Strategies for Dielectric Contrast Enhancement in 1D Planar Polymeric Photonic Crystals

Abstract

1. Introduction

2. Background

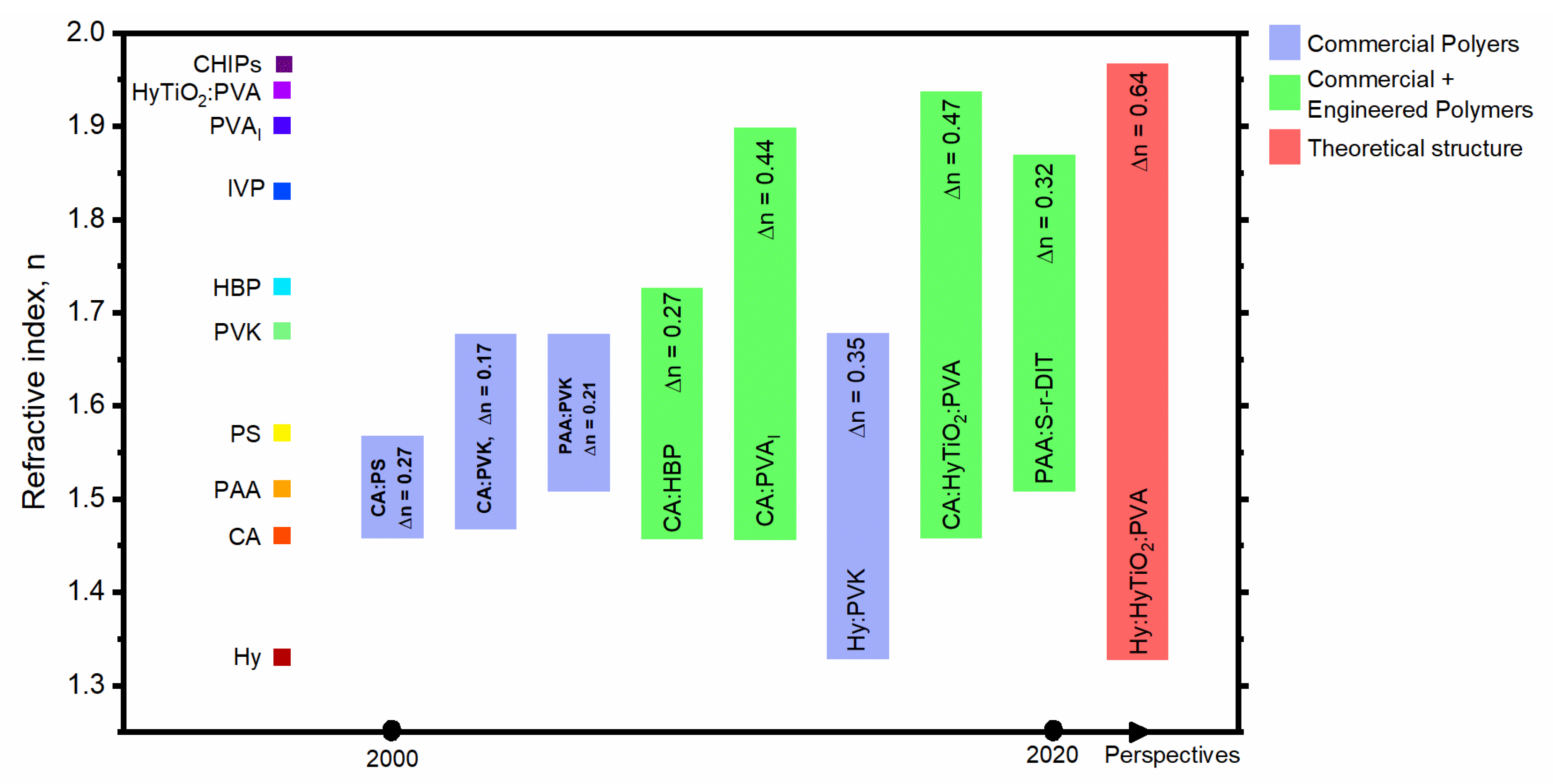

3. Strategies for the Enhancement of the Dielectric Contrast

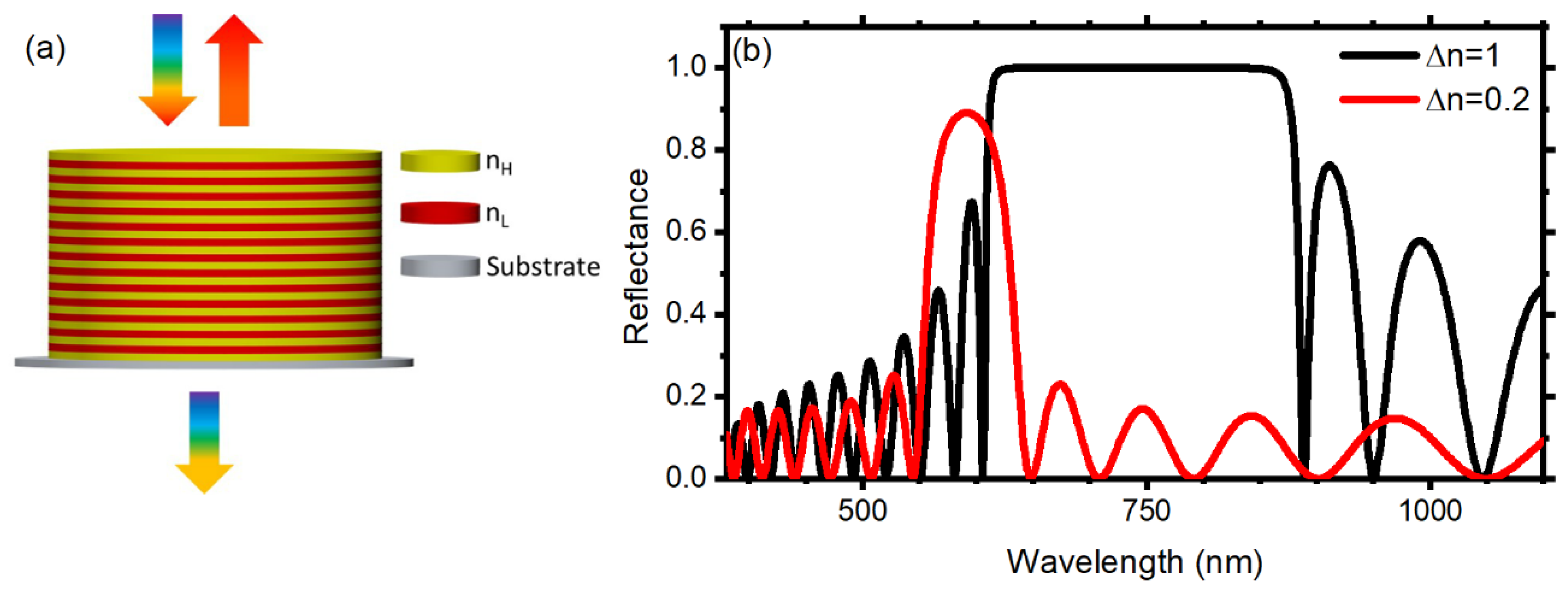

4. Role of the Dielectric Contrast in DBRs

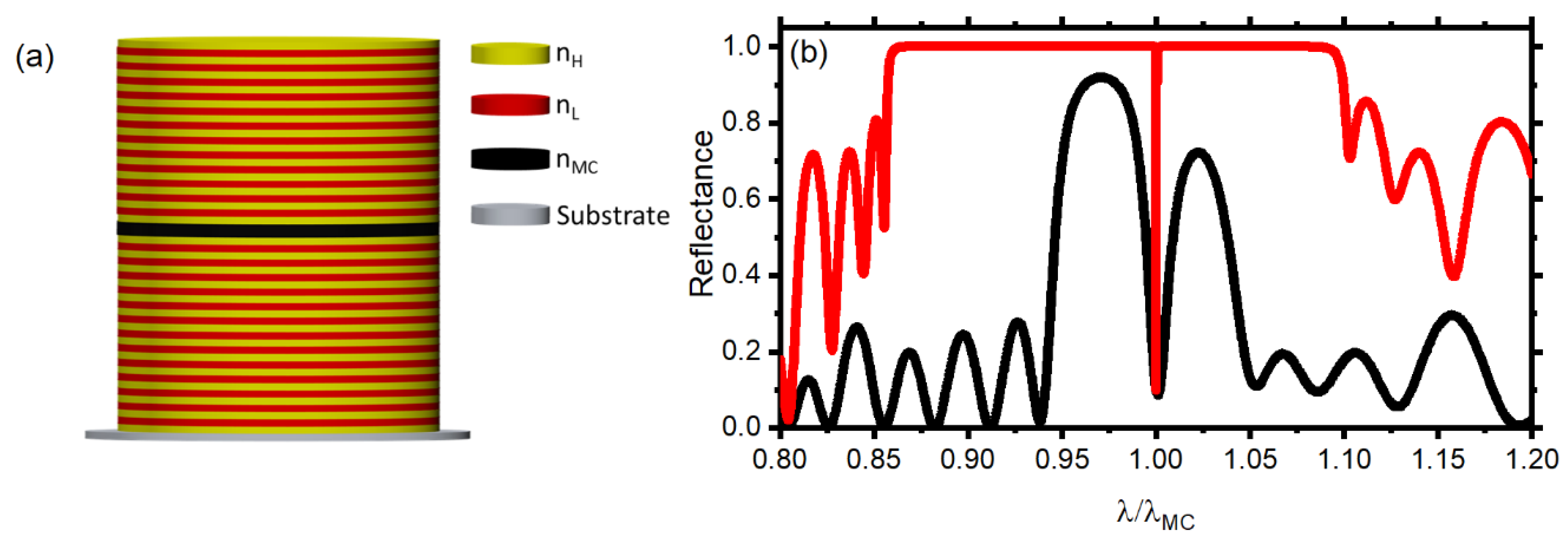

5. Prospects for Polymer Planar Microcavities

6. Conclusions and Perspectives

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Gao, S.; Tang, X.; Langner, S.; Osvet, A.; Harreiβ, C.; Barr, M.; Spiecker, E.; Bachmann, J.; Brabec, C.J.; Forberich, K. Time-Resolved Analysis of Dielectric Mirrors for Vapor Sensing. ACS Appl. Mater. Interfaces 2018, 10, 36398–36406. [Google Scholar] [CrossRef] [PubMed]

- Kuo, W.-K.; Weng, H.-P.; Hsu, J.-J.; Yu, H.H. Photonic Crystal-Based Sensors for Detecting Alcohol Concentration. Appl. Sci. 2016, 6, 67. [Google Scholar] [CrossRef]

- Lova, P.; Manfredi, G.; Bastianini, C.; Mennucci, C.; Buatier de Mongeot, F.; Servida, A.; Comoretto, D. Flory-Huggins Photonic Sensors for the Optical Assessment of Molecular Diffusion Coefficients in Polymers. ACS Appl. Mater. Interfaces 2019, 11, 16872–16880. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.-K.; Kim, C.-Y.; Lee, M. High-Sensitive TM Modes in Photonic Crystal Nanobeam Cavity with Horizontal Air Gap for Refractive Index Sensing. Appl. Sci. 2019, 9, 967. [Google Scholar] [CrossRef]

- Lova, P.; Soci, C. Nanoimprint Lithography: Toward Polymer Photonic Crystals. In Organic and Hybrid Photonic Crystals, 1st ed.; Comoretto, D., Ed.; Springer: Cham, Switzerland, 2015; Volume 1, p. 493. [Google Scholar]

- Signoretto, M.; Zink-Lorre, N.; Suárez, I.; Font-Sanchis, E.; Sastre-Santos, Á.; Chirvony, V.S.; Fernández-Lázaro, F.; Martínez-Pastor, J.P. Efficient Optical Amplification in a Sandwich-Type Active-Passive Polymer Waveguide Containing Perylenediimides. ACS Photonics 2017, 4, 114–120. [Google Scholar] [CrossRef]

- Paternò, G.M.; Moscardi, L.; Kriegel, I.; Scotognella, F.; Lanzani, G. Electro-Optic and Magneto-Optic Photonic Devices Based On Multilayer Photonic Structures. SPIE Proc. 2018, 8, 1–8. [Google Scholar] [CrossRef]

- Zhang, W.; Anaya, M.; Lozano, G.; Calvo, M.E.; Johnston, M.B.; Míguez, H.; Snaith, H.J. Highly Efficient Perovskite Solar Cells with Tunable Structural Color. Nano Lett. 2015, 15, 1698–1702. [Google Scholar] [CrossRef]

- Delgado-Sanchez, J.M.; Lillo-Bravo, I. Angular Dependence of Photonic Crystal Coupled to Photovoltaic Solar Cell. Appl. Sci. 2020, 10, 1574. [Google Scholar] [CrossRef]

- Iadanza, S.; Devarapu, C.; Liles, A.; Sheehan, R.; O’Faoláin, L. Hybrid External Cavity Laser with an Amorphous Silicon-Based Photonic Crystal Cavity Mirror. Appl. Sci. 2020, 10, 240. [Google Scholar] [CrossRef]

- Lova, P.; Giusto, P.; Stasio, F.D.; Manfredi, G.; Paternò, G.M.; Cortecchia, D.; Soci, C.; Comoretto, D. All-Polymer Methylammonium Lead Iodide Perovskite Microcavity. Nanoscale 2019, 11, 8978–8983. [Google Scholar] [CrossRef]

- Antonioli, D.; Deregibus, S.; Panzarasa, G.; Sparnacci, K.; Laus, M.; Berti, L.; Frezza, L.; Gambini, M.; Boarino, L.; Enrico, E.; et al. PTFE-PMMA core-Shell Colloidal Particles as Building Blocks for Self-Assembled Opals: Synthesis, Properties and Optical Response. Polym. Int. 2012, 61, 1294–1301. [Google Scholar] [CrossRef]

- Kriegel, I.; Scotognella, F. Indium Tin Oxide Nanoparticle: TiO2: Air Layers for One-Dimensional Multilayer Photonic Structures. Appl. Sci. 2019, 9, 2564. [Google Scholar] [CrossRef]

- Joannopoulos, J.D.; Johnson, S.G.; Winn, J.N.; Meade, R.D. Photonic Crystals: Molding the Flow of Light; Princeton University Press: Woodstock, NY, USA, 2011. [Google Scholar]

- Teyssier, J.; Saenko, S.V.; van der Marel, D.; Milinkovitch, M.C. Photonic crystals cause active colour change in chameleons. Nature Comm. 2015, 6, 6368. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Chen, Y. Nanofabrication and coloration study of artificial Morpho butterfly wings with aligned lamellae layers. Sci. Rep. 2015, 5, 16637. [Google Scholar] [CrossRef] [PubMed]

- Vigneron, J.P.; Simonis, P. Natural photonic crystals. Physica B 2012, 407, 4032–4036. [Google Scholar] [CrossRef]

- Dumanli, A.G.; Savin, T. Recent advances in the biomimicry of structural colours. Chem. Soc. Rev. 2016, 45, 6698–6724. [Google Scholar] [CrossRef]

- Choi, S.H.; Byun, K.M.; Kim, Y.L. Lasing interactions disclose hidden modes of necklace states in the anderson localized regime. ACS Photonics 2018, 5, 881–889. [Google Scholar] [CrossRef]

- Vigneron, J.P.; Pasteels, J.M.; Windsor, D.M.; Vértesy, Z.; Rassart, M.; Seldrum, T.; Dumont, J.; Deparis, O.; Lousse, V.; Biró, L.P.; et al. Switchable reflector in the panamanian tortoise beetle charidotella egregia (chrysomelidae: Cassidinae). Phys. Rev. E 2007, 76–10, 031907. [Google Scholar] [CrossRef]

- Vignolini, S.; Rudall, P.J.; Rowland, A.V.; Reed, A.; Moyroud, E.; Faden, R.B.; Baumberg, J.J.; Glover, B.J.; Steiner, U. Pointillist structural color in Pollia fruit. Proc. Natl. Acad. Sci. USA 2012, 109, 15712–15715. [Google Scholar] [CrossRef]

- Grimann, M.; Fuhrmann-Lieker, T. Biological photonic crystals. In Organic and Hybrid Photonic Crystals; Comoretto, D., Ed.; Springer International Publishing: Cham, Switzerland, 2015; pp. 57–74. [Google Scholar] [CrossRef]

- Yablonovitch, E. Inhibited spontaneous emission in solid-state physics and electronics. Phys. Rev. Lett. 1987, 58, 2059–2062. [Google Scholar] [CrossRef]

- John, S. Strong localization of photons in certain disordered dielectric superlattices. Phys. Rev. Lett. 1987, 58, 2486–2489. [Google Scholar] [CrossRef]

- Malvezzi, A.; Vecchi, G.; Patrini, M.; Guizzetti, G.; Andreani, L.; Romanato, F.; Businaro, L.; Di Fabrizio, E.; Passaseo, A.; De Vittorio, M. Resonant second-harmonic generation in a GaAs photonic crystal waveguide. Phys. Rev. B 2003, 68, 161306. [Google Scholar] [CrossRef]

- Malvezzi, A.M.; Cattaneo, F.; Vecchi, G.; Falasconi, M.; Guizzetti, G.; Andreani, L.C.; Romanato, F.; Businaro, L.; Fabrizio, E.D.; Passaseo, A.; et al. Second-harmonic generation in reflection and diffraction by a GaAs photonic-crystal waveguide. J. Opt. Soc. Am. B 2002, 19, 2122. [Google Scholar] [CrossRef]

- MacDougal, M.H.; Dapkus, P.D.; Pudikov, V.; Hanmin, Z.; Gye Mo, Y. Ultralow threshold current vertical-cavity surface-emitting lasers with AlAs oxide-GaAs distributed Bragg reflectors. IEEE Photonics Technol. Lett. 1995, 7, 229–231. [Google Scholar] [CrossRef]

- Lin, B.C.; Chen, K.J.; Han, H.V.; Lan, Y.P.; Chiu, C.H.; Lin, C.C.; Shih, M.H.; Lee, P.T.; Kuo, H.C. Advantages of Blue LEDs With Graded-Composition AlGaN/GaN Superlattice EBL. IEEE Photonics Technol. Lett. 2013, 25, 2062–2065. [Google Scholar] [CrossRef]

- Do, Y.R.; Kim, Y.C.; Song, Y.W.; Cho, C.O.; Jeon, H.; Lee, Y.J.; Kim, S.H.; Lee, Y.H. Enhanced light extraction from organic light-emitting diodes with 2D SiO2/SiNx photonic crystals. Adv. Mater. 2003, 15, 1214–1218. [Google Scholar] [CrossRef]

- Cavallo, D.; Goossens, H.; Meijer, H.E. Co-extruded multilayer polymer films for photonic applications. In Organic and Hybrid Photonic Crystals; Springer: Cham, Switzerland, 2015; pp. 145–166. [Google Scholar]

- Bailey, J.; Sharp, J.S. Thin film polymer photonics: Spin cast distributed Bragg reflectors and chirped polymer structures. Eur. Phys. J. E 2010, 33, 41–49. [Google Scholar] [CrossRef]

- Bachevillier, S.; Yuan, H.-K.; Strang, A.; Levitsky, A.; Frey, G.L.; Hafner, A.; Bradley, D.D.C.; Stavrinou, P.N.; Stingelin, N. Fully Solution-Processed Photonic Structures from Inorganic/Organic Molecular Hybrid Materials and Commodity Polymers. Adv. Func. Mater. 2019, 29, 1808152–1808157. [Google Scholar] [CrossRef]

- Cavallo, D.; Goossens, H.; Meijer, H.E.H. Organic and Hybrid Photonic Crystals, 1st ed.; Springer International Publishing: Cham, Switzerland, 2015; Volume 1, p. 493. [Google Scholar]

- Andrews, J.H.; Aviles, M.; Crescimanno, M.; Dawson, N.J.; Mazzocco, A.; Petrus, J.B.; Singer, K.D.; Baer, E.; Song, H. Thermo-spectral study of all-polymer multilayer lasers. Opt. Mater. Express 2013, 3, 1152–1160. [Google Scholar] [CrossRef]

- Zhou, J.; Singer, K.D.; Lott, J.; Song, H.; Wu, Y.; Andrews, J.; Baer, E.; Hiltner, A.; Weder, C. All-polymer distributed feedback and distributed Bragg-reflector lasers produced by roll-to-roll layer-multiplying co-extrusion. Nonlinear Opt. Quantum Opt. 2010, 41, 59–71. [Google Scholar]

- Song, H.; Singer, K.; Wu, Y.; Zhou, J.; Lott, J.; Andrews, J.; Hiltner, A.; Baer, E.; Weder, C.; Bunch, R.; et al. Layered Polymeric Optical Systems Using Continuous Coextrusion. Proc. SPIE 2009, 7467, 74670A-1–74670A-12. [Google Scholar]

- Lova, P.; Manfredi, G.; Comoretto, D. Advances in Functional Solution Processed Planar One-Dimensional Photonic Crystals. Adv. Opt. Mater. 2018, 6, 1800730. [Google Scholar] [CrossRef]

- Kao, C.-C.; Peng, Y.C.; Yao, H.H.; Tsai, J.Y.; Chang, Y.H.; Chu, J.T.; Huang, H.W.; Kao, T.T.; Lu, T.C.; Kuo, H.C.; et al. Fabrication and performance of blue GaN-based vertical-cavity surface emitting laser employing AlN∕GaN and Ta2O5∕SiO2 distributed Bragg reflector. Appl. Phys. Lett. 2005, 87, 081104–081105. [Google Scholar] [CrossRef]

- Hongjun, C.; Hao, G.; Peiyuan, Z.; Xiong, Z.; Honggang, L.; Shengkai, W.; Yiping, C. Enhanced performance of GaN-based light-emitting diodes by using al mirror and atomic layer deposition-TiO2/Al2O3 distributed bragg reflector backside reflector with patterned sapphire substrate. Appl. Phys. Express 2013, 6, 022101–022108. [Google Scholar]

- Persano, L.; Camposeo, A.; Carro, P.D.; Mele, E.; Cingolani, R.; Pisignano, D. Very high-quality distributed Bragg reflectors for organic lasing applications by reactive electron-beam deposition. Opt. Express 2006, 14, 1951–1956. [Google Scholar] [CrossRef]

- Jang, S.J.; Song, Y.M.; Yeo, C.I.; Park, C.Y.; Lee, Y.T. Highly tolerant a-Si distributed Bragg reflector fabricated by oblique angle deposition. Opt. Mater. Express 2011, 1, 451–457. [Google Scholar] [CrossRef]

- Yu, H.-C.; Zheng, Z.-W.; Mei, Y.; Xu, R.-B.; Liu, J.-P.; Yang, H.; Zhang, B.-P.; Lu, T.-C.; Kuo, H.-C. Progress and prospects of GaN-based VCSEL from near UV to green emission. Prog. Quantum Electron. 2018, 57, 1–19. [Google Scholar] [CrossRef]

- Tatum, J.A.; Gazula, D.; Graham, L.A.; Guenter, J.K.; Johnson, R.H.; King, J.; Kocot, C.; Landry, G.D.; Lyubomirsky, I.; MacInnes, A.N.; et al. VCSEL-based interconnects for current and future data centers. J. Lightwave Technol. 2015, 33, 727–732. [Google Scholar] [CrossRef]

- THORLABS. Available online: https://www.thorlabs.com/navigation.cfm?guide_id=2210 (accessed on 11 December 2019).

- Edmund Optics. Available online: https://www.edmundoptics.com/optics/optical-filters/ (accessed on 20 March 2018).

- Skorobogatiy, M.; Yang, J. Fundamentals of Photonic Crystal Guiding; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- Tao, P.; Liang, H.; Xia, X.; Liu, Y.; Jiang, J.; Huang, H.; Feng, Q.; Shen, R.; Luo, Y.; Du, G. Enhanced output power of near-ultraviolet LEDs with AlGaN/GaN distributed Bragg reflectors on 6H–SiC by metal-organic chemical vapor deposition. Superlattices Microstruct. 2015, 85, 482–487. [Google Scholar] [CrossRef]

- Guan-Jhong, W.; Bo-Syun, H.; Yi-Yun, C.; Zhong-Jie, Y.; Tzong-Liang, T.; Yung-Sen, L.; Chia-Feng, L. GaN/AlGaN ultraviolet light-emitting diode with an embedded porous-AlGaN distributed Bragg reflector. Appl. Phys. Express 2017, 10, 122102–122104. [Google Scholar]

- Dai, J.; Gao, W.; Liu, B.; Cao, X.; Tao, T.; Xie, Z.; Zhao, H.; Chen, D.; Ping, H.; Zhang, R. Design and fabrication of UV band-pass filters based on SiO2/Si3N4 dielectric distributed bragg reflectors. Appl. Surf. Sci. 2016, 364, 886–891. [Google Scholar] [CrossRef]

- Liu, X.; Poitras, D.; Tao, Y.; Py, C. Microcavity organic light emitting diodes with double sided light emission of different colors. J. Vac. Sci. Technol. A 2004, 22, 764–767. [Google Scholar] [CrossRef]

- Yablonovitch, E. Photonic Crystals: Semiconductors of Light. Sci. Am. 2001, 12, 47–55. [Google Scholar] [CrossRef]

- Available online: https://www.electrooptics.com/news/vcsel-market-be-worth-31-billion-2022 (accessed on 30 April 2018).

- Chichibu, S.F.; Ohmori, T.; Shibata, N.; Koyama, T. Dielectric SiO2∕ZrO2 distributed Bragg reflectors for ZnO microcavities prepared by the reactive helicon-wave-excited-plasma sputtering method. Appl. Phys. Lett. 2006, 88, 161914. [Google Scholar] [CrossRef]

- Sang-Hee, K.; Jong-Heon, K.; Jeon-Kook, L.; Si-Hyung, L.; Ki Hyun, Y. Bragg reflector thin film resonator using aluminium nitride deposited by RF sputtering. In Proceedings of the 2000 Asia-Pacific Microwave Conference, Sydney, Australia, 3–6 December 2000; pp. 1535–1538. [Google Scholar]

- Waldrip, K.E.; Han, J.; Figiel, J.J.; Zhou, H.; Makarona, E.; Nurmikko, A.V. Stress engineering during metalorganic chemical vapor deposition of AlGaN/GaN distributed Bragg reflectors. Appl. Phys. Lett. 2001, 78, 3205–3207. [Google Scholar] [CrossRef]

- Tan, S.T.; Chen, B.J.; Sun, X.W.; Fan, W.J.; Kwok, H.S.; Zhang, X.H.; Chua, S.J. Blueshift of optical band gap in ZnO thin films grown by metal-organic chemical-vapor deposition. J. Appl. Phys. 2005, 98, 013505–013506. [Google Scholar] [CrossRef]

- Yin, J.; Migas, D.B.; Panahandeh-Fard, M.; Chen, S.; Wang, Z.; Lova, P.; Soci, C. Charge Redistribution at GaAs/P3HT Heterointerfaces with Different Surface Polarity. J. Phys. Chem. Lett. 2013, 4, 3303–3309. [Google Scholar] [CrossRef]

- Ostroverkhova, O. Handbook of Organic Materials for Electronic and Photonic Devices; Woodhead Publishing: Sawston, Cambridge, UK, 2018. [Google Scholar]

- Yu, D.; Yang, Y.-Q.; Chen, Z.; Tao, Y.; Liu, Y.-F. Recent progress on thin-film encapsulation technologies for organic electronic devices. Opt. Commun. 2016, 362, 43–49. [Google Scholar] [CrossRef]

- Paternò, G.M.; Iseppon, C.; D’Altri, A.; Fasanotti, C.; Merati, G.; Randi, M.; Desii, A.; Pogna, E.A.A.; Viola, D.; Cerullo, G.; et al. Solution Processable and Optically Switchable 1D Photonic Structures. Sci. Rep. 2018, 8, 3517–3518. [Google Scholar] [CrossRef]

- Bisoyi, H.K.; Bunning, T.J.; Li, Q. Stimuli-driven control of the helical axis of self-organized soft helical superstructures. Adv. Mater. 2018, 30, 1706512–1706535. [Google Scholar] [CrossRef]

- Zheng, Z.-G.; Zola, R.S.; Bisoyi, H.K.; Wang, L.; Li, Y.; Bunning, T.J.; Li, Q. Controllable dynamic zigzag pattern formation in a soft helical superstructure. Adv. Mater. 2017, 29, 1701903–1701907. [Google Scholar] [CrossRef] [PubMed]

- Krishna, B.H.; Quan, L. Light-directed dynamic chirality inversion in functional self-organized helical superstructures. Angew. Chem. Int. Ed. 2016, 55, 2994–3010. [Google Scholar]

- Appold, M.; Gallei, M. Bio-Inspired Structural Colors Based on Linear Ultrahigh Molecular Weight Block Copolymers. ACS Appl. Polym. Mater. 2019, 1, 239–250. [Google Scholar] [CrossRef]

- Qiao, Y.; Zhao, Y.; Yuan, X.; Zhao, Y.; Ren, L. One-dimensional photonic crystals prepared by self-assembly of brush block copolymers with broad PDI. J. Mater. Sci. 2018, 53, 16160–16168. [Google Scholar] [CrossRef]

- Kang, H.S.; Lee, J.; Cho, S.M.; Park, T.H.; Kim, M.J.; Park, C.; Lee, S.W.; Kim, K.L.; Ryu, D.Y.; Huh, J.; et al. Printable and Rewritable Full Block Copolymer Structural Color. Adv. Mater. 2017, 29, 1700084–1700088. [Google Scholar] [CrossRef] [PubMed]

- TORAY. Available online: http://www.toray.com/ (accessed on 27 January 2020).

- 3M DICHROIC. Available online: https://www.3m.com/3M/en_US/company-us/all-3m-products/~/3M-Dichroic-Films-for-Architectural-Laminated-Glass/?N=5002385+3291680356&rt=rud (accessed on 27 January 2020).

- 3M Installation. Available online: http://www.conveniencegroup.com/3m-dichroic-film-case-study (accessed on 30 March 2018).

- Chamaleonlab. Available online: http://chameleonlab.nl/ (accessed on 11 December 2019).

- Chamenleonlab Building. Available online: https://chameleonlab.com/portfolio/la-defense/ (accessed on 30 March 2018).

- Lazarova, K.; Todorova, L.; Christova, D.; Babeva, T. Color sensing of humidity using thin films of hydrophilic cationic opolymers. In Proceedings of the 2017 40th International Spring Seminar on Electronics Technology (ISSE), Sofia, Bulgaria, 10–14 May 2017; pp. 1–6. [Google Scholar]

- Convertino, A.; Capobianchi, A.; Valentini, A.; Cirillo, E.N.M. High reflectivity bragg reflectors based on a gold nanoparticle/teflon-like composite material as a new approach to organic solvent detection. Sens. Actuators B 2004, 100, 212–215. [Google Scholar] [CrossRef]

- Convertino, A.; Capobianchi, A.; Valentini, A.; Cirillo, E.N.M. A New Approach to Organic Solvent Detection: High-Reflectivity Bragg Reflectors Based on a Gold Nanoparticle/Teflon-Like Composite Material. Adv. Mater. 2003, 15, 1103–1105. [Google Scholar] [CrossRef]

- Manfredi, G.; Mayrhofer, C.; Kothleitner, G.; Schennach, R.; Comoretto, D. Cellulose Ternary Photonic Crystal created by Solution Processing. Cellulose 2016, 23, 2853–2862. [Google Scholar] [CrossRef]

- Ho, P.K.H.; Stephen, D.; Friend, R.H.; Tessler, N. All-polymer optoelectronic devices. Science 1999, 285, 233–236. [Google Scholar] [CrossRef]

- Kuehne, A.J.C.; Gather, M.C. Organic lasers: Recent developments on materials, device geometries, and fabrication techniques. Chem. Rev. 2016, 116, 12823–12864. [Google Scholar] [CrossRef]

- Scotognella, F.; Monguzzi, A.; Cucini, M.; Meinardi, F.; Comoretto, D.; Tubino, R. One dimensional polymeric organic photonic crystals for DFB lasers. Int. J. Photoenergy 2008, 2008, 1–4. [Google Scholar] [CrossRef]

- Min, K.; Choi, S.; Choi, Y.; Jeon, H. Enhanced fluorescence from CdSe/ZnS quantum dot nanophosphors embedded in a one-dimensional photonic crystal backbone structure. Nanoscale 2014, 6, 14531–14537. [Google Scholar] [CrossRef] [PubMed]

- Menon, V.M.; Husaini, S.; Valappil, N.; Luberto, M. Photonic emitters and circuits based on colloidal quantum dot composites. In Quantum Dots, Particles, and Nanoclusters VI; SPIE: Bellingham, WA, USA, 2009; pp. 72240Q–72248Q. [Google Scholar]

- Vijisha, M.V.; Sini, V.V.; Siji Narendran, N.K.; Chandrasekharan, K. Enhanced nonlinear optical response from dihydroxy(5,10,15,20-tetraphenyl porphyrinato)tin(iv) or SnTPP in a fully plastic photonic crystal microcavity. Phys. Chem. Chem. Phys. 2017, 19, 29641–29646. [Google Scholar] [CrossRef] [PubMed]

- Passias, V.; Valappil, N.; Shi, Z.; Deych, L.; Lisyansky, A.; Menon, V.M. Luminescence properties of a Fibonacci photonic quasicrystal. Opt. Express 2009, 17, 6636–6642. [Google Scholar] [CrossRef] [PubMed]

- Kajii, H.; Yoshinaga, M.; Karaki, T.; Kawata, M.; Okui, H.; Morifuji, M.; Kondow, M. Polymer Light-Emitting Devices with Selectively Transparent Photonic Crystals Consisting of Printed Inorganic/Organic Hybrid Dielectric Films. In Proceedings of the 2019 IEEE International Meeting for Future of Electron Devices, Kansai (IMFEDK), Kyoto, Japan, 26–28 July 2004; pp. 31–34. [Google Scholar]

- Manfredi, G.; Lova, P.; Di Stasio, F.; Rastogi, P.; Krahne, R.; Comoretto, D. Lasing From Dot-In-Rod Nanocrystals in Planar Polymer Microcavities. RSC Adv. 2018, 8, 13026–13033. [Google Scholar] [CrossRef]

- Lova, P.; Olivieri, M.; Surace, A.; Topcu, G.; Emirdag-Eanes, M.; Demir, M.M.; Comoretto, D. Polymeric Planar Microcavities Doped with a Europium Complex. Crystals 2020, 10, 287. [Google Scholar] [CrossRef]

- Katouf, R.; Komikado, T.; Itoh, M.; Yatagai, T.; Umegaki, S. Ultra-fast optical switches using 1D polymeric photonic crystals. Photonic Nanostruct. 2005, 3, 116–119. [Google Scholar] [CrossRef]

- Valappil, N.V.; Luberto, M.; Menon, V.M.; Zeylikovich, I.; Gayen, T.K.; Franco, J.; Das, B.B.; Alfano, R.R. Solution Processed Microcavity Structures with Embedded Quantum Dots. Photonic Nanostruct. 2007, 5, 184–188. [Google Scholar] [CrossRef]

- Lukishova, S.G.; Bissell, L.J.; Menon, V.M.; Valappil, N.; Hahn, M.A.; Evans, C.M.; Zimmerman, B.; Krauss, T.D.; Stroud, C.R.; Boyd, R.W. Organic photonic bandgap microcavities doped with semiconductor nanocrystals for room-temperature on-demand single-photon sources. J. Mod. Opt. 2009, 56, 167–174. [Google Scholar] [CrossRef]

- Menon, V.; Valappil, N.; Zeylikovich, I.; Gayen, T.; Das, B.; Alfano, R.R. Control of Spontaneous Emission from Colloidal Quantum Dots in a Polymer Microcavity. MRS Proceedings 2011, 959. [Google Scholar] [CrossRef]

- Zhang, S.; Shen, C.; Kislyakov, I.M.; Dong, N.; Ryzhov, A.; Zhang, X.; Belousova, I.M.; Nunzi, J.-M.; Wang, J. Photonic-crystal-based broadband graphene saturable absorber. Opt. Lett. 2019, 44, 4785–4788. [Google Scholar] [CrossRef] [PubMed]

- Álvarez, A.L.; Tito, J.; Vaello, M.B.; Velásquez, P.; Mallavia, R.; Sánchez-López, M.M.; Fernández de Ávila, S. Polymeric multilayers for integration into photonic devices. Thin Solid Films 2003, 433, 277–280. [Google Scholar] [CrossRef]

- Vicini, S.; Mauri, M.; Vita, S.; Castellano, M. Alginate and alginate/hyaluronic acid membranes generated by electrospinning in wet conditions: Relationship between solution viscosity and spinnability. J. Appl. Polym. Sci. 2018, 135, 46390–46398. [Google Scholar] [CrossRef]

- Castellano, M.; Alloisio, M.; Darawish, R.; Dodero, A.; Vicini, S. Electrospun Composite Mats of Alginate with Embedded Silver Nanoparticles. J. Therm. Anal. Calorim. 2019, 137, 767–778. [Google Scholar] [CrossRef]

- Kolle, M.; Lethbridge, A.; Kreysing, M.; Baumberg, J.J.; Aizenberg, J.; Vukusic, P. Bio-Inspired Band-Gap Tunable Elastic Optical Multilayer Fibers. Adv. Mater. 2013, 25, 2239–2245. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, J.; Hu, Q.; Liao, Z.; Cui, Y.; Yang, Y.; Qian, G. Stable and mechanically tunable vertical-cavity surface-emitting lasers (VCSELs) based on dye doped elastic polymeric thin films. Dyes Pigm. 2015, 116, 114–118. [Google Scholar] [CrossRef]

- Lova, P.; Bastianini, C.; Giusto, P.; Patrini, M.; Rizzo, P.; Guerra, G.; Iodice, M.; Soci, C.; Comoretto, D. Label-free Vapor Selectivity in Poly(p-phenylene oxide) Photonic Crystal Sensors. ACS Appl. Mater. Interfaces 2016, 8, 31941–31950. [Google Scholar] [CrossRef]

- Vasudevan, K.; Divyasree, M.C.; Chandrasekharan, K. Enhanced nonlinear optical properties of ZnS nanoparticles in 1D polymer photonic crystal cavity. Opt. Laser Technol. 2019, 114, 35–39. [Google Scholar] [CrossRef]

- Lova, P.; Grande, V.; Manfredi, G.; Patrin, M.; Herbst, S.; Würthner, F.; Comoretto, D. All-Polymer Photonic Microcavities Doped with Perylene Bisimide J-Aggregates. Adv. Opt. Mater. 2017, 5, 1700523–1700528. [Google Scholar] [CrossRef]

- Bensaid, M.; Miloua, R.; Ghalouci, L.; Godey, F.; Soldera, A. Multiscale design and optimization of polymer-based photonic crystals for solar shielding. Sol. Energy Mater. Sol. Cells 2017, 171, 166–179. [Google Scholar] [CrossRef]

- Moroni, L.; Salvi, P.R.; Gellini, C.; Dellepiane, G.; Comoretto, D.; Cuniberti, C. Two-photon Spectroscopy of Pi-Conjugated Polymers: The Case of Poly 1,6-Bis(3,6-Dihexadecyl-N-Carbazolyl)-2,4-Hexadiyne (Polydchd-Hs). J. Phys. Chem. A 2001, 105, 7759–7764. [Google Scholar] [CrossRef]

- Canazza, G.; Scotognella, F.; Lanzani, G.; De Silvestri, S.; Zavelani-Rossi, M.; Comoretto, D. Lasing from all-polymer microcavities. Laser Phys. Lett. 2014, 11, 035804–035808. [Google Scholar] [CrossRef]

- Komikado, T.; Yoshida, S.; Umegaki, S. Surface-emitting distributed-feedback dye laser of a polymeric multilayer fabricated by spin coating. Appl. Phys. Lett. 2006, 89, 061123–061124. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, Y.; Liao, Z.; Yu, J.; Cui, Y.; Garcia-Moreno, I.; Wang, Z.; Costela, A.; Qian, G. Mechanically tunable organic vertical-cavity surface emitting lasers (VCSELs) for highly sensitive stress probing in dual-modes. Opt. Express 2015, 23, 4385–4396. [Google Scholar] [CrossRef]

- Knarr, R.J., III; Manfredi, G.; Martinelli, E.; Pannocchia, M.; Repetto, D.; Mennucci, C.; Solano, I.; Canepa, M.; Buatier de Mongeot, F.; Galli, G.; et al. In-plane anisotropic photoresponse in all-polymer planar microcavities. Polymer 2016, 84, 383–390. [Google Scholar] [CrossRef]

- Lova, P.; Cortecchia, D.; S. Krishnamoorthy, H.N.; Giusto, P.; Bastianini, C.; Bruno, A.; Comoretto, D.; Soci, C. Engineering the Emission of Broadband 2D Perovskites by Polymer Distributed Bragg Reflectors. ACS Photonics 2018, 5, 867–874. [Google Scholar] [CrossRef]

- Manfredi, G.; Lova, P.; Di Stasio, F.; Krahne, R.; Comoretto, D. Directional Fluorescence Spectral Narrowing in All-Polymer Microcavities Doped with CdSe/CdS Dot-in-rod Nanocrystals. ACS Photonics 2017, 4, 1761–1769. [Google Scholar] [CrossRef]

- Radice, S.V.; Gavezotti, P.; Simeone, G.; Albano, M.; Canazza, G.; Congiu, S. Photonic Crystals. WO PCT/EP2014/055590, 20 March 2014. [Google Scholar]

- Radice, S.V.; Srinivasan, P.; Comoretto, D.; Gazzo, S. One-Dimensional Planar Photonic Crystals including Fluoropolymer Compositions and Corresponding Fabrication Methods. WO 2016/087439 A1, 9 June 2016. [Google Scholar]

- Russo, M.; Campoy-Quiles, M.; Lacharmoise, P.; Ferenczi, T.A.M.; Garriga, M.; Caseri, W.R.; Stingelin, N. One-pot synthesis of polymer/inorganic hybrids: Toward readily accessible, low-loss, and highly tunable refractive index materials and patterns. J. Polym. Sci. Part B: Polym. Phys. 2012, 50, 65–74. [Google Scholar] [CrossRef]

- Giusto, P.; Lova, P.; Manfredi, G.; Gazzo, S.; Srinivasan, B.; Radice, S.V.; Comoretto, D. Colorimetric Detection of Perfluorinated Compounds by All-Polymer Photonic Transducers. ACS Omega 2018, 3, 7517–7522. [Google Scholar] [CrossRef] [PubMed]

- Higashihara, T.; Ueda, M. Recent Progress in High Refractive Index Polymers. Macromolecules 2015, 48, 1915–1929. [Google Scholar] [CrossRef]

- Kitamura, K.; Okada, K.; Fujita, N.; Nagasaka, Y.; Ueda, M.; Sekimoto, Y.; Kurata, Y. Fabrication Method of Double-Microlens Array Using Self-Alignment Technology. Jpn. J. Appl. Phys. 2004, 43, 5840–5844. [Google Scholar] [CrossRef]

- Nakamura, T.; Fujii, H.; Juni, N.; Tsutsumi, N. Enhanced Coupling of Light from Organic Electroluminescent Device Using Diffusive Particle Dispersed High Refractive Index Resin Substrate. Opt. Rev. 2006, 13, 104–110. [Google Scholar] [CrossRef]

- Krogman, K.C.; Druffel, T.; Sunkara, M.K. Anti-reflective optical coatings incorporating nanoparticles. Nanotechnology 2005, 16, S338. [Google Scholar] [CrossRef]

- Groh, W.; Zimmermann, A. What is the lowest refractive index of an organic polymer? Macromolecules 1991, 24, 6660–6663. [Google Scholar] [CrossRef]

- Gaëtan, W.; Rolando, F.; Stefan, S.; Libero, Z. Nanoporous films with low refractive index for large-surface broad-band anti-reflection coatings. Macromol. Chem. Phys. 2010, 295, 628–636. [Google Scholar]

- Xi, J.Q.; Schubert, M.F.; Kim, J.K.; Schubert, E.F.; Chen, M.; Lin, S.-Y.; Liu, W.; Smart, J.A. Optical thin-film materials with low refractive index for broadband elimination of Fresnel reflection. Nat. Photon. 2007, 1, 176–179. [Google Scholar] [CrossRef]

- Gher, R.J.; Boyd, R.W. Optical properties of nanostructured optical materials. Chem. Mater. 1996, 8, 1807–1819. [Google Scholar] [CrossRef]

- Liu, C.-C.; Li, J.-G.; Kuo, S.-W. Co-templates method provides hierarchical mesoporous silicas with exceptionally ultra-low refractive indices. RSC Adv. 2014, 4, 20262–20272. [Google Scholar] [CrossRef]

- Smirnov, J.R.C.; Ito, M.; Calvo, M.E.; López-López, C.; Jiménez-Solano, A.; Galisteo-López, J.F.; Zavala-Rivera, P.; Tanaka, K.; Sivaniah, E.; Míguez, H. Adaptable Ultraviolet Reflecting Polymeric Multilayer Coatings of High Refractive Index Contrast. Adv. Opt. Mater. 2015, 3, 1633–1639. [Google Scholar] [CrossRef][Green Version]

- Lova, P.; Manfredi, G.; Boarino, L.; Laus, M.; Urbinati, G.; Losco, T.; Marabelli, F.; Caratto, V.; Ferretti, M.; Castellano, M.; et al. Hybrid ZnO:Polystyrene Nanocomposite for All-Polymer Photonic Crystals. Phys. Status Solidi C 2015, 12, 158–162. [Google Scholar] [CrossRef]

- Nussbaumer, R.J.; Caseri, W.R.; Smith, P.; Tervoort, T. Polymer-TiO2 nanocomposites: A route towards visually transparent broadband uv filters and high refractive index materials. Macromol. Chem. Phys. 2003, 288, 44–49. [Google Scholar] [CrossRef]

- Ogata, T.; Yagi, R.; Nakamura, N.; Kuwahara, Y.; Kurihara, S. Modulation of polymer refractive indices with diamond nanoparticles for metal-free multilayer film mirrors. ACS Appl. Mater. Interfaces 2012, 4, 3769–3772. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, M.K.; Mittal, K.L. Polyimides Fundamentals and Applications, 1st ed.; CRC Press: LLC Boca Raton, FL, USA, 1996. [Google Scholar]

- Dine-Hart, R.A.; Wright, W.W. A study of some properties of aromatic imides. Makromol. Chem. 1971, 143, 189–206. [Google Scholar] [CrossRef]

- Liu, J.G.; Nakamura, Y.; Suzuki, Y.; Shibasaki, Y.; Ando, S.; Ueda, M. Highly Refractive and Transparent Polyimides Derived from 4,4‘-[m-Sulfonylbis(phenylenesulfanyl)]diphthalic Anhydride and Various Sulfur-Containing Aromatic Diamines. Macromolecules 2007, 40, 7902–7909. [Google Scholar] [CrossRef]

- Minns, R.A.; Gaudiana, R.A. Design and Synthesis of High Refractive Index Polymers. II. J. Macromol. Sci. A 1992, 29, 19–30. [Google Scholar] [CrossRef]

- Olshavsky, M.A.; Allcock, H.R. Polyphosphazenes with High Refractive Indices: Synthesis, Characterization, and Optical Properties. Macromolecules 1995, 28, 6188–6197. [Google Scholar] [CrossRef]

- Olshavsky, M.; Allcock, H.R. Polyphosphazenes with High Refractive Indices: Optical Dispersion and Molar Refractivity. Macromolecules 1997, 30, 4179–4183. [Google Scholar] [CrossRef]

- Fushimi, T.; Allcock, H.R. Cyclotriphosphazenes with sulfur-containing side groups: Refractive index and optical dispersion. Dalton Trans. 2009, 2477–2481. [Google Scholar] [CrossRef]

- Qiang, W.; Xingjie, Z.; Xianping, Q.; Gözde, Ö.; Karin, S.; Anton, K.; Brigitte, V. High refractive index hyperbranched polymers prepared by two naphthalene-bearing monomers via thiol-yne reaction. Macromol. Chem. Phys. 2016, 217, 1977–1984. [Google Scholar]

- Wei, Q.; Pötzsch, R.; Liu, X.; Komber, H.; Kiriy, A.; Voit, B.; Will, P.-A.; Lenk, S.; Reineke, S. Hyperbranched Polymers with High Transparency and Inherent High Refractive Index for Application in Organic Light-Emitting Diodes. Adv. Func. Mater. 2016, 26, 2545–2553. [Google Scholar] [CrossRef]

- Ireni, N.G.; Narayan, R.; Basak, P.; Raju, K.V.S. Functional polyurethane–urea coatings from sulfur rich hyperbranched polymers and an evaluation of their anticorrosion and optical properties. New J. Chem. 2016, 40, 8081–8092. [Google Scholar] [CrossRef]

- Gazzo, S.; Manfredi, G.; Pötzsch, R.; Wei, Q.; Alloisio, M.; Voit, B.; Comoretto, D. High Refractive Index Hyperbranched Polyvinylsulfides for Planar One-Dimensional All-Polymer Photonic Crystals. J. Polym. Sci. Part B: Polym. Phys. 2016, 54, 73–80. [Google Scholar] [CrossRef]

- Kleine, T.S.; Nguyen, N.A.; Anderson, L.E.; Namnabat, S.; LaVilla, E.A.; Showghi, S.A.; Dirlam, P.T.; Arrington, C.B.; Manchester, M.S.; Schwiegerling, J.; et al. High refractive index copolymers with improved thermomechanical properties via the inverse vulcanization of sulfur and 1,3,5-triisopropenylbenzene. ACS Macro Lett. 2016, 5, 1152–1156. [Google Scholar] [CrossRef]

- Anderson, L.E.; Kleine, T.S.; Zhang, Y.; Phan, D.D.; Namnabat, S.; LaVilla, E.A.; Konopka, K.M.; Ruiz Diaz, L.; Manchester, M.S.; Schwiegerling, J.; et al. Chalcogenide hybrid inorganic/organic polymers: Ultrahigh refractive index polymers for infrared imaging. ACS Macro Lett. 2017, 6, 500–504. [Google Scholar] [CrossRef]

- Griebel, J.J.; Namnabat, S.; Kim, E.T.; Himmelhube, R.; Moronta, D.H.; Chung, W.J.; Simmonds Adam, G.; Kim Kyung, J.; van der Laan, J.; Nguyen Ngoc, A.; et al. New infrared transmitting material via inverse vulcanization of elemental sulfur to prepare high refractive index polymers. Adv. Mater. 2014, 26, 3014–3018. [Google Scholar] [CrossRef]

- Tavella, C.; Lova, P.; Marsotto, M.; Luciano, G.; Patrini, M.; Stagnaro, P.; Comoretto, D. High Refractive Index Inverse Vulcanized Polymers for Organic Photonic Crystals. Crystals 2020, 10, 154. [Google Scholar] [CrossRef]

- Althues, H.; Henle, J.; Kaskel, S. Functional inorganic nanofillers for transparent polymers. Chem. Soc. Rev. 2007, 36, 1454–1465. [Google Scholar] [CrossRef]

- Suzuki, N.; Tomita, Y.; Ohmori, K.; Hidaka, M.; Chikama, K. Highly transparent ZrO2 nanoparticle-dispersed acrylate photopolymers for volume holographic recording. Opt. Express 2006, 14, 12712–12719. [Google Scholar] [CrossRef]

- Papadimitrakopoulos, F.; Wisniecki, P.; Bhagwagar, D.E. Mechanically Attrited Silicon for High Refractive Index Nanocomposites. Chem. Mater. 1997, 9, 2928–2933. [Google Scholar] [CrossRef]

- Lü, C.; Cui, Z.; Li, Z.; Yang, B.; Shen, J. High refractive index thin films of ZnS/polythiourethane nanocomposites. J. Mater. Chem. A 2003, 13, 526–530. [Google Scholar] [CrossRef]

- Liu, J.-G.; Nakamura, Y.; Ogura, T.; Shibasaki, Y.; Ando, S.; Ueda, M. Optically Transparent Sulfur-Containing Polyimide−TiO2 Nanocomposite Films with High Refractive Index and Negative Pattern Formation from Poly(amic acid)−TiO2 Nanocomposite Film. Chem. Mater. 2008, 20, 273–281. [Google Scholar] [CrossRef]

- Paquet, C.; Cyr, P.W.; Kumacheva, E.; Manners, I. Polyferrocenes: Metallopolymers with tunable and high refractive indices. Chem. Comm. 2004, 234–235. [Google Scholar] [CrossRef] [PubMed]

- Häußler, M.; Lam, J.W.Y.; Qin, A.; Tse, K.K.C.; Li, M.K.S.; Liu, J.; Jim, C.K.W.; Gao, P.; Tang, B.Z. Metallized hyperbranched polydiyne: A photonic material with a large refractive index tunability and a spin-coatable catalyst for facile fabrication of carbon nanotubes. Chem. Comm. 2007, 2584–2586. [Google Scholar] [CrossRef] [PubMed]

- Bhagat, S.D.; Chatterjee, J.; Chen, B.; Stiegman, A.E. High Refractive Index Polymers Based on Thiol–Ene Cross-Linking Using Polarizable Inorganic/Organic Monomers. Macromolecules 2012, 45, 1174–1181. [Google Scholar] [CrossRef]

- Castellano, M.; Turturro, A.; Marsano, E.; Conzatti, L.; Vicini, S. Hydrophobation of silica surface by silylation with new organo-silanes bearing a polybutadiene oligomer tail. Polym. Compos. 2014, 35, 1603–1613. [Google Scholar] [CrossRef]

- Boccalero, G.; Jean-Mistral, C.; Castellano, M.; Boragno, C. Soft, hyper-elastic and highly-stable silicone-organo-clay dielectric elastomer for energy harvesting and actuation applications. Compos. Part B 2018, 146, 13–19. [Google Scholar] [CrossRef]

- Colusso, E.; Perotto, G.; Wang, Y.; Sturaro, M.; Omenetto, F.; Martucci, A. Bioinspired stimuli-responsive multilayer film made of silk–titanate nanocomposites. J. Mater. Chem. C 2017, 5, 3924–3931. [Google Scholar] [CrossRef]

- Jansen, C.; Neubauer, F.; Helbig, J.; Mittleman, D.M.; Koch, M. Flexible Bragg reflectors for the terahertz regime composed of polymeric compounds. In Proceedings of the 2007 Joint 32nd International Conference on Infrared and Millimeter Waves and the 15th International Conference on Terahertz Electronics, Cardiff Whales, Wales, 2–9 September 2007; pp. 984–986. [Google Scholar]

- Uehara, T.; Nakagawa, M.; Sugihara, O. Preparation of UV-cured organic–inorganic hybrid materials with low refractive index for multilayer film applications. Opt. Mater. Express 2013, 3, 1351–1357. [Google Scholar] [CrossRef]

- Druffel, T.; Mandzy, N.; Sunkara, M.; Grulke, E. Polymer Nanocomposite Thin Film Mirror for the Infrared Region. Small 2008, 4, 459–461. [Google Scholar] [CrossRef]

- Lova, P.; Manfredi, G.; Boarino, L.; Comite, A.; Laus, M.; Patrini, M.; Marabelli, F.; Soci, C.; Comoretto, D. Polymer Distributed Bragg Reflectors for Vapor Sensing. ACS Photonics 2015, 2, 537–543. [Google Scholar] [CrossRef]

- Lova, P. Selective Polymer Distributed Bragg Reflector Vapor Sensors. Polymers 2018, 10, 1161. [Google Scholar] [CrossRef] [PubMed]

- Jeon, S.J.; Chiappelli, M.C.; Hayward, R.C. Photocrosslinkable nanocomposite multilayers for responsive 1D photonic crystals. Adv. Func. Mater. 2016, 26, 722–728. [Google Scholar] [CrossRef]

- Scotognella, F.; Varo, S.; Criante, L.; Gazzo, S.; Manfredi, G.; Knarr, R.J.; Comoretto, D. Spin-coated polymer and hybrid multilayers and microcavities. In Organic and Hybrid Photonic Crystals; Springer: Cham, Switzerland, 2015; pp. 77–102. [Google Scholar]

- Lazarova, K.; Awala, H.; Thomas, S.; Vasileva, M.; Mintova, S.; Babeva, T. Vapor responsive one-dimensional photonic crystals from zeolite nanoparticles and metal oxide films for optical sensing. Sensors 2014, 14, 12207–12218. [Google Scholar] [CrossRef] [PubMed]

- Lazarova, K.; Georgiev, R.; Vasileva, M.; Georgieva, B.; Spassova, M.; Malinowski, N.; Babeva, T. One-dimensional PMMA–V2O5 photonic crystals used as color indicators of chloroform vapors. Opt. Quant. Electron. 2016, 48, 310–317. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, J.; Wang, Z.; Shen, H.; Xie, J.; Li, Y.; Lin, L.; Yang, B. Biochemical-to-optical signal transduction by pH sensitive organic–inorganic hybrid Bragg stacks with a full color display. J. Mater. Chem. C 2013, 1, 977–983. [Google Scholar] [CrossRef]

- Yoon, J.; Lee, W.; Caruge, J.-M.; Bawendi, M.; Thomas, E.L.; Kooi, S.; Prasad, P.N. Defect-mode mirrorless lasing in dye-doped organic/inorganic hybrid one-dimensional photonic crystal. Appl. Phys. Lett. 2006, 88, 091102–091104. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, J.; Li, J.; Xie, J.; Li, Y.; Liang, S.; Tian, Z.; Li, C.; Wang, Z.; Wang, T.; et al. Colorful detection of organic solvents based on responsive organic/inorganic hybrid one-dimensional photonic crystals. J. Mater. Chem. 2011, 21, 1264–1270. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, J.; Xie, J.; Yin, Y.; Wang, Z.; Shen, H.; Li, Y.; Li, J.; Liang, S.; Cui, L.; et al. Patterning Organic/Inorganic Hybrid Bragg Stacks by Integrating One-Dimensional Photonic Crystals and Macrocavities through Photolithography: Toward Tunable Colorful Patterns as Highly Selective Sensors. ACS Appl. Mater. Interfaces 2012, 4, 1397–1403. [Google Scholar] [CrossRef]

- Convertino, A.; Valentini, A.; Ligonzo, T.; Cingolani, R. Organic–inorganic dielectric multilayer systems as high reflectivity distributed Bragg reflectors. Appl. Phys. Lett. 1997, 71, 732–734. [Google Scholar] [CrossRef]

- Wu, Y.; Shen, H.; Ye, S.; Yao, D.; Liu, W.; Zhang, J.; Zhang, K.; Yang, B. Multifunctional reversible fluorescent controller based on a one-dimensional photonic crystal. ACS Appl. Mater. Interfaces 2016, 8, 28844–28852. [Google Scholar] [CrossRef]

- Pál, E.; Seemann, T.; Zöllmer, V.; Busse, M.; Dékány, I. Hybrid ZnO/polymer thin films prepared by RF magnetron sputtering. Colloid. Polym. Sci. 2009, 287, 481–485. [Google Scholar] [CrossRef]

- Kajii, H.; Kawata, M.; Okui, H.; Morifuji, M.; Kondow, M. Fabrication of inorganic/organic hybrid distributed Bragg reflectors based on inorganic CuSCN for all-solution-processed polymer light-emitting diodose. In Proceedings of the 2018 25th International Workshop on Active-Matrix Flatpanel Displays and Devices (AM-FPD), Kyoto, Japan, 3–6 July 2018; pp. 1–4. [Google Scholar]

- Wang, Y.; Li, X.; Nalla, V.; Zeng, H.; Sun, H. Solution-Processed Low Threshold Vertical Cavity Surface Emitting Lasers from All-Inorganic Perovskite Nanocrystals. Adv. Func. Mater. 2017, 27, 1605088. [Google Scholar] [CrossRef]

- Frezza, L.; Patrini, M.; Liscidini, M.; Comoretto, D. Directional Enhancement of Spontaneous Emission in Polymer Flexible Microcavities. J. Phys. Chem. C 2011, 115, 19939–19946. [Google Scholar] [CrossRef]

- Kleine, T.S.; Diaz, L.R.; Konopka, K.M.; Anderson, L.E.; Pavlopolous, N.G.; Lyons, N.P.; Kim, E.T.; Kim, Y.; Glass, R.S.; Char, K.; et al. One Dimensional Photonic Crystals Using Ultrahigh Refractive Index Chalcogenide Hybrid Inorganic/Organic Polymers. ACS Macro Lett. 2018, 7, 875–880. [Google Scholar] [CrossRef]

- Iasilli, G.; Francischello, R.; Lova, P.; Silvano, S.; Surace, A.; Pesce, G.; Alloisio, M.; Patrini, M.; Shimizu, M.; Comoretto, D.; et al. Luminescent Solar Concentrators: Boosted Optical Efficiency by Polymer Dielectric Mirrors. Mater. Chem. Front. 2019, 3, 429–436. [Google Scholar] [CrossRef]

- Zhang, J.; Song, J.; Zhang, H.; Ding, H.; Guo, K.; Wei, B.; Zheng, Y.; Zhang, Z. Sunlight-like white organic light-emitting diodes with inorganic/organic nanolaminate distributed Bragg reflector (DBR) anode microcavity by using atomic layer deposition. Org. Electron. 2016, 33, 88–94. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, H.; Zheng, Y.; Wei, M.; Ding, H.; Wei, B.; Zhang, Z. Super color purity green organic light-emitting diodes with ZrO2/zircone nanolaminates as a distributed Bragg reflector deposited by atomic layer deposition. Nanotechnology 2016, 28, 044002–044008. [Google Scholar] [CrossRef]

- Dubey, R.S.; Ganesan, V. Fabrication and characterization of TiO2/SiO2 based Bragg reflectors for light trapping applications. Results Phys. 2017, 7, 2271–2276. [Google Scholar] [CrossRef]

- Anaya, M.; Rubino, A.; Calvo, M.E.; Miguez, H. Solution processed high refractive index contrast distributed Bragg reflectors. J. Mater. Chem. C 2016, 4, 4532–4537. [Google Scholar] [CrossRef]

- Paternò, G.M.; Moscardi, L.; Donini, S.; Ariodanti, D.; Kriegel, I.; Zani, M.; Parisini, E.; Scotognella, F.; Lanzani, G. Hybrid One-Dimensional Plasmonic–Photonic Crystals for Optical Detection of Bacterial Contaminants. J. Phys. Chem. Lett. 2019, 10, 4980–4986. [Google Scholar] [CrossRef]

- Bonifacio, L.D.; Ozin, G.A.; Arsenault, A.C. Photonic nose–sensor platform for water and food quality control. Small 2011, 7, 3153–3157. [Google Scholar] [CrossRef] [PubMed]

- Tessler, N.; Burns, S.; Becker, H.; Friend, R.H. Suppressed angular color dispersion in planar microcavities. Appl. Phys. Lett. 1997, 70, 556–558. [Google Scholar] [CrossRef]

- Grüner, J.; Cacialli, F.; Friend, R.H. Emission enhancement in single-layer conjugated polymer microcavities. J. Appl. Phys. 1996, 80, 207–215. [Google Scholar] [CrossRef]

- Lova, P.; Cortecchia, D.; Soci, C.; Comoretto, D. Solution Processed Polymer-ABX4 Perovskite-Like Microcavities. Appl. Sci. 2019, 9, 5203. [Google Scholar] [CrossRef]

- Srinivasan, K.; Borselli, M.; Painter, O.; Stintz, A.; Krishna, S. Cavity Q, mode volume, and lasing threshold in small diameter AlGaAs microdisks with embedded quantum dots. Opt. Express 2006, 14, 1094–1105. [Google Scholar] [CrossRef]

- Feng, Q.; Wei, W.; Zhang, B.; Wang, H.; Wang, J.; Cong, H.; Wang, T.; Zhang, J. O-Band and C/L-Band III-V Quantum Dot Lasers Monolithically Grown on Ge and Si Substrate. Appl. Sci. 2019, 9, 385. [Google Scholar] [CrossRef]

- Clevenson, H.; Desjardins, P.; Gan, X.; Englund, D. High sensitivity gas sensor based on high-Q suspended polymer photonic crystal nanocavity. Appl. Phys. Lett. 2014, 104, 241108. [Google Scholar] [CrossRef]

- Palatnik, A.; Tischler, Y.R. Solid-state Rhodamine 6G Microcavity Laser. IEEE Photonics Technol. Lett. 2016, 28, 1823–1826. [Google Scholar] [CrossRef]

- Liscidini, M.; Andreani, L.C. Photonic crystals: An introductory survey. In Organic and Hybrid Photonic Crystals; Comoretto, D., Ed.; Springer International Publishing: Cham, Switzerland, 2015; pp. 3–29. [Google Scholar] [CrossRef]

- Tessler, N.; Denton, G.J.; Friend, R.H. Lasing from Conjugated-Polymer Microcavities. Nature 1996, 382, 695–697. [Google Scholar] [CrossRef]

- Scotognella, F.; Monguzzi, A.; Meinardi, F.; Tubino, R. DFB laser action in a flexible fully plastic multilayer. Phys. Chem. Chem. Phys. 2010, 12, 337–340. [Google Scholar] [CrossRef]

- Dawson, N.; Singer, K.D.; Andrews, J.H.; Crescimanno, M.; Mao, G.; Petrus, J.; Song, H.; Baer, E. Post-process tunability of folded one-dimensional all-polymer photonic crystal microcavity lasers. Nonlinear Opt. Quantum Opt. 2012, 45, 101–111. [Google Scholar]

- Song, H.; Singer, K.; Lott, J.; Wu, Y.; Zhou, J.; Andrews, J.; Baer, E.; Hiltner, A.; Weder, C. Continuous melt processing of all-polymer distributed feedback lasers. J. Mater. Chem. 2009, 19, 7520–7524. [Google Scholar] [CrossRef]

- Andrews, J.H.; Crescimanno, M.; Dawson, N.J.; Mao, G.; Petrus, J.B.; Singer, K.D.; Baer, E.; Song, H. Folding flexible co-extruded all-polymer multilayer distributed feedback films to control lasing. Opt. Express 2012, 20, 15580–15588. [Google Scholar] [CrossRef] [PubMed]

- Lott, J.; Song, H.; Wu, Y.; Zhou, J.; Baer, E.; Hiltner, A.; Weder, C.; Singer, K.D. Coextruded multilayer all-polymer dye lasers. In Organic Thin Films for Photonic Applications; American Chemical Society: Washington, WA, USA, 2010; Volume 1039, pp. 171–184. [Google Scholar]

- Goldenberg, L.M.; Lisinetskii, V.; Schrader, S. Fast and simple fabrication of organic Bragg mirrors—application to plastic microchip lasers. Laser Phys. Lett. 2013, 10, 055808. [Google Scholar] [CrossRef]

- Goldenberg, L.M.; Lisinetskii, V.; Schrader, S. All-polymer spin-coated organic vertical-cavity surface-emitting laser with high conversion efficiency. Appl. Phys. B 2015, 120, 271–277. [Google Scholar] [CrossRef]

- Sakata, H.; Takeuchi, H.; Natsume, K.; Suzuki, S. Vertical-cavity organic lasers with distributed-feedback structures based on active Bragg reflectors. Opt. Express 2006, 14, 11681–11686. [Google Scholar] [CrossRef]

- Menon, V.M.; Luberto, M.; Valappil, N.V.; Chatterjee, S. Lasing from InGaP quantum dots in a spin-coated flexible microcavity. Opt. Express 2008, 16, 19535–19540. [Google Scholar] [CrossRef]

- Yoon, J.; Lee, W.; Thomas, E.L. Optically pumped surface-emitting lasing using self-assembled block-copolymer-distributed Bragg reflectors. Nano Lett. 2006, 6, 2211–2214. [Google Scholar] [CrossRef]

- Karl, M.; Glackin, J.M.E.; Schubert, M.; Kronenberg, N.M.; Turnbull, G.A.; Samuel, I.D.W.; Gather, M.C. Flexible and ultra-lightweight polymer membrane lasers. Nat. Comm. 2018, 9, 1525–1527. [Google Scholar] [CrossRef]

- Yamamoto, Y.; Machida, S.; Björk, G. Microcavity semiconductor laser with enhanced spontaneous emission. Phys. Rev. A 1991, 44, 657–668. [Google Scholar] [CrossRef]

- Skolnick, M.S.; Fisher, T.A.; Whittaker, D.M. Strong coupling phenomena in quantum microcavity structures. Semicond. Sci. Technol. 1998, 13, 645–669. [Google Scholar] [CrossRef]

- Kimble, H.J. The quantum internet. Nature 2008, 453, 1023–1030. [Google Scholar] [CrossRef] [PubMed]

- Novotny, L. Strong coupling, energy splitting, and level crossings: A classical perspective. Am. J. Phys. 2010, 78, 1199–1202. [Google Scholar] [CrossRef]

- Gerard, J.M.; Gayral, B. Strong Purcell Effect for Inas Quantum Boxes in Three-Dimensional Solid-State Microcavities. J. Lightwave Technol. 1999, 17, 2089–2095. [Google Scholar] [CrossRef]

- Laussy, F.P. Microcavities; Oxford University Press: New York, NY, USA, 2017. [Google Scholar]

- Yokoyama, H.; Nishi, K.; Anan, T.; Nambu, Y.; Brorson, S.; Ippen, E.; Suzuki, M. Controlling spontaneous emission and threshold-less laser oscillation with optical microcavities. Opt. Quantum Electron. 1992, 24, S245–S272. [Google Scholar] [CrossRef]

- McKenzie, J.; Lee, T.; Zoorob, M. Inverted-Pyramidal Photonic Crystal Light Emitting Device. U.S. Patent 7,700,962, 20 April 2010. [Google Scholar]

- Fornasari, L.; Floris, F.; Patrini, M.; Comoretto, D.; Marabelli, F. Demonstration of fluorescence enhancement via bloch surface waves in all-polymer multilayer structures. Phys. Chem. Chem. Phys. 2016, 18, 14086–14093. [Google Scholar] [CrossRef]

- Bellingeri, M.; Chiasera, A.; Kriegel, I.; Scotognella, F. Optical properties of periodic, quasi-periodic, and disordered one-dimensional photonic structures. Opt. Mater. 2017, 72, 403–421. [Google Scholar] [CrossRef]

- Savona, V.; Andreani, L.C.; Schwendimann, P.; Quattropani, A. Quantum well excitons in semiconductor microcavities: Unified treatment of weak and strong coupling regimes. Solid State Commun. 1995, 93, 733–739. [Google Scholar] [CrossRef]

- Tischler, J.R.; Bradley, M.S.; Bulovic, V.; Song, J.H.; Nurmikko, A. Strong coupling in a microcavity LED. Phys. Rev. Lett. 2005, 95, 036401–036404. [Google Scholar] [CrossRef]

- Sumioka, K.; Nagahama, H.; Tsutsui, T. Strong coupling of exciton and photon modes in photonic crystal infiltrated with organic–inorganic layered perovskite. Appl. Phys. Lett. 2001, 78, 3–4. [Google Scholar] [CrossRef]

- Schouwinka, P.; Berlepschb, H.v.; Dahnec, L.; Mahrt, R.F. Dependence of Rabi-splitting on the spatial position of the optically active layer in organic microcavities in the strong coupling regime. Chem. Phys. 2002, 285, 113–120. [Google Scholar] [CrossRef]

- Oulton, R.F.; Takada, N.; Koe, J.; Stavrinou, P.N.; Bradley, D.D.C. Strong coupling in organic semiconductor microcavities. Semicond. Sci. Technol. 2003, 18, S419. [Google Scholar] [CrossRef]

- Baba, T.; Sano, D. Low-Threshold Lasing and Purcell Effect in Microdisk Lasers at Room Temperature. IEEE J. Sel. Top. Quantum Electron. 2003, 9, 1340–1346. [Google Scholar] [CrossRef]

- Wang, J.; Cao, R.; Da, P.; Wang, Y.; Hu, T.; Wu, L.; Lu, J.; Shen, X.; Xu, F.; Zheng, G.; et al. Purcell effect in an organic-inorganic halide perovskite semiconductor microcavity system. Appl. Phys. Lett. 2016, 108, 022103. [Google Scholar] [CrossRef]

- Noda, S.; Fujita, M.; Asano, T. Spontaneous-emission control by photonic crystals and nanocavities. Nat. Photon. 2007, 1, 449–458. [Google Scholar] [CrossRef]

- Björk, G.; Machida, S.; Yamamoto, Y.; Igeta, K. Modification of Spontaneous Emission Rate in Planar Dielectric Microcavity Structures. Phys. Rev. A 1991, 44, 669–681. [Google Scholar] [CrossRef]

- Purcell, E.M. Spontaneous Emission Probabilities at Radio Frequencies; Springer: Boston, MA, USA, 1946; Volume 340, p. 681. [Google Scholar]

- Virgili, T.; Lidzey, D.G.; Grell, M.; Walker, S.; Asimakis, A.; Bradley, D.D.C. Completely polarized photoluminescence emission from a microcavity containing an aligned conjugated polymer. Chem. Phys. Lett. 2001, 341, 219–224. [Google Scholar] [CrossRef]

- Hopmeier, M.; Guss, W.; Deussen, M.; Göbel, E.O.; Mahrt, R.F. Enhanced dipole-dipole interaction in a polymer microcavity. Phys. Rev. Lett. 1999, 82, 4118–4121. [Google Scholar] [CrossRef]

- Rybin, M.V.; Zherzdev, A.V.; Feoktistov, N.A.; Pevtsov, A.B. Effect of photonic crystal stop-band on photoluminescence of a−Si1−xCx:H. Phys. Rev. B 2017, 95, 165118–165119. [Google Scholar] [CrossRef]

- Rigneault, H.; Monneret, S. Modal analysis of spontaneous emission in a planar microcavity. Phys. Rev. A 1996, 54, 2356–2368. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, K.; Nakamura, T.; Takamatsu, W.; Yamanishi, M.; Lee, Y.; Ishihara, T. Cavity-Induced Changes of Spontaneous Emission Lifetime in One-Dimensional Semiconductor Microcavities. Phys. Rev. Lett. 1995, 74, 3380–3383. [Google Scholar] [CrossRef]

- Jin, R.; Tobin, M.; Leavitt, R.; Gibbs, H.; Khitrova, G.; Boggavarapu, D.; Lyngnes, O.; Lindmark, E.; Jahnke, F.; Koch, S. Order of magnitude enhanced spontaneous emission from room-temperature bulk GaAs. In Microcavities and Photonic Bandgaps: Physics and Applications; Springer: New York, NY, USA, 1996; pp. 95–103. [Google Scholar]

- Tzeng, P.; Hewson, D.J.; Vukusic, P.; Eichhorn, S.J.; Grunlan, J.C. Bio-inspired iridescent layer-by-layer assembled cellulose nanocrystal Bragg stacks. J. Mater. Chem. C 2015, 3, 4260–4264. [Google Scholar] [CrossRef]

- Stefik, M.; Guldin, S.; Vignolini, S.; Wiesner, U.; Steiner, U. Block copolymer self-assembly for nanophotonics. Chem. Soc. Rev. 2015, 44, 5076–5091. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Zheng, Y.; Pribyl, J.; Benicewicz, B.C. A versatile approach to different colored photonic films generated from block copolymers and their conversion into polymer-grafted nanoplatelets. J. Mater. Chem. C 2017, 5, 9873–9878. [Google Scholar] [CrossRef]

- Bachevillier, S.; Yuan, H.-K.; Strang, A.; Levitsky, A.; Frey, G.L.; Hafner, A.; Bradley, D.D.C.; Stavrinou, P.N.; Stingelin, N. Dae-Hwan Jung, In Jun Park, Young Kook Choi, Soo-Bok Lee, Hyung Sang Park, and Jürgen Rühe Perfluorinated Polymer Monolayers on Porous Silica for Materials with Super Liquid Repellent Properties. Langmuir 2002, 18, 6133–6139. [Google Scholar]

- Vesel, A.; Kovac, J.; Primc, G.; Junkar, I.; Mozetic, M. Effect of H2S plasma treatment on the surface modification of a polyethylene terephthalate surface. Materials 2016, 9, 95. [Google Scholar] [CrossRef] [PubMed]

- Miron, C.; Sava, I.; Jepu, I.; Osiceanu, P.; Lungu, C.P.; Sacarescu, L.; Harabagiu, V. Surface Modification of the Polyimide Films by Electrical Discharges in Water. Plasma Processes Polym. 2013, 10, 798–807. [Google Scholar] [CrossRef]

- Dufour, T.; Hubert, J.; Viville, P.; Duluard, C.Y.; Desbief, S.; Lazzaroni, R.; Reniers, F. PTFE Surface Etching in the Post-discharge of a Scanning RF Plasma Torch: Evidence of Ejected Fluorinated Species. Plasma Processes Polym. 2012, 9, 820–829. [Google Scholar] [CrossRef]

- Yang, Y.; Strobel, M.; Kirk, S.; Kushner, M.J. Fluorine Plasma Treatments of Poly(propylene) Films, 2—Modeling Reaction Mechanisms and Scaling. Plasma Processes Polym. 2010, 7, 123–150. [Google Scholar] [CrossRef]

- Kirk, S.; Strobel, M.; Lee, C.-Y.; Pachuta, S.J.; Prokosch, M.; Lechuga, H.; Jones, M.E.; Lyons, C.S.; Degner, S.; Yang, Y.; et al. Fluorine Plasma Treatments of Polypropylene Films, 1—Surface Characterization. Plasma Processes Polym. 2010, 7, 107–122. [Google Scholar] [CrossRef]

- Avasthi, D.K.; Mishra, Y.K.; Kabiraj, D.; Lalla, N.P.; Pivin, J.C. Synthesis of metal–polymer nanocomposite for optical applications. Nanotechnology 2007, 18, 125604. [Google Scholar] [CrossRef]

| Polymer | Refractive Index (at 600 nm) | Solvent | Ref. | |

|---|---|---|---|---|

| HI | PVK | 1.68 | Toluene, dichlorobenzene | [95] |

| PPO | 1.57 | Toluene, carbon tetrachloride | [96] | |

| PS | 1.57 | Toluene | [81,97] | |

| LH | PAA | 1.51 | 2-Methyl-2-pentanol | [98] |

| CA | 1.46 | Diacetone alcohol | [81,97] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lova, P.; Megahd, H.; Stagnaro, P.; Alloisio, M.; Patrini, M.; Comoretto, D. Strategies for Dielectric Contrast Enhancement in 1D Planar Polymeric Photonic Crystals. Appl. Sci. 2020, 10, 4122. https://doi.org/10.3390/app10124122

Lova P, Megahd H, Stagnaro P, Alloisio M, Patrini M, Comoretto D. Strategies for Dielectric Contrast Enhancement in 1D Planar Polymeric Photonic Crystals. Applied Sciences. 2020; 10(12):4122. https://doi.org/10.3390/app10124122

Chicago/Turabian StyleLova, Paola, Heba Megahd, Paola Stagnaro, Marina Alloisio, Maddalena Patrini, and Davide Comoretto. 2020. "Strategies for Dielectric Contrast Enhancement in 1D Planar Polymeric Photonic Crystals" Applied Sciences 10, no. 12: 4122. https://doi.org/10.3390/app10124122

APA StyleLova, P., Megahd, H., Stagnaro, P., Alloisio, M., Patrini, M., & Comoretto, D. (2020). Strategies for Dielectric Contrast Enhancement in 1D Planar Polymeric Photonic Crystals. Applied Sciences, 10(12), 4122. https://doi.org/10.3390/app10124122