Seismic Behavior of RC Beam Column Joints with 600 MPa High Strength Steel Bars

Abstract

1. Introduction

2. Experimental Investigation

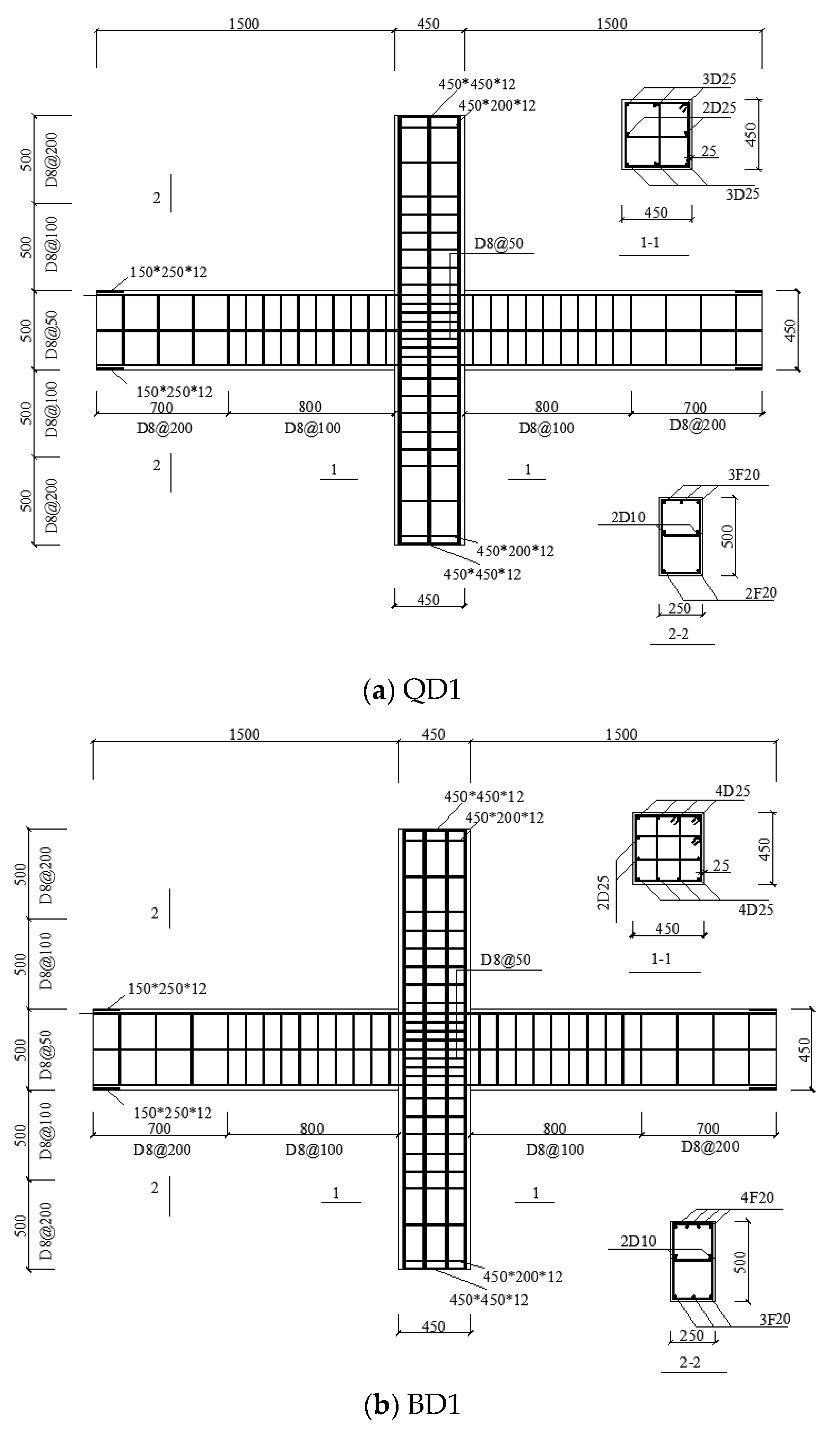

2.1. Description of Specimens

2.2. Material Properties

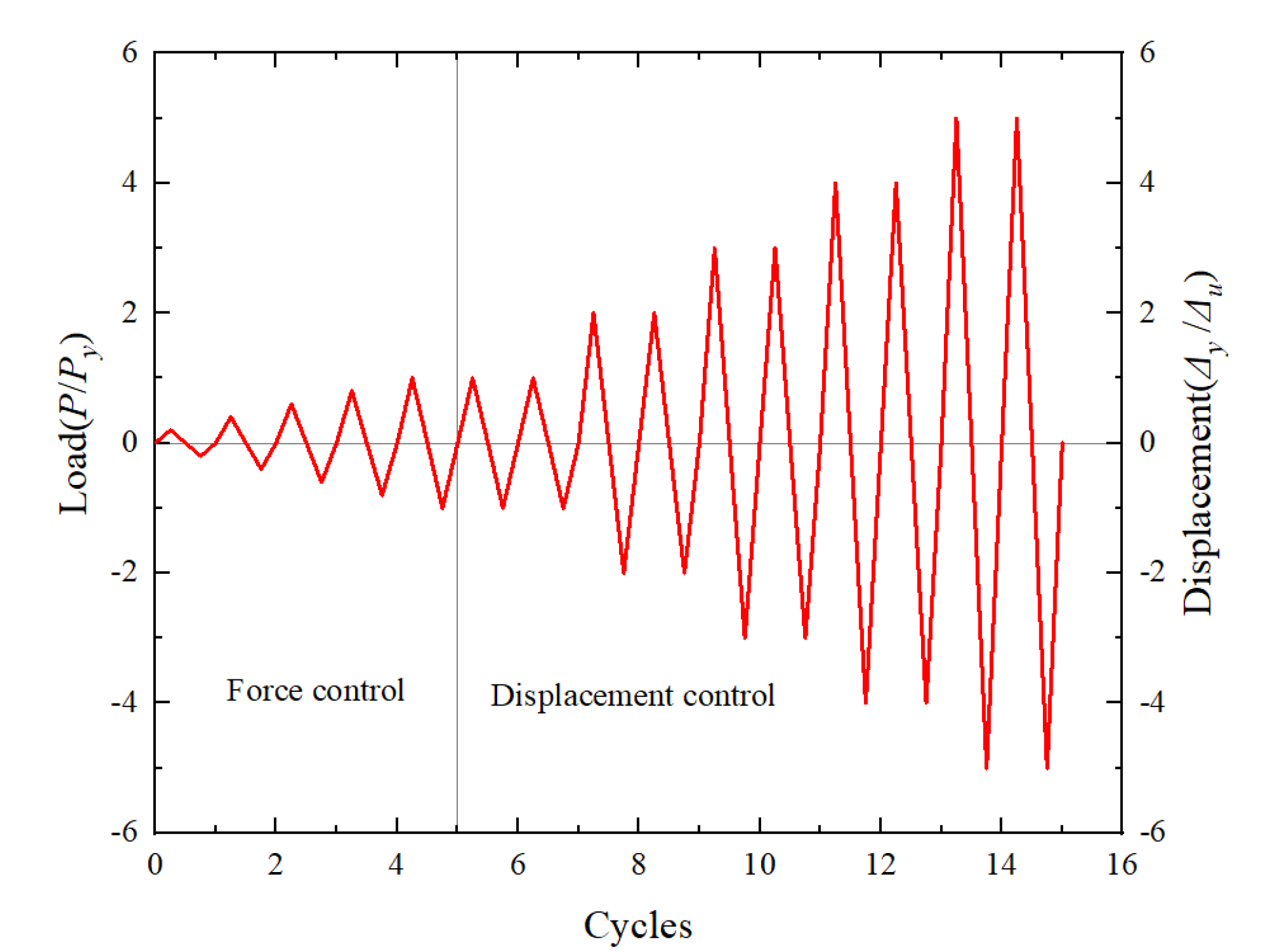

2.3. Test Setup and Loading System

3. Experimental Results and Discussion

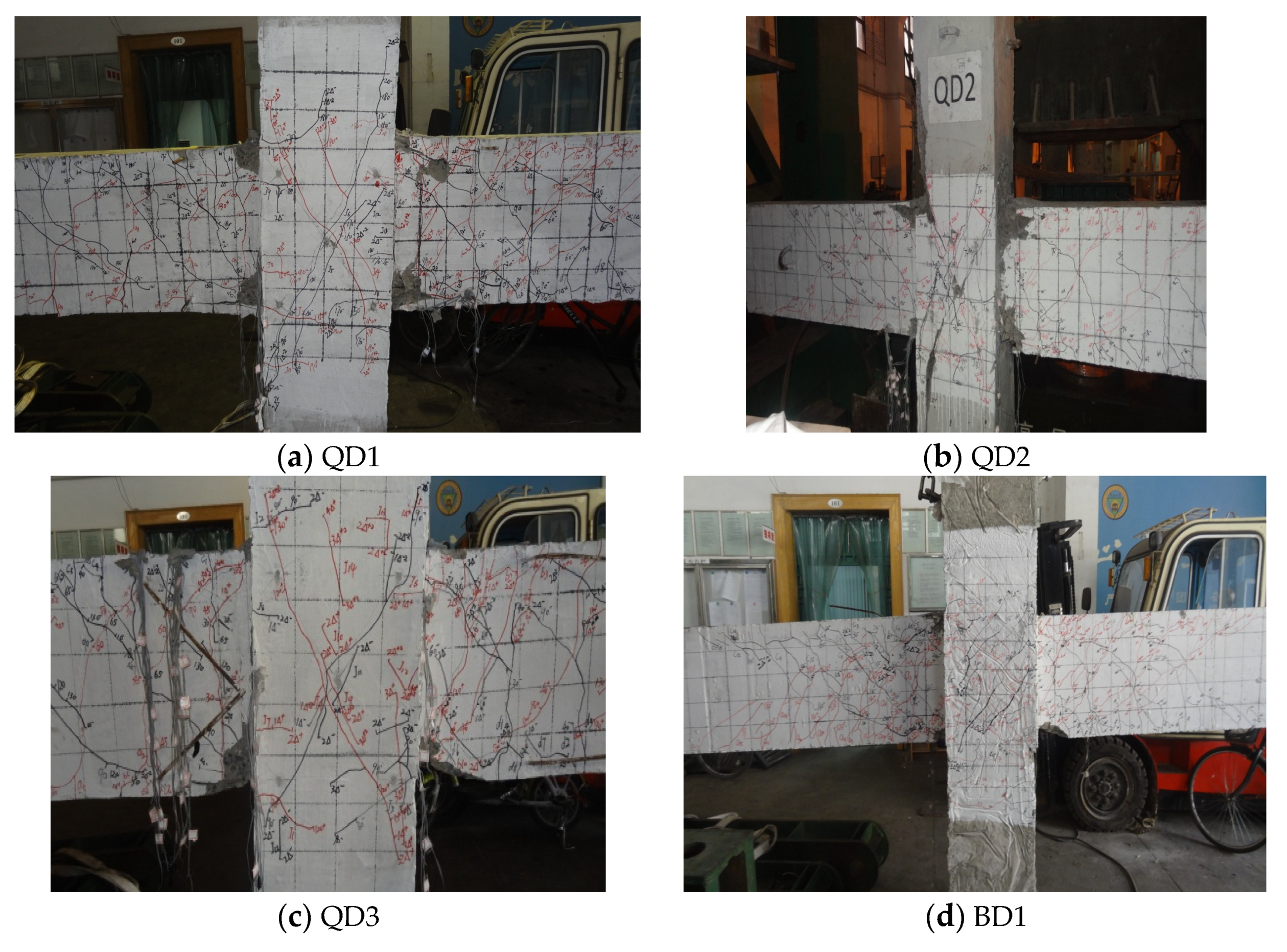

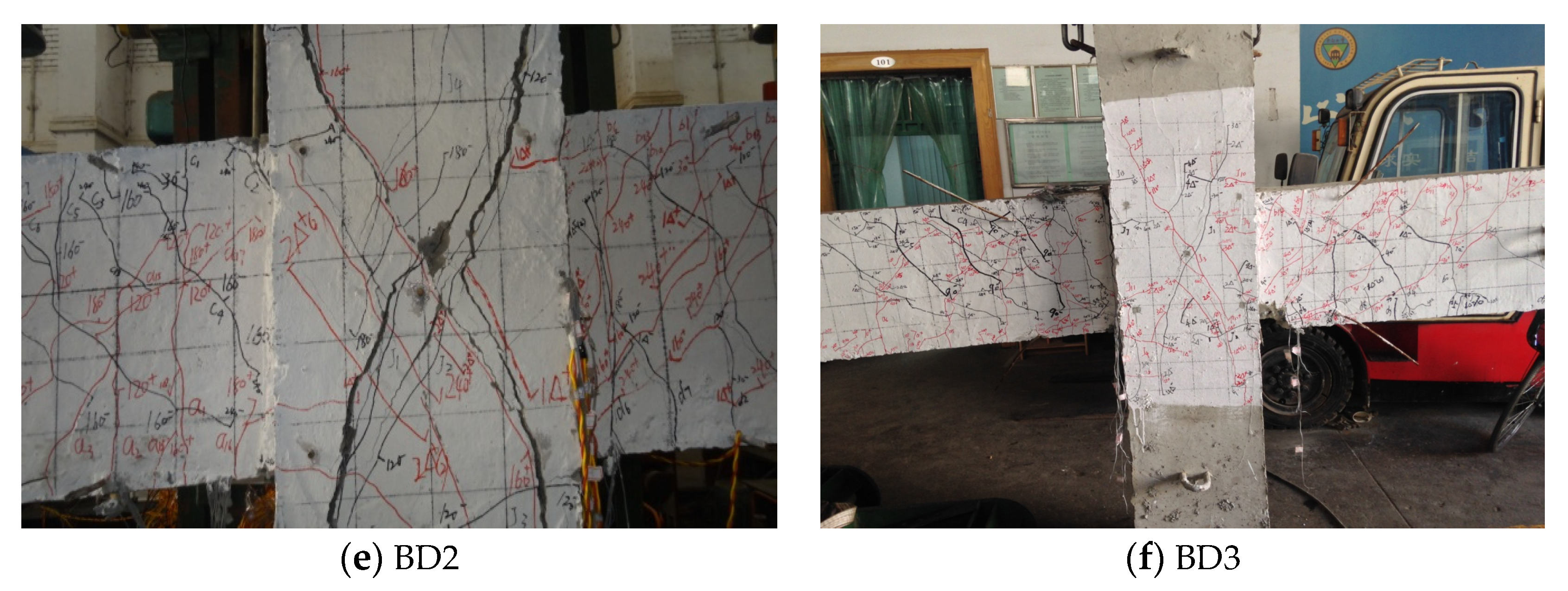

3.1. Failure Mode

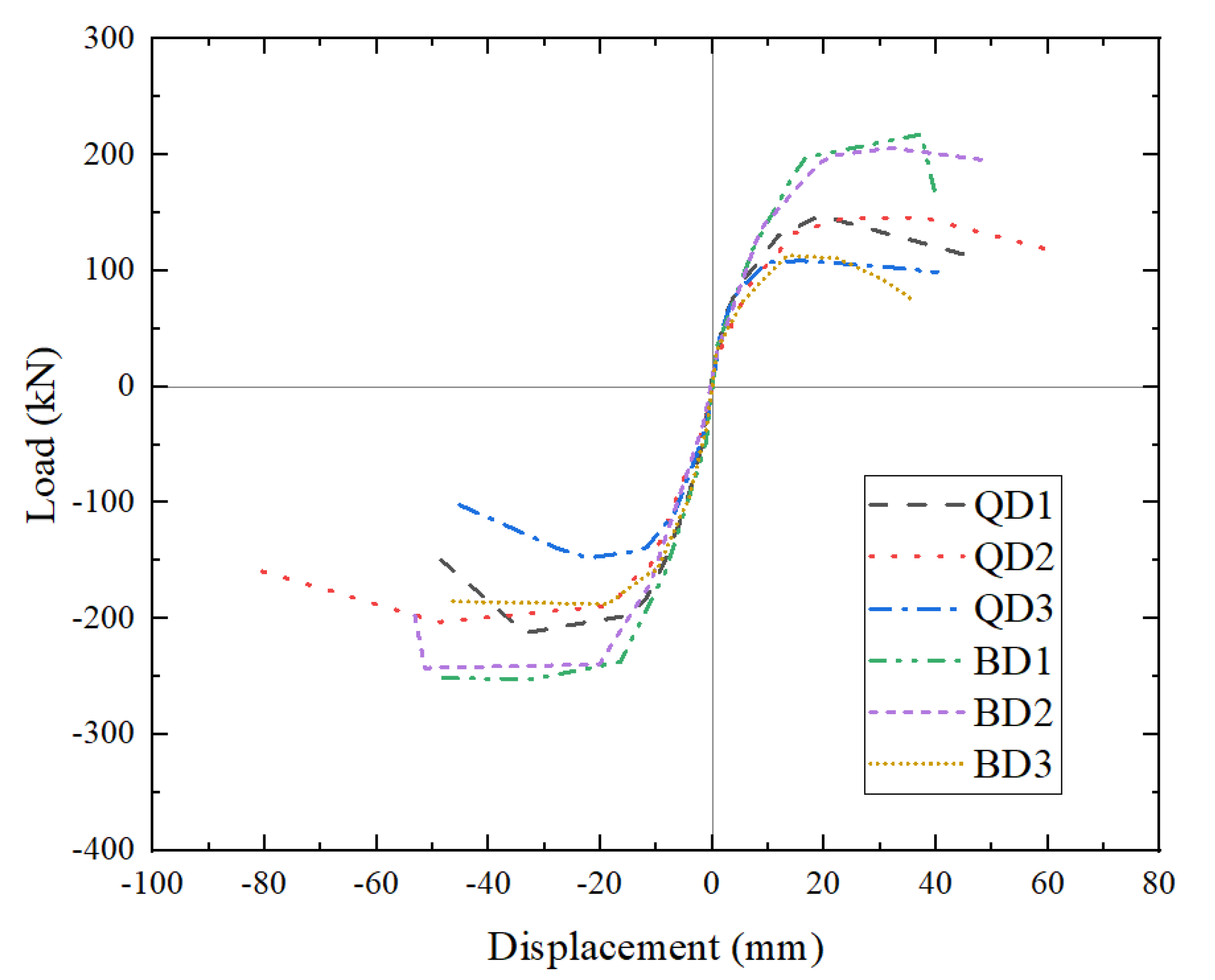

3.2. Hysteretic Curves and Skeleton Curves

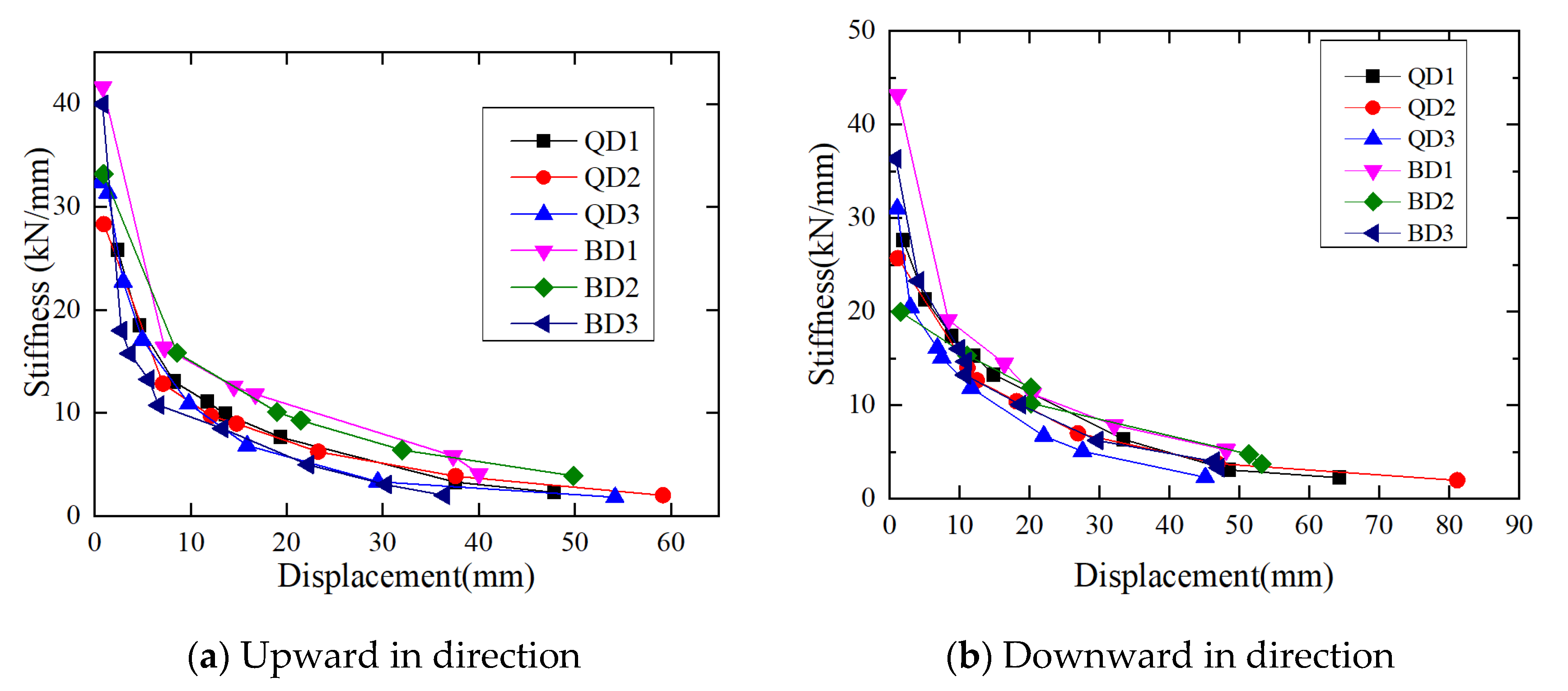

3.3. Stiffness Degradation

3.4. Ductility Comparison

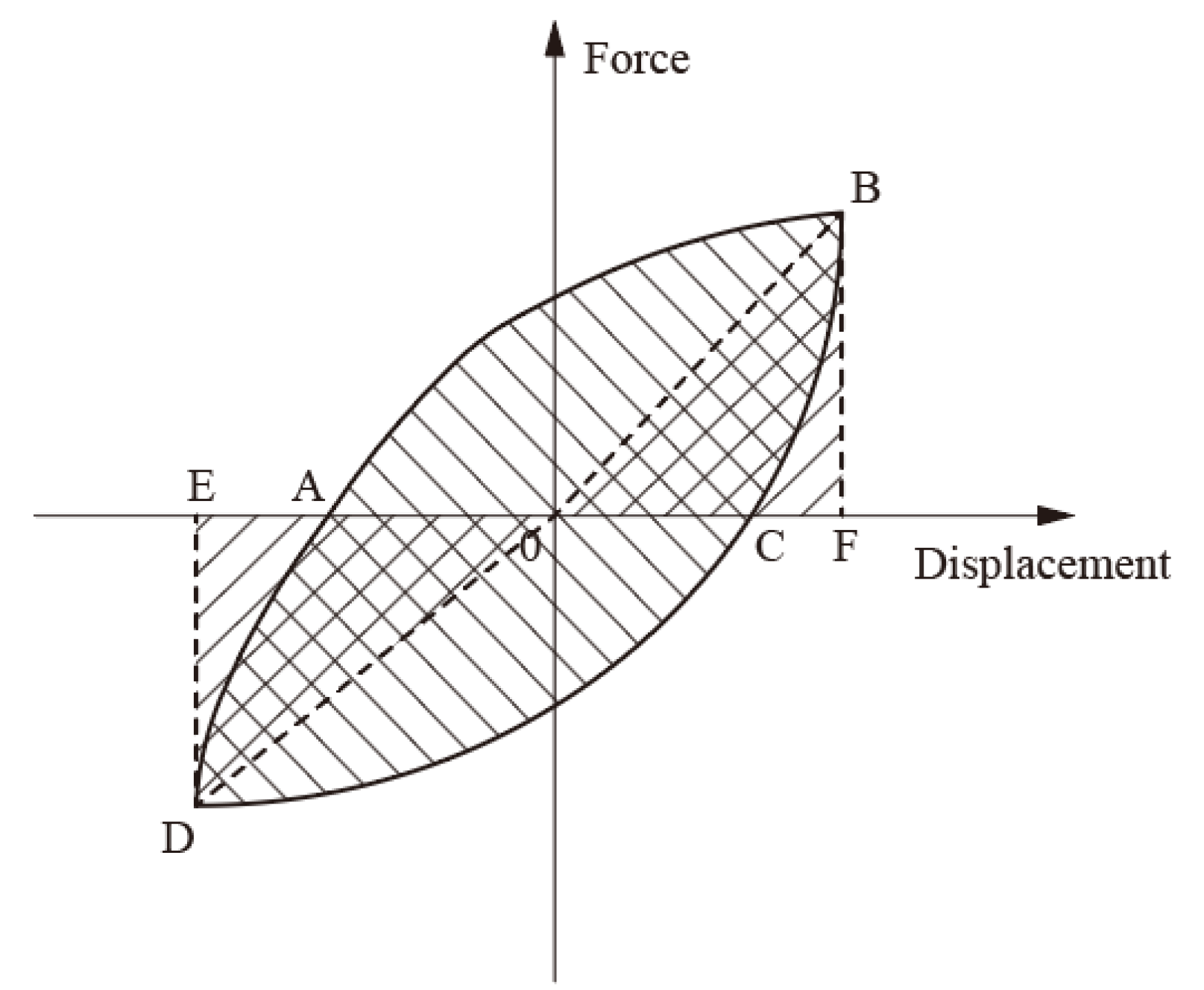

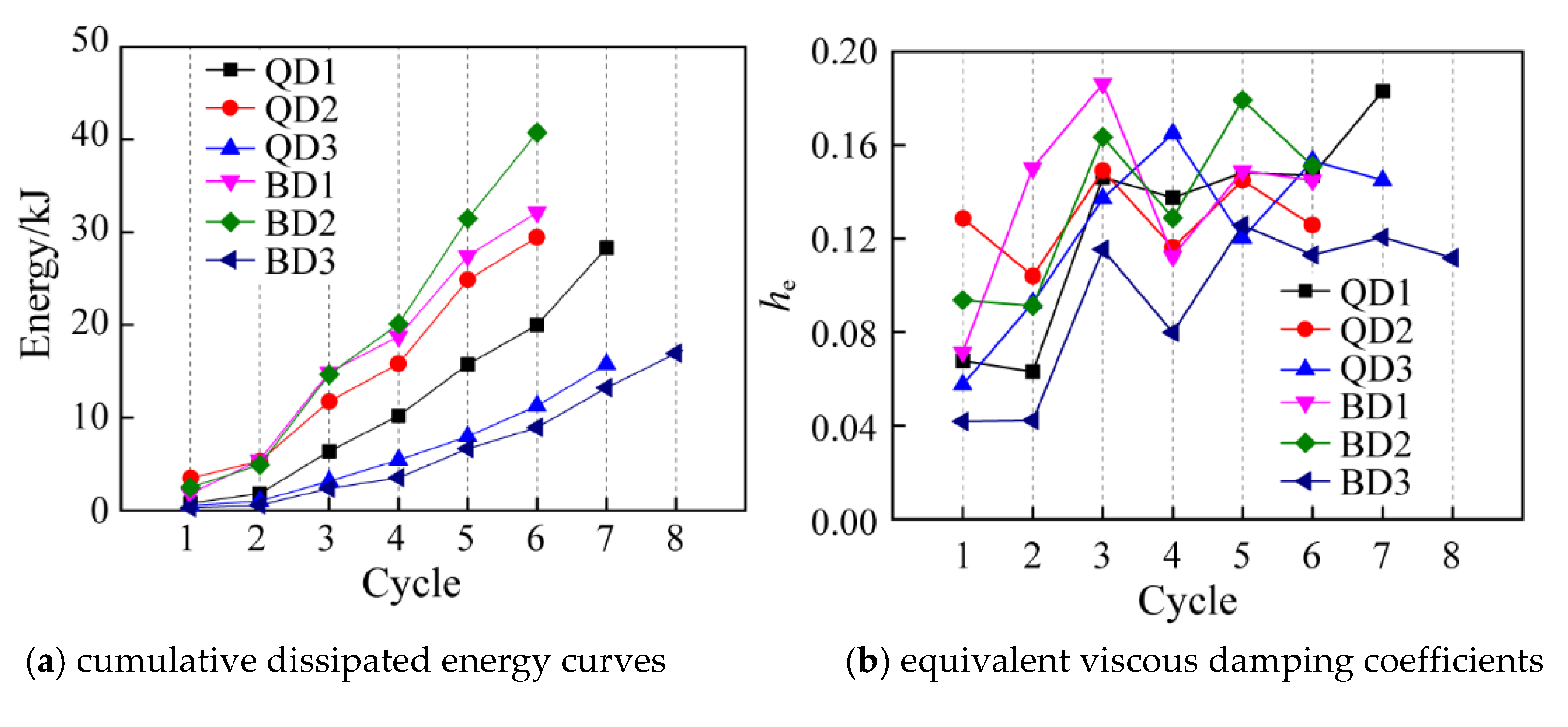

3.5. Energy Dissipation

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kim, J.; LaFave, J.M. Key influence parameters for the joint shear behaviour of reinforced concrete (RC) beam–column connections. Eng. Struct. 2007, 29, 2523–2539. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, B.; Cai, J.; Lee, D.S.-H.; Deng, X.; Feng, J. Experimental study on seismic behavior of precast concrete column with grouted sleeve connections considering ratios of longitudinal reinforcement and stirrups. Bull. Earthq. Eng. 2018, 16, 6077–6104. [Google Scholar] [CrossRef]

- Liu, Y.; Cai, J.; Deng, X.; Cao, Y.; Feng, J. Experimental study on effect of length of service hole on seismic behavior of exterior precast beam-column connections. Struct. Concr. 2018, 20, 85–96. [Google Scholar] [CrossRef]

- Alaee, P.; Li, B. Analytical Investigations of Reinforced Concrete Beam–Column Joints Constructed Using High-Strength Materials. J. Earthq. Eng. 2018, 24, 774–802. [Google Scholar] [CrossRef]

- Behnam, H.; Kuang, J.; Huang, Y. Exterior RC wide beam-column connections: Effect of beam width ratio on seismic behaviour. Eng. Struct. 2017, 147, 27–44. [Google Scholar] [CrossRef]

- Favvata, M.J.; Karayannis, C.G. Influence of pinching effect of exterior joints on the seismic behavior of RC frames. Earthq. Struct. 2014, 6, 89–110. [Google Scholar] [CrossRef]

- Shafaei, J.; Hosseini, A.; Marefat, M.S. Seismic retrofit of external RC beam–column joints by joint enlargement using prestressed steel angles. Eng. Struct. 2014, 81, 265–288. [Google Scholar] [CrossRef]

- Yang, I.-H.; Park, J.; Bui, T.Q.; Kim, K.-C.; Joh, C.; Lee, H. An Experimental Study on the Ductility and Flexural Toughness of Ultrahigh-Performance Concrete Beams Subjected to Bending. Materials 2020, 13, 2225. [Google Scholar] [CrossRef]

- Bywalski, C.; Kaźmierowski, M.; Kamiński, M.; Drzazga, M. Material Analysis of Steel Fibre Reinforced High-Strength Concrete in Terms of Flexural Behaviour. Experimental and Numerical Investigation. Materials 2020, 13, 1631. [Google Scholar] [CrossRef]

- Ahmed, T.W.; Ali, A.A.M.; Zidan, R.S. Properties of high strength polypropylene fiber concrete containing recycled aggregate. Constr. Build. Mater. 2020, 241, 118010. [Google Scholar] [CrossRef]

- Ashtiani, M.S.; Dhakal, R.P.; Scott, A.N. Seismic Performance of High-Strength Self-Compacting Concrete in Reinforced Concrete Beam-Column Joints. J. Struct. Eng. 2014, 140, 04014002. [Google Scholar] [CrossRef]

- Lee, H.-S.; Jang, H.-O.; Cho, K. Evaluation of Bonding Shear Performance of Ultra-High-Performance Concrete with Increase in Delay in Formation of Cold Joints. Materials 2016, 9, 362. [Google Scholar] [CrossRef]

- Restrepo, J.I.; Seible, F.; Stephan, B.; Schoettler, M.J. Seismic Testing of Bridge Columns Incorporating High-Performance Materials. ACI Struct. J. 2006, 103, 496–504. [Google Scholar] [CrossRef]

- Li, B.; Leong, C.L. Experimental and Numerical Investigations of the Seismic Behavior of High-Strength Concrete Beam-Column Joints with Column Axial Load. J. Struct. Eng. 2015, 141, 04014220. [Google Scholar] [CrossRef]

- Alavi-Dehkordi, S.; Mostofinejad, D.; Alaee, P. Effects of high-strength reinforcing bars and concrete on seismic behavior of RC beam-column joints. Eng. Struct. 2019, 183, 702–719. [Google Scholar] [CrossRef]

- Guo, Z.; Ma, Y.; Wang, L.; Zhang, J.; Harik, I.E. Corrosion Fatigue Crack Propagation Mechanism of High-Strength Steel Bar in Various Environments. J. Mater. Civ. Eng. 2020, 32, 04020115. [Google Scholar] [CrossRef]

- Li, L.; Zheng, W.; Wang, Y. Strain Penetration of High-Strength Steel Bars Anchored in Reinforced Concrete Beam-Column Connections. Struct. Eng. Mech. 2019, 72, 367–382. [Google Scholar] [CrossRef]

- Kim, C.; Kim, S.; Kim, K.-H.; Shin, D.; Haroon, M.; Lee, J.-Y. Torsional Behavior of Reinforced Concrete Beams with High-Strength Steel Bars. ACI Struct. J. 2019, 116, 251–263. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Cao, W.; Yu, C. Cyclic behavior of steel tube-reinforced high-strength concrete composite columns with high-strength steel bars. Eng. Struct. 2019, 189, 565–579. [Google Scholar] [CrossRef]

- Lee, H.J.; Chang, C.-J. High-Strength Reinforcement in Exterior Beam-Column Joints under Cyclic Loading. ACI Struct. J. 2017, 114, 1325–1338. [Google Scholar] [CrossRef]

- Tavallali, H.; Lepage, A.; Rautenberg, J.M.; Pujol, S. Concrete Beams Reinforced with High-Strength Steel Subjected to Displacement Reversals. ACI Struct. J. 2014, 111, 1037–1047. [Google Scholar] [CrossRef]

- ACI Committee 318. Building Code Requirements for Structural Concrete (ACI 318-14) and Commentary (318R-14); American Concrete Institute: Farmington Hills, MI, USA, 2014. [Google Scholar]

- MOHURD (Ministry of Housing and Urban-Rural Development of the People’s Republic of China). Code for Design of Concrete Structures (2015 Version), GB 50010-2010; China Architecture & Building Press: Beijing, China, 2015. (In Chinese)

- Hwang, S.-J.; Lee, H.-J.; Liao, T.-F.; Wang, K.-C.; Tsai, H.-H. Role of Hoops on Shear Strength of Reinforced Concrete Beam-Column Joints. ACI Struct. J. 2005, 102, 445–453. [Google Scholar] [CrossRef]

- Hwang, H.-J.; Park, H.-G.; Choi, W.-S.; Chung, L.; Kim, J.-K. Cyclic Loading Test for Beam-Column Connections with 600 MPa (87 ksi) Beam Flexural Reinforcing Bars. ACI Struct. J. 2014, 111, 913–924. [Google Scholar] [CrossRef]

- Wang, D.; Ju, Y.Z.; Zheng, W.Z. Strength of Reactive Powder Concrete Beam-Column Joints Reinforced with High-Strength (HRB600) Bars Under Seismic Loading. Strength Mater. 2017, 33, 139–151. [Google Scholar] [CrossRef]

- Alaee, P.; Li, B. High-strength concrete exterior beam-column joints with high-yield strength steel reinforcements. Eng. Struct. 2017, 145, 305–321. [Google Scholar] [CrossRef]

- Kang, T.H.-K.; Kim, S.; Shin, J.H.; LaFave, J.M. Seismic Behavior of Exterior Beam-Column Connections with High-Strength Materials and Steel Fibers. ACI Struct. J. 2019, 116, 31–43. [Google Scholar] [CrossRef]

- MOHURD (Ministry of Housing and Urban-Rural Development of the People’s Republic of China). Code for Seismic Design of Buildings (2016 Version), GB 50011-2010; China Architecture & Building Press: Beijing, China, 2016. (In Chinese)

- MOHURD (Ministry of Housing and Urban-Rural Development of the People’s Republic of China). Specification of Testing Methods for Earthquake Resistant Building, JGJ/T101-2015; China Architecture & Building Press: Beijing, China, 2015. (In Chinese)

| Series | QD | BD |

|---|---|---|

| Site category | Ⅱ | Ⅱ |

| Seismic fortification intensity | 7 | 8 |

| Ground acceleration value | 0.1 g | 0.2 g |

| Anti-seismic grade | Ⅲ | Ⅱ |

| Specimen | QD1 | QD2 | QD3 | BD1 | BD2 | BD3 | |

|---|---|---|---|---|---|---|---|

| Beam | Top bars (area ratio %) | 3F20 (0.820) | 3F20 (0.820) | 3F16 (0.520) | 4F20 (1.100) | 4F20 (1.100) | 4F16 (0.696) |

| Bottom bars (area ratio %) | 2F20 (0.546) | 2F20 (0.546) | 2F16 (0.346) | 3F20 (0.820) | 3F20 (0.820) | 2F16 (0.348) | |

| Stirrups | D8@100 | D8@100 | D8@100 | D8@100 | D8@100 | D8@100 | |

| Column | Steel Bars (area ratio %) | 8D25 (1.940) | 8D22 (1.500) | 8D20 (1.240) | 12D25 (2.910) | 12D22 (2.250) | 8D20 (1.240) |

| Stirrups | D8@100 | D8@100 | D8@100 | D8@100 | D8@100 | D8@100 | |

| Axial compression ratios | 0.300 | 0.220 | 0.220 | 0.300 | 0.220 | 0.220 | |

| Type of Reinforcement | D8 | D20 | D22 | D25 | F16 | F20 |

|---|---|---|---|---|---|---|

| fy1 (MPa) | 527 | 496 | 481 | 487 | 685 | 633 |

| Es2 (105 MPa) | 2.0 | 1.99 | 1.95 | 1.96 | 1.85 | 1.97 |

| Specimen | Loading Direction | Yield Load fy (kN) | Ultimate Load fu (kN) | Failure Load f l (kN) | fu/fy |

|---|---|---|---|---|---|

| QD1 | up | 129.82 | 147.54 | 123.90 | 1.14 |

| down | 182.73 | 212.28 | 180.00 | 1.16 | |

| QD2 | up | 120.80 | 145.84 | 124.00 | 1.20 |

| down | 182.79 | 202.95 | 171.70 | 1.11 | |

| QD3 | up | 87.00 | 108.60 | 92.30 | 1.25 |

| down | 133.00 | 147.72 | 125.60 | 1.11 | |

| BD1 | up | 182.28 | 217.54 | 184.90 | 1.19 |

| down | 237.37 | 252.28 | 214.40 | 1.06 | |

| BD2 | up | 186.00 | 205.96 | 175.10 | 1.11 |

| down | 229.85 | 242.46 | 206.10 | 1.05 | |

| BD3 | up | 74.00 | 113.20 | 96.20 | 1.53 |

| down | 158.00 | 187.50 | 159.40 | 1.19 |

| Specimen | Loading Direction | Δy (mm) | Δu (mm) | μ |

|---|---|---|---|---|

| QD1 | up | 12 | 37.57 | 3.13 |

| down | 15 | 46.30 | 3.09 | |

| QD2 | up | 13 | 55.36 | 4.26 |

| down | 17 | 71.40 | 4.20 | |

| QD3 | up | 9 | 40.22 | 4.47 |

| down | 11 | 34.12 | 3.10 | |

| BD1 | up | 14 | 40.00 | 2.86 |

| down | 16 | 48.09 | 3.00 | |

| BD2 | up | 16 | 50.99 | 3.19 |

| down | 18 | 53.16 | 2.95 | |

| BD3 | up | 7 | 30.33 | 4.33 |

| down | 10 | 47.05 | 4.70 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, J.; Wang, S.; Meloni, M.; Zhang, Q.; Yang, J.; Cai, J. Seismic Behavior of RC Beam Column Joints with 600 MPa High Strength Steel Bars. Appl. Sci. 2020, 10, 4684. https://doi.org/10.3390/app10134684

Feng J, Wang S, Meloni M, Zhang Q, Yang J, Cai J. Seismic Behavior of RC Beam Column Joints with 600 MPa High Strength Steel Bars. Applied Sciences. 2020; 10(13):4684. https://doi.org/10.3390/app10134684

Chicago/Turabian StyleFeng, Jian, Shuo Wang, Marco Meloni, Qian Zhang, Jingwen Yang, and Jianguo Cai. 2020. "Seismic Behavior of RC Beam Column Joints with 600 MPa High Strength Steel Bars" Applied Sciences 10, no. 13: 4684. https://doi.org/10.3390/app10134684

APA StyleFeng, J., Wang, S., Meloni, M., Zhang, Q., Yang, J., & Cai, J. (2020). Seismic Behavior of RC Beam Column Joints with 600 MPa High Strength Steel Bars. Applied Sciences, 10(13), 4684. https://doi.org/10.3390/app10134684