Airflow Characteristics Downwind a Naturally Ventilated Pig Building with a Roofed Outdoor Exercise Yard and Implications on Pollutant Distribution

Abstract

:1. Introduction

- It is the first to provide detailed airflow information around a naturally ventilated livestock building combined with a roofed outdoor area;

- It predicts the potential distribution of gaseous pollutants from the building using airflow measurement results;

- It provides a large amount of experimental data of both mean velocity and turbulent fluctuations downwind the building with a high resolution that can be used for CFD validation.

2. Materials and Methods

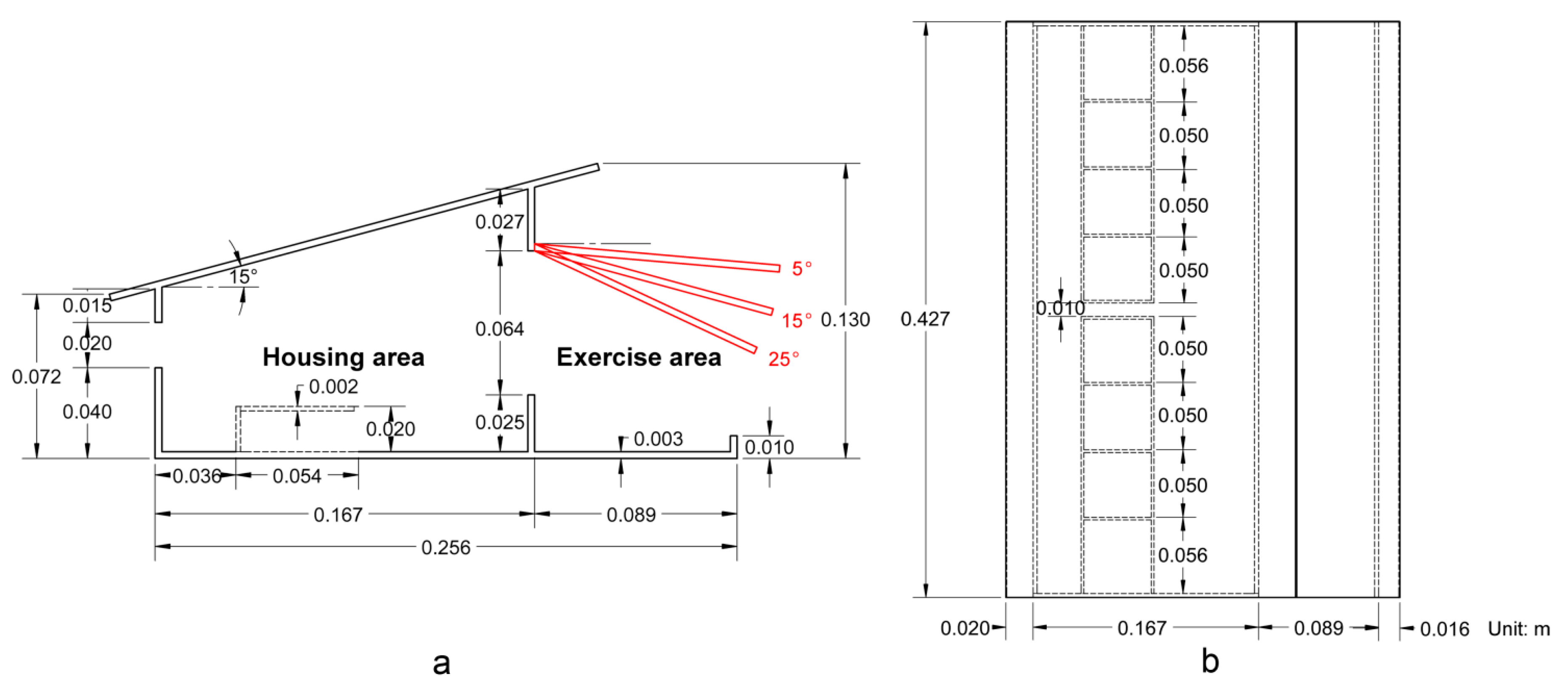

2.1. Scaled Pig Building Model

2.2. Boundary Layer Wind Tunnel and Measurement Devices

2.3. Measurement of Boundary Layer Profile

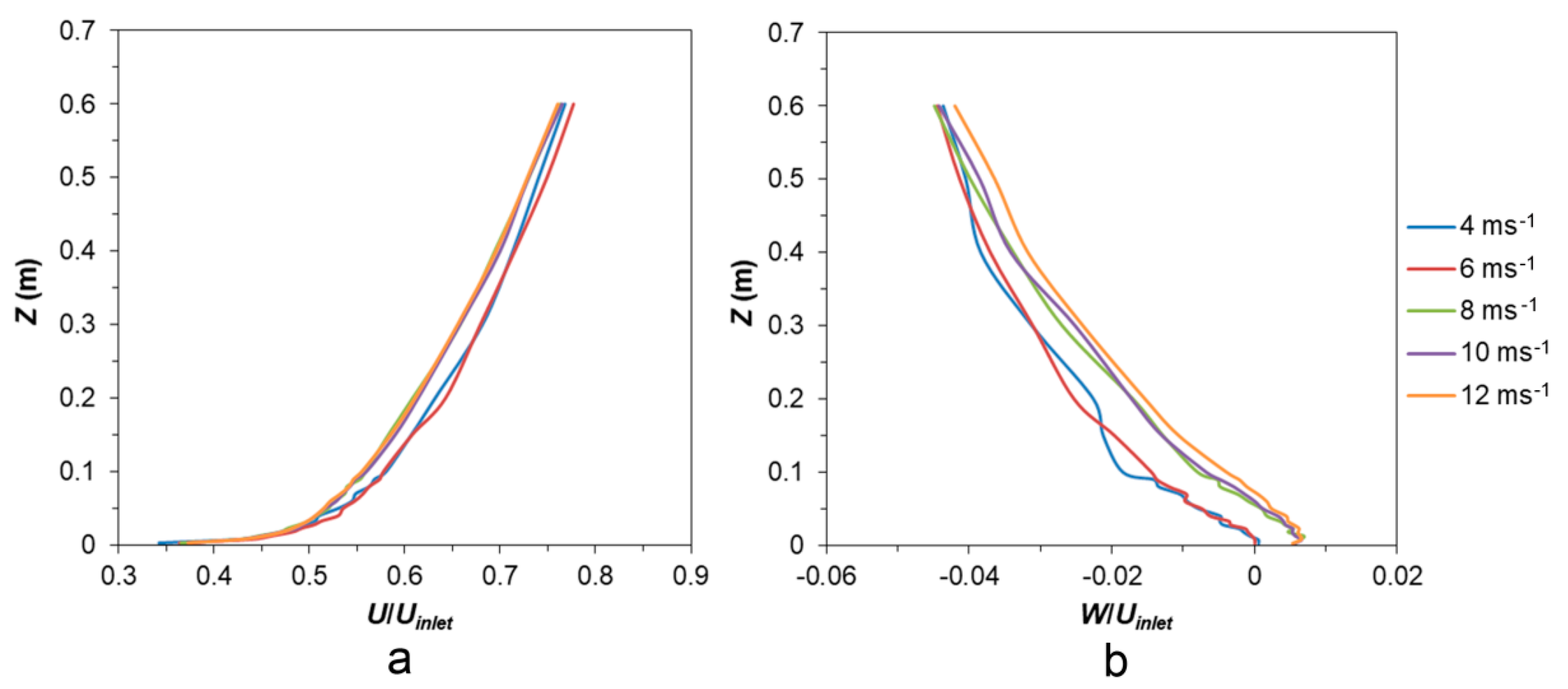

2.3.1. Reynolds Number Independence Study

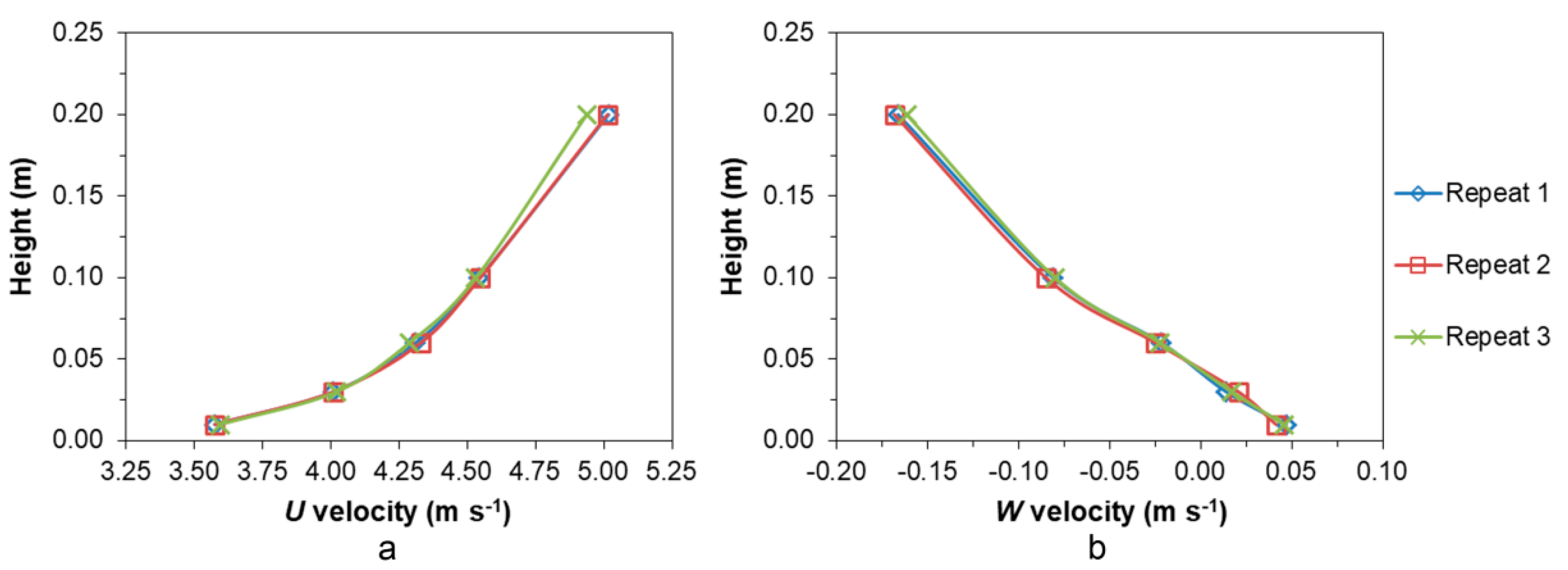

2.3.2. Stability Study

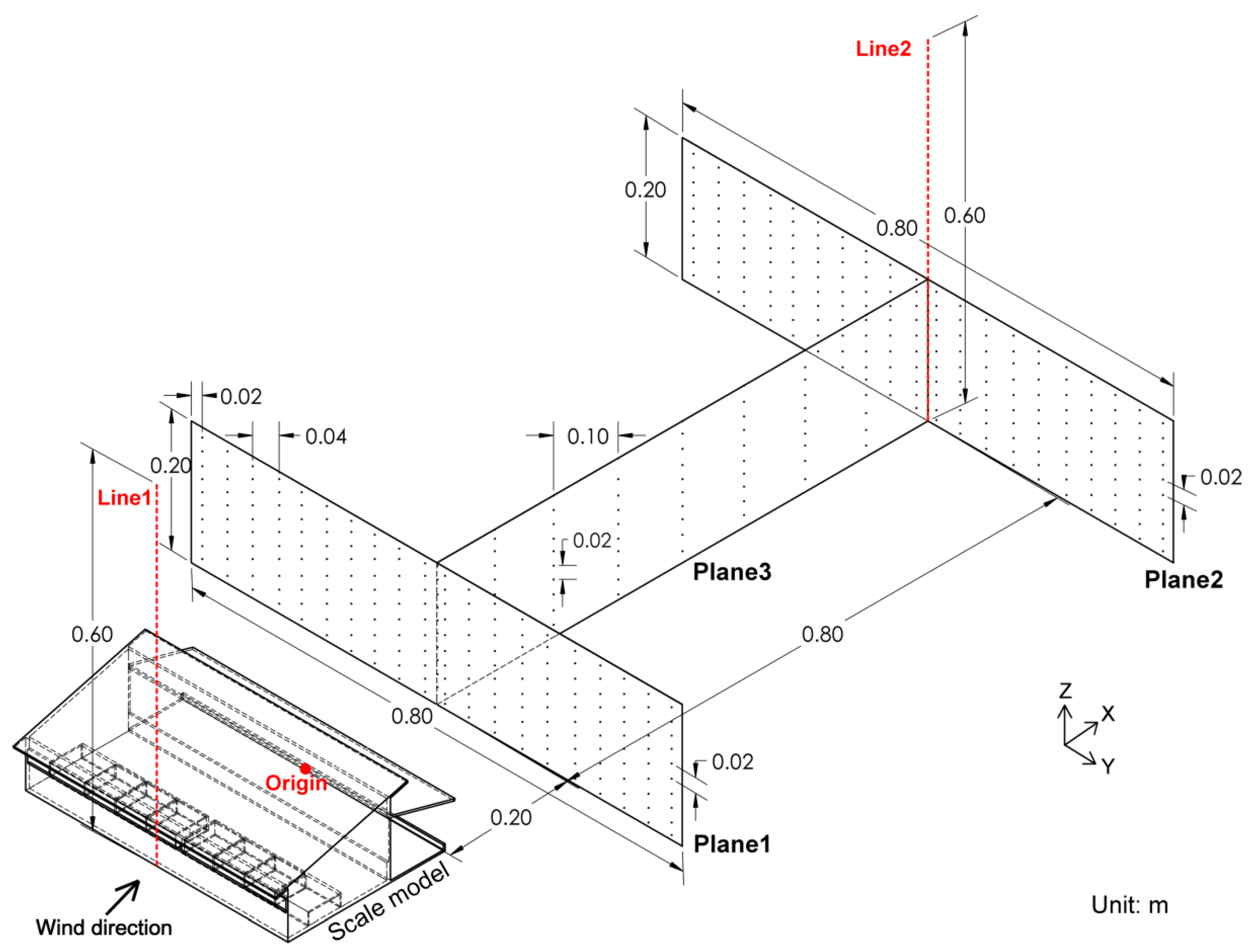

2.4. Measurement of Airflows Downwind the Building

2.5. Data Analysis

3. Results and Discussion

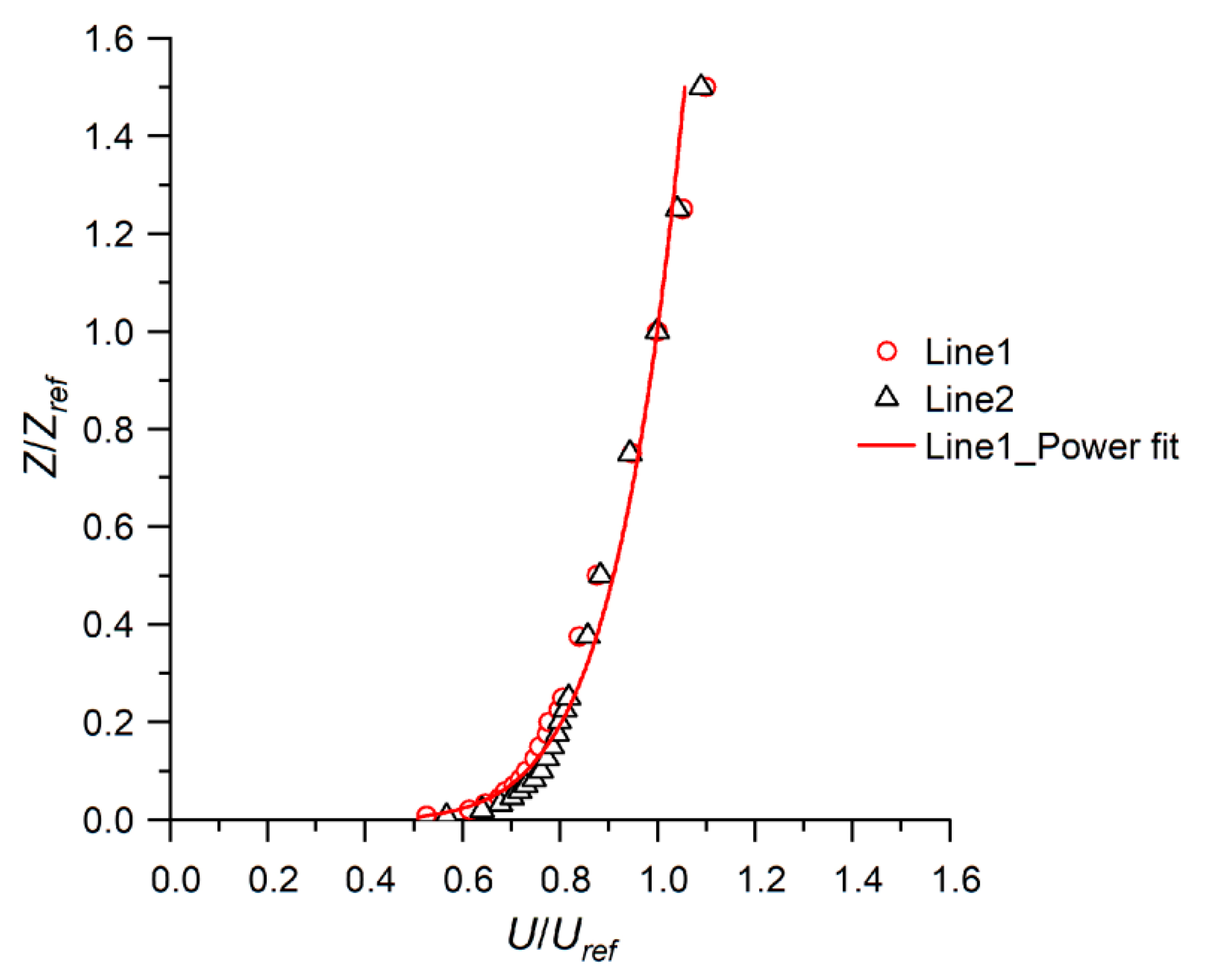

3.1. Boundary Layer Profile

3.1.1. Reynolds Number Independence Study

3.1.2. Stability Study and Wind Profile Properties

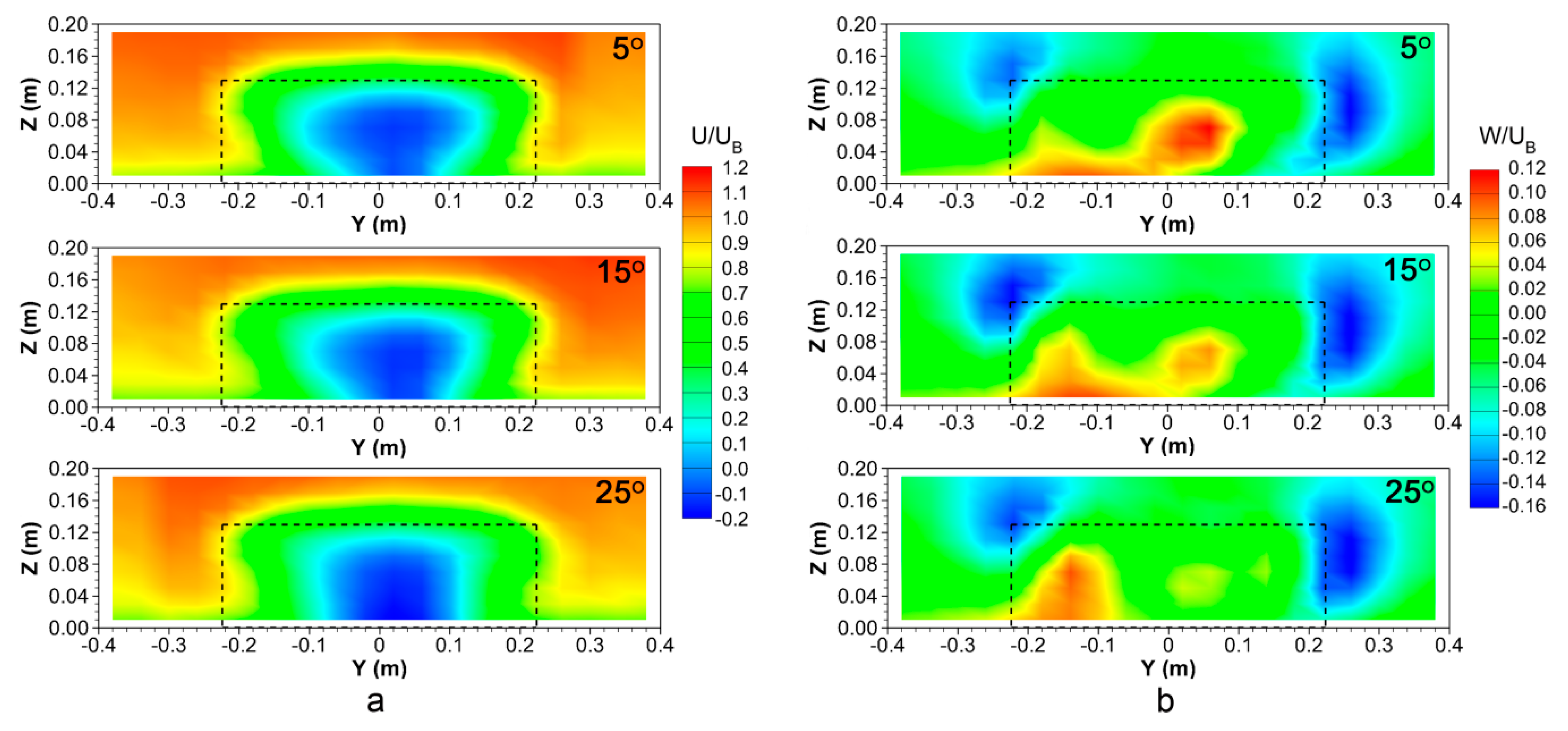

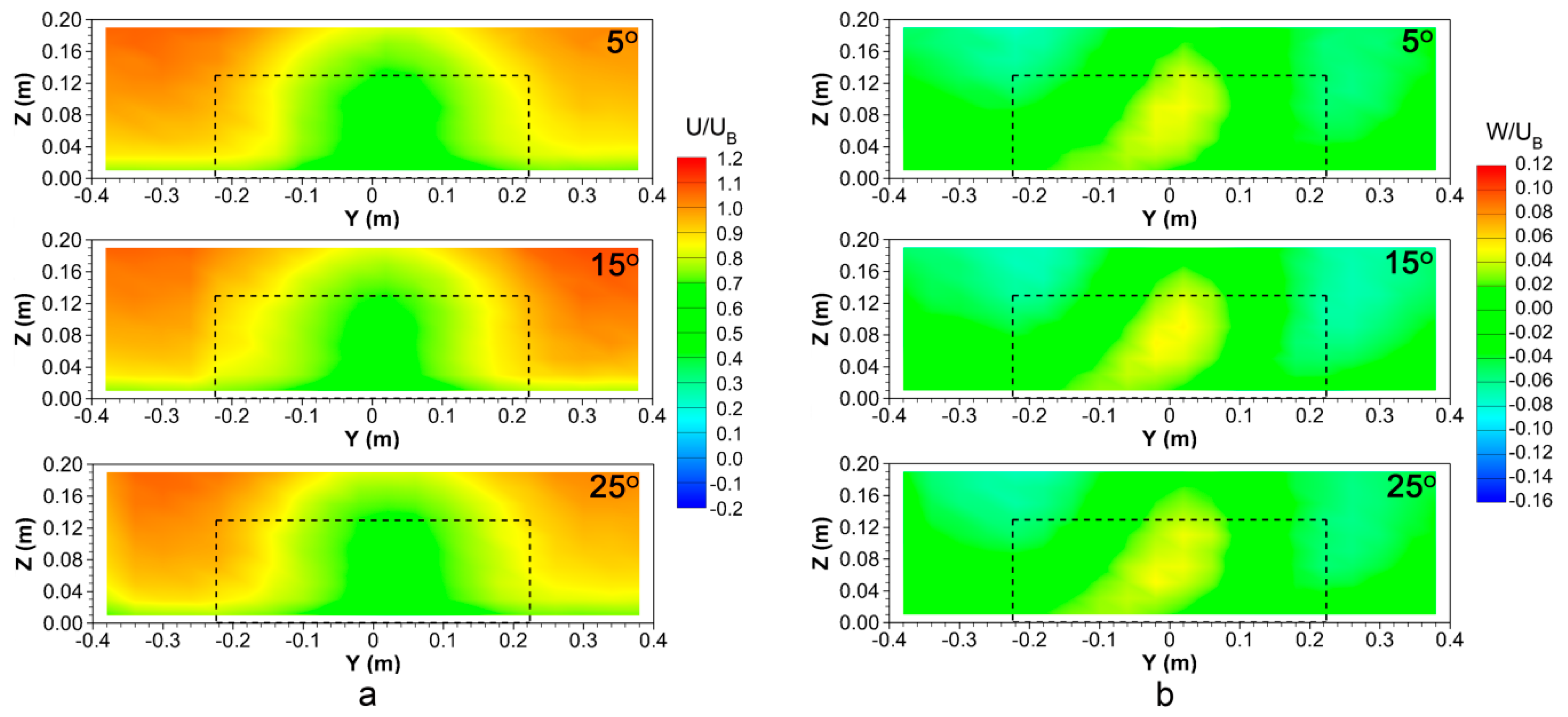

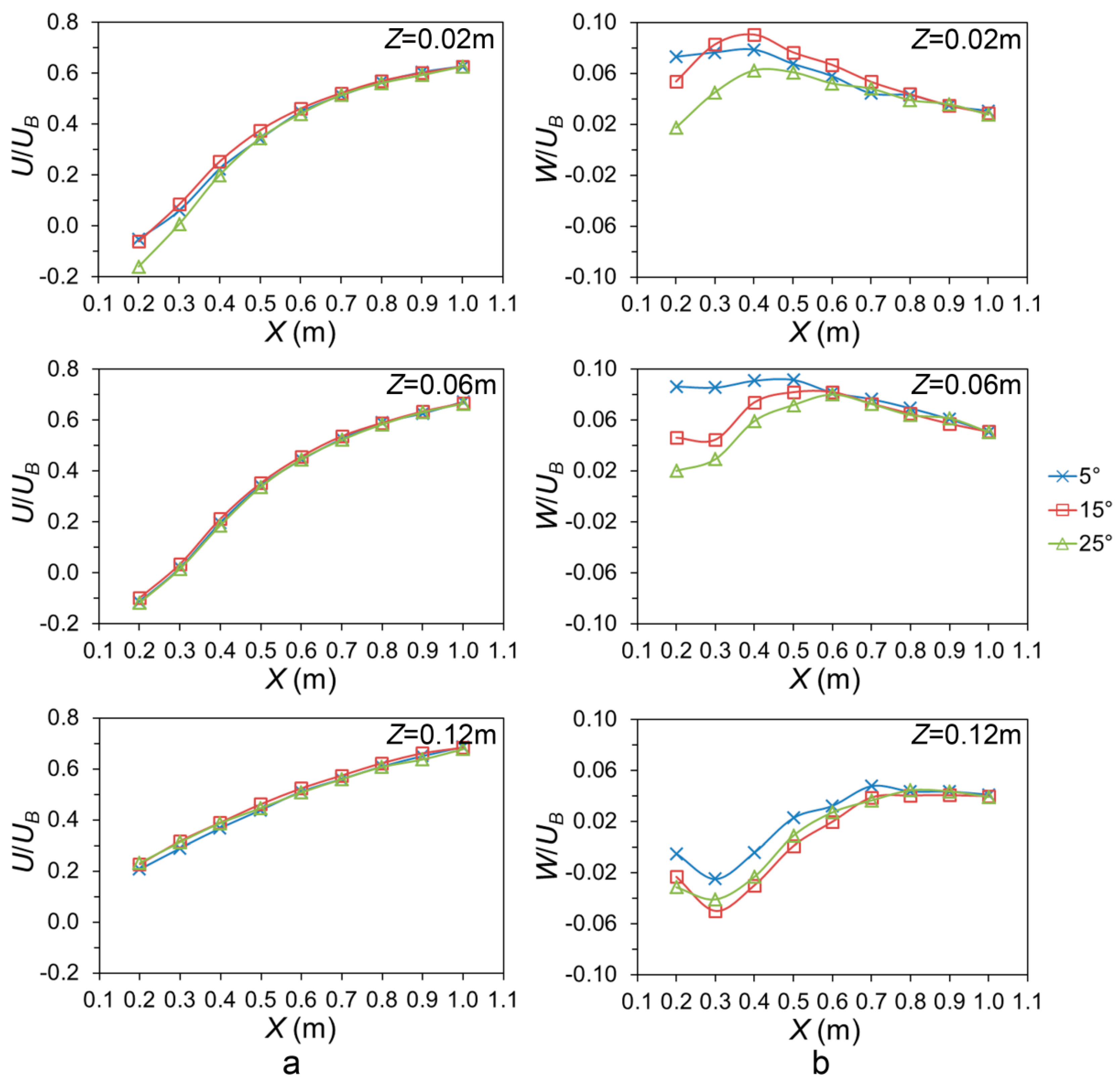

3.2. Mean Air Velocities Downwind the Building

3.3. Air Turbulence Downwind the Building

4. Conclusions

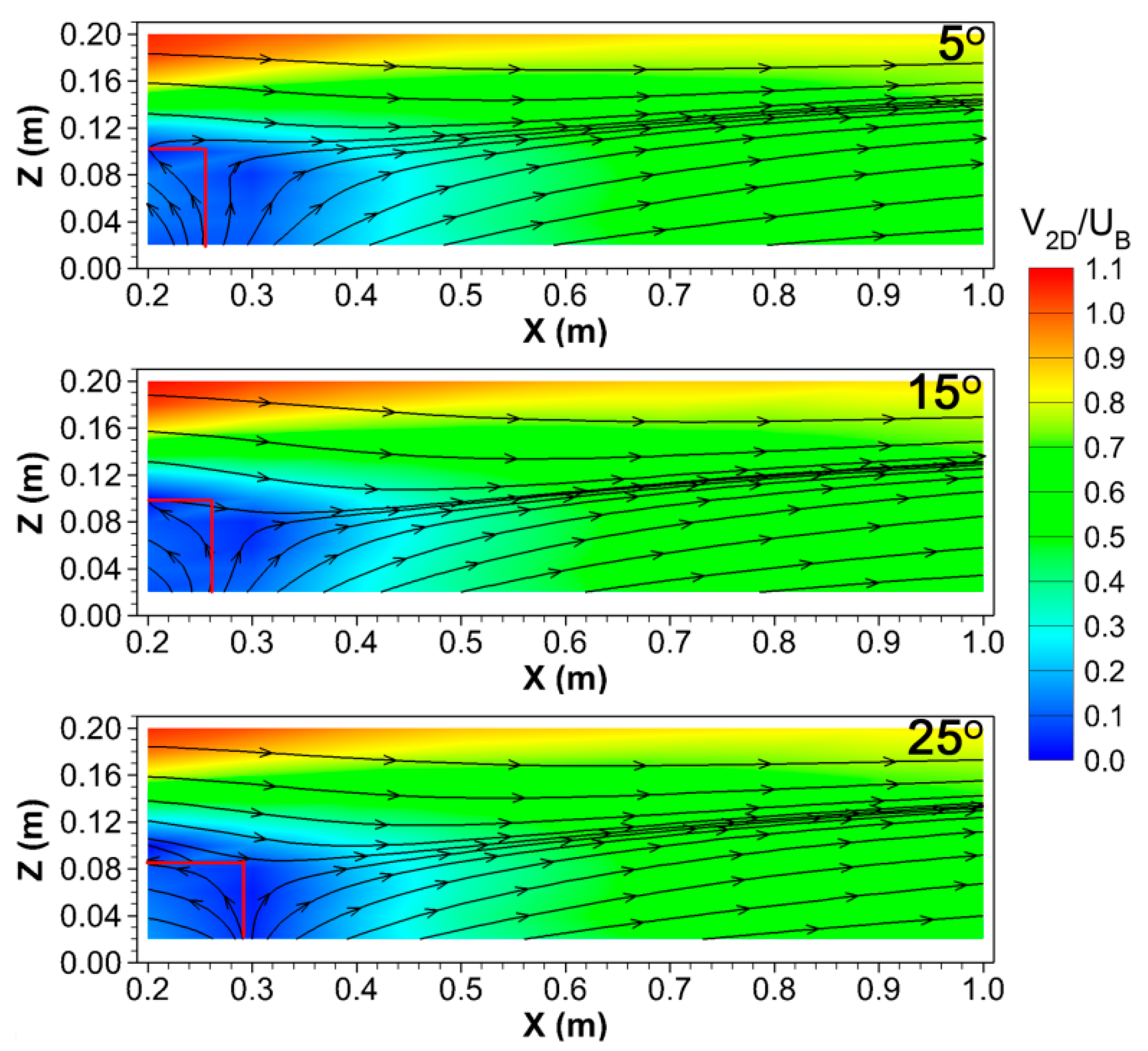

- Reduced air velocities were observed right behind the building. At the vertical plane parallel to the building sidewalls with a distance 0.2 m (i.e., 1.5ZB, where ZB is the building height) downwind the building, reverse flows occurred in the centre of the plane and were affected by the roof slope.

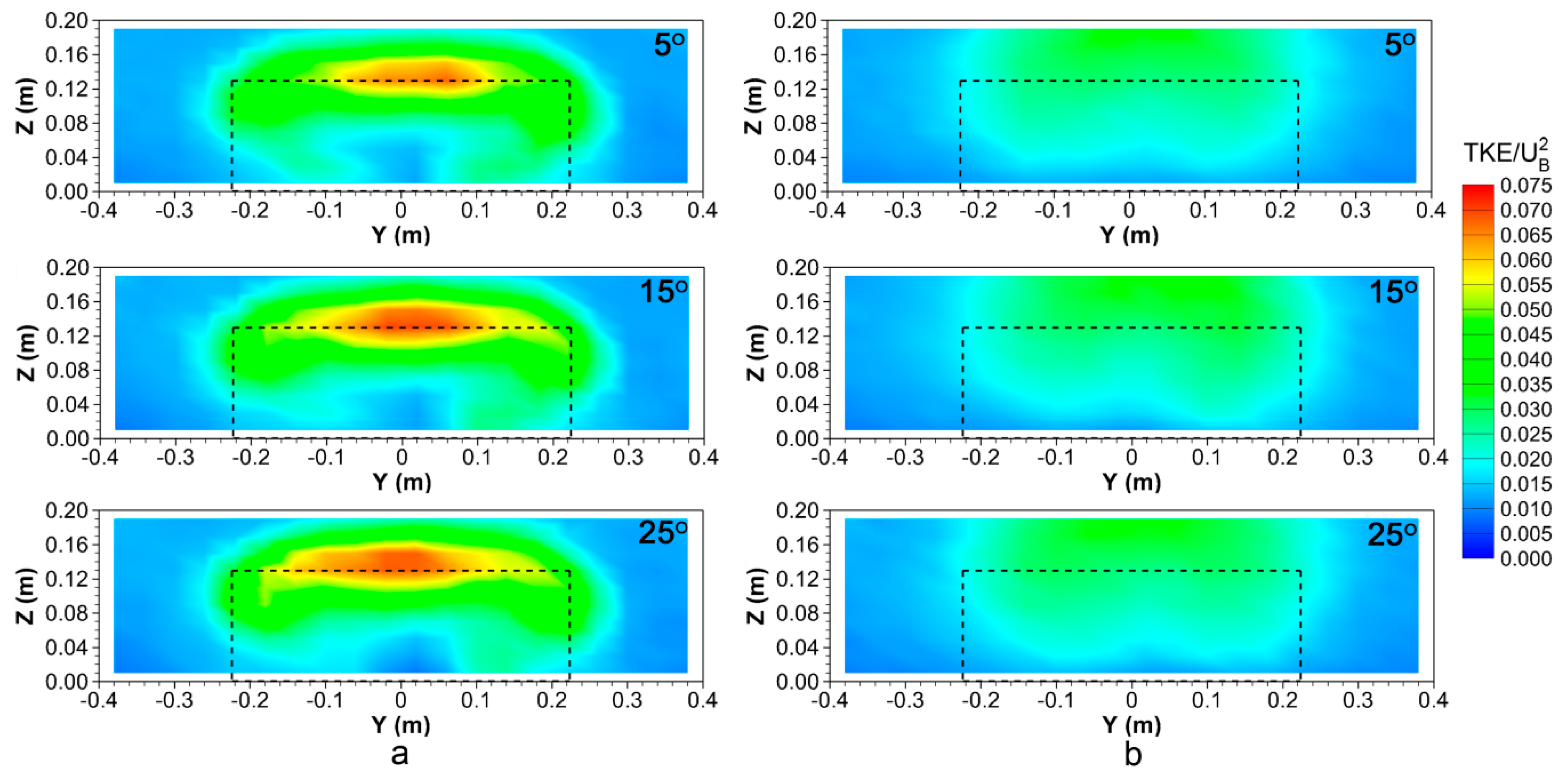

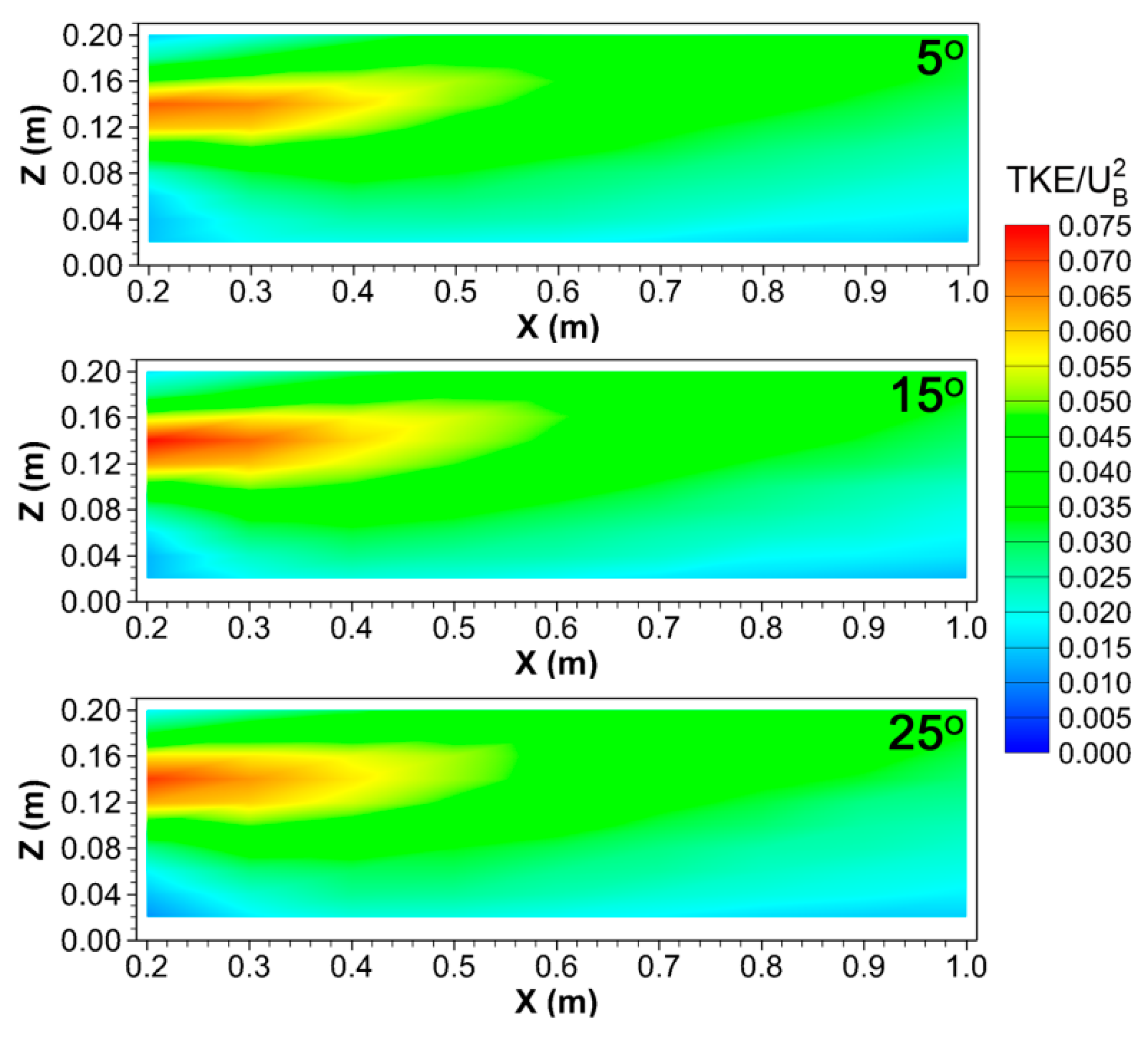

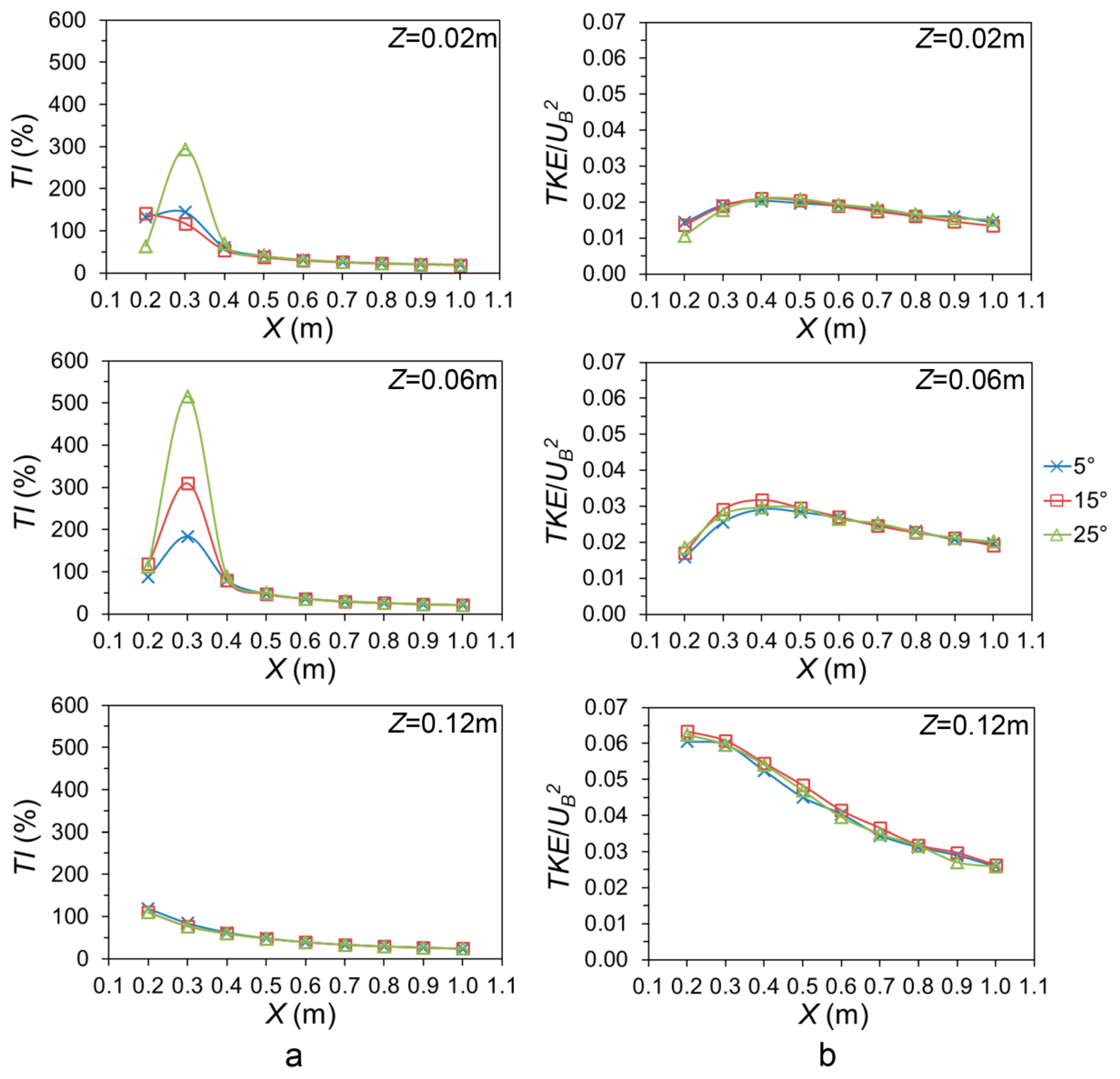

- An elliptic-shaped low air velocity region along the distance to the building was found. It had a similar height as the building and reached 0.5 m (i.e., 3.8ZB and corresponded to 25 m in full-scale) downwind from the building. Within this region, the mean air velocities were low and thus might result in a higher gaseous pollutant concentration. This suggested that applying additional treatment technologies to trap the high-concentrated gaseous pollutants (e.g., odours or ammonia) in this region might contribute to the mitigation of pollutant emissions to the atmosphere and alleviation of the burden to the surrounding environment. Apart from the mean air velocity, the transport of the air pollutants in this region was likely attributed to the turbulent eddies.

- A wake zone with recirculated air was observed for all three roof slope cases. The larger the roof slope was, the lower and longer the wake zone became. It indicated that a steeper roof could result in the accumulated air pollutants dispersing to a farther distance.

- The effect of the roof slope to the mean air velocity and the air turbulence could reach up to distances of 0.8 m (i.e., 6.2ZB) and 0.5 m (i.e., 3.8ZB) downwind from the building, respectively.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Stavrakakis, G.M.; Koukou, M.K.; Vrachopoulos, M.G.; Markatos, N.C. Natural cross-ventilation in buildings: Building-scale experiments, numerical simulation and thermal comfort evaluation. Energy Build. 2008, 40, 1666–1681. [Google Scholar] [CrossRef]

- De Paepe, M.D.; Pieters, J.G.; Cornelis, W.M.; Gabriels, D.; Merci, B.; Demeyer, P. Airflow measurements in and around scale model cattle barns in a wind tunnel: Effect of ventilation opening height. Biosyst. Eng. 2012, 113, 22–32. [Google Scholar] [CrossRef]

- Honeyman, M.S. Extensive bedded indoor and outdoor pig production systems in USA: Current trends and effects on animal care and product quality. Livest. Prod. Sci. 2005, 94, 15–24. [Google Scholar] [CrossRef]

- Park, H.-S.; Min, B.; Oh, S.-H. Research trends in outdoor pig production—A review. Asian-Australas J. Anim. Sci. 2017, 30, 1207–1214. [Google Scholar] [CrossRef] [Green Version]

- Gade, P.B. Welfare of animal production in intensive and organic systems with special reference to Danish organic pig production. Meat Sci. 2002, 62, 353–358. [Google Scholar] [CrossRef]

- Møller, F. Housing of finishing pigs within organic farming. In Ecological Animal Husbandry in the Nordic Countries, Proceedings of the NJF-Seminar No. 303, Horsens, Denmark, 16–17 September 1999; Danish Research Centre for Organic Farming: Horsens, Denmark, 1999; pp. 93–98. [Google Scholar]

- Hansen, L.L.; Claudi-Magnussen, C.; Jensen, S.K.; Andersen, H.J. Effect of organic pig production systems on performance and meat quality. Meat Sci. 2006, 74, 605–615. [Google Scholar] [CrossRef] [Green Version]

- Fraser, D. Understanding animal welfare. Acta Vet. Scand. 2008, 50, S1. [Google Scholar] [CrossRef] [Green Version]

- Ikeguchi, A.; Zhang, G.; Okushima, L.; Bennetsen, J.C. Windward windbreak effects on airflow in and around a scale model of a naturally ventilated pig barn. Trans. ASAE 2003, 46, 789–795. [Google Scholar] [CrossRef]

- Mendes, L.B.; Pieters, J.G.; Snoek, D.; Ogink, N.W.M.; Brusselman, E.; Demeyer, P. Reduction of ammonia emissions from dairy cattle cubicle houses via improved management- or design-based strategies: A modeling approach. Sci. Total Environ. 2017, 574, 520–531. [Google Scholar] [CrossRef]

- Aubrun, S.; Leitl, B. Unsteady characteristics of the dispersion process in the vicinity of a pig barn. Wind tunnel experiments and comparison with field data. Atmos. Environ. 2004, 38, 81–93. [Google Scholar] [CrossRef]

- Samer, M.; Ammon, C.; Loebsin, C.; Fiedler, M.; Berg, W.; Sanftleben, P.; Brunsch, R. Moisture balance and tracer gas technique for ventilation rates measurement and greenhouse gases and ammonia emissions quantification in naturally ventilated buildings. Build. Environ. 2012, 50, 10–20. [Google Scholar] [CrossRef]

- Pasquill, F. Atmospheric Diffusion: The Dispersion of Windborne Material from Industrial and Other Sources, 2nd ed.; Ellis Horwood Ltd.: Chichester, UK, 1974. [Google Scholar]

- Wyngaard, J.C.; Brost, R.A. Top-down and bottom-up diffusion of a scalar in the convective boundary layer. J. Atmos. Sci. 1984, 41, 102–112. [Google Scholar] [CrossRef]

- Angevine, W.M.; Edwards, J.M.; Lothon, M.; LeMone, M.A.; Osborne, S.R. Transition periods in the diurnally-varying atmospheric boundary layer over land. Bound. -Layer Meteorol. 2020, 1–19. [Google Scholar] [CrossRef]

- Caughey, S.J.; Wyngaard, J.C.; Kaimal, J.C. Turbulence in the evolving stable boundary layer. J. Atmos. Sci. 1979, 36, 1041–1052. [Google Scholar]

- Sastre, M.; Yagüe, C.; Román-Cascón, C.; Maqueda, G. Atmospheric boundary-layer evening transitions: A comparison between two different experimental sites. Bound. -Layer Meteorol. 2015, 157, 375–399. [Google Scholar] [CrossRef]

- Ikeguchi, A.; Okushima, L. Airflow patterns related to polluted air dispersion in open free-stall dairy houses with different roof shapes. Trans. ASAE 2001, 44, 1797–1805. [Google Scholar] [CrossRef]

- Tyndall, J.; Colletti, J. Mitigating swine odor with strategically designed shelterbelt systems: A review. Agroforest. Syst. 2007, 69, 45–65. [Google Scholar] [CrossRef]

- Lin, X.-J.; Barrington, S.; Nicell, J.; Choiniere, D.; Vezina, A. Influence of windbreaks on livestock odour dispersion plume in the field. Agric. Ecosyst. Environ. 2006, 116, 263–272. [Google Scholar] [CrossRef]

- Bottcher, R.W.; Keener, K.M.; Munilla, R.D. Comparison of Odor Control Mechanisms for Wet Pad Scrubbing, Indoor Ozonation, Windbreak Walls and Biofilters; ASAE Paper; ASAE: St. Joseph, MI, USA, 2000; pp. 49085–49659. [Google Scholar]

- Parker, D.B.; Malone, G.W.; Walter, W.D. Vegetative environmental buffers and exhaust fan deflectors for reducing downwind odor and VOCs from tunnel-ventilated swine barns. Trans. ASABE 2012, 55, 227–240. [Google Scholar] [CrossRef]

- Tominaga, Y.; Akabayashi, S.-I.; Kitahara, T.; Arinami, Y. Air flow around isolated gable-roof buildings with different roof pitches: Wind tunnel experiments and CFD simulations. Build. Environ. 2015, 84, 204–213. [Google Scholar] [CrossRef]

- Yi, Q.; Li, H.; Wang, X.; Zong, C.; Zhang, G. Numerical investigation on the effects of building configuration on discharge coefficient for a cross-ventilated dairy building model. Biosyst. Eng. 2019, 182, 107–122. [Google Scholar] [CrossRef]

- Sauer, T.; Hatfield, J.L.; Haan, F.L. A wind tunnel study of airflow near model swine confinement buildings. Trans. ASABE 2011, 54, 643–652. [Google Scholar] [CrossRef]

- Ahmad, K.; Khare, M.; Chaudhry, K.K. Wind tunnel simulation studies on dispersion at urban street canyons and intersections—A review. J. Wind Eng. Ind. Aerodyn. 2005, 93, 697–717. [Google Scholar] [CrossRef]

- Huang, Y.-D.; Xu, X.; Liu, Z.-Y.; Deng, J.-T.; Kim, C.-N. Impacts of shape and height of building roof on airflow and pollutant dispersion inside an isolated street canyon. Environ. Forensics 2016, 17, 361–379. [Google Scholar] [CrossRef]

- Takano, Y.Y.; Moonen, P. On the influence of roof shape on flow and dispersion in an urban street canyon. J. Wind Eng. Ind. Aerodyn. 2013, 123, 107–120. [Google Scholar] [CrossRef]

- Lee, I.-B.; Kang, C.; Lee, S.; Kim, G.; Heo, J.; Sase, S. Development of vertical wind and turbulence profiles of wind tunnel boundary layers. Trans. ASAE 2004, 47, 1717–1726. [Google Scholar] [CrossRef]

- Lee, I.; Sase, S.; Okushima, L.; Ikeguchi, A.; Choi, K.; Yun, J. A wind tunnel study of natural ventilation for multi-span greenhouse scale models using two-dimensional particle image velocimetry (PIV). Trans. ASAE 2003, 46, 763–772. [Google Scholar]

- Etheridge, D.W.; Sandberg, M. Building Ventilation: Theory and Measurement; John Wiley & Sons: Chichester, UK, 1996. [Google Scholar]

- Olsen, A.W.; Dybkjær, L.; Simonsen, H.B. Behaviour of growing pigs kept in pens with outdoor runs II. Temperature regulatory behaviour, comfort behaviour and dunging preferences. Livest. Prod. Sci. 2001, 69, 265–278. [Google Scholar] [CrossRef]

- Nosek, Š.; Kluková, Z.; Jakubcová, M.; Yi, Q.; Janke, D.; Demeyer, P.; Jaňour, Z. The impact of atmospheric boundary layer, opening configuration and presence of animals on the ventilation of a cattle barn. J. Wind Eng. Ind. Aerodyn. 2020, 201, 104185. [Google Scholar] [CrossRef]

- Amon, T.; Yi, Q.; Heinicke, J.; Pinto, S.; Hoffmann, G.; Hempel, S.; Siemens, T.M.; Janke, D.; Ammon, C.; Amon, B. Optimisation of environment-animal-welfare interactions in high-performance dairy cows housed in naturally ventilated barns. In Proceedings of the 2019 International Symposium on Animal Environment and Welfare (2019 ISAEW), Chongqing, China, 21–24 October 2019; pp. 223–231. [Google Scholar]

- König, M.; Bonkoß, K.; Amon, T. Wind tunnel measurements on reduction of near surface concentrations through naturally barrier on emissions from naturally ventilated barn. In Proceedings of the Physmod 2017—International Workshop on Physical Modelling of Flow and Dispersion Phenomena, Dynamics of Urban and Coastal Atmosphere, Nantes, France, 23–25 August 2017. [Google Scholar]

- Yi, Q.; König, M.; Janke, D.; Hempel, S.; Zhang, G.; Amon, B.; Amon, T. Wind tunnel investigations of sidewall opening effects on indoor airflows of a cross-ventilated dairy building. Energy Build. 2018, 175, 163–172. [Google Scholar] [CrossRef]

- Yi, Q.; Zhang, G.; König, M.; Janke, D.; Hempel, S.; Amon, T. Investigation of discharge coefficient for wind-driven naturally ventilated dairy barns. Energy Build. 2018, 165, 132–140. [Google Scholar] [CrossRef]

- Yi, Q.; Wang, X.; Zhang, G.; Li, H.; Janke, D.; Amon, T. Assessing effects of wind speed and wind direction on discharge coefficient of sidewall opening in a dairy building model—A numerical study. Comput. Electron. Agric. 2019, 162, 235–245. [Google Scholar] [CrossRef]

- Yi, Q.; Zhang, G.; Li, H.; Wang, X.; Janke, D.; Amon, B.; Hempel, S.; Amon, T. Estimation of opening discharge coefficient of naturally ventilated dairy buildings by response surface methodology. Comput. Electron. Agric. 2020, 169, 105224. [Google Scholar] [CrossRef]

- VDI, Guideline 3783/12. In Physical Modelling of Flow and Dispersion Processes in the Atmospheric Boundary Layer—Application of Wind Tunnels; Beuth Verlag: Berlin, Germany, 2000; Volume 3783/12.

- Uehara, K.; Wakamatsu, S.; Ooka, R. Studies on critical Reynolds number indices for wind-tunnel experiments on flow within urban areas. Bound. -Layer Meteorol. 2003, 107, 353–370. [Google Scholar] [CrossRef]

- Castro, I.P.; Robins, A.R. The flow around a surface-mounted cube in uniform and turbulent streams. J. Fluid Mech. 1977, 79, 307–335. [Google Scholar] [CrossRef]

- Snyder, W.H. Similarity criteria for the application of fluid models to the study of air pollution meteorology. Bound. -Layer Meteorol. 1972, 3, 113–134. [Google Scholar] [CrossRef]

- Shimogata, S.; Sugawara, K.; Yokoyama, O. Wind tunnel experiment of diffusion of exhaust gas emitted from roof ventilator of long factory building. Pollut. Control 1974, 9, 62–70. [Google Scholar]

- Ntinas, G.K.; Zhang, G.; Fragos, V.P.; Bochtis, D.D.; Nikita-Martzopoulou, C. Airflow patterns around obstacles with arched and pitched roofs: Wind tunnel measurements and direct simulation. Eur. J. Mech. B Fluid. 2014, 43, 216–229. [Google Scholar] [CrossRef]

- Tominaga, Y.; Blocken, B. Wind tunnel experiments on cross-ventilation flow of a generic building with contaminant dispersion in unsheltered and sheltered conditions. Build. Environ. 2015, 92, 452–461. [Google Scholar] [CrossRef] [Green Version]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yi, Q.; Janke, D.; Thormann, L.; Zhang, G.; Amon, B.; Hempel, S.; Nosek, Š.; Hartung, E.; Amon, T. Airflow Characteristics Downwind a Naturally Ventilated Pig Building with a Roofed Outdoor Exercise Yard and Implications on Pollutant Distribution. Appl. Sci. 2020, 10, 4931. https://doi.org/10.3390/app10144931

Yi Q, Janke D, Thormann L, Zhang G, Amon B, Hempel S, Nosek Š, Hartung E, Amon T. Airflow Characteristics Downwind a Naturally Ventilated Pig Building with a Roofed Outdoor Exercise Yard and Implications on Pollutant Distribution. Applied Sciences. 2020; 10(14):4931. https://doi.org/10.3390/app10144931

Chicago/Turabian StyleYi, Qianying, David Janke, Lars Thormann, Guoqiang Zhang, Barbara Amon, Sabrina Hempel, Štěpán Nosek, Eberhard Hartung, and Thomas Amon. 2020. "Airflow Characteristics Downwind a Naturally Ventilated Pig Building with a Roofed Outdoor Exercise Yard and Implications on Pollutant Distribution" Applied Sciences 10, no. 14: 4931. https://doi.org/10.3390/app10144931

APA StyleYi, Q., Janke, D., Thormann, L., Zhang, G., Amon, B., Hempel, S., Nosek, Š., Hartung, E., & Amon, T. (2020). Airflow Characteristics Downwind a Naturally Ventilated Pig Building with a Roofed Outdoor Exercise Yard and Implications on Pollutant Distribution. Applied Sciences, 10(14), 4931. https://doi.org/10.3390/app10144931