Quality Monitoring for Micro Resistance Spot Welding with Class-Imbalanced Data Based on Anomaly Detection

Abstract

1. Introduction

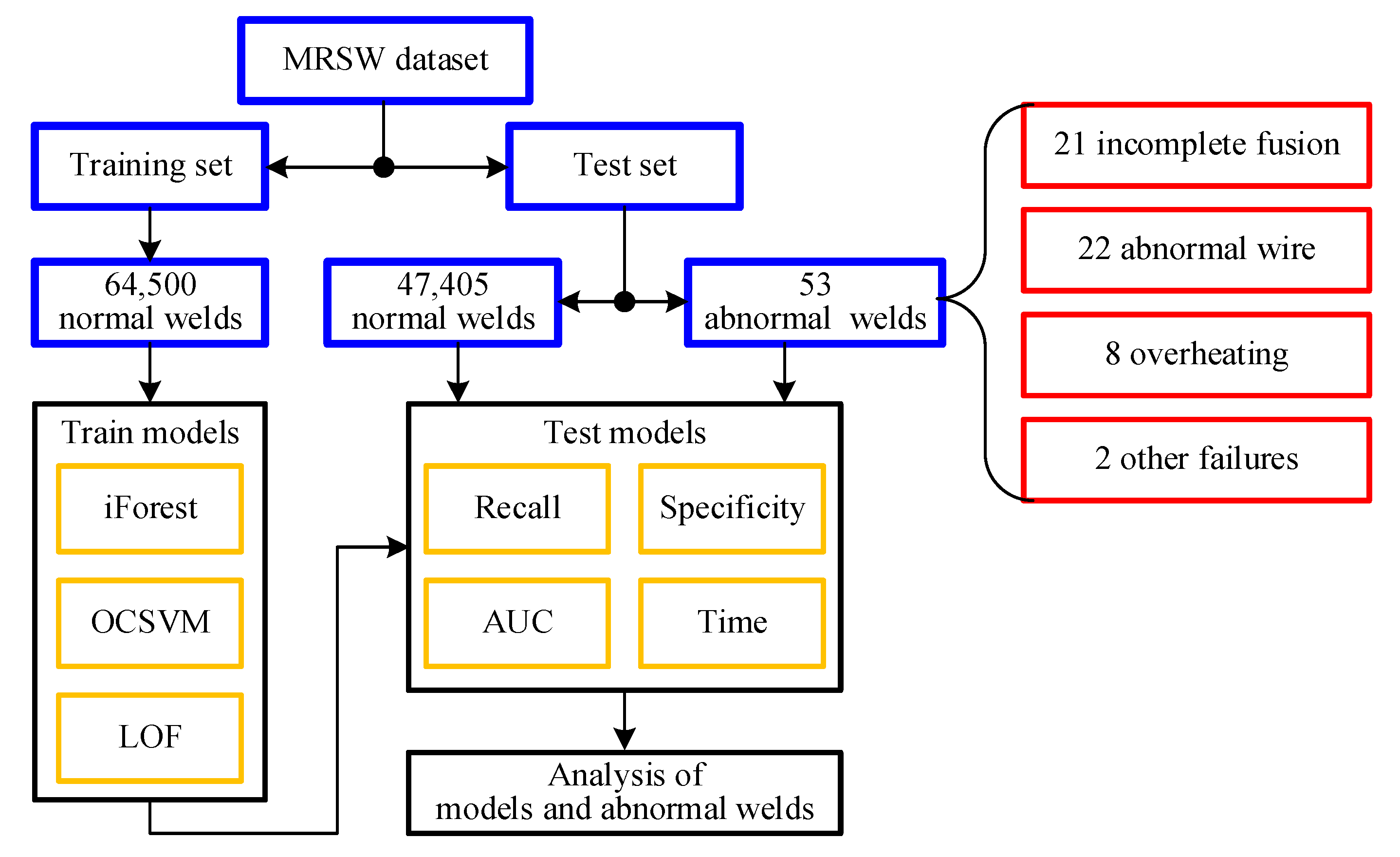

2. Materials and Methods

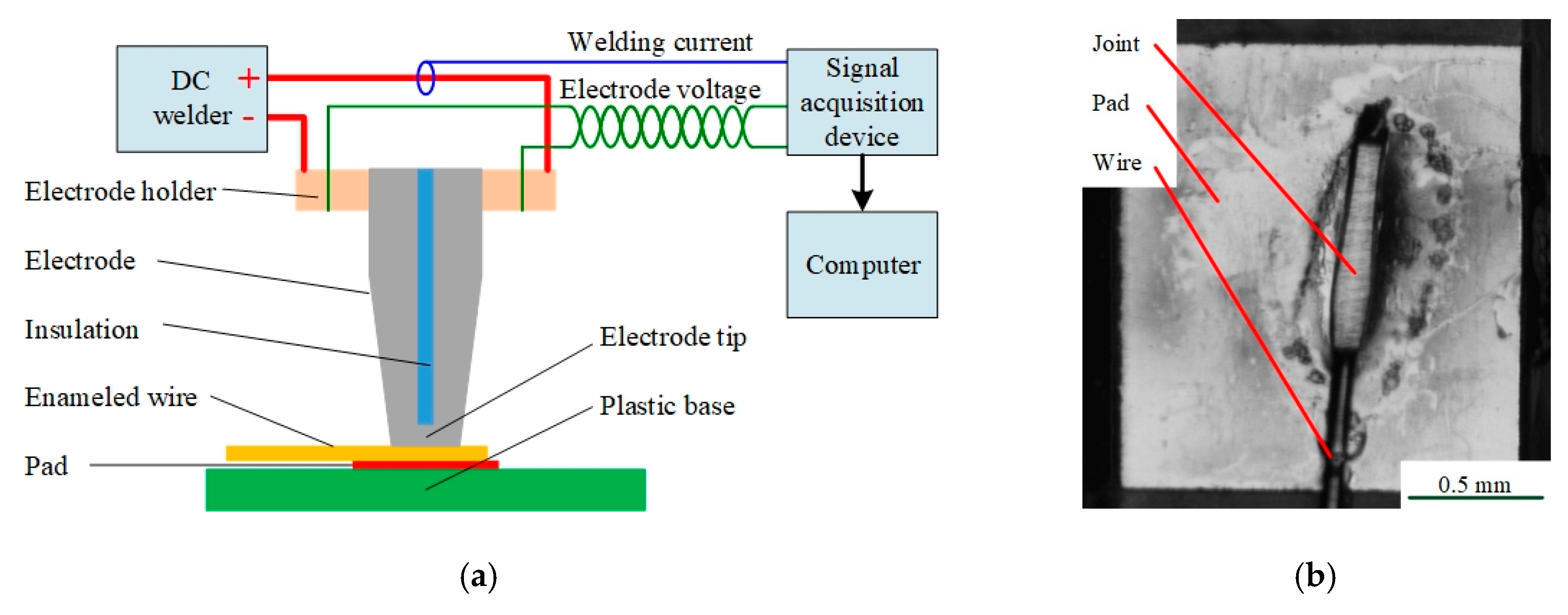

2.1. Materials and Equipment

2.2. Process Data Aacquisition

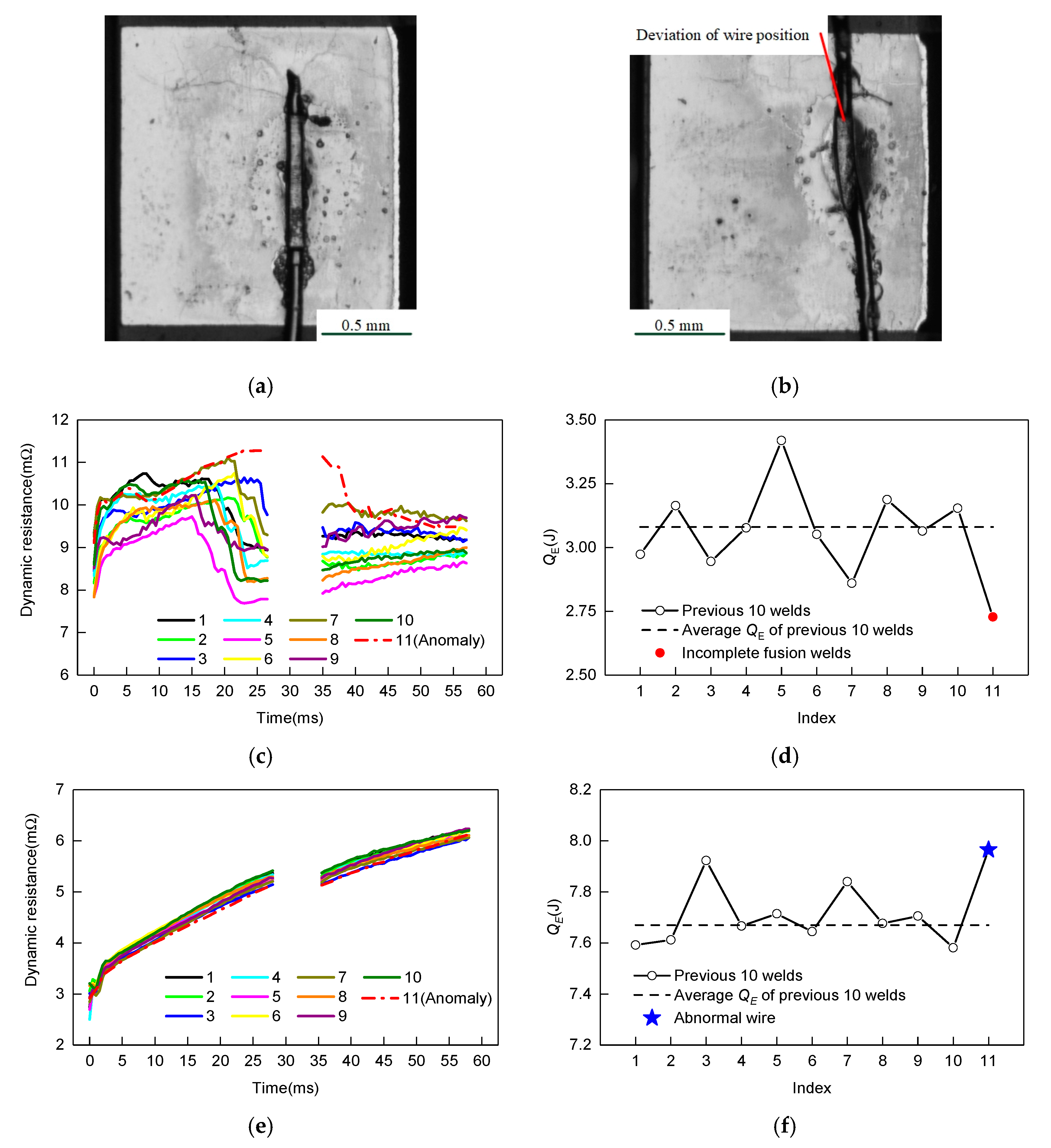

2.3. Weld Quality Determination

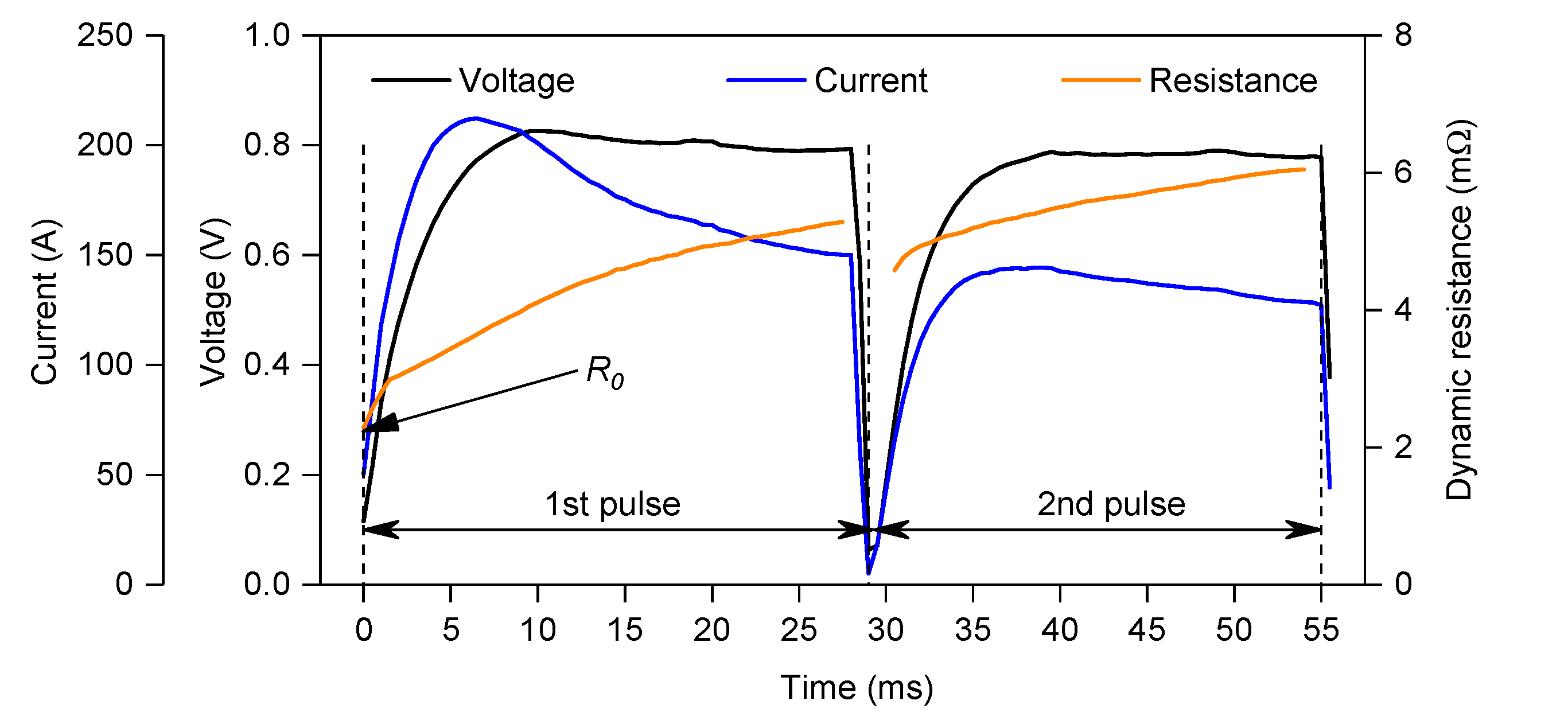

2.4. Welding Process Analysis

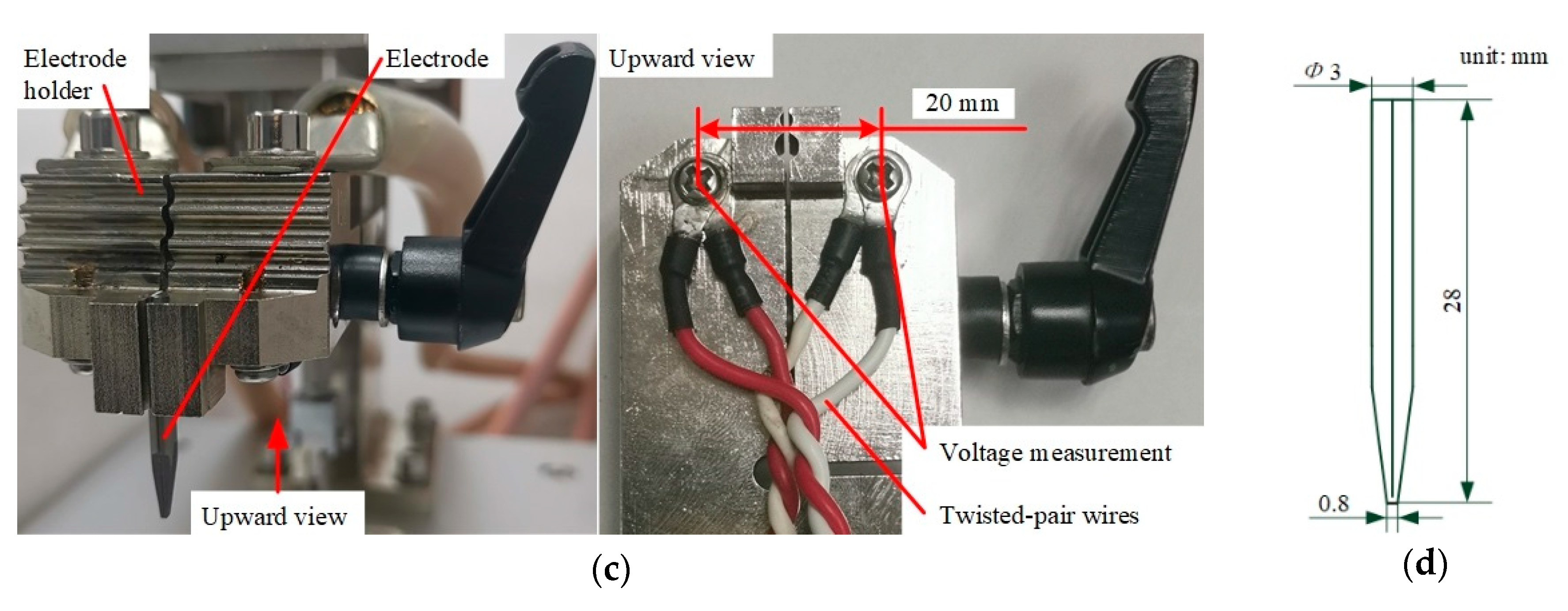

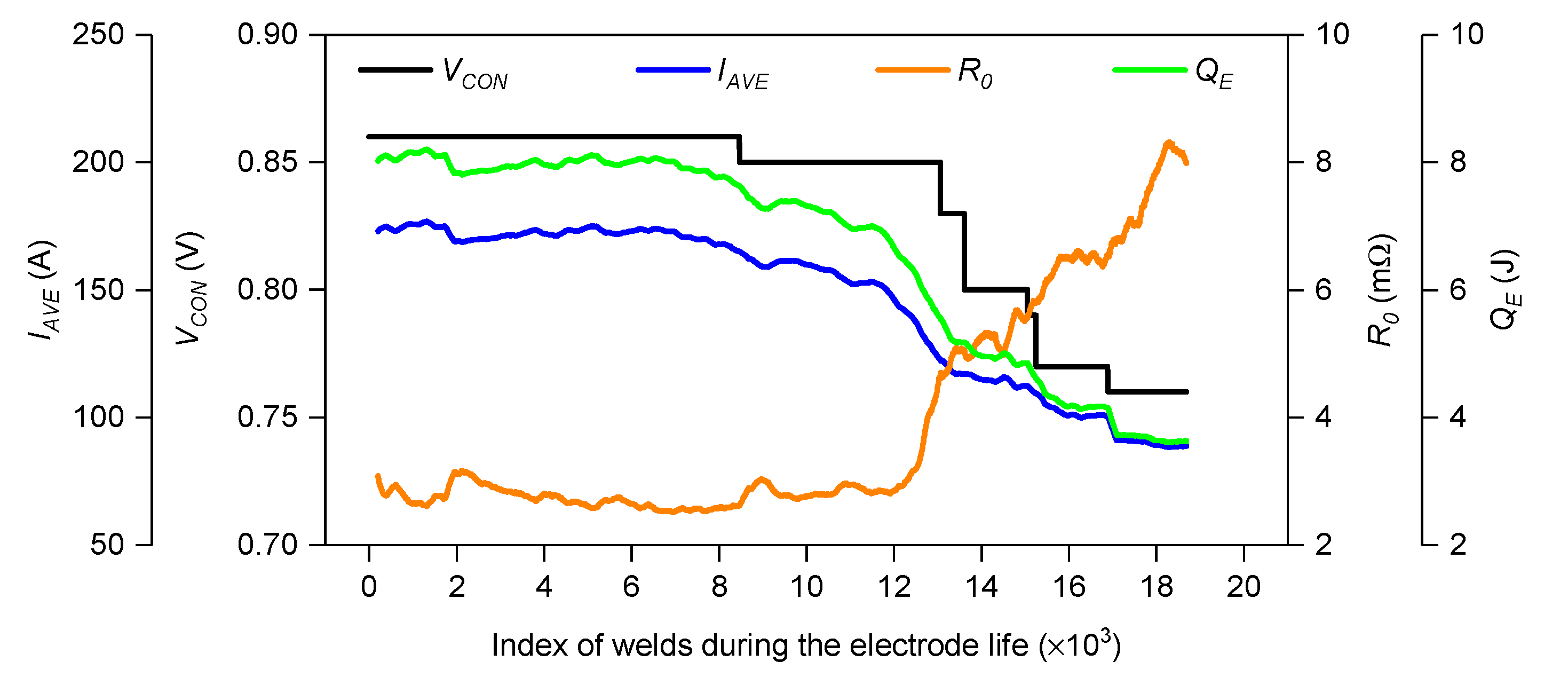

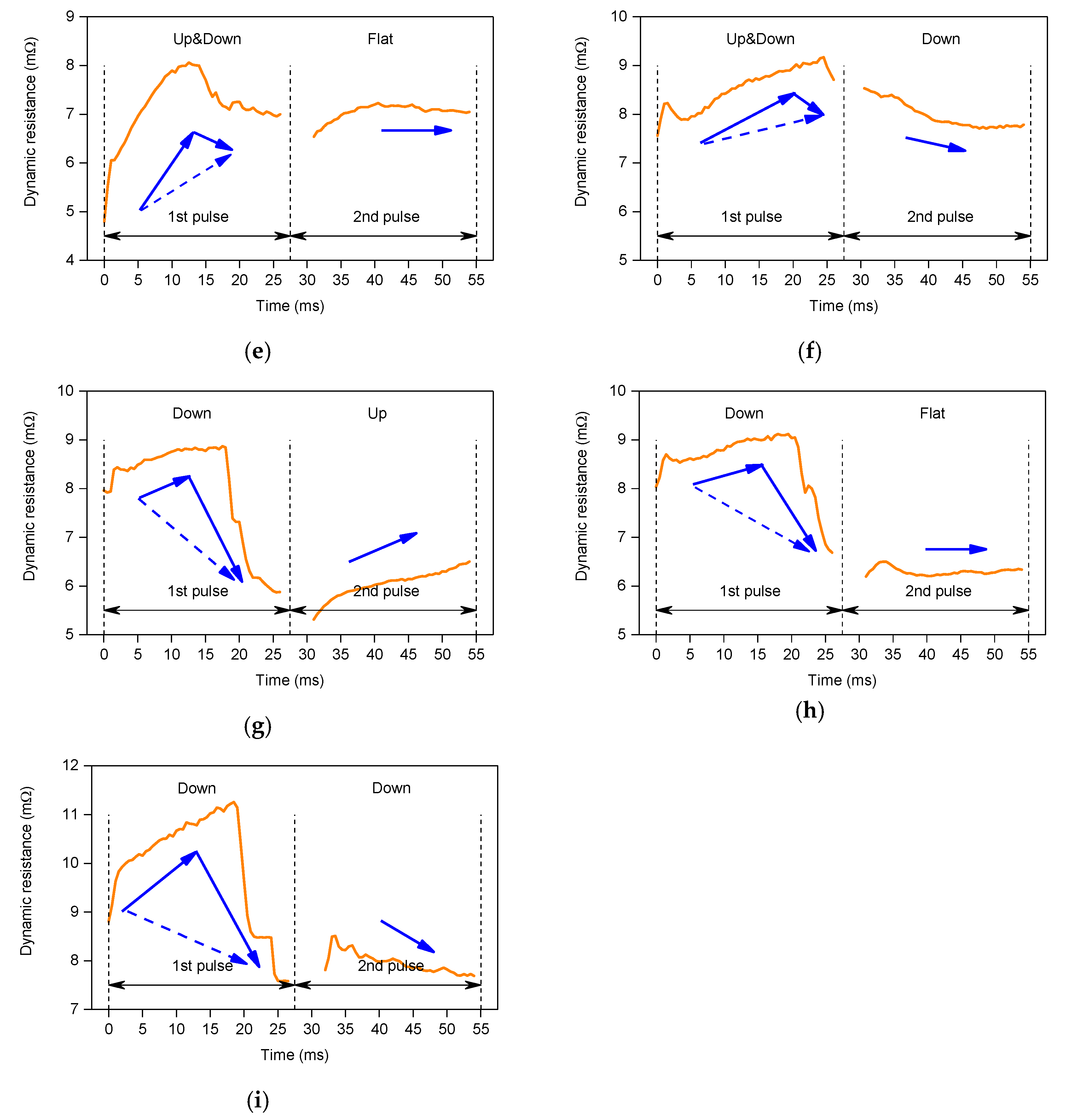

2.4.1. Dynamic Resistance

- Factor 2: the temperature increase. The electrode temperature increases because of the net energy input of electrode, and the heat transferred to the workpieces also causes their temperature to increase. Therefore, the resistivity of the electrode and workpieces increases in the welding process.

- Factor 3: the shunting effect. Because of the low resistivity of copper, more or less of the current is diverted to the joint of copper wire to the pad. The RW starts to influence Rt after the insulation coating is removed. When the RTip becomes higher in the middle and late stage of the electrode life, the resistance curve may drop obviously due to the shunting effect.

- Factor 1: its effect can be observed from the R0, due to the slight effect of Factor 2 and Factor 3 when the welding just starts. After the electrode has been used for a long time, it is prone to wear out, which is reflected in the steep rise of R0. It can be observed in Figure 3 also.

- Factor 2: it generates the ‘Up’ profile, which is the majority of the resistance curves shown in Figure 5.

- Factor 3: it can be seen obviously in the middle and late stage of electrode life. After the removal of the insulation coating, part of current is shunted to the wire and the pad, causing Rt to drop to some extent. Figure 5 shows the ‘Up&Down’ profile, but the ‘Down’ profile may occur because of the greater effect of Factor 3 than that of Factor 2.

- The balance between Factor 2 and Factor 3 may result in the ‘Flat’ profile.

2.4.2. Heat Input

2.5. Methods

2.5.1. Anomaly Detection Algorithms

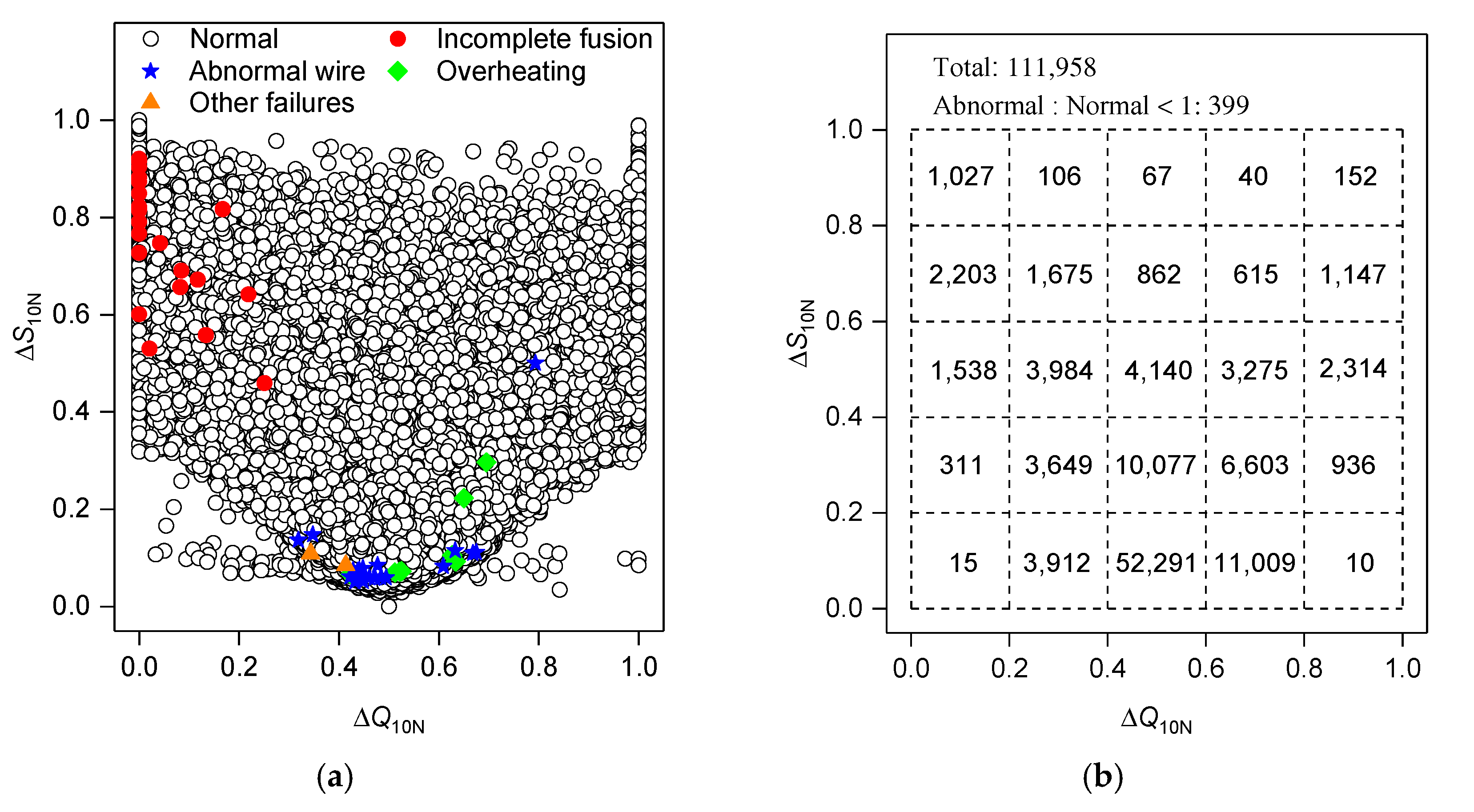

2.5.2. Feature Extraction

2.5.3. Model Construction

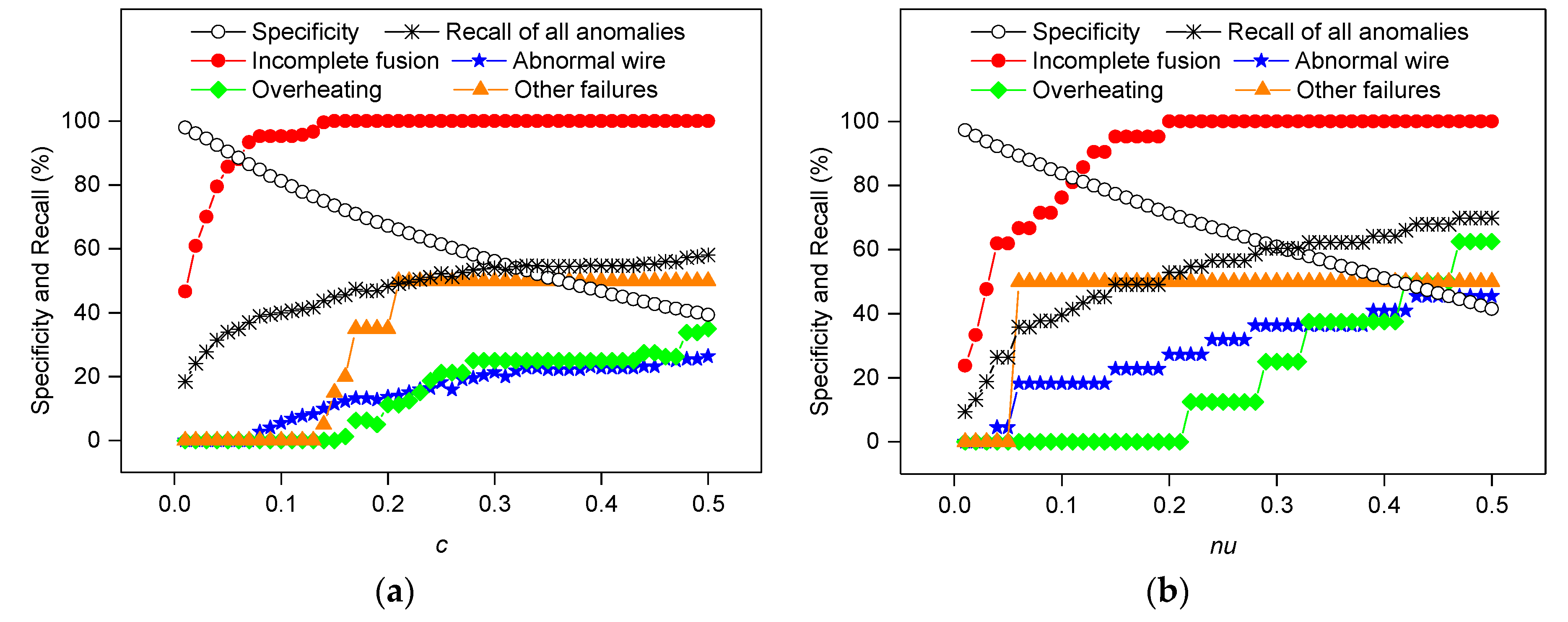

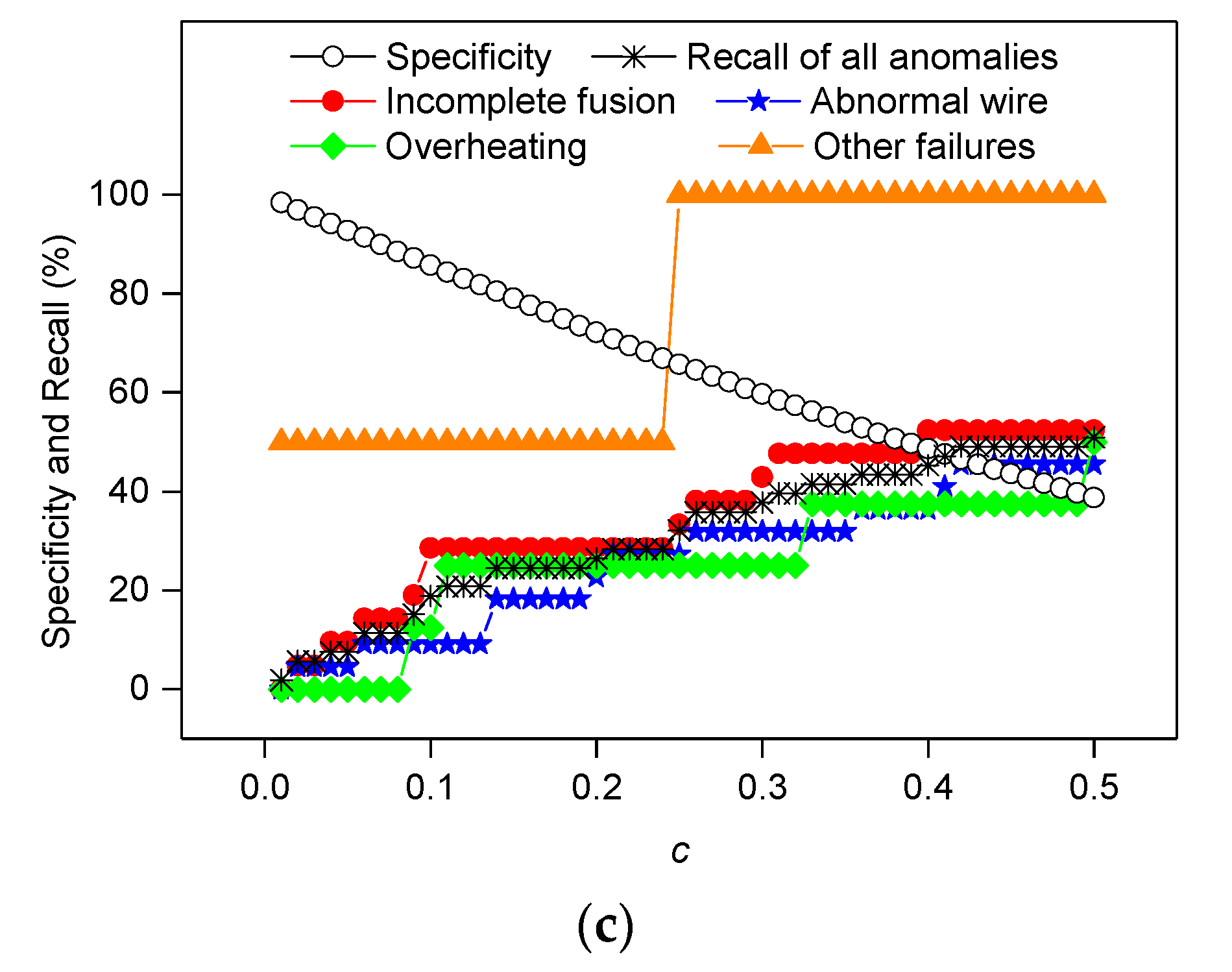

3. Results and Discussion

4. Conclusions

- Class imbalance and overlap exist in the quality estimation of MRSW production and require proper anomaly detection algorithms for quality monitoring.

- The similarity of dynamic resistance profile and heat input compared with the previous ten welds are valid features for detecting incomplete fusion welds.

- For the classification of incomplete fusion welds and normal welds, the iForest model is a good candidate with a high AUC score of 0.9525 and high efficiency.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yang, S.; Li, Y.; Lin, J. Stripping weld—A new technique of welding enamelled wires by resistance weld. Trans. China Weld. Inst. 2008, 29, 21–25. [Google Scholar]

- Zeng, J.; Cao, B.; Yang, K.; Wu, M. Analysis method of electrode ignition loss state in enameled wire resistance spot welding. J. South China Univ. Technol. 2019, 47, 32–37. [Google Scholar]

- Zhao, D.; Wang, Y.; Liang, D. Correlating variations in the dynamic power signature to nugget diameter in resistance spot welding using Kriging model. Measurement 2019, 135, 6–12. [Google Scholar] [CrossRef]

- Wan, X.; Wang, Y.; Zhao, D. Quality evaluation in small-scale resistance spot welding by electrode voltage recognition. Sci. Technol. Weld. Join. 2016, 21, 358–365. [Google Scholar] [CrossRef]

- Wan, X.; Wang, Y.; Zhao, D.; Huang, Y. A comparison of two types of neural network for weld quality prediction in small scale resistance spot welding. Mech. Syst. Signal. Process. 2017, 93, 634–644. [Google Scholar] [CrossRef]

- Yue, X.; Tong, G.; Chen, F.; Ma, X.; Gao, X. Optimal welding parameters for small-scale resistance spot welding with response surface methodology. Sci. Technol. Weld. Join. 2017, 22, 143–149. [Google Scholar] [CrossRef]

- Chen, F.; Wang, Y.; Sun, S.; Ma, Z.; Huang, X. Multi-objective optimization of mechanical quality and stability during micro resistance spot welding. Int. J. Adv. Manuf. Technol. 2019, 101, 1903–1913. [Google Scholar] [CrossRef]

- Rikka, V.R.; Sahu, S.R.; Roy, A.; Jana, S.N.; Sivaprahasam, D.; Prakash, R. Tailoring micro resistance spot welding parameters for joining nickel tab to inner aluminium casing in a cylindrical lithium ion cell and its influence on the electrochemical performance. J. Manuf. Process. 2020, 49, 463–471. [Google Scholar] [CrossRef]

- Zhou, K.; Yao, P. Overview of recent advances of process analysis and quality control in resistance spot welding. Mech. Syst. Signal Process. 2019, 124, 170–198. [Google Scholar] [CrossRef]

- Xia, Y.; Li, Y.; Lou, M.; Lei, H. Recent advances and analysis of quality monitoring and control technologies for RSW. China Mech. Eng. 2020, 31, 100–125. [Google Scholar]

- Adams, D.W.; Summerville, C.; Voss, B.M.; Jeswiet, J.; Doolan, M.C. Correlating variations in the dynamic resistance signature to weld strength in resistance spot welding using principal component analysis. J. Manuf. Sci. Eng. 2017, 139, 44502. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, J.; Yan, H.; Pang, C. Quality monitoring of spot welding with advanced signal processing and data-driven techniques. Trans. Inst. Meas. Control 2018, 40, 2291–2302. [Google Scholar] [CrossRef]

- Chen, S.; Wu, N.; Xiao, J.; Li, T.; Lu, Z. Expulsion identification in resistance spot welding by electrode force sensing based on wavelet decomposition with multi-Indexes and BP neural networks. Appl. Sci. 2019, 9, 4028. [Google Scholar] [CrossRef]

- Xing, B.; Xiao, Y.; Qin, Q. Characteristics of shunting effect in resistance spot welding in mild steel based on electrode displacement. Measurement 2018, 115, 233–242. [Google Scholar] [CrossRef]

- Wen, J.; Jia, H.; Wang, C. Quality Estimation system for resistance spot welding of stainless steel. ISIJ Int. 2019, 59, 2073–2076. [Google Scholar] [CrossRef]

- Gavidel, S.Z.; Lu, S.; Rickli, J.L. Performance analysis and comparison of machine learning algorithms for predicting nugget width of resistance spot welding joints. Int. J. Adv. Manuf. Technol. 2019, 105, 3779–3796. [Google Scholar] [CrossRef]

- Amiri, N.; Farrahi, G.H.; Kashyzadeh, K.R.; Chizari, M. Applications of ultrasonic testing and machine learning methods to predict the static & fatigue behavior of spot-welded joints. J. Manuf. Process. 2020, 52, 26–34. [Google Scholar]

- Boersch, I.; Füssel, U.; Gresch, C.; Großmann, C.; Hoffmann, B. Data mining in resistance spot welding. Int. J. Adv. Manuf. Technol. 2018, 99, 1085–1099. [Google Scholar] [CrossRef]

- Xing, B.; Xiao, Y.; Qin, Q.; Cui, H. Quality assessment of resistance spot welding process based on dynamic resistance signal and random forest based. Int. J. Adv. Manuf. Technol. 2018, 94, 327–339. [Google Scholar] [CrossRef]

- Pereda, M.; Santos, J.I.; Martín, O.; Galán, J.M. Direct quality prediction in resistance spot welding process: Sensitivity, specificity and predictive accuracy comparative analysis. Sci. Technol. Weld. Join. 2015, 20, 679–685. [Google Scholar] [CrossRef]

- Guo, H.; Li, Y.; Shang, J.; Gu, M.; Huang, Y.; Gong, B. Learning from class-imbalanced data: Review of methods and applications. Expert Syst. Appl. 2017, 73, 220–239. [Google Scholar]

- Liu, J.; Gu, J.; Li, H.; Carlson, K.H. Machine learning and transport simulations for groundwater anomaly detection. J. Comput. Appl. Math. 2020, 380, 112982. [Google Scholar] [CrossRef]

- Su, Z.; Xia, Y.; Shen, Y.; Li, Y. A novel real-time measurement method for dynamic resistance signal in medium-frequency DC resistance spot welding. Meas. Sci. Technol. 2020, 31, 55011. [Google Scholar] [CrossRef]

- Li, W.; Cerjanec, D.; Grzadzinski, G.A. A comparative study of single-phase AC and multiphase DC resistance spot welding. J. Manuf. Sci. Eng. 2005, 127, 583–589. [Google Scholar] [CrossRef]

- Liu, F.; Ting, K.; Zhou, Z. Isolation-based anomaly detection. ACM Trans. Knowl. Discov. Data 2012, 6, 1–39. [Google Scholar] [CrossRef]

- Schölkopf, B.; Platt, J.; Shawe-Taylor, J.; Smola, A.; Williamson, R. Estimating the Support of a high-dimensional distribution. Neural Comput. 2001, 13, 1443–1471. [Google Scholar] [CrossRef]

- Breunig, M.; Kriegel, H.; Ng, R.; Sander, J. LOF: Identifying density-based local outliers. In Proceedings of the 2000 ACM SIGMOD–International Conference on Management of Data, Dallas, Texas, USA, 16–18 May 2000; pp. 93–104. [Google Scholar]

- An, H.; Wang, Z.; Wang, G.; Song, Q.; Liu, F.; Zhong, C. Research on on-line monitoring of surface roughness in composite drilling and adaptive optimization of parameters. J. Mech. Eng. 2020, 56, 27–34. [Google Scholar]

- Shi, L.; Zhou, R.; Li, J.; Wang, L.; Xu, F.; Wang, Y. New energy—Load characteristic index based on time series similarity measurement. Electr. Pow. Autom. EQ. 2019, 39, 75–81. [Google Scholar]

- Qiu, Y.; Hu, H.; Zheng, J.; Chen, Q. On-line handwriting signature verification based on curve similarity. Syst. Eng. Electron. 2014, 36, 1016–1020. [Google Scholar]

- Pedregosa, F.; Varoquaux, G.; Michel, V.; Thirion, B.; Grisel, O.; Blondel, M. Scikit-learn: Machine learning in python. J. Mach. Learn. Res. 2011, 12, 2825–2830. [Google Scholar]

| Number of Heating Pulse | Voltage Setting (V) | Welding Time (ms) | Electrode Force (N) |

|---|---|---|---|

| 2 | 0.68–0.90 | 55–60 | 5.2 |

| Normal Welds | Incomplete Fusion | Abnormal Wire | Overheating | Other Failures | Defectrate |

|---|---|---|---|---|---|

| 111,905 | 21 | 22 | 8 | 2 | <0.25% |

| Main Trend | Pulse | Code | Notation |

|---|---|---|---|

| Up | 1st | 0 | Rt keeps rising mainly. |

| Up&Down | 1st | 1 | Rt starts to rise and then a drop occurs. However, it does not decline in general. |

| Down | 1st | 2 | Rt declines in general since its decline is obviously greater than its rise. |

| Up | 2nd | 0 | Rt keeps rising mainly. |

| Flat | 2nd | 1 | Rt has obvious stages of slight change despite the local increase. |

| Down | 2nd | 2 | Rt declines in general despite the local increase. |

| Profile Type | Ratio | Profile Type | Ratio | Profile Type | Ratio |

|---|---|---|---|---|---|

| Up–Up | 59.68 | Up&Down–Up | 26.86 | Down–Up | 2.10 |

| Up–Flat | 1.95 | Up&Down–Flat | 5.88 | Down–Flat | 0.65 |

| Up–Down | 1.73 | Up&Down–Down | 1.07 | Down–Down | 0.08 |

| Algorithm | Major Parameters |

|---|---|

| iForest | trees = 100, subsampling size = 256, contamination (c) ∈ [0.01, 0.02, …, 0.49, 0.49999] |

| OCSVM | kernel = ‘rbf’, gamma = ‘scale’, nu ∈ [0.01, 0.02, …, 0.49, 0.49999] |

| LOF | neighbors = 20, contamination (c) ∈ [0.01, 0.02, …, 0.49, 0.49999] |

| Algorithm | AUC | Recall | Processing Time (s) | ||

|---|---|---|---|---|---|

| Specificity of 90% | Specificity of 80% | Train | Test | ||

| iForest | 0.9525 | 0.8633 | 0.9524 | 1.79 | 1.11 |

| OCSVM | 0.9047 | 0.6437 | 0.9037 | 53.29 | 9.46 |

| LOF | NA | 0.1429 | 0.2857 | 0.43 | 0.25 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, J.; Cao, B.; Tian, R. Quality Monitoring for Micro Resistance Spot Welding with Class-Imbalanced Data Based on Anomaly Detection. Appl. Sci. 2020, 10, 4204. https://doi.org/10.3390/app10124204

Zeng J, Cao B, Tian R. Quality Monitoring for Micro Resistance Spot Welding with Class-Imbalanced Data Based on Anomaly Detection. Applied Sciences. 2020; 10(12):4204. https://doi.org/10.3390/app10124204

Chicago/Turabian StyleZeng, Jiaquan, Biao Cao, and Ran Tian. 2020. "Quality Monitoring for Micro Resistance Spot Welding with Class-Imbalanced Data Based on Anomaly Detection" Applied Sciences 10, no. 12: 4204. https://doi.org/10.3390/app10124204

APA StyleZeng, J., Cao, B., & Tian, R. (2020). Quality Monitoring for Micro Resistance Spot Welding with Class-Imbalanced Data Based on Anomaly Detection. Applied Sciences, 10(12), 4204. https://doi.org/10.3390/app10124204