most of the kinetic energy is lost at the two-phase interface.

- The 5° nozzle-twisted lance exhibits good performance in both impact kinetic energy and swirl of the blow gas.

- The impact kinetic energy of the 8° oxygen lance is weak, whereas the tangential force of molten steel is remarkable, which is more likely to produce swirling.

- The greatest kinetic energy dissipation occurs in the 13° oxygen lance blowing processing, and the top-blowing effect is the worst. However, the tangential velocity component also increases correspondingly.

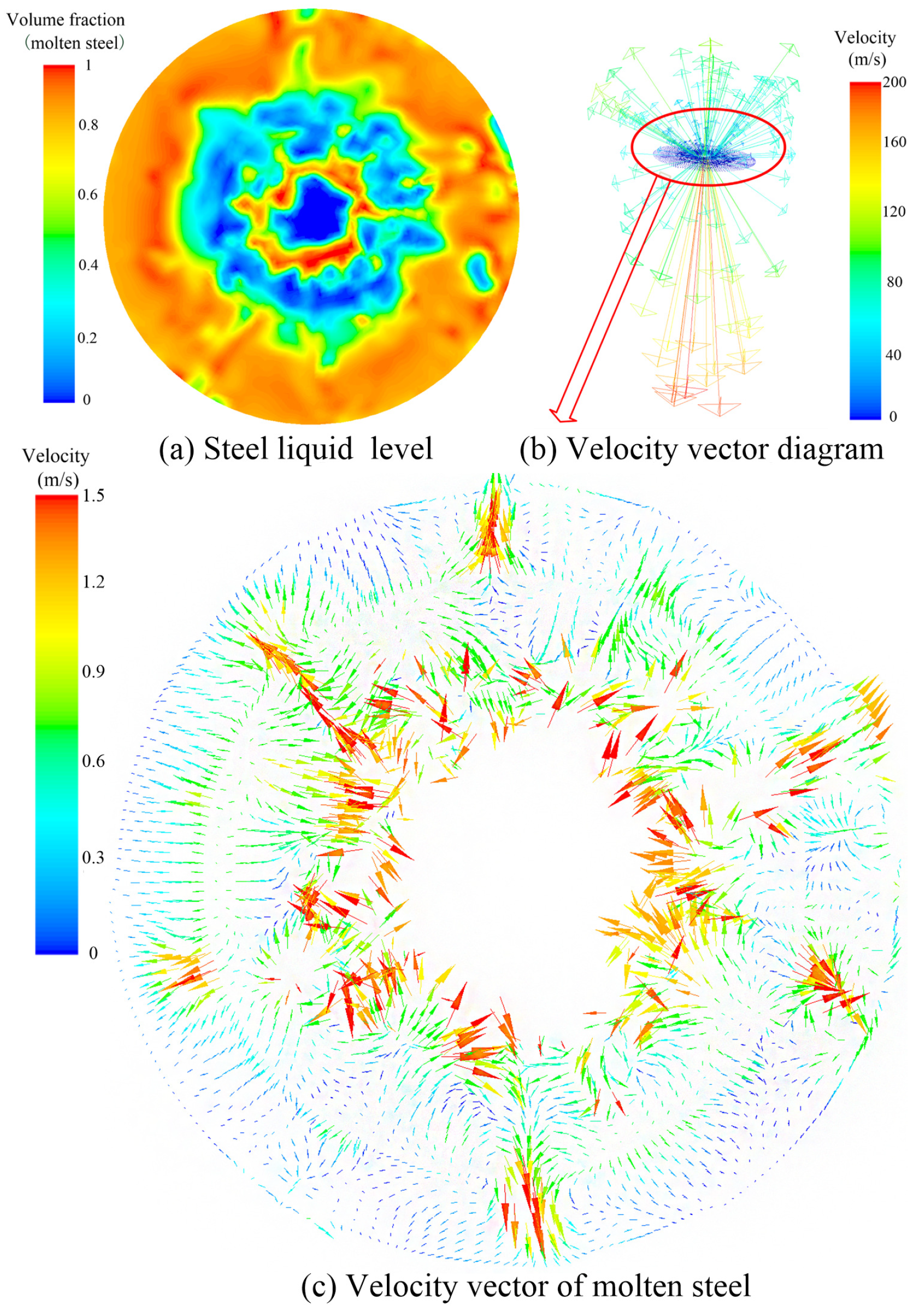

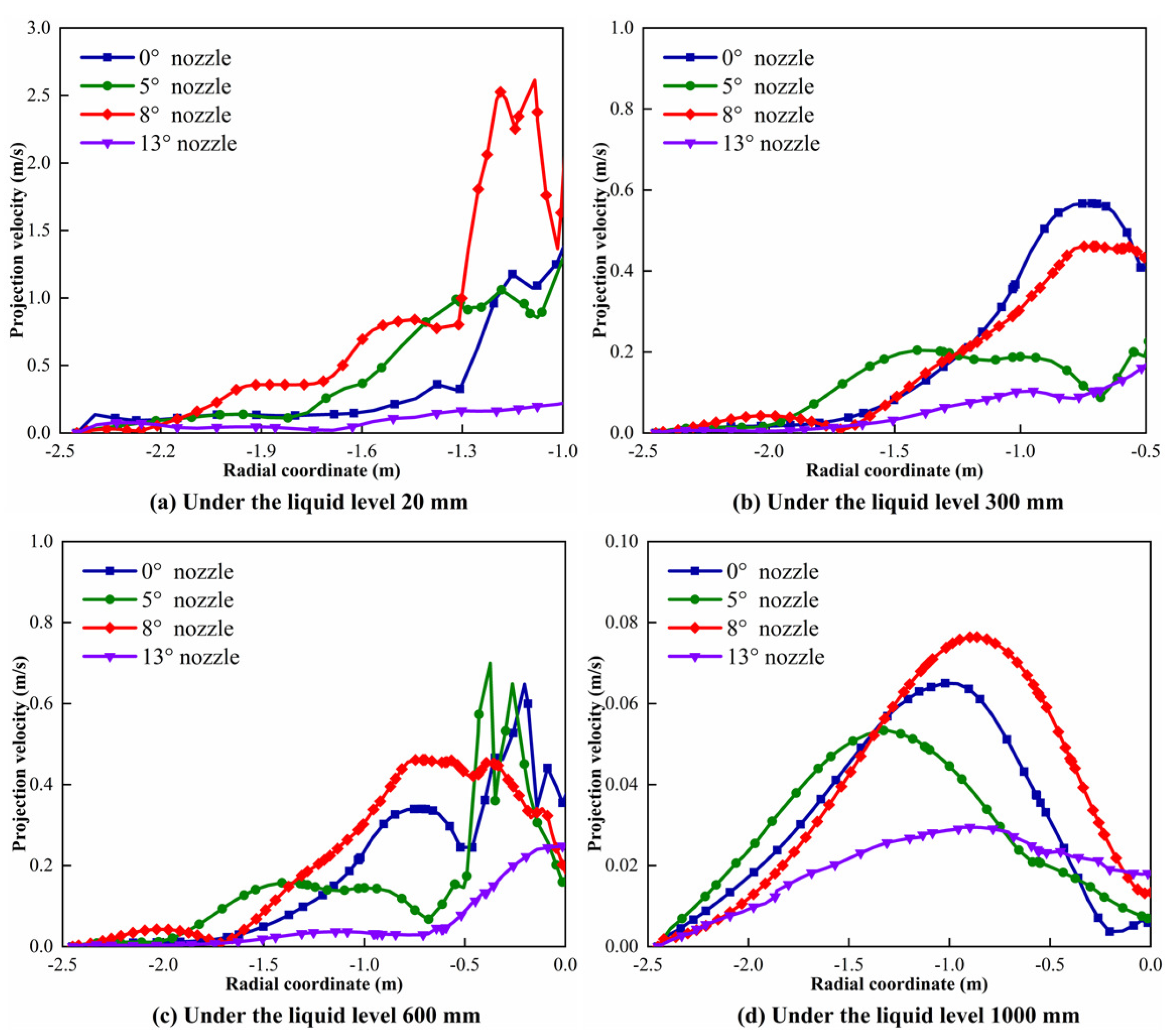

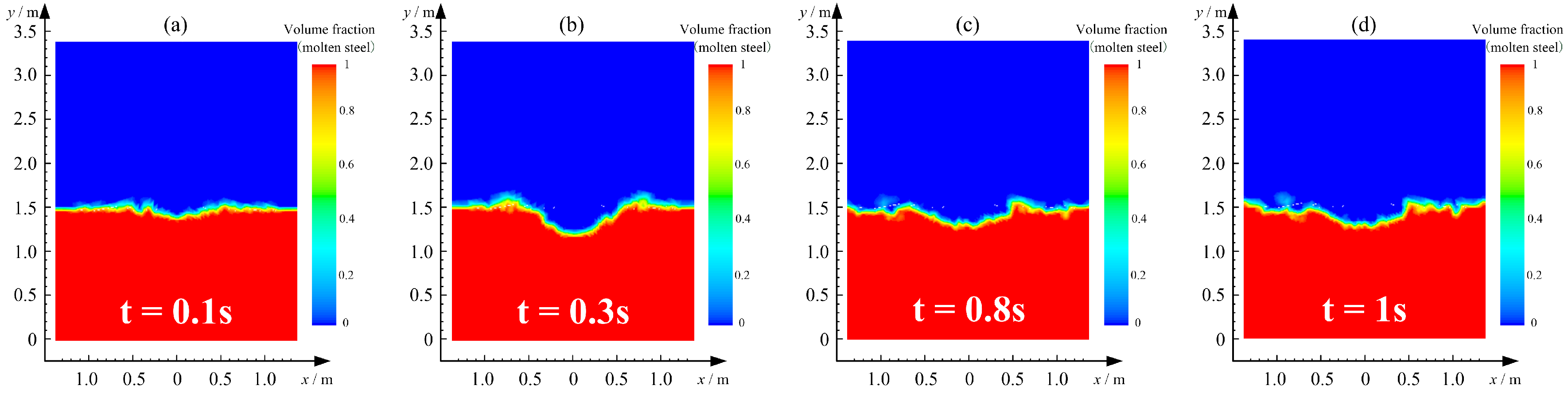

3.2. Analysis of Stirring Effects and Impact Characteristics in Molten Bath Flow

4. Control Strategy for Multi-Nozzle Oxygen Lances

5. Conclusions

- On the basis of the standard k-ω turbulence model and LSM, a fluid dynamics model for a BOF was set up and the four key factors (i.e., supersonic coherent jet behavior, stirring effect, energy transfer mechanism, slag–metal–gas emulsion) were obtained. The results show that the dynamic pressure and velocity of the conventional oxygen lance are the largest, and the impact depth is considerable. However, most of the kinetic energy is lost at the two-phase interface. In comparison, the coherent jet not only induces tangential velocity but also causes a decrease of the blown kinetic energy. Therefore, appropriate tangential velocity can improve the stirring effect and accelerate the slagging reaction. However, excessive cohesion will cause serious energy loss and cannot promote the slag–metal–gas emulsification.

- To confirm the optimal design scheme for the slagging reaction, the stirring effect of different NTA oxygen lances was investigated. The comparison indicated that the 5° nozzle has apparent advantages over the conventional oxygen lance at the liquid level, but the improvement in the whole molten bath is not obvious. The 8° oxygen lance has a substantial stirring effect, but the near-wall velocity was weak. The results suggested that a uniform slagging reaction was achieved when the 8° oxygen lance was used. Otherwise, the optimal design scheme can improve the energy transfer efficiency and reduce the spray of the molten bath.

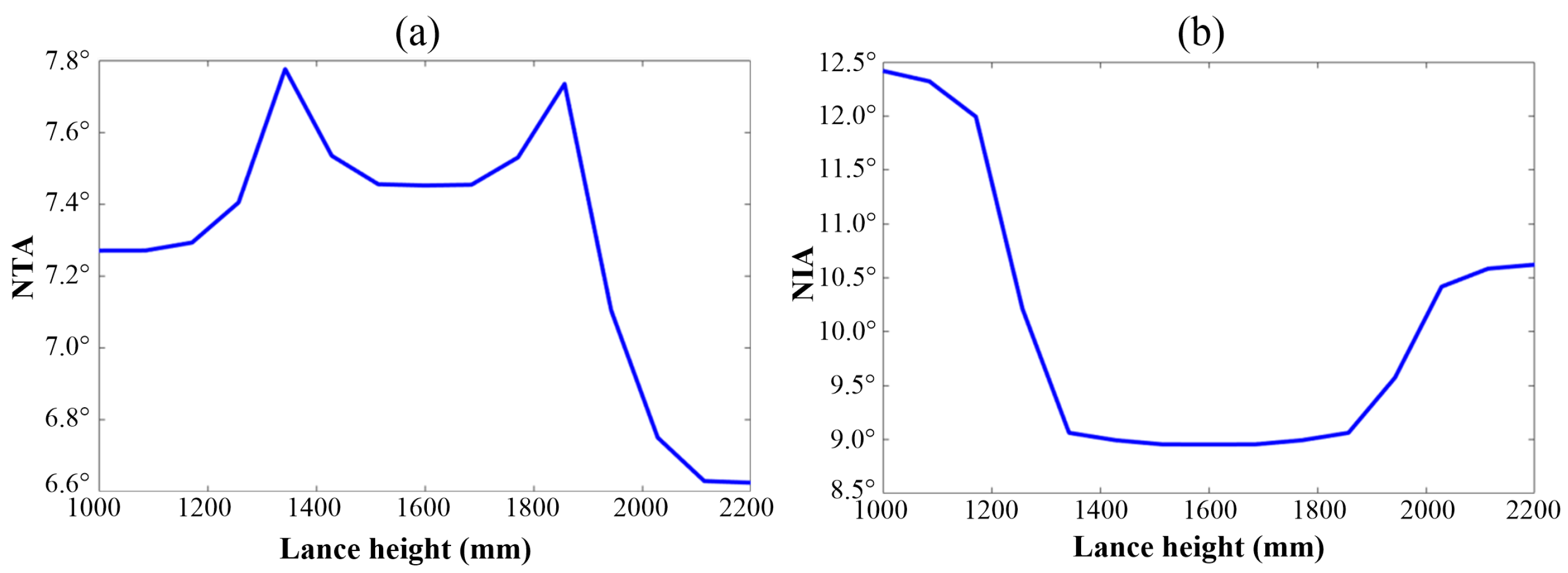

- With respect to lance height, the self-adjustment control strategy for a multi-nozzle oxygen lance was adopted. The predictions indicated that the optimal NTA was within the range from 7.2° to 7.8°, and the superior NIA distribution from 9.0° to 12.5°. When the lance is at a low height, the optimal NIA is inversely proportional to the lance height. Within the lance height range of 1400–1800 mm, the optimal NTA and NIA are relatively stable. With the continued increasing of lance height, the optimal NTA decreases. It is in good agreement with previous studies, theoretical analyses, and simulations. The results presented here can provide support for saving and refining energy, improving top-blowing efficiency, and accelerating slagging reactions.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| LSM | Level Set Method |

| CFD | Computational Fluid Dynamics |

| NTA | Nozzle Twist Angle |

| RANs | Reynolds Averaged Naiver–Stokes |

| FVM | Finite Volume Method |

| PRESTO | Pressure Staggering Option |

| CFL | Courant–Friedrichs–Lewy |

| NIA | Nozzle Inclination Angle |

| dt | Nozzle throat diameter |

| de | Nozzle exit diameter |

| Ln | Nozzle divergent length |

| Nozzle inclination angle | |

| Nozzle twist angle | |

| Hl | Oxygen lance height |

| Ma | Design Mach number |

| D | Steel converter diameter |

| H | Steel converter height |

| Hs | Steel liquid level |

| Generalized dependent variable | |

| Generalized source term | |

| u | Velocity vector |

| Generalized diffusion coefficient | |

| Eddy viscosity | |

| Sij | Mean-velocity strain-rate tensor |

| Kronecker delta | |

| k | Turbulence kinetic energy |

| Turbulence dissipation rate | |

| Fluid density | |

| l1 | The dispersed phase |

| l2 | The continuous phase |

| Boundary | |

| continuous dielectric surface | |

| Fluid density | |

| Virtual time | |

| d | Distance function |

| Modified value |

References

- Wei, G.S.; Zhu, R.; Cheng, T.; Dong, K.; Liu, R.Z. Modelling on the penetration depth of the coherent supersonic jet in EAF steelmaking. Ironmak. Steelmak. 2018, 45, 828–838. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, K.; Wang, R.F.; Liu, C.J.; Jiang, M.F. Physical Modelling of Splashing Triggered by the Gas Jet of an Oxygen Lance in a Converter. Metals 2019, 9, 409. [Google Scholar] [CrossRef]

- Pan, Y.; Ji, S.; Tan, D.; Cao, H. Cavitation based soft abrasive flow processing method. Int. J. Adv. Manuf. Technol. 2019, in press. [Google Scholar] [CrossRef]

- Cao, L.L.; Liu, Q.; Wang, Z.; Li, N. Interaction behaviour between top blown jet and molten steel during BOF steelmaking process. Ironmak. Steelmak. 2018, 45, 239–248. [Google Scholar] [CrossRef]

- Li, Z.L.; Cang, D.Q. Numerical Simulation of Supersonic Oxygen Jets at High Ambient Temperature. J. Iron Steel Res. Int. 2017, 88, 1600209. [Google Scholar] [CrossRef]

- Li, M.M.; Li, Q.; Kuang, S.B.; Zou, Z.S. Transferring Characteristics of Momentum/Energy during Oxygen Jetting into the Molten Bath in BOFs: A Computational Exploration. Steel Res. Int. 2016, 87, 288–300. [Google Scholar] [CrossRef]

- Sun, Y.H.; Liang, X.T.; Zeng, J.H.; Chen, J.; Chen, L. Numerical simulation and application of oxygen lance in 120t BOF of PANSTEEL. Ironmak. Steelmak. 2017, 44, 76–80. [Google Scholar] [CrossRef]

- Tan, D.P.; Yang, T.; Zhao, J. Free sink vortex Ekman suction-extraction evolution mechanism. Acta Phys. Sin. 2016, 65, 054701. [Google Scholar] [CrossRef]

- Kadrolkar, A.; Dogan, N. Model Development for Refining Rates in Oxygen Steelmaking: Impact and Slag-Metal Bulk Zones. Metals. 2019, 9, 309. [Google Scholar] [CrossRef]

- Higuchi, Y.; Tago, Y. Effect of nozzle twisted lance on jet behavior and spitting rate in top blown process. ISIJ Int. 2003, 43, 1410–1414. [Google Scholar] [CrossRef]

- Li, M.M.; Li, Q.; Zou, Z.S.; An, X.Z. Computational Investigation of Swirling Supersonic Jets Generated Through a Nozzle-Twisted Lance. Metall. Mater. Trans. B 2017, 48, 713–725. [Google Scholar] [CrossRef]

- Li, L.; Qi, H.; Yin, Z.C.; Li, D.F.; Zhu, Z.L.; Tangwarodomnukun, V.; Tan, D.P. Investigation on the multiphase sink vortex Ekman pumping effects by CFD-DEM coupling method. Powder Technol. 2019, 360, 462–480. [Google Scholar] [CrossRef]

- Liu, F.; Sun, D.; Zhu, R.; Zhao, F.; Ke, J. Effect of nozzle twisted oxygen lance on flow field and dephosphorisation rate in converter steelmaking process. Ironmak. Steelmak. 2017, 44, 640–648. [Google Scholar] [CrossRef]

- Tan, D.P.; Li, L.; Yin, Z.C.; Li, D.F.; Zhu, Y.L.; Zheng, S. Ekman boundary layer mass transfer mechanism of free sink vortex. Int. J. Heat Mass Transfer. 2020, 150, 119250. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Ni, P.C.; Wen, D.H.; Lin, Q.; Wang, D.J.; Ma, C.Q.; Rao, Y.J.; Wang, H.P.; Tan, D.P. Dynamic Performance Optimization of Circular Sawing Machine Gearbox. Appl. Sci. Basel. 2019, 9, 4458. [Google Scholar] [CrossRef]

- Chen, S.T.; Tan, D.P. A SA-ANN-Based Modeling Method for Human Cognition Mechanism and the PSACO Cognition Algorithm. Complexity 2018, 2018, 6264124. [Google Scholar] [CrossRef]

- Wang, J.X.; Cao, B.; Zheng, X.; Tan, D.P.; Fan, J. Detecting Difference Between Process Models Using Edge Network. IEEE Access 2019, 7, 142916–142925. [Google Scholar] [CrossRef]

- Cao, B.; Wang, J.X.; Fan, J.; Yin, J.W.; Dong, T.Y. Querying Similar Process Models Based on the Hungarian Algorithm. IEEE Trans. Serv. Comput. 2017, 10, 121–135. [Google Scholar] [CrossRef]

- Tan, D.P.; Li, L.; Zhu, Y.L.; Zheng, S.; Ruan, H.J.; Jiang, X.Y. An Embedded Cloud Database Service Method for Distributed Industry Monitoring. IEEE Trans. Ind. Inform. 2018, 14, 2881–2893. [Google Scholar] [CrossRef]

- Tong, Z.M.; Xin, J.G.; Tong, S.G.; Yang, Z.Q.; Zhao, J.Y.; Mao, J.H. Internal flow structure, fault detection, and performance optimization of centrifugal pumps. J. Zhejiang Univ. SCI A 2017, 24, 85–117. [Google Scholar] [CrossRef]

- Maia, B.T.; Imagawa, R.K.; Petrucelli, A.C.; Tavares, R.P. Effect of blow parameters in the jet penetration by physical model of BOF converter. J. Mater. Res. Technol. JMRT 2014, 3, 244–256. [Google Scholar] [CrossRef]

- Tan, D.P.; Li, L.; Zhu, Y.L.; Zheng, S.; Yin, Z.C.; Li, D.F. Critical penetration condition and Ekman suction-extraction mechanism of a sink vortex. J. Zhejiang Univ. SCI A 2019, 20, 61–72. [Google Scholar] [CrossRef]

- Lv, M.; Zhu, R. Research on coherent jet oxygen lance in BOF steelmaking process. Metall. Res. Technol. 2019, 116, 502. [Google Scholar] [CrossRef]

- Jin, Z.J.; Qiu, C.; Jiang, C.H.; Wu, J.Y.; Qian, J.Y. Effect of valve core shapes on cavitation flow through a sleeve regulating valve. J. Zhejiang Univ. SCI A 2020, 21, 1–14. [Google Scholar] [CrossRef]

- Tan, D.P.; Zhang, L.B.; Ai, Q.L. An embedded self-adapting network service framework for networked manufacturing system. J. Intell. Manuf. 2019, 30, 539–556. [Google Scholar] [CrossRef]

- Li, L.; Lu, J.; Fang, H.; Yin, Z.; Wang, T.; Wang, R.; Fan, X.; Zhao, L.; Tan, D.; Wan, Y. Lattice Boltzmann method for fluid-thermal systems: Status, hotspots, trends and outlook. IEEE Access 2020, 8, 27649–27675. [Google Scholar] [CrossRef]

- Wilcox, D.C. Turbulence Modeling For CFD; DCW Industries, Inc.: La Canada, CA, USA, 1994; pp. 83–87. [Google Scholar]

- Luo, K.; Shao, C.X.; Yang, Y.; Fan, J.R. A mass conserving level set method for detailed numerical simulation of liquid atomization. J. Comput. Phys. 2015, 298, 495–519. [Google Scholar] [CrossRef]

- Balcazar, N.; Lehrrikuhl, O.; Jofre, L.; Oliva, A. Level-set simulations of buoyancy-driven motion of single and multiple bubbles. Int. J. Heat Fluid Flow. 2015, 56, 91–107. [Google Scholar] [CrossRef]

- Kinzel, M.P.; Lindau, J.W.; Kunz, R.F. A Multiphase Level-Set Approach for All-Mach Numbers. Comput. Fluids 2018, 167, 1–16. [Google Scholar] [CrossRef]

- Tan, D.P.; Chen, S.T.; Bao, G.J.; Zhang, L.B. An embedded lightweight GUI component library and ergonomics optimization method for industry process monitoring. Front. Inform. Technol. Elect. Eng. 2018, 19, 604–625. [Google Scholar] [CrossRef]

- Lu, J.F.; Wang, T.; Li, L.; Yin, Z.C.; Wang, R.H.; Fan, X.H.; Tan, D.P. Dynamic characteristics and wall effects of bubble bursting in gas-liquid-solid three-phase particle flow. Processes 2020, 80, 760, in press. [Google Scholar] [CrossRef]

- Li, X.J.; Yuan, Y.; Liu, L.Y.; Leung, Y.S.; Chen, Y.Y.; Guo, Y.X.; Chai, Y.; Chen, Y. 3D printing of hydroxyapatite/tricalcium phosphate scaffold with hierarchical porous structure for bone regeneration. Bio-Des. Manuf. 2020, 3, 15–29. [Google Scholar] [CrossRef]

- Wang, Y.C.; Wang, Y.; Mei, D.Q.; Yu, Z.K.; Xue, D. Standing surface acoustic wave-assisted fabrication of patterned microstructures for enhancing cell migration. Bio-Des. Manuf. 2020, 3, 87–97. [Google Scholar] [CrossRef]

- Li, Y.B.; Zheng, H.; Chen, B.; Sun, P.; Wang, Z.S.; Shuai, K.; Yue, Y. Dynamic Modeling and Analysis of 5-PSS/UPU Parallel Mechanism with Elastically Active Branched Chains. Chin. J. Mech. Eng. 2020, 33, 44. [Google Scholar] [CrossRef]

- Liu, Y.; Zheng, J.F.; Song, R.Y.; Xu, Q.N.; Chen, J.H.; Huang, F.P. Standing surface acoustic wave-assisted fabrication of patterned microstructures for enhancing cell migration. Chin. J. Mech. Eng. 2020, 33, 5. [Google Scholar] [CrossRef]

- Wang, J.X.; Tan, D.P.; Cao, B.; Fan, J.; Deep, S. Independent path-based process recommendation algorithm for improving biomedical process modelling. Electron. Lett. 2020, 56, 11–531. [Google Scholar] [CrossRef]

- Chen, J.L.; Xu, F.; Tan, D.P.; Shen, Z.; Zhang, L.B.; Ai, Q.L. A control method for agricultural greenhouses heating based on computational fluid dynamics and energy prediction model. Appl. Energ. 2015, 141, 106–118. [Google Scholar] [CrossRef]

- Tan, D.P.; Ni, Y.S.; Zhang, L.B. Two-phase sink vortex suction mechanism and penetration dynamic characteristics in ladle teeming process. J. Iron Steel Res. Int. 2017, 24, 667–677. [Google Scholar] [CrossRef]

- Zuo, Q.; Sun, J.L.; Lu, Q.Q.; Ruan, J. Experimental and numerical investigations of the ball-screw-type coupling in two-dimensional electro-hydraulic proportional directional valve. Adv. Mech. Eng. 2018, 10, 1687814018802509. [Google Scholar] [CrossRef]

| Geometrical Parameters | Value | Unit |

|---|---|---|

| Nozzle throat diameter (dt) | 35 | mm |

| Nozzle exit diameter (de) | 48 | mm |

| Nozzle divergent length (Ln) | 100 | mm |

| Nozzle inclination angle (θ) | 13.5 | degree |

| Nozzle twist angle (α) | 0, 5, 8, 13 | degree |

| Oxygen lance height (Hl) | 1100–2100 | mm |

| Design Mach number (Ma) | 1.8 | 1 |

| Steel converter diameter (D) | 5000 | mm |

| Steel converter height (H) | 8000 | mm |

| Steel liquid level (Hs) | 2000 | mm |

| Equation | |||

|---|---|---|---|

| Continuity | 0 | 1 | 0 |

| Momentum | u | ||

| Energy | i |

| Item | Attribute |

|---|---|

| Inlet | Pressure inlet (0.9 MPa) |

| Outlet | Pressure outlet (0.1 MPa) |

| Wall | No slip wall |

| Reference pressure | 1.01 × 105 Pa |

| Zone | Oxygen, molten steel |

| Physical Property | Oxygen | Molten Steel | Unit |

|---|---|---|---|

| Density | compressible | 7200 | kg/m3 |

| Temperature | 300 | 1900 | K |

| Dynamic viscosity | 1.9 × 10−5 | 6.5 ×10−3 | Pa·S |

| Specific heat capacity | 919 | 670 | J/(kg·K) |

| Heat conductivity | 0.025 | 15.000 | W/(m·K) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, Z.; Lu, J.; Li, L.; Wang, T.; Wang, R.; Fan, X.; Lin, H.; Huang, Y.; Tan, D. Optimized Scheme for Accelerating the Slagging Reaction and Slag–Metal–Gas Emulsification in a Basic Oxygen Furnace. Appl. Sci. 2020, 10, 5101. https://doi.org/10.3390/app10155101

Yin Z, Lu J, Li L, Wang T, Wang R, Fan X, Lin H, Huang Y, Tan D. Optimized Scheme for Accelerating the Slagging Reaction and Slag–Metal–Gas Emulsification in a Basic Oxygen Furnace. Applied Sciences. 2020; 10(15):5101. https://doi.org/10.3390/app10155101

Chicago/Turabian StyleYin, Zichao, Jianfei Lu, Lin Li, Tong Wang, Ronghui Wang, Xinghua Fan, Houkai Lin, Yuanshun Huang, and Dapeng Tan. 2020. "Optimized Scheme for Accelerating the Slagging Reaction and Slag–Metal–Gas Emulsification in a Basic Oxygen Furnace" Applied Sciences 10, no. 15: 5101. https://doi.org/10.3390/app10155101

APA StyleYin, Z., Lu, J., Li, L., Wang, T., Wang, R., Fan, X., Lin, H., Huang, Y., & Tan, D. (2020). Optimized Scheme for Accelerating the Slagging Reaction and Slag–Metal–Gas Emulsification in a Basic Oxygen Furnace. Applied Sciences, 10(15), 5101. https://doi.org/10.3390/app10155101