Abstract

Polycrystalline bulks of Hf-doped Cu0.01Bi2Te2.7Se0.3 are prepared via a conventional melt-solidification process and subsequent spark plasma sintering technology, and their thermoelectric performances are evaluated. To elucidate the effect of Hf-doping on the thermoelectric properties of n-type Cu0.01Bi2Te2.7Se0.3, electronic and thermal transport parameters are estimated from the measured data. An enlarged density-of-states effective mass (from ~0.92 m0 to ~1.24 m0) is obtained due to the band modification, and the power factor is improved by Hf-doping benefitting from the increase in carrier concentration while retaining carrier mobility. Additionally, lattice thermal conductivity is reduced due to the intensified point defect phonon scattering that originated from the mass difference between Bi and Hf. Resultantly, a peak thermoelectric figure of merit zT of 0.83 is obtained at 320 K for Cu0.01Bi1.925Hf0.075Te2.7Se0.3, which is a ~12% enhancement compared to that of the pristine Cu0.01Bi2Te2.7Se0.3.

1. Introduction

Thermoelectric (TE) technology is widely used for cooling and energy harvesting applications, since it can directly convert thermal energy into electricity (and vice versa) by using semiconducting TE materials. Bi2Te3-based alloys (p-type Sb-substituted and n-type Se-substituted Bi2Te3 compounds) with narrow bandgap (~130 meV) semiconductor characteristics [1] are the only commercialized TE materials for solid-state cooling and low-temperature power generation. One of the most critical factors to determine the efficiency of TE systems is the performance of the TE materials, which can be denoted by a dimensionless figure of merit, zT ( = S2σT/κ, where S is the Seebeck coefficient, σ is the electrical conductivity, and κ is the thermal conductivity at a given absolute temperature T). Another issue in Bi2Te3-based TE materials is their low mechanical reliability when fabricated as ingots by using a directional solidification method, such as zone melting; this because the 00l planes held together by weak van der Waals interactions are highly aligned along the growth direction [2]. Thus, many researches have been focusing on the development of polycrystalline materials with enhanced zT due to their intrinsically high mechanical strength compared to that of ingots.

Recently, significantly enhanced zTs have been obtained via nanostructuring approaches [3,4,5]; however, a zT enhancement by a facile and straightforward compositional tuning is always favorable. For p-type Sb-substituted Bi2Te3 alloys (Bi–Sb–Te), doping Ag, Cu, or Pb at Bi/Sb-sites has been effective to improve zT, especially at higher temperatures, mainly due to the suppression of bipolar thermal conduction [6,7,8]. Substitutional doping also provides a chance to enhance zT due to the enlarged density-of-states (DOS) by band engineering (e.g., band flattening, band convergence, and resonant state formation) [9,10,11,12] and/or intensified phonon scattering by the formation of point defects [13]. A higher maximum zT (zTmax), over 1.2 times that of commercial ingot (zTmax ~1.0), has been observed in p-type Bi-Sb-Te by compositional tuning. However, the zTmax of n-type Se-substituted Bi2Te3 compounds (Bi–Te–Se) remained about 1.0 [14].

In the present study, Cu-introduced Bi2Te2.7Se0.3 (Cu0.01Bi2Te2.7Se0.3) is selected as a pristine compound due to its highly reproducible TE properties as well as high zT; furthermore, polycrystalline bulks of Hf-doped Cu0.01Bi2Te2.7Se0.3 are prepared by using a conventional melt-solidification process and a subsequent spark plasma sintering (SPS) technique. The electronic and thermal transport parameters are estimated to elucidate the Hf-doping effect (at Bi-sites) on the TE transport properties of n-type Bi–Te–Se alloys. The power factor is improved due to the enlarged DOS effective mass, and lattice thermal conductivity (κlat = κ-κele, where κele is the electronic contribution to the thermal conduction) is reduced simultaneously. Resultantly, an enhanced zT of 0.83 at 320 K is obtained in 3.75 at.% Hf-doped Cu0.01Bi2Te2.7Se0.3.

2. Materials and Methods

Firstly, the ingots of Cu0.01Bi2Te2.7Se0.3 and Hf-doped Cu0.01Bi2Te2.7Se0.3 (Cu0.01Bi2-xHfxTe2.7Se0.3, x = 0.05, 0.075, 0.1, 0.125) were synthesized by using a conventional melt-solidification process. According to the stoichiometric compositions, the starting raw elements (high purity Cu, Bi, Te, Se, and Hf) were weighed and vacuum sealed (~10−3 Pa) in quartz tubes to prevent oxidation during the melting. The mixtures in the sealed quartz tubes were melted in a rocking furnace (rocking angle ~120°) for 5 h at 1453 K and cooled to room temperature. The acquired ingots were pulverized into powders by using a ball mill for 10 min and screened with a 325 mesh (~44 μm) sieve. The powders were compacted by SPS under 30 MPa for 2 min at 753 K in a dynamic vacuum. Dense polycrystalline bulks (11 mm in diameter and 13 mm in thickness) with a relative density ~96% were fabricated.

Phase formation behavior was confirmed by X-ray diffraction (XRD, Smartlab, Rigaku, Japan) with Cu Kα radiation (λ = 1.5418 Å). From the SPSed discs, bar-type samples (2 mm × 2 mm × 8 mm) for measurement of the electronic transport properties and cuboidal samples (10 mm × 10 mm × 1 mm) for measurement of thermal diffusivity (λ) were cut in a plane perpendicular and parallel to the SPS pressing direction, respectively. Thus, all three parameters (σ, S, and λ) were measured along the same direction. Temperature-dependent S and σ were measured from 300–480 K by using a TE property measurement system (ZEM-3, ULVAC-RICO, Japan). The Hall carrier concentration (nH) and Hall mobility (μH) were obtained by Hall effect measurement at room temperature in the van der Pauw configuration (magnetic field of 0.5 T, HMS-S5500, Ecopia, South Korea). The temperature-dependent κ values were estimated from density (ρ), specific heat capacity (Cp), and λ. Between 300–410 K, the Cp was measured by using a physical properties measurement system (PPMS, Quantum Design, San Diego, CA, USA) and the Dulong–Petit fitting was used to estimate the Cp up to 480 K. The temperature-dependent λ values were measured under vacuum by using the laser-flash method (TC-1200RH, ULVAC-RICO, Japan).

3. Results and Discussions

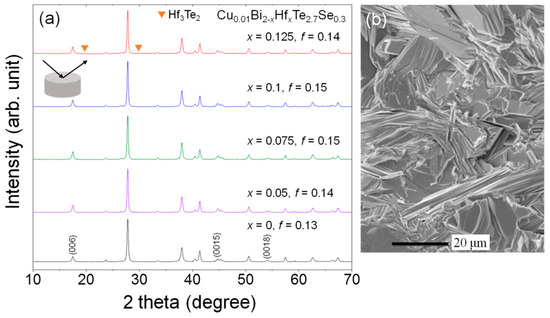

Because of the anisotropic crystal structure of the Bi2Te3-based alloys, their electronic and thermal transport properties are strongly influenced by the measurement directions (00l orientation characteristics). To minimize this effect, we prepared the SPSed bulks with a similar 00l orientation by controlling the SPS conditions. As shown in Figure 1 (XRD patterns for the SPSed bulks of Cu0.01Bi2-xHfxTe2.7Se0.3 (x = 0, 0.05, 0.075, 0.1, 0.125)), the 00l orientation, which can be denoted by a Lotgering factor f (f00l = (p00l–p0)/(1–p0), where p00l = ΣI00l/ΣIhkl and p0 = ΣI000l/ΣI0hkl with Ihkl and I0hkl being the intensities of the (h k l) peaks for the textured and randomly oriented sample), for all samples are almost the same (f = 0.13–0.15). This suggests that the electronic and thermal transport parameters for these samples can provide reliable information to investigate the Hf-doping effect on the TE properties of Cu0.01Bi2Te2.7Se0.3. It is noted that a single-phase without any Hf-related secondary phases is observed up to 5 at.% Hf-doped Cu0.01Bi2Te2.7Se0.3; however, a small amount of Hf3Te2 is observed in 6.25 at.% Hf-doped Cu0.01Bi2Te2.7Se0.3. Peak positions in all samples are nearly constant due to the similar atomic radii of Bi (~230 pm) and Hf (~225 pm). Figure 1b shows the SEM image of the fractured surface of the SPSed Cu0.01Bi1.9Hf0.1Te2.7Se0.3. The average grain size is about 10–20 μm, and no inclusions and secondary phases were observed.

Figure 1.

(a) X-ray diffraction patterns of the spark plasma sintered (SPSed) Cu0.01Bi2-xHfxTe2.7Se0.3 (x = 0, 0.05, 0.075, 0.1, 0.125) bulks in the planes perpendicular to the SPS press direction. (b) SEM image of the fractured surface of the SPSed Cu0.01Bi1.9Hf0.1Te2.7Se0.3.

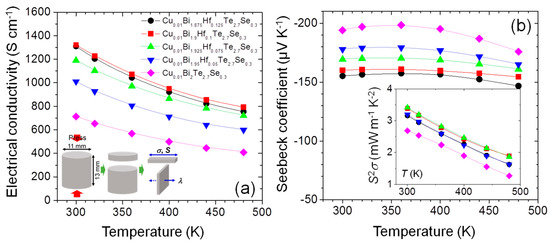

Figure 2a shows the temperature dependence of σ for the SPSed bulks of Cu0.01Bi2-xHfxTe2.7Se0.3. The measurement directions for σ and other parameters (S and λ) are illustrated in the inset of Figure 2a. The σ value of the pristine Cu0.01Bi2Te2.7Se0.3 is ~712 S cm−1 at 300 K, and it gradually increases with an increasing Hf-doping content up to x = 0.1. This suggests that Hf is an effective doping element at the Bi-site to generate electron carriers. The decreased σ observed in Cu0.01Bi1.875Hf0.125Te2.7Se0.3 is considered to be related to the generation of Hf3Te2 owing to the solid solution limit of Hf at the Bi-site.

Figure 2.

Temperature dependences of the (a) electrical conductivity (σ) and (b) Seebeck coefficient (S) for the SPSed Cu0.01Bi2-xHfxTe2.7Se0.3 (x = 0, 0.05, 0.075, 0.1, 0.125) bulks. Insets in (a) and (b) show the thermoelectric measurement orientations and the temperature-dependent power factor (S2σ), respectively.

On the other hand, S shows the trade-off relationship with σ, as shown in Figure 2b. The calculated power factor (S2σ) is shown in the inset of Figure 2b. The maximum power factor of ~3.41 mW m−1 K−2 is obtained at 300 K in Cu0.01Bi1.925Hf0.075Te2.7Se0.3, which is improved by ~27% compared to that of the pristine Cu0.01Bi2Te2.7Se0.3 (~2.68 mW m−1 K−2).

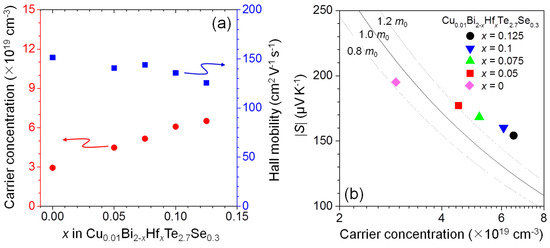

To clarify the electronic transport properties, we estimated the nH and μH at 300 K according to Hf-doping content (Figure 3a). The nH increases systematically with the increasing Hf-doping content up to x = 0.1, which suggests that Hf (Hf4+) is an effective doping element at the Bi (Bi3+)-site to generate electron carriers. Thus, the one of the main reasons for the decrease in S by Hf-doping (Figure 2b) is increased nH. On the other hand, μH is slightly decreased by Hf-doping due to the increase both in electron–electron scattering and carrier scattering by point defects (HfBi). The significant increase in the power factor (inset of Figure 2b) observed in Cu0.01Bi1.95Hf0.05Te2.7Se0.3 suggests that the band structure would be modified by Hf-doping. Because the DOS effective mass (md*) is the critical parameter that determines S, we estimated md* based on the following Equation (1), assuming a single parabolic band model [15], where e, h, and kB are the elementary charge, Plank’s constant, and Boltzmann constant, respectively.

Figure 3.

(a) Hall carrier concentration (nH) and Hall mobility (μH) as a function of Hf-doping content. (b) Pisarenko plot (lSl-nH) for the SPSed Cu0.01Bi2-xHfxTe2.7Se0.3 (x = 0, 0.05, 0.075, 0.1, 0.125) bulks.

Figure 3b shows the Pisarenko plot (lSl-nH) for the SPSed Cu0.01Bi2-xHfxTe2.7Se0.3 bulks. Interestingly, the md* value at 300 K of the pristine Cu0.01Bi2Te2.7Se0.3 (~0.92 m0, where m0 is the free electron mass) is increased to ~1.24 m0 by Hf-doping, indicating that the electronic structure of the conduction band is modified. The possible mechanisms for band modification are band convergence, band flattening, or resonant state formation by Hf-doping [16]. These results observed in the electronic transport parameters suggest that the improved power factor of Cu0.01Bi1.925Hf0.075Te2.7Se0.3 is mainly due to the increase in nH without severe deterioration in μH.

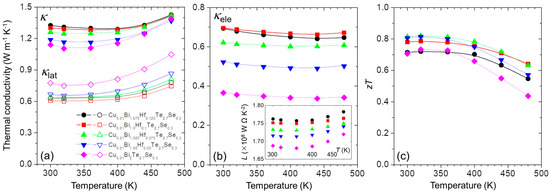

Doping of Hf at the Bi-site generates point defects (HfBi), and it can act as a scattering center, especially for a high-frequency phonon. To confirm the effect of Hf-doping on the thermal transport properties of Cu0.01Bi2Te2.7Se0.3, κlat was calculated by subtracting κele from the measured κ (Figure 4a). Figure 4b shows the temperature dependence of κele, which is estimated based on the Wiedemann–Franz law (κele = LσT). The temperature-dependent Lorenz number (L in W Ω K−2) was calculated by using the following Equation (2) [17] and represented in the inset of Figure 4b.

Figure 4.

Temperature dependences of (a) total thermal conductivity (κ) and lattice thermal conductivity (κlat); (b) electronic thermal conductivity (κele); and (c) a dimensionless figure of merit (zT) for the SPSed Cu0.01Bi2-xHfxTe2.7Se0.3 (x = 0, 0.05, 0.075, 0.1, 0.125) bulks. The inset of (b) shows the temperature-dependent Lorenz number (L).

As shown in Figure 4a, the acquired temperature-dependent behavior is not ruled by a typical T−1 relationship, suggesting that the bipolar thermal conduction (κbp) is included, and its contribution increases with temperature. To clarify the point defect phonon scattering effect, we compared the room temperature κlat values since the κbp can be neglected at low temperatures. The κlat value of the pristine Cu0.01Bi2Te2.7Se0.3 (~0.785 W m−1 K−1) at 300 K is gradually reduced with the Hf-doping content up to x = 0.1, and reaches the minimum value of ~0.612 W m−1 K−1 due to the intensified alloy scattering of the phonons. Phonon scattering by HfBi is determined by (1) the fraction of the point defect (HfBi); (2) the mass difference between the doping element (Hf) and host atom (Bi); and (3) the lattice mismatch between the disordered and pure alloys according to the Callaway model and following the phonon scattering parameter (Γ) in Equation (3), where x is the fraction of the doping element, ΔM/M is the rate of change of the atomic mass, ε is the elastic property, and adisorder and apure are the lattice parameters of the disordered and pure alloys, respectively [18,19].

Thus, the κlat reduction by Hf-doping might be related both with mass fluctuation (by the atomic mass difference between Bi (MBi = 208.98) and Hf (MHf = 178.49)) and strain field fluctuation (by the atomic radius difference between Bi (230 pm) and Hf (225 pm). Despite the small mass and size difference between Bi and Hf, κlat is reduced ~25%, since high-frequency phonons are dominant in Bi–Te-based alloys [6]. A slightly increased κlat value in Cu0.01Bi1.875Hf0.125Te2.7Se0.3 is owing to the formation of the secondary phase (Hf3Te2). Figure 4c shows the temperature dependences of the zT values for the Cu0.01Bi2-xHfxTe2.7Se0.3 bulks. An enhanced zT of 0.83 is obtained at 320 K in Cu0.01Bi1.925Hf0.075Te2.7Se0.3 due to the simultaneous improvement of the electronic and thermal transport properties by Hf-doping.

4. Conclusions

In summary, we demonstrate the important role of Hf-doping at the Bi-site to enhance the thermoelectric performance of n-type Cu0.01Bi2Te2.7Se0.3 based on the theoretical and experimental considerations for the transport parameters. Hf-doping induces the modification of the conduction band, which results in the enlarged density-of-states effective mass. Additionally, lattice thermal conductivity is significantly reduced due to the mass-difference (between Bi and Hf) in phonon scattering, especially in the high-frequency region. A peak zT of 0.83 at 320 K is obtained for Cu0.01Bi1.925Hf0.075Te2.7Se0.3. The acquired zT in the present study is moderate considering the higher zT (~0.95 at 300 K) of a commercial n-type Bi2Te3-based ingot. However, our approach for simultaneous engineering of electronic and thermal transport properties via compositional tuning highlights the possibility of further improvement in thermoelectric performance by the introduction of nanostructuring and/or defect engineering.

Author Contributions

H.-S.K. and K.H.L. conceived and led the research; J.Y.H., S.C., S.-i.K., J.-H.L., S.-M.C. and H.Y. prepared the samples, measured the thermoelectric properties, and the performed analysis; All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Global Frontier Program through the Global Frontier Hybrid Interface Materials (GFHIM) project (Grant 2013M3A6B1078870). This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (NRF-2019R1A6A1A11055660 and NRF-2015R1A6A1A03031833).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Sher, R.; Testardi, L.R. The optical properties of p-type Bi2Te3-Sb2Te3 alloys between 2–15 microns. J. Phys. Chem. Solids 1962, 23, 1219–1224. [Google Scholar] [CrossRef]

- Jiang, J.; Chen, L.; Bai, S.; Yao, Q.; Wang, Q. Thermoelectric properties of textured p-type (Bi,Sb)2Te3 fabricated by spark plasma sintering. Scr. Mater. 2005, 52, 347–351. [Google Scholar] [CrossRef]

- Mamur, H.; Bhuiyan, M.R.A.; Korkmaz, F.; Nil, M. A review on bismuth telluride (Bi2Te3) nanostructure for thermoelectric applications. Renew. Sust. Energy Rev. 2018, 82, 4159–4169. [Google Scholar] [CrossRef]

- Mun, H.; Choi, S.-M.; Lee, K.H.; Kim, S.W. Boundary engineering for the thermoelectric performance of bulk alloys based on bismuth telluride. ChemSusChem 2015, 8, 2312–2326. [Google Scholar] [CrossRef] [PubMed]

- Saleemi, M.; Toprak, M.S.; Li, S.; Johnsson, M.; Muhammed, M. Synthesis, processing, and thermoelectric properties of bulk nanostructured bismuth telluride (Bi2Te3). J. Mater. Chem. 2012, 22, 725–730. [Google Scholar] [CrossRef]

- Kim, K.; Kim, G.; Kim, S.I.; Lee, K.H.; Lee, W. Clarification of electronic and thermal transport properties of Pb-, Ag-, and Cu-doped p-type Bi0.52Sb1.48Te3. J. Alloys Compd. 2019, 772, 593–602. [Google Scholar] [CrossRef]

- Lim, Y.S.; Song, M.; Lee, S.; An, T.H.; Park, C.; Seo, W.S. Enhanced thermoelectric properties and their controllability in p-type (Bi,Sb)2Te3 compounds through simultaneous adjustment of charge and thermal transports by Cu incorporation. J. Alloys Compd. 2016, 687, 320–325. [Google Scholar] [CrossRef]

- Cui, J.L.; Xue, H.F.; Xiu, W.J.; Yang, W.; Xu, X.B. Thermoelectric properties of Cu-doped p-type pseudo-binary CuxBi0.5Sb1.5-xTe3 (x = 0.05–0.4) alloys prepared by spark plasma sintering. Scr. Mater. 2006, 55, 371–374. [Google Scholar] [CrossRef]

- Kim, H.S. Effect of density-of-states effective mass on transport properties of two converging valence bands. J. Korean Ceram. Soc. 2019, 56, 325–330. [Google Scholar] [CrossRef]

- Kim, H.S.; Heinz, N.A.; Gibbs, Z.M.; Tang, Y.; Kang, S.D.; Snyder, G.J. High thermoelectric performance in (Bi0.25Sb0.75)2Te3 due to band convergence and improved by carrier concentration control. Mater. Today 2017, 20, 452–459. [Google Scholar] [CrossRef]

- Jaworski, C.M.; Kulbachinskii, V.; Heremans, J.P. Resonant level formed by tin in Bi2Te3 and the enhancement of room-temperature thermoelectric power. Phys. Rev. B 2009, 80, 233201. [Google Scholar] [CrossRef]

- Pei, Y.; Wang, H.; Snyder, G.J. Band engineering of thermoelectric materials. Adv. Mater. 2012, 24, 6125–6135. [Google Scholar] [CrossRef] [PubMed]

- Goldsmid, H.J. Recent studies of bismuth telluride and its alloys. J. Appl. Phys. 1961, 32, 2198–2202. [Google Scholar] [CrossRef]

- Liu, W.-S.; Zhang, Q.; Lan, Y.; Chen, S.; Yan, X.; Zhang, Q.; Wang, H.; Wang, D.; Chen, G.; Ren, Z. Thermoelectric property studies on Cu-doped n-type CuxBi2Te2.7Se0.3 nanocomposites. Adv. Energy Mater. 2011, 1, 577–587. [Google Scholar] [CrossRef]

- Snyder, G.J.; Toberer, E.S. Complex thermoelectric materials. Nat. Mater. 2008, 7, 105–114. [Google Scholar] [CrossRef] [PubMed]

- Suwardi, A.; Bash, D.; Ng, H.K.; Gomez, J.R.; Repaka, D.V.M.; Kumar, P.; Hippalgaonkar, K. Inertial effective mass as an effective descriptor for thermoelectric via data-driven evaluation. J. Mater. Chem. A 2019, 7, 23762–23769. [Google Scholar] [CrossRef]

- Kim, H.S.; Gibbs, Z.M.; Tang, Y.; Wang, H.; Snyder, G.J. Characterization of Lorenz number with Seebeck coefficient measurement. APL Mater. 2015, 3, 041506. [Google Scholar] [CrossRef]

- Callaway, J.; Baeyer, H.C. Effect of point imperfections on lattice thermal conductivity. Phys. Rev. 1960, 120, 1149. [Google Scholar] [CrossRef]

- Abeles, B. Lattice thermal conductivity of disordered semiconductor alloys at high temperatures. Phys. Rev. 1963, 131, 1906. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).