Applications of the Open-Source Hardware Arduino Platform in the Mining Industry: A Review

Abstract

1. Introduction

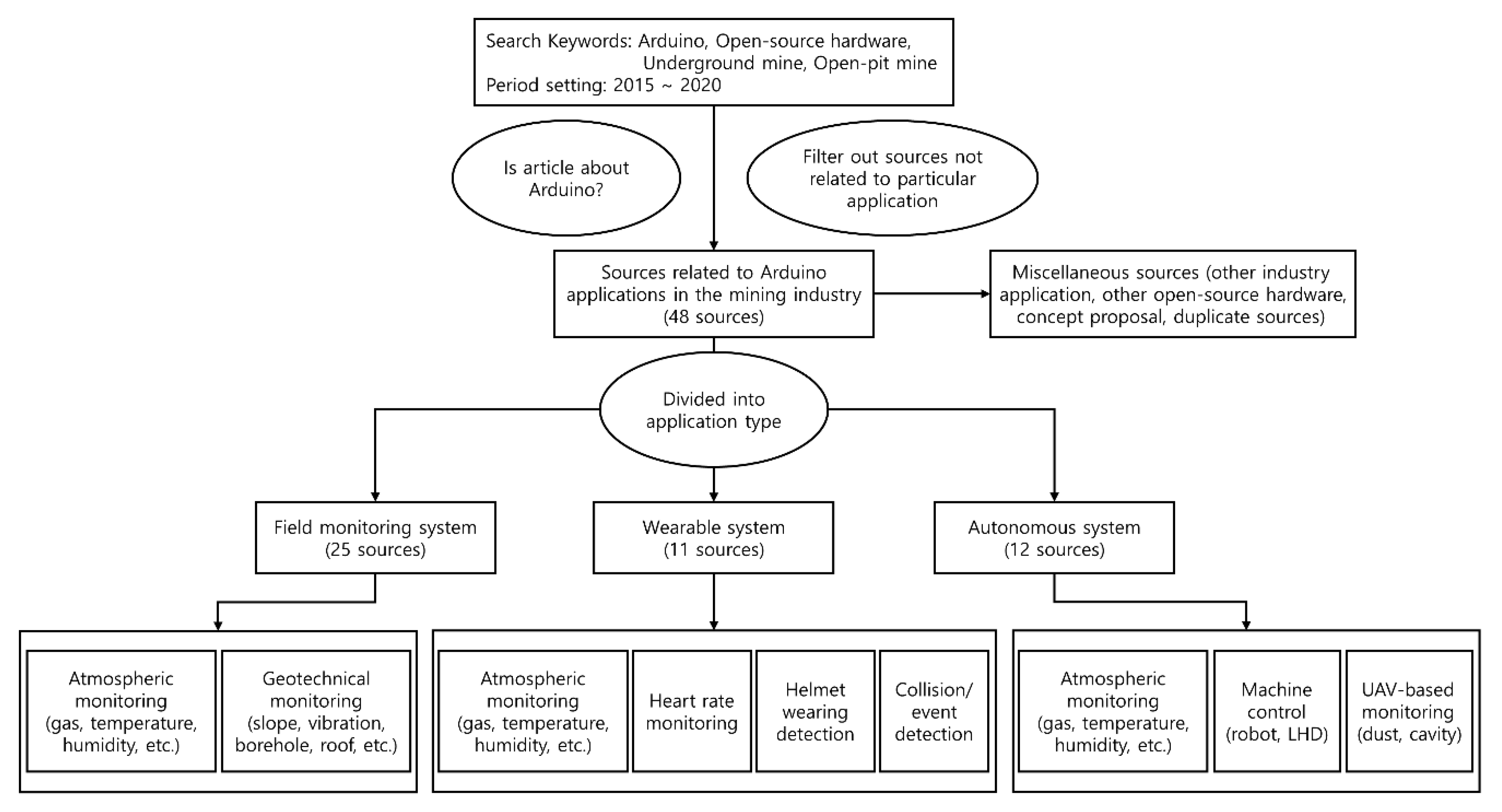

2. Arduino in Field Monitoring Systems

2.1. Overview

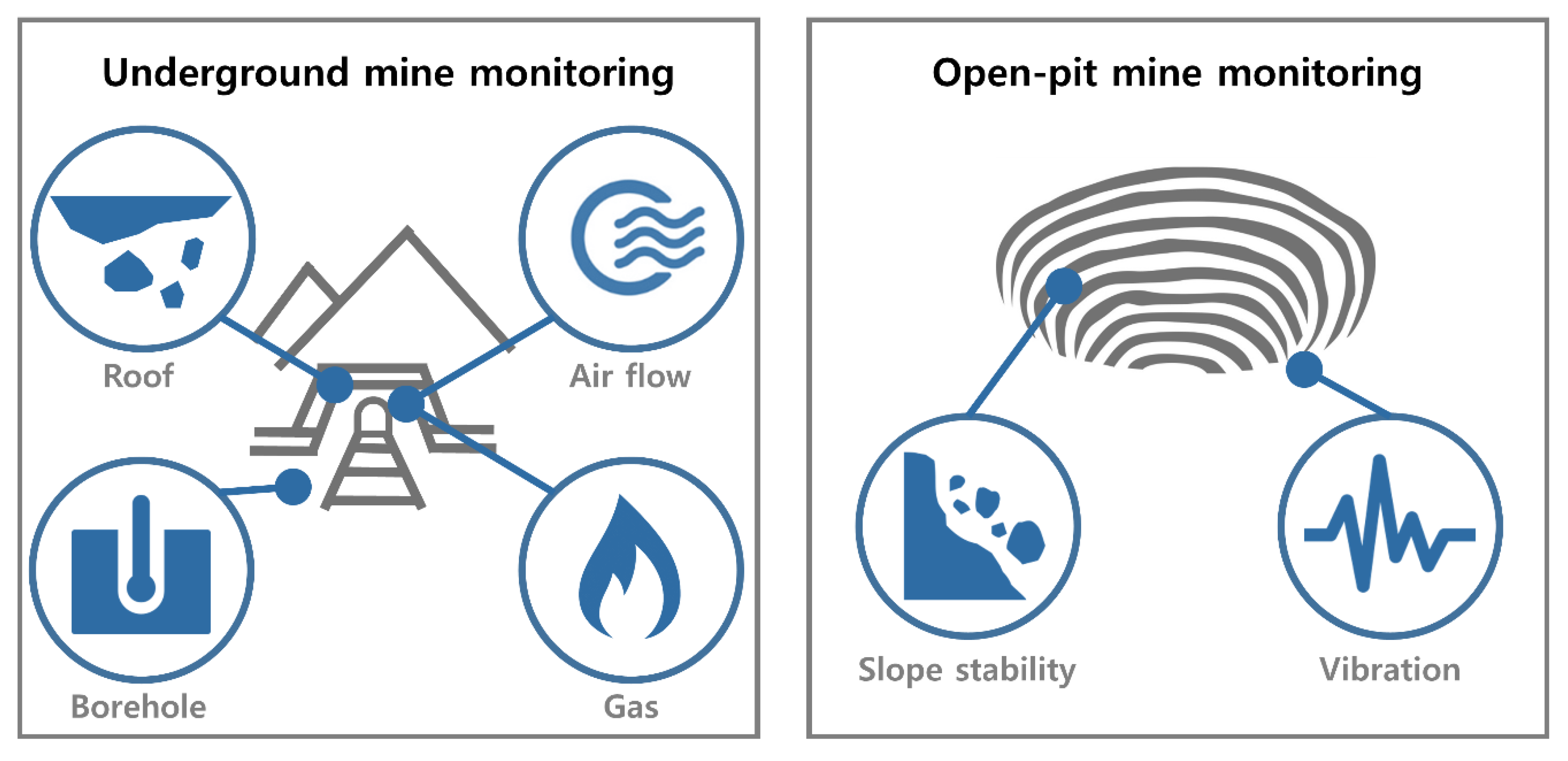

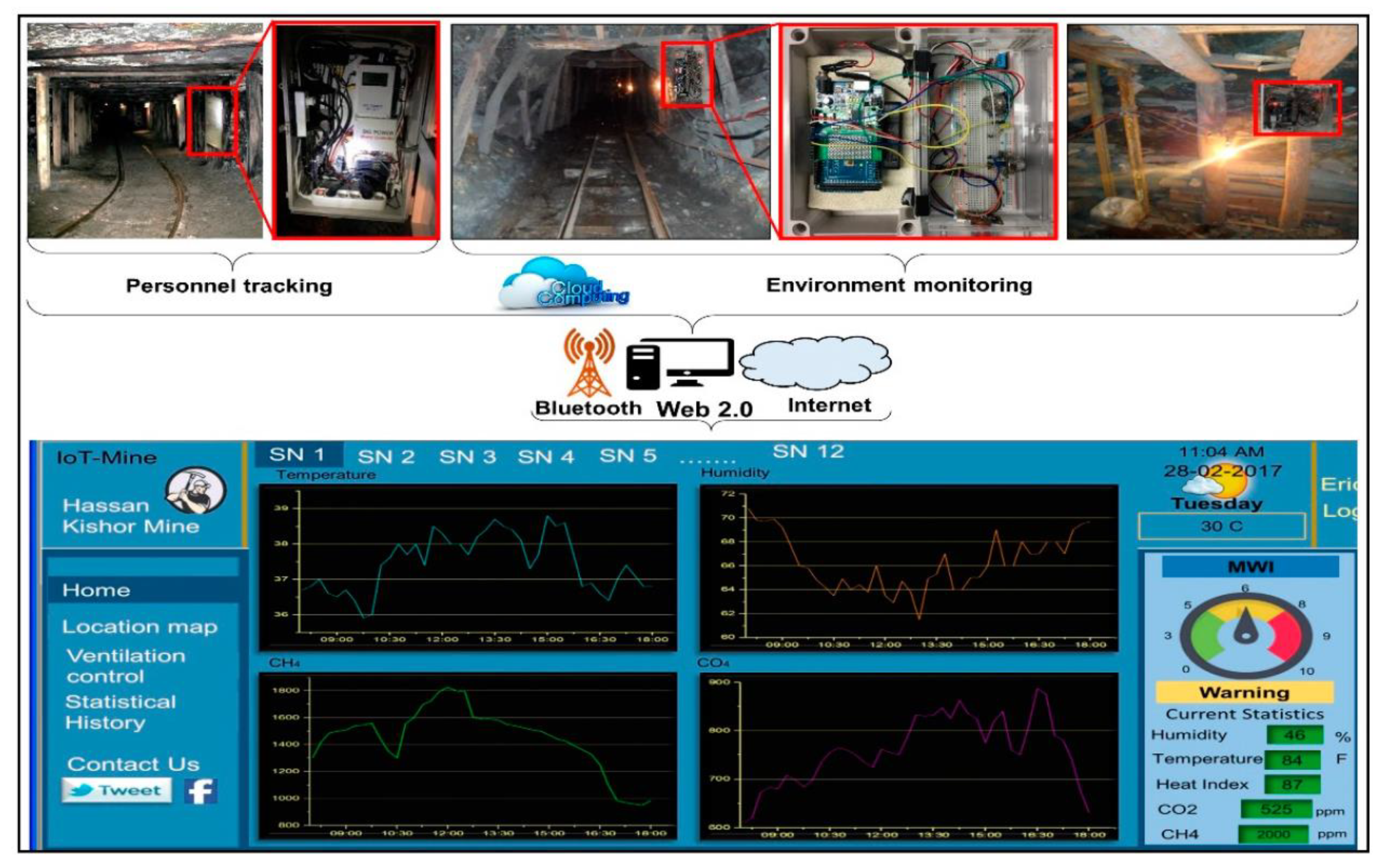

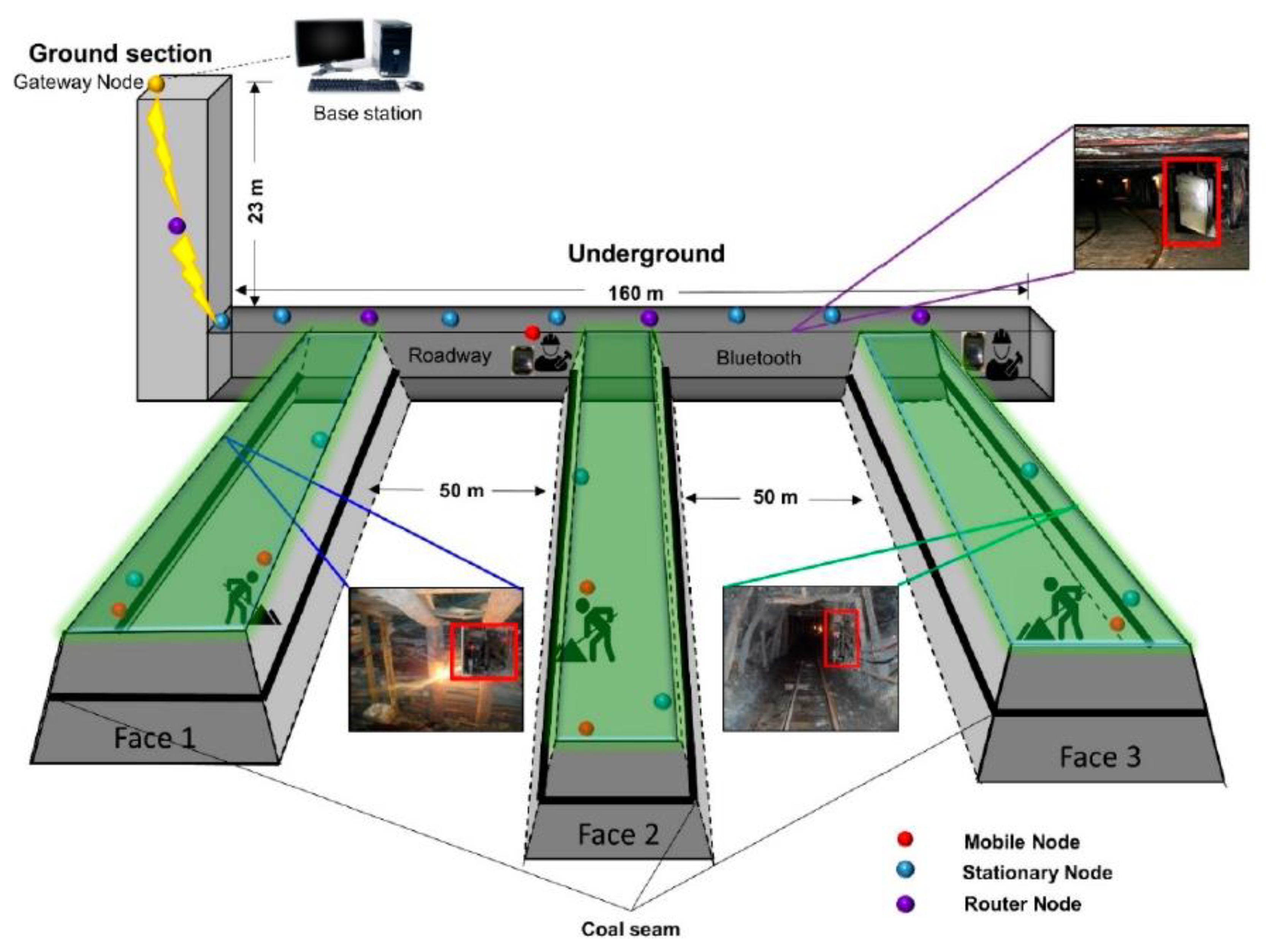

2.2. Atmospheric Monitoring

2.3. Geotechnical Monitoring

3. Arduino in Wearable Systems

3.1. Overview

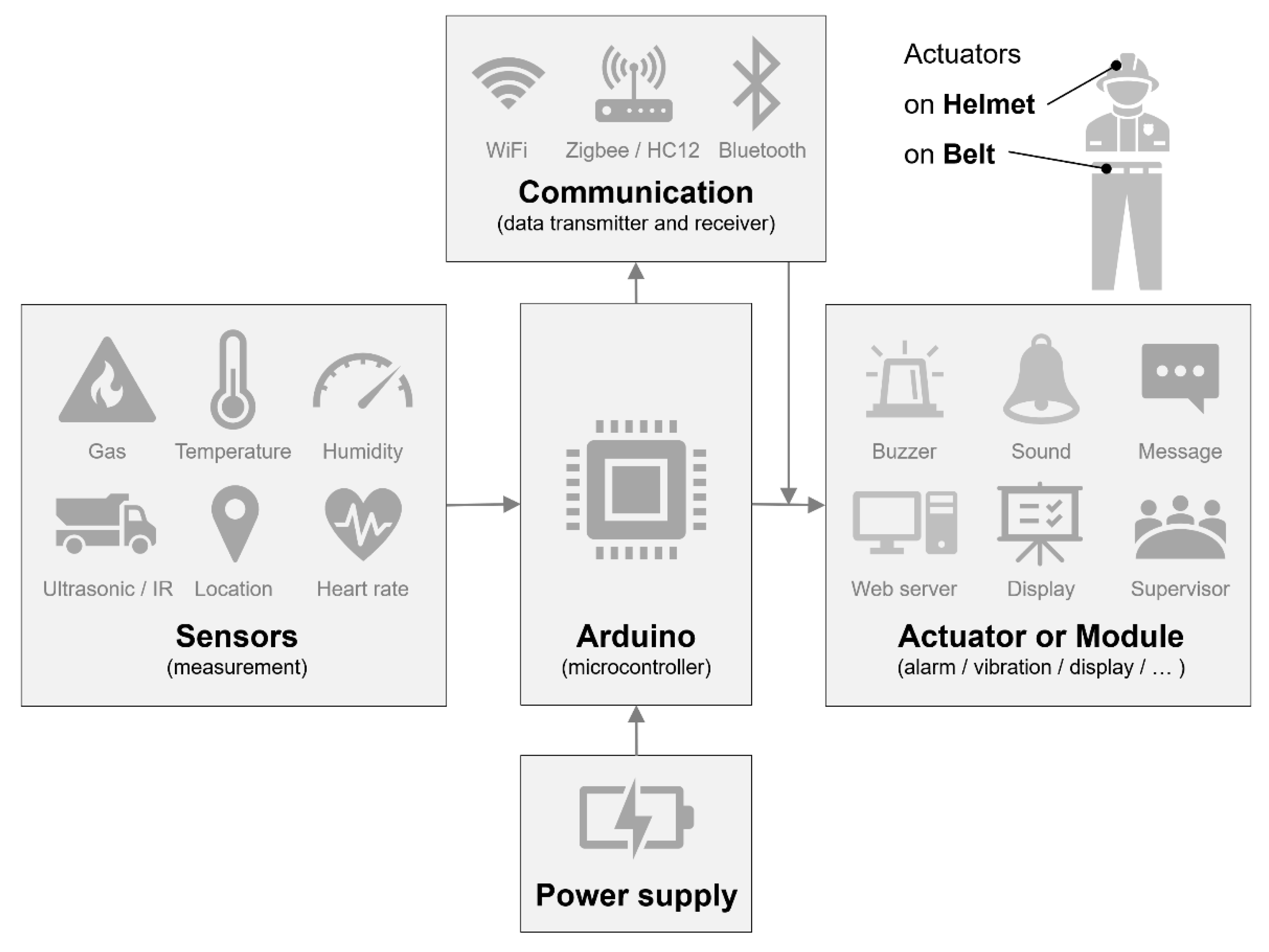

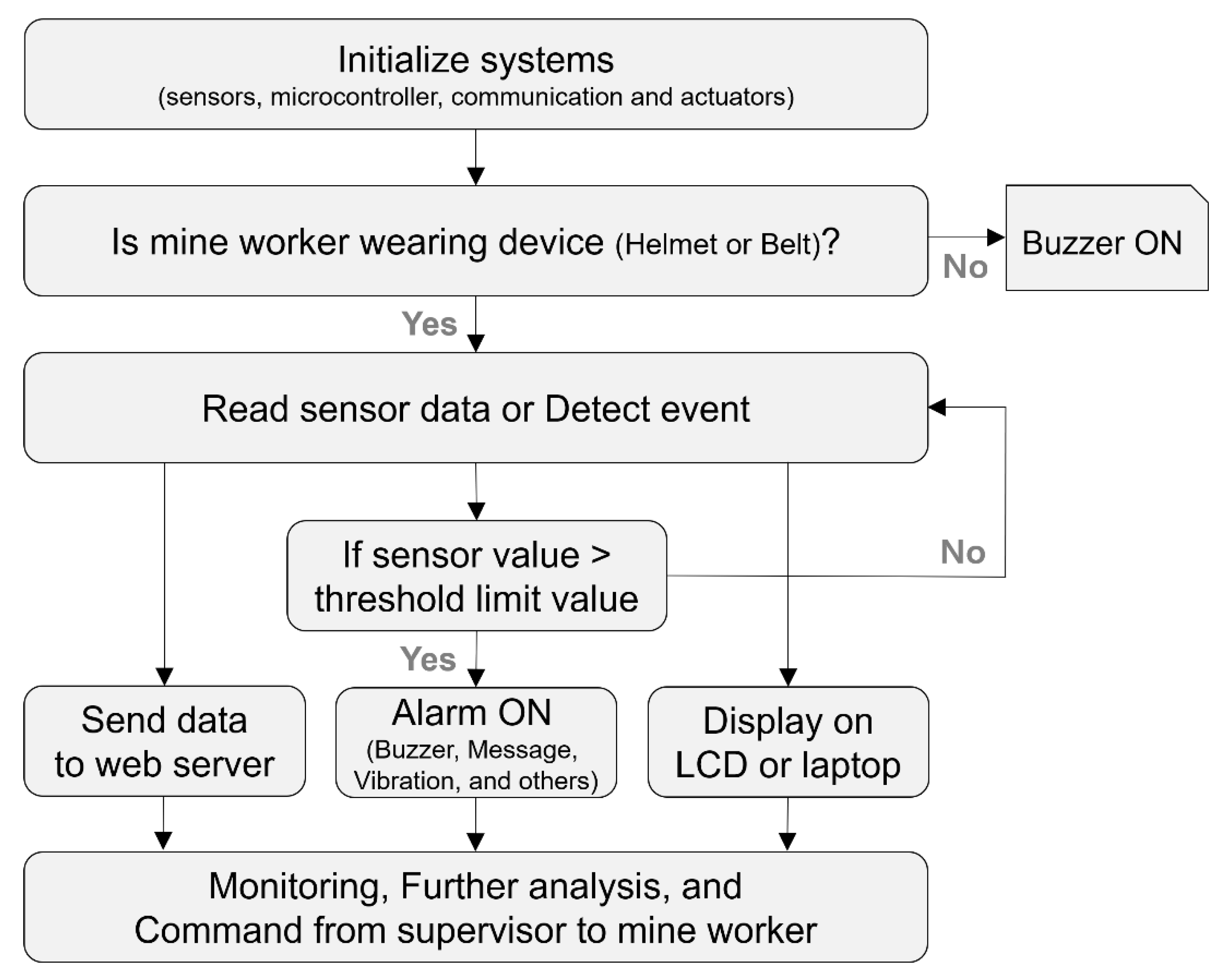

- The sensor in wearable systems is closely related to the purpose of the system being developed. Various types of sensors are available on the market and are usually found on consumer wearable devices according to the intended application, such as environmental sensors, biosensors, and position tracking sensors. These sensors are embedded in wearable devices for observing or measuring real-time underground parameters, such as the gas concentration, temperature, humidity, atmospheric pressure, oxygen concentration (for air quality or air density monitoring purposes), piezoelectric characteristics (for device wearing status monitoring purposes), vibrations (for destructive event or collision detection purpose), human heart rates or pulse rates (for human biocharacteristics monitoring purposes), and positions of machines or workers (for location monitoring purposes).

- The microcontroller serves as a platform for receiving the data measured by sensors (sensor output) and for transmitting the data to monitoring stations through wireless communication or actuating a device (e.g., providing alarms such as a buzzer) under specific conditions (called threshold limit values or critical safety values) using the measured data, based on coding or programming an Arduino IDE or Python. Arduino is a widely used hardware with low power usage and an easy-to-use open-source software platform for most electronics projects. Thus, the Arduino Mega, Arduino Nano, and Arduino UNO board (models) are frequently used to control microcontroller boards in systems.

- A wireless communication function is necessary to transmit data to a remote office or web server at a control station, as a communication network is generally not installed in underground mines. To establish a wireless communication network, various wireless communication technologies for data transmission and receiving have been utilized in the reviewed published literature, such as ZigBee, Bluetooth, and radio frequency identification.

- An actuator refers to something (e.g., wearable device) that actuates something else (e.g., a sound, message, display, or vibration). In particular, an actuator is usually an electric device that causes a mechanical device to switch in some fashion. Various wearable devices have been developed, such as smartwatches, smart eyewear, fitness trackers, smart clothing, and wearable cameras, according to their functional properties and capabilities (Figure 8) [58]. However, most of the studies reviewed in this section employed a (smart) helmet as an actuator. The reason for this is as follows. All mine workers must wear a helmet during work hours for safety, regardless of the type of mine. Therefore, designing a system on a helmet has an advantage in that miners can always wear it, and it can reduce unnecessary costs, e.g., purchasing other wearable equipment.

3.2. Surrounding Information

3.3. Human Bioinformation

4. Arduino in Autonomous Mine Systems

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Smart Mining. Available online: https://www.riotinto.com/about/innovation/smart-mining (accessed on 5 July 2020).

- How the Internet-of-Things Is Transforming Mining. Available online: http://www.clresearch.com/research/detail.cfm?guid=A5E6FEAF-3048-79ED-99C9-EA62EBCCD605 (accessed on 5 July 2020).

- Open Source Software for Industry 4.0. Available online: https://iot.eclipse.org/community/resources/white-papers/industry40 (accessed on 10 March 2020).

- The Future with Open-Source Hardware. Available online: http://www.digitalqatar.qa/en/2015/02/19/the-future-with-open-source-hardware (accessed on 5 April 2020).

- Open Source Organizations. Available online: https://opensource.com/resources/organizations (accessed on 5 April 2020).

- What Is Open Hardware? Available online: https://opensource.com/resources/what-open-hardware (accessed on 15 March 2020).

- Damjanovic-Behrendt, V.; Behrendt, W. An open source approach to the design and implementation of Digital Twins for Smart Manufacturing. Int. J. Comput. Integr. Manuf. 2019, 32, 366–384. [Google Scholar] [CrossRef]

- Fisher, D.K.; Gould, P.J. Open-source hardware is a low-cost alternative for scientific instrumentation and research. Mod. Instrum. 2012, 1, 8–20. [Google Scholar] [CrossRef]

- Hopkins, M.A.; Kibbe, A.M. Open-source hardware in controls education. Comput. Educ. J. 2014, 5, 62–70. [Google Scholar]

- Reguera, P.; García, D.; Domínguez, M.; Prada, M.A.; Alonso, S. A low-cost open source hardware in control education. Case study: Arduino-feedback Ms-150. IFAC-PapersOnLine 2015, 48, 117–122. [Google Scholar] [CrossRef]

- Schelly, C.; Anzalone, G.; Wijnen, B.; Pearce, J.M. Open-source 3-D printing technologies for education: Bringing additive manufacturing to the classroom. J. Vis. Lang. Comput. 2015, 28, 226–237. [Google Scholar] [CrossRef]

- Athani, S.; Tejeshwar, C.H.; Patil, M.M.; Patil, P.; Kulkarni, R. Soil moisture monitoring using IoT enabled arduino sensors with neural networks for improving soil management for farmers and predict seasonal rainfall for planning future harvest in North Karnataka-India. In Proceedings of the 2017 International Conference on I-SMAC (IoT in Social, Mobile, Analytics and Cloud), Palladam, India, 10–11 February 2017; pp. 43–48. [Google Scholar] [CrossRef]

- Bitella, G.; Rossi, R.; Bochicchio, R.; Perniola, M.; Amato, M. A novel low-cost open-hardware platform for monitoring soil water content and multiple soil-air-vegetation parameters. Sensors 2014, 14, 19639–19659. [Google Scholar] [CrossRef]

- Patil, A.; Beldar, M.; Naik, A.; Deshpande, S. Smart farming using Arduino and data mining. In Proceedings of the 2016 3rd International Conference on Computing for Sustainable Global Development (INDIACom), New Delhi, India, 16–18 March 2016; pp. 1913–1917. [Google Scholar]

- Mesas-Carrascosa, F.J.; Santano, D.V.; Meroño, J.E.; De La Orden, M.S.; García-Ferrer, A. Open source hardware to monitor environmental parameters in precision agriculture. Biosyst. Eng. 2015, 137, 73–83. [Google Scholar] [CrossRef]

- Wishkerman, A.; Wishkerman, E. Application note: A novel low-cost open-source LED system for microalgae cultivation. Comput. Electron. Agric. 2017, 132, 56–62. [Google Scholar] [CrossRef]

- Open-Source CNC Farming. Available online: https://farm.bot (accessed on 27 November 2019).

- Ferdoush, S.; Li, X. Wireless sensor network system design using raspberry pi and Arduino for environmental monitoring applications. Procedia Comput. Sci. 2014, 34, 103–110. [Google Scholar] [CrossRef]

- Lockridge, G.; Dzwonkowski, B.; Nelson, R.; Powers, S. Development of a low-cost arduino-based sonde for coastal applications. Sensors 2016, 16, 528. [Google Scholar] [CrossRef]

- Steiniger, S.; Hay, G.J. Free and open source geographic information tools for landscape ecology. Ecol. Inform. 2009, 4, 183–195. [Google Scholar] [CrossRef]

- Gad, H.E.; Gad, H.E. Development of a new temperature data acquisition system for solar energy applications. Renew. Energy 2015, 74, 337–343. [Google Scholar] [CrossRef]

- Hars, A. Working for free? Motivations of participating in open source projects. In Proceedings of the 34th Hawaii International Conference on System Sciences, Maui, HI, USA, 6 January 2001; pp. 1–9. [Google Scholar] [CrossRef]

- List of Open-Source Hardware Projects. Available online: https://en.wikipedia.org/wiki/List_of_open-source_hardware_projects (accessed on 3 March 2020).

- List of Open-Source Computing Hardware. Available online: https://en.wikipedia.org/wiki/List_of_open-source_computing_hardware (accessed on 3 March 2020).

- What Is Arduino? Available online: https://www.arduino.cc/en/Guide/Introduction (accessed on 15 March 2020).

- Mardonova, M.; Choi, Y. Toward Open-Source Hardware and Software for the Mining Industry: A Case Study of Low-Cost Environmental Monitoring System for Non-Metallic Underground Mines. Min. Metall. Explor. 2019, 36, 657–674. [Google Scholar] [CrossRef]

- Kim, S.M. Review of Internet of Things and Open-Source Hardware Technologies Use in the Mining Industry. J. Korean Soc. Miner. Energy Resour. Eng. 2019, 56, 447–456. [Google Scholar] [CrossRef]

- Jo, B.W.; Khan, R.M.A. An event reporting and early-warning safety system based on the internet of things for underground coal mines: A case study. Appl. Sci. 2017, 7, 925. [Google Scholar] [CrossRef]

- Alam, M.M.; Chakraborty, P.P.; Biswas, S.; Islam, A.J. Design of an intelligent helmet for mine workers. In Proceedings of the International Conference on Mechanical Engineering and Renewable Energy 2015, Chittagong, Bangladesh, 26–29 November 2015; pp. 1–5. [Google Scholar]

- Sakthi, S.; Niresh, J.; Neelakrishnan, S. Adaptive Admittance Control for Autonomous Loading of Load Haul Dumper in Underground Coal Mining. In Proceedings of the 5th International Conference on Mechatronics and Robotics Engineering, Rome, Italy, 16–19 February 2019; pp. 73–77. [Google Scholar] [CrossRef]

- A Comparison of Popular Arduino Boards. Available online: https://maker.pro/arduino/tutorial/a-comparison-of-popular-arduino-boards (accessed on 10 March 2020).

- Matin, M.A.; Islam, M.M. Overview of wireless sensor network. In Wireless Sensor Networks-Technology and Protocols; InTech: Rijeka, Croatia, 2012. [Google Scholar] [CrossRef]

- Naidu, K.P.S.S.V.; Visalakshi, P.; Chowdary, P.C. Coal mine safety system using Li-Fi technology. Int. J. Adv. Res. Ideas Innov. 2019, 5, 1288–1291. [Google Scholar]

- Anitha, K.; Seshagiri, T. Implementation of Wireless Sensor in Coal Mine Safety System using ZigBee. Int. Res. J. Eng. Tech. 2019, 6, 1467–1472. [Google Scholar]

- Srivastava, S.K. Real Time Monitoring System for Mine Safety Using Wireless Sensor Network (Multi-Gas Detector). Master’s Thesis, National Institute of Technology Rourkela, Rourkela, India, 2015. [Google Scholar]

- Kugan, R.S.; Gobi, K.R.; Mohan, M.; Gowtham, V.; Praveena, R. Coal mine monitoring and alert system with data acquisition. Int. J. Innov. Res. Adv. Eng. 2019, 6, 186–191. [Google Scholar]

- Bhagat, N.B. Wireless Surveillance and Safety System for Mine Workers Using ZigBee. Ph.D. Thesis, Nagpur University, Nagpur, Maharashtra, 2016. [Google Scholar]

- Ünsal, E.; Akkan, T.; Akkan, L.Ö.; Çebi, Y. Power management for Wireless Sensor Networks in underground mining. In Proceedings of the 24th Signal Processing and Communication Application Conference (SIU), Zonguldak, Turkey, 16–19 May 2016; pp. 1053–1056. [Google Scholar] [CrossRef]

- Nath, S.; Dey, A.; Pachal, P.; Chowdhury, S.R.; Sing, J.K.; Sarkar, S.K. Nano Structured Gas Sensing Device and Its Application in Underground Mines. In Proceedings of the 2018 IEEE Electron Devices Kolkata Conference (EDKCON), Kolkata, India, 24–25 November 2018; pp. 445–449. [Google Scholar] [CrossRef]

- Shah, A.; Patel, D.; Desai, P. IoT enabled worker safety system. J. Inf. Comput. Sci. 2019, 9, 732–744. [Google Scholar]

- Rajalakshmi, R.; Vidhya, J. Toxic Environment Monitoring Using Sensors Based on Arduino. In Proceedings of the 2019 IEEE International Conference on System, Computation, Automation and Networking (ICSCAN), Pondicherry, India, 29–30 March 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Sudila, N.; Elvitigala, C.S.; Wijebandara, L.R.; Gamage, G.S.; Jayakody, J.A.R.S.; Yapa, K.G.D.T. A IoT Proactive Disaster Management System for Mines. In Proceedings of the 18th International Symposium on Advanced Intelligent Systems (ISIS2017), Daegu, Korea, 11–14 October 2017; pp. 1–4. [Google Scholar]

- Durán, C.A.; Goméz, P.M.; Acosta, R.R. Wireless Smell System for Hazardous Gases Detection. Preprints 2018, 1–14. [Google Scholar] [CrossRef]

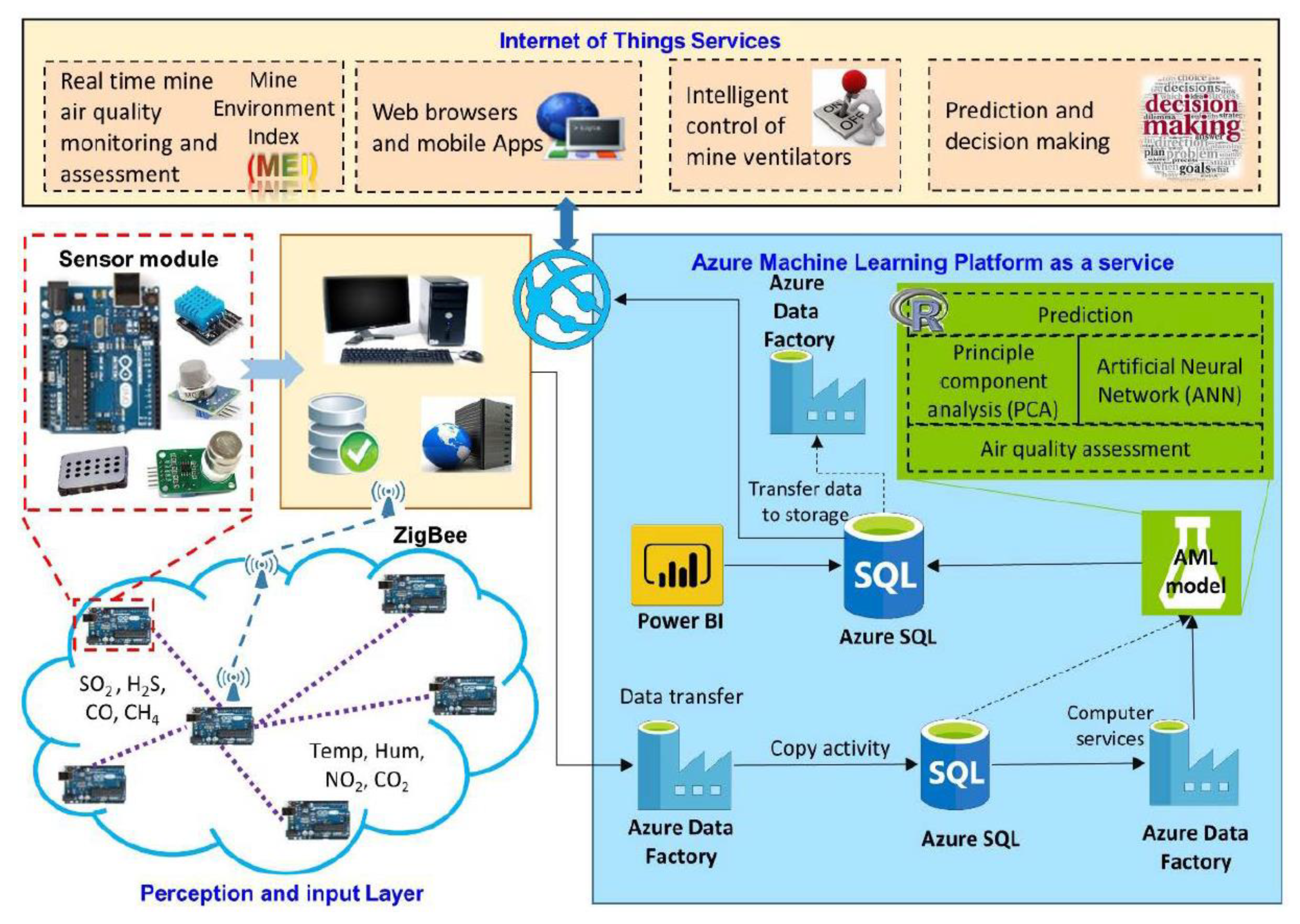

- Jo, B.; Khan, R.M.A. An internet of things system for underground mine air quality pollutant prediction based on azure machine learning. Sensors 2018, 18, 930. [Google Scholar]

- Mondal, B.; Meetei, M.S.; Das, J.; Chaudhuri, C.R.; Saha, H. Quantitative recognition of flammable and toxic gases with artificial neural network using metal oxide gas sensors in embedded platform. Eng. Sci. Technol. Int. J. 2015, 18, 229–234. [Google Scholar] [CrossRef]

- Rodriguez-Diaz, O.O.; Novella-Rodriguez, D.F.; Witrant, E.; Franco-Mejía, E. Benchmark for analysis, modeling and control of ventilation systems in small-scale mine. In Proceedings of the 2019 International Conference on Control, Automation and Diagnosis (ICCAD), Grenoble, France, 2–4 July 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Adjiski, V.; Despodov, Z.; Serafimovski, D.; Mijalkovski, S. Methodology for evaluation of the evacuation time in case of fire in underground mines. In Proceedings of the XII Стручнo сoветување oд oбласта на пoдземната и пoвршинската експлoатација (Пoдекс-Пoвекс 2019), Strumica, Macedonia, 1–3 November 2019; pp. 12–21. [Google Scholar]

- Adjiski, V.; Despodov, Z.; Serafimovski, D.; Mijalkovski, S. System for prediction of carboxyhemoglobin levels as an indicator for on-time installation of self-contained self-rescuers in case of fire in underground mines. Geosci. Eng. 2019, 65, 23–37. [Google Scholar] [CrossRef]

- Pop, E.; Ilcea, G.I.; Popa, I.A.; Bogdanffy, L. Increasing the Safety of People Activity in Aggressive Potential Locations, Analyzed through the Probability Theory, Modeling/Simulation and Application in Underground Coal Mining. Engineering 2019, 11, 93–106. [Google Scholar] [CrossRef]

- Jayanthu, S.; Karthik, G.; Yadav, D.K. Current Trends in Slope Stability Monitoring in Opencast Mines Vis-À-Vis Time Domain Reflectometry. In Proceedings of the Current Practices in Mining & Allied Industries, Keonjhar, India, 23–24 September 2017; pp. 62–70. [Google Scholar]

- Karthik, G.; Jayanthu, S. Selection of suitable location and method for installation of TDR in opencast mine-an experimental approach. Math. Model. Eng. Probl. 2018, 5, 256–259. [Google Scholar] [CrossRef]

- Jayanthu, S.; Karthik, G. Development of Effective Technology for Online Slope Monitoring in Opencast Mines-R&D Initiative. In Proceedings of the Workshop on Emerging Mining Technologies and Low-Carbon Footprints with Waste Management, Vigyan Bhawan, New Delhi, India, 13–14 February 2017; pp. 1–11. [Google Scholar]

- Jayanthu, S.; Karthik, G.; Shohood A, P.M.G. Development of Indigenous Wireless Tiltmeter for Slope Stability Monitoring in Opencast Mines. In Proceedings of the Seminar on Make in India Initiatives in Mining, Satna, India, 23 December 2016; pp. 1–7. [Google Scholar]

- Prashanth, R.; Nimaje, D.S. Development of blast-induced ground vibration wireless monitoring system. In Proceedings of the 39th Application of Computers and Operations Research in the Mineral Industry (APCOM 2019), Wroclaw, Poland, 4–6 June 2019; pp. 1–8. [Google Scholar] [CrossRef]

- Tiwari, S.; Arya, A.; Chatterjee, A.; Mishra, P.K.; Banerjee, G. Development of laboratory scale wireless borehole extensometer for underground mines. In Proceedings of the Seminar on Technological Advancement and Emerging Mining Methods (TAEMM 2018), Dhanbad, India, 24–25 August 2018; pp. 252–255. [Google Scholar]

- Alzahrani, A.A.M. Detection of Mine Roof Failure Using Inexpensive LiDAR Technology. Master’s Thesis, Missouri University of Science and Technology, Rolla, MO, USA, 2017. [Google Scholar]

- Mukherjee, M.; Jayanthu, S. Innovative Application of T-Ray Imaging Unit for Crack Detection and Mine Safety–An Appraisal for Experimental Trial. In Proceedings of the 2nd National Conference on Current Practices in Mining and Allied Industries (CPMAI 2018), Keonjhar, Odisha, India, 6–7 October 2018; pp. 1–14. [Google Scholar]

- Mardonova, M.; Choi, Y. Review of Wearable Device Technology and Its Applications to the Mining Industry. Energies 2018, 11, 547. [Google Scholar] [CrossRef]

- Majee, A. IoT Based Automation of Safety and Monitoring System Operations of Mines. Int. J. Elect. Electron. Eng. 2016, 3, 17–21. [Google Scholar] [CrossRef]

- Harshitha, K.; Sreeja, K.; Manusha, N.; Harika, E.; Rao, P.K. ZigBee based intelligent helmet for coal miners safety purpose. Int. J. Innov. Technol. 2018, 6, 403–406. [Google Scholar]

- Roja, P.; Srihari, D. Iot based smart helmet for air quality used for the mining industry. Int. J. Res. Sci. Eng. Technol. 2018, 4, 514–521. [Google Scholar]

- Bhuttoa, G.M.; Daudpotoa, J.; Jiskanib, I.M. Development of a wearable safety device for coal miners. Int. J. Chem. Env. Eng. 2016, 7, 225–229. [Google Scholar]

- Noorin, M.; Suma, K.V. IoT based wearable device using WSN technology for miners. In Proceedings of the 3rd IEEE International Conference on Recent Trends in Electronics, Information & Communication Technology (RTEICT), Bangalore, India, 18–19 May 2018; pp. 992–996. [Google Scholar] [CrossRef]

- Priyadarsini, V.; Verma, A.; Singh, M.; Netam, S.; Chandrakar, D. LabVIEW Based Real Time Monitoring System for Coal Mine Worker. J. Digit. Signal Process. 2018, 6, 1–6. [Google Scholar] [CrossRef]

- Dudwadkar, A.; Parkhi, N.; Kulkarni, M.; Shah, H.; Gupta, R. Wireless Mine Surveillance with Data Logging. Int. J. Adv. Res. Elect. Electron. Instru. Eng. 2016, 5, 2401–2406. [Google Scholar] [CrossRef]

- Oliveira, V.A.D.J.; Marques, E.; de Lemos Peroni, R.; Maciel, A. Tactile interface for navigation in underground mines. In Proceedings of the 2014 XVI Symposium on Virtual and Augmented Reality, Piata Salvador, Brazil, 12–15 May 2014; pp. 230–237. [Google Scholar] [CrossRef]

- Dewarkar, A.; Lengure, R.; Thool, S.; Borakhade, S. Smart Device for Security of Coal Mine Workers. Int. J. Innov. Res. Technol. 2019, 5, 351–353. [Google Scholar]

- Sanjay, B.S.; Dilip, K.A.; Balasaheb, T.A.; KinnuKumar, S.; Chandrabhushan, P.; Saware, N.P. Smart Helmet Using ZigBee. Int. J. Innov. Res. Tech. 2019, 6, 144–148. [Google Scholar]

- Azizi, M.; Tarshizi, E. Autonomous control and navigation of a lab-scale underground mining haul truck using LiDAR sensor and triangulation-feasibility study. In Proceedings of the 2016 IEEE Industry Applications Society Annual Meeting, Portland, OR, USA, 2–6 October 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Ledange, S.M.; Mathurkar, S.S. Robot based wireless monitoring and safety system for underground coal mines using ZigBee. Int. J. Electron. Commun. Eng. 2016, 3, 23–26. [Google Scholar] [CrossRef]

- Salazar, R.; Conislla, O.; Cornejo, J. Design and Construction of a Remotely Controlled Truck Robot for Detecting Harmful and Flammable Gases in Underground Mining. Available online: http://acreditacion.uni.edu.pe/wp-content/uploads/2017/05/Design-and-Construction-of-a-Remotely-Controlled-Truck-Robot-for-Detecting-Harmful-and-Flammable-Gases-in-Underground-Mining.pdf (accessed on 7 April 2020).

- Cekova, K.; Martinovska Bande, C.; Velkova, A.; Stojkovic, N. Mobile Sensor System for Detection of Toxic Gases in Mines. In Proceedings of the 10th ICT Innovations, Engineering and Life Sciences WEB, Metropol Lake Resort, Ohrid, Macedonia, 17–19 September 2018; pp. 112–123. [Google Scholar]

- Bai, L.; Huang, X.; Liu, X.; Gao, H.; Huang, M. Mechanical–electrical–pneumatic systematic design exploration of hexapod robot experimental prototype. J. Eng. 2019, 23, 8932–8936. [Google Scholar] [CrossRef]

- Kumar, S.S.; Jabannavar, S.S.; Shashank, K.R.; Nagaraj, M.; Shreenivas, B. Localization and tracking of unmanned vehicles for underground mines. In Proceedings of the 2017 Second International Conference on Electrical, Computer and Communication Technologies (ICECCT), Coimbatore, India, 22–24 February 2017; pp. 1–4. [Google Scholar] [CrossRef]

- Alvarado, M.; Gonzalez, F.; Fletcher, A.; Doshi, A. Towards the development of a low cost airborne sensing system to monitor dust particles after blasting at open-pit mine sites. Sensors 2015, 15, 19667–19687. [Google Scholar] [CrossRef] [PubMed]

- Martin, P.G.; Payton, O.D.; Fardoulis, J.S.; Richards, D.A.; Scott, T.B. The use of unmanned aerial systems for the mapping of legacy uranium mines. J. Environ. Radioactiv. 2015, 143, 135–140. [Google Scholar] [CrossRef] [PubMed]

- Mitchell, J.; Marshall, J.A. Towards a novel auto-rotating lidar platform for cavity surveying. Tunn. Undergr. Space Technol. 2020, 97, 103260. [Google Scholar] [CrossRef]

- Videla, A.R.; Morales, R.; Saint-Jean, T.; Gaete, L.; Vargas, Y.; Miller, J.D. Ultrasound treatment on tailings to enhance copper flotation recovery. Miner. Eng. 2016, 99, 89–95. [Google Scholar] [CrossRef]

- Deen, K.M.; Asselin, E. Integration of Cu extraction and Zn electrowinning processes for energy storage. J. Clean. Prod. 2020, 253, 119779. [Google Scholar] [CrossRef]

- Liu, X.; Li, X.; Li, F.; Zhao, G.; Qin, Y. 3D cavity detection technique and its application based on cavity auto scanning laser system. J. Central South Univ. Technol. 2008, 15, 285–288. [Google Scholar] [CrossRef]

| Computer Systems | Communications | Robotics | Machines and Production Tools | Science |

|---|---|---|---|---|

|

|

|

|

|

| Reference | Mine type | Purpose of Field Monitoring System | Microcontroller | Sensor | Communication | Actuator or Other Modules | Additional Analysis |

|---|---|---|---|---|---|---|---|

| Naidu et al. [33] | underground | air quality monitoring | Arduino UNO | gas (MQ2), temperature (LM35) | Li-Fi 1 | headphone | N/A |

| Anitha and Seshagiri [34] | underground | air quality monitoring | Arduino UNO | gas (MQ6), temperature (LM35), fire sensor | ZigBee (Xbee) | buzzer | N/A |

| Srivastava [35] | underground | air quality monitoring | Arduino UNO | gas (MQ4, MQ7, MG811), temperature and humidity (DHT11) | ZigBee (Xbee) | buzzer, LCD 2 | N/A |

| Kugan et al. [36] | underground | air quality monitoring | Arduino Mega | gas (MID04), temperature (LM35), pressure, heart beat sensor | GSM 3 (SIM800) | buzzer, LED 4 | N/A |

| Bhagat [37] | underground | air quality monitoring | Arduino UNO | gas (MQ4), temperature and humidity (DHT11) | ZigBee (Xbee) | N/A | N/A |

| Ünsal et al. [38] | underground | air quality monitoring | Arduino UNO | gas (MQ4, MQ7, MQ9), temperature and humidity (DHT22) | RF 5 (nRF24L01) | N/A | battery life analysis |

| Nath et al. [39] | underground | air quality monitoring | Node MCU | gas (Au-ZnO, Au-WO3, Au-TiO2, Au-CuO) | Wi-Fi (ESP8266) | alarm system | N/A |

| Shah et al. [40] | polluted area | air quality monitoring | Arduino Mega | gas (MQ2, MQ4, MQ7, MQ135), temperature and humidity (DHT11, DHT22) | Wi-Fi (ESP8266) | LCD | N/A |

| Rajalakshmi and Vidhya [41] | polluted area | air quality monitoring | Arduino UNO | gas (MQ2, MQ7, MQ8, MQ9), temperature (LM35) | GSM (SIM900A) | N/A | N/A |

| Sudila and Elvitigala [42] | underground | air quality monitoring | Arduino UNO, Mega | gas (MQ2, MQ7) | GSM (SIM800) | Buzzer, LCD, RTC 6 | regression analysis |

| Jo and Khan [28] | underground | air quality monitoring | Arduino Mega | gas (MQ4, MQ9, MQ135), temperature and humidity (DHT11) | BLE 7 (BLE shield) | N/A | k-means clustering |

| Durán et al. [43] | underground | air quality monitoring | Arduino UNO | gas (MQ2, MQ3, MQ6, MQ7, MQ8, MQ9), | ZigBee (Xbee) | Vacuum pump (T2-03) | PCA 8, LDA 9 |

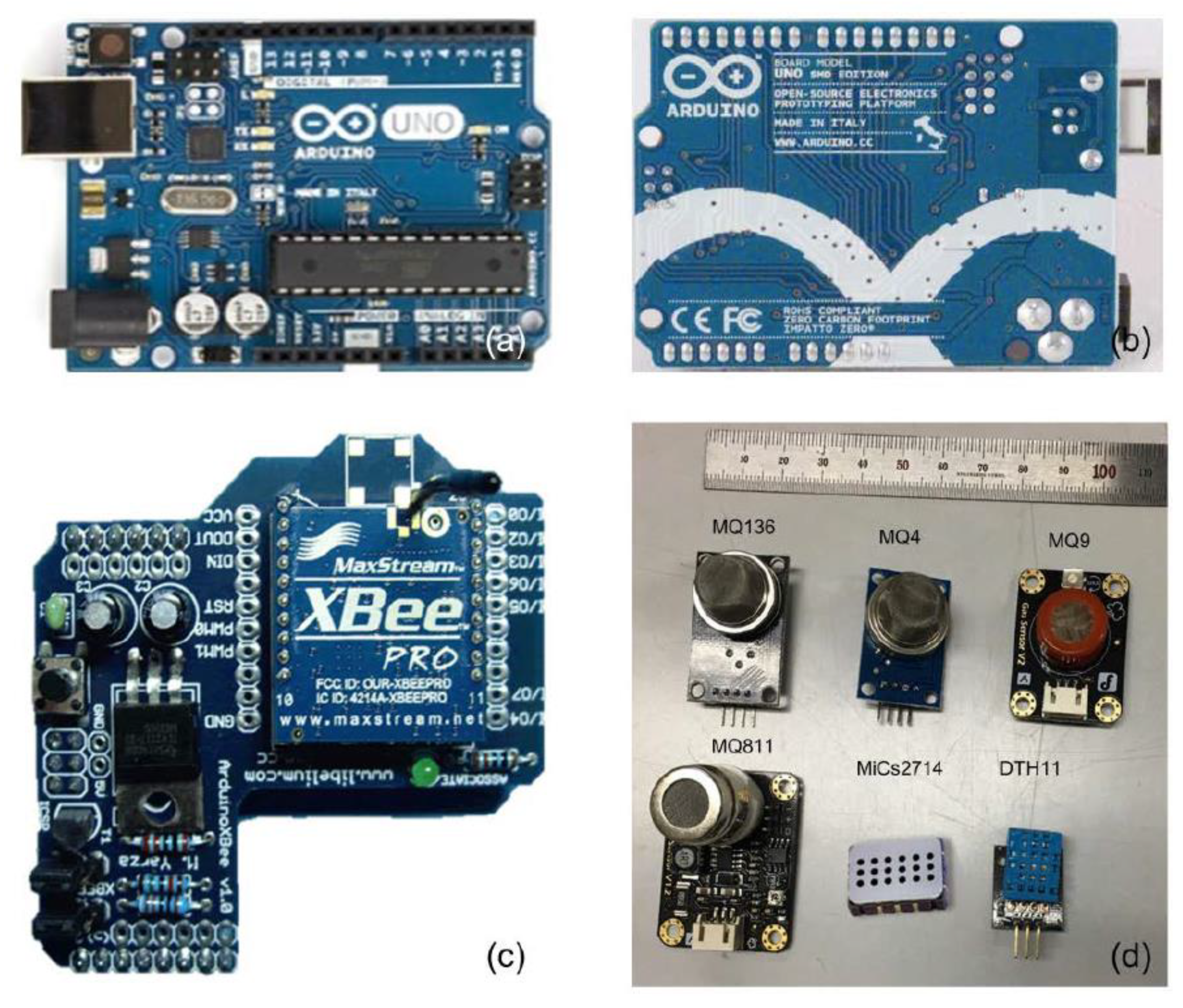

| Jo and Khan [44] | underground | air quality monitoring | Arduino UNO | gas (MQ4, MQ9, MG811, MQ136, MiCs2714) | ZigBee (Xbee) | N/A | PCA, ANN 10 |

| Mondal et al. [45] | underground | air quality monitoring | Arduino Due | gas (ZnO, ZnO-SnO2) | N/A | N/A | gas classification (ANN) |

| Rodriguez-Diaz et al. [46] | underground | air flow monitoring | Arduino Mega | air flow (hot wire sensor, mass flow sensor, orifice plate sensor) | N/A | centrifugal fan | ventilation network modeling |

| Adjiski et al. [47] | underground | air quality monitoring | Arduino Nano | gas (MQ7) | Bluetooth (HC05) | N/A | COHb 11 calculation |

| Adjiski et al. [48] | underground | air quality monitoring | Arduino Nano | gas (MQ7) | Bluetooth (HC05) | N/A | COHb calculation, fire scenario simulation |

| Pop et al. [49] | underground | air quality monitoring | Arduino UNO | gas (MQ2) | ZigBee (Xbee) | N/A | probabilistic strategy for potentially explosive area |

| Jayanthu et al. [50] | open-pit | slope monitoring | Arduino Mega | time domain reflectometry (TDR) | ZigBee (Xbee) | N/A | N/A |

| Karthik and Jayanthu [51] | open-pit | slope monitoring | Arduino Mega | time domain reflectometry (TDR) | ZigBee (Xbee) | N/A | Zigbee module range test |

| Jayanthu and Karthik [52] | open-pit | slope monitoring | Arduino Mega | time domain reflectometry (TDR) | ZigBee (Xbee) | N/A | Zigbee module range test |

| Jayanthu et al. [53] | open-pit | slope monitoring | Arduino UNO | accelerometer (ADXL345) | GSM (SIM800) | N/A | N/A |

| Prashanth and Nimaje [54] | open-pit | vibration monitoring | Arduino UNO | accelerometer (ADXL335) | GSM (SIM800) | N/A | N/A |

| Tiwari et al. [55] | underground | borehole monitoring | Arduino UNO | ultrasonic sensor | N/A | N/A | N/A |

| Alzahrani [56] | underground | roof monitoring | Arduino UNO | LiDAR 12 sensor (M16) | ZigBee (Xbee) | linear actuator (EZC4-05M), motor controller | statistical analysis for removing anomalies |

| Sensor Name | Sensor Type | Detect |

|---|---|---|

| MQ2 | Gas sensor | Methane, butane, LPG 1, smoke |

| MQ3 | Gas sensor | Alcohol, ethanol, smoke |

| MQ4 | Gas sensor | Methane, natural gas |

| MQ6 | Gas sensor | LPG, butane gas |

| MQ7 | Gas sensor | Carbon monoxide |

| MQ8 | Gas sensor | Hydrogen gas |

| MQ9 | Gas sensor | Carbon monoxide, flammable gases. |

| MQ135 | Gas sensor | Air quality (benzene, alcohol, smoke) |

| MQ136 | Gas sensor | Hydrogen sulfide gas |

| MG811 | Gas sensor | Carbon dioxide |

| MiCs2714 | Gas sensor | Nitrogen dioxide |

| DHT11 | Temperature and Humidity sensor | Temperature range: 0–50 °C (±2 °C) Humidity range: 20–80%RH (±5%RH 2) |

| DHT22 | Temperature and Humidity sensor | Temperature range: −40–80°C (±0.5 °C) Humidity range: 0–100%RH (±2%RH) |

| LM35 | Temperature sensor | Temperature range: −55 °C to 150°C (±0.5 °C) |

| ADXL335 | Accelerometer | 3-axis sensing (±3 g measurement range) |

| ADXL345 | Accelerometer | 3-axis sensing (±16 g measurement range) |

| Reference | Type of Mine | Purpose of Wearable System | Microcontroller | Sensor | Communication | Actuator or Other Modules |

|---|---|---|---|---|---|---|

| Majee [59] | Underground coal | Air quality monitoring Air density | Arduino Nano Arduino UNO | Gas (MQ2, MQ4, and MQ135), air density, temperature and humidity (DHT11) | ZigBee Wi-Fi (ESP8266) | Helmet with alarm system Web server (at control station) |

| Harshitha et al. [60] | Underground coal | Air quality monitoring | Arduino UNO | Gas (MQ2), temperature (LM35), humidity (DHT11), | ZigBee | Helmet with buzzer Web server (at control station) |

| Roja and Srihari [61] | Underground coal | Air quality monitoring Helmet wearing status | Arduino UNO | Gas (MQ6 and MQ7), Infrared (IR), piezoelectric sensor | GSM (SIM800L) | Helmet with buzzer LCD (liquid crystal display) |

| Bhuttoa et al. [62] | Underground coal | Air quality monitoring Collision detection | Arduino Nano | Gas (MQ2), temperature and humidity (DHT11), ultrasonic (HC-SR04) | N/A | Leather belt with buzzer, |

| Noorin and Suma [63] | Underground | Air quality monitoring Collision detection Helmet wearing status | Arduino Nano | Gas (MQ4), temperature and humidity (DHT11), vibration (SW420) | Wi-Fi | Helmet with buzzer and OLED Alert to supervisor |

| Priyadarsini et al. [64] | Underground coal | Heart rate monitoring | Arduino UNO | Heartbeat rate (ECG AD8232) | LabVIEW | Laptop (at control station) |

| Dudwadkar et al. [65] | Underground coal | Air quality monitoring Heart rate monitoring | Arduino | Gas (MQ135), temperature and humidity (DHT11), heartbeat rate (IR light reflection and refraction) | ZigBee (XBEE) | Laptop (at control station) |

| Oliveira et al. [66] | Underground | Navigation Heart rate monitoring | Arduino Mega | Heartbeat rate | N/A | Vibrotactile belt |

| Alam et al. [29] | Underground coal | Air quality monitoring Heart rate monitoring | Arduino Mega | Gas (MQ5), temperature and humidity (HSM-20G), heartbeat rate (ear clip kit) | ZigBee | Helmet with buzzer, LCD (at control station) |

| Dewarkar et al. [67] | Underground coal | Air quality monitoring Position monitoring Pulse rate monitoring | Arduino Nano | Gas (MQ7), temperature, pulses rate, GPS | RF (HC12) | Helmet with buzzer Display screen |

| Sanjay et al. [68] | Underground coal | Air quality monitoring Destructive event detection Pulse rate monitoring | Arduino Nano | Gas (MQ135), humidity, atmospheric pressure and temperature (BMP180), Infrared (IR), pulses rate | ZigBee (S2C) | Helmet with buzzer and LED Alert to supervisor |

| Sensing Items | Sensor Name | Permissible Limits | Threshold Set | |

|---|---|---|---|---|

| Gas | Combustible gas and smoke | MQ-02 | Less than 30% | 30% |

| Methane, Butane, and natural gas | MQ-4 | Less than 10% | 12% | |

| Sulfides, Benzene, and Ammonia | MQ-135 | Less than 25% | 30% | |

| Temperature | DHT11 | 25–40 °C | 50 °C | |

| Humidity | DHT11 | 15–70% | 70% | |

| Reference | Type of Mine | Purpose of Autonomous System | Microcontroller | Sensor | Communication | Actuator or Other Modules |

|---|---|---|---|---|---|---|

| Ledange and Mathurkar [70] | underground | underground monitoring robot | Arduino UNO | gas (MQ2), temperature and humidity (DHT11), tilt (ADXL335) | ZigBee (Xbee) | DC motors, motor driver (L293D) |

| Salazar et al. [71] | underground | underground monitoring robot | Arduino Mega | gas (MQ135), wireless camera | Bluetooth (HC05) | DC motors, motor driver (L298N) |

| Cekova et al. [72] | underground | underground monitoring robot | Arduino UNO | gas (MQ2, MQ7, MQ135), temperature and humidity (DHT11) | Wi-Fi (ESP8266) | DC motors |

| Bai et al. [73] | underground | underground monitoring and rescue robot | Arduino Leonardo | N/A | N/A | nitrogen cylinder, electromagnetic valve and driver |

| Sakthi et al. [30] | underground | automated bucket of Load Haul Dumper (LHD) | Arduino UNO | pressure (unknown) | N/A | boom and the bucket actuators |

| Azizi and Tarshizi [69] | underground | automated haul truck | Arduino Mega | LiDAR (RPLIDAR A1) | N/A | RC truck (1/14 8x8 Armageddon Hydraulic Dump) |

| Kumar et al. [74] | underground | underground monitoring robot | Arduino Mega | infrared (FC51), gas (MQ2), temperature (LM35) | ZigBee (Xbee) | DC motors, motor driver (L293D) |

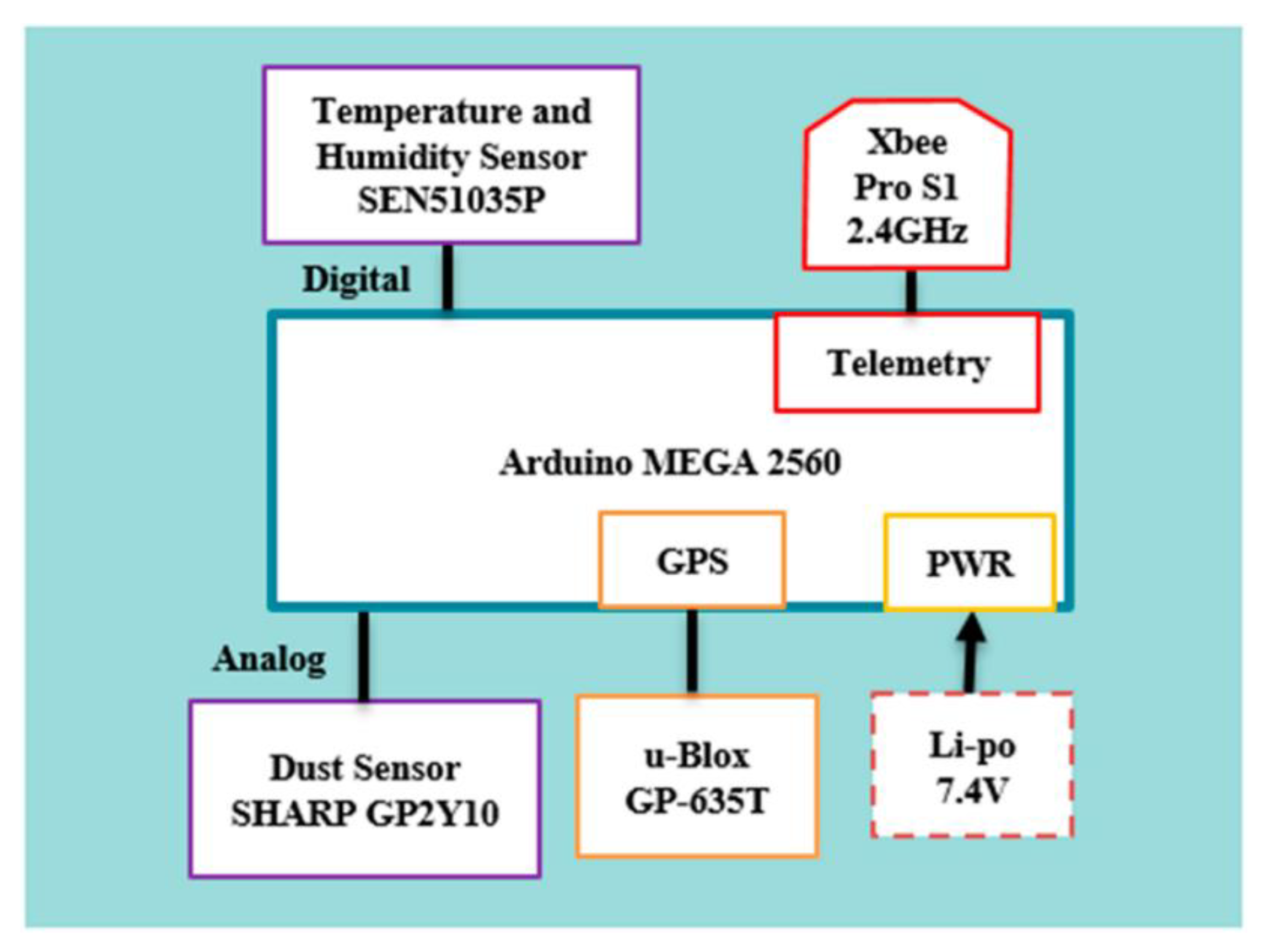

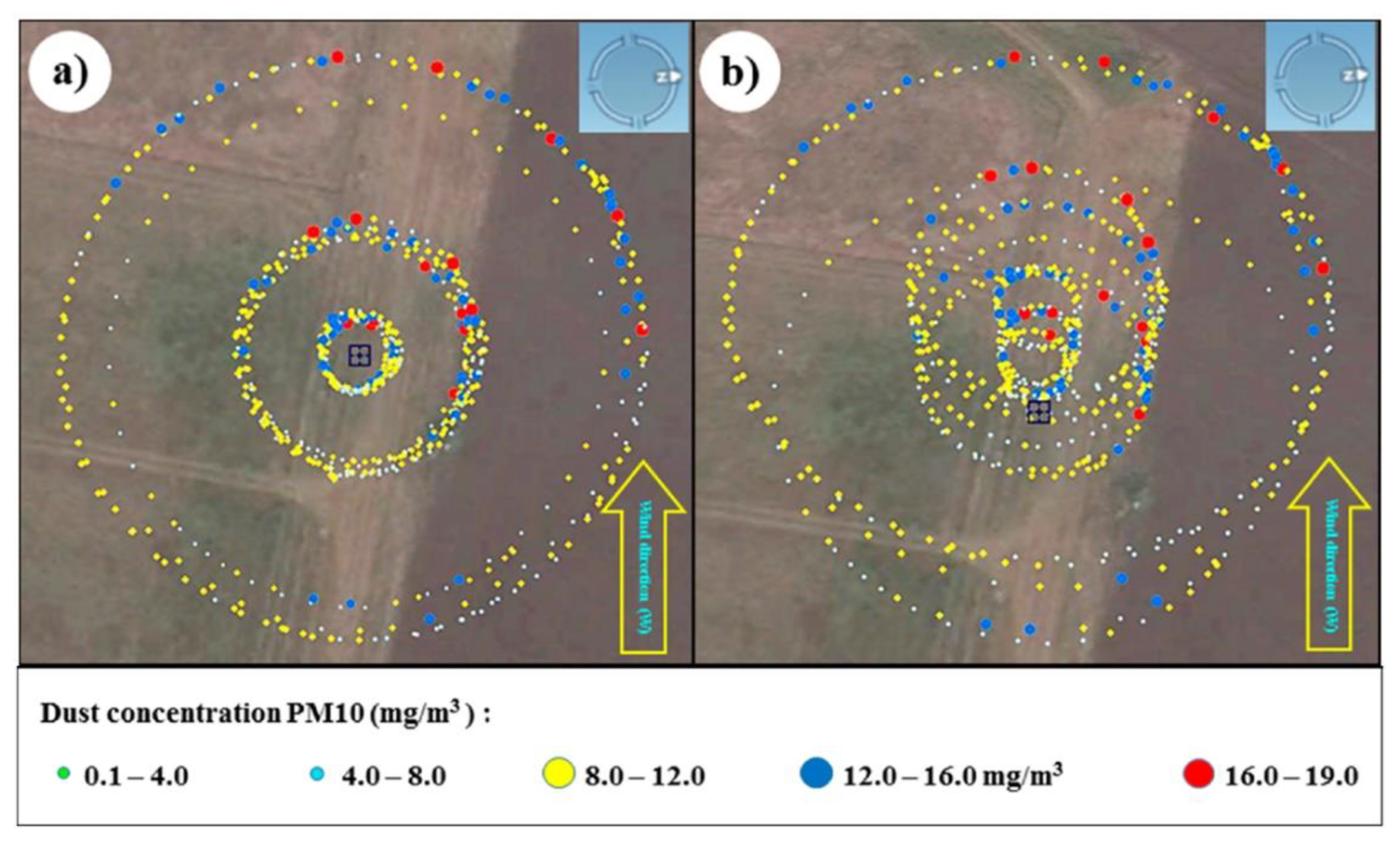

| Alvarado et al. [75] | open-pit | dust sensing unmanned aerial vehicle (UAV) | Arduino Mega | dust (GP2Y10, DSM501A), temperature and humidity (SEN51035P), GPS (GP635T) | ZigBee (Xbee) | rotary-wing UAV |

| Martin et al. [76] | Polluted area | pollution monitoring unmanned aerial vehicle (UAV) | Arduino Mega | gamma-ray spectrometer (GR1), GPS, LiDAR (AR2500) | unknown | rotary-wing UAV |

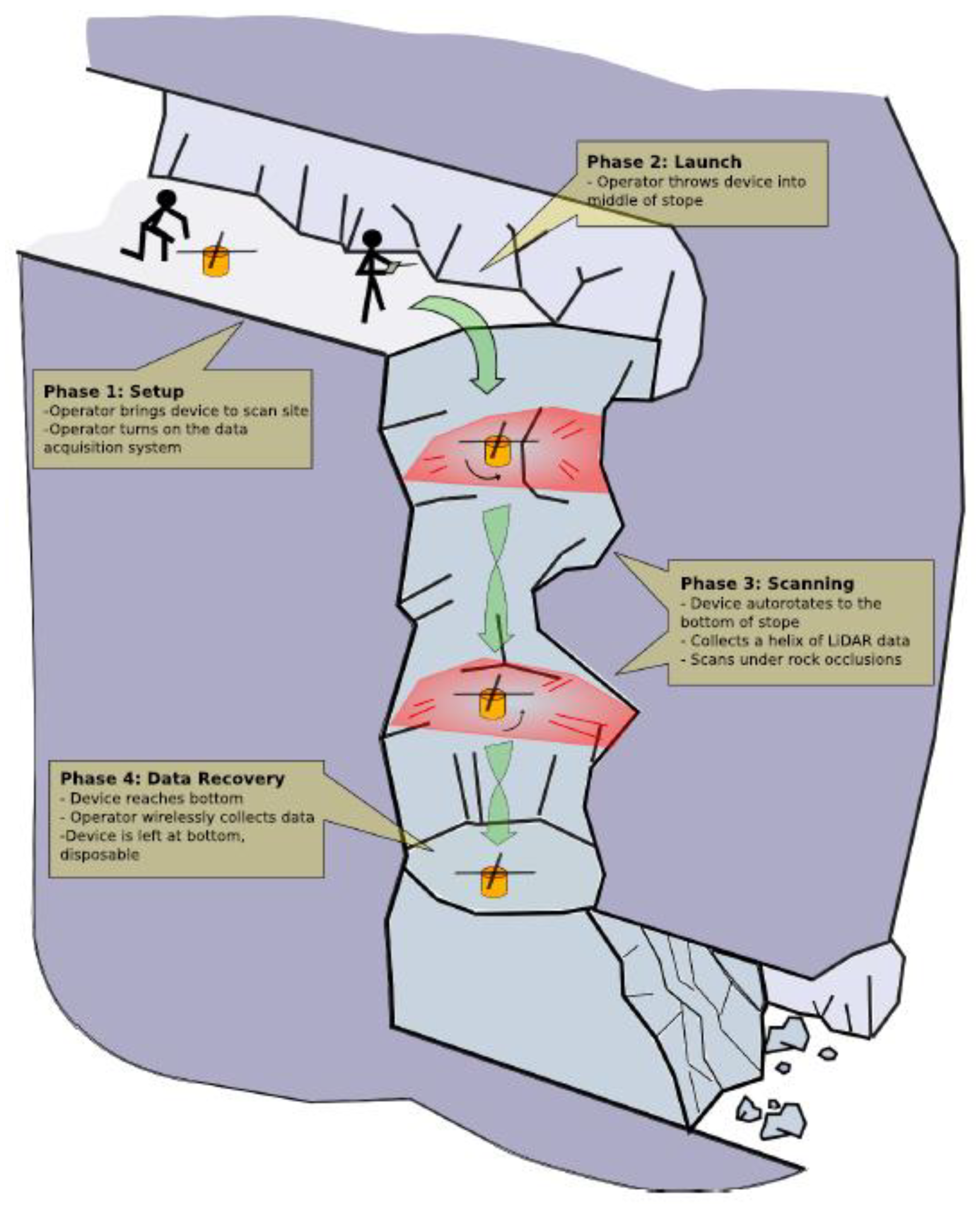

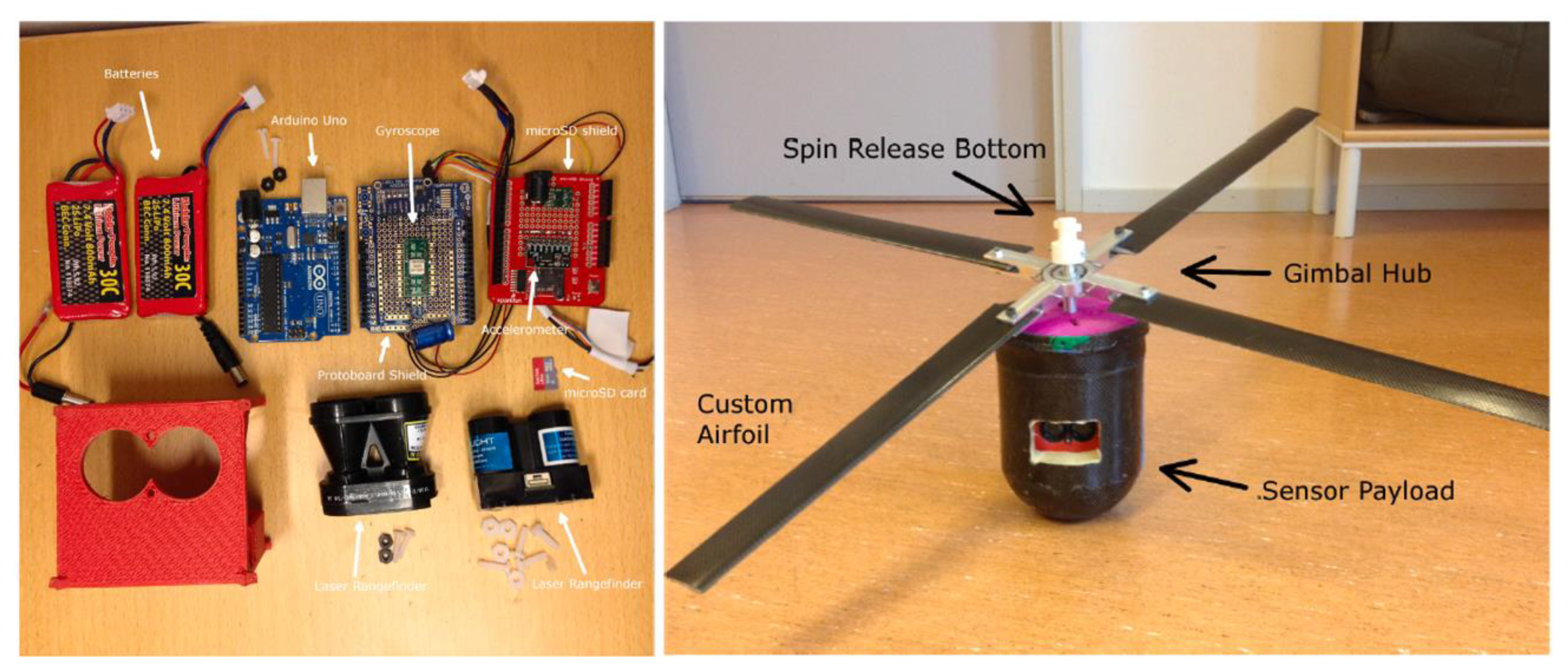

| Mitchell and Marshall [77] | open-pit | cavity monitoring unmanned aerial vehicle (UAV) | Arduino UNO | LiDAR (LiDAR-Lite V2, SF30/B), gyroscope (ADXRS649), accelerometer (ADXL345) | N/A | rotary-wing UAV |

| Videla et al. [78] | undefined | efficiency improvement of mineral recovery | Arduino (unknown) | calibrated probe for acoustic fields | N/A | Denver flotation machine |

| Deen and Asselin [79] | undefined | efficiency improvement of mineral recovery | Arduino (unknown) | trifunctional battery (TFB) | N/A | LED |

| Mine Type | Field Monitoring Systems | Wearable Systems | Autonomous Mine Systems | Sum (Percentage) |

|---|---|---|---|---|

| Underground | 18 (37.5%) | 11 (22.9%) | 7 (14.6%) | 36 (75.0%) |

| Open-pit | 5 (10.4%) | 0 (0.0%) | 2 (4.2%) | 7 (14.6%) |

| Polluted area | 2 (4.2%) | 0 (0.0%) | 1 (2.1%) | 3 (6.2%) |

| Undefined | 0 (0.0%) | 0 (0.0%) | 2 (4.2%) | 2 (4.2%) |

| Sum (Percentage) | 25 (52.1%) | 11 (22.9%) | 12 (25.0%) | 48 (100.0%) |

| Purpose | Field Monitoring Systems | Wearable Systems | Autonomous Mine Systems | Sum (Percentage) |

|---|---|---|---|---|

| Atmospheric monitoring | 18 (26.9%) | 10 (14.9%) | 6 (9.0%) | 34 (50.7%) |

| Slope monitoring | 4 (6.0%) | 0 (0.0%) | 0 (0.0%) | 4 (6.0%) |

| Vibration monitoring | 1 (1.5%) | 0 (0.0%) | 0 (0.0%) | 1 (1.5%) |

| Borehole monitoring | 1 (1.5%) | 0 (0.0%) | 0 (0.0%) | 1 (1.5%) |

| Roof monitoring | 1 (1.5%) | 0 (0.0%) | 0 (0.0%) | 1 (1.5%) |

| Helmet wearing detection | 0 (0.0%) | 2 (3.0%) | 0 (0.0%) | 2 (3.0%) |

| Collision/event detection | 0 (0.0%) | 3 (4.5%) | 0 (0.0%) | 3 (4.5%) |

| Heart rate (pulse) monitoring | 0 (0.0%) | 6 (9.0%) | 0 (0.0%) | 6 (9.0%) |

| Navigation/ position monitoring | 0 (0.0%) | 2 (3.0%) | 1 (1.5%) | 3 (4.5%) |

| Machine/robot control | 0 (0.0%) | 0 (0.0%) | 7 (10.4%) | 7 (10.4%) |

| UAV-based monitoring | 0 (0.0%) | 0 (0.0%) | 3 (4.5%) | 3 (4.5%) |

| Efficiency improvement of mineral recovery | 0 (0.0%) | 0 (0.0%) | 2 (3.0%) | 2 (3.0%) |

| Sum | 25 (37.3%) | 23 (34.3%) | 19 (28.4%) | 67 (100.0%) |

| Arduino Type | Field Monitoring Systems | Wearable Systems | Autonomous Mine Systems | Sum (Percentage) |

|---|---|---|---|---|

| UNO | 14 (28.6%) | 4 (8.2%) | 4 (8.2%) | 22 (44.9%) |

| Mega | 8 (16.3%) | 2 (4.1%) | 5 (10.2%) | 15 (30.6%) |

| Nano | 2 (4.1%) | 5 (10.2%) | 0 (0.0%) | 7 (14.3%) |

| Due | 1 (2.0%) | 0 (0.0%) | 0 (0.0%) | 1 (2.0%) |

| Leonardo | 0 (0.0%) | 0 (0.0%) | 1 (2.0%) | 1 (2.0%) |

| Etc. | 1 (2.0%) | 0 (0.0%) | 2 (4.1%) | 3 (6.1%) |

| Sum | 26 (53.1%) | 11 (22.4%) | 12 (24.5%) | 49 (100.0%) |

| Sensor | Field Monitoring Systems | Wearable Systems | Autonomous Mine Systems | Sum (Percentage) |

|---|---|---|---|---|

| Gas | 17 (15.9%) | 9 (8.4%) | 4 (3.7%) | 30 (28.0%) |

| Temperature | 9 (8.4%) | 8 (7.5%) | 4 (3.7%) | 21 (19.6%) |

| Humidity | 5 (4.7%) | 7 (6.5%) | 3 (2.8%) | 15 (14.0%) |

| Heart beat | 1 (0.9%) | 6 (5.6%) | 0 (0.0%) | 7 (6.5%) |

| Accelerometer or vibration | 2 (1.9%) | 1 (0.9%) | 2 (1.9%) | 5 (4.7%) |

| Pressure | 1 (0.9%) | 1 (0.9%) | 1 (0.9%) | 3 (2.8%) |

| LiDAR | 1 (0.9%) | 0 (0.0%) | 3 (2.8%) | 4 (3.7%) |

| IR | 0 (0.0%) | 2 (1.9%) | 1 (0.9%) | 3 (2.8%) |

| TDR | 3 (2.8%) | 0 (0.0%) | 0 (0.0%) | 3 (2.8%) |

| Air flow or density | 1 (0.9%) | 1 (0.9%) | 0 (0.0%) | 2 (1.9%) |

| Ultrasonic | 1 (0.9%) | 1 (0.9%) | 1 (0.9%) | 3 (2.8%) |

| GPS | 0 (0.0%) | 1 (0.9%) | 2 (1.9%) | 3 (2.8%) |

| Gyroscope | 0 (0.0%) | 0 (0.0%) | 1 (0.9%) | 1 (0.9%) |

| Etc. | 1 (0.9%) | 1 (0.9%) | 5 (4.7%) | 7 (6.5%) |

| Sum | 42 (39.3%) | 38 (35.5%) | 27 (25.2%) | 107 (100.0%) |

| Communication | Field Monitoring Systems | Wearable Systems | Autonomous Mine Systems | Sum (Percentage) |

|---|---|---|---|---|

| ZigBee | 10 (26.3%) | 5 (13.2%) | 3 (7.9%) | 18 (47.4%) |

| GSM | 5 (13.2%) | 1 (2.6%) | 0 (0.0%) | 6 (15.8%) |

| Wi-Fi | 2 (5.3%) | 2 (5.3%) | 1 (2.6%) | 5 (13.2%) |

| Bluetooth | 3 (7.9%) | 0 (0.0%) | 1 (2.6%) | 4 (10.5%) |

| RF | 1 (2.6%) | 1 (2.6%) | 0 (0.0%) | 2 (5.3%) |

| Etc. | 1 (2.6%) | 1 (2.6%) | 1 (2.6%) | 3 (7.9%) |

| Sum | 22 (57.9%) | 10 (26.3%) | 6 (15.8%) | 38 (100.0%) |

| Actuator or Other Modules | Field Monitoring Systems | Wearable Systems | Autonomous Mine Systems | Sum (Percentage) |

|---|---|---|---|---|

| Buzzer | 5 (11.6%) | 8 (18.6%) | 0 (0.0%) | 13 (30.2%) |

| LCD | 3 (7.0%) | 3 (7.0%) | 0 (0.0%) | 6 (14.0%) |

| Motors or motor driver | 1 (2.3%) | 0 (0.0%) | 4 (9.3%) | 5 (11.6%) |

| LED | 1 (2.3%) | 2 (4.7%) | 1 (2.3%) | 4 (9.3%) |

| UAV | 0 (0.0%) | 0 (0.0%) | 3 (7.0%) | 3 (7.0%) |

| Vacuum pump | 1 (2.3%) | 0 (0.0%) | 0 (0.0%) | 1 (2.3%) |

| Centrifugal fan | 1 (2.3%) | 0 (0.0%) | 0 (0.0%) | 1 (2.3%) |

| Vibrotactile belt | 0 (0.0%) | 1 (2.3%) | 0 (0.0%) | 1 (2.3%) |

| RC truck | 0 (0.0%) | 0 (0.0%) | 1 (2.3%) | 1 (2.3%) |

| Etc. | 3 (7.0%) | 1 (2.3%) | 4 (9.3%) | 8 (18.6%) |

| Sum | 15 (34.9%) | 15 (34.9%) | 13 (30.2%) | 43 (100.0%) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.-M.; Choi, Y.; Suh, J. Applications of the Open-Source Hardware Arduino Platform in the Mining Industry: A Review. Appl. Sci. 2020, 10, 5018. https://doi.org/10.3390/app10145018

Kim S-M, Choi Y, Suh J. Applications of the Open-Source Hardware Arduino Platform in the Mining Industry: A Review. Applied Sciences. 2020; 10(14):5018. https://doi.org/10.3390/app10145018

Chicago/Turabian StyleKim, Sung-Min, Yosoon Choi, and Jangwon Suh. 2020. "Applications of the Open-Source Hardware Arduino Platform in the Mining Industry: A Review" Applied Sciences 10, no. 14: 5018. https://doi.org/10.3390/app10145018

APA StyleKim, S.-M., Choi, Y., & Suh, J. (2020). Applications of the Open-Source Hardware Arduino Platform in the Mining Industry: A Review. Applied Sciences, 10(14), 5018. https://doi.org/10.3390/app10145018