Development of Bonded Natural Stone Pavement Using Ultra-Rapid-Hardening Mortar

Abstract

1. Introduction

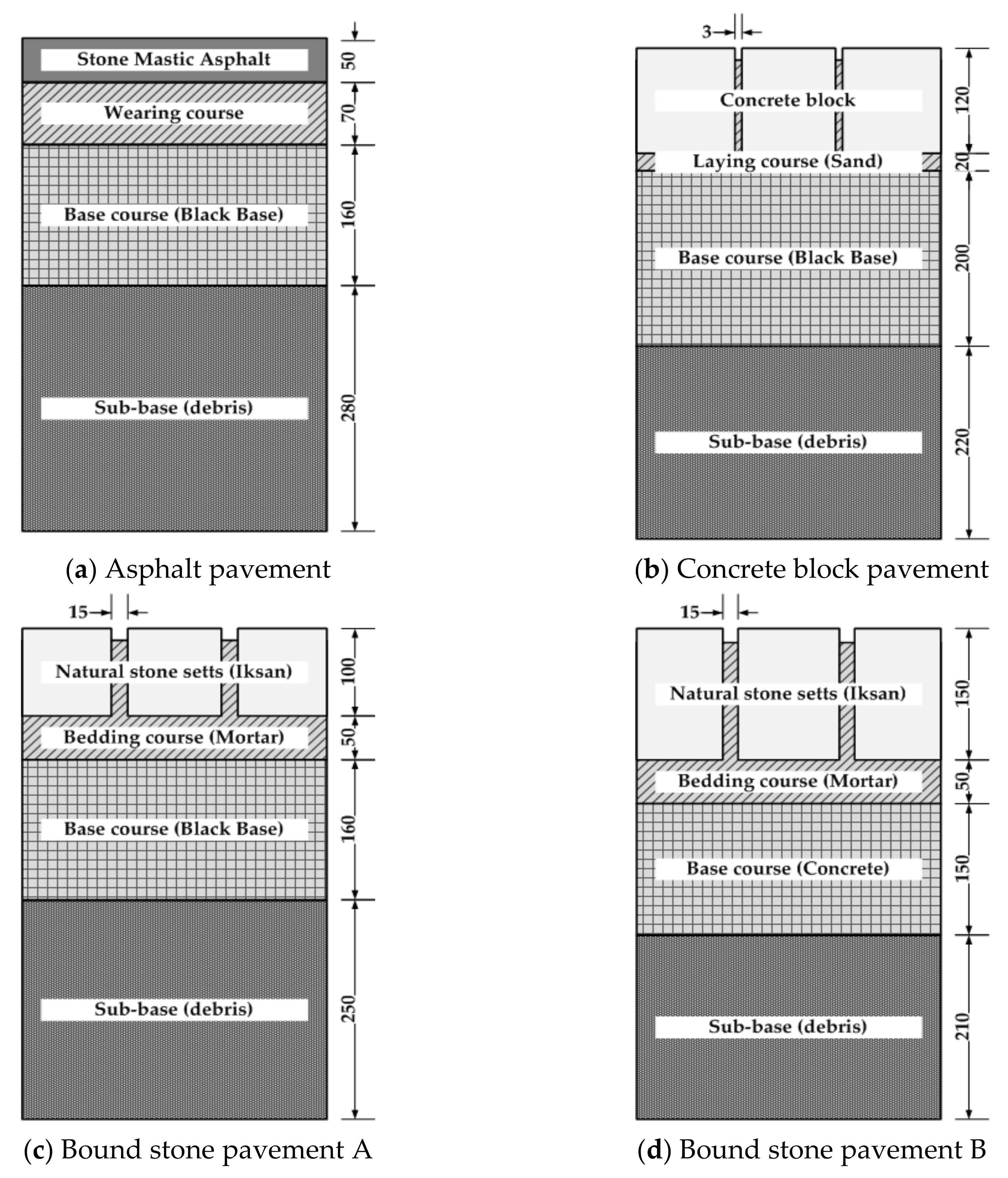

2. Pavement Profiles and Material Tests

2.1. Pavement Profiles

2.2. Material Tests

2.2.1. Asphalt

2.2.2. Sand

2.2.3. Mortar

2.2.4. Concrete

2.2.5. Natural Stone Sett

2.2.6. Concrete Block

3. Experimental Methods

3.1. Plate Load Test

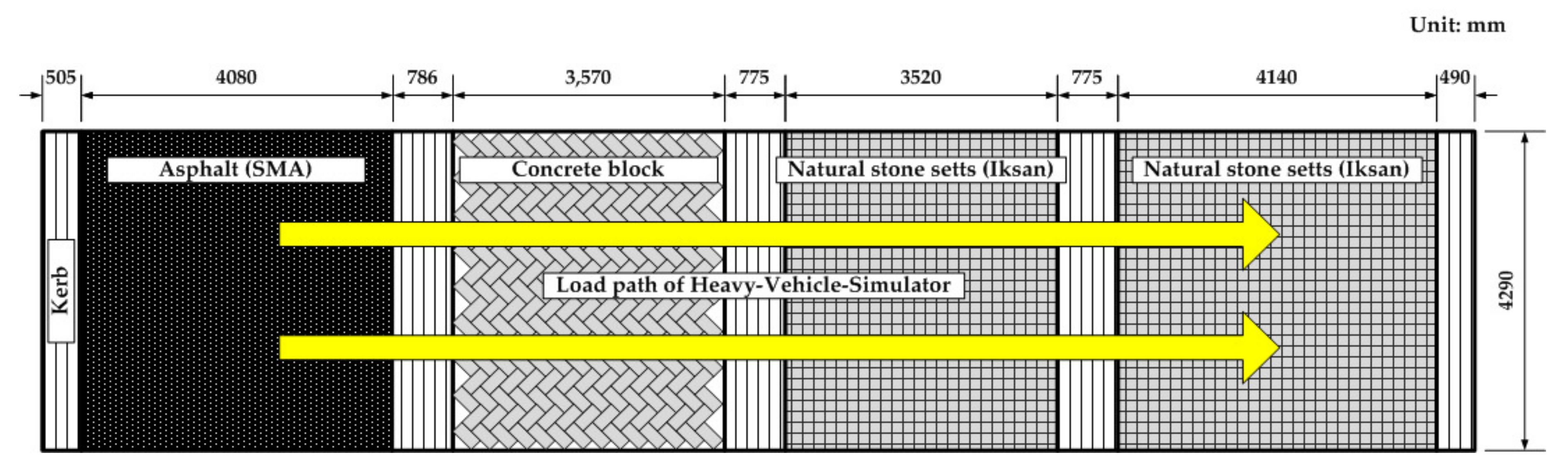

3.2. Accelerated Pavement Test

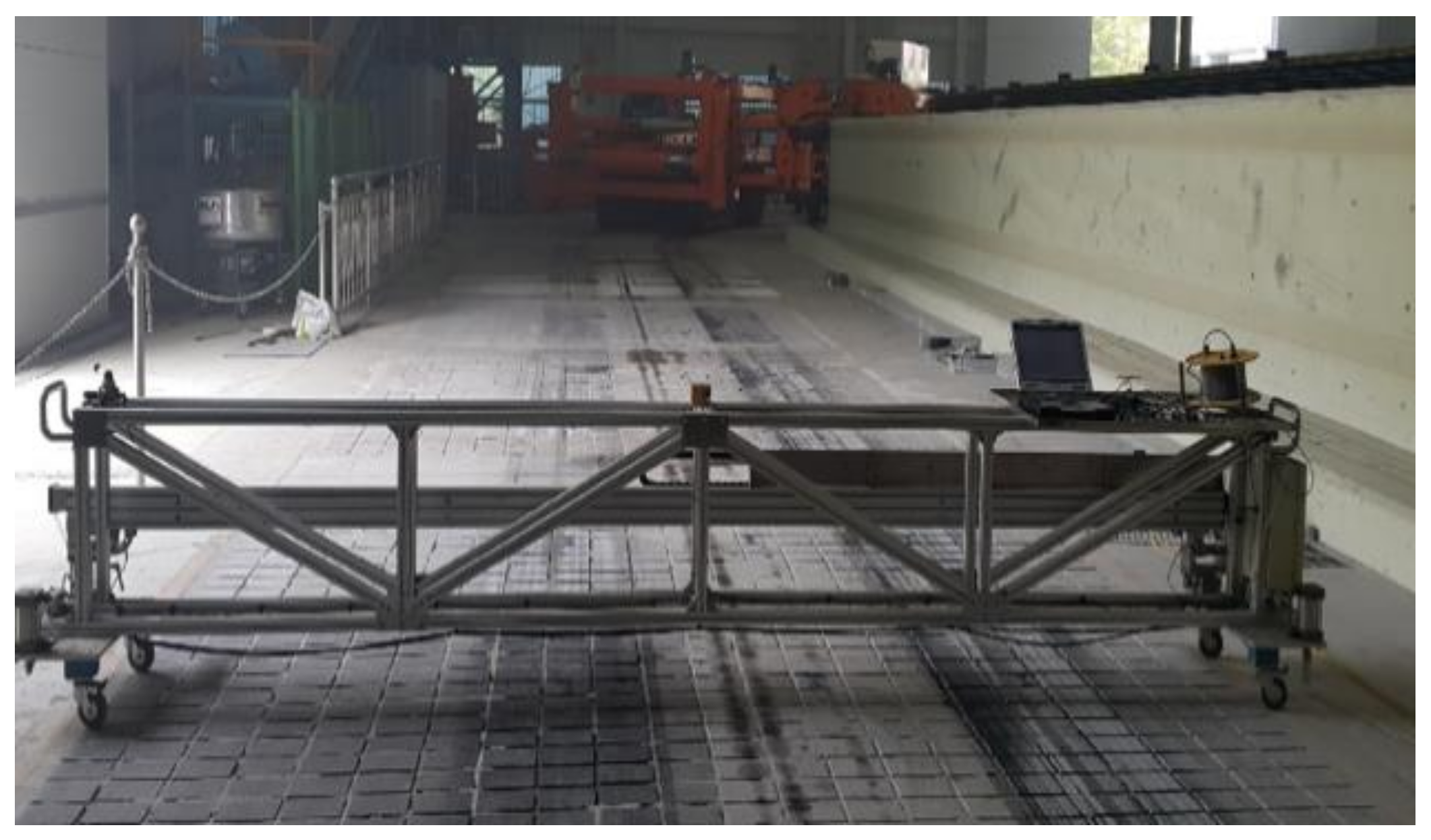

3.3. Transverse Profile Measurement

3.4. Falling Weight Deflectometer Test

4. Results and Discussion

4.1. Plate Load Test

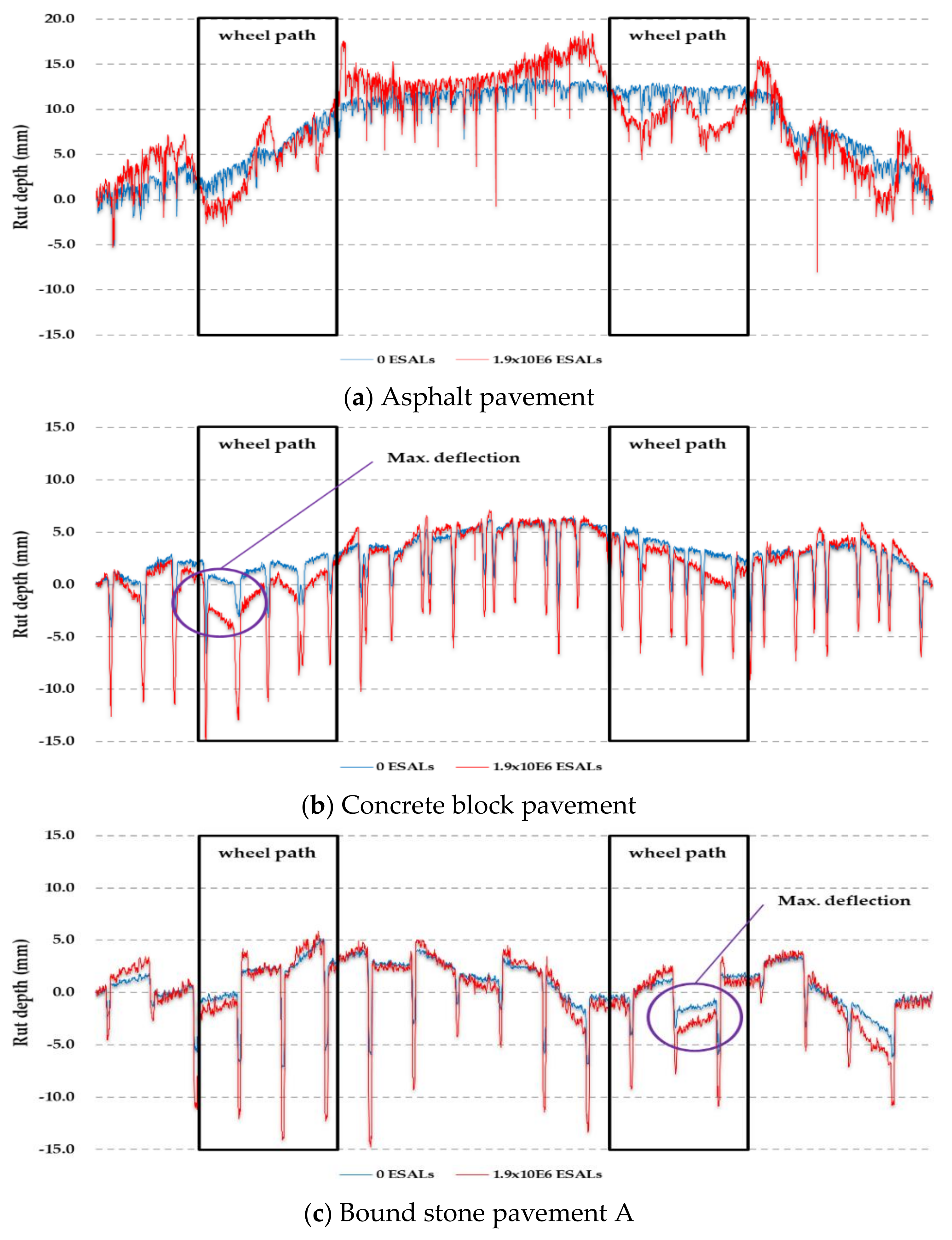

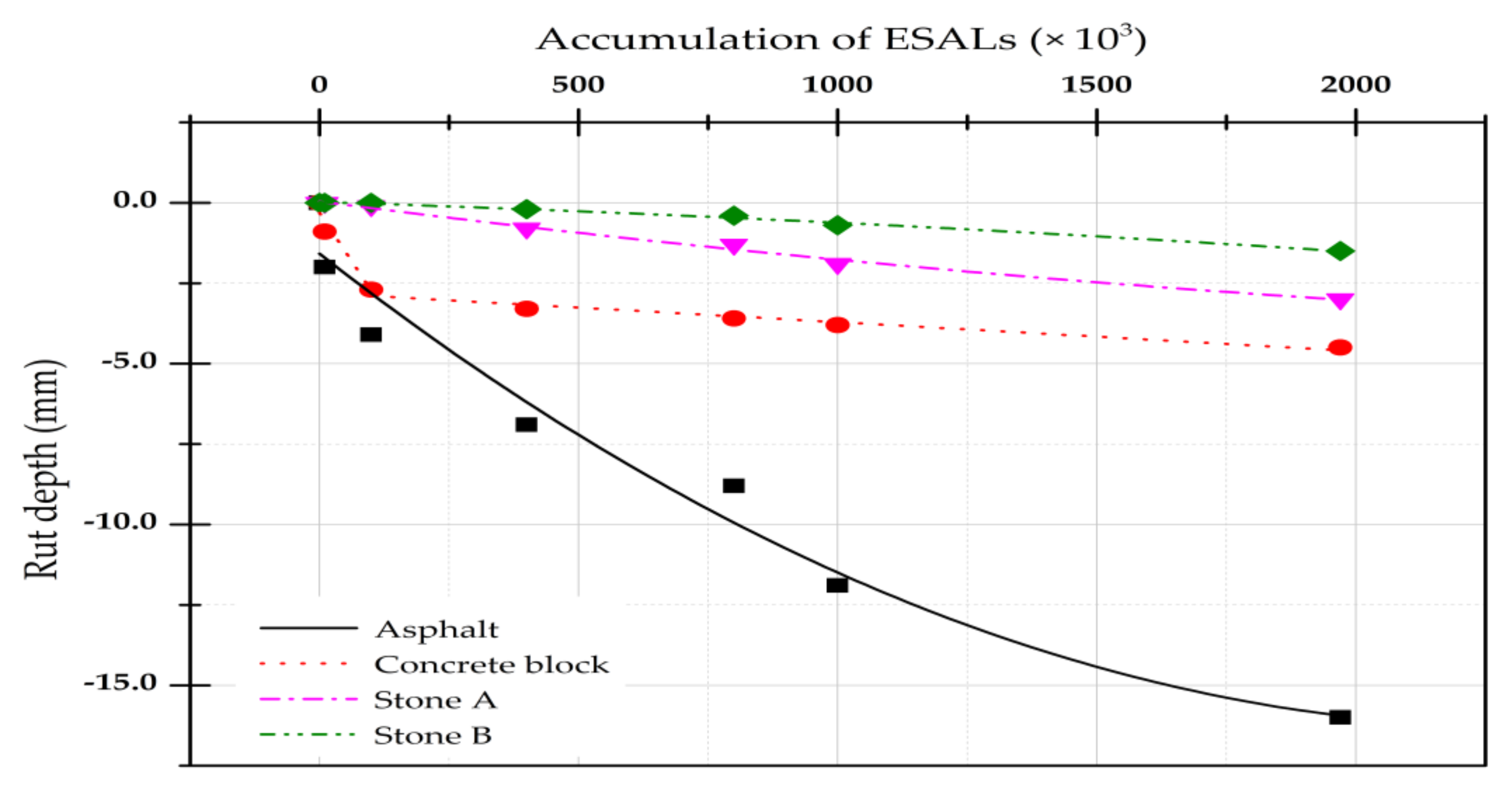

4.2. Rut Depth Measurement and Visual Inspection

4.3. Falling Weight Deflectometer Test

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Coni, M.; Portas, S.; Maltinti, F.; Pinna, F. Sealing of paving stone joints. Int. J. Pavement Res. Technol. 2018, 11, 819–828. [Google Scholar] [CrossRef]

- Zoccali, P.; Moretti, L.; Mascio, P.D.; Loprencipe, G.; D’Andrea, A.; Bonin, G.; Teltayev, B.; Caro, S. Analysis of natural stone block pavements in urban shared areas. Case Stud. Constr. Mater. 2018, 8, 498–506. [Google Scholar] [CrossRef]

- Han, E.S.; Gong, J.; Cho, D.; Park, S.K. Experimental investigation on the application of ultra-rapid-hardening mortar for rigid small element pavement. Adv. Mater. Sci. Eng. 2019, 2625437. [Google Scholar] [CrossRef]

- Miccoli, S.; Finucci, F.; Murro, R. Social evaluation approaches in landscape projects. Sustainability 2014, 6, 7906–7920. [Google Scholar] [CrossRef]

- Moretti, L.; Mascio, P.D.; D’Andrea, A. Environmental impact assessment of road asphalt pavements. Mod. Appl. Sci. 2013, 7, 1–11. [Google Scholar] [CrossRef]

- Miccoli, S.; Finucci, F.; Murro, R. Assessing project quality: A multidimensional approach. Adv. Mater. Res. 2014, 1030–1032, 2519–2522. [Google Scholar] [CrossRef]

- Nobili, A.; Lanzoni, L.; Tarantino, A.M. Experimental investigation and monitoring of a polypropylene-based fiber reinforced concrete road pavement. Constr. Build. Mater. 2013, 47, 888–895. [Google Scholar] [CrossRef]

- Harvey, J.; Popescu, L. Accelerated pavement testing of rutting performance of two caltrans overlay strategies. Transp. Res. Rec. 2000, 1716, 116–125. [Google Scholar] [CrossRef]

- Erlingsson, S. Performance of two thin pavement structures during accelerated pavement testing using a Heavy Vehicle Simulator. In Proceedings of the 2nd Int. Conferences on Accelerated Pavement Testing, Minneapolis, MN, USA, 26–29 September 2004. [Google Scholar]

- Romanoschi, S.A.; Metcalf, J.B.; Li, Y.; Rasoulian, M. Assessment of pavement life at first full-scale accelerated pavement test in Louisiana. Transp. Res. Rec. 1999, 1655, 219–226. [Google Scholar] [CrossRef]

- Kogbara, R.B.; Masad, E.A.; Kassem, E.; Scarpas, A.; Anupam, K. A state-of-the-art review of parameters influencing measurement and modeling of skid resistance of asphalt pavements. Constr. Build. Mater. 2016, 114, 602–617. [Google Scholar] [CrossRef]

- Gokhale, S.; Choubane, B.; Byron, T.; Tia, M. Rut initiation mechanisms in asphalt mixtures as generated under accelerated pavement testing. Transp. Res. Rec. 2005, 1940, 136–145. [Google Scholar] [CrossRef]

- Du Plessis, L.; Ulloa-Calderon, A.; Harvey, J.T.; Coetzee, N.F. Accelerated pavement testing efforts using the Heavy Vehicle Simulator. Int. J. Pavement Res. Technol. 2018, 11, 327–338. [Google Scholar] [CrossRef]

- Hugo, F.; Martin, A.E. NCHRP Synthesis 325: Significant Findings from Full-Scale Accelerated Pavement Testing; NCHRP Synthesis 325, Transportation Research Board: Washington DC, USA, 2004. [Google Scholar]

- Metcalf, J.B. NCHRP Synthesis 235: Application of Full-Scale Accelerated Pavement Testing; Transportation Research Board: Washington DC, USA, 1996. [Google Scholar]

- Yang, S.-C.; You, T.-S.; Eom, J.-Y. Development status of Korea accelerated loading and environment simulator (KALES). Int. J. Highw. Eng. 2000, 2, 139–148. [Google Scholar]

- Zoccali, P.; Loprencipe, G.; Galoni, A. Sampietrini stone pavements: Distress analysis using pavement condition Index Method. Appl. Sci. 2017, 7, 669. [Google Scholar] [CrossRef]

| Sieve Size (mm) | 30 | 25 | 20 | 13 | 10 | 5.0 | 2.5 | 0.6 | 0.3 | 0.15 | 0.08 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Percent by mass passing (%) | Base course | 100 | 90–100 | 71–90 | 56–80 | 45–72 | 29–59 | 19–45 | 7–25 | 5–17 | 3–12 | 1–7 |

| Wearing course | - | 100 | 90–100 | 69–84 | 56–74 | 35–55 | 23–38 | 10–23 | 5–16 | 3–12 | 2–10 | |

| SMA | - | - | - | 100 | 90–100 | 25–45 | 15–30 | 11–20 | 10–16 | 9–15 | 8–13 | |

| Properties | Recommended | |||||

|---|---|---|---|---|---|---|

| Base Course | Wearing Course | SMA | ||||

| Marshall stability (N) | ≥5000 | ≥6000 | Asphalt content (%) ≥6.6 | |||

| Flow (1/100 cm) | 10–40 | 15–40 | Drain down (%) ≤0.3 | |||

| Air void (%) | 4–6 | 3–5 | 2–4 | |||

| Saturation (%) | 65–75 | 70–85 | ≥75 | |||

| Tamping (no.) | 75 (Marshall compaction) | |||||

| Voids in the Mineral Aggregate (VMS) (%) | Max. size of aggregate (mm) | Target air void (%) | ||||

| 3.0 | 4.0 | 5.0 | 6.0 | < 2.0–3.0 | ||

| 13 | ≥13.0 | ≥14.0 | ≥15.0 | ≥16.0 | ≥18.0 | |

| 20 | ≥12.0 | ≥13.0 | ≥14.0 | ≥15.0 | ||

| 25 | ≥11.0 | ≥12.0 | ≥13.0 | ≥14.0 | ||

| 30 | ≥10.5 | ≥11.5 | ≥12.5 | ≥13.5 | ||

| 40 | ≥10.0 | ≥11.0 | ≥12.0 | ≥13.0 | ||

| Properties | Bedding Course | Joint Material | ||

|---|---|---|---|---|

| Result | Recommended | Result | Recommended | |

| Percent passing (0.08 mm sieve size) | 1.02% | ≤5% | 1.08% | ≤10% |

| Maximum size | ≤5.0 mm | ≤5.0 mm | ≤2.5 mm | ≤2.5 mm |

| Fineness modulus | 3.38 | 1.5–5.5 | - | - |

| Test Item | Compressive Strength (MPa) | Flexural Strength (MPa) | ||||

|---|---|---|---|---|---|---|

| 4 h | 3 Days | 28 Days | 4 h | 3 Days | 28 Days | |

| Laying course | 32.45 | 45.58 | 54.55 | 7.09 | 7.99 | 8.6 |

| Joint | 28.92 | 36.93 | 38.47 | 7.23 | 7.67 | 7.67 |

| Cement | Water | Fine Aggregate | Coarse Aggregate | Fly Ash | Blast-Furnace Slag |

|---|---|---|---|---|---|

| 294 | 111 | 683 | 963 | 52 | 2.42 |

| Age (Days) | Compressive Strength (MPa) | Recommended (MPa) | |||

|---|---|---|---|---|---|

| 1 | 2 | 3 | Average | ||

| 7 | 18.1 | 17.7 | 18.5 | 18.1 | ≥5.0 |

| 14 | 22.2 | 20.0 | 21.6 | 21.3 | - |

| 28 | 23.7 | 23.0 | 23.1 | 23.2 | - |

| Type of Stone | Compressive Strength (MPa) | Water Absorption (%) | ||

|---|---|---|---|---|

| Result | Recommended | Result | Recommended | |

| Iksan | 95.4 | ≥80 | 0.21 | ≤3.0 |

| Test Item | Compressive Strength (MPa) | Flexural Strength (MPa) | ||

|---|---|---|---|---|

| Result | Recommended | Result | Recommended | |

| Concrete block paver | 28.6 | ≥20 | 7.16 | ≥5 |

| Pavement Construction | Bearing Capacity (MN/m3) | Recommended (MN/m3) |

|---|---|---|

| Asphalt pavement | 474 | ≥294 (Asphalt) |

| Concrete block pavement | 463 | |

| Bound stone pavement A | 501 | |

| Bound stone pavement B | 518 | ≥196 (Concrete) |

| Pavement Structure | Max. Vertical Deflection (μm/kN) | ||

|---|---|---|---|

| 0 ESALs | 0.4 × 106 ESALs | 1.97 × 106 ESALs | |

| Asphalt pavement | 2.89 | 3.28 | 2.84 |

| Concrete block pavement | 5.88 | 4.65 | 4.17 |

| Bound stone pavement A | 2.14 | 4.04 | 3.86 |

| Bound stone pavement B | 2.58 | 2.45 | 2.38 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, E.-S.; Gong, J.; Jeong, H.; Cho, D. Development of Bonded Natural Stone Pavement Using Ultra-Rapid-Hardening Mortar. Appl. Sci. 2020, 10, 3576. https://doi.org/10.3390/app10103576

Han E-S, Gong J, Jeong H, Cho D. Development of Bonded Natural Stone Pavement Using Ultra-Rapid-Hardening Mortar. Applied Sciences. 2020; 10(10):3576. https://doi.org/10.3390/app10103576

Chicago/Turabian StyleHan, Eui-Seok, Junho Gong, Hoseong Jeong, and Dooyong Cho. 2020. "Development of Bonded Natural Stone Pavement Using Ultra-Rapid-Hardening Mortar" Applied Sciences 10, no. 10: 3576. https://doi.org/10.3390/app10103576

APA StyleHan, E.-S., Gong, J., Jeong, H., & Cho, D. (2020). Development of Bonded Natural Stone Pavement Using Ultra-Rapid-Hardening Mortar. Applied Sciences, 10(10), 3576. https://doi.org/10.3390/app10103576