The Value and Optimal Sizes of Energy Storage Units in Solar-Assist Cogeneration Energy Hubs

Abstract

1. Introduction

1.1. Literature Review

1.2. Novelty and Contribution

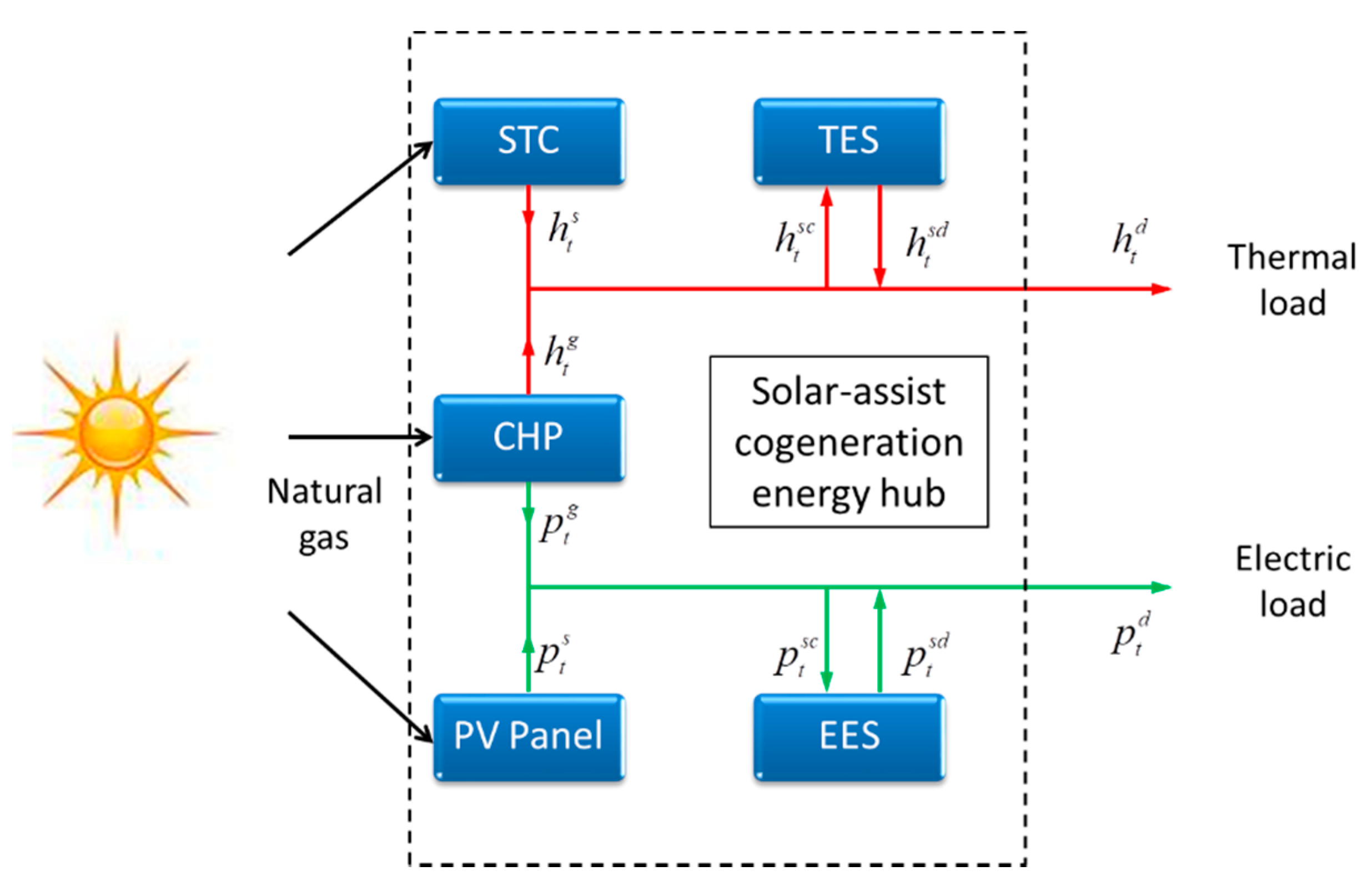

2. System Configuration and Operation

3. Quantifying the Value of Energy Storage

| Algorithm 1 Constructing the Optimal Value Function |

| 1: Step 1: Create uniformly distributed grid points , in the parameter set . 2: Step 2: Solve linear program (10) for each ; the corresponding optimal solution is . 3: Step 3: Remove duplicated dual variables, and calculate and ; construct 4: Step 4: Redundancy screen. For each linear function in the optimal value function, solve.LP (15). If the optimal value is strictly positive, then remove this linear function from . 5: Step 5: Construct critical regions according to (14). |

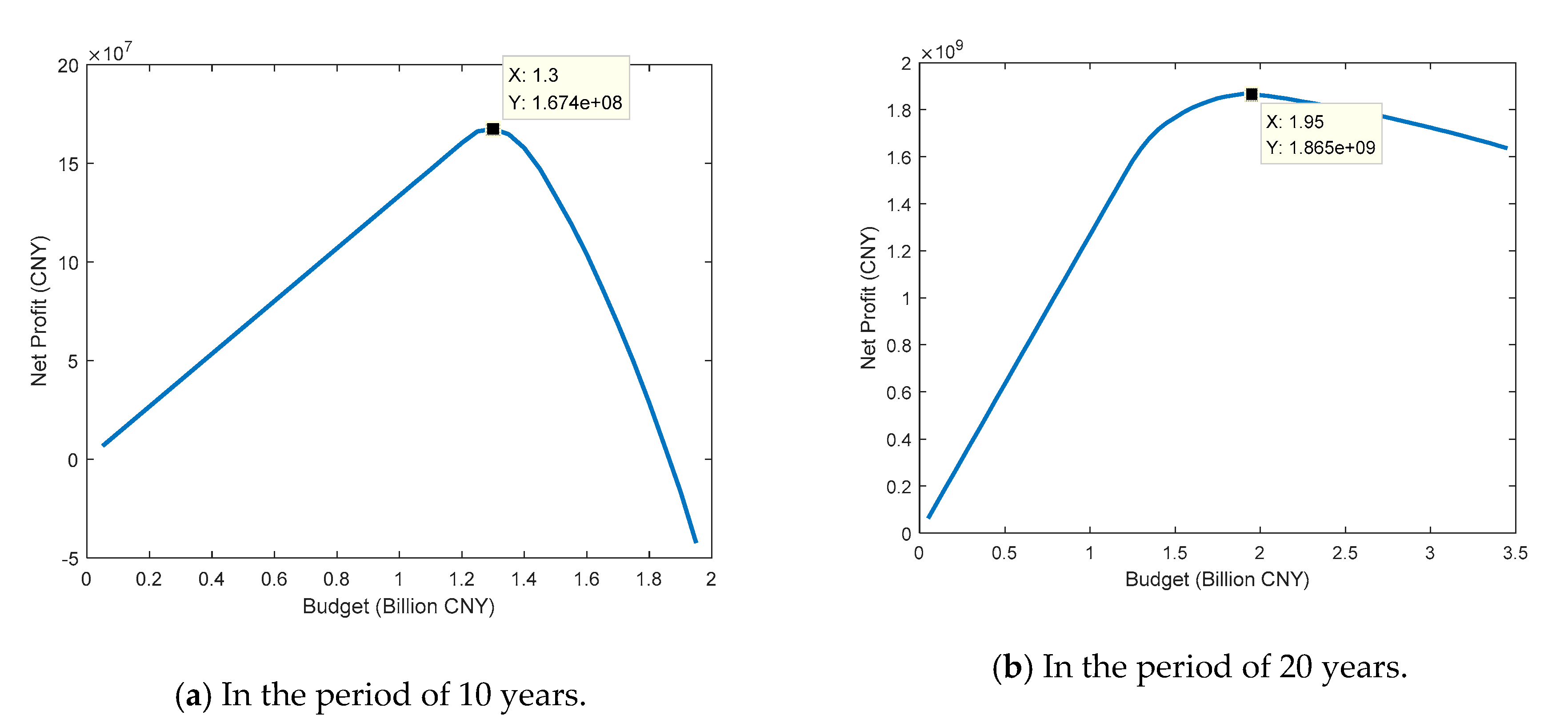

4. Sizing System Components

4.1. Sizing the Combined Heat and Power (CHP) Unit

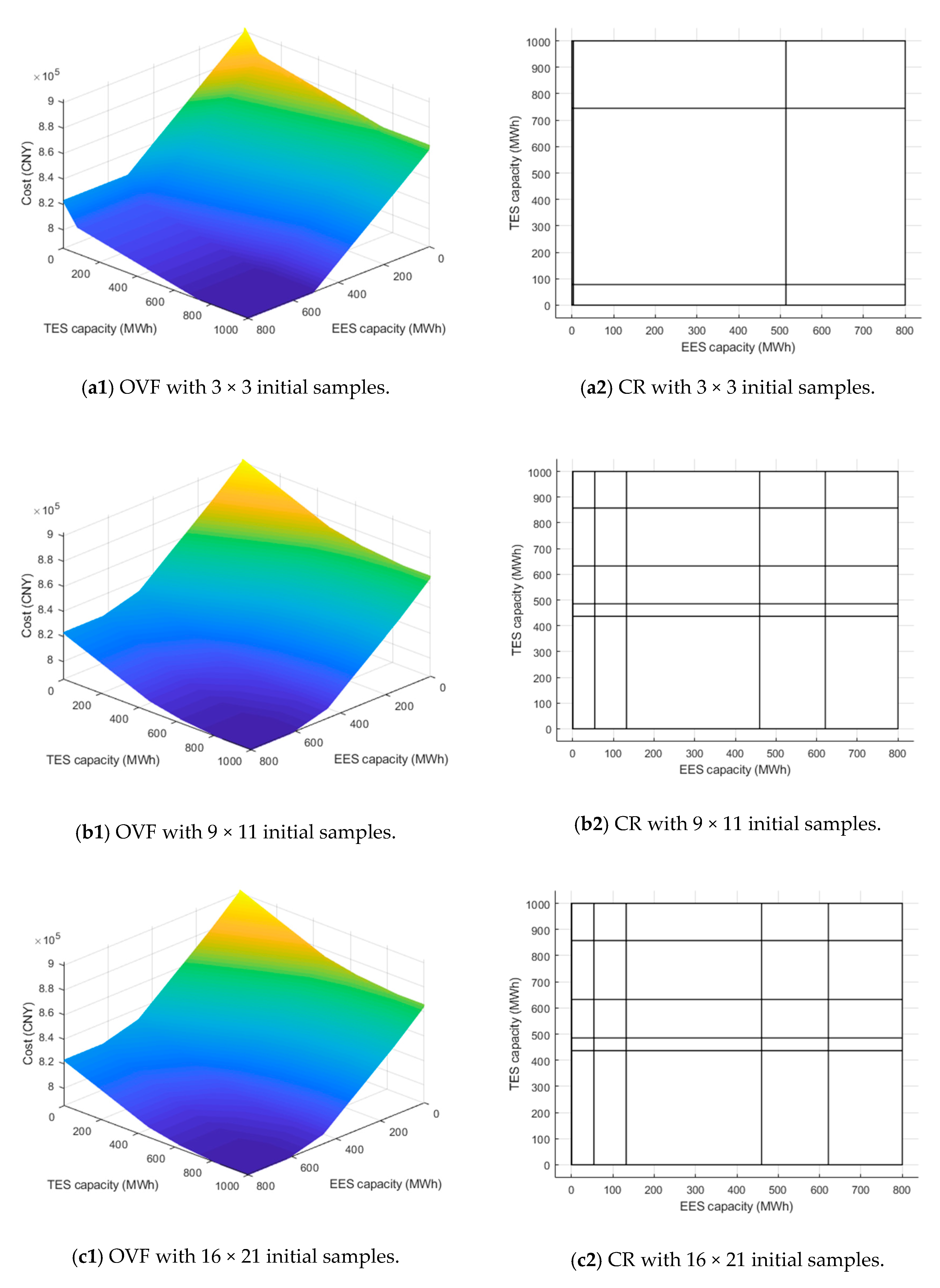

4.2. Sizing Energy Storage Units with Fixed Solar Capacities

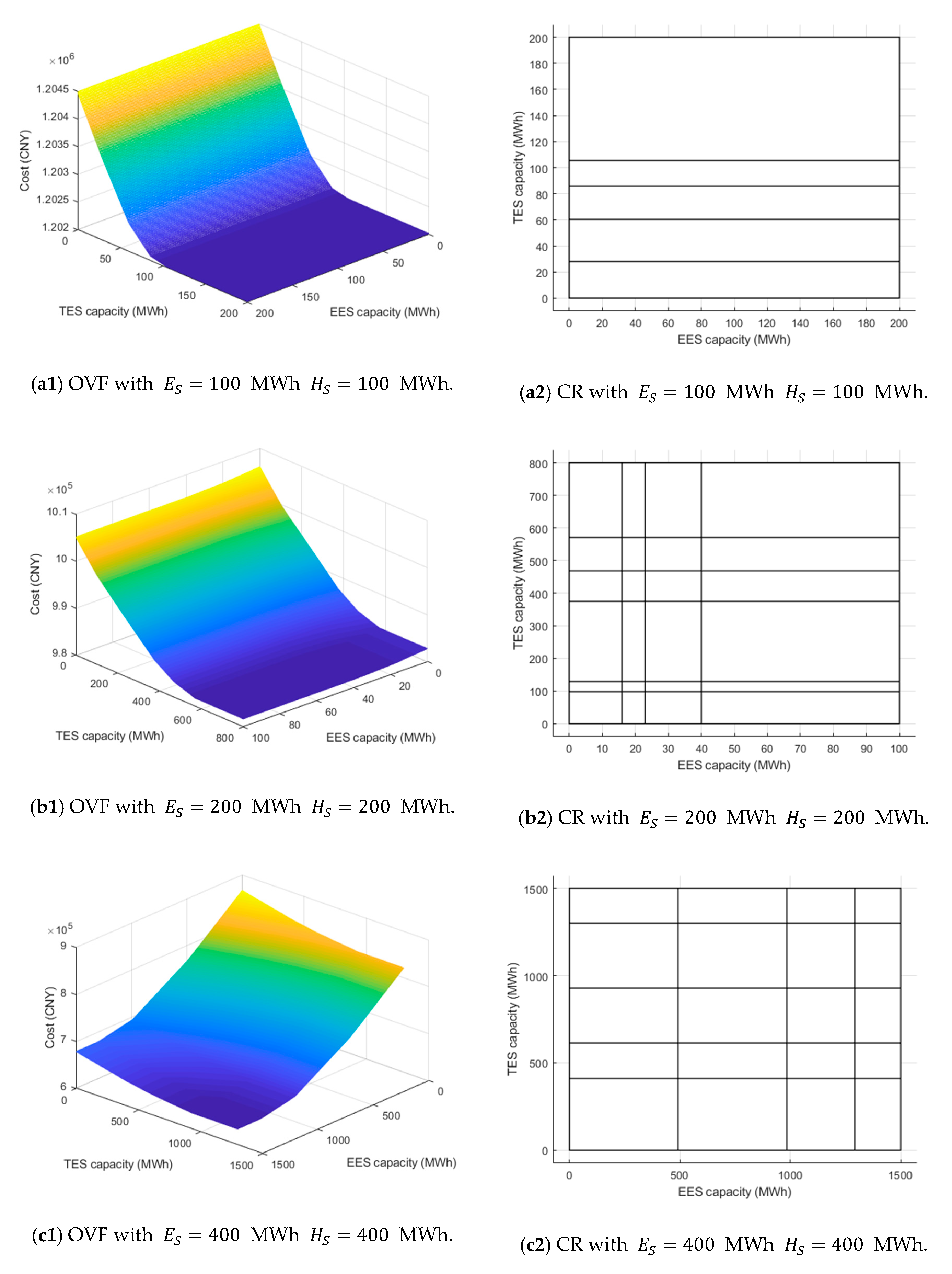

4.3. Sizing Solar and Energy Storage Units

5. Case Studies

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Constant coefficient related to the maximum thermal output of CHP unit. | |

| Constant coefficients in the cost function of CHP unit. | |

| Constant coefficient indicating the minimum and maximum electric storage level. | |

| Constant coefficient indicating the minimum and maximum thermal storage level. | |

| Energy to power ratio of electric/thermal energy storage, constant coefficient | |

| Capacity of CHP unit, parameter. | |

| Capacity of the electric/thermal storage unit, parameter. | |

| Initial state-of-charge of the electric/thermal storage unit, depending on . | |

| Heat load curve, problem data. | |

| Thermal output of CHP unit, decision variable. | |

| Generation profile of solar thermal collector, problem data. | |

| Charging/discharging power of thermal energy storage in period t. | |

| Electric load curve, problem data | |

| Electric output of CHP unit, decision variable. | |

| Generation profile of solar panel, problem data. | |

| Charging/discharging power of electric energy storage in period t. | |

| Charging/dispatching efficiency of electric energy storage, constant coefficient. | |

| Charging/dispatching efficiency of the thermal energy storage, constant coefficient. | |

| Efficiency of electricity/heat conversion of CHP unit, constant coefficient. | |

| Duration of period t. |

References

- Horlock, J.H. Cogeneration: Combined Heat and Power, Thermodynamics and Economics; Pergamon: Oxford, UK, 1987. [Google Scholar]

- Baljit, S.S.S.; Chan, H.Y.; Sopian, K. Review of building integrated applications of photovoltaic and solar thermal systems. J. Clean. Prod. 2016, 137, 677–689. [Google Scholar] [CrossRef]

- Geidl, M.; Andersson, G. Optimal power flow of multiple energy carriers. IEEE Trans. Power Syst. 2007, 22, 145–155. [Google Scholar] [CrossRef]

- Geidl, M.; Koeppel, G.; Favre-Perrod, P.; Klockl, B.; Andersson, G.; Frohlich, K. Energy hubs for the future. IEEE Power Energy Mag. 2006, 5, 24–30. [Google Scholar] [CrossRef]

- Ma, T.; Wu, J.; Hao, L. Energy flow modeling and optimal operation analysis of the micro energy grid based on energy hub. Energy Convers. Manag. 2017, 133, 292–306. [Google Scholar] [CrossRef]

- Shao, C.; Wang, X.; Shahidehpour, M.; Wang, B.; Wang, X. An MILP-based optimal power flow in multicarrier energy systems. IEEE Trans. Sustain. Energy 2016, 8, 239–248. [Google Scholar] [CrossRef]

- Li, R.; Chen, L.; Zhao, B.; Wei, W.; Liu, F.; Xue, X.; Mei, S.; Yuan, T. Economic dispatch of an integrated heat-power energy distribution system with a concentrating solar power energy hub. J. Energy Eng. 2017, 143, 04017046. [Google Scholar] [CrossRef]

- Yao, Y.; Ye, L.; Qu, X.; Lu, P.; Zhao, Y.; Wang, W.; Fan, Y.; Dong, L. Coupled model and optimal operation analysis of power hub for multi-heterogeneous energy generation power system. J. Clean. Prod. 2020, 249, 119432. [Google Scholar] [CrossRef]

- Brahman, F.; Honarmand, M.; Jadid, S. Optimal electrical and thermal energy management of a residential energy hub, integrating demand response and energy storage system. Energy Build. 2015, 90, 65–75. [Google Scholar] [CrossRef]

- Bahrami, S.; Sheikhi, A. From demand response in smart grid toward integrated demand response in smart energy hub. IEEE Trans. Smart Grid 2015, 7, 1. [Google Scholar] [CrossRef]

- Rastegar, M.; Fotuhi-Firuzabad, M.; Lehtonen, M. Home load management in a residential energy hub. Electr. Power Syst. Res. 2015, 119, 322–328. [Google Scholar] [CrossRef]

- Qi, F.; Wen, F.; Liu, X.; Salam, A. A residential energy hub model with a concentrating solar power plant and electric vehicles. Energies 2017, 10, 1159. [Google Scholar] [CrossRef]

- Ha, T.; Zhang, Y.; Thang, V.V.; Huang, J. Energy hub modeling to minimize residential energy costs considering solar energy and BESS. J. Mod. Power Syst. Clean Energy 2017, 29, 399–707. [Google Scholar] [CrossRef]

- Li, D.; Xu, X.; Yu, D.; Dong, M.; Liu, H. Rule based coordinated control of domestic combined micro-chp and energy storage system for optimal daily cost. Appl. Sci. 2017, 8, 8. [Google Scholar] [CrossRef]

- Parisio, A.; Del Vecchio, C.; Vaccaro, A. A robust optimization approach to energy hub management. Int. J. Electr. Power Energy Syst. 2012, 42, 98–104. [Google Scholar] [CrossRef]

- Lu, X.; Liu, Z.; Ma, L.; Wang, L.; Zhou, K.; Feng, N. A robust optimization approach for optimal load dispatch of community energy hub. Appl. Energy 2020, 259, 114195. [Google Scholar] [CrossRef]

- Lu, X.; Liu, Z.; Ma, L.; Wang, L.; Zhou, K.; Yang, S. A robust optimization approach for coordinated operation of multiple energy hubs. Energy 2020, 197, 117171. [Google Scholar] [CrossRef]

- Vahid-Pakdel, M.; Nojavan, S.; Mohammadi-Ivatloo, B.; Zare, K. Stochastic optimization of energy hub operation with consideration of thermal energy market and demand response. Energy Convers. Manag. 2017, 145, 117–128. [Google Scholar] [CrossRef]

- Moazeni, S.; Miragha, A.H.; Defourny, B. A risk-averse stochastic dynamic programming approach to energy hub optimal dispatch. IEEE Trans. Power Syst. 2018, 34, 2169–2178. [Google Scholar] [CrossRef]

- Huo, D.; Gu, C.; Ma, K.; Wei, W.; Xiang, Y.; Le Blond, S. Chance-constrained optimization for multienergy hub systems in a smart city. IEEE Trans. Ind. Electron. 2018, 66, 1402–1412. [Google Scholar] [CrossRef]

- Rastegar, M.; Fotuhi-Firuzabad, M.; Zareipour, H.; Moeini-Aghtaieh, M. A Probabilistic energy management scheme for renewable-based residential energy hubs. IEEE Trans. Smart Grid 2017, 8, 2217–2227. [Google Scholar] [CrossRef]

- Zhao, P.; Gu, C.; Huo, D.; Shen, Y.; Hernando-Gil, I. Two-stage distributionally robust optimization for energy hub systems. IEEE Trans. Ind. Inform. 2020, 16, 3460–3469. [Google Scholar] [CrossRef]

- Bahrami, S.; Toulabi, M.; Ranjbar, S.; Moeini-Aghtaie, M.; Ranjbar, A.M. A Decentralized energy management framework for energy hubs in dynamic pricing markets. IEEE Trans. Smart Grid 2017, 9, 6780–6792. [Google Scholar] [CrossRef]

- Liang, Y.; Wei, W.; Wang, C. A generalized nash equilibrium approach for autonomous energy management of residential energy hubs. IEEE Trans. Ind. Inform. 2019, 15, 5892–5905. [Google Scholar] [CrossRef]

- Li, Y.; Li, T.-Y.; Zhou, J.; Huang, B.-N. Double-consensus based distributed optimal energy management for multiple energy hubs. Appl. Sci. 2018, 8, 1412. [Google Scholar] [CrossRef]

- Davatgaran, V.; Saniei, M.; Mortazavi, S.S. Optimal bidding strategy for an energy hub in energy market. Energy 2018, 148, 482–493. [Google Scholar] [CrossRef]

- Li, R.; Wei, W.; Mei, S.; Hu, Q.; Wu, Q. Participation of an energy hub in electricity and heat distribution markets: An mpec approach. IEEE Trans. Smart Grid 2019, 10, 3641–3653. [Google Scholar] [CrossRef]

- Chen, Y.; Wei, W.; Liu, F.; Sauma, E.; Mei, S. Energy trading and market equilibrium in integrated heat-power distribution systems. IEEE Trans. Smart Grid 2019, 10, 4080–4094. [Google Scholar] [CrossRef]

- Najafi, A.; Falaghi, H.; Contreras, J.; Ramezani, M. A Stochastic bilevel model for the energy hub manager problem. IEEE Trans. Smart Grid 2017, 8, 2394–2404. [Google Scholar] [CrossRef]

- Khazeni, S.; Sheikhi, A.; Rayati, M.; Soleymani, S.; Ranjbar, A.M.; Rayiati, M. Retail market equilibrium in multicarrier energy systems: A game theoretical approach. IEEE Syst. J. 2019, 13, 738–747. [Google Scholar] [CrossRef]

- Heidari, A.; Mortazavi, S.S.; Bansal, R.C. Equilibrium state of a price-maker energy hub in a competitive market with price uncertainties. IET Renew. Power Gener. 2020, 14, 976–985. [Google Scholar] [CrossRef]

- Chen, Y.; Wei, W.; Liu, F.; Wu, Q.; Mei, S. Analyzing and validating the economic efficiency of managing a cluster of energy hubs in multi-carrier energy systems. Appl. Energy 2018, 230, 403–416. [Google Scholar] [CrossRef]

- Zhang, X.; Shahidehpour, M.; AlAbdulwahab, A.; Abusorrah, A. Optimal expansion planning of energy hub with multiple energy infrastructures. IEEE Trans. Smart Grid 2015, 6, 1. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, N.; Zhuo, Z.; Kang, C.; Kirschen, D. Mixed-integer linear programming-based optimal configuration planning for energy hub: Starting from scratch. Appl. Energy 2018, 210, 1141–1150. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, N.; Yang, J.; Wang, Y.; Kang, C. Optimal configuration planning of multi-energy systems considering distributed renewable energy. IEEE Trans. Smart Grid 2017, 10, 1452–1464. [Google Scholar] [CrossRef]

- Sani, M.M.; Noorpoor, A.R.; Motlagh, M.S.-P. Optimal model development of energy hub to supply water, heating and electrical demands of a cement factory. Energy 2019, 177, 574–592. [Google Scholar] [CrossRef]

- Ge, S.; Li, J.; Liu, H.; Sun, H.; Wang, Y. Research on operation-planning double-layer optimization design method for multi-energy microgrid considering reliability. Appl. Sci. 2018, 8, 2062. [Google Scholar] [CrossRef]

- Amiri, S.; Honarvar, M.; Sadegheih, A. Providing an integrated model for planning and scheduling energy hubs and preventive maintenance. Energy 2018, 163, 1093–1114. [Google Scholar] [CrossRef]

- Moradi, S.; Ghaffarpour, R.; Ranjbar, A.M.; Mozaffari, B. Optimal integrated sizing and planning of hubs with midsize/large CHP units considering reliability of supply. Energy Convers. Manag. 2017, 148, 974–992. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, N.; Lu, Z.; Kang, C. Planning multiple energy systems toward low-carbon society: A decentralized approach. IEEE Trans. Smart Grid 2019, 10, 4859–4869. [Google Scholar] [CrossRef]

- Dolatabadi, A.; Mohammadi-Ivatloo, B.; Abapour, M.; Tohidi, S. Optimal stochastic design of wind integrated energy hub. IEEE Trans. Ind. Inform. 2017, 13, 2379–2388. [Google Scholar] [CrossRef]

- Pazouki, S.; Haghifam, M.-R. Optimal planning and scheduling of energy hub in presence of wind, storage and demand response under uncertainty. Int. J. Electr. Power Energy Syst. 2016, 80, 219–239. [Google Scholar] [CrossRef]

- Hemmati, S.; Ghaderi, S.; Ghazizadeh, M. Sustainable energy hub design under uncertainty using Benders decomposition method. Energy 2018, 143, 1029–1047. [Google Scholar] [CrossRef]

- Chen, C.; Sun, H.; Shen, X.; Guo, Y.; Guo, Q.; Xia, T. Two-stage robust planning-operation co-optimization of energy hub considering precise energy storage economic model. Appl. Energy 2019, 252, 113372. [Google Scholar] [CrossRef]

- Karamdel, S.; Moghaddam, M.P. Robust expansion co-planning of electricity and natural gas infrastructures for multi energy-hub systems with high penetration of renewable energy sources. IET Renew. Power Gener. 2019, 13, 2287–2297. [Google Scholar] [CrossRef]

- Cao, Y.; Wei, W.; Wang, J.; Mei, S.; Shafie-Khah, M.; Catalao, J.P.S. Capacity planning of energy hub in multi-carrier energy networks: A data-driven robust stochastic programming approach. IEEE Trans. Sustain. Energy 2020, 11, 3–14. [Google Scholar] [CrossRef]

- Mohammadi, M.; Noorollahi, Y.; Mohammadi-Ivatloo, B.; Hosseinzadeh, M.; Yousefi, H.; Khorasani, S.T. Optimal management of energy hubs and smart energy hubs—A review. Renew. Sustain. Energy Rev. 2018, 89, 33–50. [Google Scholar] [CrossRef]

- Mohammadi, M.; Noorollahi, Y.; Mohammadi-Ivatloo, B.; Yousefi, H.; Jalilinasrabady, S. Optimal scheduling of energy hubs in the presence of uncertainty—A review. J. Energy Manag. Tech. 2017, 1, 1–17. [Google Scholar]

- Sadeghi, H.; Rashidinejad, M.; Moeini-Aghtaie, M.; Abdollahi, A. The energy hub: An extensive survey on the state-of-the-art. Appl. Therm. Eng. 2019, 161, 114071. [Google Scholar] [CrossRef]

- Liu, M.; Shi, Y.; Fang, F. Combined cooling, heating and power systems: A survey. Renew. Sustain. Energy Rev. 2014, 35, 1–22. [Google Scholar] [CrossRef]

- Guo, T.; Henwood, M.; van Ooijen, M. An algorithm for combined heat and power economic dispatch. IEEE Trans. Power Syst. 1996, 11, 1778–1784. [Google Scholar] [CrossRef]

- Wei, W.; Wang, J. Modeling and Optimization of Interdependent Energy Infrastructures; Springer Science and Business Media LLC: Berlin, Germany, 2020. [Google Scholar]

- Solar Data. Available online: https://www.renewables.ninja (accessed on 15 June 2020).

| EES Unit | TES Unit | CHP Unit | |||

|---|---|---|---|---|---|

| Parameter | Value | Parameter | Value | Parameter | Value |

| 0.95/0.95 | 0.98/0.98 | 0.30 | |||

| 0.20/0.95 | 0.10/1.00 | 0.90 | |||

| 0.20 | 0.20 | 0.50 | |||

| PV Panel (MWh) | STC (MWh) | V(0) CNY | Vmin CNY | ES (MWh) | HS (MWh) | Reduction % |

|---|---|---|---|---|---|---|

| 100 | 100 | 1,204,493 | 1,202,018 | 0 | 105 | 0.2 |

| 200 | 200 | 1,006,167 | 981,740 | 40 | 570 | 2.4 |

| 300 | 300 | 902,698 | 785,671 | 621 | 858 | 13.0 |

| 400 | 400 | 865,776 | 634,128 | 1292 | 949 | 26.8 |

| 500 | 500 | 846,545 | 588,265 | 1370 | 1279 | 30.5 |

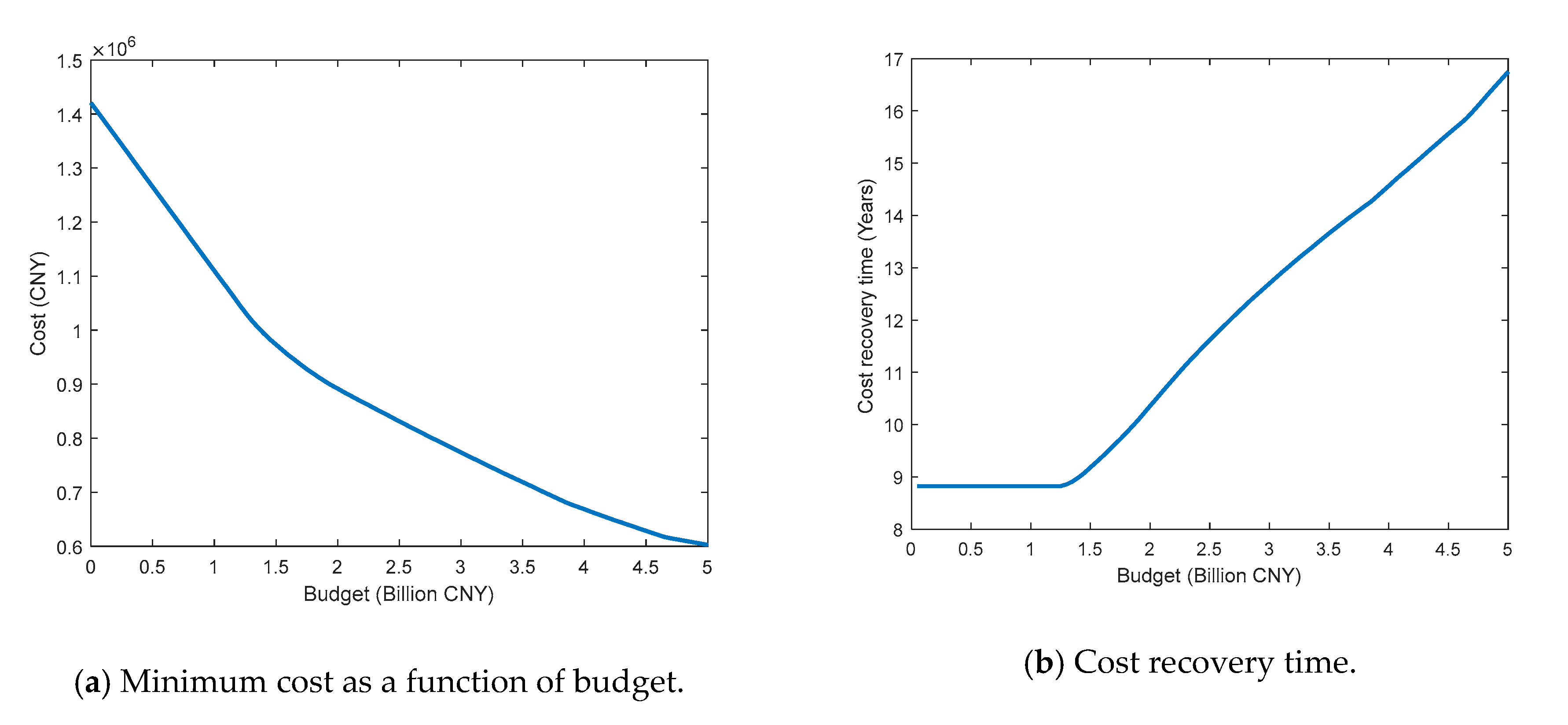

| Budget | PV Panel | STC | EES | TES |

|---|---|---|---|---|

| (MW) | (MW) | (MWh) | (MWh) | |

| 0.5 | 70 | 80 | 0 | 0 |

| 1.0 | 153.3 | 80 | 0 | 0 |

| 1.5 | 231.7 | 106.8 | 0 | 15.95 |

| 2.0 | 270.3 | 241.1 | 20.3 | 559.8 |

| 2.5 | 283.2 | 259.7 | 328.7 | 650.7 |

| 3.0 | 315.4 | 259.7 | 574.3 | 650.7 |

| PV Panel | STC | EES | TES | Payback | Net Profit | ||

|---|---|---|---|---|---|---|---|

| CNY/MW | CNY/MWh | (MW) | (MW) | (MWh) | (MWh) | Time (days) | CNY |

| 5.6 × | 1.2 × | 240.6 | 133.9 | 0 | 92.6 | 3207 | 2.07 × |

| 5.2 × | 1.1 × | 250.9 | 156.5 | 0 | 194.7 | 3080 | 2.78 × |

| 4.8 × | 1.0 × | 264.9 | 174.9 | 0 | 267.5 | 3033 | 3.05 × |

| 4.4 × | 0.9 × | 271.1 | 205.8 | 23.4 | 401.1 | 3030 | 3.07 × |

| 4.0 × | 0.8 × | 280.6 | 133.9 | 275.4 | 117.1 | 3028 | 3.08 × |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Si, Y.; Liu, C.; Chen, L.; Xue, X.; Guo, Y.; Mei, S. The Value and Optimal Sizes of Energy Storage Units in Solar-Assist Cogeneration Energy Hubs. Appl. Sci. 2020, 10, 4994. https://doi.org/10.3390/app10144994

Chen X, Si Y, Liu C, Chen L, Xue X, Guo Y, Mei S. The Value and Optimal Sizes of Energy Storage Units in Solar-Assist Cogeneration Energy Hubs. Applied Sciences. 2020; 10(14):4994. https://doi.org/10.3390/app10144994

Chicago/Turabian StyleChen, Xiaotao, Yang Si, Chengkui Liu, Laijun Chen, Xiaodai Xue, Yongqing Guo, and Shengwei Mei. 2020. "The Value and Optimal Sizes of Energy Storage Units in Solar-Assist Cogeneration Energy Hubs" Applied Sciences 10, no. 14: 4994. https://doi.org/10.3390/app10144994

APA StyleChen, X., Si, Y., Liu, C., Chen, L., Xue, X., Guo, Y., & Mei, S. (2020). The Value and Optimal Sizes of Energy Storage Units in Solar-Assist Cogeneration Energy Hubs. Applied Sciences, 10(14), 4994. https://doi.org/10.3390/app10144994