Removable Weighing Lysimeter for Use in Horticultural Crops

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Design Process of the Weighing Lysimeter

2.1.1. Crop Type Selection

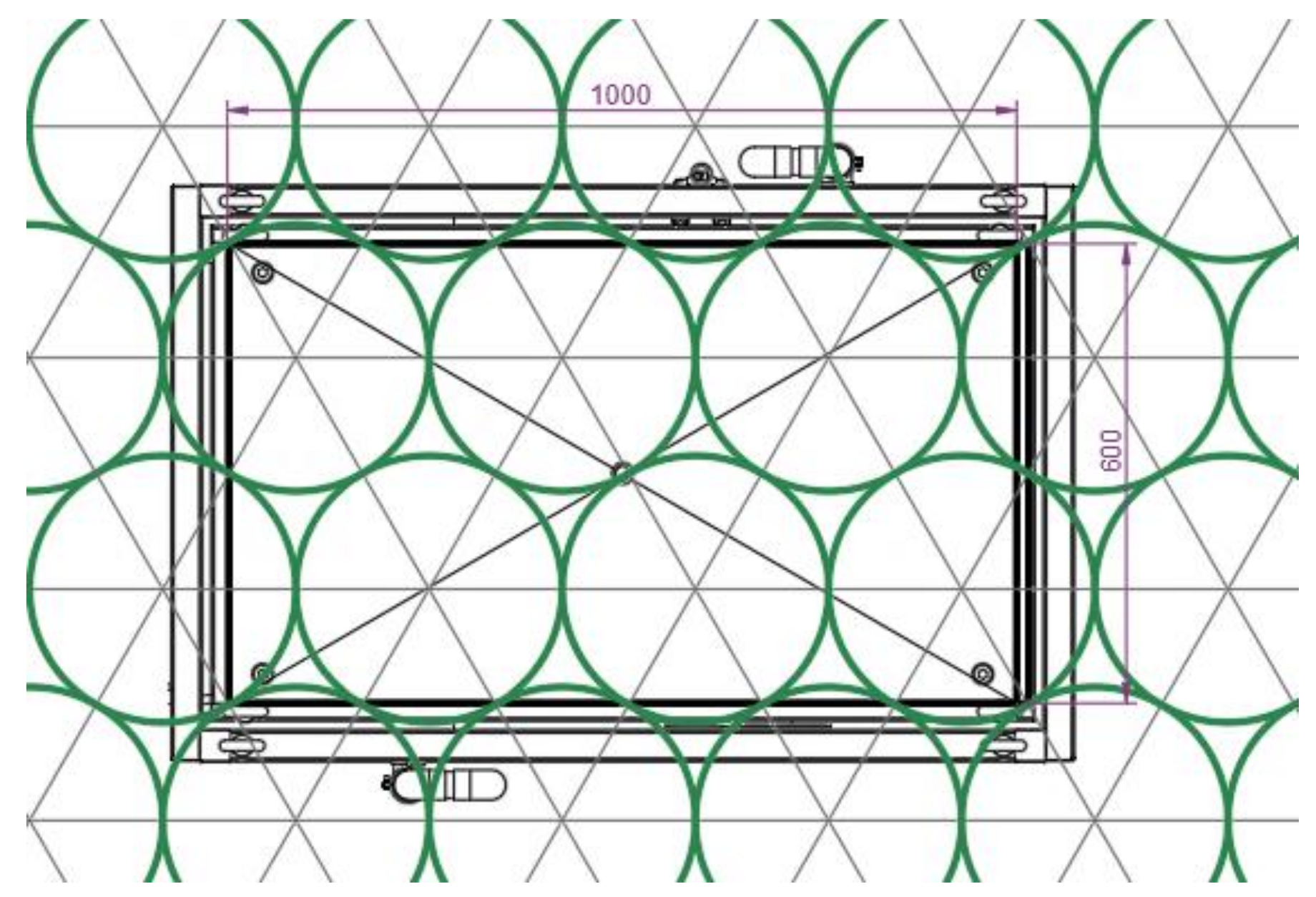

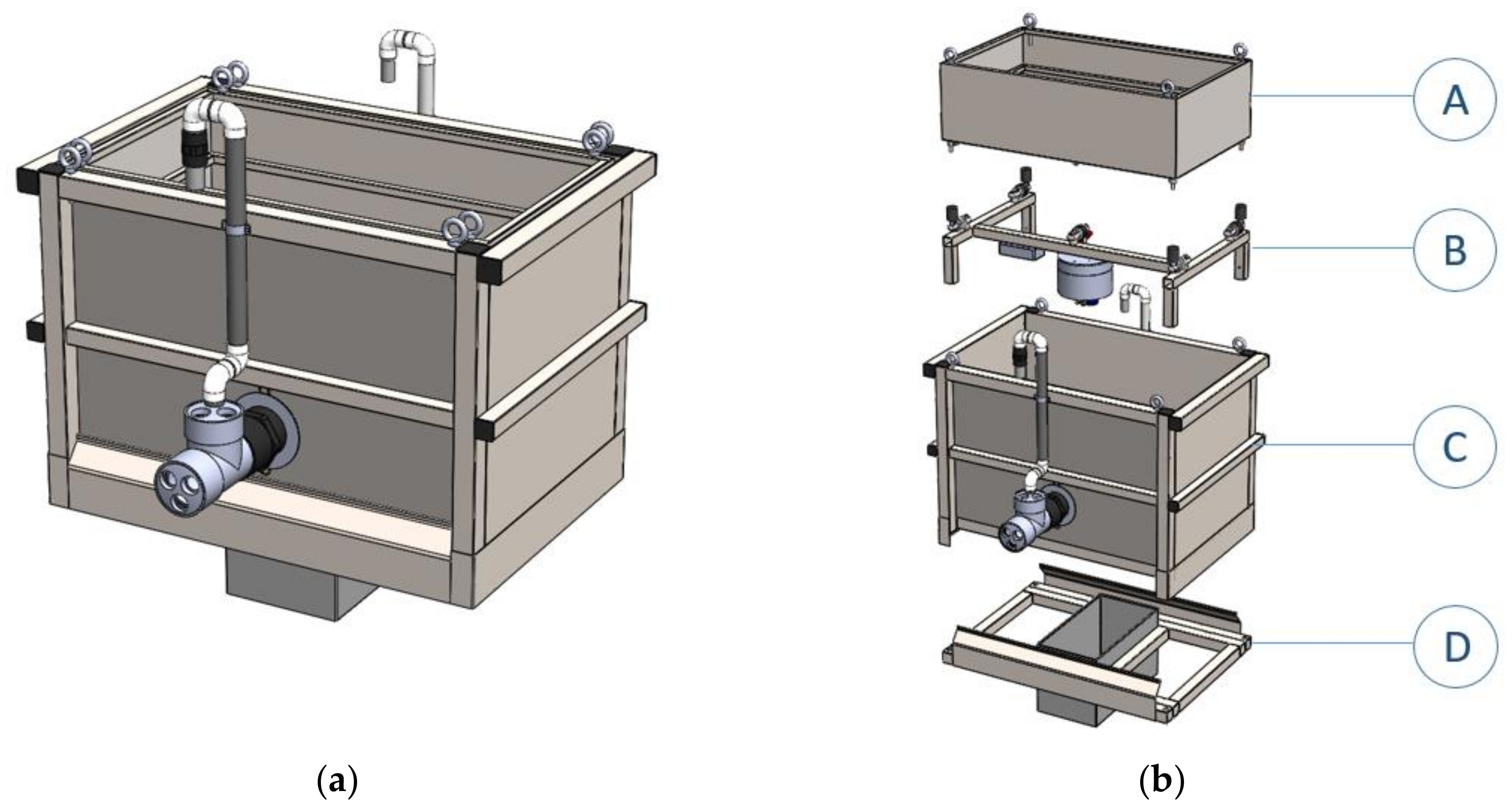

2.1.2. Weighing Lysimeter Design

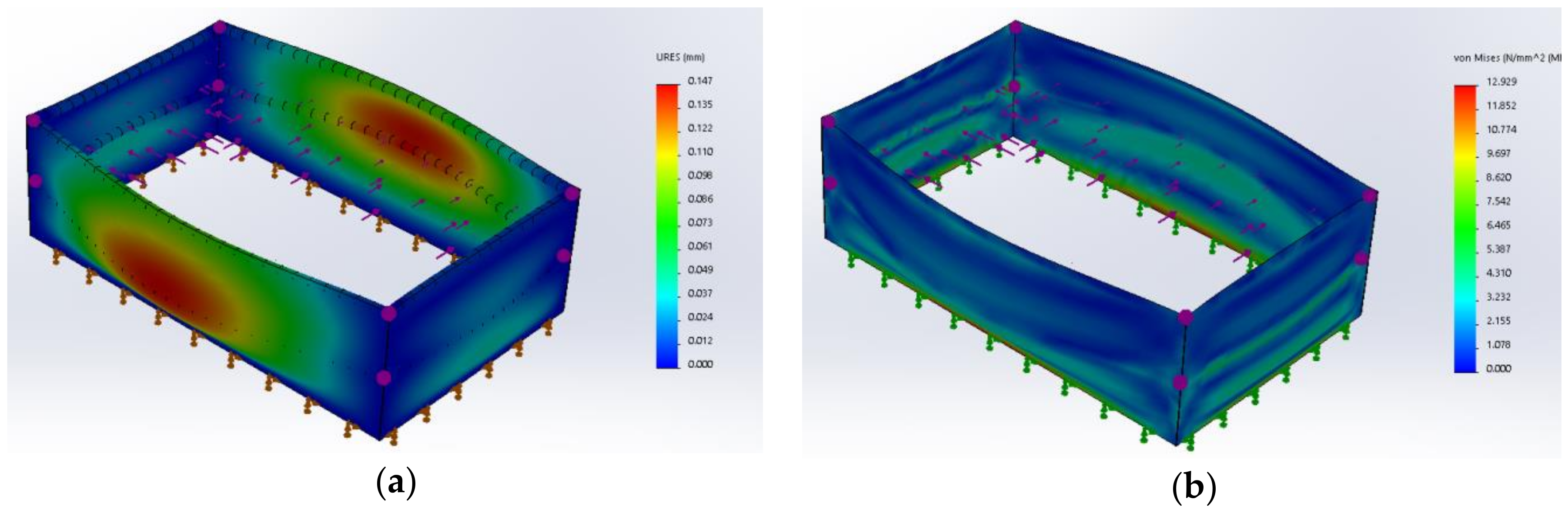

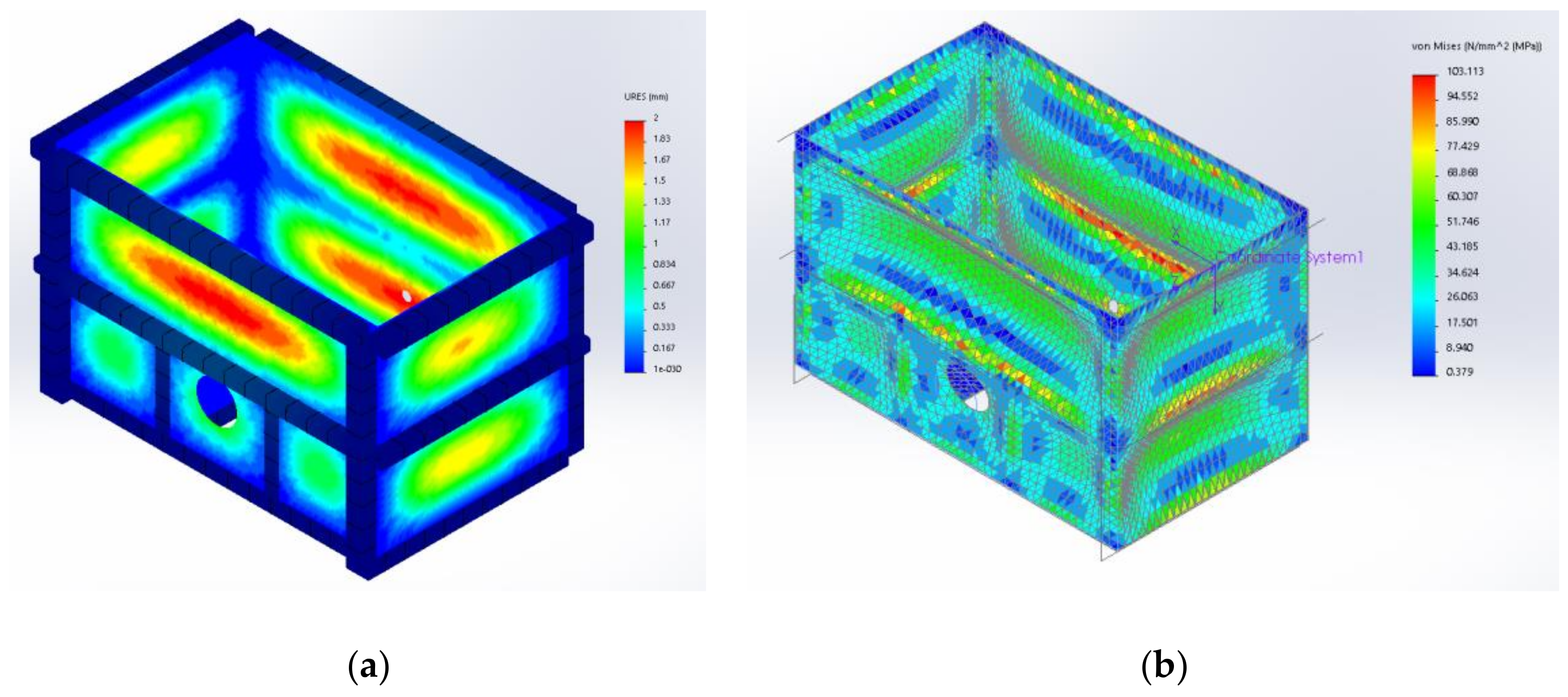

2.2. Structural Analysis

2.3. Acquisition and Control System

2.4. Validation

3. Results

3.1. Structural Analysis

3.2. Construction

3.3. Installation

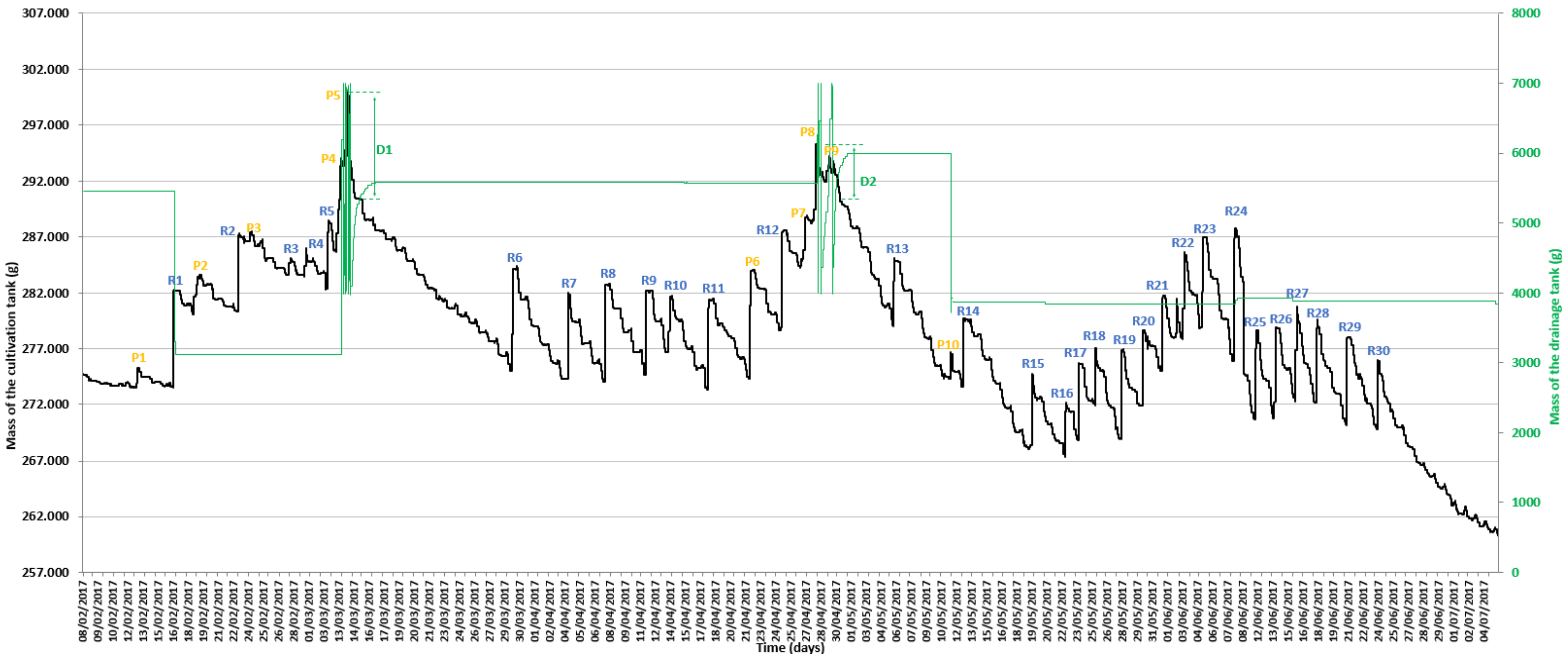

3.4. Operation Results

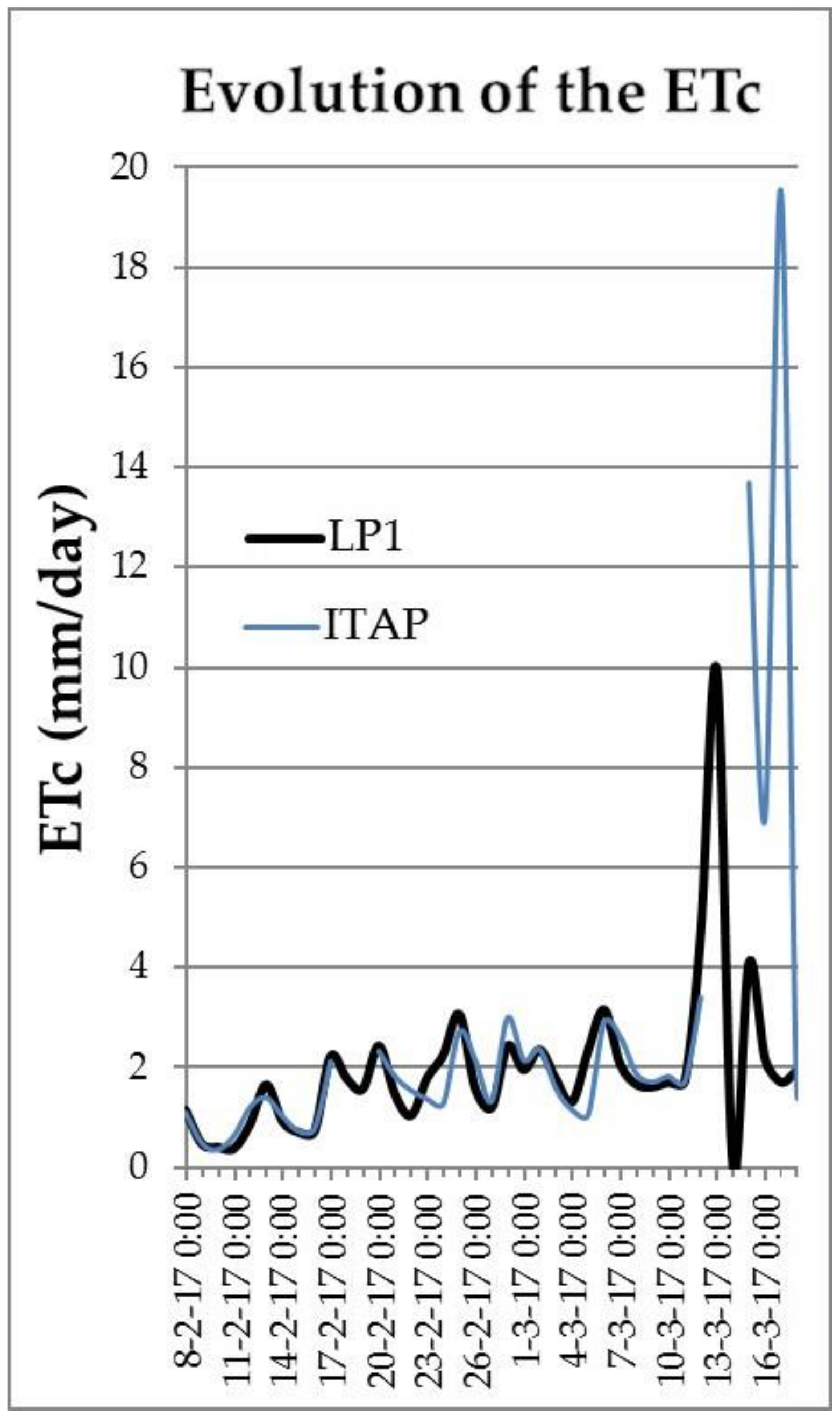

3.5. Validation of the Obtained Data

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- González-Esquiva, J.; García-Mateos, G.; Escarabajal-Henarejos, D.; Hernández-Hernández, J.; Ruiz-Canales, A.; Molina-Martínez, J. A new model for water balance estimation on lettuce crops using effective diameter obtained with image analysis. Agric. Water Manag. 2017, 183, 116–122. [Google Scholar] [CrossRef]

- Hernández-Hernández, J.; Ruiz-Hernández, J.; García-Mateos, G.; González-Esquiva, J.; Ruiz-Canales, A.; Molina-Martínez, J. A new portable application for automatic segmentation of plants in agriculture. Agric. Water Manag. 2017, 183, 146–157. [Google Scholar] [CrossRef]

- Nie, Y.; Avraamidou, S.; Xiao, X.; Pistikopoulos, E.N.; Li, J.; Zeng, Y.; Song, F.; Yu, J.; Zhu, M. A food-energy-water nexus approach for land use optimization. Sci. Total Environ. 2019, 659, 7–19. [Google Scholar] [CrossRef] [PubMed]

- Jiménez-Buendía, M.; Ruiz-Peñalver, L.; Vera-Repullo, J.; Intrigliolo-Molina, D.; Molina-Martínez, J. Development and assessment of a network of water meters and rain gauges for determining the water balance. New scada monitoring software. Agric. Water Manag. 2015, 151, 93–102. [Google Scholar] [CrossRef]

- Liu, J.; Yang, H.; Gosling, S.N.; Kummu, M.; Flörke, M.; Pfister, S.; Hanasaki, N.; Wada, Y.; Zhang, X.; Zheng, C. Water scarcity assessments in the past, present, and future. Earth’s Future 2017, 5, 545–559. [Google Scholar] [CrossRef] [PubMed]

- López-Urrea, R.; de Santa Olalla, F.M.; Fabeiro, C.; Moratalla, A. Testing evapotranspiration equations using lysimeter observations in a semiarid climate. Agric. Water Manag. 2006, 85, 15–26. [Google Scholar] [CrossRef]

- Uniyal, B.; Dietrich, J.; Vu, N.Q.; Jha, M.K.; Arumí, J.L. Simulation of regional irrigation requirement with swat in different agro-climatic zones driven by observed climate and two reanalysis datasets. Sci. Total Environ. 2019, 649, 846–865. [Google Scholar] [CrossRef]

- Allen, R.G.; Pereira, L.S.; Raes, D.; Smith, M. Crop Evapotranspiration-Guidelines for Computing Crop Water Requirements-FAO Irrigation and Drainage Paper 56; FAO: Rome, Italy, 1998; Volume 300, p. D05109. [Google Scholar]

- Mateo-Aroca, A.; García-Mateos, G.; Ruiz-Canales, A.; Molina-García-Pardo, J.M.; Molina-Martínez, J.M. Remote image capture system to improve aerial supervision for precision irrigation in agriculture. Water 2019, 11, 255. [Google Scholar] [CrossRef]

- Escarabajal-Henarejos, D.; Molina-Martínez, J.; Fernández-Pacheco, D.; Cavas-Martínez, F.; García-Mateos, G. Digital photography applied to irrigation management of little gem lettuce. Agric. Water Manag. 2015, 151, 148–157. [Google Scholar] [CrossRef]

- Aboukhaled, A.; Alfaro, J.; Smith, M. Los Lisímetros. Estudios FAO, Serie Riego y Drenaje; FAO: Roma, Italy, 1986.

- Howell, T.A.; Schneider, A.D.; Jensen, M.E. History of Lysimeter Design and Use for Evapotranspiration Measurements; ASCE: New York, NY, USA, 1991; pp. 1–9. [Google Scholar]

- Kohfahl, C.; Molano-Leno, L.; Martínez, G.; Vanderlinden, K.; Guardiola-Albert, C.; Moreno, L. Determining groundwater recharge and vapor flow in dune sediments using a weighable precision meteo lysimeter. Sci. Total Environ. 2019, 656, 550–557. [Google Scholar] [CrossRef]

- Ruiz-Peñalver, L.; Vera-Repullo, J.; Jiménez-Buendía, M.; Guzmán, I.; Molina-Martínez, J. Development of an innovative low cost weighing lysimeter for potted plants: Application in lysimetric stations. Agric. Water Manag. 2015, 151, 103–113. [Google Scholar] [CrossRef]

- Vera-Repullo, J.; Ruiz-Peñalver, L.; Jiménez-Buendía, M.; Rosillo, J.; Molina-Martínez, J. Software for the automatic control of irrigation using weighing-drainage lysimeters. Agric. Water Manag. 2015, 151, 4–12. [Google Scholar] [CrossRef]

- Raij, I.; Ben-Gal, A.; Lazarovitch, N. Soil and irrigation heterogeneity effects on drainage amount and concentration in lysimeters: A numerical study. Agric. Water Manag. 2018, 195, 1–10. [Google Scholar] [CrossRef]

- Bello, Z.A.; Van Rensburg, L.D. Development, calibration and testing of a low-cost small lysimeter for monitoring evaporation and transpiration. Irrig. Drain. 2017, 66, 263–272. [Google Scholar] [CrossRef]

- Jiménez-Carvajal, C.; Ruiz-Peñalver, L.; Vera-Repullo, J.; Jiménez-Buendía, M.; Antolino-Merino, A.; Molina-Martínez, J. Weighing lysimetric system for the determination of the water balance during irrigation in potted plants. Agric. Water Manag. 2017, 183, 78–85. [Google Scholar] [CrossRef]

- Amaral, A.M.; Cabral Filho, F.R.; Vellame, L.M.; Teixeira, M.B.; Soares, F.A.; dos Santos, L.N. Uncertainty of weight measuring systems applied to weighing lysimeters. Comput. Electron. Agric. 2018, 145, 208–216. [Google Scholar] [CrossRef]

- Chen, Y.; Marek, G.; Marek, T.; Moorhead, J.; Heflin, K.; Brauer, D.; Gowda, P.; Srinivasan, R. Assessment of alternative agricultural land use options for extending the availability of the ogallala aquifer in the northern high plains of Texas. Hydrology 2018, 5, 53. [Google Scholar] [CrossRef]

- Hertel, C.; von Unold, G. Third-generation lysimeters: Scientific engineered monitoring systems. In Novel Measurement and Assessment Tools for Monitoring and Management of Land and Water Resources in Agricultural Landscapes of Central Asia; Springer: Berlin/Heidelberg, Germany, 2014; pp. 175–184. [Google Scholar]

- Meissner, R.; Rupp, H.; Seyfarth, M. Advanced technologies in lysimetry. In Novel Measurement and Assessment Tools for Monitoring and Management of Land and Water Resources in Agricultural Landscapes of Central Asia; Springer: Berlin/Heidelberg, Germany, 2014; pp. 159–173. [Google Scholar]

- Payero, J.O.; Irmak, S. Construction, installation, and performance of two repacked weighing lysimeters. Irrig. Sci. 2008, 26, 191–202. [Google Scholar] [CrossRef]

- Allen, R.G.; Pereira, L.S.; Raes, D.; Smith, M. Evapotranspiración del Cultivo: Guías Para la Determinación de los Requerimientos de Agua de Los Cultivos; FAO: Roma, Italy, 2006; Volume 298. [Google Scholar]

- Andales, A.A.; Straw, D.; Marek, T.H.; Simmons, L.H.; Bartolo, M.E.; Ley, T.W. Design and construction of a precision weighing lysimeter in southeast Colorado. Trans. Asabe 2018, 61, 509–521. [Google Scholar] [CrossRef]

- Anapalli, S.S.; Ahuja, L.R.; Gowda, P.H.; Ma, L.; Marek, G.; Evett, S.R.; Howell, T.A. Simulation of crop evapotranspiration and crop coefficients with data in weighing lysimeters. Agric. Water Manag. 2016, 177, 274–283. [Google Scholar] [CrossRef]

- Benli, B.; Kodal, S.; Ilbeyi, A.; Ustun, H. Determination of evapotranspiration and basal crop coefficient of alfalfa with a weighing lysimeter. Agric. Water Manag. 2006, 81, 358–370. [Google Scholar] [CrossRef]

- Evett, S.R.; Schwartz, R.C.; Howell, T.A.; Baumhardt, R.L.; Copeland, K.S. Can weighing lysimeter et represent surrounding field et well enough to test flux station measurements of daily and sub-daily et? Adv. Water Resour. 2012, 50, 79–90. [Google Scholar] [CrossRef]

- Fisher, D.K. Simple weighing lysimeters for measuring evapotranspiration and developing crop coefficients. Int. J. Agric. Biol. Eng. 2012, 5, 35–43. [Google Scholar] [CrossRef]

- Lorite, I.J.; Santos, C.; Testi, L.; Fereres, E. Design and construction of a large weighing lysimeter in an almond orchard. Span. J. Agric. Res. 2012, 10, 238–250. [Google Scholar] [CrossRef]

- Mariano, D.D.C.; Faria, R.T.D.; Freitas, P.S.L.D.; Lena, B.P.; Johann, A.L. Construction and calibration of a bar weighing lysimeter. Acta Sci. Agron. 2015, 37, 271–278. [Google Scholar] [CrossRef][Green Version]

- Misra, R.; Padhi, J.; Payero, J. A calibration procedure for load cells to improve accuracy of mini-lysimeters in monitoring evapotranspiration. J. Hydrol. 2011, 406, 113–118. [Google Scholar] [CrossRef]

- Libardi, L.G.P.; de Faria, R.T.; Dalri, A.B.; de Souza Rolim, G.; Palaretti, L.F.; Coelho, A.P.; Martins, I.P. Evapotranspiration and crop coefficient (kc) of pre-sprouted sugarcane plantlets for greenhouse irrigation management. Agric. Water Manag. 2019, 212, 306–316. [Google Scholar] [CrossRef]

- Doležal, F.; Hernandez-Gomis, R.; Matula, S.; Gulamov, M.; Miháliková, M.; Khodjaev, S. Actual evapotranspiration of unirrigated grass in a smart field lysimeter. Vadose Zone J. 2018, 17, 1–13. [Google Scholar] [CrossRef]

- Rafi, Z.; Merlin, O.; Le Dantec, V.; Khabba, S.; Mordelet, P.; Er-Raki, S.; Amazirh, A.; Olivera-Guerra, L.; Hssaine, B.A.; Simonneaux, V. Partitioning evapotranspiration of a drip-irrigated wheat crop: Inter-comparing eddy covariance-, sap flow-, lysimeter-and fao-based methods. Agric. For. Meteorol. 2019, 265, 310–326. [Google Scholar] [CrossRef]

- Hagenau, J.; Meissner, R.; Borg, H. Effect of exposure on the water balance of two identical lysimeters. J. Hydrol. 2015, 520, 69–74. [Google Scholar] [CrossRef]

- Cásseres, E. Producción de Hortalizas; Instituto Interamericano de Cooperación para la Agricultura (IICA): San José, Costa Rica, 1966. [Google Scholar]

- Ministry of Housing. Technical Building Code (Real Decreto 314/2006, de 17 de Marzo, por el que se Aprueba el Código Técnico de la Edificación); Ministry of Housing: Madrid, Spain, 2006.

- Gómez Gonzalez, S. Solidworks Simulation; Alfaomega: Madrid, Spain, 2010. [Google Scholar]

- Ministry of Housing. Technical Building code, db se-c Structural Safety Basic Document—Foundations (Real Decreto 1371/2007, de 19 de Marzo, por el que se Aprueba el Código Técnico de la Edificación); Ministry of Housing: Madrid, Spain, 2007.

- Akin, J.E. Finite Element Analysis Concepts: Via Solidworks; World Scientific: Singapore, 2010. [Google Scholar]

| Load Case | Value of the Load (N/m2) | Load Distribution | |

|---|---|---|---|

| Cultivation tank | 1. Self-weight | - | - |

| 2. Lateral earth pressure | 10,000 | Triangular | |

| Load combination 1 | Load cases 1 y 2 | ||

| Main structure | 1. Self-weight | - | - |

| 2. Lateral earth pressure | 10,000 | Triangular | |

| 3. Live load A | 2640 | Uniform | |

| 4. Live load B | 5280 | Uniform | |

| 5. Live load C | 7920 | Uniform | |

| Load combination 1 | Load cases 1 y 2 | ||

| Load combination 2 | Load cases 1, 2 y 3 | ||

| Load combination 3 | Load cases 1, 2 y 4 | ||

| Load combination 4 | Load cases 1, 2 y 5 | ||

| Base structure | 1. Self-weight | - | |

| 2. Live load A | 300 | ||

| 3. Live load B | 600 | ||

| 4. Live load C | 900 | ||

| Von Mises Equivalent Stress (MPa) | URES: Resulting Displacement (mm) | Security Factor | ||

|---|---|---|---|---|

| Cultivation tank | Load combination 1 | 12.982 | 0.147 | 10.76 |

| Main structure | Load combination 1 | 36.254 | 0.746 | 5.633 |

| Load combination 2 | 59.604 | 1.161 | 3.409 | |

| Load combination 3 | 84.979 | 1.576 | 2.402 | |

| Load combination 4 | 113.850 | 2.000 | 1.795 | |

| Base structure | Load cases 1 and 2 | 10.803 | 0.364 | |

| Load cases 1 and 3 | 21.616 | 0.659 | ||

| Load cases 1 and 4 | 32.429 | 0.955 |

| Water Film (mm) | Mass (g) | Difference In-O (g) | ||

|---|---|---|---|---|

| Inputs (In) | Rainfall (R) | 92.4 | 49,630 | +3.00 |

| Irrigation (I) | 399.1 | 214,333 | ||

| Condensation (C) | 37.8 | 20,284 | ||

| Outputs (O) | ETc | 496.4 | 266,562 | |

| Drainage (D) | 32.9 | 17,682 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nicolás-Cuevas, J.A.; Parras-Burgos, D.; Soler-Méndez, M.; Ruiz-Canales, A.; Molina-Martínez, J.M. Removable Weighing Lysimeter for Use in Horticultural Crops. Appl. Sci. 2020, 10, 4865. https://doi.org/10.3390/app10144865

Nicolás-Cuevas JA, Parras-Burgos D, Soler-Méndez M, Ruiz-Canales A, Molina-Martínez JM. Removable Weighing Lysimeter for Use in Horticultural Crops. Applied Sciences. 2020; 10(14):4865. https://doi.org/10.3390/app10144865

Chicago/Turabian StyleNicolás-Cuevas, Juan Antonio, Dolores Parras-Burgos, Manuel Soler-Méndez, Antonio Ruiz-Canales, and José Miguel Molina-Martínez. 2020. "Removable Weighing Lysimeter for Use in Horticultural Crops" Applied Sciences 10, no. 14: 4865. https://doi.org/10.3390/app10144865

APA StyleNicolás-Cuevas, J. A., Parras-Burgos, D., Soler-Méndez, M., Ruiz-Canales, A., & Molina-Martínez, J. M. (2020). Removable Weighing Lysimeter for Use in Horticultural Crops. Applied Sciences, 10(14), 4865. https://doi.org/10.3390/app10144865