A User-Friendly Tool to Characterize the Moisture Transfer in Porous Building Materials: FLoW1D

Abstract

Featured Application

Abstract

1. Introduction

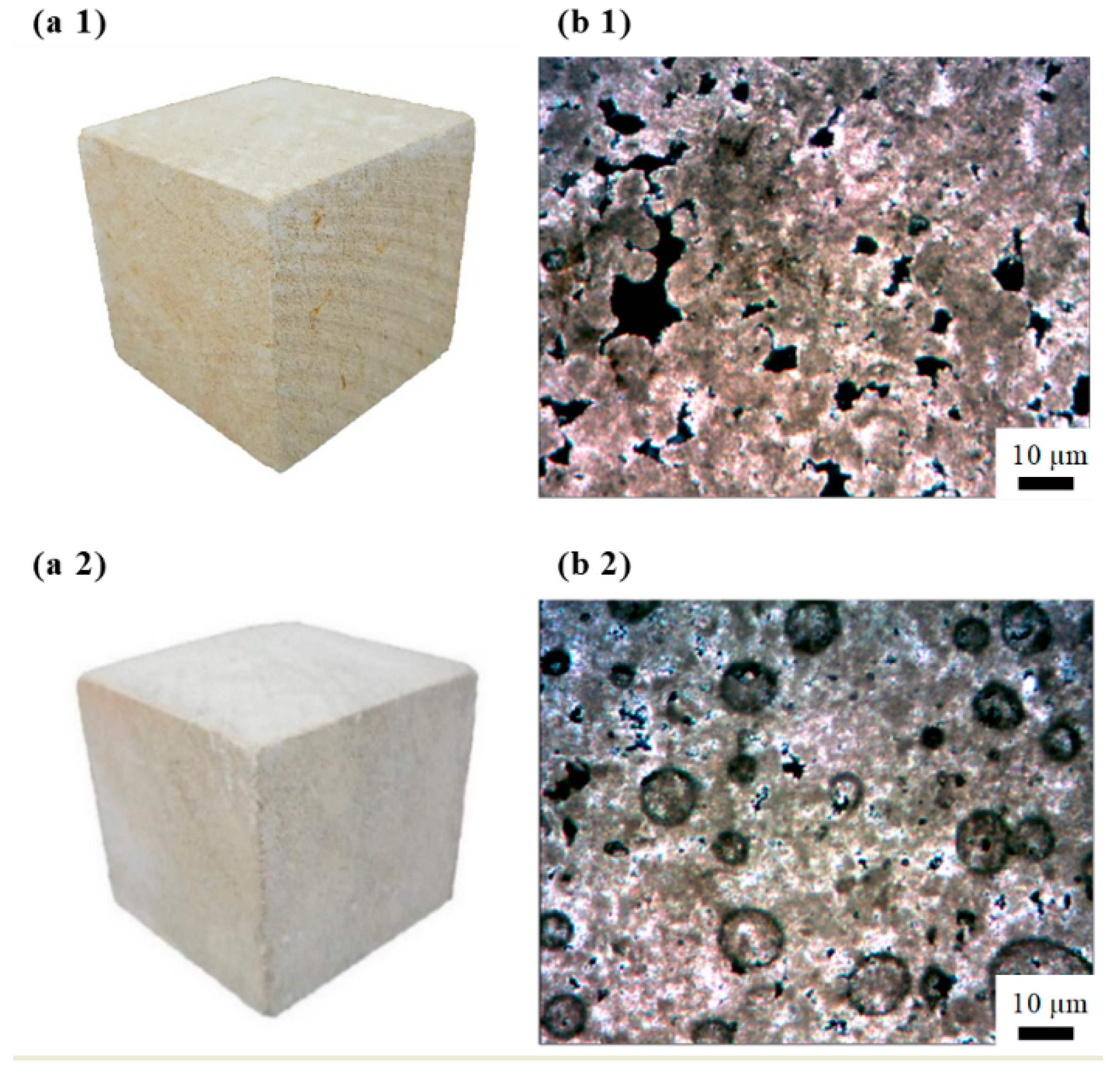

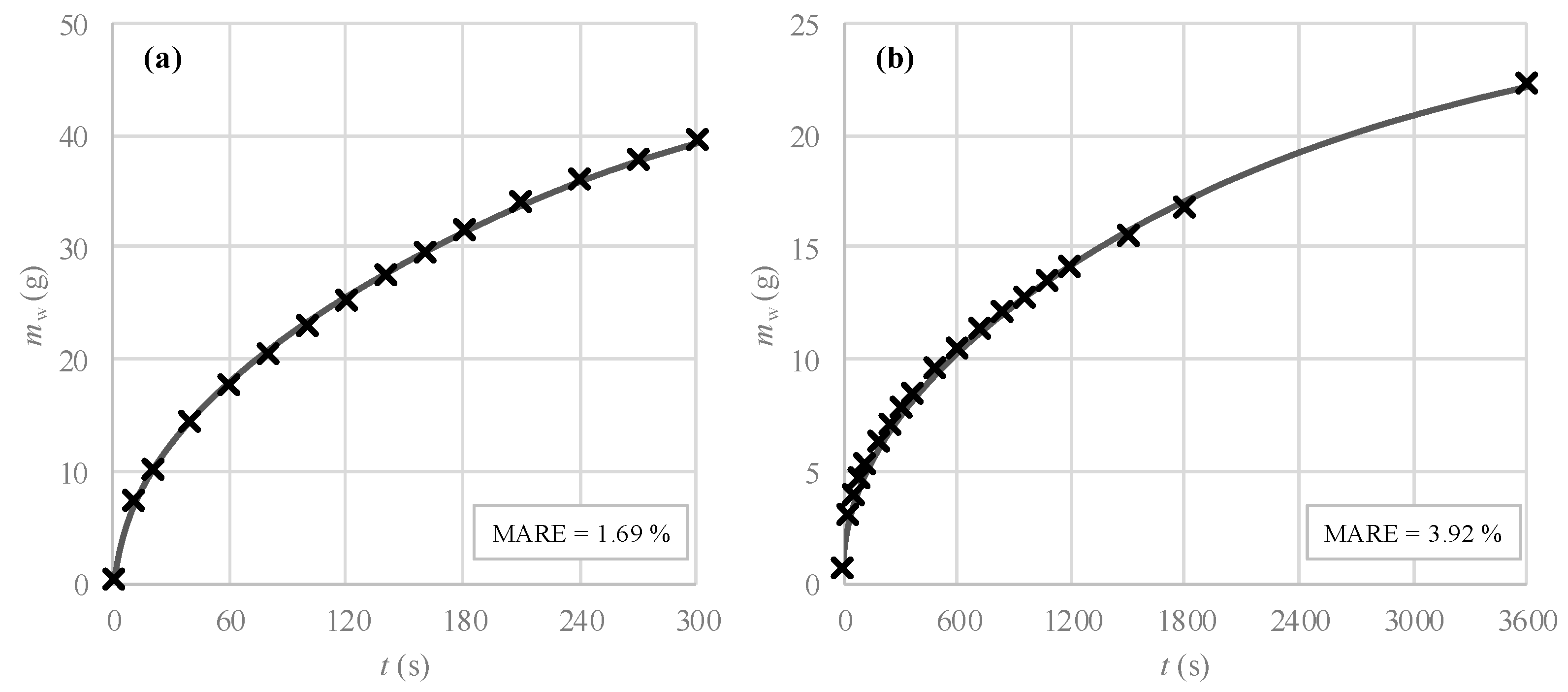

2. Experimental Test

3. Conceptual Model and Numerical Implementation

3.1. Conceptual Model

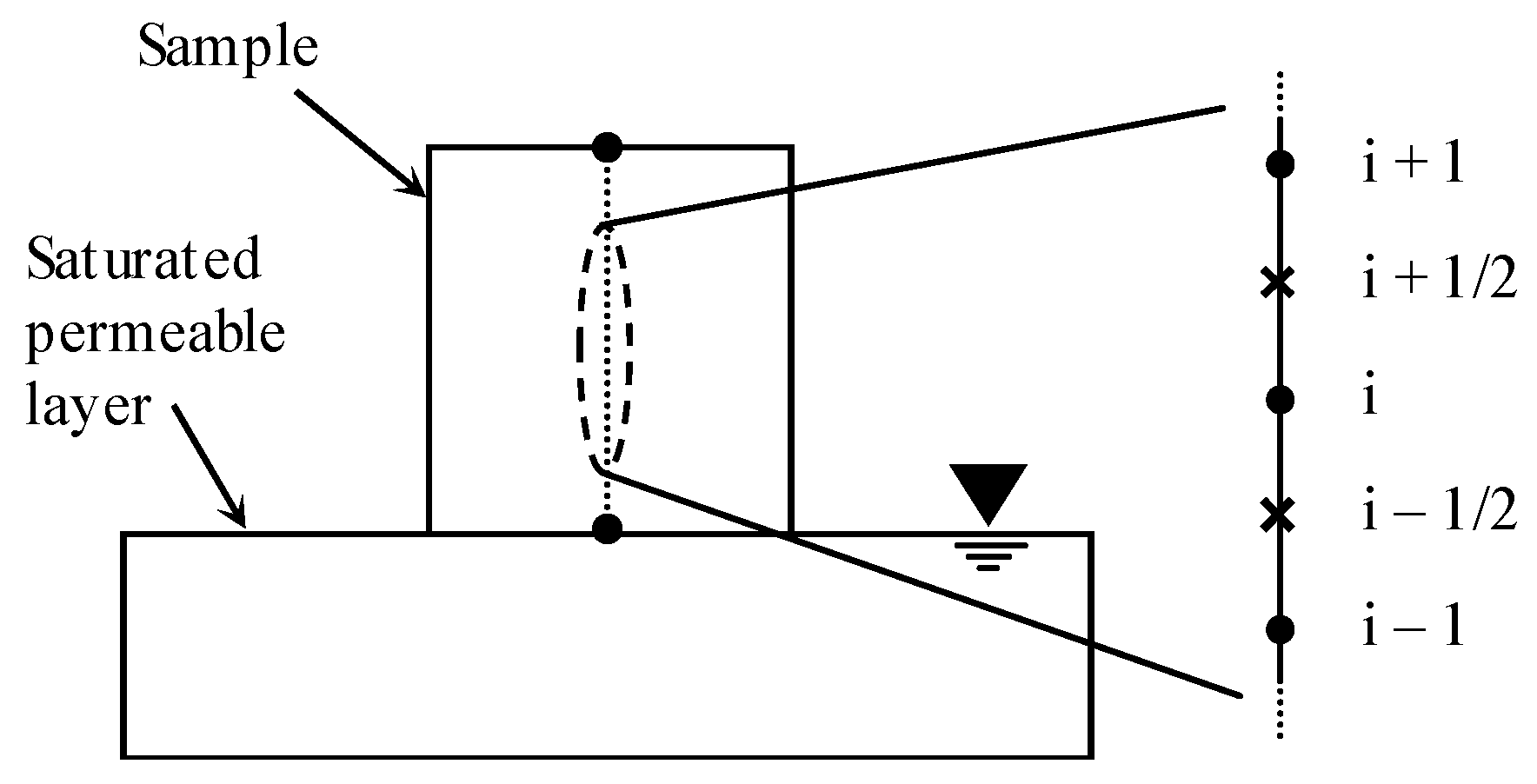

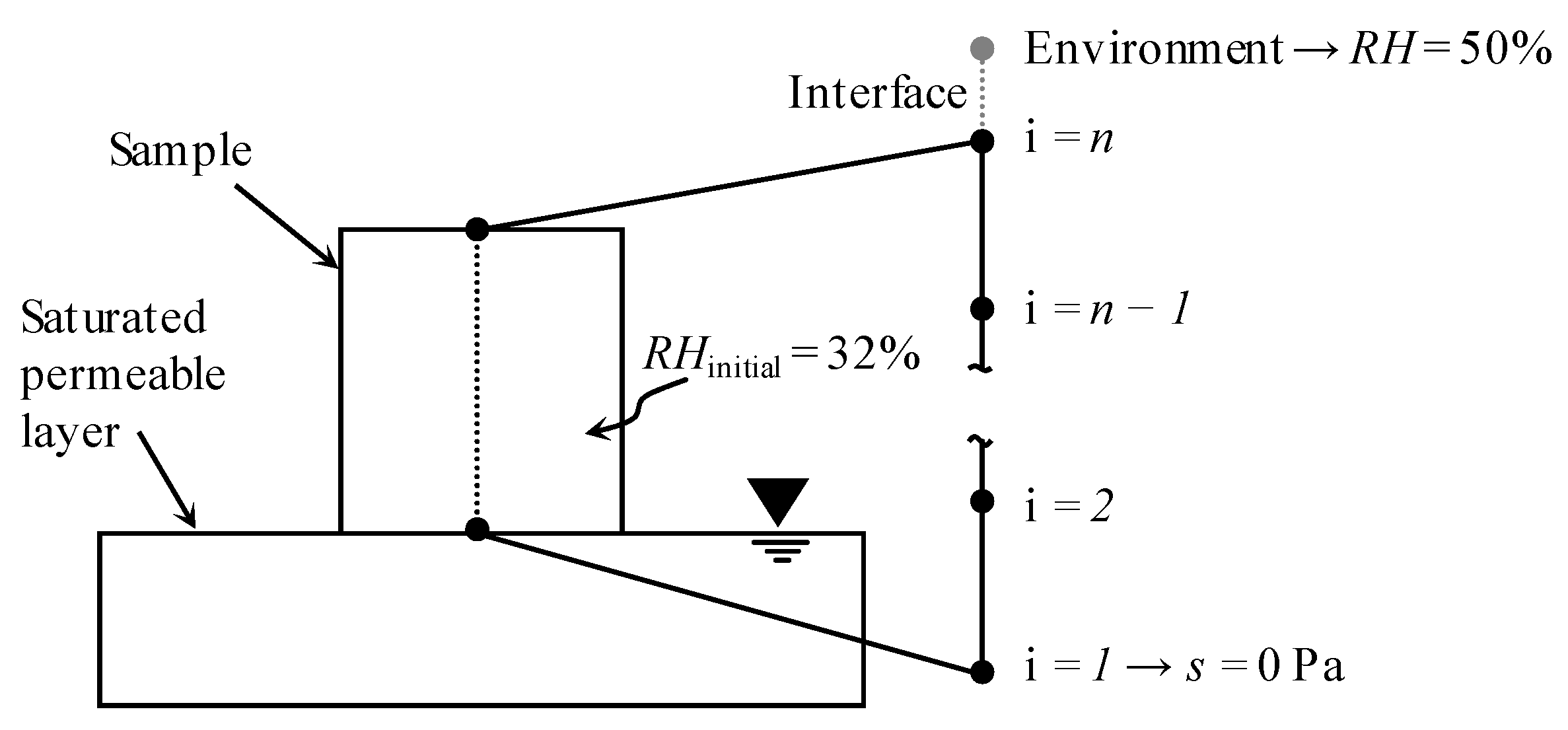

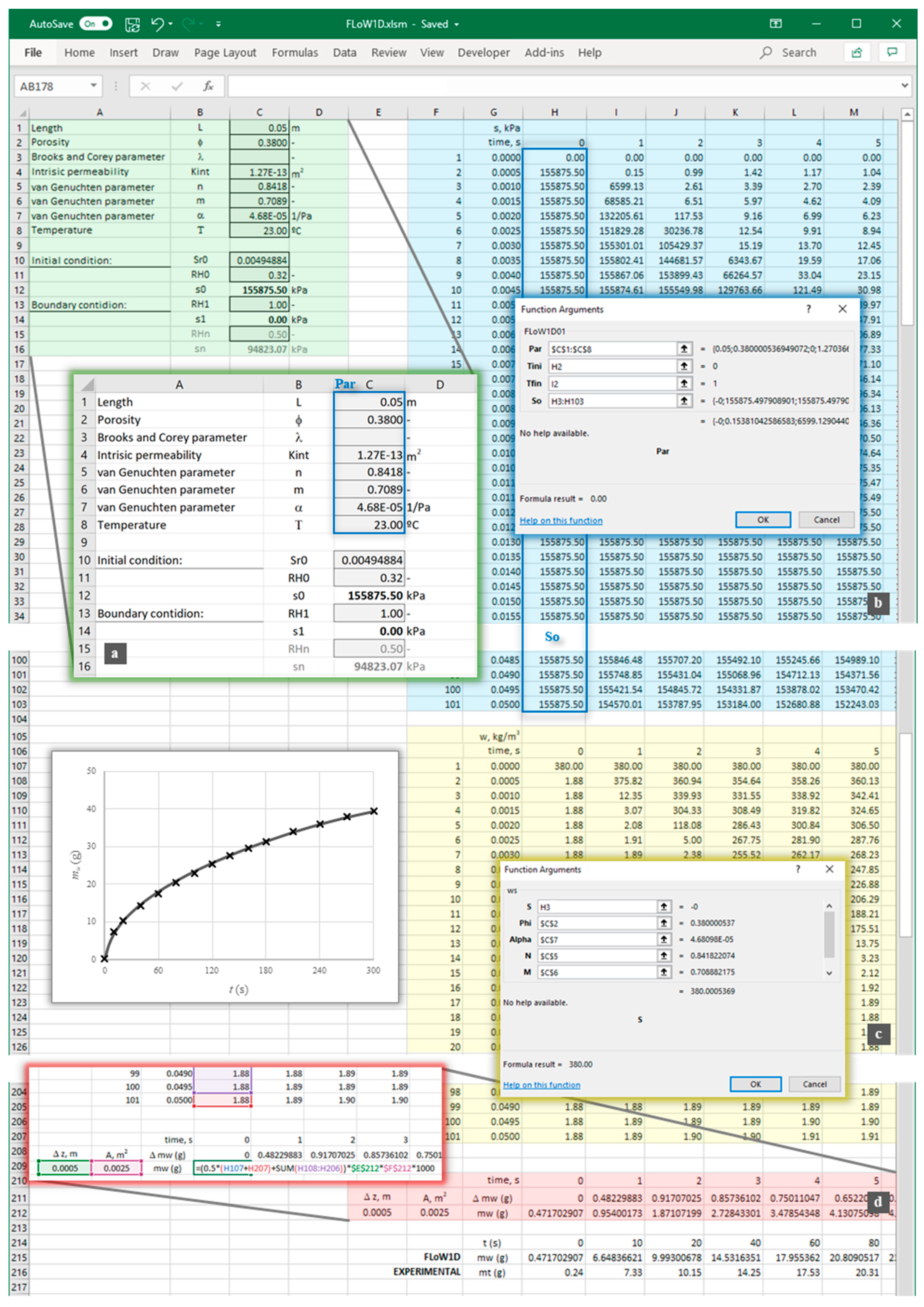

3.2. Numerical Model and System Abstraction

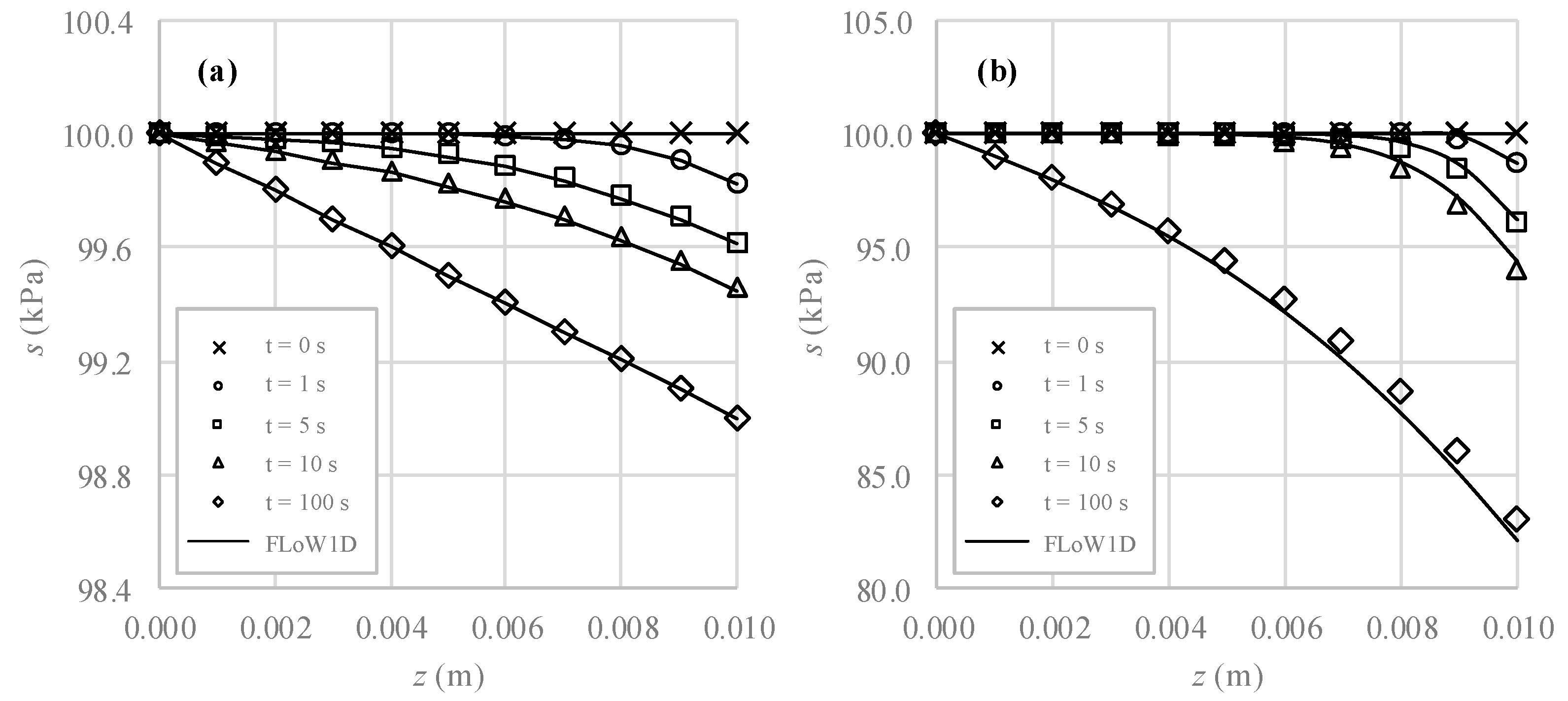

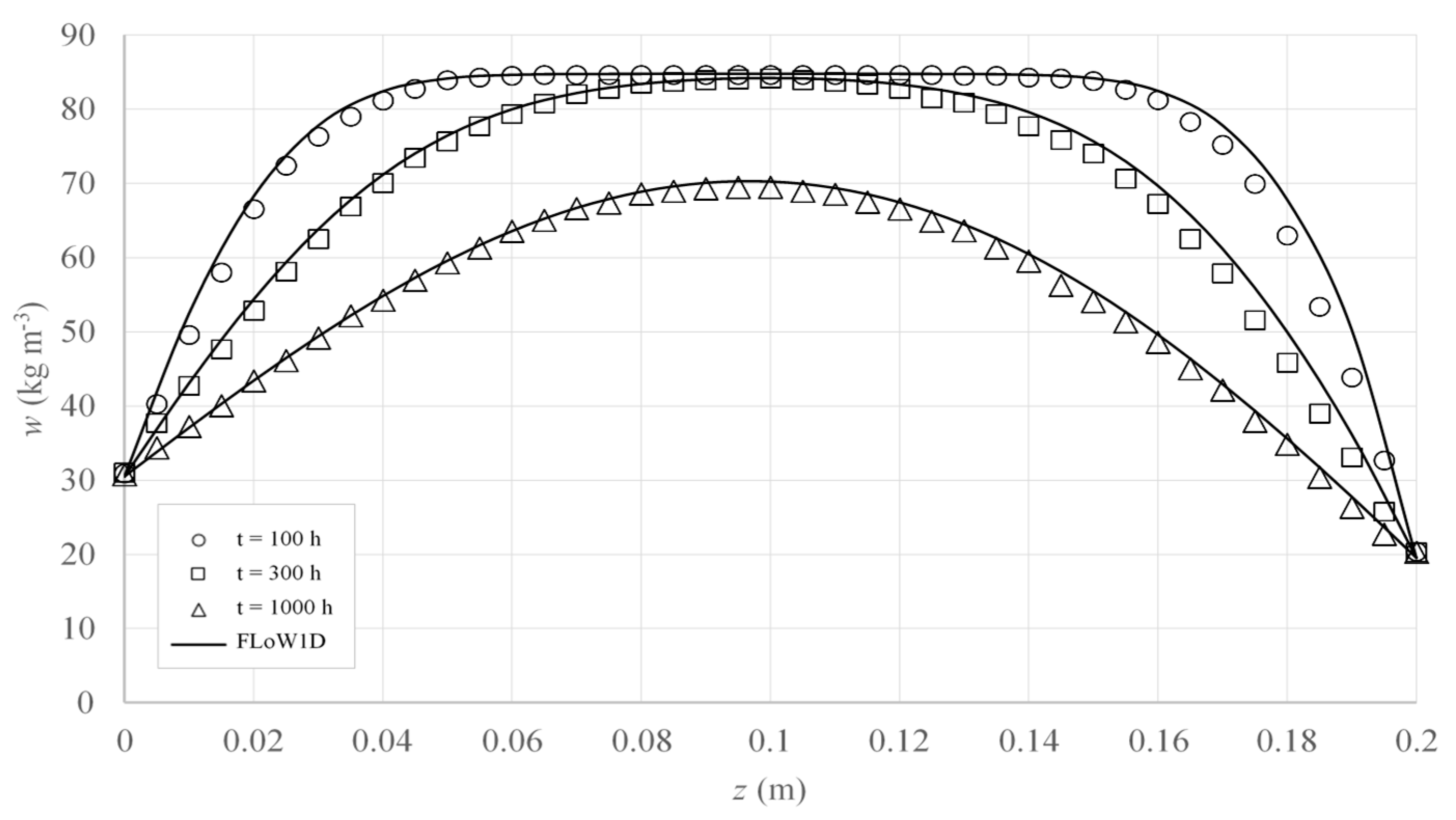

3.3. Verification Process

4. Model Application

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Appendix A. List of Symbols

| Linear water retention curve parameter | |

| Linear water retention curve parameter | |

| Binary diffusion coefficient of water vapor | |

| Liquid water diffusivity | |

| Water flow rate | |

| Water vapor flow rate | |

| Liquid water flow rate | |

| k | Liquid conductivity |

| K | Intrinsic permeability |

| Ksat | Saturated conductivity |

| L | Length of the sample |

| Relative mass of water | |

| m | Parameter of the van Genuchten’s water retention curve |

| n | Parameter of the van Genuchten’s water retention curve |

| Gas pressure | |

| Liquid water pressure | |

| Water vapor pressure | |

| Water vapor pressure at vapor saturated conditions | |

| Environmental water vapor pressure (bottom interface) | |

| Water vapor pressure at grid point 1 | |

| Water vapor pressure at grid point n | |

| Environmental water vapor pressure (top interface) | |

| Ideal gas constant | |

| RH | Relative humidity |

| Matric suction | |

| Suction at the beginning of WAC test | |

| Equivalent vapor diffusion thickness of the bottom interfaces | |

| Equivalent vapor diffusion thickness of the top interfaces | |

| Degree of saturation | |

| Degree of saturation at the beginning of WAC test | |

| t | Time |

| T | Absolute temperature |

| Temperature in Celsius | |

| Water content | |

| Liquid water content | |

| Water vapor content | |

| Water content at the beginning of WAC test | |

| Mass fraction of the vapor | |

| z | Spatial coordinate |

| α | Parameter of the van Genuchten’s water retention curve |

| Specific weight of water | |

| Vapor permeability of still air | |

| Vapor permeability | |

| Volumetric water content | |

| Volumetric water content in saturated conditions | |

| Relative permeability | |

| Empiric parameter of the Brooks and Corey model | |

| Diffusion resistance factor | |

| Dynamic viscosity of the liquid water | |

| Gas density | |

| Water vapor density | |

| Water vapor density in saturated conditions | |

| Liquid water density | |

| Tortuosity | |

| Porosity |

Appendix B. Water Properties

Appendix C. Numerical Model

References

- Fierascu, R.C.; Doni, M.; Fierascu, I. Selected aspects regarding the restoration/conservation of traditional wood and masonry building materials: A short overview of the last decade findings. Appl. Sci. 2020, 10, 1164. [Google Scholar] [CrossRef]

- Kis, Z.; Sciarretta, F.; Szentmiklósi, L. Water uptake experiments of historic construction materials from Venice by neutron imaging and PGAI methods. Mater. Struct. Mater. Constr. 2017, 50. [Google Scholar] [CrossRef]

- Grazzini, A.; Fasana, S.; Zerbinatti, M.; Lacidogna, G. Non-destructive tests for damage evaluation of stone columns: The case study of sacro monte in ghiffa (Italy). Appl. Sci. 2020, 10, 2673. [Google Scholar] [CrossRef]

- Portal, N.W.; van Schijndel, A.W.M.; Kalagasidis, A.S. The multiphysics modeling of heat and moisture induced stress and strain of historic building materials and artefacts. Build. Simul. 2014, 7, 217–227. [Google Scholar] [CrossRef]

- Moropoulou, A.; Avdelidis, N.P.; Karoglou, M.; Delegou, E.T.; Alexakis, E.; Keramidas, V. Multispectral applications of infrared thermography in the diagnosis and protection of built cultural heritage. Appl. Sci. 2018, 8, 284. [Google Scholar] [CrossRef]

- AENOR. UNE 41810:2017. Conservación del patrimonio cultural. In Criterios de Intervención en Materiales Pétreos; Asociación Española de Normalización: Madrid, Spain, 2017. [Google Scholar]

- CEN. UNE-EN 16515:2015. Conservation of Cultural Heritage—Guidelines to Characterize Natural Stone Used in Cultural Heritage; European Committee for Standardization: Brussels, Belgium, 2015. [Google Scholar]

- Delgado, J.M.P.Q.; Ramos, N.M.M.; Barreira, E.; De Freitas, V.P. A critical review of hygrothermal models used in porous building materials. J. Porous Media 2010, 13, 221–234. [Google Scholar] [CrossRef]

- Hens, H.L.S.C. Combined heat, air, moisture modelling: A look back, how, of help? Build. Environ. 2015, 91, 138–151. [Google Scholar] [CrossRef]

- Van Schijndel, A.W.M. Multiphysics modeling of building physical constructions. Build. Simul. 2011, 4, 49–60. [Google Scholar] [CrossRef]

- Gasparin, S.; Berger, J.; Dutykh, D.; Mendes, N. Stable explicit schemes for simulation of nonlinear moisture transfer in porous materials. J. Build. Perform. Simul. 2018, 11, 129–144. [Google Scholar] [CrossRef]

- Qin, Y.; Hiller, J.E. Simulating moisture distribution within concrete pavement slabs: Model development and sensitivity study. Mater. Struct. Mater. Constr. 2014, 47, 351–365. [Google Scholar] [CrossRef]

- CEN. EN 15026:2007. Hygrothermal Performance of Building Components and Building Elements—Assessment of Moisture Transfer by Numerical Simulation; European Committee for Standardization: Brussels, Belgium, 2007. [Google Scholar]

- CEN. EN 15801:2009. Conservation of Cultural Property-Test Methods-Determination of Water Absorption by Capillarity; European Committee for Standardization: Brussels, Belgium, 2009. [Google Scholar]

- Carmeliet, J.; Roels, S. Determination of the Isothermal Moisture Transport Properties of Porous Building Materials. J. Therm. Envel. Build. Sci. 2001, 24, 183–210. [Google Scholar] [CrossRef]

- Roels, S.; Carmeliet, J.; Hens, H.; Adan, O.; Brocken, H.; Cerny, R.; Pavlik, Z.; Ellis, A.T.; Hall, C.; Kumaran, K.; et al. A Comparison of Different Techniques to Quantify Moisture Content Profiles in Porous Building Materials. J. Therm. Envel. Build. Sci. 2004, 27, 261–276. [Google Scholar] [CrossRef]

- Gomez, I.; Sala, J.M.; Millan, J.A. Characterization of moisture transport properties for lightened clay brick—Comparison between two manufacturers. J. Build. Phys. 2007, 31, 179–194. [Google Scholar] [CrossRef]

- Galvan, S.; Pla, C.; Cueto, N.; Martínez-Martínez, J.; García-del-Cura, M.A.; Benavente, D. A comparison of experimental methods for measuring water permeability of porous building rocks. Mater. Constr. 2014, 64. [Google Scholar] [CrossRef]

- Amirkhanov, I.V.; Pavlušová, E.; Pavluš, M.; Puzynina, T.P.; Puzynin, I.V.; Sarhadov, I. Numerical solution of an inverse diffusion problem for the moisture transfer coefficient in a porous material. Mater. Struct. Mater. Constr. 2008, 41, 335–344. [Google Scholar] [CrossRef]

- Rouchier, S.; Woloszyn, M.; Kedowide, Y.; Béjat, T. Identification of the hygrothermal properties of a building envelope material by the covariance matrix adaptation evolution strategy. J. Build. Perform. Simul. 2016, 9, 101–114. [Google Scholar] [CrossRef]

- Guardia, C.; Schicchi, D.S.; Caggiano, A.; Barluenga, G.; Koenders, E. On the capillary water absorption of cement-lime mortars containing phase change materials: Experiments and simulations. Build. Simul. 2019. [Google Scholar] [CrossRef]

- Cabrera, V.; López-Vizcaíno, R.; Yustres, Á.; Ruiz, M.Á.; Torrero, E.; Navarro, V. A functional structure for state functions of moisture transfer in heritage building elements. J. Build. Eng. 2020, 29, 101201. [Google Scholar] [CrossRef]

- Van Genuchten, M.T. A closed-form equation for predicting the hydraulic conductivity of unsaturated soils. Soil Sci. Soc. Am. J. 1980, 44, 892–898. [Google Scholar] [CrossRef]

- Mualem, Y. A new model for predicting the hydraulic conductivity of unsaturated porous media. Water Resour. Res. 1976, 12, 513–522. [Google Scholar] [CrossRef]

- Pollock, D.W. Simulation of fluid-flow and energy transport processes associated with high-level radioactive-waste disposal in unsaturated alluvium. Water Resour. Res. 1986, 22, 765–775. [Google Scholar] [CrossRef]

- Brooks, R.H.; Corey, A.T. Hydraulic Properties of Porous Media; Colorado State University: Fort Collins, CO, USA, 1964. [Google Scholar]

- Microsoft Office. Guidelines and Examples of Array Formulas. Available online: https://support.microsoft.com/en-us/office/guidelines-and-examples-of-array-formulas-7d94a64e-3ff3-4686-9372-ecfd5caa57c7 (accessed on 15 June 2020).

- Carslaw, H.S.; Jaeger, J.C. Conduction of Heat in Solids, 2nd ed.; Clarendon Press: Oxford, UK, 1959; p. 510. [Google Scholar] [CrossRef]

- GEO-SLOPE. Seepage Modeling with SEEP/W. In An Engineering Methodology; GeoStudio: Calgary, AB, Canada, 2012. [Google Scholar]

- Hagentoft, C.E.; Kalagasidis, A.S.; Adl-Zarrabi, B.; Roels, S.; Carmeliet, J.; Hens, H.; Grunewald, J.; Funk, M.; Becker, R.; Shamir, D.; et al. Assessment Method of Numerical Prediction Models for Combined Heat, Air and Moisture Transfer in Building Components: Benchmarks for One-dimensional Cases. J. Build. Phys. 2004, 27, 327–352. [Google Scholar] [CrossRef]

- Adan, O.; Brocken, H.; Carmeliet, J.; Hens, H.; Roels, S.; Hagentoft, C.E. Determination of Liquid Water Transfer Properties of Porous Building Materials and Development of Numerical Assessment Methods: Introduction to the EC HAMSTAD Project. J. Build. Phys. 2004, 27, 253–260. [Google Scholar] [CrossRef]

- CEN. EN 1936:2006. Natural Stone Test Methods—Determination of Real Density and Apparent Density, and of Total and Open Porosity; European Committee for Standardization: Brussels, Belgium, 2006. [Google Scholar]

- Torrero, E.; Sanz, D.; Navarro, V. Porosity and Pore Size Distribution of the Dimension Stone in the Historic City of Cuenca. In Construction and Building Research; Llinares-Millán, C., Fernández-Plazaola, I., Hidalgo-Delgado, F., Martínez-Valenzuela, M.M., Medina-Ramón, F.J., Oliver-Faubel, I., Rodríguez-Abad, I., Salandin, A., Sánchez-Grandia, R., Tort-Ausina, I., Eds.; Springer: Dordrecht, The Netherlands, 2014; pp. 523–529. [Google Scholar] [CrossRef]

- Abadie, J.; Carpentier, J. Generalization of the Wolfe reduced gradient method to the case of nonlinear constraints. In Optimization; Fletcher, R., Ed.; Academic Press: New York, NY, USA, 1969. [Google Scholar]

- Frank, M.; Wolfe, P. An Algorithm for Quadratic Programming. Nav. Res. Logist. Q. 1956, 3, 95–110. [Google Scholar] [CrossRef]

- Lasdon, L.S.; Waren, A.D.; Jain, A.; Ratner, M. Design and Testing of a Generalized Reduced Gradient Code for Nonlinear Constrained Programming. ACM Trans. Math. Softw. 1978, 4, 34–50. [Google Scholar] [CrossRef]

- Lasdon, L.S.; Waren, A.D. Generalized Reduced Gradient Software for Linearly and Nonlinearly Constrained Problems; Sijthoff and Noordhoff: Amsterdam, The Netherlands, 1978; pp. 363–397. [Google Scholar]

- Abadie, J. The GRG Method for Nonlinear Programmin; Sijthoff and Noordhoof: Amsterdam, The Netherlands, 1978; pp. 335–363. [Google Scholar]

- Wolfe, P. Methods of Nonlinear Programming; John Wiley: New York, NY, USA, 1976. [Google Scholar]

- Lasdon, L.S.; Waren, A.D. GRG2: An all FORTRAN general purpose nonlinear optimizer. SIGMAP Bull. 1981, 10–11. [Google Scholar] [CrossRef]

- Fylstra, D.; Lasdon, L.S.; Watson, J.; Waren, A.D. Design and use of the Microsoft Excel Solver. Interfaces 1998, 28, 29–55. [Google Scholar] [CrossRef]

- ISO. ISO 17892-1:2014. Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 1: Determination of Water Content; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- Philip, J.R.; De Vries, D.A. Moisture movement in porous materials under temperature gradients. Eos Trans. Am. Geophys. Union 1957, 38, 222–232. [Google Scholar] [CrossRef]

- Edlefsen, N.E.; Anderson, A.B.C. Thermodynamics of soil moisture. Hilgardia 1943, 15, 31–298. [Google Scholar] [CrossRef]

- Ewen, J.; Thomas, H.R. HEATING UNSATURATED MEDIUM SAND. Geotechnique 1989, 39, 455–470. [Google Scholar] [CrossRef]

| Parameters | Qualification Exercises | ||

|---|---|---|---|

| Liquid Transport | Liquid and Vapor Transport | ||

| QE1 Analytic | QE2 Seep/W | QE3 HAMSTAD. Benchmark 2 | |

| Parameters and Dimensions | |||

| (m) | 0.01 | 0.01 | 0.20 |

| 0.3241 | 0.3241 | 0.1160 | |

| Water retention function | |||

| (Pa−1) | 4.13 × 10−6 | - | - |

| (Pa−1) | - | 2.30 × 10−4 | 6.26 × 10−8 |

| 1 | - | - | |

| - | 1.39 | 0.869 | |

| m | - | ||

| κ | 1 | - | |

| (m2) | 3.10 × 10−15 | 3.10 × 10−15 | - |

| (m2 s−1) | - | - | 6.00 × 10−10 |

| (°C) | 22 | 22 | 20 |

| (s) | - | - | 1.00 × 10−15 |

| Initial and boundary conditions | |||

| Initial condition | s = 100 kPa | s = 100 kPa | RH = 95% |

| Top condition | RH = 65% | ||

| Bottom condition | s = 100 kPa | s = 100 kPa | RH = 45% |

| Sample | WAC Coefficient (kg m−2 s−1/2) | R2 |

|---|---|---|

| OPS | 0.9157 | 0.976 |

| SPS | 0.1655 | 0.998 |

| Sample | K (m2) | n (–) | m (–) | α (Pa−1) |

|---|---|---|---|---|

| OPS | 1.27 × 10−13 | 0.84 | 0.70 | 4.68 × 10−5 |

| SPS | 8.38 × 10−15 | 0.62 | 0.66 | 7.08 × 10−5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cabrera, V.; López-Vizcaíno, R.; Yustres, Á.; Ruiz, M.Á.; Torrero, E.; Navarro, V. A User-Friendly Tool to Characterize the Moisture Transfer in Porous Building Materials: FLoW1D. Appl. Sci. 2020, 10, 5090. https://doi.org/10.3390/app10155090

Cabrera V, López-Vizcaíno R, Yustres Á, Ruiz MÁ, Torrero E, Navarro V. A User-Friendly Tool to Characterize the Moisture Transfer in Porous Building Materials: FLoW1D. Applied Sciences. 2020; 10(15):5090. https://doi.org/10.3390/app10155090

Chicago/Turabian StyleCabrera, Virginia, Rubén López-Vizcaíno, Ángel Yustres, Miguel Ángel Ruiz, Enrique Torrero, and Vicente Navarro. 2020. "A User-Friendly Tool to Characterize the Moisture Transfer in Porous Building Materials: FLoW1D" Applied Sciences 10, no. 15: 5090. https://doi.org/10.3390/app10155090

APA StyleCabrera, V., López-Vizcaíno, R., Yustres, Á., Ruiz, M. Á., Torrero, E., & Navarro, V. (2020). A User-Friendly Tool to Characterize the Moisture Transfer in Porous Building Materials: FLoW1D. Applied Sciences, 10(15), 5090. https://doi.org/10.3390/app10155090