Abstract

The long-term deformation of a geodesic spherical frame structure with a diameter of 20 m made from wood plastic composite (WPC) lumber (struts) is described using the Norton-Bailey power law model to predict the service life creep behavior (the creep strain ()) of the WPC. The Norton-Bailey power law model parameters, A the power law multiplier, n the stress order, and m the time order, were obtained from experimental four-point bending flexural creep measurements of WPC lumber subjected to three levels of flexural stress: 7, 14, and 29% of the ultimate flexural strength for 200 days. The parameters obtained from the experiments showed good agreement to the model of the WPC lumber in flexure. The Norton-Bailey power law parameters were then implemented to describe the long-term deformation of the spherical frame structure. The limit of failure was considered when the WPC creep strain reaches the value of 1%. However, the FEA predicted the maximum creep strain to be 20% of the failure strain. This modeling approach is considered useful to describe and predict the long-term deformation of aquacultural structures made from viscoelastic materials during the envisioned service life (10 years) based on experimental creep data for the members that form the structure.

1. Introduction

Many researchers [1,2,3,4,5,6,7] have investigated the use of wood plastic composites (WPCs) in structural applications attributable to their mechanical properties, durability, and their competing commercial prices with conventional lumber [1,2,4,8,9]. Furthermore, WPCs made from thermally modified wood have shown potential to be used in structural applications, because of the relatively low time-dependent deformation under sustained flexural load [10,11,12]. Furthermore, WPCs have been used in the construction of marine aquacultural structures [10,11,13], where the fish-farming industry use different types of the aquacultural structures to raise fish in marine rather than terrestrial fish pens. Different types of aquacultural structures are used: tension-leg systems, flexible, and rigid-frame cage structures [13]. Various studies [14,15,16,17,18,19,20] have been conducted on the development of aquaculture rigid frames (cages); the material used in the construction of the structure of these cages, the mooring system, the effect of the biofouling [14,21] on the service life of the structure, and their offshore structural design and analysis. Different types of the aquaculture cages are used depending on their need and controlling environmental conditions or the required size of the cage [21]. The Aquapod Net Pen (AquapodTM [22]) cage is a patented marine aquaculture structure that is made of triangular net panels fastened together to form a spherical shape. These cages are produced in different sizes, the most common cage that has approximately 20 m diameter (the volume is 4700 m3) [22]. The cages are immersed in water when they are under service and different configurations of the mooring system are used for these structures. When these structures are immersed and under service, their mooring (more than four points) and buoyancy systems result in decreasing the dead load of these rigid structures. However, there is a periodic cleaning to these structures which encompasses hanging the whole structure from four points in the air exposed to the sun for several days to assist in the removal of biofouling [23]. This is usually considered the most critical loading case when the whole dead load of the structure is applied at four points (supports).

Since WPCs are viscoelastic materials, there is a need to investigate their time-dependent behavior and their structural performance. Physical and empirical models were used in previous studies to describe the time-dependent creep behavior of viscoelastic materials [24,25]. In physical models, the viscoelastic time-dependent behavior is described based on spring and dashpot element arrangements. For instance, a generalized Burger’s model was used to describe the creep response of a wood-polypropylene composite in tension [26]. Empirical and generalized viscoelastic one-dimensional (1D) models, for instance, power law models, have been used to describe the creep behavior of WPCs [11,26,27,28]. A standard nonlinear solid viscoelastic model was used as an analogous model to Prony series to describe the response of the viscoelastic materials in creep [27]. A Power law model was successfully implemented to describe the short-term (30 and 250 min) and the long-term (180-day) creep behavior of WPC lumber [10,11] under combined environmental conditions (temperature and water immersion). Further implementation of an empirical 1D power law was conducted to predict the failure occurrence of WPC lumber in flexure (three- and four-point bending) at a strain value of 1%, in accordance with the strain failure mentioned in ASTM D6109 [11,13]. A Norton-Bailey power law was used to describe the creep behavior (the creep strain ()), and the model parameters were computed based on nonlinear curve regression to experimental data [29,30,31], as shown in Equation (1).

where A (power law multiplier), n (stress order), and m (time order) are the Norton-Bailey power law parameters. The symbols and t represent the applied flexural stress and the creep time, respectively. A wood plastic composite lumber element made from a patent pending formulation of a thermally modified wood flour and a high-strength styrenic copolymer system in an equivalent weight ratio has shown potential to be used in aquacultural marine structures attributable to its stiffer response under hygrothermal effects compared with WPCs made from conventional wood flour and polymer [10]. The WPC lumber made from thermally modified wood was investigated to be used in the construction of an aquacultural geodesic spherical shape rigid structure with a diameter of approximately 5 m which is 1:4 scale of the commercially available aquacultural geodesic spherical structure made from high density polyethylene (HDPE) lumber (a.k.a. AquaPod Net Pen cage structure [23,24,32,33]. The investigation included a short-term (30- and 250-min) hygrothermal creep investigation, long-term (180-day) creep investigation, and the structural performance of triangular panels (components) of the aquacultural geodesic spherical rigid structure, respectively [10,11,13]. Even though numerous structural studies (static and dynamic type of analyses) were conducted on different types of aquacultural cage structures and their mooring systems [34,35,36,37,38,39,40], the time-dependent deformation of the aquacultural rigid structures has not yet been studied. Moreover, the time-dependent deformation analysis for an aquacultural structure made from viscoelastic material in general, and wood plastic composites in particular has not yet been studied [13,41]. With the increasing demand to use bio-based fillers (as fiber) with viscoelastic materials (as matrix) in structural applications, there is an increasing necessity to have analysis tools that predict the time-dependent behavior of these structures. The commercial software Abaqus has the ability to implement the Norton-Bailey power law that models the time-dependent creep behavior of viscoelastic materials for structural analysis.

The objective of this study is to evaluate the time-dependent deformation of structures made from thermoplastic viscoelastic materials during the structure service life and subjected to constant load. Five specimens with a span of 853 mm were subjected to flexural stresses in a four-bending configuration at three stress levels in accordance with ASTM D6109 and ASTM D6815.

2. Experimental

2.1. Material

The WPC lumber cross section with cross section dimensions (width (w) = 139 mm, thickness (h) = 33.5 mm) was produced using a twin-screw Davis-Standard WoodtruderTM in the Advanced Structures and Composites Center (ASCC) at the University of Maine, Orono, Maine. The WPC lumber cross section has two grooves along the longitudinal direction (extrusion direction) of the lumber at the top layer with 3 mm width and 1.8 mm depth, and these grooves are located at 21.9 mm from the short edges of the WPC lumber. The WPC examined here is based on a patent-pending formulation, in accordance with the International Publication Number WO 2018/142314 A1 dated in 09 August, 2018, combining thermally modified wood flour (as a cellulosic material) that has been produced at Uimaharju sawmill in Finland and a high-strength styrenic copolymer system (high-impact polystyrene (HIPS) and styrene maleic anhydride (SMA)) in an equivalent weight ratio to each of the two constituents. Further details about the WPC lumber were mentioned elsewhere [10].

2.2. WPC Specimen Preparation

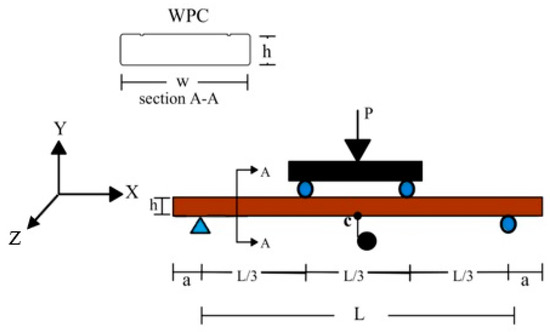

In accordance with ASTM D6109, WPC lumber specimens with dimensions (w = 139 mm, h = 33.5 mm) were cut to an adequate length to fit the span (L), 853 mm with an adequate length for the overhang at each support (a = 51 mm), as shown in Figure 1. To achieve the magnetic mounting of the string potentiometer that measures the creep deflection to the midspan of the specimens, a 3-min corona treatment (Figure 2A) and 5-min hardening epoxy were used to adhere a square metal piece (19 × 19 mm) to the midspan of each specimen (flatwise), as shown at point c in Figure 1. Afterwards, a magnetic hook was mounted on the square metal and the string potentiometer was attached to the hook during the creep loading, and hence, the creep midspan deflection was acquired, accordingly. This type of hook was used to avoid any damage might occur to the string potentiometer in case the specimen experienced an abrupt failure during the creep experiment.

Figure 1.

Schematic of the WPC lumber specimen in creep in a four-point bending test setup configuration. The grooved upper layer of the Section A-A is located at the loading noses along the X-axis, and the flat bottom layer of the section is located at the supports side along the X-axis.

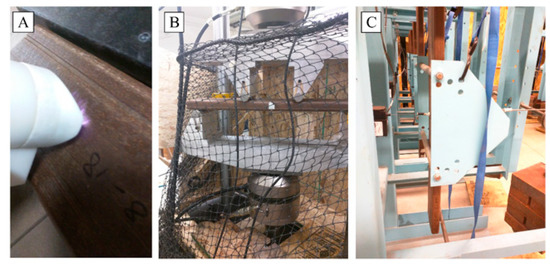

Figure 2.

Experimental work. (A) Corona treatment prior to adhering the square metal at the midspan of WPC. (B) Four-point bending flexure test with L/h ratio of 16 in accordance with ASTM D6109 to obtain the flexural strength and the apparent elastic modulus of WPC lumber. (C) Long-term creep WPC specimens, the test setup test rigs, and the WPC specimens with L/h ratio of 25.5.

2.3. Quasi-Static Testing

To obtain the apparent elastic modulus (E) and the mean of the flexural strength (Fb), five specimens of the WPC lumber were cut with a span (L) to depth (h) ratio 16:1 with an adequate overhang length over the supports of the fixture, to be tested in 4-point bending, in accordance with ASTM D6109 [42] (quasi-static testing), as shown in Figure 2B. Prior to the 4-point bending test, the specimens were preconditioned for four days at a temperature of 23 ± 2 °C and a relative humidity of 50 ± 5%, in accordance with ASTM D618 [43], in a climate controlled mechanical testing laboratory at the ASCC at the University of Maine, Orono, Maine. The crosshead rate of the WPC specimens during the 4-point bending test were selected in accordance with ASTM D6109 to be 15.9 mm/min.

For the 200-day creep experiments (Figure 2C), three levels of flexural creep stress were applied to each group of the WPC specimens (five specimens in each group). These three levels were 7.0, 14.0, and 29.0% of the mean of the flexural strength (Fb) obtained from the quasi-static testing. The reason to select these levels of stress was mentioned elsewhere [13]. The determination of E of the WPC specimens was performed in accordance with ASTM D6109 [39], by computing the slope of the line obtained from the linear regression to the linear portion in the load–midspan deflection curve. Since the span to depth ratio (L/h) of the tested WPC specimens meet the recommended L/h in the ASTM standards, the shear deformation was ignored in the computation of the apparent elastic modulus. Based on ASTM D6109, the mean of the ultimate flexural strength of WPC specimens was determined by the ultimate flexural stress at failure or at 1% of the flexural strain.

2.4. 200-Day Creep Experimental Setup

Prior to the creep loading and in accordance with ASTM D618, 15 WPC specimens (five WPC specimens subjected to each of the three flexural stress levels) were preconditioned in the climate control creep room at the ASCC for one week. According to the limitation in the available creep test rigs at the ASCC, five specimens of WPC at each stress level were studied. The 200-day creep loading procedure, the data acquisition system, and the flexural creep deflection measured of each WPC specimen at the applied flexural stress were mentioned elsewhere [13]. Figure 2 summarizes the experimental work conducted in this study. Thus, the WPC specimens were divided into three groups corresponding to the three stress levels, respectively.

2.5. Finite Element Modeling of Time-Dependent Deformation of WPC Specimens

Modeling the long-term deformation of an aquacultural geodesic spherical structure made from wood plastic composite lumber (as a thermoplastic and viscoelastic material) was performed using the Norton-Bailey [29,30,31,44,45,46] power law model. The model uses the one-dimensional experimental flexural creep data from of WPC lumber tested for 200 days tested at three different stress levels. The time-dependent deformation of an aquacultural geodesic spherical frame structure with a diameter of 20 m made from WPC struts–lumbers was analyzed via a finite element model using the available commercial software, Abaqus [47,48].

To implement the computed parameters of the Norton-Bailey power law model, a structural analysis of time-dependent deformation was carried out using the available commercial finite element analysis (FEA) software, Abaqus/CAE [47]. The Norton-Bailey power law model in time-hardening was adopted for the material.

The 4-point bending tests were modeled using Timoshenko (shear flexible) beam elements (B31) (2-node linear beam in space) (i.e., six-degrees of freedom (dof) at each node of the element) [37,49] that allow for transverse shear deformation. To investigate the time-dependent behavior of these elements to model the 200-day creep experiments, a preliminary quasi-static Abaqus model in a flat-wise 4-point pending with a value of L/h of 16:1 was conducted using B31 elements. The values of the apparent elastic moduli required for the models were 4340 MPa for the WPC lumber. The preliminary study encompassed a convergence study to the number of elements required to discretize the WPC and HDPE lumber in the 4-point bending models, and it was found that the discretized WPC lumber with the number of B31 elements greater than 10 elements have had the same values of the mid span deflection [point c in Figure 1, 17.6 mm (2% greater than the value of the experimental mid span deflection), and 32.6 mm (6% greater than the value of the experimental mid span deflection)] respectively. Thus, 95 elements type B31 were used to model the creep of WPC in four-point bending. The boundary conditions in the models were set as follows: (1) the supports had a free axial movement in the X-direction and free rotation around the Z-direction and had restricted axial movement in the Y- and Z-direction and restricted rotation around the X- and Y-direction (directions are illustrated in Figure 1); (2) the loading noses (where the flexural load was applied) had free axial movement in the X and Y-direction and free rotation around the Z-direction, whereas, the loading noses had a restricted axial movement in the Z-direction and restricted rotation around the X-direction and Y-direction. The time-step was selected to be instantaneous when the point load was applied during the creep modeling. The time-step (increment) used to model the creep behavior was in days. To minimize computational time for the model analysis, each time-increment (step) (t) was considered as 1 day. The FEA was carried out to model the creep behavior of WPC specimens subjected to 7, 14, and 29% of Fb. The creep models during the 250 days of all the three stress levels are reported in Figure 3. The FEA showed a good agreement with the experimental data.

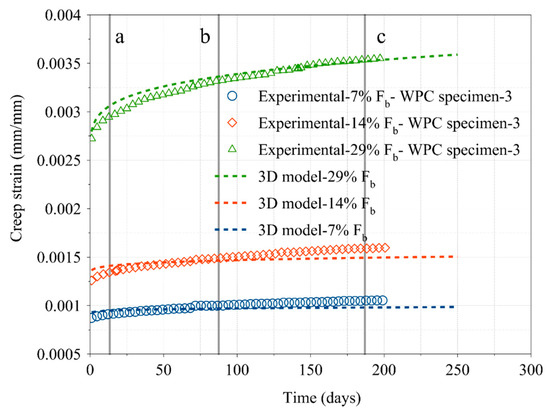

Figure 3.

Typical experimental flexural creep strain of WPC specimens subjected to three levels of stress (7% Fb, 14% Fb, and 29% Fb) and the corresponding Norton-Bailey power low model prediction.

After conducting the one-dimensional (1D) modeling experiment to describe the 200-day flexural creep behavior of WPC lumber, testing was expanded to model the three-dimensional (3D) creep behavior of a 20-m-diameter aquacultural geodesic spherical rigid frame structure. The following assumptions and simplifications were considered in the model: (1) the WPC cross-section was assumed to have a rectangular cross-section where the grooved areas on the top layer were not included in the modeling computations. (2) The dead load was computed for the structure that included the struts and the steel mesh of the cage. However, the structure was analyzed as a space frame without considering the interaction among the struts and the steel mesh. The reason behind neglecting the metal mesh was because: (a) it does not experience viscoelastic behavior, (b) since the time-dependent model was assumed to be the worst-case loading scenario, and since the wire mesh increases the strength of the frame by two times the strength of the frame without wire mesh [33], (3) the total load of the 216 triangular panels of the frame were computed and divided on the 110 nodes of the cage to act as point loads, to be 2043 N at each node of the structures made from WPC lumber (strut), (4) the implication of the point load (the dead load at each node) was instantaneous, (5) the same parameters of the FEA time-dependent viscoelastic models to describe the 250-day creep experiments of WPCs were used in this 3D modeling, (6) any type of steel reinforcement which is conventionally implemented to support the struts in tension during the cage service life was ignored and not considered in the FEA, (7) the four hanging points were assumed to be pin-supports. A total of 51,525 beam space elements (B31) were used in the FEA of the WPC struts, (8) the failure at the connection points of the struts (hubs) were not considered in this 3D modeling, (9) the aquacultural cage structure has a mooring system that connects it through many points when it is immersed in water and the dead load of the structure is considered lighter when it is immersed attributable to buoyancy system of the structure. However, the worst case was considered when it is hanging from four connection points only from the top and when it is not immersed in water.

The objectives of this modeling are: (1) to adopt the time-dependent viscoelastic behavior observed from the 200-day creep experiment and implement it to describe the long-term deformation of the Aquapod cage constructed using the WPC lumber using FEA [47]. (2) To conduct the analysis for 10 years for the aquacultural geodesic rigid frame structure assuming failure at 1% as strain, in accordance with ASTM D6109.

3. Results and Discussions

3.1. Application of 1D Norton-Bailey Time-Hardening Power Law

The parameters of the Norton-Bailey power law (time-hardening) in Equation (1) were obtained using an approach similar to the one presented by Gordon and Segletes [30]. Three locations were selected from the creep strain versus time relationship, and their corresponding strain values were selected at the given stress values, as shown in lines a, b, and c in Figure 3. Thus, the parameters were computed based on Equations (2) and (3). This approach assumes that the model parameters are stress independent [50,51]. By substituting the computed parameters m and n in Equation (1), the value of A was determined.

Table 1 represents: a summary to the experimental results obtained from the quasi-static testing, the applied levels of stress (flexural) to each group of WPC and the stress level applied to each WPC specimen in each group, the values of inserted in Equations (2) and (3), and the computed parameters. Figure 3 shows a typical relationship between the experimental creep strain versus time of three WPC specimens at three different stress levels (7% Fb, 14% Fb, and 29% Fb) and the selected lines (a, b, and c) on these relationships used to compute the Norton-Bailey parameters [19,20]. The mechanical properties were: Fb = 41.2 MPa and E = 4.34 GPa. The applied stress levels were: 2.98 ± 0.08, 5.88 ± 0.04, and 11.84 ± 0.1 MPa.

Table 1.

Experimental results and the computed parameters of Norton-Bailey power law model.

3.2. Modeling the Long-Term Deformation of an Aquacultural Geodesic Spherical Rigid Frame Structure Made from WPC Lumber

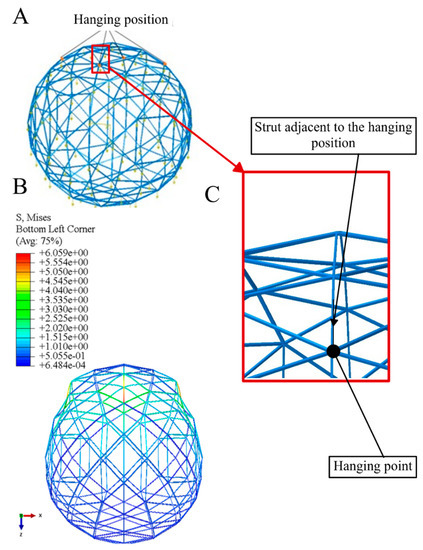

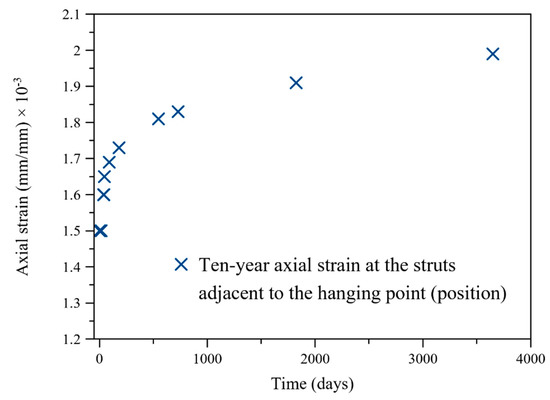

WPCs showed a potential to be used in the construction of the rigid frame structure of the Aquapod in addition to its relatively high elastic modulus compared with HDPE lumber (approximately five times higher) [13,14]. However, the WPCs time-dependent behavior is a subject of concern during the service life of the structure. Figure 4A,B shows the FEA time-dependent model of the aquacultural geodesic spherical rigid frame structure for 10 years and subjected to the weight of the structure distributed among the hubs (the points that connects the WPC struts). The maximum creep strain (in-plane strain at the hanging points shown in Figure 4A) was 0.002 which is 20% of the strain at failure established for this 3D model. In the design of conventional structures (steel or reinforced concrete) different methods are used to compute the factor of safety of the structure. Allowable stress design (ASD) method for instance, it is based on the design strength of the material at the lower 5th percentile during the service life (10 years) [3]. The factor of safety which is the ratio between the design strength to the applied stresses (working stresses) for structures is selected based on the environmental conditions, the design factors, and the types of loads applied to the structure. In this method (ASD), it is assumed that the structure is linearly elastic and the deformation is computed accordingly. However, to consider the viscoelastic materials in structural application, the time-dependent deformation has to be computed during the service life of the structure (for instance 10 years) to be included in the total deformation of the structure. Thus, this study enables the time-dependent analysis of the structures to compute the time-dependent deformation attributable to a constant applied load, so that it can be included in the computation of the total deformation of the structures when one the design methods is conducted. The 10-year long-term axial deformation (strain) at the struts adjacent to the hanging points (Figure 4C) were reported in Figure 5. As a creep phenomenon, the applied stress should be constant during the creep duration. However, a reduction in the applied creep stress was observed from the beginning of load application to the end of load application. This descending behavior in the creep stress (constant stress) is believed to be attributable to the mesh refinement and the time step selected to minimize the computational efforts [51,52]. To characterize the long-term deformation of the aquacultural geodesic spherical rigid frame structure, a convergence study was conducted and reported in Table 2 based on the mesh (number of elements) refinement and the time-stem intervals and their effects on the axial deformation and the axial stress in the strut adjacent to the hanging point. An approximately 7% reduction in the applied stress was observed during the 10 years FEA modeling. However, there was a similarity in the resulted axial strain at the strut adjacent to the hanging position for the FEA model with the lowest number of elements (2676 beam element) at the time increment t = 0.125 day and the FEA model with 51,552 beam element at the time step (increment) t = 1 day as shown in Table 2. It is computationally not possible to have a finer mesh with a smaller time step to conduct such a long-term FEA study for this structure. Thus, the FEA model was conducted using 51,552 beam elements and at time step t = 1 day. To comply with the acceptance criteria of the creep behavior of the material mentioned in the ASTM D6815, the creep rate should be decreasing during the service life of the structure. The strain rate was selected for one-year intervals and was reported for four intervals as shown in Table 3. The strain rate of the axial strain at the struts adjacent to the hanging point showed a descending pattern which means the axial long-term deformation is accepted.

Figure 4.

A 10-year Abaqus FEA time-dependent deformation of a 20-m-diameter aquacultural rigid frame structure made from WPC struts. (A) Non-deformed structure in four-point hanging position, and (B) deformed shape after ten years. (C) the strut adjacent to the hanging point.

Figure 5.

Ten-year (3650 days) time-dependent axial strain of the WPC strut adjacent to the hanging position of the cage structure.

Table 2.

Convergence study of the total number of elements (at two different time increments t) of the structure based on the long-term axial strain (ε) and the axial stress (σ) at the strut adjacent to the hanging point as shown in Figure 4C at given time values. Units of axial stress are MPa and the units of strain are (mm/mm × 10−3).

Table 3.

Long-term axial strain rate (at the strut adjacent to the hanging point as shown in Figure 4C at four time intervals.

4. Conclusions

The Norton-Bailey power law model was implemented to predict the long-term deformation of WPC lumber in flexure.

FEA was used to conduct the time-dependent structural analysis of an aquacultural geodesic spherical rigid frame structure made from WPC lumber. The WPC lumber shows potential to be used in structural applications because of its relatively low creep strain during the service life.

This study enabled envisioning the long-term deformation of structures during their service life, based on the experimental time-dependent deformation of the material that form the structures.

The stress intendency of the Norton-Bailey parameters is very beneficial to model structures under a level of stress differs from the stress levels applied experimentally on the material to obtain the parameters.

The Norton-Bailey parameters are temperature and moisture dependent. Thus, the temperature and moisture conditions used in the experiments to obtain the Norton-Bailey parameters, must be as same as the temperature and moisture conditions that the structure is exposed to during its service life. This explains the consistency behind modeling the geodesic spherical cage in four-point hanging position (dry) based on the 200-day creep experiment in dry conditions.

Author Contributions

Conceptualization, the first author M.A.A.A. and the second author D.J.G.; methodology, M.A.A.A.; software, M.A.A.A.; validation, M.A.A.A., D.J.G. and the third author R.A.L.-A.; formal analysis, M.A.A.A.; investigation, M.A.A.A. and D.J.G.; resources, D.J.G.; data curation, M.A.A.A.; writing—Original draft preparation, M.A.A.A.; writing—Review and editing, M.A.A.A., D.J.G., and R.A.L.-A.; visualization, M.A.A.A., D.J.G. and R.A.L.-A.; supervision, D.J.G.; project administration, D.J.G.; funding acquisition, D.J.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

The work described in this document was conducted at the Advanced Structures and Composites Center at the University of Maine, Orono, Maine (USA). This project was supported by the USDA National Institute of Food and Agriculture, Hatch (or McIntire-Stennis, Animal Health, etc.) Project number ME0-41809 through the Maine Agricultural & Forest Experiment Station. Maine Agricultural and Forest Experiment Publication Number 3753. The University of Maine research reinvestment funds (RRF) Seed Grant entitled (Development of structural wood plastic composite timber for innovative marine application) and the United Stated Department of Agriculture (USDA)—the agricultural research service (ARS) Funding Grant Number (58-0204-6-003) have provided the financial support for this project. The wood plastic composites are based on a patent-pending formulation that has the publication number (WO2018/142314). The thermally modified wood fiber used in this research is supplied by Stora Enso (Finland).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Slaughter, A.E. Design and Fatigue of a Structural Wood-Plastic Composite. Master’s Thesis, Washington State University, Pullman, WA, USA, 2004. [Google Scholar]

- Alvarez-Valencia, D.; Dagher, H.J.; Davids, W.G.; Lopez-Anido, R.A.; Gardner, D.J. Structural performance of wood plastic composite sheet piling. J. Mater. Civ. Eng. 2010, 22, 1235–1243. [Google Scholar] [CrossRef]

- Gardner, D.; Han, Y. Towards structural wood-plastic composites: Technical innovations. In Proceedings of the 6th Meeting of the Nordic-Baltic Network in Wood Material Science and Engineering (WSE), Tallinn, Estonia, 21–22 October 2010. [Google Scholar]

- Haiar, K.J. Performance and Design of Prototype Wood-Plastic Composite Sections. Master’s Thesis, Washington State University, Pullman, WA, USA, 2000. [Google Scholar]

- Hamel, S.E. Modeling the Time-Dependent Flexural Response of Wood-Plastic Composite Materials. Ph.D. Thesis, University of Wisconsin-Madison, Madison, WI, USA, 2011. [Google Scholar]

- Dura, M.J. Behavior of Hybrid Wood Plastic Composite-Fiber Reinforced Polymer Structural Members for Use in Sustained Loading Applications. Bachelor’s Thesis, The University of Maine, Orono, ME, USA, 2005. Available online: https://digitalcommons.library.umaine.edu/etd/853 (accessed on 15 December 2019).

- Kahl, M. Structural Design of Hollow Extruded WPC Sheet Piling. Bachelor’s Thesis, The University of Maine, Orono, ME, USA, 2006. Available online: https://digitalcommons.library.umaine.edu/etd/117 (accessed on 23 November 2019).

- Bright, K.D.; Smith, P.M. Perceptions of new and established waterfront materials by US marine decision makers. Wood Fiber Sci. 2007, 34, 186–204. [Google Scholar]

- Tamrakar, S.; Lopez-Anido, R.A. Water absorption of wood polypropylene composite sheet piles and its influence on mechanical properties. Constr. Build. Mater. 2011, 25, 3977–3988. [Google Scholar] [CrossRef]

- Alrubaie, M.A.A.; Lopez-Anido, R.A.; Gardner, D.J.; Tajvidi, M.; Han, Y. Experimental investigation of the hygrothermal creep strain of wood–plastic composite lumber made from thermally modified wood. J. Thermoplast. Compos. Mater. 2019. [Google Scholar] [CrossRef]

- Alrubaie, M.A.A.; Lopez-Anido, R.A.; Gardner, D.J.; Tajvidi, M.; Han, Y. Modeling the hygrothermal creep behavior of wood plastic composite (WPC) lumber made from thermally modified wood. J. Thermoplast. Compos. Mater. 2019. [Google Scholar] [CrossRef]

- Alrubaie, M.A.A.; Lopez-Anido, R.A.; Gardner, D.J. Flexural Creep Behavior of High-Density Polyethylene Lumber and Wood Plastic Composite Lumber Made from Thermally Modified Wood. Polymers 2020, 12, 262. [Google Scholar] [CrossRef]

- Alrubaie, M.A. Investigating the Time-dependent and the Mechanical Behavior of Wood Plastic Composite Lumber Made from Thermally Modified Wood in the Use of Marine Aquacultural Structures. Bachelor’s Thesis, The University of Maine, Orono, ME, USA, 2019. Available online: https://digitalcommons.library.umaine.edu/etd/3026 (accessed on 16 April 2020).

- Gardner, D.J. Development of Structural Wood Plastic Composite Timber for Innovative Marine Application, in Research Reinvestment Funds (RRF) Seed Grant Program; The University of Maine: Orono, ME, USA, 2015; p. 23. [Google Scholar]

- DeCew, J.; Tsukrov, I.; Risso, A.; Swift, M.R.; Celikkol, B. Modeling of dynamic behavior of a single-point moored submersible fish cage under currents. Aquac. Eng. 2010, 43, 38–45. [Google Scholar] [CrossRef]

- Fredriksson, D.W.; Swift, M.R.; Irish, J.D.; Tsukrov, I.; Celikkol, B. Fish cage and mooring system dynamics using physical and numerical models with field measurements. Aquac. Eng. 2003, 27, 117–146. [Google Scholar] [CrossRef]

- Fredriksson, D.W.; DeCew, J.C.; Tsukrov, I. Development of structural modeling techniques for evaluating HDPE plastic net pens used in marine aquaculture. Ocean Eng. 2007, 34, 2124–2137. [Google Scholar] [CrossRef]

- Fredriksson, D.W.; DeCew, J.; Swift, M.R.; Tsukrov, I.; Chambers, M.D.; Celikkol, B. The Design and Analysis Of A Four-Cage Grid Mooring For Open Ocean Aquaculture. Aquac. Eng. 2004, 32, 77–94. [Google Scholar] [CrossRef]

- DeCew, J.; Celikkol, B.; Baldwin, K.; Chambers, M.; Irish, J.; Swift, M.R.; Tsukrov, I. Assessment of a Mooring System for Offshore Aquaculture. World Aquac. 2012, 43, 32. [Google Scholar]

- Decew, J. Development of Engineering Tools to Analyze and Design Flexible Structures in Open Ocean Environments; University of New Hampshire: Durham, NH, USA, 2011. [Google Scholar]

- Vandenbroucke, K.; Metzlaff, M. Abiotic Stress Tolerant Crops: Genes, Pathways and Bottlenecks. Sustain. Food Prod. 2013, 1–17. [Google Scholar] [CrossRef]

- InnovaSea Systems, Inc. A 4700 Bridle System in Grid Mooring Cell. 2016. Available online: www.innovasea.com (accessed on 17 September 2017).

- InnovaSea Systems, Inc. Report on Structural Damage to A4800 AquaPod; InnovaSea Inc.: Morrill, ME, USA, 2015. [Google Scholar]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A. Woods and composites cantilever beam: A comprehensive review of experimental and numerical creep methodologies. J. Mater. Res. Technol. 2020, 9, 6759–6776. [Google Scholar] [CrossRef]

- Sepiani, H.; Polak, M.A.; Penlidis, A. Modeling short- and long-term time-dependent nonlinear behavior of polyethylene. Mech. Adv. Mater. Struct. 2018, 25, 600–610. [Google Scholar] [CrossRef]

- Tamrakar, S.; Lopez-Anido, R.A.; Kiziltas, A.; Douglas, J.G. Time and temperature dependent response of a wood–polypropylene composite. Compos. Part A Appl. Sci. Manuf. 2011, 42, 834–842. [Google Scholar] [CrossRef]

- Barbero, E.J. Finite Element Analysis of Composite Materials Using AbaqusTM; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- De Luca, V.; Della Chiesa, A. A creep non-linear FEM analysis of glulam timber. Mech. Adv. Mater. Struct. 2013, 20, 489–496. [Google Scholar] [CrossRef]

- Betten, J. Creep Mechanics; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- May, D.; Gordon, A.; Segletes, D. The application of the Norton-Bailey law for creep prediction through power law regression. In ASME Turbo Expo 2013: Turbine Technical Conference and Exposition; American Society of Mechanical Engineers: San Antonio, TX, USA, 2013. [Google Scholar]

- Ouyang, F. Abaqus Implementation of Creep Failure in Polymer Matrix Composites with Transverse Isotropy. Master’s Thesis, Master of Science, University of Akron, Akron, OH, USA, 2005. [Google Scholar]

- Page, S.H. Aquapod Systems aquaculture Aquapod systems for Sustainable Ocean Aquaculture Aquaculture. Sustain. Food Prod. 2013, 223–235. [Google Scholar] [CrossRef]

- Alrubaie, M.A.A.; Gardner, D.J.; Lopez-Anido, R.A. Structural performance of HDPE and WPC lumber components used in aquacultural geodesic spherical cages. Polymers 2020, 12, 26. [Google Scholar] [CrossRef]

- Hou, H.M.; Xu, T.J.; Dong, G.H.; Zhao, Y.P.; Bi, C.W. Time-dependent reliability analysis of mooring lines for fish cage under corrosion effect. Aquac. Eng. 2017, 77, 42–52. [Google Scholar] [CrossRef]

- Drach, A.; Tsukrov, I.; DeCew, J.; Celikkol, B. Engineering procedures for design and analysis of submersible fish cages with copper netting for exposed marine environment. Aquac. Eng. 2016, 70, 1–14. [Google Scholar] [CrossRef]

- Gansel, L.C.; Oppedal, F.; Birkevold, J.; Tuene, S.A. Drag forces and deformation of aquaculture cages—Full-scale towing tests in the field. Aquac. Eng. 2018, 81, 46–56. [Google Scholar] [CrossRef]

- DeCew, J.; Fredriksson, D.W.; Lader, P.F.; Chambers, M.; Howell, W.H.; Osienki, M.; Høy, E. Field measurements of cage deformation using acoustic sensors. Aquac. Eng. 2013, 57, 114–125. [Google Scholar] [CrossRef]

- Lader, P.; Dempster, T.; Fredheim, A.; Jensen, Ø. Current induced net deformations in full-scale sea-cages for Atlantic salmon (Salmo salar). Aquac. Eng. 2008, 38, 52–65. [Google Scholar] [CrossRef]

- Huang, C.-C.; Tang, H.-J.; Liu, J.-Y. Modeling volume deformation in gravity-type cages with distributed bottom weights or a rigid tube-sinker. Aquac. Eng. 2007, 37, 144–157. [Google Scholar] [CrossRef]

- Zhao, Y.P.; Li, Y.C.; Dong, G.H.; Gui, F.K.; Teng, B. Numerical simulation of the effects of structure size ratio and mesh type on three-dimensional deformation of the fishing-net gravity cage in current. Aquac. Eng. 2007, 36, 285–301. [Google Scholar] [CrossRef]

- Hamel, S.E.; Hermanson, J.C.; Cramer, S.M. Predicting the flexure response of wood-plastic composites from uni-axial and shear data using a finite-element model. J. Mater. Civ. Eng. 2014, 26, 04014098. [Google Scholar] [CrossRef]

- ASTM International. ASTM International. Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastic Lumber and Related Products, D6109-13; ASTM: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM International. Standard Specification for Evaluation of Duration of Load and Creep Effects of Wood and Wood-Based Products, D6815-09 (Reapproved 2015); ASTM: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Tumur-Ochir, E.; Jeon, C.H.; Yum, Y.J.; Kim, Y.S. Experimental and finite element creep analyses of plastics used in automotive instrument panel. In Proceedings of the 2011 6th International Forum on Strategic Technology, Harbin, China, 22–24 August 2011. [Google Scholar]

- Finck, D.; Seidel, C.; Hausmann, J.; Rief, T. Creep-Induced Screw Preload Loss of Carbon-Fiber Sheet Molding Compound at Elevated Temperature. Materials 2019, 12, 3598. [Google Scholar] [CrossRef]

- Mayookh Lal, H.; Xian, G.; Thomas, S.; Zhang, L.; Zhang, Z.; Wang, H. Experimental Study on the Flexural Creep Behaviors of Pultruded Unidirectional Carbon/Glass Fiber-Reinforced Hybrid Bars. Materials 2020, 13, 976. [Google Scholar] [CrossRef]

- Abaqus/CAE. Computer Software; SIMULIA Inc.: Providence, RI, USA, 2017. [Google Scholar]

- BAHEI-EL-DIN, Y.A. Finite Element Analysis of Viscoplastic Composite Materials and Structures. Mech. Compos. Mater. Struct. Int. J. 1996, 3, 1–28. [Google Scholar] [CrossRef]

- Dassault Systems. Abaqus User Manual/Viscoelasticity. 2002–2018 December 2018. Available online: https://www.3ds.com/products-services/simulia/products/abaqus/abaquscae/ (accessed on 23 June 2019).

- Mandalapu, H.; Karanamsetty, S. Parameter Analysis of Creep Models of PP/CaCo3 Nanocomposites. Master’s Thesis, Master of Mechanical Engineering, Blekinge Institute of Technology, Karlskrona, Sweden, 2007. [Google Scholar]

- Lucas, G.E.; Pelloux, R.M.N. Some Observations on Time-Hardening and Strain-Hardening Rules for Creep in Zircaloy-2. Nucl. Technol. 1981, 53, 46–57. [Google Scholar] [CrossRef]

- León, E.P.; Rodríguez-Castellanos, A.; Flores-Guzmán, N.; Olivera-Villaseñor, E. Combined plasticity and creep analysis in 2D by means of the boundary element method. Eng. Anal. Bound. Elem. 2013, 37, 1436–1444. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).