Study on the Thermal Performance and Temperature Distribution of Ball Bearings in the Traction Motor of a High-Speed EMU

Abstract

1. Introduction

2. Model Establishment

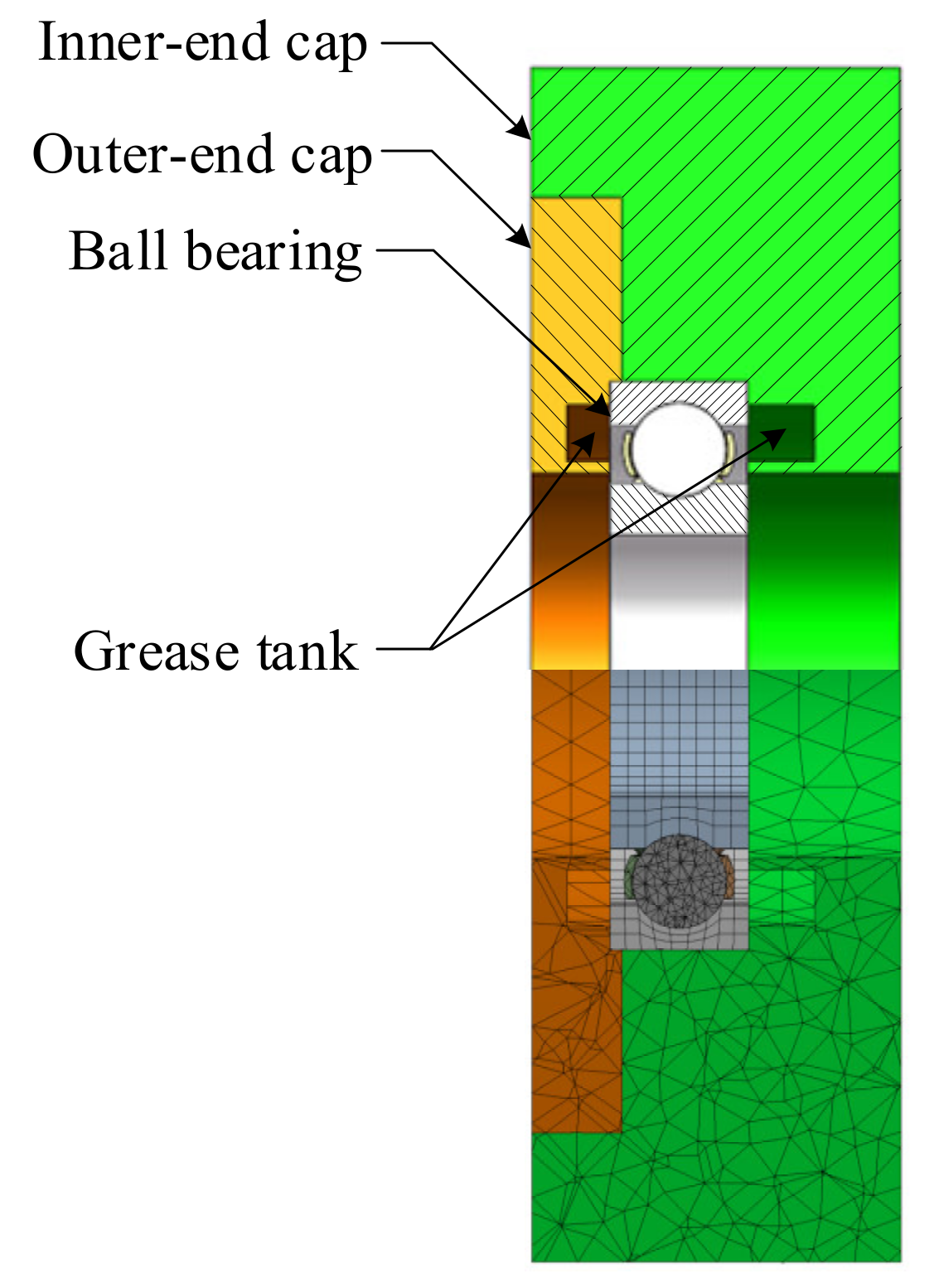

2.1. Establishment of a Finite Element Transient Temperature Solution Model

2.2. Heat Generation Calculation

2.3. Convective Heat Transfer of Bearings

2.4. Problem Analysis

3. Correction of Mathematical Model

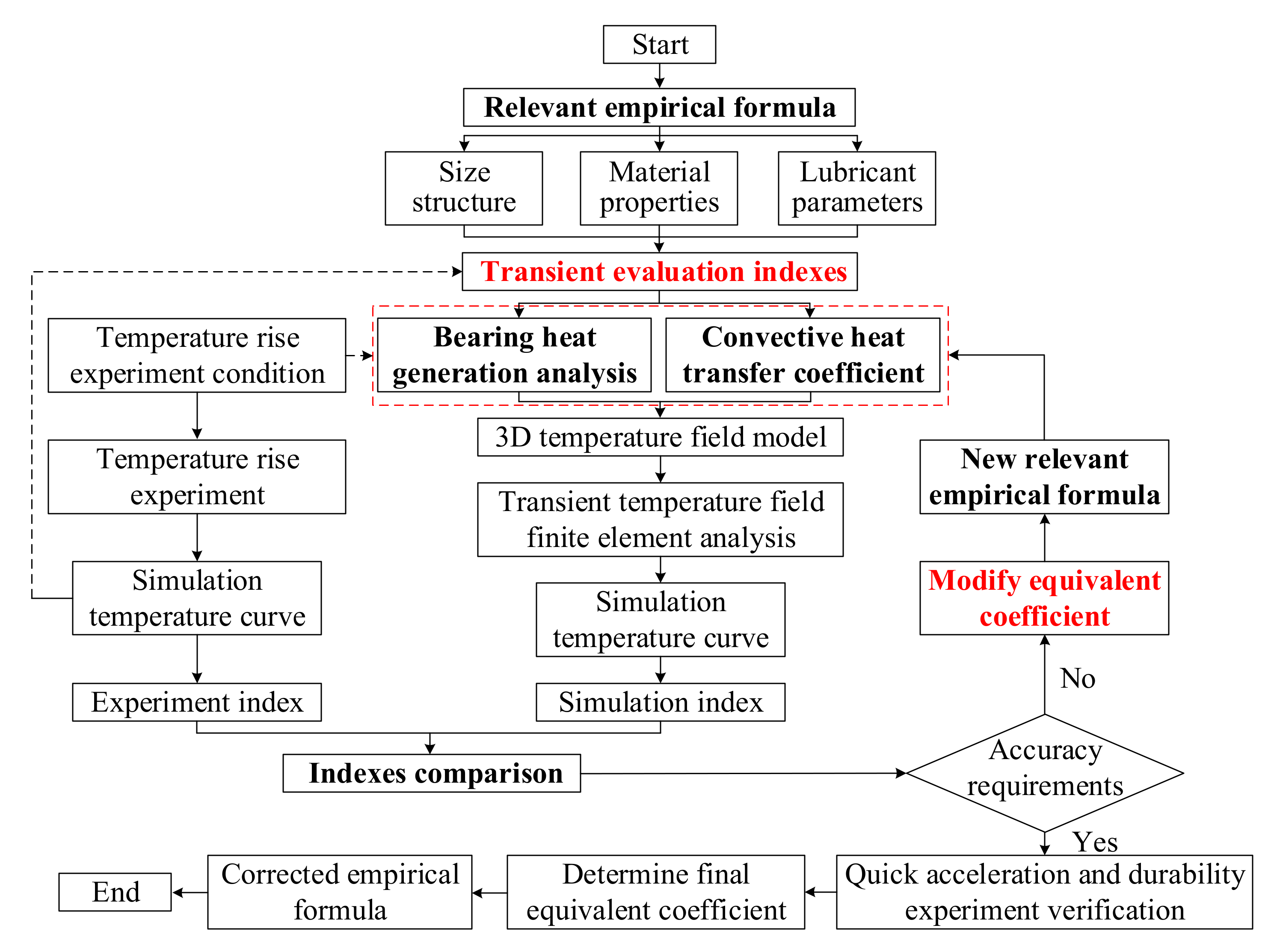

3.1. Correction Method of Empirical Formula

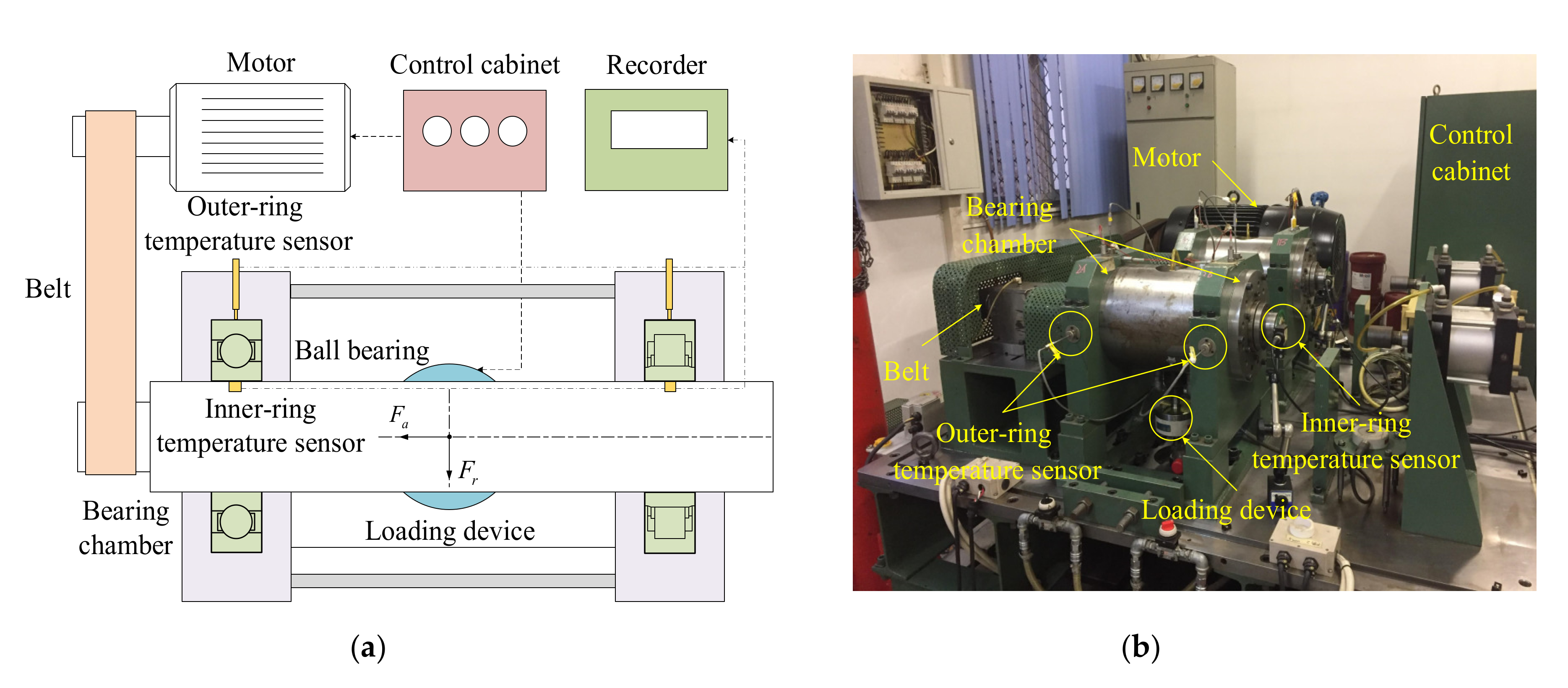

3.2. Correction Process

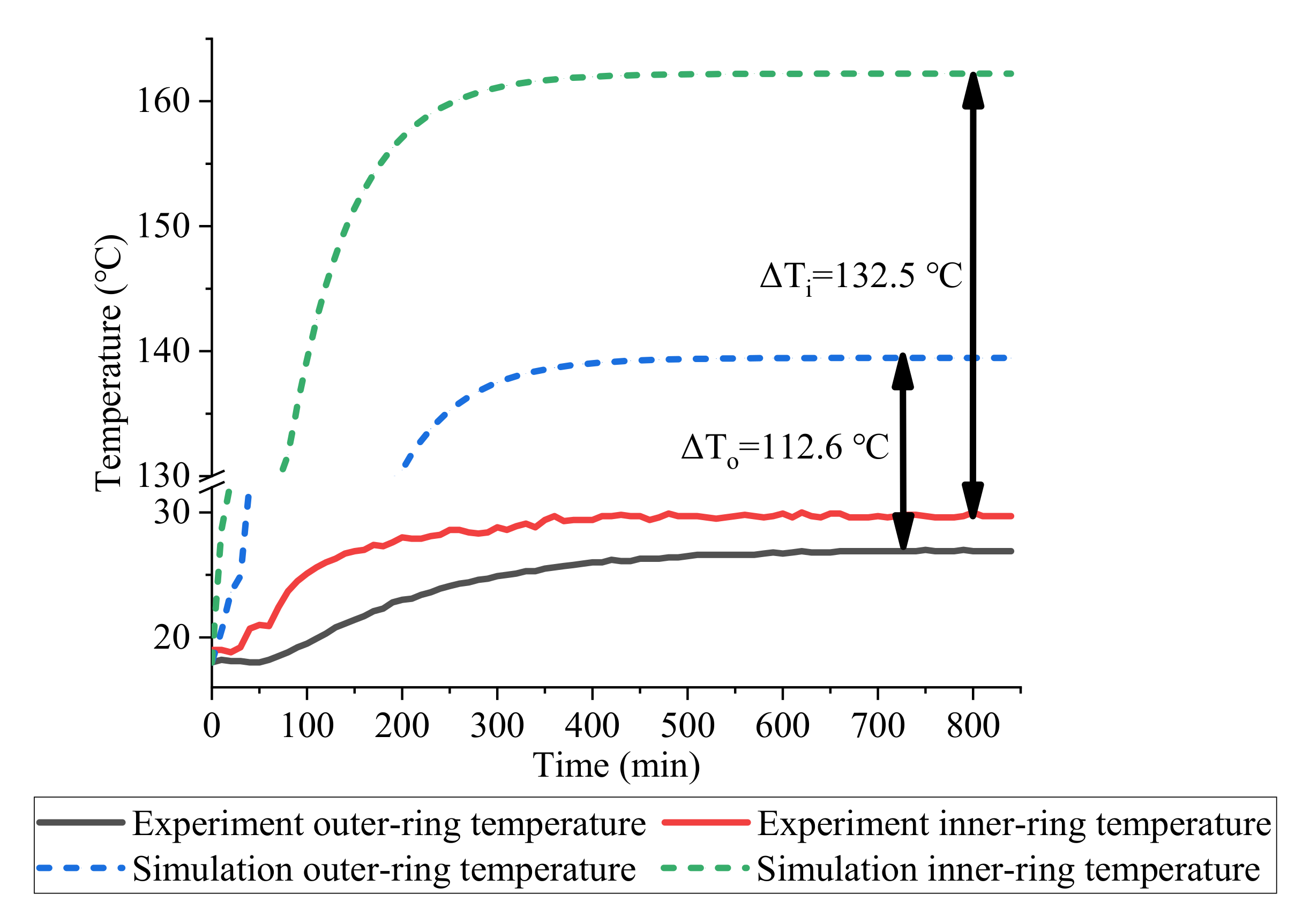

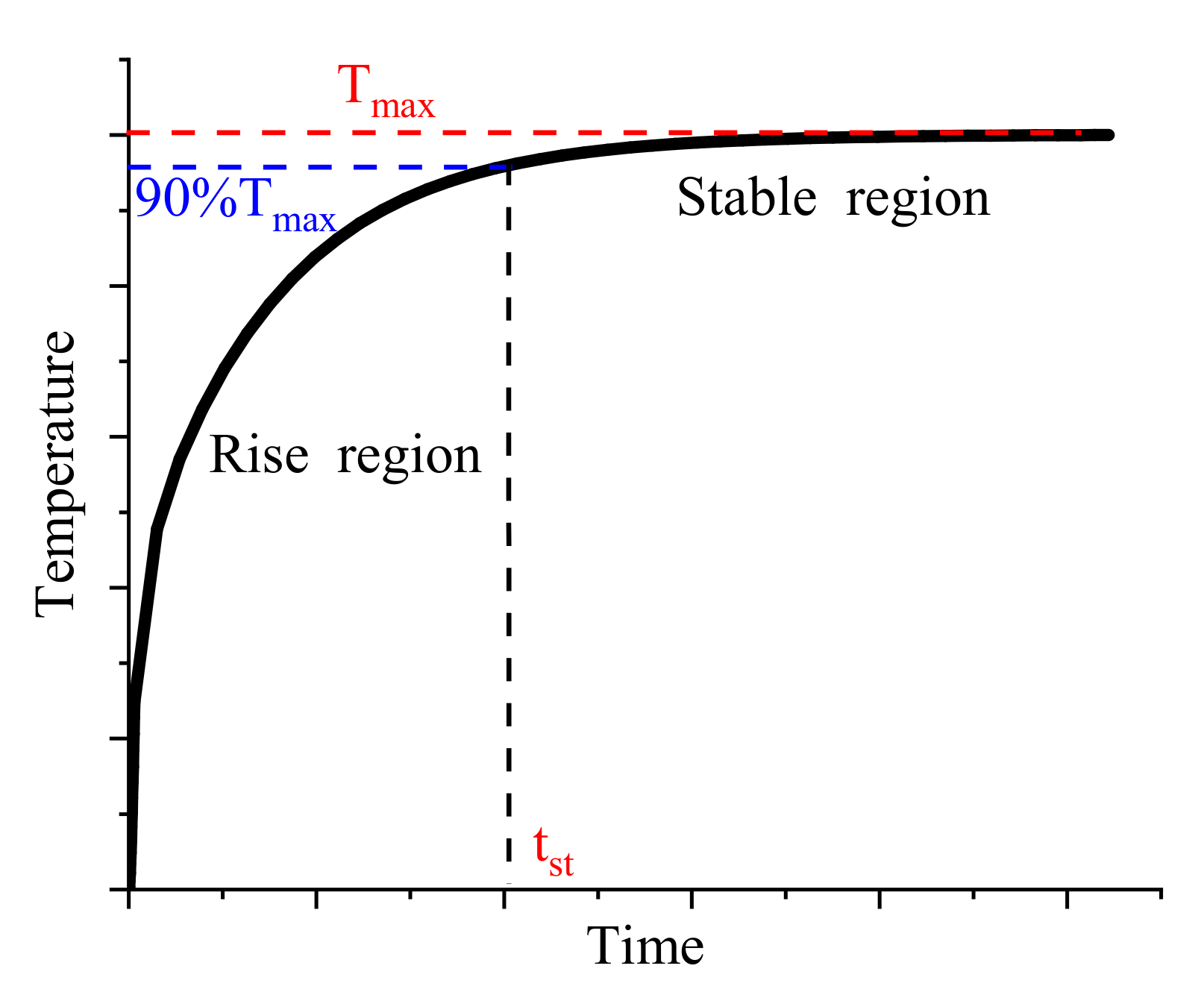

3.2.1. Selection of Transient Evaluation Indexes

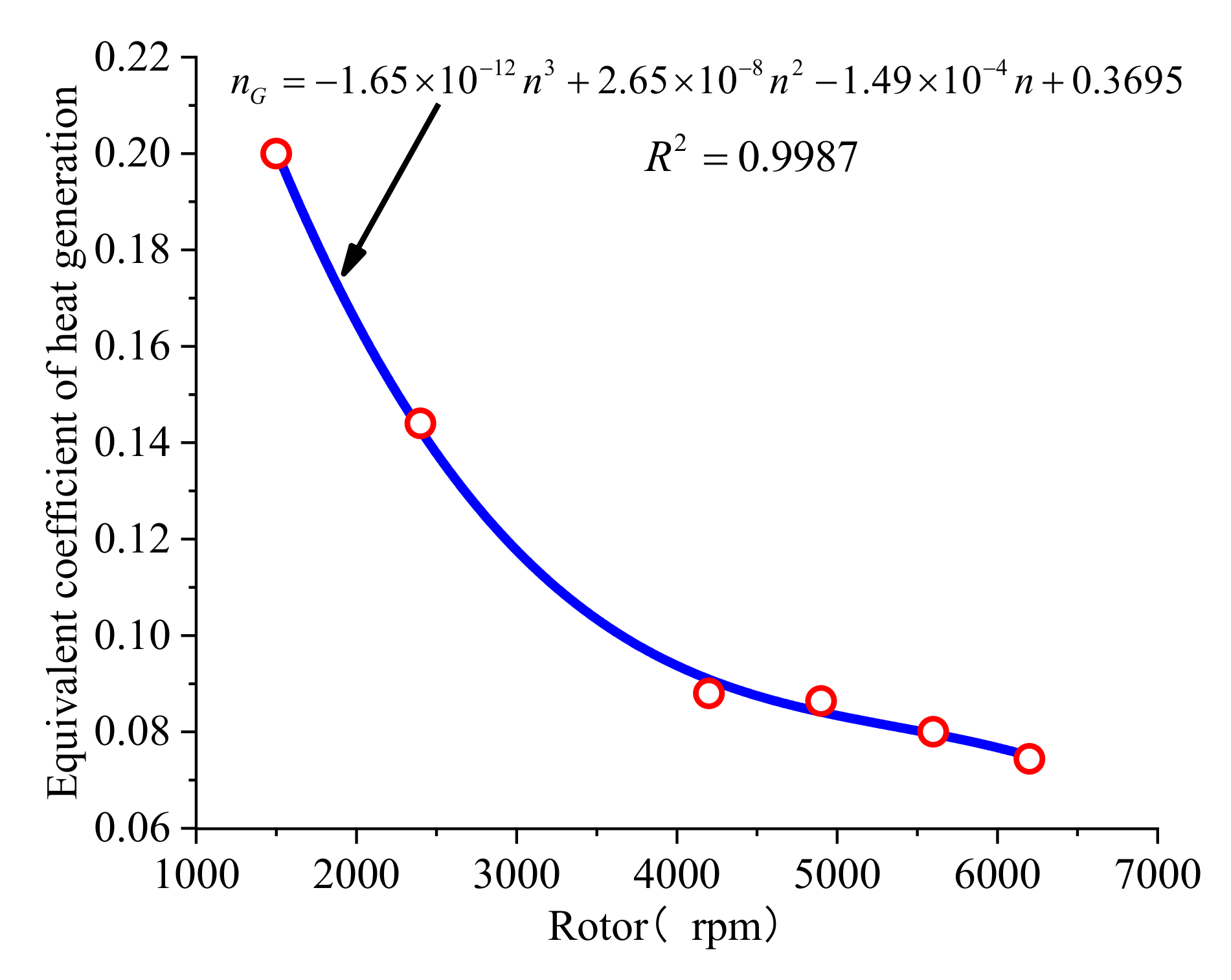

3.2.2. Empirical Formula Correction

4. Analysis of the Thermal Performance and Temperature Field

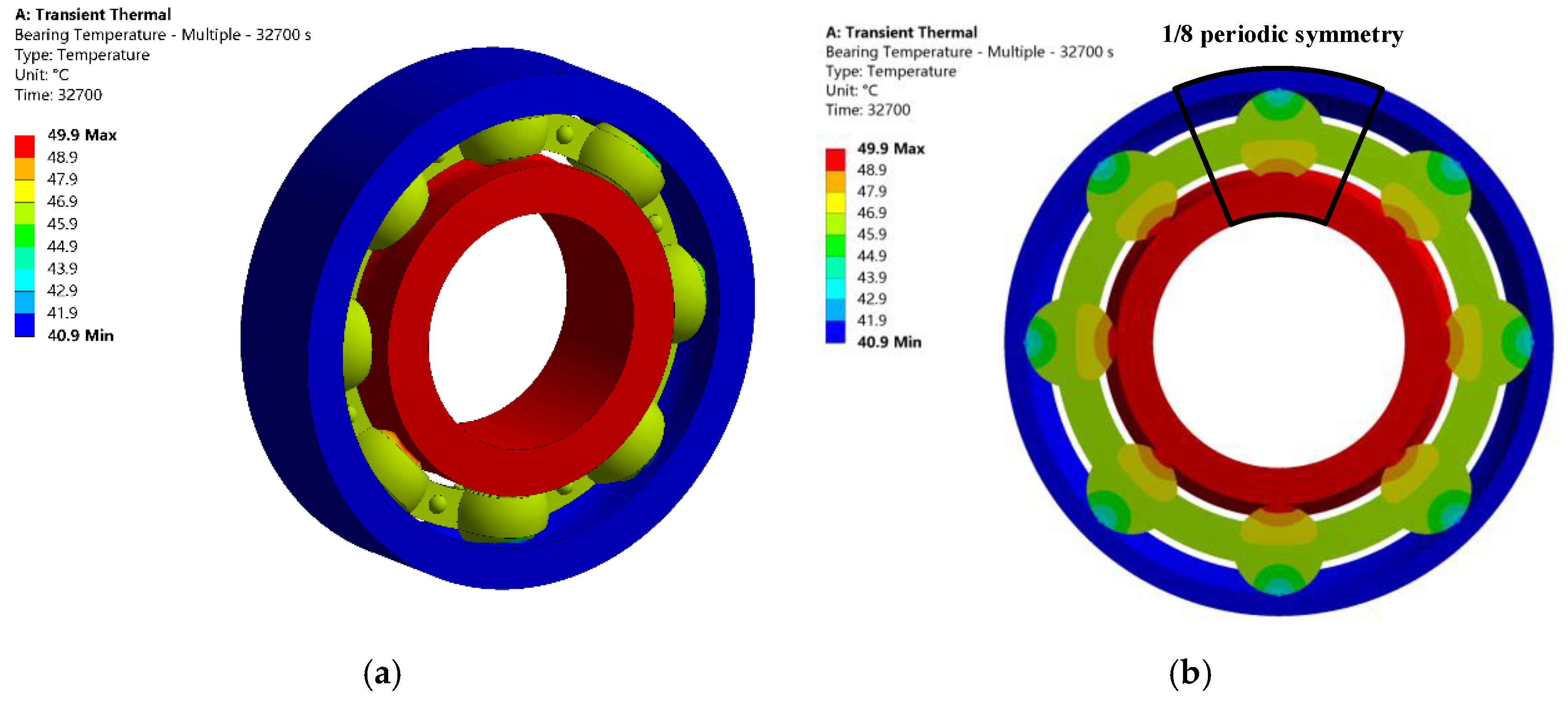

4.1. Analysis of the Temperature Distribution of the Rolling Bearing

4.2. Influence of Speed and Load on Bearing Temperature

5. Conclusions

- (1)

- A correction of the mathematical model related to temperature analysis is proposed, and an accurate calculation formula for the heat generation and lubricant convection heat transfer coefficient of a ball bearing at the non-driving end in the traction motor of a high-speed EMU is derived. The accuracy of results is verified with durability experiment data.

- (2)

- The temperature distribution law of a grease-lubricated bearing under different working conditions is studied, and the heat transfer mechanism of each component of the rolling bearing is revealed. The ball bearing shows an obvious temperature distribution, with the temperature gradually falling from the inner ring to the outer ring.

- (3)

- Under the condition of constant load/variable speed and constant speed/variable load, the influence of bearing speed and radial load on bearing temperature is analyzed. The results show that the contribution of speed to bearing temperature is much higher than that of load.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| bearing rated static load (N) | bearing speed (r/min) | ||

| bearing pitch diameter (m) | speed of bearing cage (r/min) | ||

| diameter of bearing chamber (m) | equivalent coefficient of convective heat transfer | ||

| coefficient related to bearing type and lubrication method | fitted equivalent coefficient formula of heat generation | ||

| coefficient related to bearing type and load | bearing equivalent static load (N) | ||

| bearing radial load (N) | calculated load to determine bearing friction moment (N) | ||

| bearing axial load (N) | lubricant grease Prandtl number | ||

| heat generation (W) | transient stability time | ||

| corrected heat generation (W) | final temperature stability value | ||

| lubricant grease convective heat transfer coefficient (W·m−2·°C−1) | surface speed of bearing cage (m/s) | ||

| corrected lubricant convection heat transfer coefficient | flow rate of air (m/s) | ||

| lubricant grease thermal conductivity (W·m−1·K−1) | lubricant kinematic viscosity(m2/s) | ||

| thermal conductivity of air (W·m−1·K−1) | lubricant grease kinematic viscosity (m2/s) | ||

| friction torque of rolling bearing(N·m) | kinematic viscosity of air(m2/s) | ||

| moment related to lubricant hydrodynamic losses (N·m) | convection heat transfer coefficient between bearing outer surface and air | ||

| moment related to load various friction losses (N·m) |

References

- Yu, G. Fault feature extraction using independent component analysis with reference and its application on fault diagnosis of rotating machinery. Neural Comput. Appl. 2015, 26, 187–198. [Google Scholar] [CrossRef]

- Huang, W.; Sun, H.; Luo, J.; Wang, W. Periodic feature oriented adapted dictionary free OMP for rolling element bearing incipient fault diagnosis. Mech. Syst. Signal Process. 2019, 126, 137–160. [Google Scholar] [CrossRef]

- Kavathekar, S.; Upadhyay, N.; Kankar, P.K. Fault Classification of Ball Bearing by Rotation Forest Technique. Procedia Technol. 2016, 23, 187–192. [Google Scholar] [CrossRef]

- Wang, S.; Cusano, C.; Conry, T.F. A dynamic model of the torque and heat generation rate in tapered roller bearings under excessive sliding conditions. Tribol. Trans. 1993, 36, 513–524. [Google Scholar] [CrossRef]

- Palmgren, A. Ball and Roller Bearing Engineering, 3rd ed.; SKF Industries Inc.: Philadelphia, PA, USA, 1959. [Google Scholar]

- Harris, T.A. Rolling Bearing Analysis, 2nd ed.; John Wiley and Sons: New York, NY, USA, 1984. [Google Scholar]

- Changenet, C.; Marlot, X.O.; Velex, P. Power loss predictions in geared transmissions using thermal networks-applications to a six-speed manual gearbox. J. Mech. Des. 2006, 128, 618–625. [Google Scholar] [CrossRef]

- Ma, F.; Li, Z.; Qiu, S.; Wu, B.; An, A. Transient thermal analysis of grease-lubricated spherical roller bearings. Tribol. Int. 2016, 93, 115–123. [Google Scholar] [CrossRef]

- Hao, X.; Yun, X.; Han, Q. Thermal-Fluid-Solid Coupling in Thermal Characteristics Analysis of Rolling Bearing System under Oil Lubrication. J. Tribol. 2019, 142, 1–41. [Google Scholar] [CrossRef]

- Zheng, D.; Chen, W. Thermal performances on angular contact ball bearing of high-speed spindle considering structural constraints under oil-air lubrication. Tribol. Int. 2017, 109, 593–601. [Google Scholar] [CrossRef]

- Yan, W.; Xiao-Dong, R.; Xue-Song, L.; Chun-Wei, G. Numerical Investigation of Air-Oil-Thermal Coupling Mechanism in Floating Ring Bearings. J. Tribol. 2017, 140, 031701. [Google Scholar] [CrossRef]

- Sibilli, T.; Igie, U. Transient Thermal Modeling of Ball Bearing Using Finite Element Method. J. Eng. Gas Turbines Power: Trans. ASME 2018, 140, 032501. [Google Scholar] [CrossRef]

- Pouly, F.; Changenet, C.; Ville, F. Investigations on the power losses and thermal behavior of rolling element bearings. Proc. Inst. Mech. Eng. Part J: J. Eng. Tribol. 2010, 224, 925–933. [Google Scholar] [CrossRef]

- Neurouth, A.; Changenet, C.; Ville, F.; Arnaudon, A. Thermal modeling of a grease lubricated thrust ball bearing. Proc. Inst. Mech. Eng. Part J: J. Eng. Tribol. 2014, 228, 1266–1275. [Google Scholar] [CrossRef]

- Li, X.H.; Lv, Y.F.; Yan, K.; Liu, J.; Hong, J. Study on the influence of thermal characteristics of rolling bearings and spindle resulted in condition of improper assembly. Appl. Therm. Eng. 2017, 114, 221–233. [Google Scholar] [CrossRef]

- Yan, K.; Hong, J.; Zhang, J.; Mi, W.; Wu, W. Thermal-deformation coupling in thermal network for transient analysis of spindle-bearing system. Int. J. Therm. Sci. 2016, 104, 1–12. [Google Scholar] [CrossRef]

- Blanuša, V.; Zeljković, M.; Milisavlevich, B.M.; Savić, B. Mathematical modelling of thermal behaviour of cylindrical roller bearing for towed railway vehicles. Teh. Vjesn. Tech. Gaz. 2017, 24, 211–217. [Google Scholar]

- Ai, S.; Wang, W.; Wang, Y.; Zhao, Z. Temperature rise of double-row tapered roller bearings analyzed with the thermal network method. Tribol. Int. 2015, 87, 11–22. [Google Scholar] [CrossRef]

- De-Xing, Z.; Weifang, C.; Miaomiao, L. An optimized thermal network model to estimate thermal performances on a pair of angular contact ball bearings under oil-air lubrication. Appl. Therm. Eng. 2018, 131, 328–339. [Google Scholar] [CrossRef]

- Song, Y.; Gu, C.W. Development and Validation of a Three-Dimensional Computational Fluid Dynamics Analysis for Journal Bearings Considering Cavitation and Conjugate Heat Transfer. J. Eng. Gas Turbines Power: Trans. ASME 2015, 137, 122502. [Google Scholar] [CrossRef]

- Eckert, E. Introduction to the Transfer of Heat and Mass; McGraw-Hill: New York, NY, USA, 1950. [Google Scholar]

- Ma, C.; Yang, J.; Zhao, L.; Mei, X.; Shi, H. Simulation and experimental study on the thermally induced deformations of high-speed spindle system. Appl. Therm. Eng. 2015, 86, 251–268. [Google Scholar] [CrossRef]

- Takabi, J.; Khonsari, M.M. Experimental testing and thermal analysis of ball bearings. Tribol. Int. 2013, 60, 93–103. [Google Scholar] [CrossRef]

- Badruddin, I.A.; Zainal, Z.A.; Narayana, P.A.; Seetharamu, K.N. Numerical analysis of convection conduction and radiation using a non-equilibrium model in a square porous cavity. Int. J. Therm. Sci. 2007, 46, 20–29. [Google Scholar] [CrossRef]

- Burton, R.A.; Staph, H.E. Thermally activated seizure of angular contact bearing. ASLE Trans. 1967, 10, 408–417. [Google Scholar] [CrossRef]

- Mcgregor, W.M.; Fomara, D.; Pellizzon, T.; Bassi, G.L. Process for the Cleaning of Oil and Gas Wellbores. U.S. Patent 6672388, 27 May 2004. [Google Scholar]

- Crecelius, W.J.; Pirvics, J. Computer Program Operation Manual on SHABERTH. A Computer Program for the Analysis of the Steady State and Transient Thermal Performance of Shaft-Bearing Systems; SKF Industries INC King of Prussia PA Research LAB; Defense Technical Information Center: Fort Belvoir, VA, USA, 1976. [Google Scholar]

| Type | Out Diameter /mm | Inner Diameter /mm | Number of Balls/Rollers | Width/mm |

|---|---|---|---|---|

| Ball bearing | 120 | 55 | 8 | 29 |

| Type | Oil-Mist Lubrication | Oil-Bath/Grease Lubrication | Vertical Oil-Bath/Spray-Grease Lubrication |

|---|---|---|---|

| Ball bearing | 0.7~1 | 1.5~2 | 3~4 |

| Type | ||

|---|---|---|

| Ball bearing |

| Base-Oil Type | Kinematic Viscosity | Thermal Conductivity | Prandtl Number |

|---|---|---|---|

| Synthetic oil | 88.74 | 0.1324 | 1532.44 |

| Time/min | 90 | 180 | 270 | 360 | 450 | 540 |

|---|---|---|---|---|---|---|

| Speed/rpm | 1500 | 2400 | 4200 | 4900 | 5600 | 6200 |

| Radial load/N | 2650 | 2650 | 2650 | 2650 | 2650 | 2650 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Cao, J.; Tong, Q.; An, G.; Liu, R.; Zhang, Y.; Yan, H. Study on the Thermal Performance and Temperature Distribution of Ball Bearings in the Traction Motor of a High-Speed EMU. Appl. Sci. 2020, 10, 4373. https://doi.org/10.3390/app10124373

Wang Y, Cao J, Tong Q, An G, Liu R, Zhang Y, Yan H. Study on the Thermal Performance and Temperature Distribution of Ball Bearings in the Traction Motor of a High-Speed EMU. Applied Sciences. 2020; 10(12):4373. https://doi.org/10.3390/app10124373

Chicago/Turabian StyleWang, Yu, Junci Cao, Qingbin Tong, Guoping An, Ruifang Liu, Yihuang Zhang, and Hua Yan. 2020. "Study on the Thermal Performance and Temperature Distribution of Ball Bearings in the Traction Motor of a High-Speed EMU" Applied Sciences 10, no. 12: 4373. https://doi.org/10.3390/app10124373

APA StyleWang, Y., Cao, J., Tong, Q., An, G., Liu, R., Zhang, Y., & Yan, H. (2020). Study on the Thermal Performance and Temperature Distribution of Ball Bearings in the Traction Motor of a High-Speed EMU. Applied Sciences, 10(12), 4373. https://doi.org/10.3390/app10124373