1. Introduction

Solar irradiation exploitation is an effective weapon in order to face critical issues such as population growth which leads to higher energy consumption [

1], the need for sustainable energy systems [

2] and various environmental problems related to greenhouses emissions [

3]. Concentrating solar power is an efficient way to produce high quantities of useful heating at various temperatures in order to fulfill the energy needs of numerous applications such as space-heating, industrial-heating, air-conditioning, refrigeration, electricity, desalination, industrial heat and methanol-reforming [

4], while a lot of interest exists in hybrid solar concentrating systems [

5]. The cogeneration [

6] and the trigeneration systems [

7] are highly efficient technologies because they produce many useful outputs by utilizing waste heat quantities from one subsystem to another, and so overall there is lower entropy generation. The exploitation of solar energy in order to drive or to assist a trigeneration system seems to be a sustainable choice in order to create efficient systems that are also environmentally friendly [

8].

Solar-driven trigeneration systems are usually applied in the building sector which is responsible for a great part of worldwide energy consumption [

9]. The building sector needs mainly electricity, heating and cooling; three kinds of energy which are usually produced by the trigeneration configurations. Moreover, it must be stated that the trigeneration systems aid the efficient operation of the utilized devices and the exploitation of solar irradiation reduces fossil fuel consumption and grid electricity consumption. Moreover, it is useful to state that there are extra ways of enhancing the energy behavior of the buildings such as sustainable ventilation strategies [

10] and novel architecture techniques [

11].

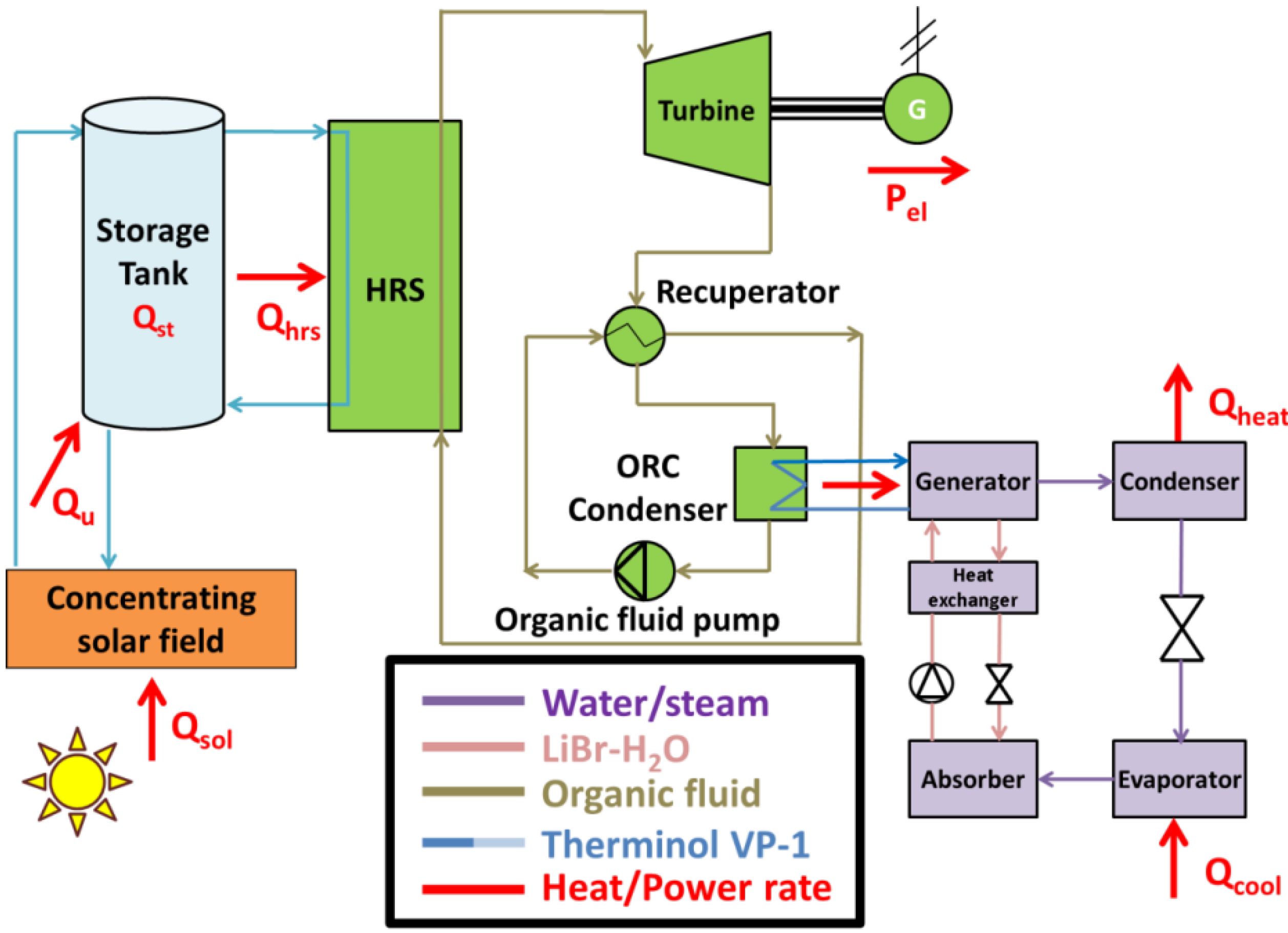

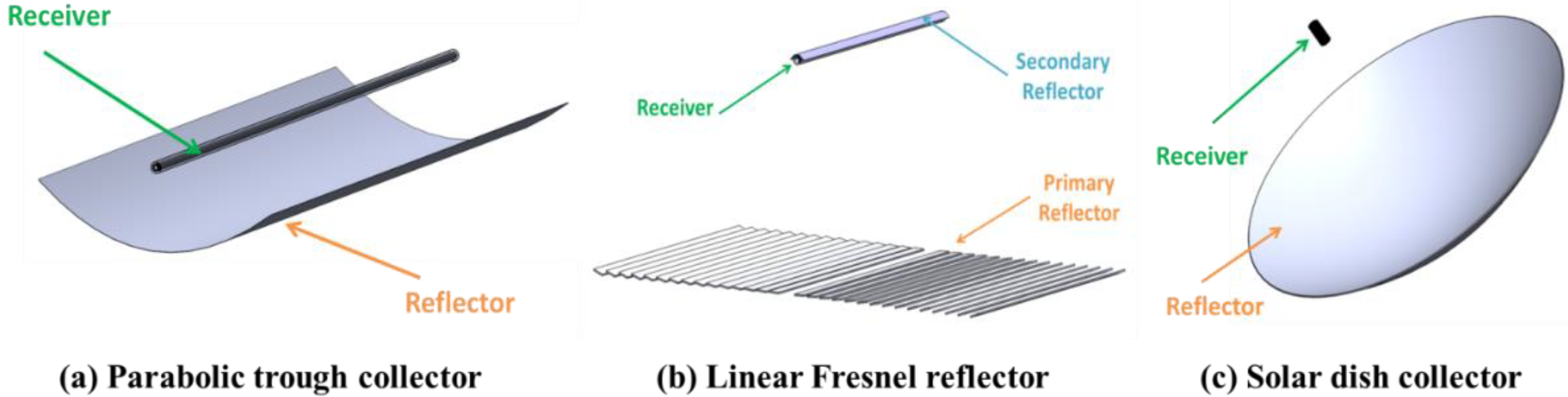

In the literature, the utilization of solar concentrating power for feeding trigeneration systems has been examined by many researchers. Usually, the organic Rankine cycle (ORC) is used as a primary mover, and it is combined with heat pumps which can be vapor-compressors or absorption heat pumps. Al-Sulaiman et al. [

12] carried out thermodynamic studies of a solar-fed trigeneration unit with a parabolic trough collector (PTC), absorption machine and ORC. The solar collectors give useful heat in the ORC, and the ORC condenser transfers heat to the absorption heat pump. According to their findings, the system presents exergy efficiency close to 20%. In addition, Bellos and Tzivanidis [

13] examined a similar system and they calculated that the optimized configurations present 29.4% exergy efficiency and approximately 150% energy efficiency. The high value of the system energy efficiency is explained by the use of the absorption chiller as a heat transformer in order to exploit the cooling production as the energy input and partially to make heating production. Eisavi et al. [

14] carried out a study of a system with an organic Rankine cycle and a double-stage absorption machine, and they found the maximum exergy efficiency to be approximately 13% while the respective energy efficiency is about 95%. Zhao et al. [

15] conducted a comparative work of the optimum way for combining an absorption chiller, ORC and parabolic trough collectors. They found that feeding the absorption chiller by the waste heat of the ORC is the best way to achieve a maximum exergy efficiency of around 41%. Khalid et al. [

16] examined the use of an absorption chiller and an ORC in the solar field loop. Moreover, there is an assisted vapor compression cycle for heating production which is driven by the ORC waste heat, while geothermal and wind energy are included in this work. They found that the exergetic performance of the unit is 7.3% and the energetic 76.1%, while the system net present value is USD 345,000. Bellos et al. [

17] examined a unit with a vapor compression heat pump coupled with an organic Rankine cycle. This system is fed by PTCs and a biomass boiler, while heating is produced in two temperatures (low and medium levels). They calculated the energy and exergy efficiency values at 51.3% and 21.8%, respectively. Moreover, they concluded that the investment is sustainable with a payback period of about 5 years. A comparative study of different configurations of trigeneration systems [

18] coupled with a PTC proved that the connection of an absorption chiller in the ORC condenser is the best technique, and the separate use of the ORC and an absorption chiller is the second, while the connection of a vapor cooling compression cycle to the ORC turbine is the less efficient choice. In another work, Dabwan et al. [

19] tried to use a PTC in a Brayton–Rankine combined cycle in order to reduce fuel consumption. According to their results, it is found that the cost of the produced power can be 22% lower with the exploitation of the solar irradiation.

The utilization of Linear Fresnel reflectors (LFR) has been examined by Moaleman et al. [

20]. More specifically, they examined a system with (LFR) coupled with a thermal photovoltaic absorber for heating and power production. Moreover, this unit included a storage tank, an absorption machine and heat exchanging surfaces. They found that the yearly production of electricity, cooling and heating is 2.29, 3.94 and 6.53 MWh, respectively. Another literature study with an LFR-based trigeneration system has been conducted by Thomas et al. [

21]. They designed a system of 45 kW electricity power which also produces heating and cooling, while its main devices are a Rankine power block, absorption chiller, adsorption chiller and cooling towers. Dawban et al. [

22] found that the integration of LFR in a Brayton–Rankine combined cycle leads to a levelized cost of electricity close to USD 0.06/kWh, an overall plant efficiency at 80%, and the solar share reaches close to 10%.

The use of solar dishes (SD) has been investigated by Hogerwaard et al. [

23] in a unit with a Brayton cycle, an organic Rankine cycle and an absorption machine for desalination, heating and electricity production. They calculated the energy and exergy efficiencies at 28.4% and 27%, respectively, while the daily fresh water production was 1.5 m

3 at 70 °C. They compared their system with a Kalina cycle for electricity production, and they generally found similar efficiencies; the Kalina cycle has lower energy efficiency and higher efficiency. However, they stated that the multigeneration system is more efficient because it can cover more energy needs and not only electricity production.

Moreover, in another literary work, El-Emam and Dincer [

24] studied a unit with solar dishes and a biomass boiler which includes a Brayton cycle, fuel-cell, absorption chiller and gasifier, while the useful products are cooling, electricity and hydrogen. The energetic and exergetic efficiencies were calculated at 40% and 27%, respectively. Ullvius and Rokni [

25] studied a system with solar dishes coupled with the Stirling engine, PTC, solid oxide fuel cell and desalination unit. The useful outputs of this system are hydrogen, fresh water and electricity, while the system energy efficiency is around 19% and the daily water production is 8.5 m

3.

Lastly, there are some studies with solar towers in trigeneration systems. Mohammadi and McGowan [

26] studied a system with a solar tower, Rankine cycle, absorption chiller, distillation unit and back-up boiler which produces fresh water, electricity and cooling power. According to their results, this trigeneration system presents system energy efficiency at 35%. In another work, with a tower in the trigeneration system, Khalid et al. [

27] studied the combination of a Rankine cycle to a Brayton cycle for electricity, heating and cooling production with energy and exergy efficiencies at 67% and 40%, respectively.

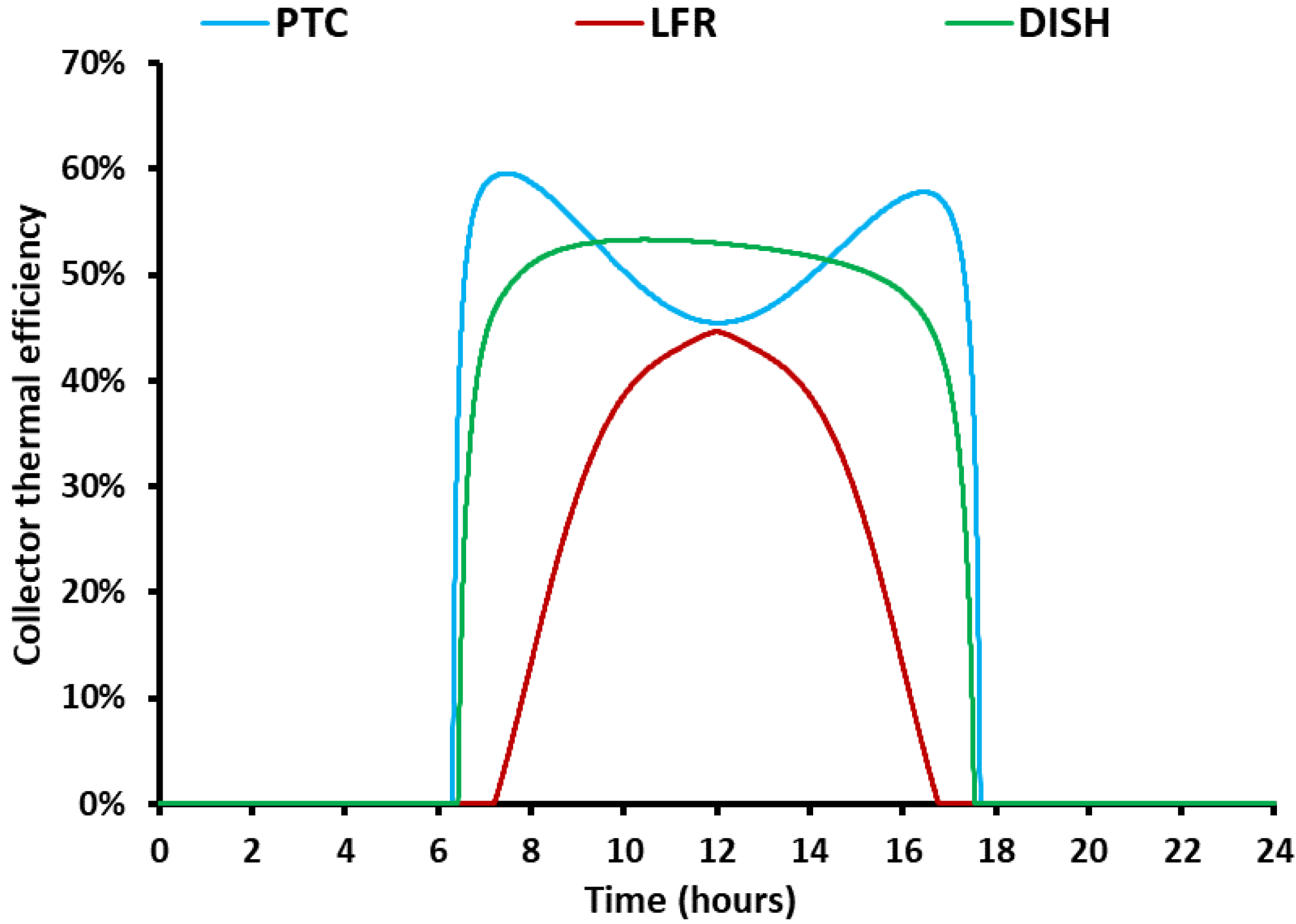

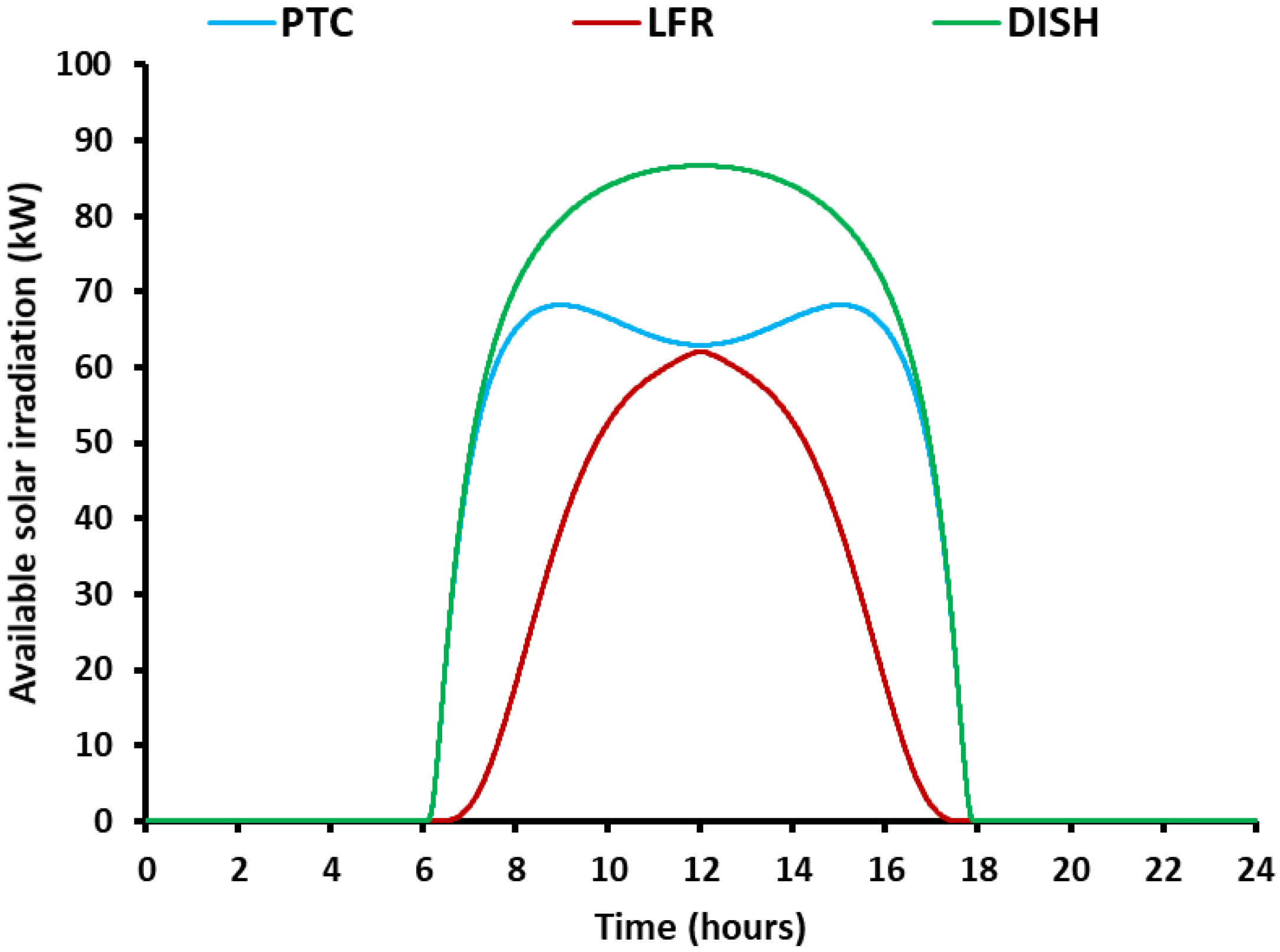

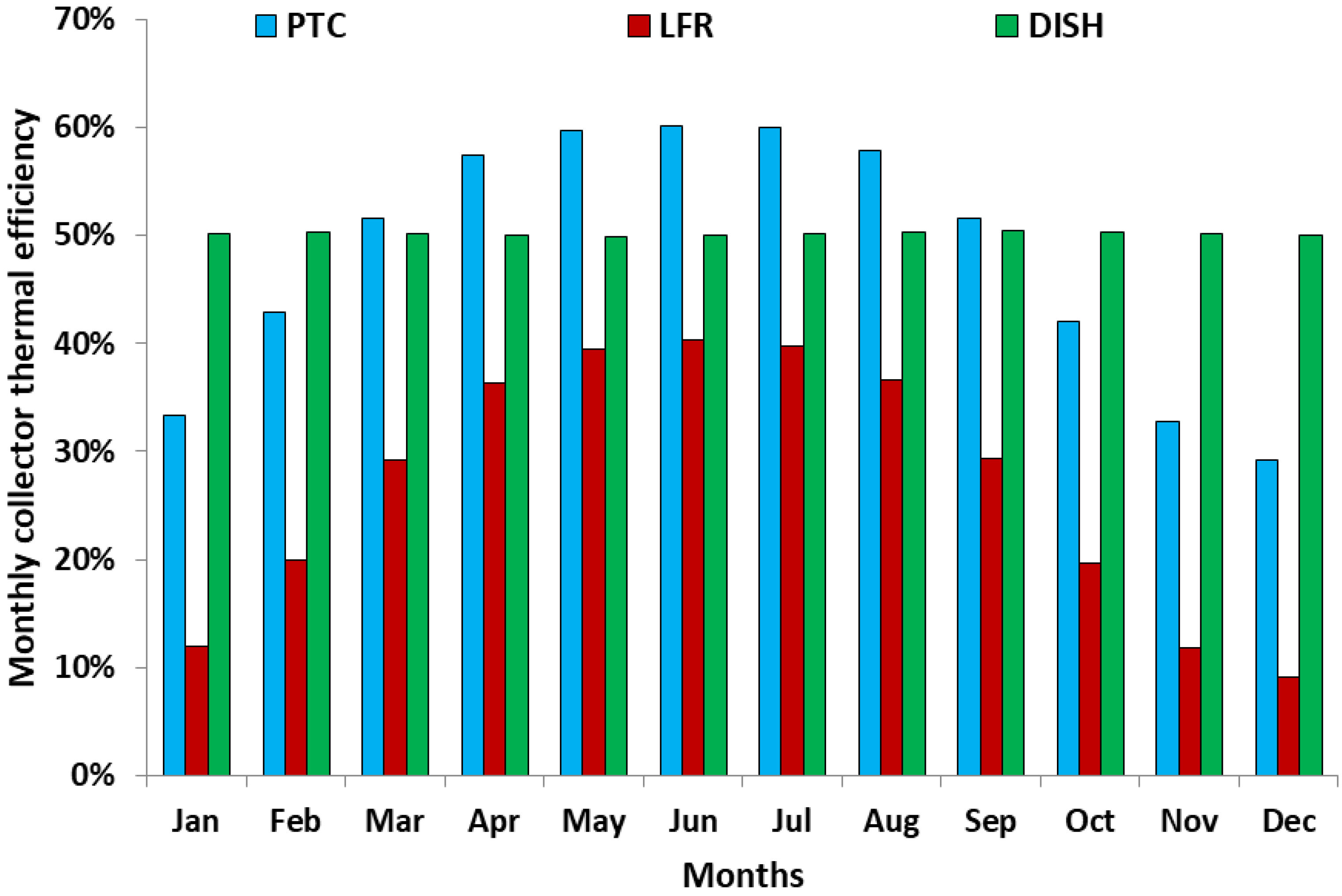

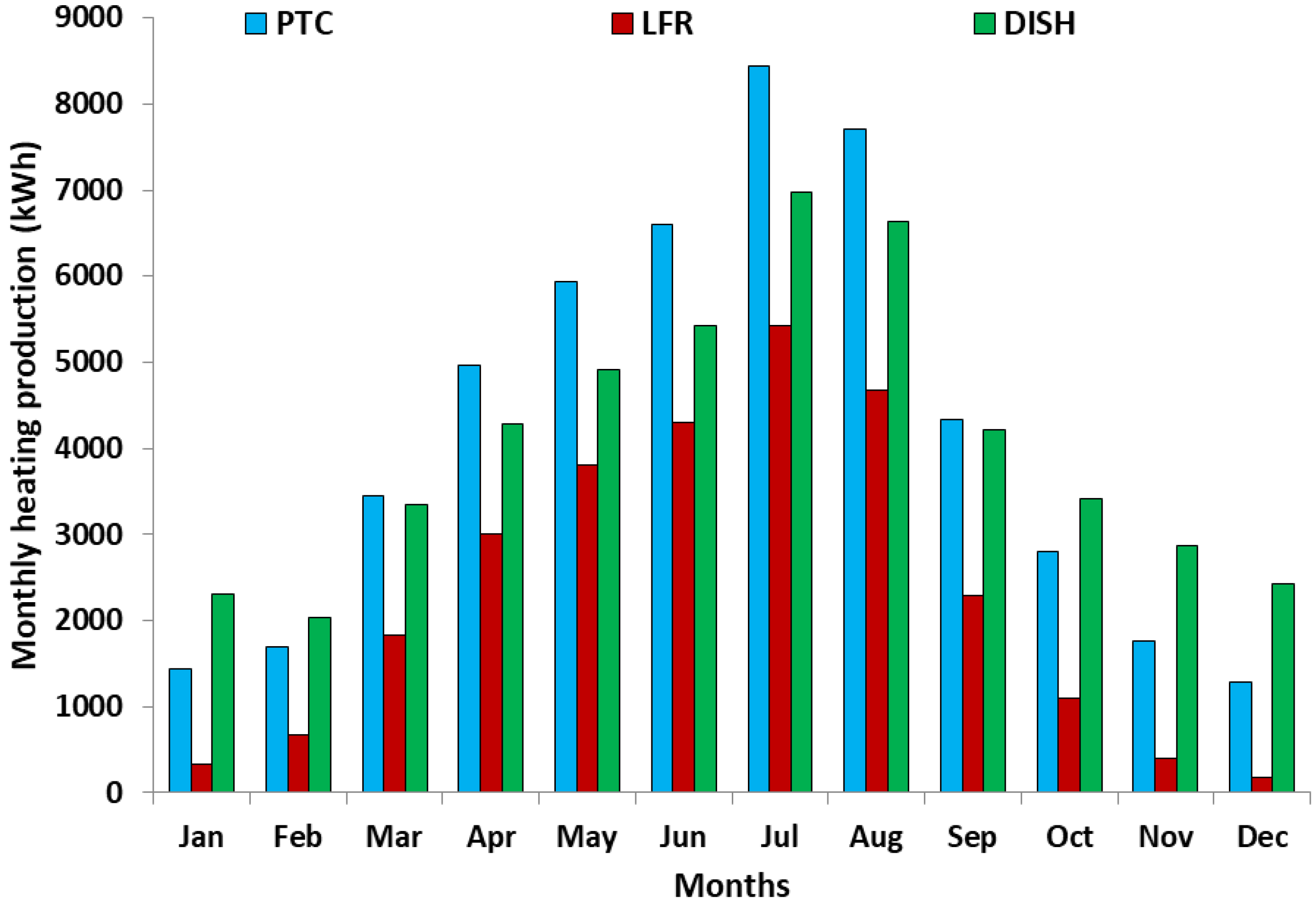

The aforementioned literature review demonstrates the great scientific interest in the investigation of solar-driven trigeneration units. The objective of this investigation is the comparison of different solar concentrating technologies in a promising and highly efficient trigeneration system. Parabolic trough solar collectors (PTC), linear Fresnel solar reflectors (LFR) and solar dish collectors (SD) are the studied solar technologies that are applied for the weather data of Athens in Greece. The results are evaluated in energetic and economic terms. More specifically, this work studies, in dynamic conditions, the three most usual solar concentrating collectors for medium- and high-temperature applications (300–400 °C). The results are evaluated in energy, exergy and financial terms in order to perform a multilateral work. According to the literature review of this work, the studies usually select one kind of solar collector and investigate it. To our knowledge, there are no studies that examine and compare different solar concentrating technologies in trigeneration systems in order to determine the most efficient and viable configurations. So, the present work aims to give an answer to the question about the most efficient and most viable scenario by comparing three solar concentrating systems. The selected trigeneration “block” includes an ORC coupled with an absorption chiller. This design is the most efficient, according to the results of reference [

18]. The thermodynamic analysis of the unit is conducted by a homemade thermodynamic program in Engineering Equation Solver (EES) [

28] and a homemade dynamic code that is developed in the programming language FORTRAN.