Characterization of Demolition Construction Waste Containing Asbestos, and the Release of Fibrous Dust Particles

Abstract

1. Introduction

2. Materials and Methods

2.1. Building Containing Asbestos–Cement (AC) Materials

2.2. Characterization of Demolition Asbestos-Containing Waste

2.3. Sampling Plan for Measuring Asbestos Dust

2.4. Sampling Posts for Quality Monitoring of Indoor Air

2.5. Sampling of Released Asbestos Dust

2.6. Determining the Number and Mass Concentration

2.7. Removal of Asbestos–Cement Materials (ACMs)

3. Results and Discussion

3.1. Characterization of AC Waste

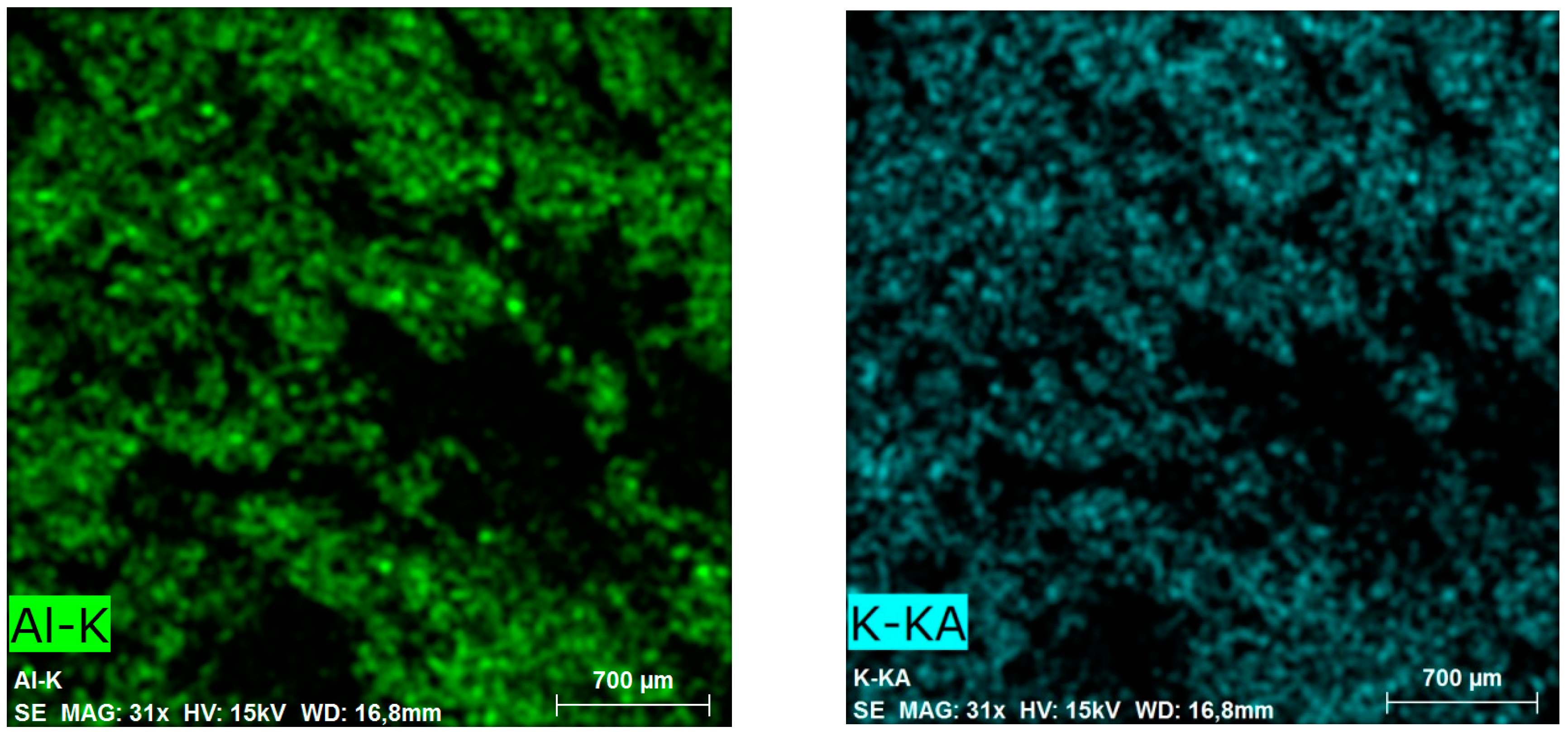

3.1.1. Chemical Composition and Surface Morphology of AC Waste

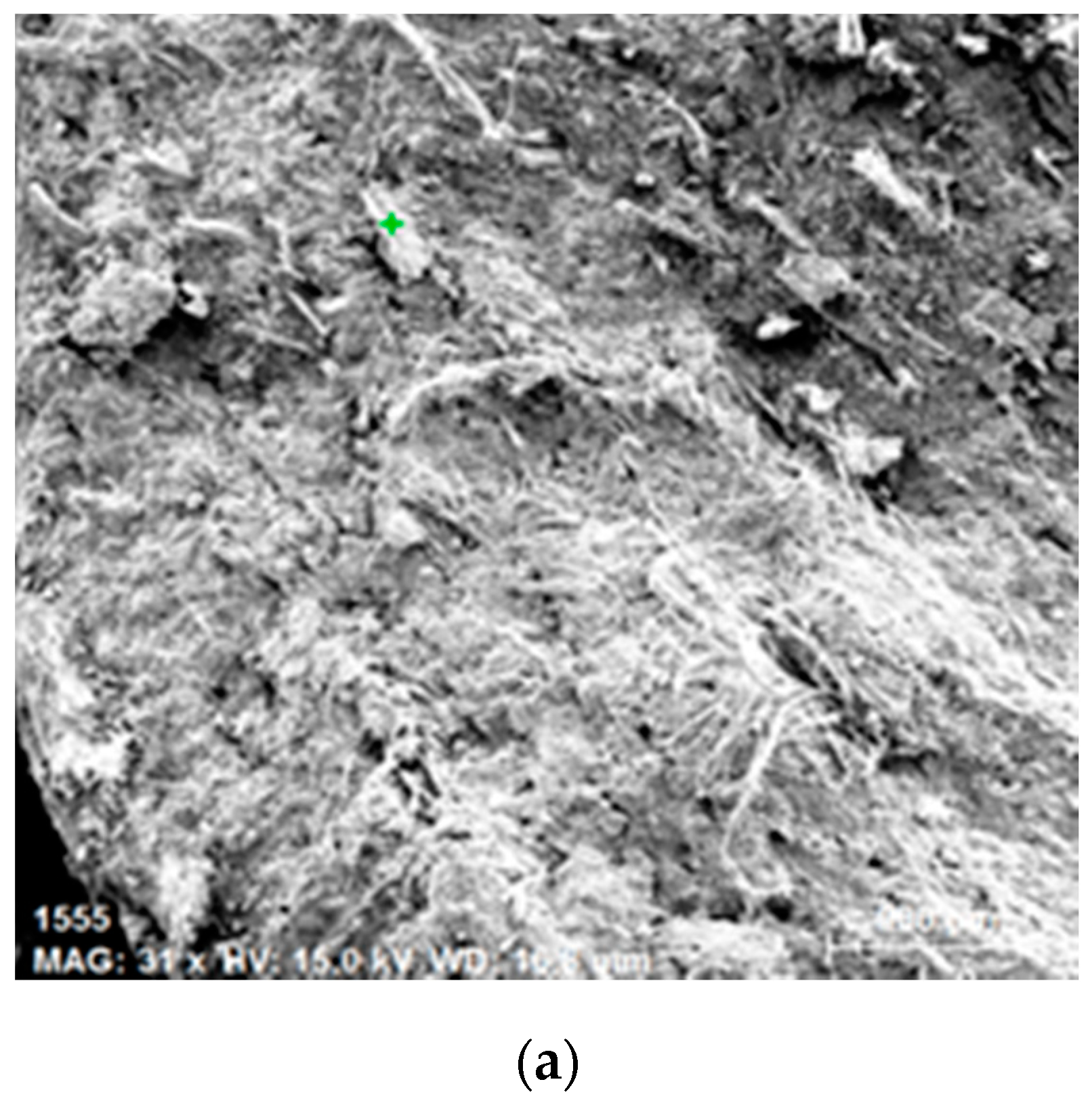

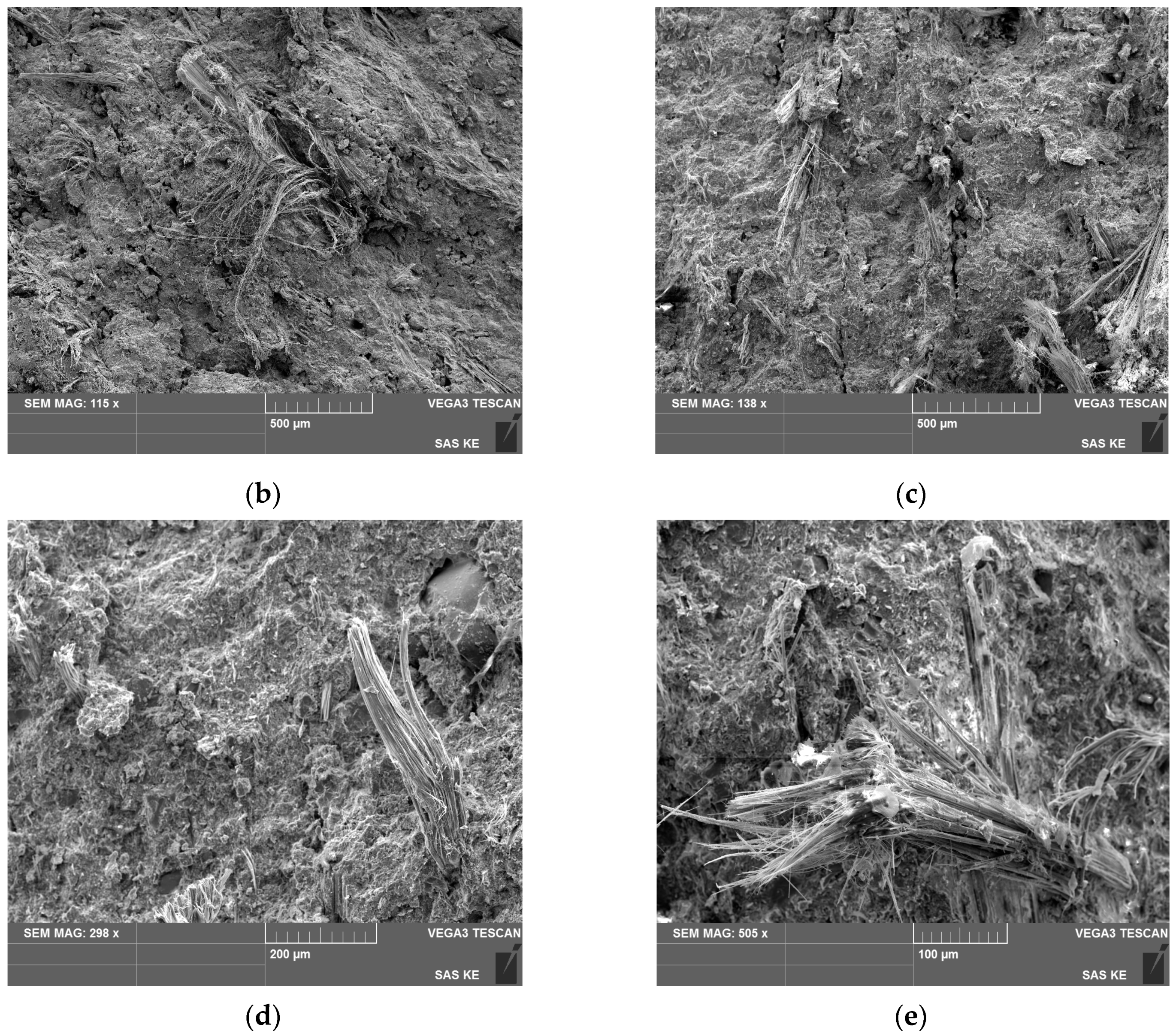

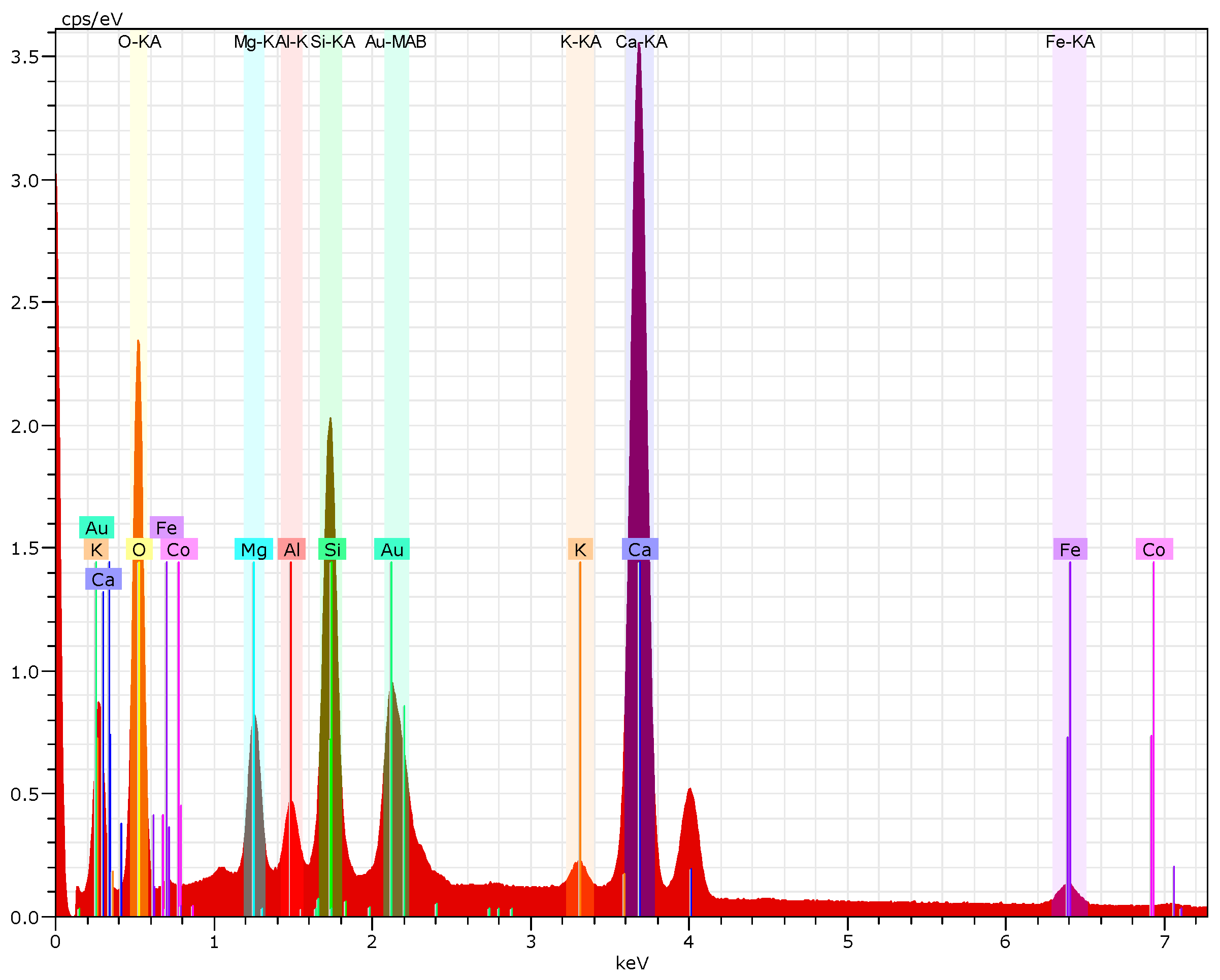

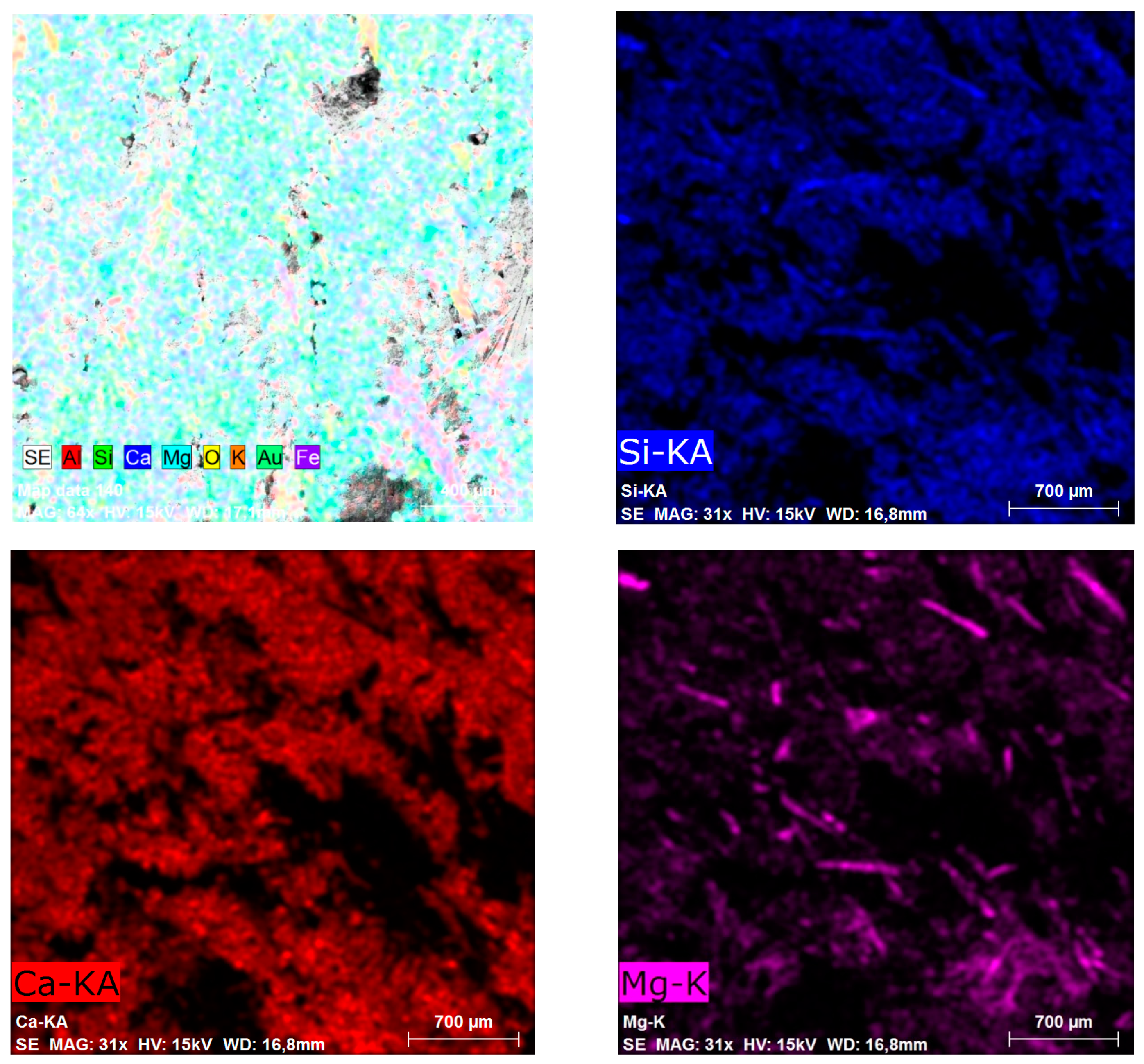

3.1.2. Scanning Electron Microscopy (SEM) and Energy-Dispersive X-ray Spectroscopy (EDS) Investigations of AC Waste

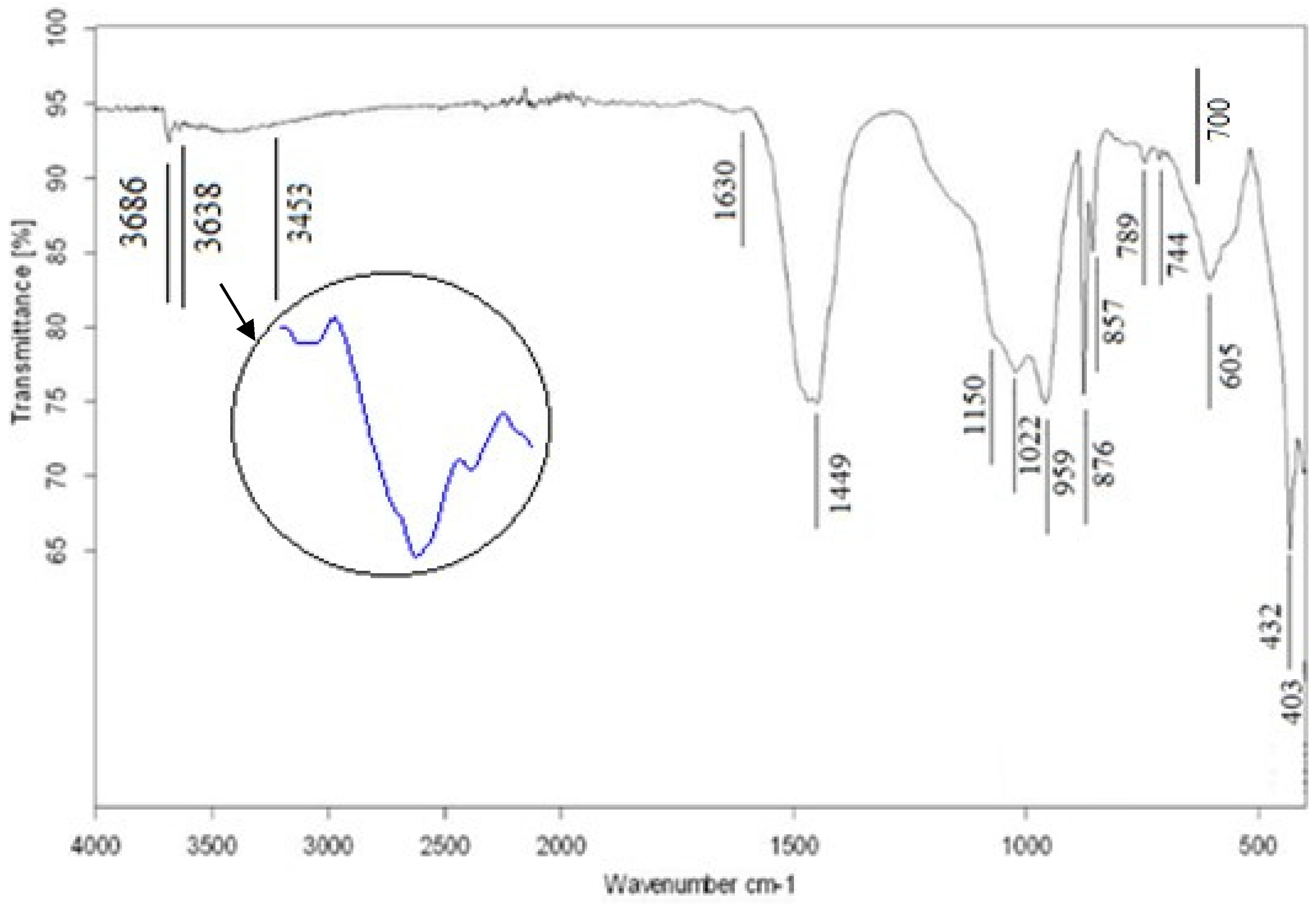

3.1.3. Fourier Transform Infrared (FTIR) Spectroscopy and X-ray Diffraction (XRD) Study of AC Waste

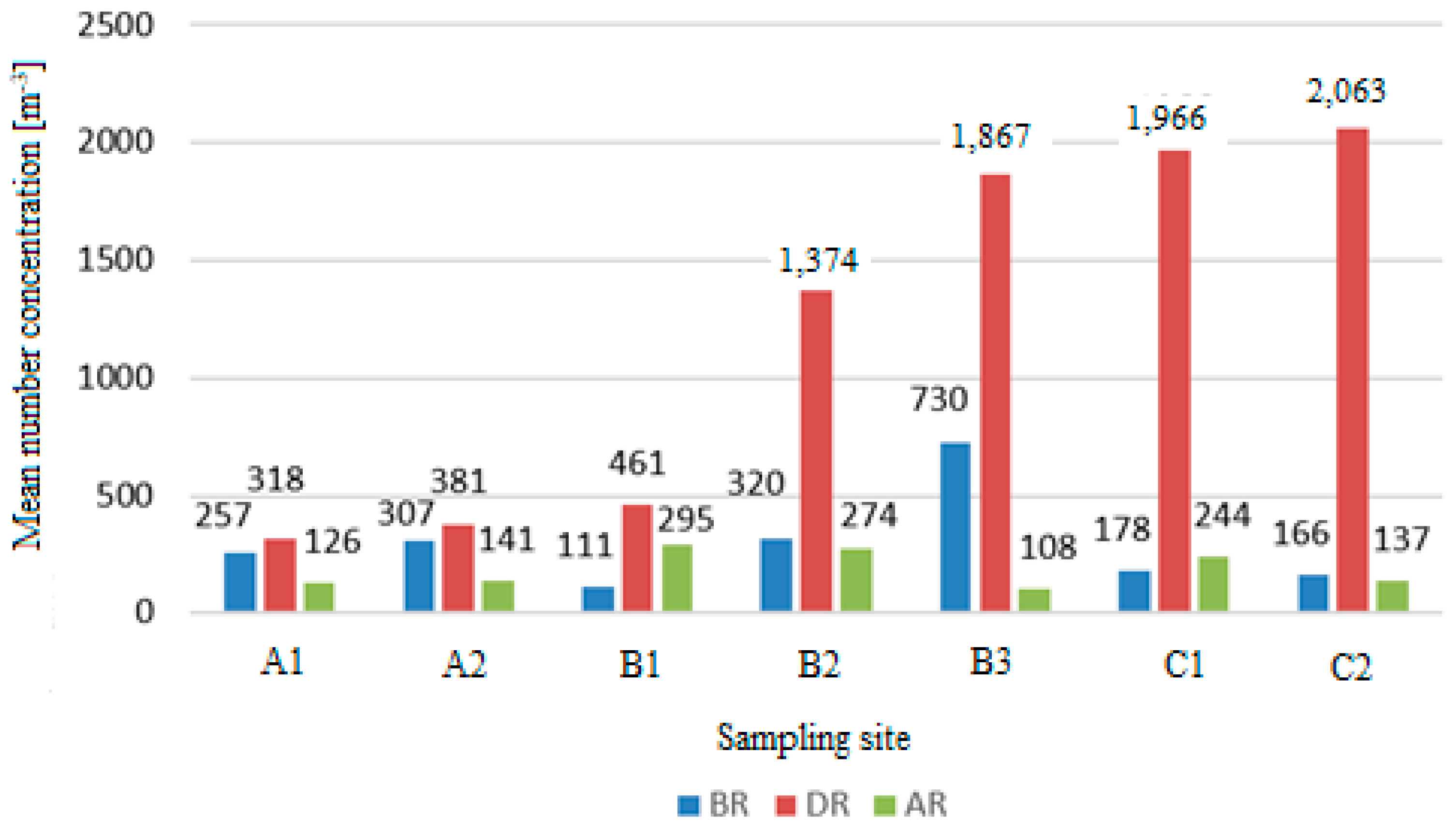

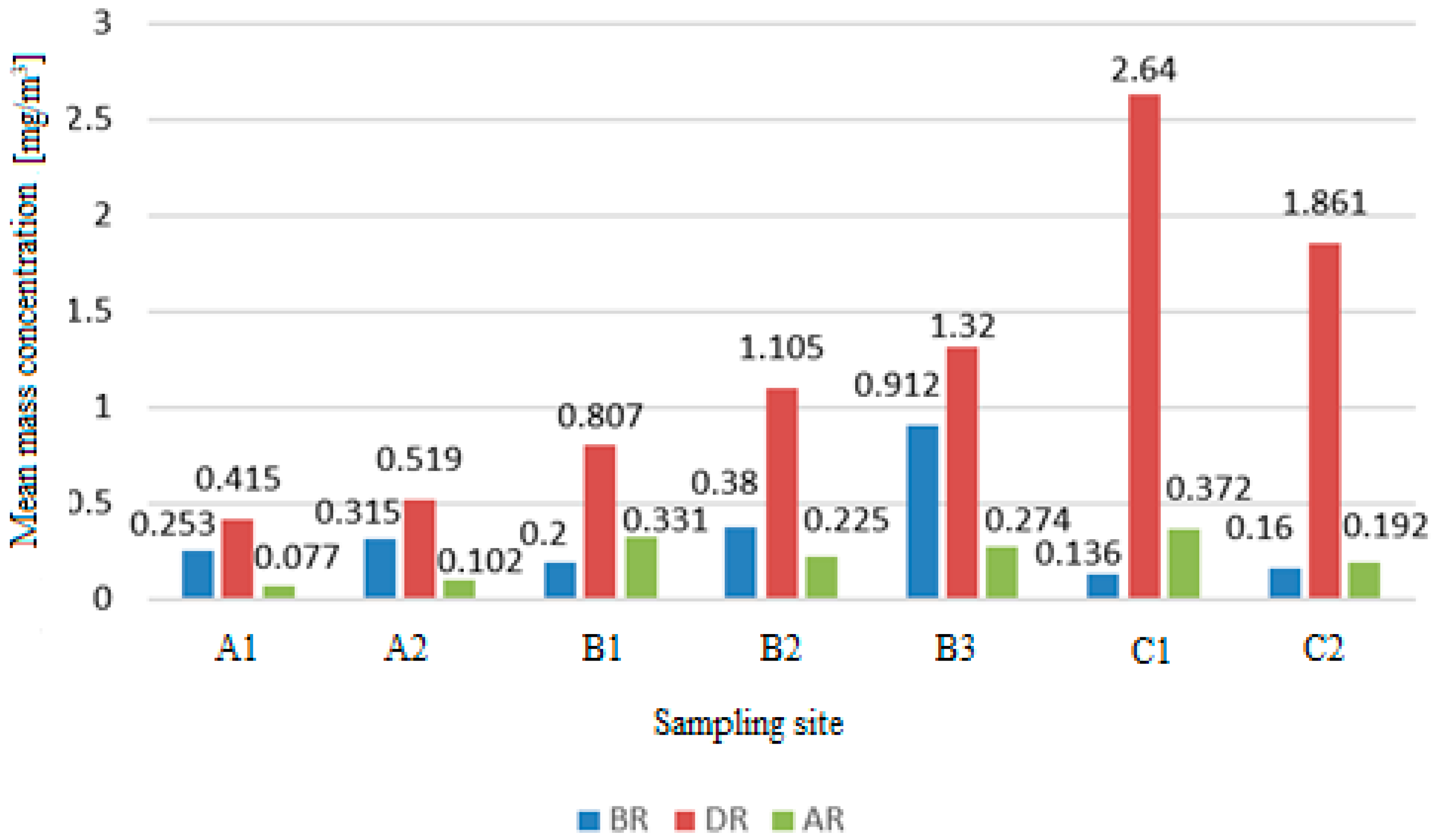

3.2. Monitoring of Airborne Asbestos Fibers

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- International Agency of Research on Cancer (IARC) monographs, suppl. 7, 1987, 139–142. In Overall Evaluations of Carcinogenity: An Updating of IARC Monographs Volumes 1 to 42; International Agency of Research on Cancer: Lyon, France, 1987.

- World Health Organization (WHO). Elimination of Asbestos-Related Diseases. 2006. Available online: https://apps.who.int/iris/handle/10665/69479 (accessed on 14 May 2020).

- Abelmann, A.; Glynn, M.E.; Pierce, J.S.; Scott, P.K.; Serrano, S.; Paustenbach, D.J. Historical ambient airborne asbestos concentrations in the United States—An analysis of published and unpublished literature (1960s–2000s). Inhal. Toxicol. 2015, 27, 754–766. [Google Scholar] [CrossRef] [PubMed]

- Świątkowska, B.; Szeszenia-Dąbrowska, N.; Wilczyńska, U. Medical monitoring of asbestos-exposed workers: Experience from Poland. Bull. World. Health Organ. 2016, 94, 599–604. [Google Scholar] [CrossRef] [PubMed]

- Baur, X.; Soskolne, C.L.; Lemen, R.A.; Schneider, J.; Woitowitz, H.J.; Budnik, L.T. How conflicted authors undermine the World Health Organization (WHO) campaign to stop all use of asbestos: Spotlight on studies showing that chrysotile is carcinogenic and facilitates other non-cancer asbestos-related diseases. Int. J. Occup. Environ. Health 2015, 21, 176–179. [Google Scholar] [CrossRef]

- Commission Directive 1999/77/EC of 26 July 1999. Official Journal of the European Communities, 6 August 1999.

- Li, J.; Dong, Q.; Yu, K.; Liu, L. Asbestos and asbestos waste management in the Asian-Pacific region: Trends, challenges and solutions. J. Clean. Prod. 2014, 81, 218–226. [Google Scholar] [CrossRef]

- Baur, X.; Frank, A.L.; Budnik, L.T.; Woitowitz, H.J.; Oliver, L.C.; Welch, L.S.; Landrigan, P.; Lemen, R. Collegium Ramazzini: Comments on the 2014 Helsinki consensus report on asbestos. Am. J. Ind. Med. 2016, 59, 591–594. [Google Scholar] [CrossRef] [PubMed]

- Marsili, D.; Terracini, B.; Santana, V.S.; Ramos-Bonilla, J.P.; Pasetto, R.; Mazzeo, A.; Loomis, D.; Comba, P.; Algranti, E. Prevention of asbestos-related disease in countries currently using asbestos. Int. J. Environ. Res. Public Health 2016, 13, 494. [Google Scholar] [CrossRef] [PubMed]

- Hurbánková, M. Ceramic fibres—Properties, use, effects on respiratory system. Czech Occup. Med. 2006, 4, 203–208. [Google Scholar]

- Bobst, S. The history of risk assessment within OSHA and ACGIH: Asbestos case study. In History of Risk Assessment in Toxicology, A Volume in History of Toxicology and Environmental Health; Bobst, S., Ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 27–30. [Google Scholar] [CrossRef]

- OSHA Fact Sheet. Asbestos. Available online: https://www.osha.gov/Publications/OSHA3507.pdf (accessed on 14 May 2020).

- Directive 2003/18/EC of the European Parliament and of the Council of 27 March 2003 Amending Council Directive 83/477/EEC on the Protection of Workers from the Risks Related to Exposure to Asbestos at Work. Official Journal L 97, 15/04/2003, pp. 48–52. Available online: http://data.europa.eu/eli/dir/2003/18/oj (accessed on 14 May 2020).

- Directive 2009/148/EC of the European Parliament and of the Council of 30 November 2009 on the Protection of Workers from the Risks Related to Exposure to Asbestos at Work. Official Journal L 330, 16.12.2009, pp. 28–36. Available online: http://data.europa.eu/eli/dir/2009/148/oj (accessed on 14 May 2020).

- Bujak-Pietrek, S.; Szadkowska-Stańczyk, I. Exposure to respirable asbestos fibers at various stage of asbestos removal work. Med. Pr. 2012, 63, 191–198. [Google Scholar]

- Neitzel, R.L.; Sayler, S.K.; Demond, A.H.; Arcy, H.; Garabant, D.H.; Franzblau, A. Measurement of asbestos emissions associated with demolition of abandoned residential dwellings. Sci. Total Environ. 2020, 722, 137891. [Google Scholar] [CrossRef]

- Sakol, G.; Muszyňska-Graca, M. Air pollution during asbestos removal. Pol. J. Environ. Stud. 2019, 28, 1–5. [Google Scholar] [CrossRef]

- Szeszenia-Dąbrowska, N.; Sobala, W.; Swiątkowska, B.; Stroszejn-Mrowca, G.; Wilczyńska, U. Environmental asbestos pollution—Situation in Poland. Int. J. Occup. Med. Environ. Health 2012, 25, 3–13. [Google Scholar] [CrossRef] [PubMed]

- Lange, J.; Thomulka, K. Airborne exposure concentrations during asbestos abatement of ceiling and wall plaster. Bull. Environ. Contam. Toxicol. 2002, 69, 712–718. [Google Scholar] [CrossRef] [PubMed]

- Perkins, R.A.; Hargesheimer, J.; Fourie, W. Asbestos release from whole-building demolition of buildings with asbestos-containing material. J. Occup. Environ. Hyg. 2007, 4, 889–894. [Google Scholar] [CrossRef] [PubMed]

- Brown, S.K. Asbestos exposure during renovation and demolition of asbestos cement clad buildings. Am. Ind. Hyg. Assoc. J. 1987, 48, 478–486. [Google Scholar] [CrossRef] [PubMed]

- Darcy, D.J.; Feltner, C. Occupational and environmental exposure to asbestos. In Pathology of Asbestos-Associated Diseases, 1st ed.; Oury, D., Sporn, T.A., Roggli, V.L., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 11–24. [Google Scholar]

- Obminski, A.; Janeczek, J. The effectiveness of asbestos stabilizers during abrasion of asbestos-cement sheets. Constr. Build. Mater. 2020, 249, 118767. [Google Scholar] [CrossRef]

- Kinney, P.L.; Satterfield, M.H.; Shaikh, R.A. Aiborne fiber levels during asbestos operations and maitance work in a large office building. Appl. Occup. Environ. Hyg. 1994, 9, 825–835. [Google Scholar] [CrossRef]

- Boulanger, G.; Andujar, P.; Pairon, J.C.; Billon-Galland, M.A.; Dion, C.; Dumortier, P.; Brochard, P.; Sobaszek, A.; Bartsch, P.; Paris, C.; et al. Quantification of short and long asbestos fibers to assess asbestos exposure: A review of fiber size toxicity. Environ. Health 2014, 13, 59. [Google Scholar] [CrossRef]

- Suzuki, Y.; Yuen, S.R.; Ashley, R. Short, thin asbestos fibers contribute to the development of human malignant mesothelioma: Pathological evidence. Int. J. Hyg. Environ. Health 2005, 208, 201–210. [Google Scholar] [CrossRef]

- IARC Monograph: Asbestos (Chrysotile, Amosite, Crocidolite, Tremolite, Actinolite, and Anthophyllite). In Metals, Arsenic, Dusts and Fibres; IARC Monographs on the Evaluation of Carcinogenic Risks to Humans Volume 100C; IARC: Lyon, France, 2012; pp. 219–309. Available online: http://monographs.iarc.fr/ENG/Monographs/vol100C/mono100C-11.pdf (accessed on 14 May 2020).

- Bernstein, D.M. The health risk of chrysotile asbestos. Curr. Opin. Pulm. Med. 2014, 20, 366–370. [Google Scholar] [CrossRef]

- Hashim, D.; Boffetta, P. Occupational and environmental exposures and cancers in developing countries. Ann. Glob. Health 2014, 80, 393–411. [Google Scholar] [CrossRef]

- Kratzke, P.; Kratzke, R.A. Asbestos-related disease. J. Radiol. Nurs. 2018, 37, 21–26. [Google Scholar] [CrossRef]

- Nynäs, P.; Pukkala, E.; Vainio, H.; Oksa, P. Cancer incidence in asbestos-exposed workers: An update on four Finnish cohorts. Saf. Health Work 2017, 8, 169–174. [Google Scholar] [CrossRef]

- Takala, J. Eliminating occupational cancer. Ind. Health 2015, 53, 307–309. [Google Scholar] [CrossRef]

- Gilham, C.; Rake, C.; Hodgson, J.; Darnton, A.; Burdett, G.; Wild, J.P.; Newton, N.A.; Davidson, L.; Shires, M.; Treasure, T.; et al. Current asbestos exposure and future mesothelioma risks in Britain: The Inhaled Particles Study (TIPS). Int. J. Epidemiol. 2018, 47, 1745–1756. [Google Scholar] [CrossRef]

- Felten, M.; Khatab, K.; Knoll, L.; Schetten, T.; Muller-Berndorff, H.; Kraus, T. Changes of mesothelin and osteopontin levels over time in formerly asbestos-exposed power industry workers. Int. Arch. Occup. Environ. Health 2014, 87, 195–204. [Google Scholar] [CrossRef]

- Kim, Y.C.; Hong, W.H. Optimal management program for asbestos containing building materials to be available in the event of a disaster. Waste Manag. 2017, 64, 272–285. [Google Scholar] [CrossRef]

- Baek, S.C.; Kim, Y.C.; Hong, W.H. Determination of the essential activity elements of an asbestos management system in the event of a disaster and their prioritization. J. Clean. Prod. 2016, 137, 414–426. [Google Scholar] [CrossRef]

- Paglietti, F.; Malinconico, S.; Conestabiledella-Staffa, B.; Bellagamba, S.; De Simone, P. Classification and management of asbestos-containing waste: European legislation and the Italian experience. Waste Manag. 2016, 50, 130–150. [Google Scholar] [CrossRef]

- Serranti, S.; Bonifazi, G. Detection and classification of asbestos and other contminnts in C&DW by advenced Technologies. In Advances in Construction and Demolition Waste Recycling. Management, Processing and Environmental Assessment; Pacheco-Torgal, F., Ding, Y., Colangelo, F., Tuladhar, R., Koutamanis, A., Eds.; Woodhead Publishing Series in Civil and Structural Engineering; Elsevier: Amsterdam, The Netherlands, 2020; pp. 407–437. [Google Scholar] [CrossRef]

- STN EN ISO 16000-7. Indoor Air—Part 7: Sampling Strategy for Determination of Airborne Asbestos Fibre Concentrations (ISO 16000-7:2007); Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 2008.

- Pawełczyk, A.; Božek, F. Health risk associated with airborne asbestos. Environ. Monit. Assess. 2015, 187, 428. [Google Scholar] [CrossRef]

- ISO 8672 Air Quality—Determination of the Number Concentration of Airborne Inorganic Fibres by Phase Contrast Optical Microscopy—Membrane Filter Method; American National Standards Institute: Washington, DC, USA, 2014.

- ISO 14966 Ambient Air—Determination of Numerical Concentration of Inorganic Fibrous Particles—Scanning Electron Microscopy Method; American National Standards Institute: Washington, DC, USA, 2002.

- Technische Regeln für Gefahrstoffe Asbest Abbruch-, Sanierungs- oder Instandhaltungsarbeiten (TRGS 519). Bundesanstalt für Arbeitschutz und Arbeitmedizin, 2014. Available online: www.baua.de/ags (accessed on 14 May 2020).

- National Council of the Slovak Republic. Law 335/2007 on the Protection, Promotion and Development of Public Health and on Amendments to Certain Acts. Collection of Laws 103/2015; Resort of Justice of the Slovak Republic: Bratislava, Slovakia, 2015.

- Regulation of the Government of the Slovak Republic 356/2006 on the Protection of the Health of Workers from Risks Related to Exposure to Carcinogenic and Mutagenic Factors at Work; Resort of Justice of the Slovak Republic: Bratislava, Slovakia, 2006.

- Regulations of the Goverment of the Slovak Republic 355/2006 Coll. on the Protection of Employees from Risk Related to Exposure to Chemical Agents at Work, as Amended; Resort of Justice of the Slovak Republic: Bratislava, Slovakia, 2006.

- Regulations of the Goverment of the Slovak Republic 83/2015 Coll. on the Protection of Employees´ Health against Risks Related to Exposure to Carcinogenic and Mutagenic Factors at Work, as Amended; Resort of Justice of the Slovak Republic: Bratislava, Slovakia, 2015.

- Witek, J.; Kusiorowski, R. Neutralisation of asbestos-containing waste by melting in an arc-resistance furnace. Waste Manag. 2017, 69, 336–345. [Google Scholar] [CrossRef]

- Viani, A.; Gualtieri, A.F.; Secco, M.; Peruzzo, L.; Artioli, G.; Cruciani, G. Crystal chemistry of cement–asbestos. Am. Miner. 2013, 98, 1095–1105. [Google Scholar] [CrossRef]

- Kusiorowski, R.; Zaremba, T.; Piotrowski, J. The potential use of cement-asbestos waste in the ceramic masses destined for sintered wall clay brick manufacture. Ceram. Int. 2014, 40, 11995–12002. [Google Scholar] [CrossRef]

- Tomasetti, L.; Di Giuseppe, D.; Zoboli, A.; Paolini, V.; Torre, M.; Paris, E.; Guerriero, E.; Petracchini, F.; Gualtieri, A.F. Emission of fibres and atmospheric pollutants from the thermal treatment of asbestos containing waste (ACW). J. Clean. Prod. 2020, 268, 122179. [Google Scholar] [CrossRef]

- Anbalagan, G.; Sivakumar, G.; Prabakaran, A.R.; Gunasekaran, S. Spectroscopic characterization of natural chrysotile. Vib. Spectrosc. 2010, 52, 122–127. [Google Scholar] [CrossRef]

- Wypych, F.; Schreiner, W.H.; Mattoso, N.; Mosca, D.H.; Marangoni, R.; Bento, C.A.d.S. Covalent grafting of phenylphosphonate groups onto layered silica derived from in situ-leached chrysotile fibers. J. Mater. Chem. 2003, 13, 304–307. [Google Scholar] [CrossRef]

- Zaharaki, D.; Komnitsas, K.; Perdikatsis, V. Use of analytical techniques for identification of inorganic polymer gel composition. J. Mater. Sci. 2010, 4, 2715–2724. [Google Scholar] [CrossRef]

- Colangelo, F.; Cioffi, R.; Lavorgna, M.; Verdolotti, L.; De Stefano, L. Treatment and recycling of asbestos-cement containing waste. J. Hazard. Mater. 2011, 195, 391–397. [Google Scholar] [CrossRef]

- Šontevska, V.; Jovanovski, G.; Makreski, P. Minerals from Macedonia. Part XIX. Vibrational spectroscopy as identification tool for some sheet silicate minerals. J. Mol. Struct. 2007, 318, 834–836. [Google Scholar] [CrossRef]

- Nakagaki, S.; Castro, K.D.F.; Machado, G.S.; Halma, M.; Drechsel, S.M.; Wypych, F. Catalytic activity in oxidation reactions of anionic iron (III) porphyrins immobilized on raw and grafted chrysotile. Int. J. Braz. Chem. Soc. 2006, 17, 1672–1678. [Google Scholar] [CrossRef]

- Accardo, G.; Cioffi, R.; Colangelo, F.; d’Angelo, R.; De Stefano, L.; Paglietti, F. Diffuse reflectance infrared fourier transform spectroscopy for the determination of asbestos species in bulk building materials. Materials 2014, 7, 457–470. [Google Scholar] [CrossRef]

- Felleto, E.; Schonfeld, S.J.; Kovalevskiy, E.V.; Bukhtiyrov, I.V.; Kashanskiy, S.V.; Moissonnier, M.; Straif, K.; Schüz, J. A comparison of paralle dust and fibre measurements of airborne chrysotile asbestos in a large mine and processing factories in the Russian Federation. Int. J. Hyg. Environ. Health 2017, 220, 857–868. [Google Scholar] [CrossRef] [PubMed]

| Dust Sampling Site | Number of Samples | Activity | |

|---|---|---|---|

| A1 | Ground floor | 10 | BR |

| 9 | DR | ||

| 10 | AR | ||

| A2 | Ground floor | 9 | BR |

| 10 | DR | ||

| 9 | AR | ||

| B1 | 1st floor | 9 | BR |

| 10 | DR | ||

| 9 | AR | ||

| B2 | 1st floor | 8 | BR |

| 10 | DR | ||

| 10 | AR | ||

| B3 | 1st floor | 11 | BR |

| 10 | DR | ||

| 9 | AR | ||

| C1 | 2nd floor | 10 | BR |

| 15 | DR | ||

| 11 | AR | ||

| C2 | 2nd floor | 11 | BR |

| 15 | DR | ||

| 10 | AR | ||

| Components | Content (wt.%) | Elements | Average Content (wt.%) | ||

|---|---|---|---|---|---|

| Sample 1 | Sample 2 | Sample 3 | |||

| SiO2 | 20.67 | 19.14 | 20.30 | Si | 9.36 |

| CaO | 40.02 | 38.82 | 40.54 | Ca | 28.44 |

| MgO | 5.85 | 5.65 | 5.36 | Mg | 3.39 |

| Al2O3 | 2.98 | 3.02 | 2.40 | Al | 0.74 |

| Fe2O3 | 2.16 | 2.20 | 2.05 | Fe | 0.74 |

| SO3 | 2.34 | 2.53 | 2.35 | S | 0.96 |

| P2O5 | 0.12 | 0.11 | 0.10 | P | 0.02 |

| K2O | 0.34 | 0.31 | 0.29 | K | 0.13 |

| Cl | 0.02 | 0.02 | 0.02 | Cl | 0.02 |

| LOI * | 25.30 | 25.90 | 26.60 | - | - |

| Others | 0.20 | 2.30 | - | - | - |

| Element | Content (wt.%) | ||

|---|---|---|---|

| Area 1 | Area 2 | Point | |

| Si | 4.35 ± 0.32 | 9.79 ± 0.36 | 12.39 ± 0.39 |

| Ca | 54.75 ± 1.48 | 31.70 ± 0.80 | 8.20 ± 0.21 |

| Mg | 2.28 ± 0.26 | 1.33 ± 0.09 | 14.43 ± 0.57 |

| Al | 3.55 ± 0.30 | 0.63 ± 0.06 | - |

| Fe | - | - | 1.25 ± 0.07 |

| K | - | 0.52 ± 0.50 | - |

| O | 22.05 ± 5.86 | 34.31 ± 3.78 | 33.47 ± 2.81 |

| C | 2.05 ± 1.15 | 6.48 ± 1.00 | 9.12 ± 0.94 |

| Au | 6.39 ± 0.47 | 15.25 ± 0.50 | 21.14 ± 0.59 |

| hkl | d | 2θ | Intensity |

|---|---|---|---|

| 7.70681 | 11.473 | 11 | |

| 002 | 7.32795 | 12.068 | 100 |

| 020 | 4.52638 | 19.597 | 16 |

| 004 | 3.64902 | 24.373 | 71 |

| 2.74175 | 32.634 | 6 | |

| 131 | 2.60217 | 34.438 | 9 |

| −202 | 2.53238 | 35.418 | 6 |

| 202 | 2.45262 | 36.610 | 16 |

| 204 | 2.09669 | 43.109 | 6 |

| 060 | 1.53239 | 60.355 | 12 |

| 247 | 1.31305 | 71.839 | 6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stevulova, N.; Estokova, A.; Holub, M.; Singovszka, E.; Csach, K. Characterization of Demolition Construction Waste Containing Asbestos, and the Release of Fibrous Dust Particles. Appl. Sci. 2020, 10, 4048. https://doi.org/10.3390/app10114048

Stevulova N, Estokova A, Holub M, Singovszka E, Csach K. Characterization of Demolition Construction Waste Containing Asbestos, and the Release of Fibrous Dust Particles. Applied Sciences. 2020; 10(11):4048. https://doi.org/10.3390/app10114048

Chicago/Turabian StyleStevulova, Nadezda, Adriana Estokova, Marian Holub, Eva Singovszka, and Kornel Csach. 2020. "Characterization of Demolition Construction Waste Containing Asbestos, and the Release of Fibrous Dust Particles" Applied Sciences 10, no. 11: 4048. https://doi.org/10.3390/app10114048

APA StyleStevulova, N., Estokova, A., Holub, M., Singovszka, E., & Csach, K. (2020). Characterization of Demolition Construction Waste Containing Asbestos, and the Release of Fibrous Dust Particles. Applied Sciences, 10(11), 4048. https://doi.org/10.3390/app10114048