The Experimental Study on Mechanical Behavior of Conveyor Belt Rubber Bearings

Abstract

1. Introduction

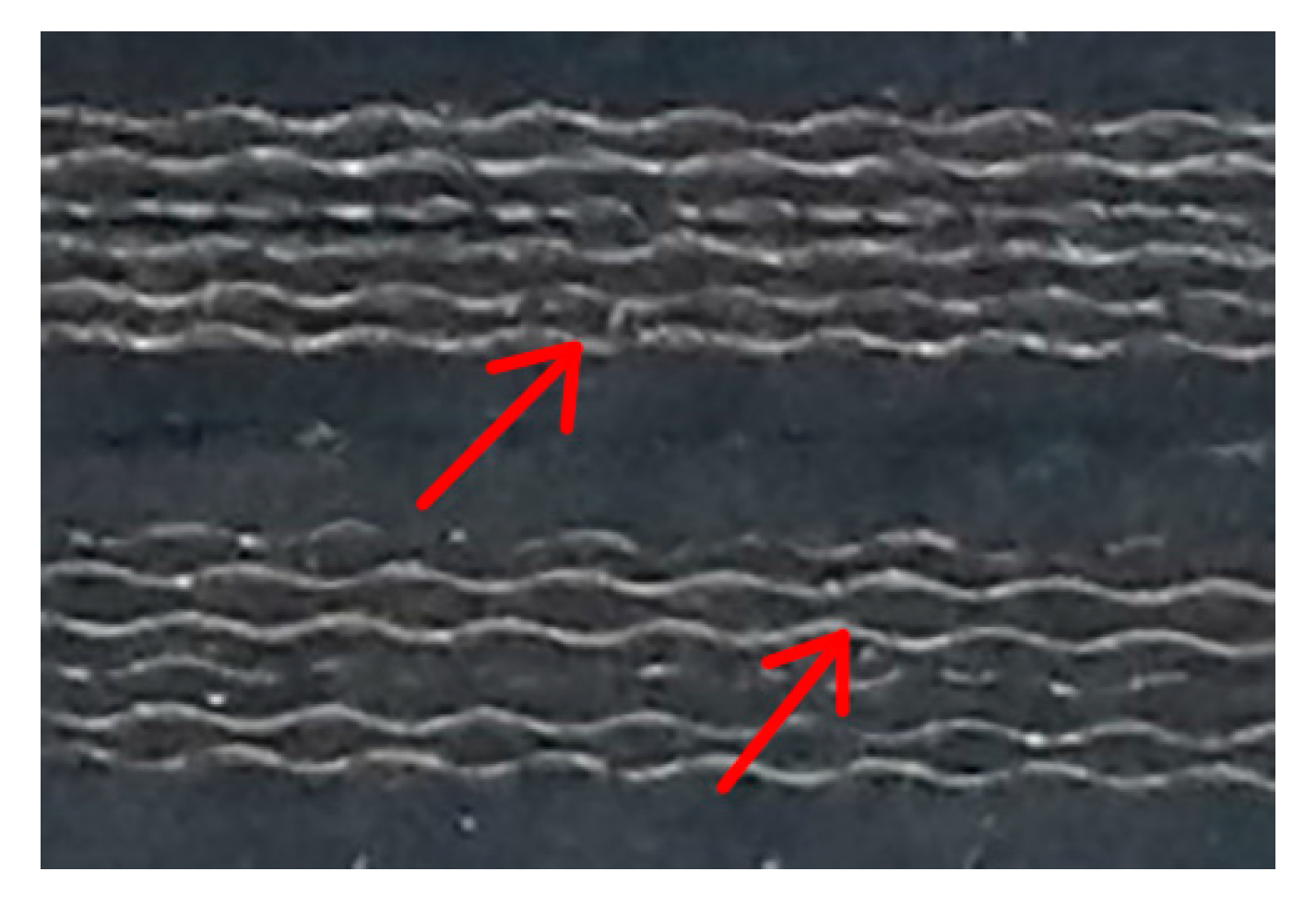

2. Fabric Core Conveyor Belt Rubber Bearings

2.1. Manufacturing Method of Bearings

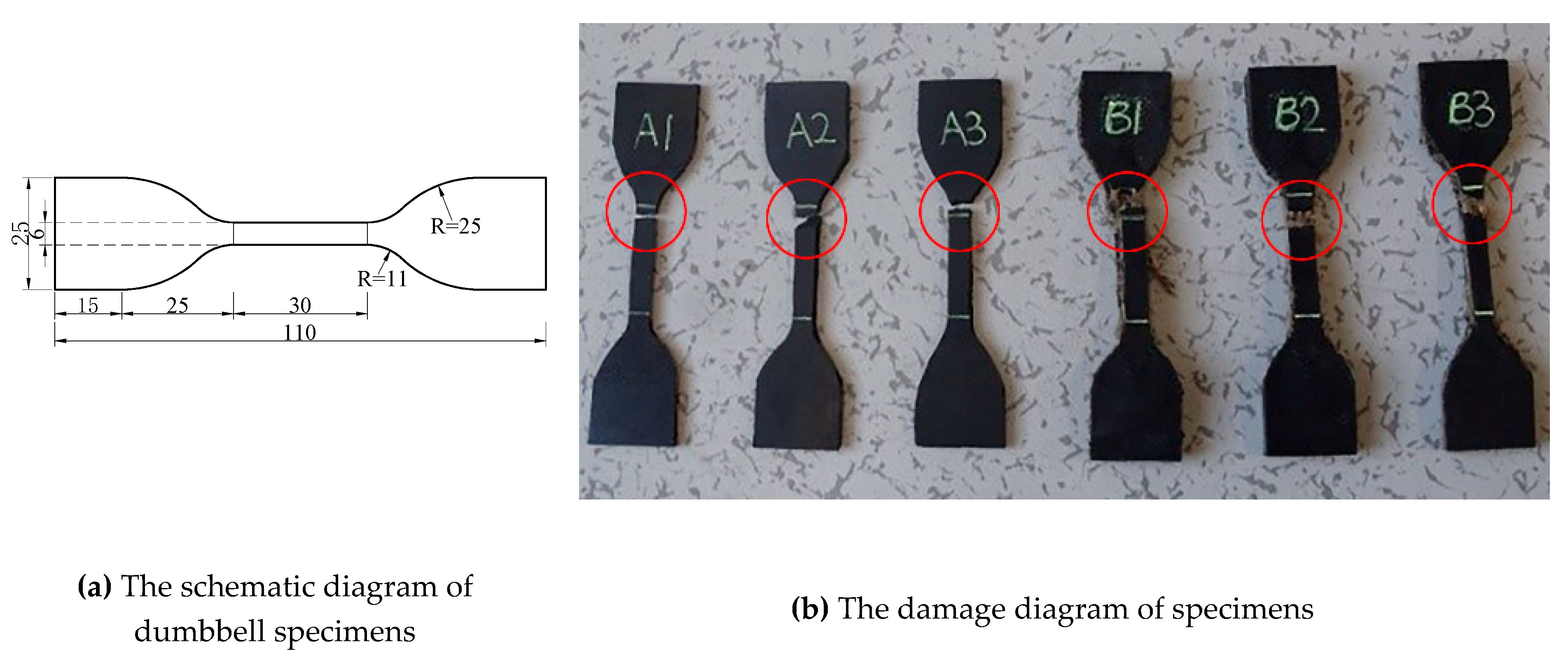

2.2. Uniaxial Tensile Test of Fabric Core Conveyor Belt

3. Vertical Mechanical Properties Test of Rubber Bearing of Fabric Core Conveyor Belt

3.1. Vertical Tests Program

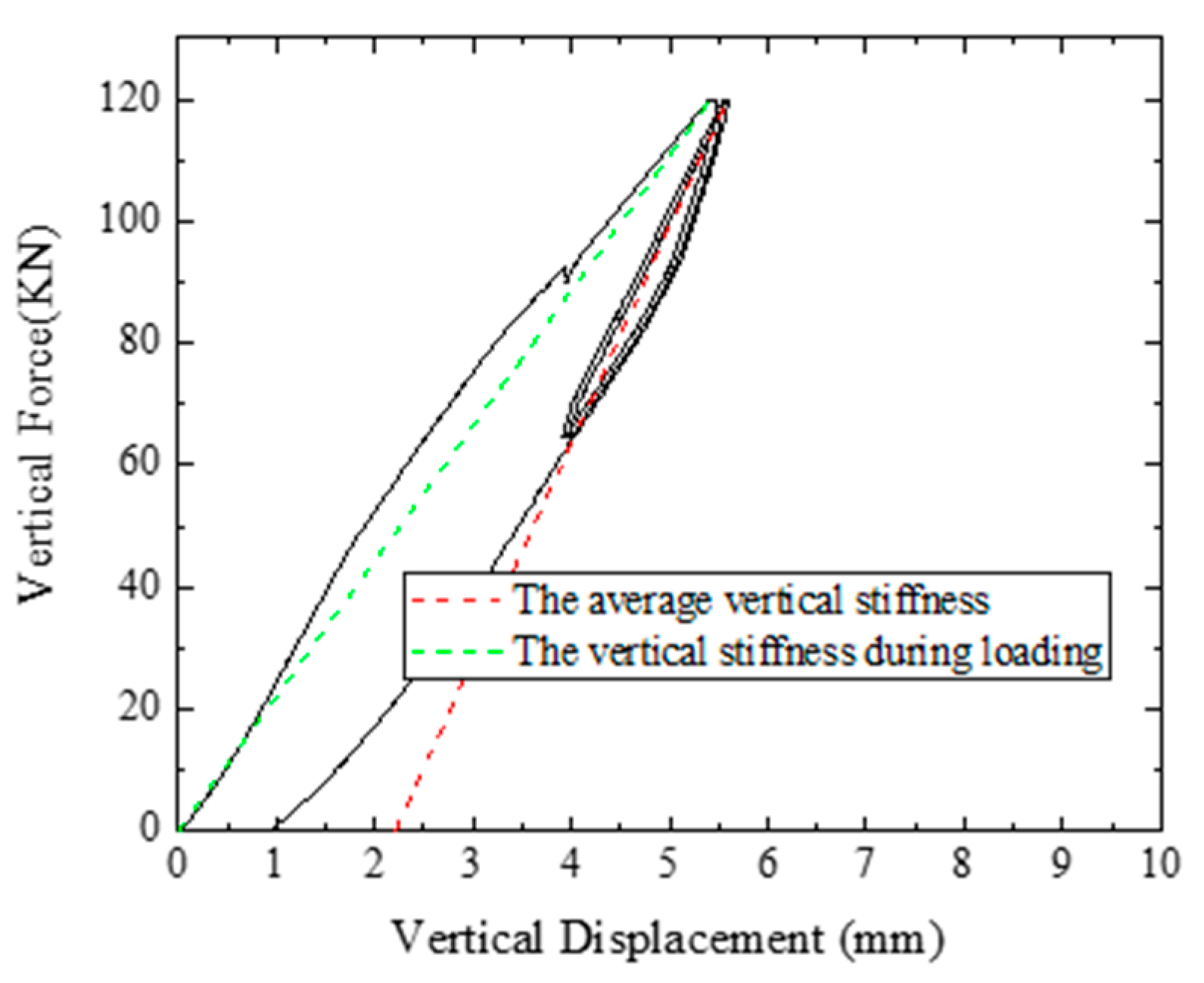

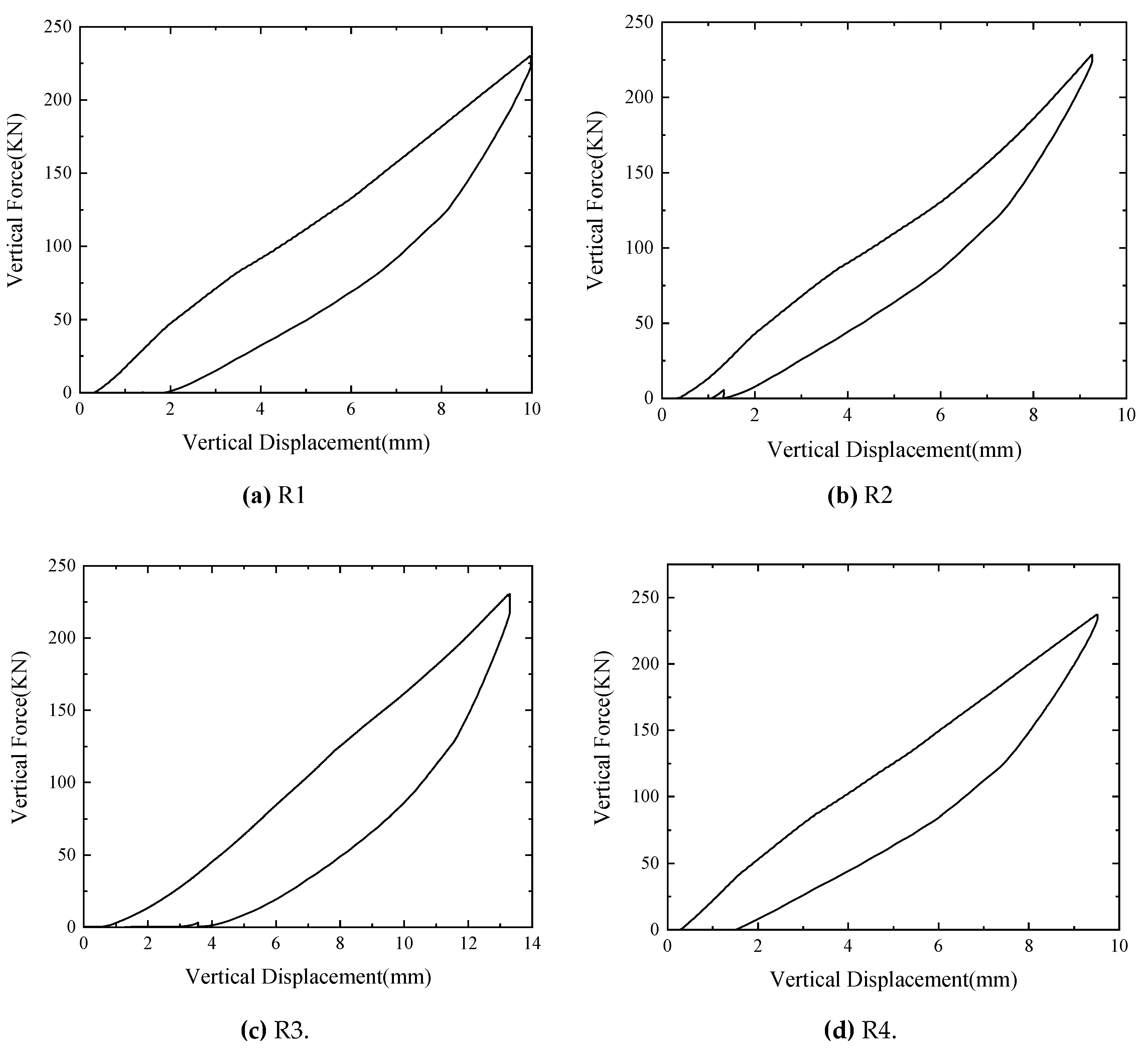

3.2. Vertical Compressive Test

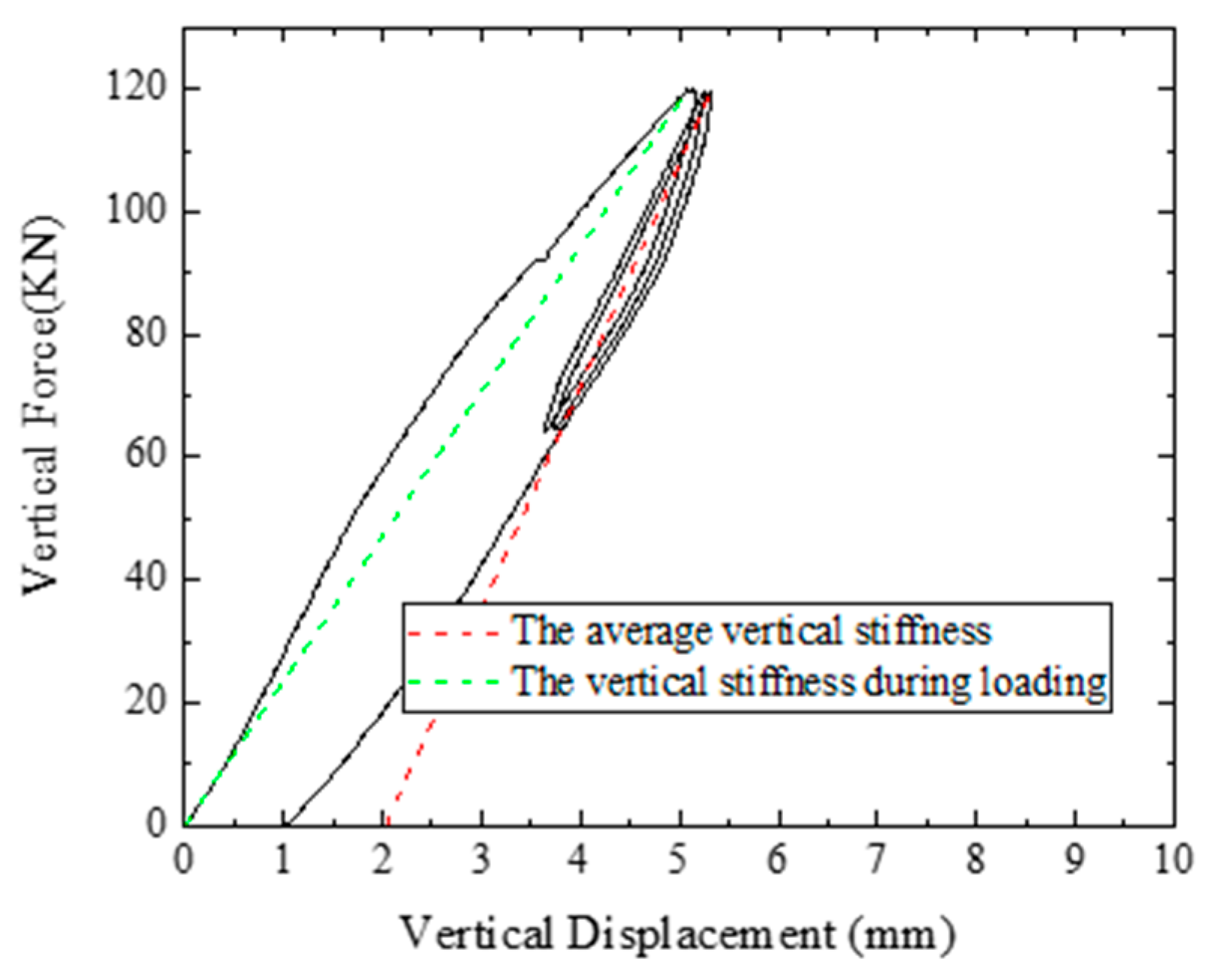

3.3. Overpressure Vertical Compressive Test

4. Horizontal Mechanical Properties Tests of CBRBs

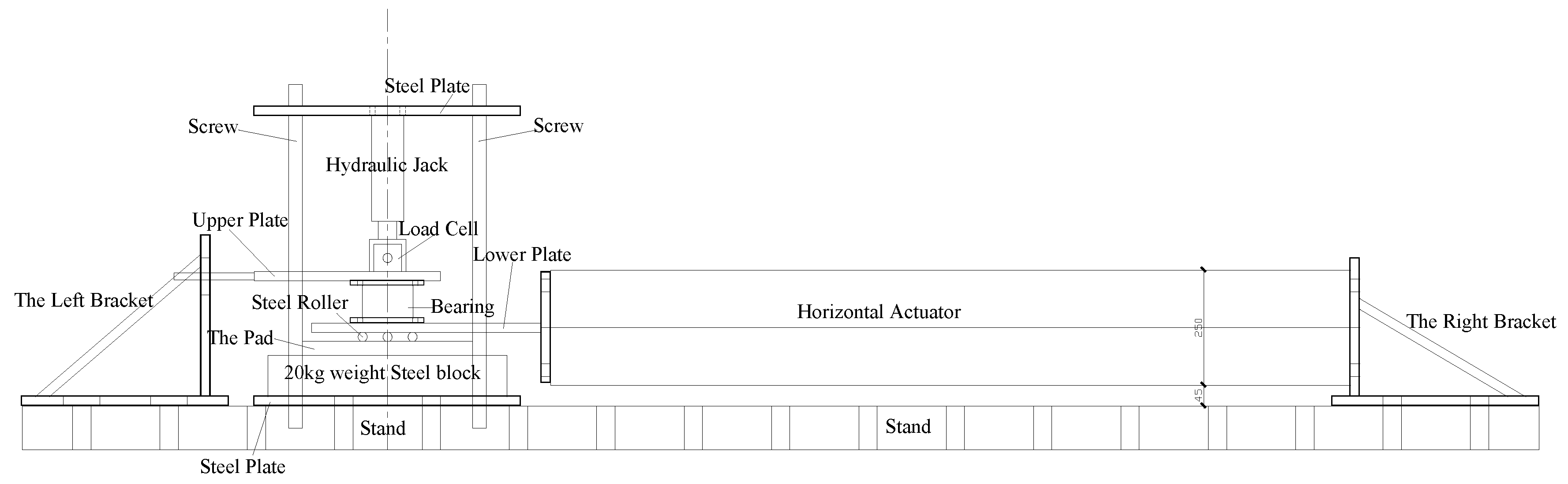

4.1. Test Procedure and Setup for Horizontal Shear Test

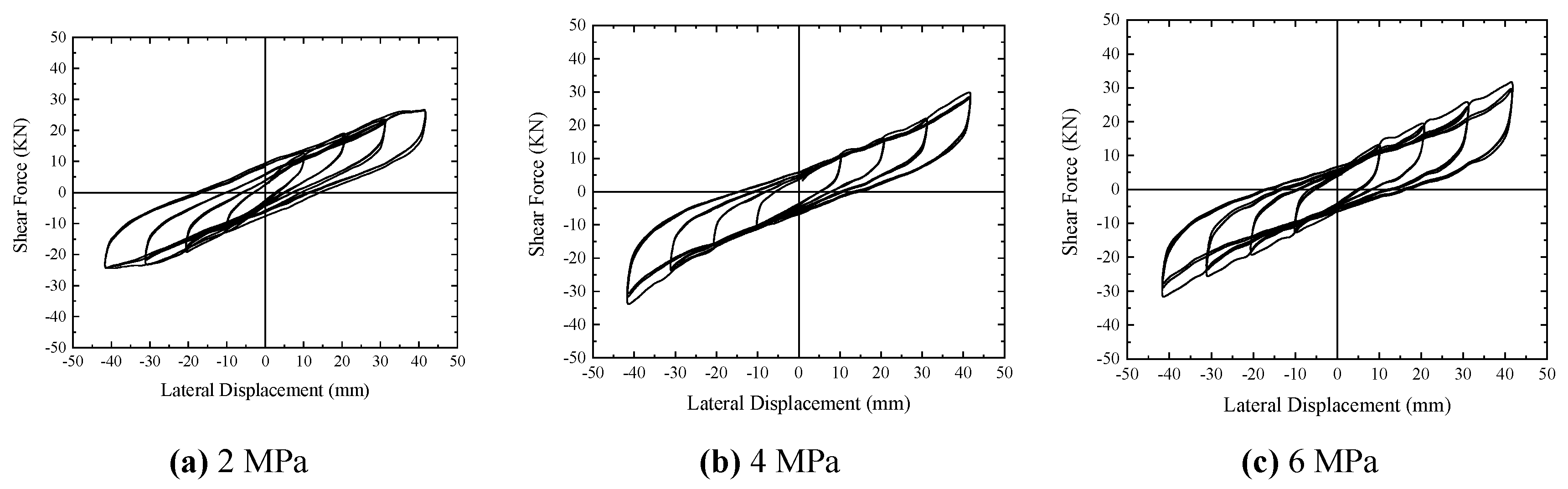

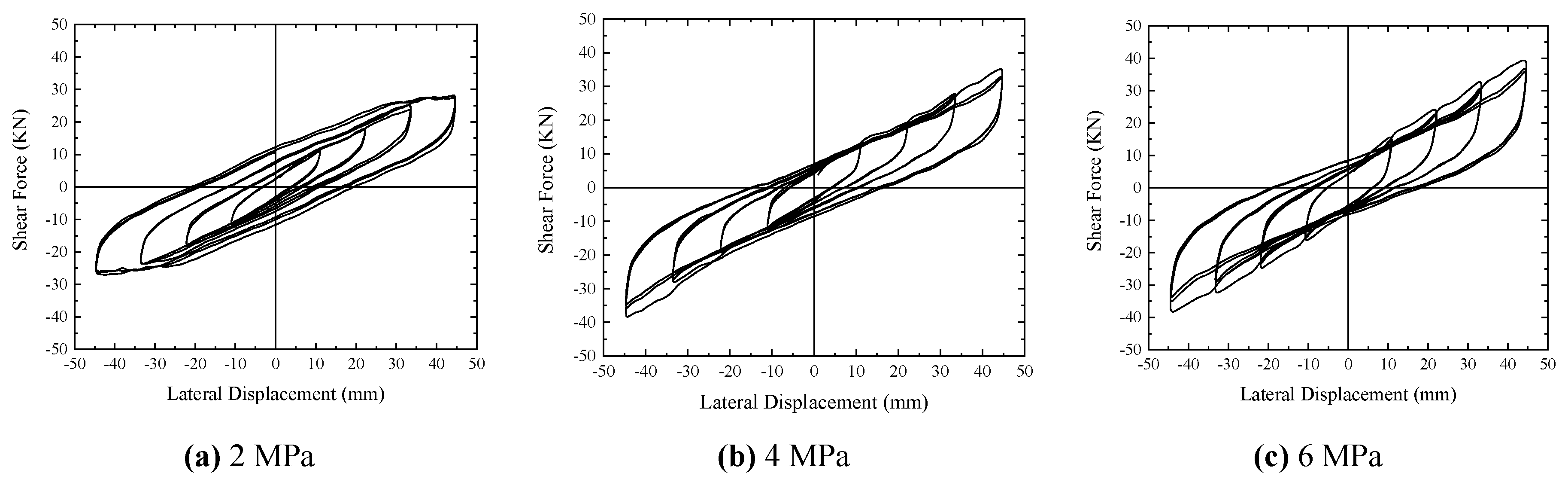

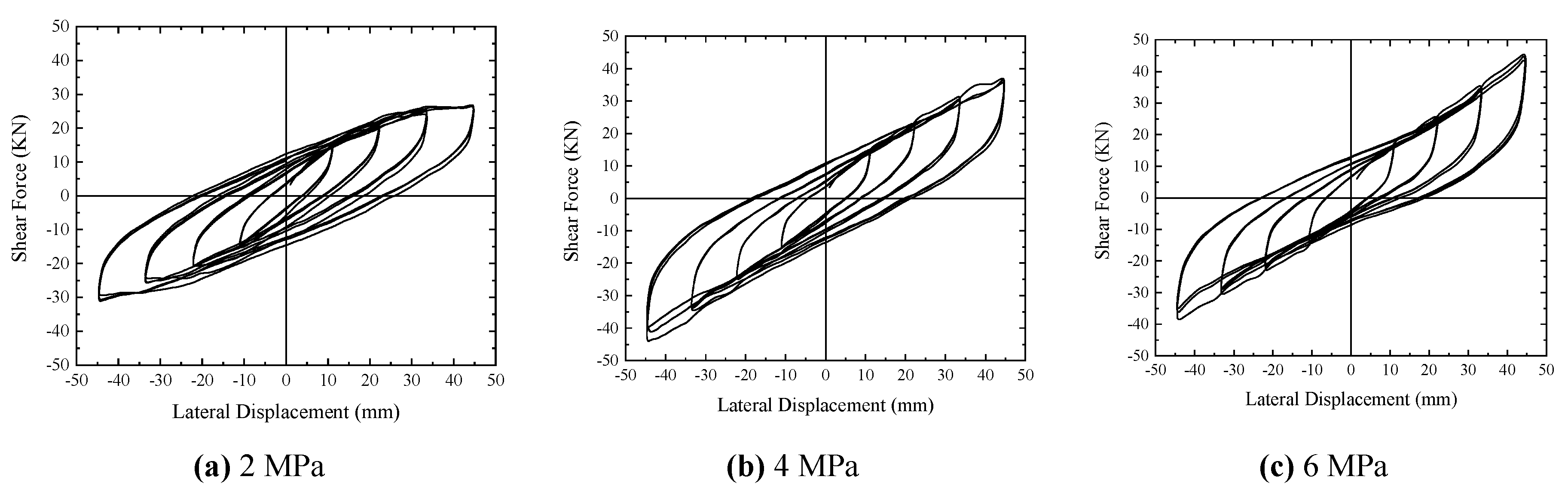

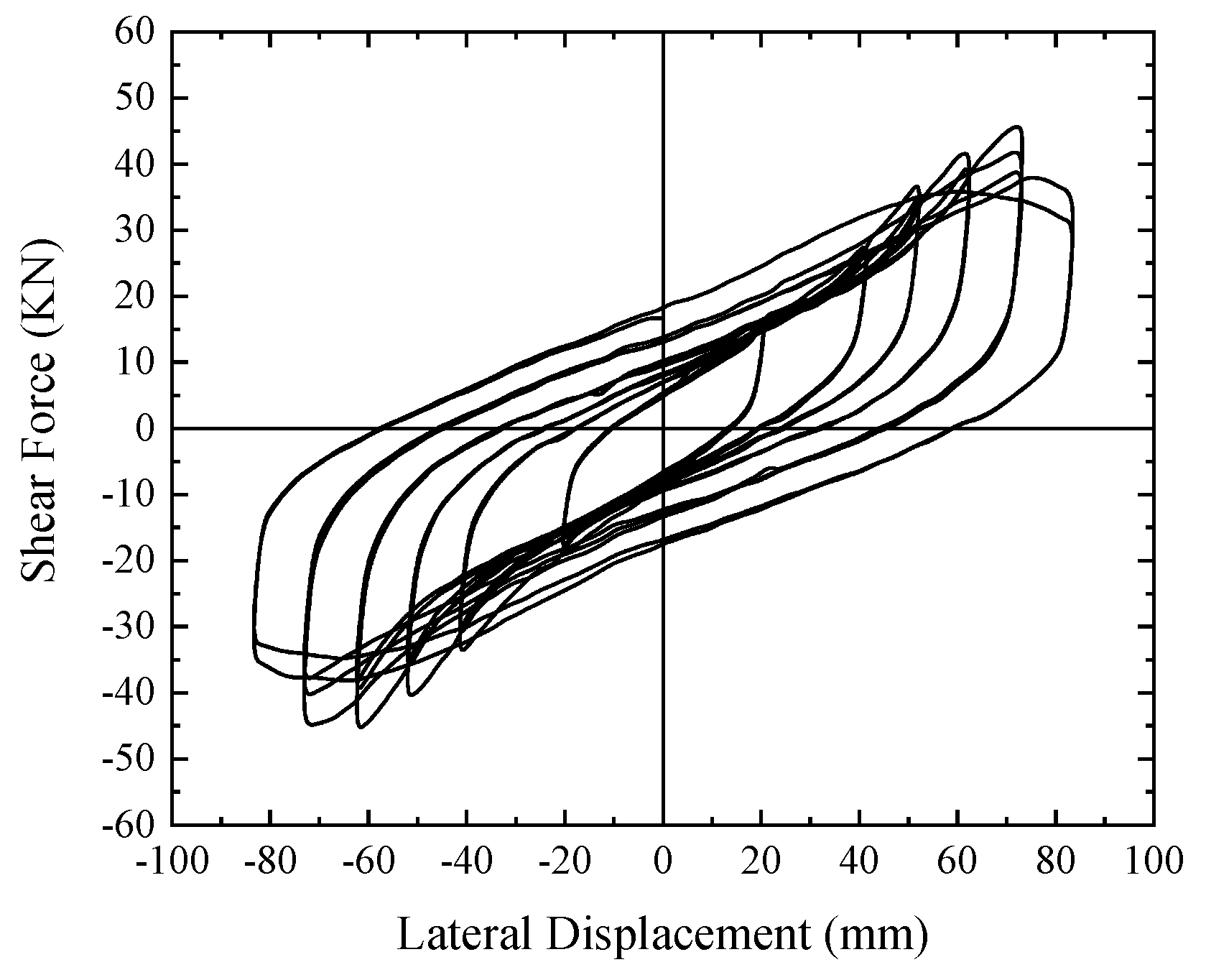

4.2. Horizontal Compression-Shear Cyclic Test

4.2.1. Description of the Test

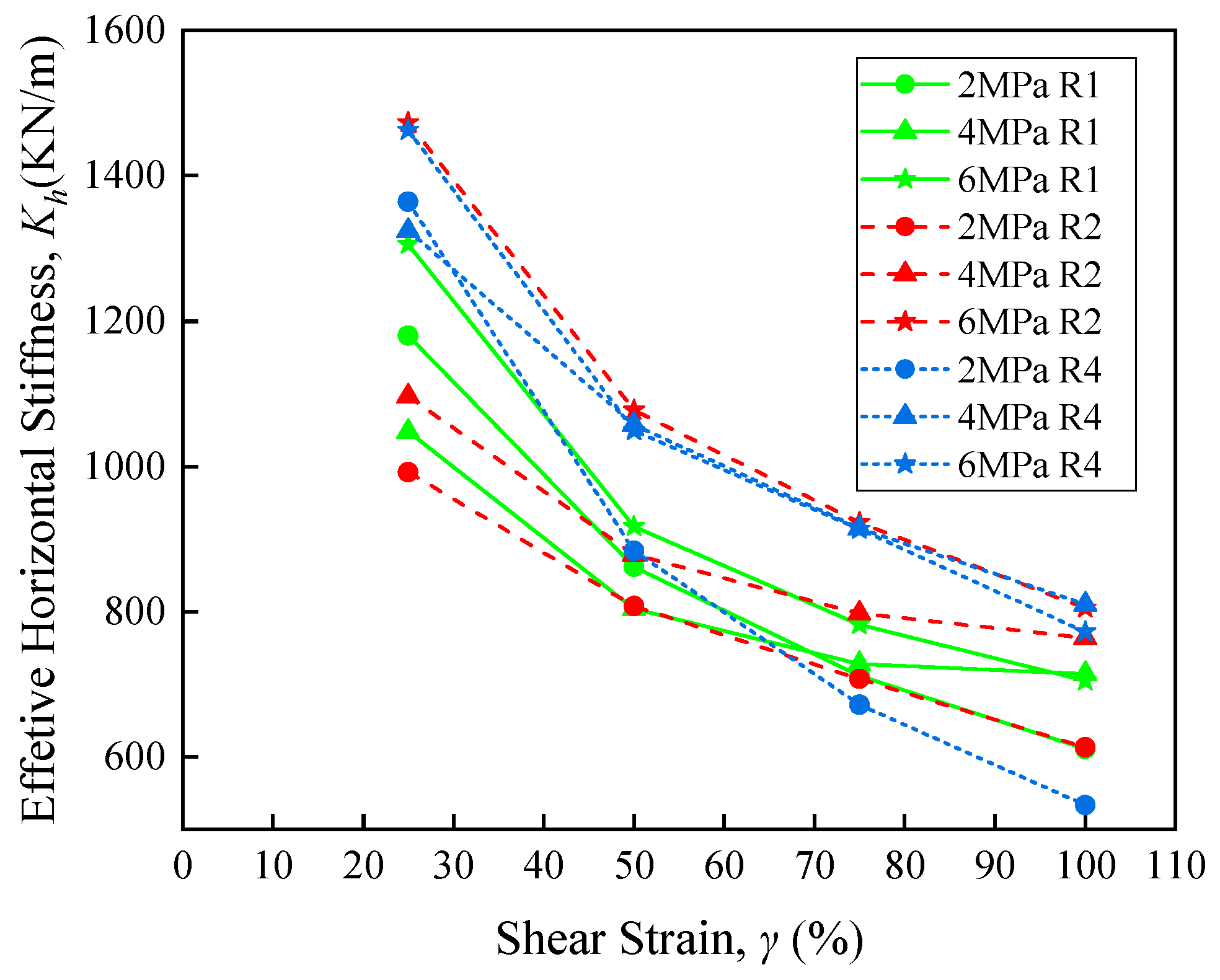

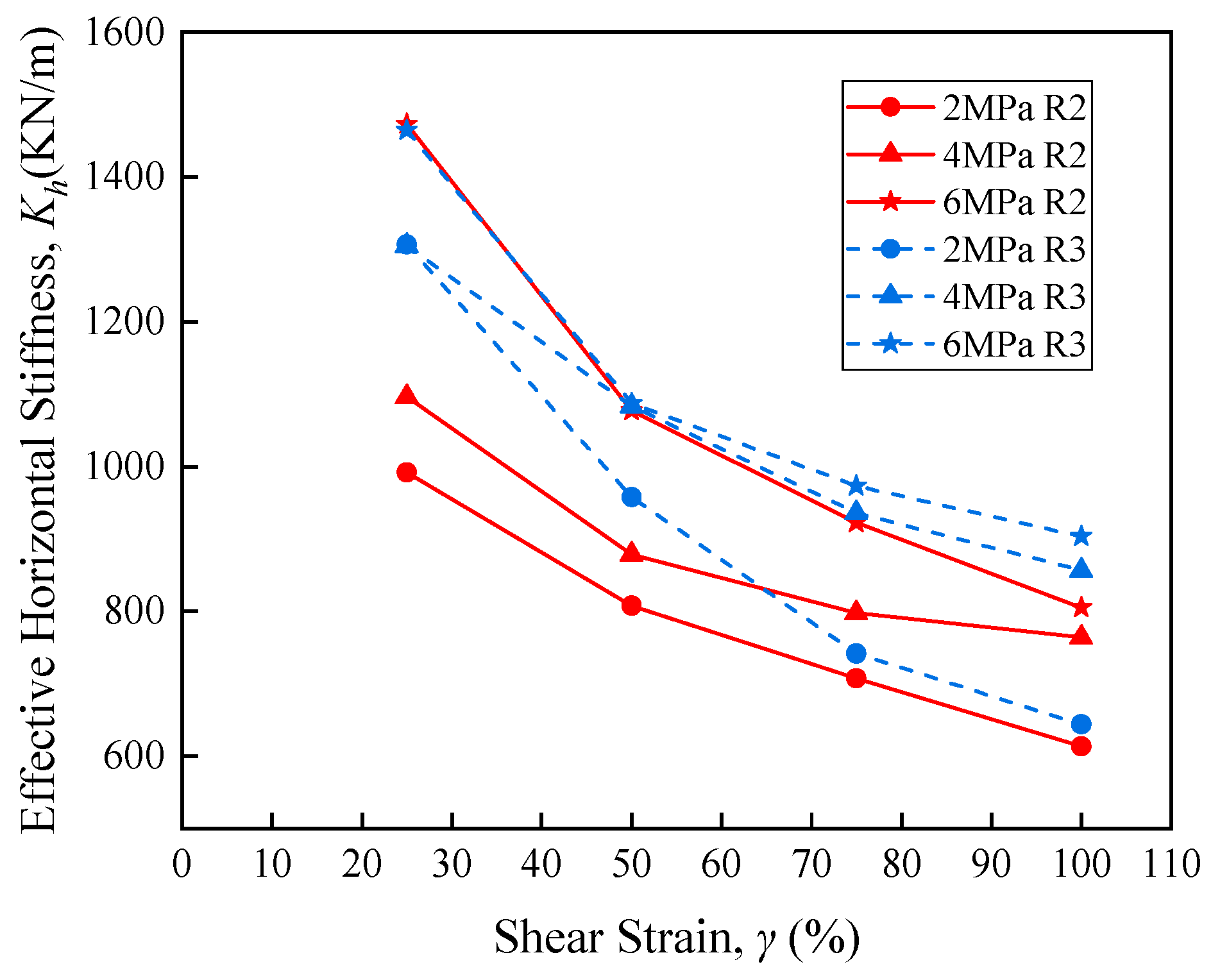

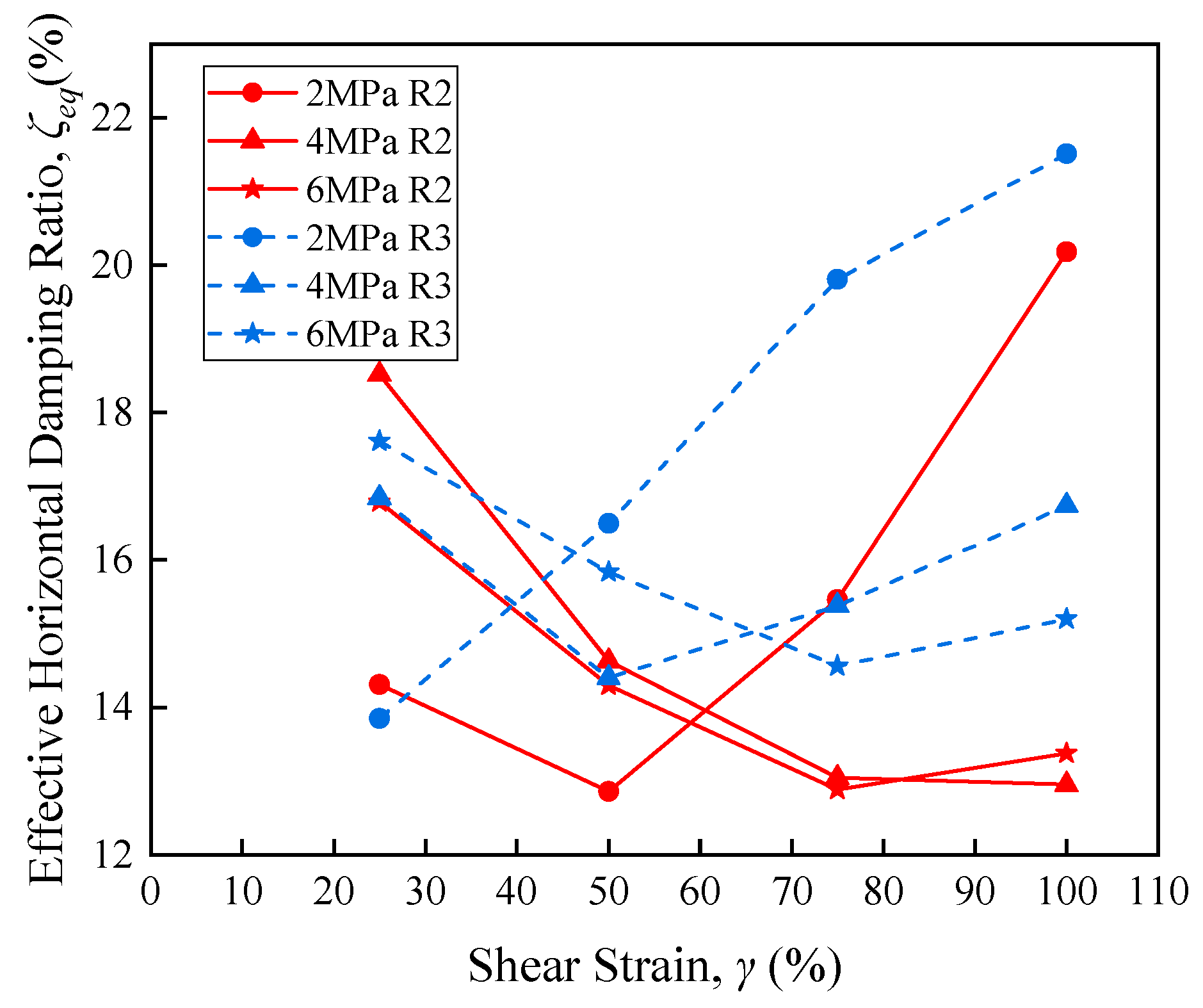

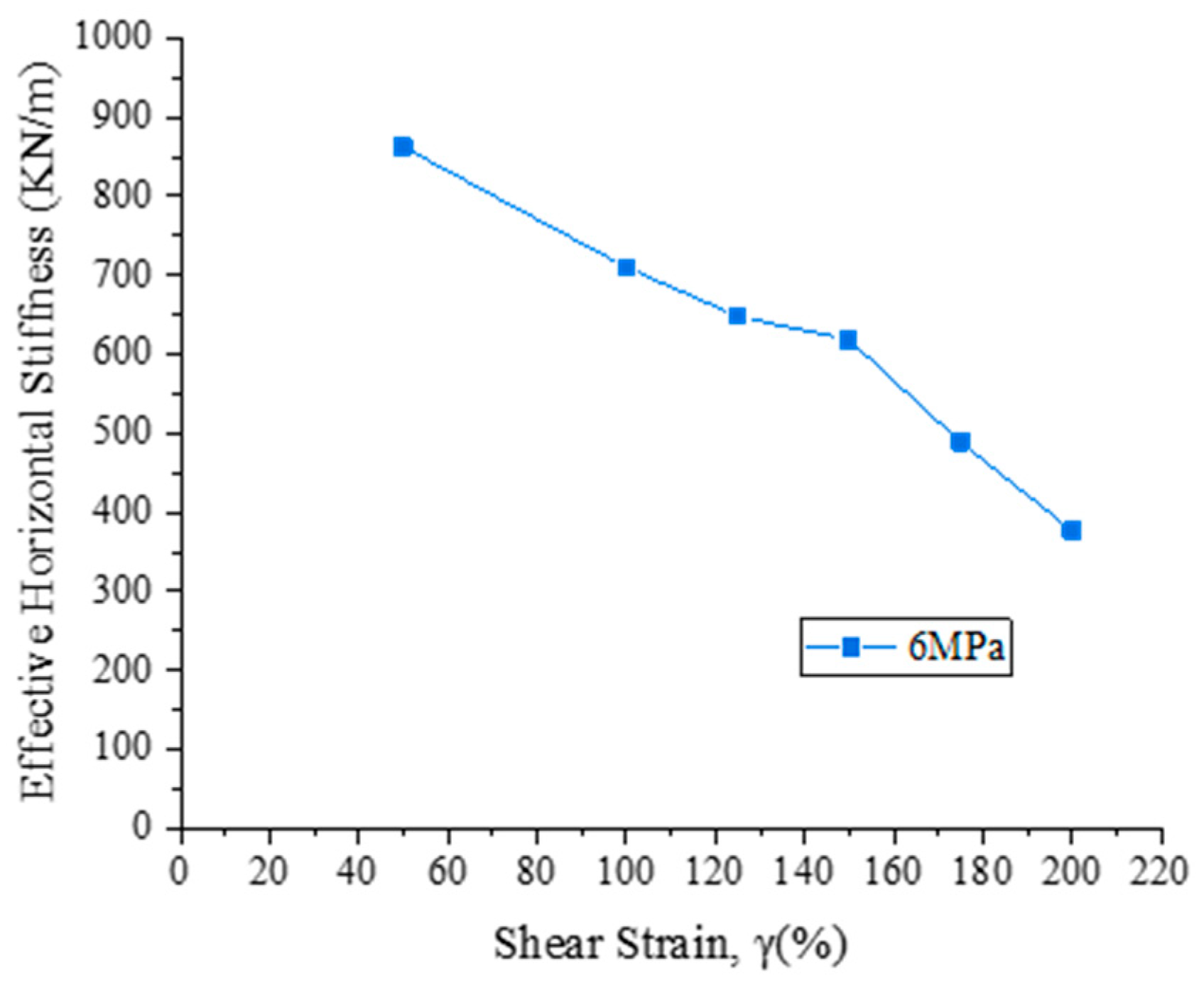

4.2.2. Mechanical Properties Analyses

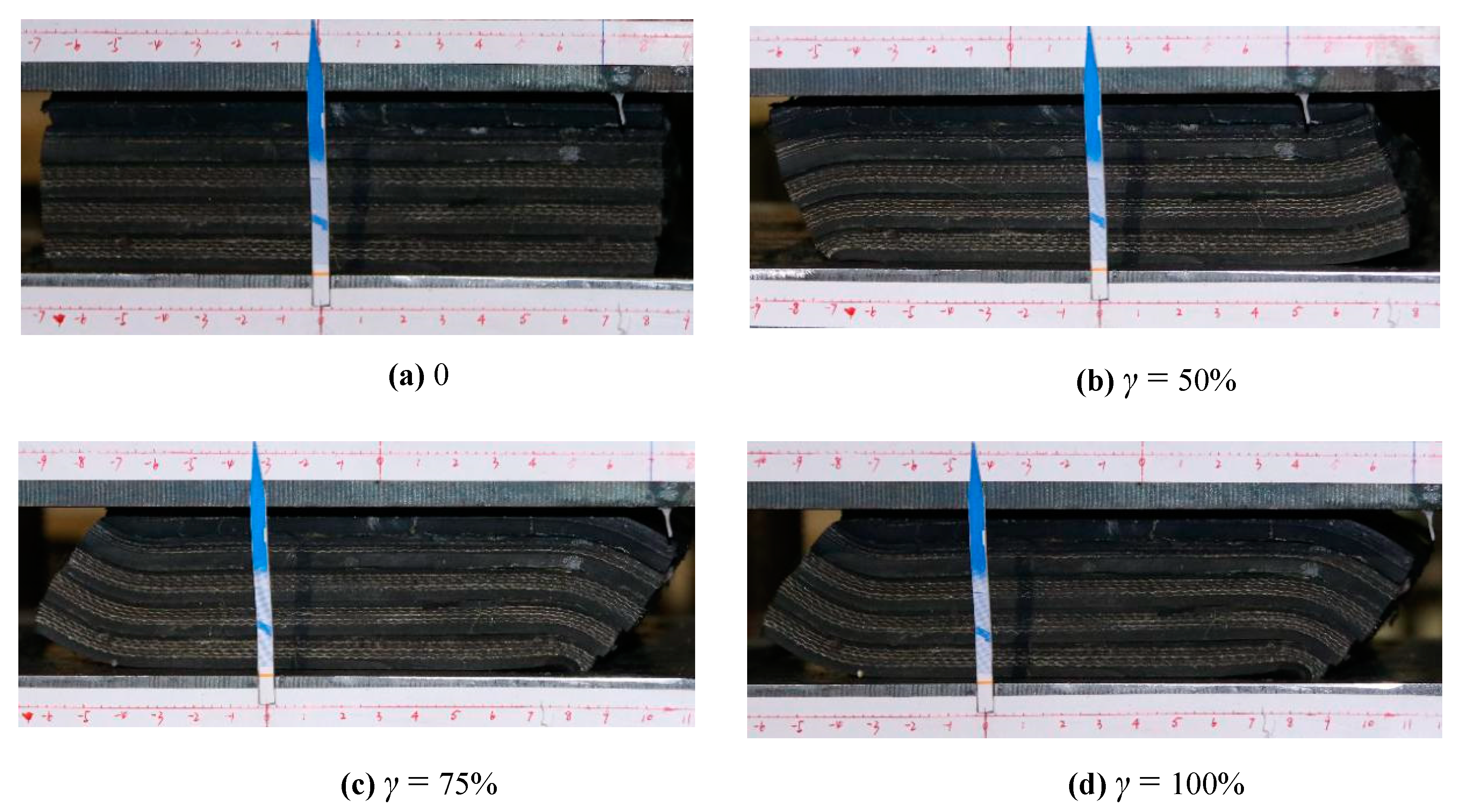

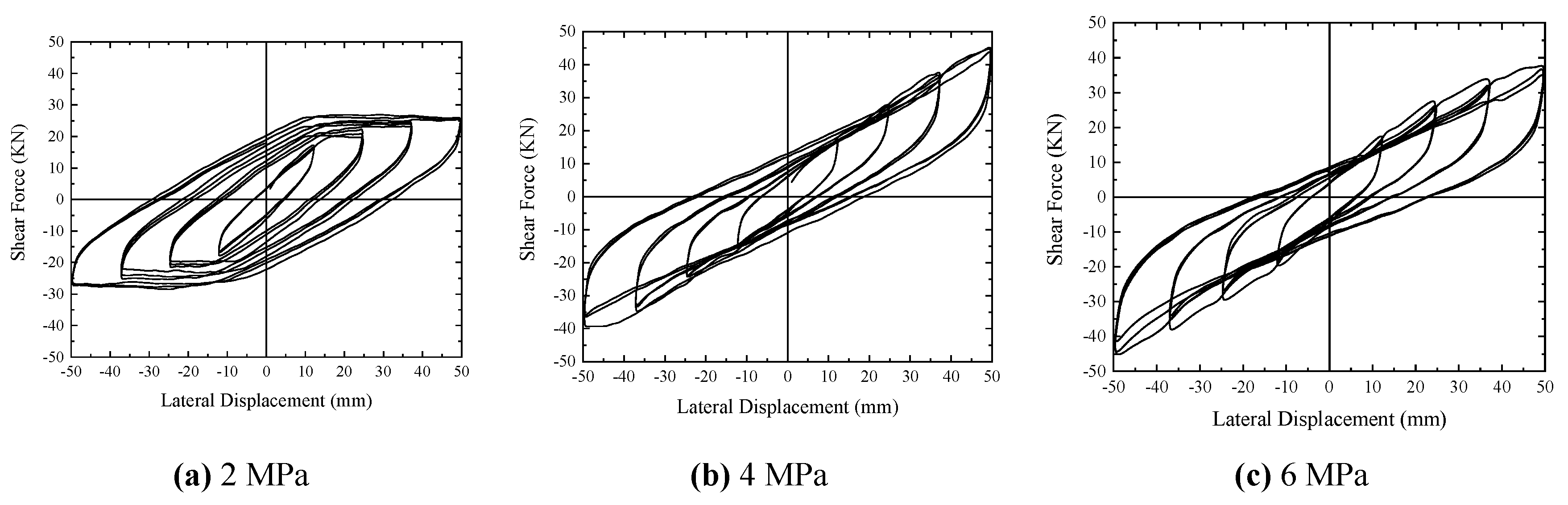

4.3. Ultimate Horizontal Shear Test

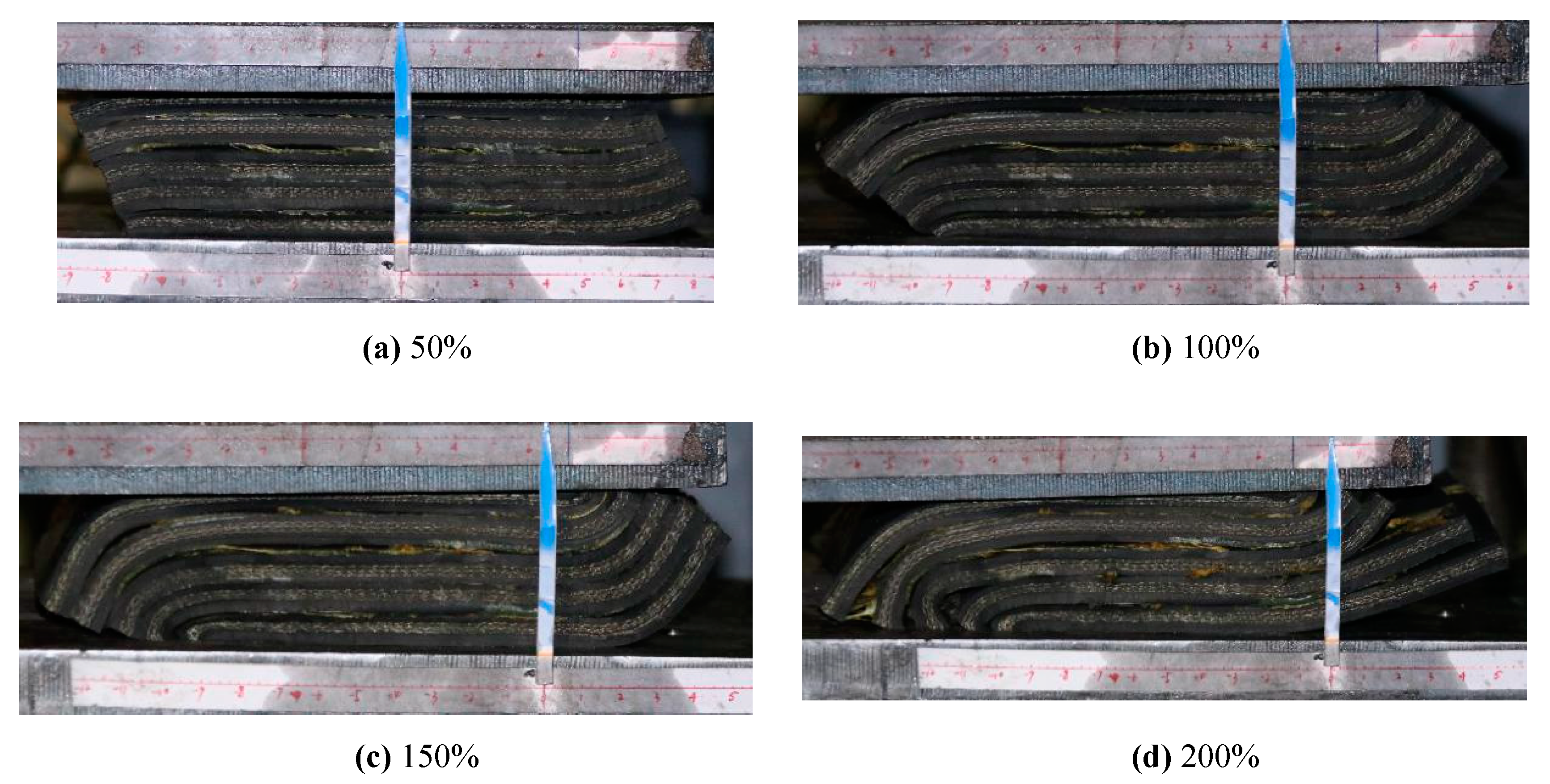

4.3.1. Description of the Test

4.3.2. Mechanical Properties Analyses

5. Conclusions

- Under a vertical pressure of 4 Mpa, as the number of fabric core layer increases, the vertical stiffness of the bearings increases, while the damping ratio decreases. The minimum value of the vertical damping ratio is 6.3%. In the overpressure test, the vertical pressure of CBRB reached 10 MPa without damage.

- CBRB works very well within 100% shear strain. The horizontal stiffness of the bearings decreases with increasing shear strain. When the bearings do not slide, the effective horizontal damping ratio decreases with increasing shear strain, and the damping ratio is about 15%. The effective horizontal stiffness and damping ratio of the patterned bearing are slightly larger, but considering that its residual displacement during vertical compression is significantly larger, it is not recommended to be used in structures.

- In the ultimate horizontal shear test of CBRB, when the shear strain exceeds 150%, the interlayer dislocation within the bearing was already obvious. The reason is that the bonding quality between the conveyor belt layers limits the continued loading. The question of how to improve the bonding quality and the shear deformation capacity of CBRB will be the focus of subsequent researches.

- From the comprehensive view of the mechanical properties of CBRB, the bearing has low horizontal stiffness, good energy dissipation capacity, low cost and convenient production and construction. Therefore, it is very suitable for the earthquake-resistant construction of low-rise buildings in high intensity areas, to reduce the loss of life and improve property safety.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chopra, A.K. Dynamics of Structures: Theory and Applications to Earthquake Engineering, 2nd ed.; Prentice-Hall: Upper Saddle River, NJ, USA, 2001; pp. 741–742. [Google Scholar]

- Van Engelen, N.C. Fiber-reinforced elastomeric isolators: A review. Soil Dyn. Earthq. Eng. 2019, 125, 105621. [Google Scholar] [CrossRef]

- Kelly, J.M. Analysis of fiber-reinforced elastomeric isolators. J. Seismol. Earthq. Eng. 1999, 2, 19–34. [Google Scholar]

- Moon, B.Y.; Kang, G.J.; Kang, B.S.; Kelly, J.M. Design and manufacturing of fiber reinforced elastomeric isolator for seismic isolation. J. Mater. Process. Tech. 2002, 130, 145–150. [Google Scholar] [CrossRef]

- Strauss, A.; Apostolidi, E.; Zimmermann, T.; Gerhaher, U.; Dritsos, S. Experimental investigations of fiber and steel reinforced elastomeric bearings: Shear modulus and damping coefficient. Eng. Struct. 2014, 75, 402–413. [Google Scholar] [CrossRef]

- Kang, B.S.; Kang, G.J.; Moon, B.Y. Hole and lead plug effect on fiber reinforced elastomeric isolator for seismic isolation. J. Mater. Process. Tech. 2003, 140, 592–597. [Google Scholar] [CrossRef]

- Toopchi-Nezhad, H.; Tait, M.J.; Drysdale, R.G. Testing and modeling of square carbon fiber-reinforced elastomeric seismic isolators. Struct. Contr. Health. Monit. 2008, 15, 876–900. [Google Scholar] [CrossRef]

- Toopchi-Nezhad, H.; Tait, M.J.; Drysdale, R.G. Lateral response evaluation of fiber-reinforced neoprene seismic isolators utilized in an unbonded application. J. Struct. Eng. 2008, 134, 1627–1637. [Google Scholar] [CrossRef]

- Toopchi-Nezhad, H.; Drysdale, R.G.; Tait, M.J. Parametric study on the response of stable unbonded-fiber reinforced elastomeric isolators (SU-FREIs). J. Compos. Mater. 2009, 43, 1569–1587. [Google Scholar] [CrossRef]

- Toopchi-Nezhad, H.; Tait, M.J.; Drysdale, R.G. Simplified analysis of a low-rise building seismically isolated with stable unbonded fiber reinforced elastomeric isolators. Can. J. Civ. Eng. 2009, 36, 1182–1194. [Google Scholar] [CrossRef]

- Toopchi-Nezhad, H.; Tait, M.J.; Drysdale, R.G. Bonded versus unbonded strip fiber reinforced elastomeric isolators: Finite element analysis. Compos. Struct. 2011, 93, 850–859. [Google Scholar] [CrossRef]

- Al-Anany, Y.M.; Tait, M.J. A numerical study on the compressive and rotational behaviour of fiber reinforced elastomeric isolators (FREI). Compos. Struct. 2015, 133, 1249–1266. [Google Scholar] [CrossRef]

- Van Engelen, N.C.; Osgooei, P.M.; Tait, M.J.; Konstantinidis, D. Partially bonded fiber-reinforced elastomeric isolators (PB-FREIs). Struct. Contr. Health Monit. 2015, 22, 417–432. [Google Scholar] [CrossRef]

- Van Engelen, N.C.; Tait, M.J.; Konstantinidis, D. Investigation of partially bonded fiber-reinforced elastomeric isolators (PB-FREIs) with nominal vertical tensile loads. Can. J. Civ. Eng. 2019, 46, 669–676. [Google Scholar] [CrossRef]

- Mordini, A.; Strauss, A. An innovative earthquake isolation system using fibre reinforced rubber bearings. Eng. Struct. 2008, 30, 2739–2751. [Google Scholar] [CrossRef]

- Das, A.; Deb, S.K.; Dutta, A. Shake table testing of un-reinforced brick masonry building test model isolated by U-FREI. Earthq. Eng. Struct. Dyn. 2016, 45, 253–272. [Google Scholar] [CrossRef]

- Thuyet, V.N.; Deb, S.K.; Dutta, A. Mitigation of seismic vulnerability of prototype low-rise masonry building using U-FREIs. J. Perform. Constr. Facil. 2017, 32, 04017136. [Google Scholar] [CrossRef]

- Al-Anany, Y.M.; Moustafa, M.A.; Tait, M.J. Modeling and evaluation of a seismically isolated bridge using unbonded fiber-reinforced elastomeric isolators. Earthq. Spectra. 2018, 34, 145–168. [Google Scholar] [CrossRef]

- Ashkezari, G.D.; Aghakouchak, A.A.; Kokabi, M. Design, manufacturing and evaluation of the performance of steel like fiber reinforced elastomeric seismic isolators. J. Mater. Process. Technol. 2008, 197, 140–150. [Google Scholar] [CrossRef]

- Dezfuli, F.H.; Alam, M.S. Performance of carbon fiber-reinforced elastomeric isolators manufactured in a simplified process: Experimental investigations. Struct. Contr. Health Monit. 2014, 21, 1347–1359. [Google Scholar] [CrossRef]

- Dezfuli, F.H.; Alam, M.S. Experiment-based sensitivity analysis of scaled carbon-fiber-reinforced elastomeric isolators in bonded applications. Fibers 2016, 4, 4. [Google Scholar] [CrossRef]

- Naghshineh, A.K.; Akyuz, U.; Caner, A. Lateral response comparison of unbonded elastomeric bearings reinforced with carbon fiber mesh and steel. Shock Vib. 2015, 1–10. [Google Scholar] [CrossRef]

- Naghshineh, A.K.; Akyuz, U.; Caner, A. Comparison of fundamental properties of new types of fiber-meshreinforced seismic isolators with conventional isolators. Earthq. Eng. Struct. Dyn. 2014, 43, 301–316. [Google Scholar] [CrossRef]

- Spizzuoco, M.; Calabrese, A.; Serino, G. Innovative low-cost recycled rubber-fiber reinforced isolator: Experimental test and finite element analyses. Eng. Struct. 2014, 76, 99–111. [Google Scholar] [CrossRef]

- Ping, T.; Kai, X.; Bin, W.; Fulin, Z. Performance study of isolated rural buildings using novel simple isolators. China Civ. Eng. J. 2013, 46, 64–70. [Google Scholar] [CrossRef]

- Hua, Z.; Tianbo, P.; Jianzhong, L.; Wenxiao, L. Experimental study of FRP rubber bearing. Adv. Mater. Res. 2011, 168, 1621–1624. [Google Scholar] [CrossRef]

- Menga, N.; Foti, D.; Carbone, G. Viscoelastic frictional properties of rubber-layer roller bearings (RLRB) seismic isolators. Meccanica 2017, 52, 2807–2817. [Google Scholar] [CrossRef]

- Shuai, C. Study on the Preparation and Properties of Cover Rubber Material for Ablation Resistant Conveyor Belt; Beijing University of Chemical Technology: Beijing, China, 2017; pp. 1–2. [Google Scholar]

- Gent, A.N. On the Relation between Indentation Hardness and Young’s Modulus. Rubber Chem. Technol. 1958, 31, 896–906. [Google Scholar] [CrossRef]

- Imbimbo, M.; De Luca, A.F.E. stress analysis of rubber bearings under axial loads. Comput. Struct. 1998, 68, 31–39. [Google Scholar] [CrossRef]

- Kelly, J.M. Analysis of the run-in effect in fiber-reinforced isolators under vertical load. J. Mech. Mater. Struct. 2008, 3, 1383–1401. [Google Scholar] [CrossRef][Green Version]

- Ministry of Transport of the People’s Republic of China. Code for Design of Highway Reinforced Concrete and Prestressed Concrete Bridges and Culverts; Ministry of Transport of the People’s Republic of China: Beijing, China, 2004; pp. 79–80.

| Specimen Number | Conveyor Belt Layers | Fabric Layers in Each Belt Layer | Total Rubber Thickness (mm) | Bearing Size (mm × mm × mm) | S |

|---|---|---|---|---|---|

| R1 | 5 | 4 | 37 | 150 × 150 × 42 | 5.07 |

| R2 | 5 | 5 | 38.75 | 150 × 150 × 45 | 4.84 |

| R3 | 5 | 5 | 38.75 | 150 × 150 × 45 | 4.84 |

| R4 | 5 | 6 | 42.5 | 150 × 150 × 50 | 4.41 |

| Sample No. | Specimen L0*W*t (mm * mm * mm) | Maximum Tensile Force Fm (N) | Tensile Strength TS (MPa) | Elongation at Break Eb (%) | |||

|---|---|---|---|---|---|---|---|

| Single Value | Average Value | Single Value | Average Value | Single Value | Average Value | ||

| A1 | 30 × 6.03 × 3.75 | 98.57 | 107.37 | 4.48 | 4.76 | 243.53 | 238.71 |

| A2 | 30 × 6.01 × 3.80 | 113.92 | 4.99 | 237.99 | |||

| A3 | 30 × 5.98 × 3.81 | 109.63 | 4.81 | 234.61 | |||

| B1 | 30 × 6.02 × 9.03 | 3412.24 | 3258.77 | 62.77 | 59.81 | 86.58 | 83.67 |

| B2 | 30 × 6.05 × 9.08 | 3238.43 | 58.95 | 83.24 | |||

| B3 | 30 × 6.01 × 9.01 | 3125.64 | 57.72 | 81.21 | |||

| Mechanical Parameters | R1 | R2 | R3 | R4 |

|---|---|---|---|---|

| The effective vertical stiffness | 34.1 KN/mm | 35.3 KN/mm | 32.4 KN/mm | 36.7 KN/mm |

| The effective vertical damping ratio | 8.9% | 8.3% | 7.9% | 6.3% |

| Test Procedure | Parameters |

|---|---|

| Compression-shear test | Different vertical pressures of 2 MPa, 4 MPa and 6 MPa, with the shear strain including 25%, 50%, 75% and 100%. |

| Ultimate compression- shear test | The constant vertical pressure of 6 MPa, with the shear strain including 50%, 100%, 125%, 150%, 175% and 200%. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Zhang, Y.; Li, A.; Zhang, G. The Experimental Study on Mechanical Behavior of Conveyor Belt Rubber Bearings. Appl. Sci. 2020, 10, 4452. https://doi.org/10.3390/app10134452

Wu Y, Zhang Y, Li A, Zhang G. The Experimental Study on Mechanical Behavior of Conveyor Belt Rubber Bearings. Applied Sciences. 2020; 10(13):4452. https://doi.org/10.3390/app10134452

Chicago/Turabian StyleWu, Yifeng, Yan Zhang, Aiqun Li, and Guodong Zhang. 2020. "The Experimental Study on Mechanical Behavior of Conveyor Belt Rubber Bearings" Applied Sciences 10, no. 13: 4452. https://doi.org/10.3390/app10134452

APA StyleWu, Y., Zhang, Y., Li, A., & Zhang, G. (2020). The Experimental Study on Mechanical Behavior of Conveyor Belt Rubber Bearings. Applied Sciences, 10(13), 4452. https://doi.org/10.3390/app10134452