A New Method of Contact Stress Measurement for Analyzing Internal Impingement Syndrome of the Shoulder: Potentials and Preliminary Evaluation

Abstract

1. Introduction

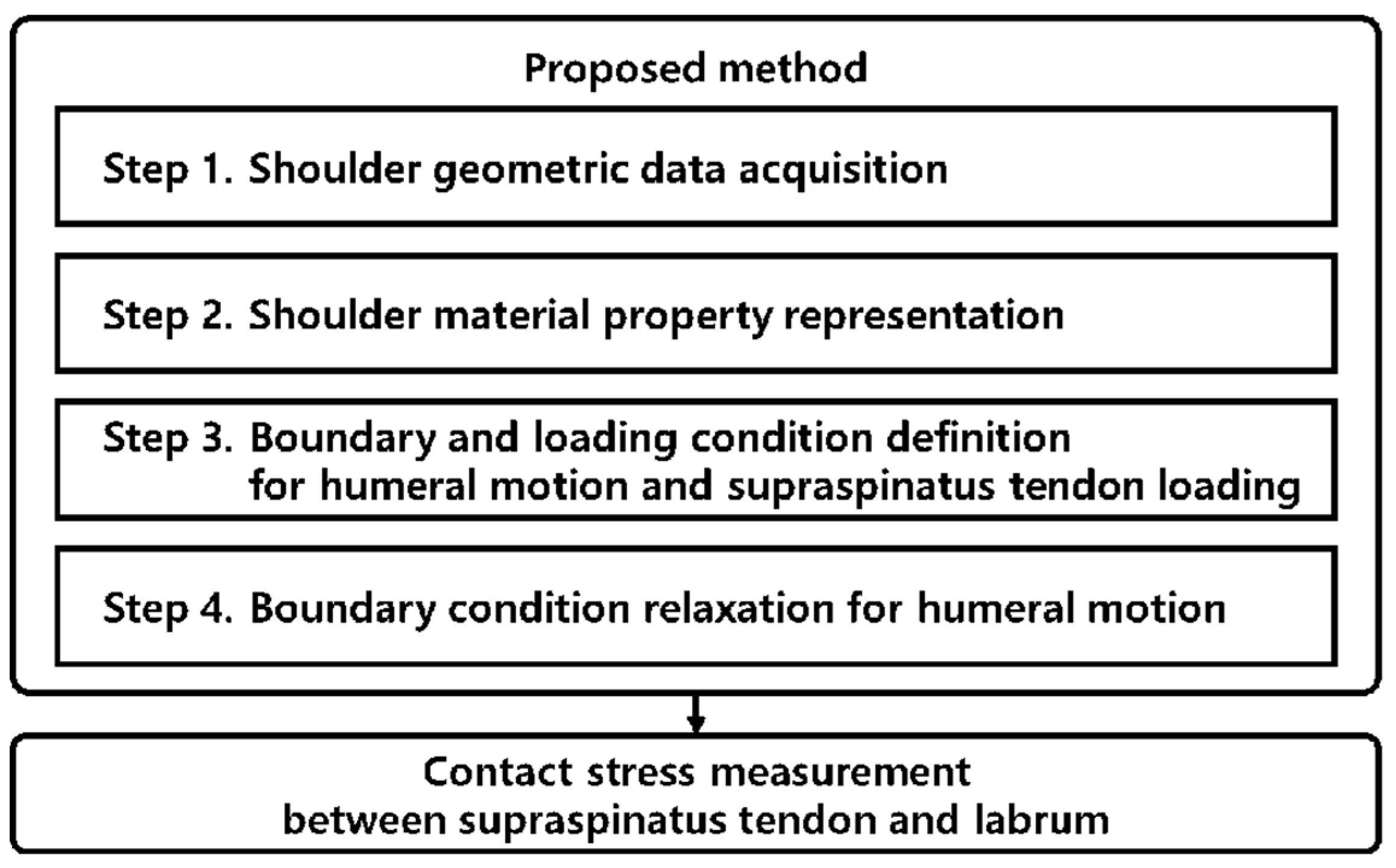

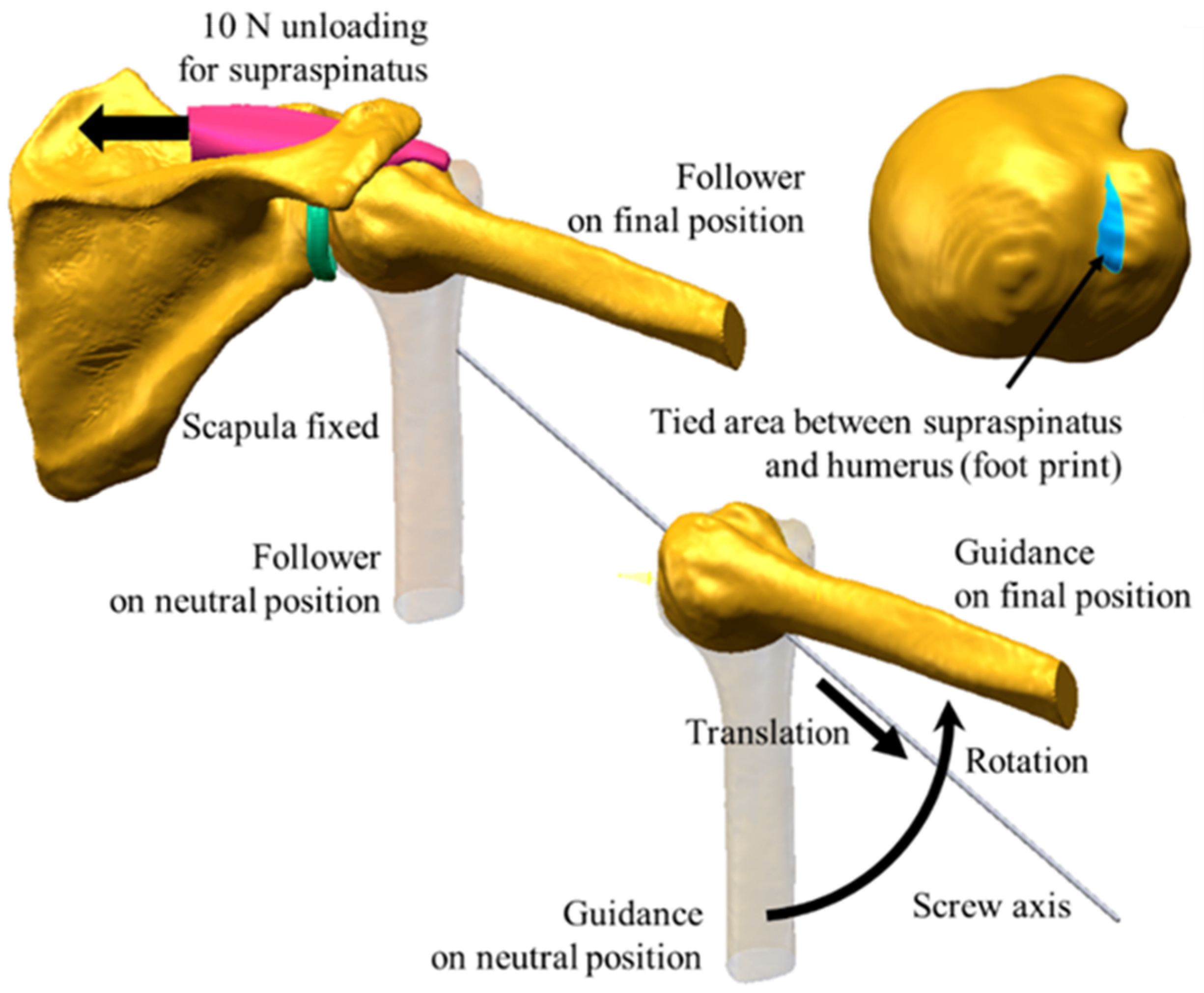

2. Materials and Methods

2.1. Design and Setting

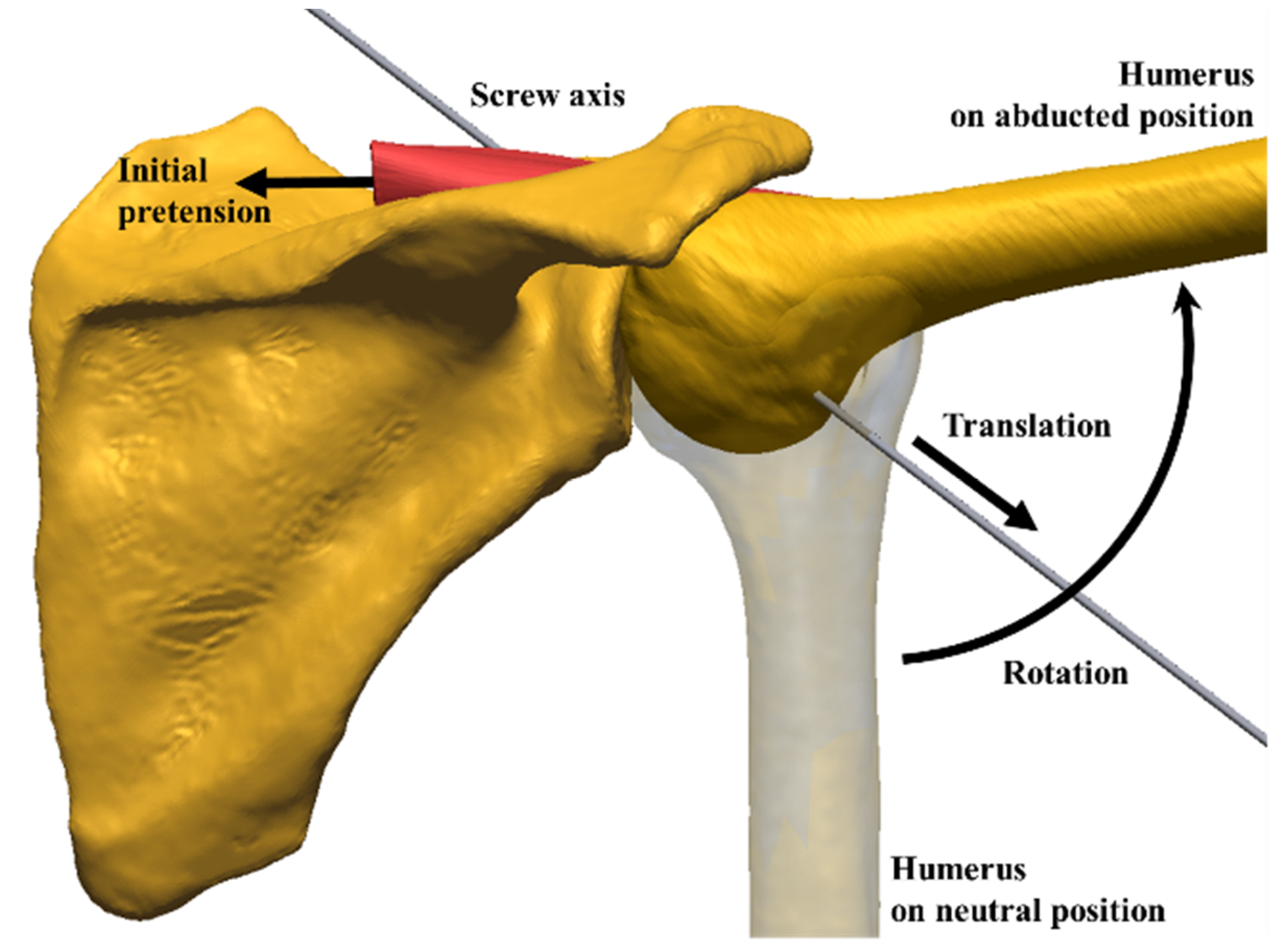

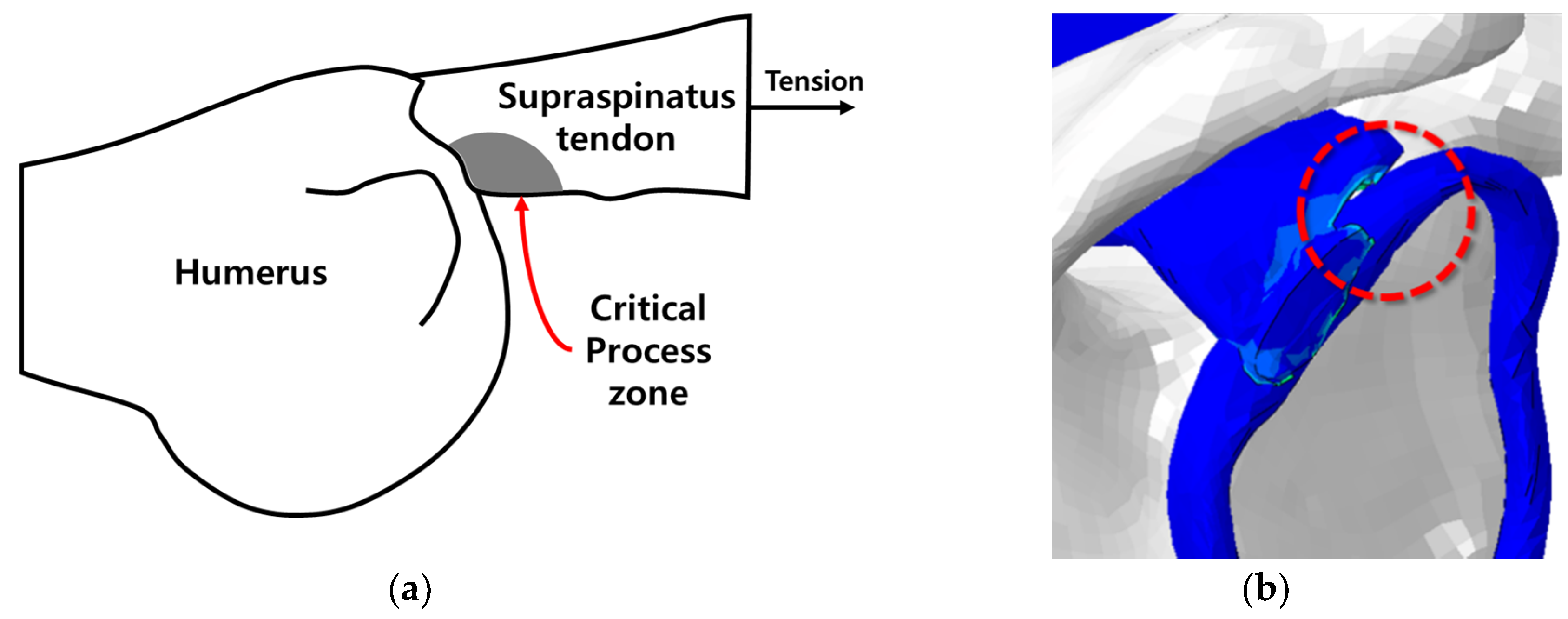

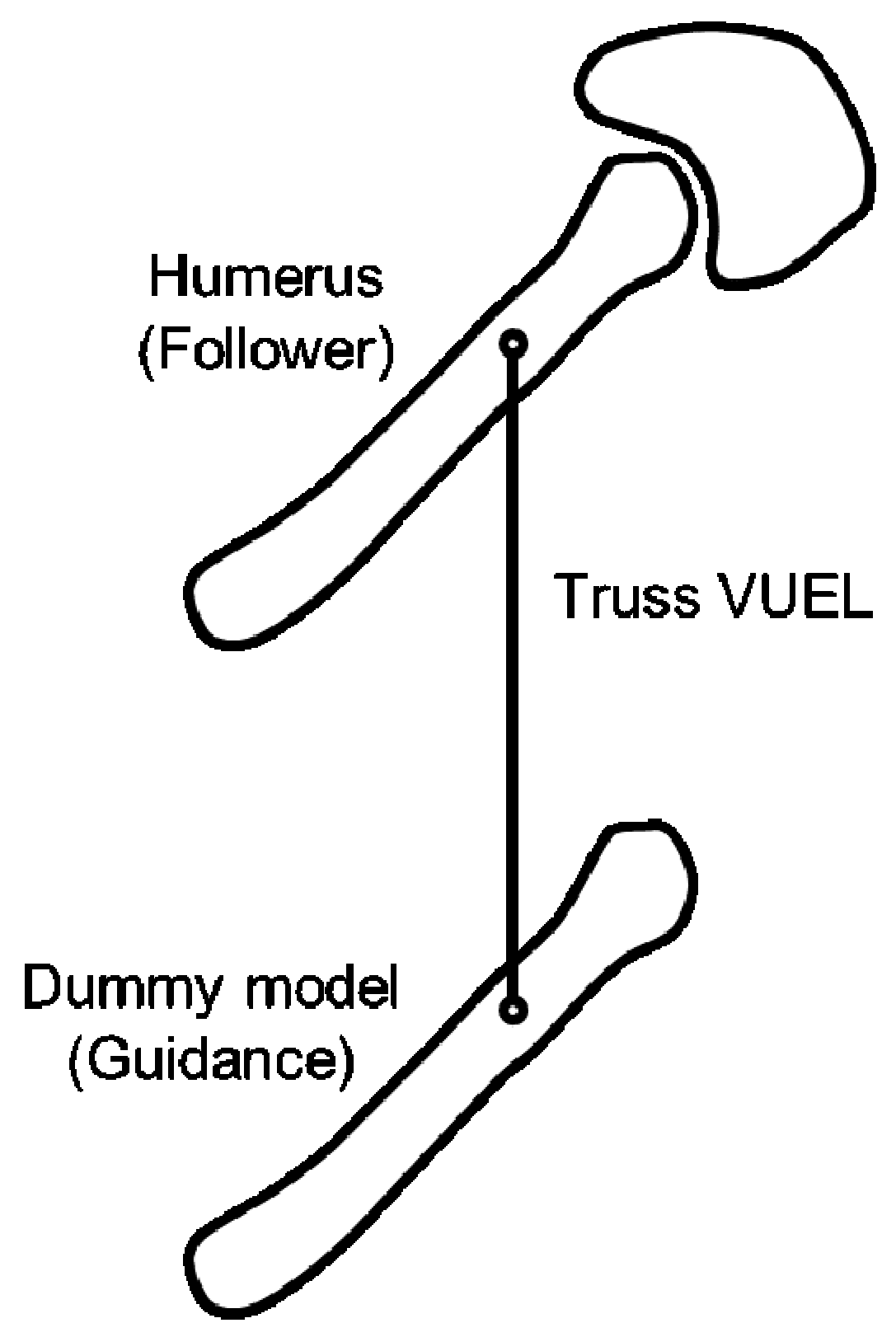

2.2. Finite Element Simulation

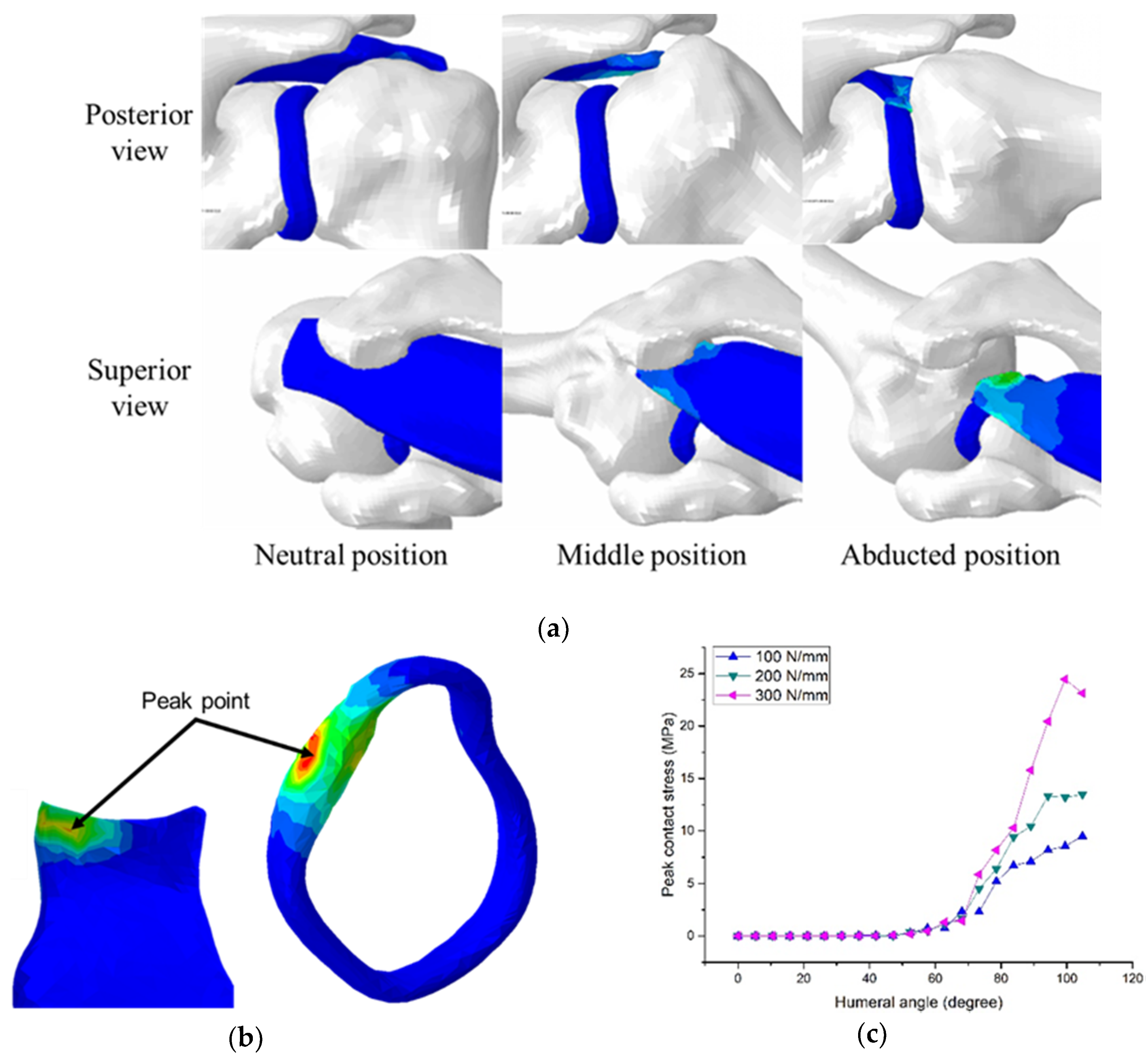

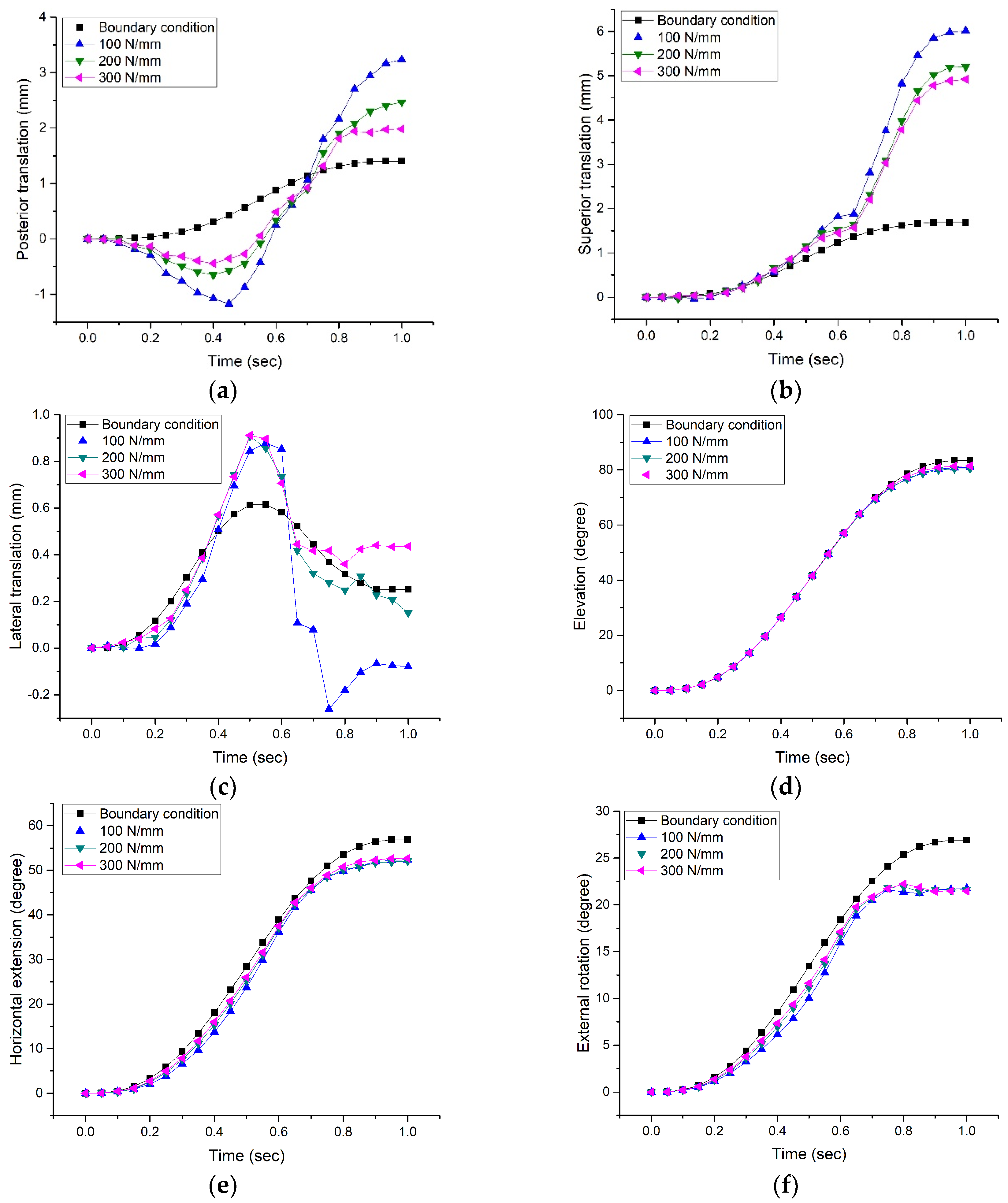

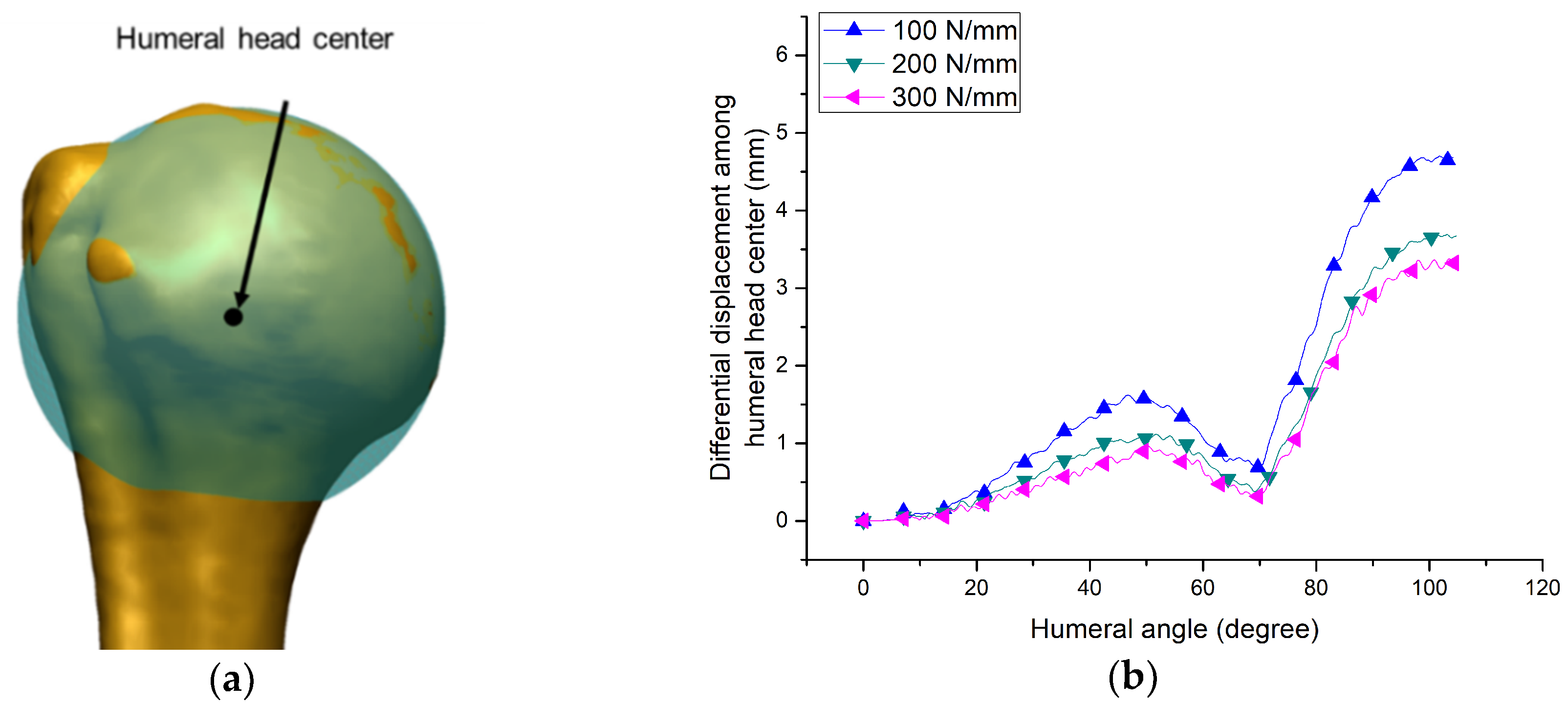

3. Results

4. Discussion

4.1. Principal Results

4.2. Limitations

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ludewig, P.M.; Reynolds, J.F. The association of scapular kinematics and glenohumeral joint pathologies. J. Orthop. Sports Phys. Ther. 2009, 39, 90–104. [Google Scholar] [CrossRef] [PubMed]

- Heyworth, B.E.; Williams, R.J. Internal impingement of the shoulder. J. Sports Med. 2009, 37, 1024–1037. [Google Scholar] [CrossRef] [PubMed]

- Halbrecht, J.L.; Tirman, P.; Atkin, D. Internal impingement of the shoulder: Comparison of findings between the throwing and nonthrowing shoulders of college baseball players. Arthroscopy 1999, 15, 253–258. [Google Scholar] [CrossRef]

- Borsa, P.A.; Wilk, K.E.; Jacobson, J.A.; Scibek, J.S.; Dover, G.C.; Reinold, M.M.; Andrews, J.R. Correlation of range of motion and glenohumeral translation in professional baseball pitchers. J. Sports Med. 2005, 33, 1392–1399. [Google Scholar] [CrossRef]

- Ostrander, R.; Escamilla, R.F.; Hess, R.; Witte, K.; Wilcox, L.; Andrews, J.R. Glenohumeral rotation deficits in high school, college, and professional baseball pitchers with and without a medial ulnar collateral ligament injury. J. Shoulder Elb. Surg. 2019, 28, 423–429. [Google Scholar] [CrossRef]

- Jobe, C.M. Posterior superior glenoid impingement: Expanded spectrum. Arthroscopy 1995, 11, 530–536. [Google Scholar] [CrossRef]

- Spiegl, U.J.; Warth, R.J.; Millett, P.J. Symptomatic internal impingement of the shoulder in overhead athletes. Sports Med. Arthrosc. Rev. 2014, 22, 120–129. [Google Scholar] [CrossRef]

- Mackenzie, T.A.; Herrington, L.; Horlsey, I.; Cools, A. An evidence-based review of current perceptions with regard to the subacromial space in shoulder impingement syndromes: Is it important and what influences it? Clin. Biomech. 2015, 30, 641–648. [Google Scholar] [CrossRef]

- Seo, Y.J.; Yoo, Y.S.; Kim, D.Y.; Noh, K.C.; Shetty, N.S.; Lee, J.H. Trans-tendon arthroscopic repair for partial-thickness articular side tears of the rotator cuff. Knee Surg. Sports Traumatol. Arthrosc. 2011, 19, 1755–1759. [Google Scholar] [CrossRef]

- Engelhardt, C.; Ingram, D.; Müllhaupt, P.; Farron, A.; Becce, F.; Pioletti, D.; Terrier, A. Effect of partial-thickness tear on loading capacities of the supraspinatus tendon: A finite element analysis. Comput. Methods Biomech. Biomed. Eng. 2016, 19, 875–882. [Google Scholar] [CrossRef]

- Huang, C.Y.; Stankiewicz, A.; Ateshian, G.A.; Mow, V.C. Anisotropy in homogeneity and tension–compression nonlinearity of human glenohumeral cartilage in finite deformation. J. Biomech. 2005, 38, 799–809. [Google Scholar] [CrossRef] [PubMed]

- Thunes, J.; Miller, R.M.; Pal, S.; Damle, S.; Debski, R.E.; Maiti, S. The effect of size and location of tears in the supraspinatus tendon on potential tear propagation. J. Biomech. 2015, 137, 081012. [Google Scholar] [CrossRef] [PubMed]

- Sreehari, C.K.; Varshney, A.; Yoo, Y.S.; Lee, S.J. Arthroscopic intra-articular spinoglenoid cyst resection following SLAP repair. Arthrosc. Tech. 2017, 6, e1795–e1799. [Google Scholar]

- Jobe, C.M.; Sidles, J. Evidence for a Superior Glenoid Impingement upon the Rotator Cuff: Anatomic, Kinesiologic, MRI and Arthroscopic Findings. In Proceedings of the 5th International Conference on Surgery of the Shoulder, Paris, France, 12–15 July 1992. [Google Scholar]

- Burkhart, S.S. Internal impingement of the shoulder. Instr. Course Lect. 2006, 55, 29–34. [Google Scholar]

- Walch, G.; Boileau, P.; Noel, E.; Donell, S.T. Impingement of the deep surface of the supraspinatus tendon on the posterosuperior glenoid rim: An arthroscopic study. J. Shoulder Elb. Surg. 1992, 1, 238–245. [Google Scholar] [CrossRef]

- Mihata, T.; Gates, J.; McGarry, M.H.; Neo, M.; Lee, T.Q. Effect of posterior shoulder tightness on internal impingement in a cadaveric model of throwing. Knee Surg. Sports Traumatol. Arthrosc. 2015, 23, 548–554. [Google Scholar] [CrossRef]

- Decker, S.; Ford, J. Accuracy and reliability of soft tissue depth measurements from CT for forensic facial reconstruction. J. Forensic Radiol. Imaging 2013, 1, 82. [Google Scholar] [CrossRef]

- Zheng, M.; Zou, Z.; Bartolo, P.J.D.S.; Peach, C.; Ren, L. Finite element models of the human shoulder complex: A review of their clinical implications and modelling techniques. Int. J. Numer. Meth. Biomed. 2017, 33, e02777. [Google Scholar] [CrossRef]

- Adams, C.R.; Baldwin, M.A.; Laz, P.J.; Rullkoetter, P.J.; Langenderfer, J.E. Effects of rotator cuff tears on muscle moment arms: A computational study. J. Biomech. 2007, 40, 3373–3380. [Google Scholar] [CrossRef]

- Gatti, C.J.; Maratt, J.D.; Palmer, M.L.; Hughes, R.E.; Carpenter, J.E. Development and validation of a finite element model of the superior glenoid labrum. Ann. Biomed. Eng. 2010, 38, 3766–3776. [Google Scholar] [CrossRef]

- Jang, S.W.; Yoo, Y.S.; Lee, H.Y.; Kim, Y.S.; Srivastava, P.K.; Nair, A.V. Stress distribution in superior labral complex and rotator cuff during in vivo shoulder motion: A finite element analysis. Arthroscopy 2015, 31, 2073–2081. [Google Scholar] [CrossRef] [PubMed]

- Clavert, P.; Zerah, M.; Krier, J.; Mille, P.; Kempf, J.F.; Kahn, J.L. Finite element analysis of the strain distribution in the humeral head tubercles during abduction: Comparison of young and osteoporotic bone. Surg. Radiol. Anat. 2006, 28, 581–587. [Google Scholar] [CrossRef] [PubMed]

- Smith, C.D.; Masouros, S.D.; Hill, A.M.; Wallace, A.L.; Amis, A.A.; Bull, A.M.J. Tensile properties of the human glenoid labrum. J. Anat. 2008, 212, 49–54. [Google Scholar] [CrossRef]

- Itoi, E.; Berglund, L.J.; Grabowski, J.J.; Schultz, F.M.; Growney, E.S.; Morrey, B.F.; An, K.N. Tensile properties of the supraspinatus tendon. J. Orthop. Res. 1995, 13, 578–584. [Google Scholar] [CrossRef] [PubMed]

- Halder, A.M.; Kuhl, S.G.; Zobitz, M.E.; Larson, D.; An, K.N. Effects of the glenoid labrum and glenohumeral abduction on stability of the shoulder joint through concavity-compression: An in vitro study. J. Bone Joint Surg.-Am. Vol. 2001, 83, 1062–1069. [Google Scholar] [CrossRef] [PubMed]

- Sahara, W.; Sugamoto, K.; Murai, M.; Tanaka, H.; Yoshikawa, H. 3D kinematic analysis of the acromioclavicular joint during arm abduction using vertically open MRI. J. Orthop. Res. 2006, 24, 1823–1831. [Google Scholar] [CrossRef]

- Jang, S.W.; Seo, Y.J.; Yoo, Y.S.; Kim, Y.S. Computed tomographic image analysis based on FEM performance comparison of segmentation on knee joint reconstruction. Sci. World. J. 2014, 2014, 235858. [Google Scholar] [CrossRef]

- Belytschiko, T.; Liu, W.; Moran, B. Nonlinear Finite Element for Continua and Structures; John Wiley and Sons Ltd.: Chichester, UK, 2000. [Google Scholar]

- Yang, S. Conversion of ABAQUS user material subroutines. J. Comput. Struct. Eng. Inst. Korea 2010, 23, 635–640. [Google Scholar]

- Sano, H.; Wakabayashi, I.; Itoi, E. Stress distribution in the supraspinatus tendon with partial-thickness tears: Ananalys is using two-dimensional finite element model. J. Shoulder Elb. Surg. 2006, 15, 100–105. [Google Scholar] [CrossRef]

- Wu, G.; Van der Helm, F.C.; Veeger, H.D.; Makhsous, M.; Van Roy, P.; Anglin, C.; Werner, F.W. ISB recommendation on definitions of joint coordinate systems of various joints for the reporting of human joint motion—Part II: Shoulder, elbow, wrist and hand. J. Biomech. 2005, 38, 981–992. [Google Scholar] [CrossRef]

- Massimini, D.F.; Boyer, P.J.; Papannagari, R.; Gill, T.J.; Warner, J.P.; Li, G. In-vivo glenohumeral translation and ligament elongation during abduction and abduction with internal and external rotation. J. Orthop. Surg. Res. 2012, 7, 29. [Google Scholar] [CrossRef] [PubMed]

| Feature | Type | Mechanical Properties | Number of Elements (Element Type) | Reference |

|---|---|---|---|---|

| Scapula | Rigid body | E = 15,000 MPa, v = 0.3 | 12,967 (S4R) | [23] |

| Humerus | 3482 (S4R) | [23] | ||

| Labrum | Linear elasticity | E = 33 MPa, v = 0.497 | 5622 (C3D8R) | [24] |

| Supraspinatus tendon | Hyper-elasticity | 1775 (C3D8R) | [25,26] |

| Data Finite element model by the acquired shoulder geometry Result Shoulder motion without excessive distortion and its contact stress measurement result |

| For = 1 to n do Boundary condition generation for humeral motion based on screw axis Loading condition generation for initial pretension of supraspinatus tendon |

| if not at excessive distortion of finite element then Displacement boundary condition relaxation by penalty function occurrence Contact stress measurement between supraspinatus tendon and labrum else close; end end |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jang, S.-w.; Yoo, Y.-S.; Kim, Y.S. A New Method of Contact Stress Measurement for Analyzing Internal Impingement Syndrome of the Shoulder: Potentials and Preliminary Evaluation. Appl. Sci. 2020, 10, 4165. https://doi.org/10.3390/app10124165

Jang S-w, Yoo Y-S, Kim YS. A New Method of Contact Stress Measurement for Analyzing Internal Impingement Syndrome of the Shoulder: Potentials and Preliminary Evaluation. Applied Sciences. 2020; 10(12):4165. https://doi.org/10.3390/app10124165

Chicago/Turabian StyleJang, Seong-wook, Yon-Sik Yoo, and Yoon Sang Kim. 2020. "A New Method of Contact Stress Measurement for Analyzing Internal Impingement Syndrome of the Shoulder: Potentials and Preliminary Evaluation" Applied Sciences 10, no. 12: 4165. https://doi.org/10.3390/app10124165

APA StyleJang, S.-w., Yoo, Y.-S., & Kim, Y. S. (2020). A New Method of Contact Stress Measurement for Analyzing Internal Impingement Syndrome of the Shoulder: Potentials and Preliminary Evaluation. Applied Sciences, 10(12), 4165. https://doi.org/10.3390/app10124165