Material Flow Behavior on Weld Pool Surface in Plasma Arc Welding Process Considering Dominant Driving Forces

Abstract

:1. Introduction

2. Material and Experimental Methods

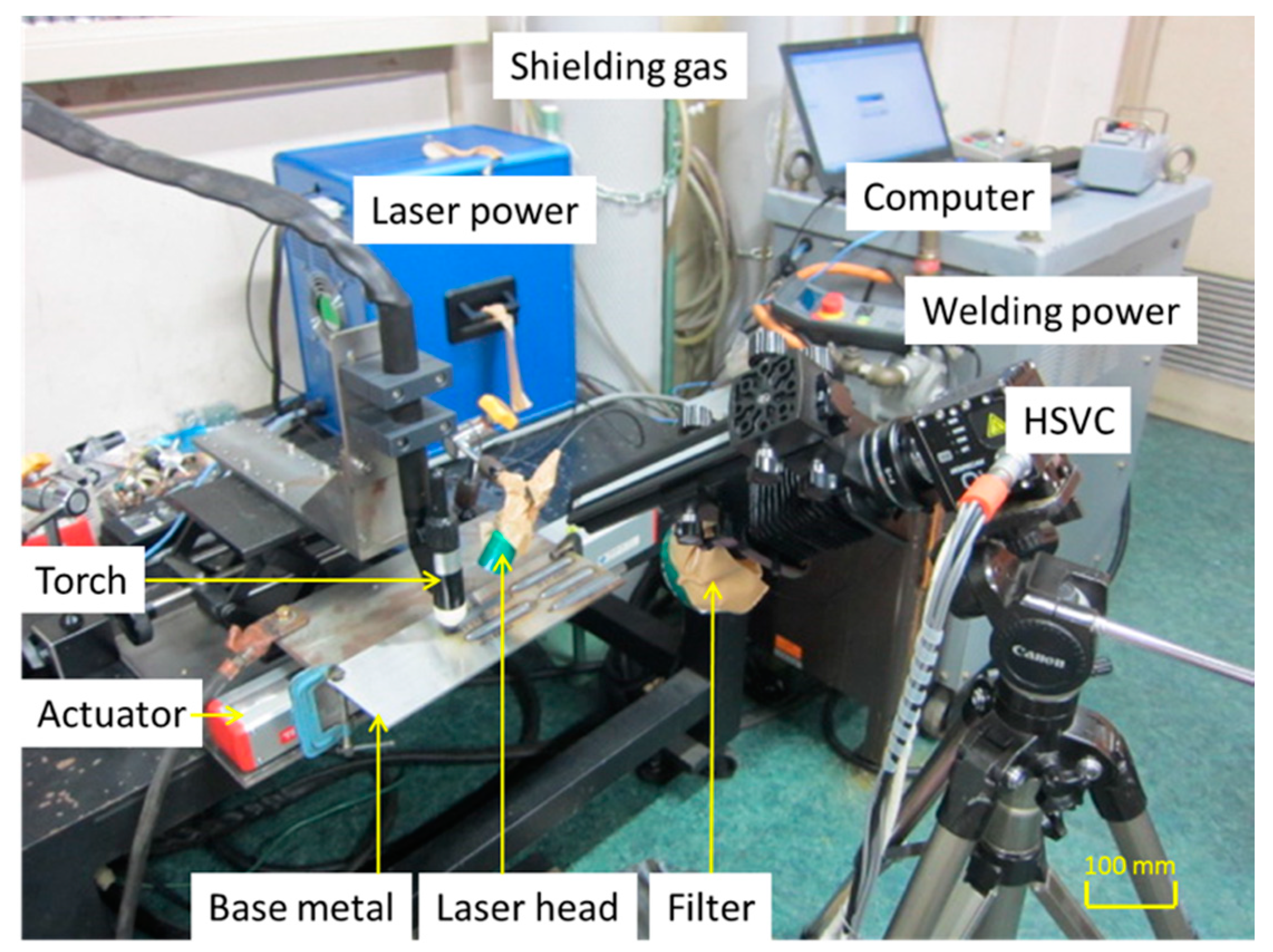

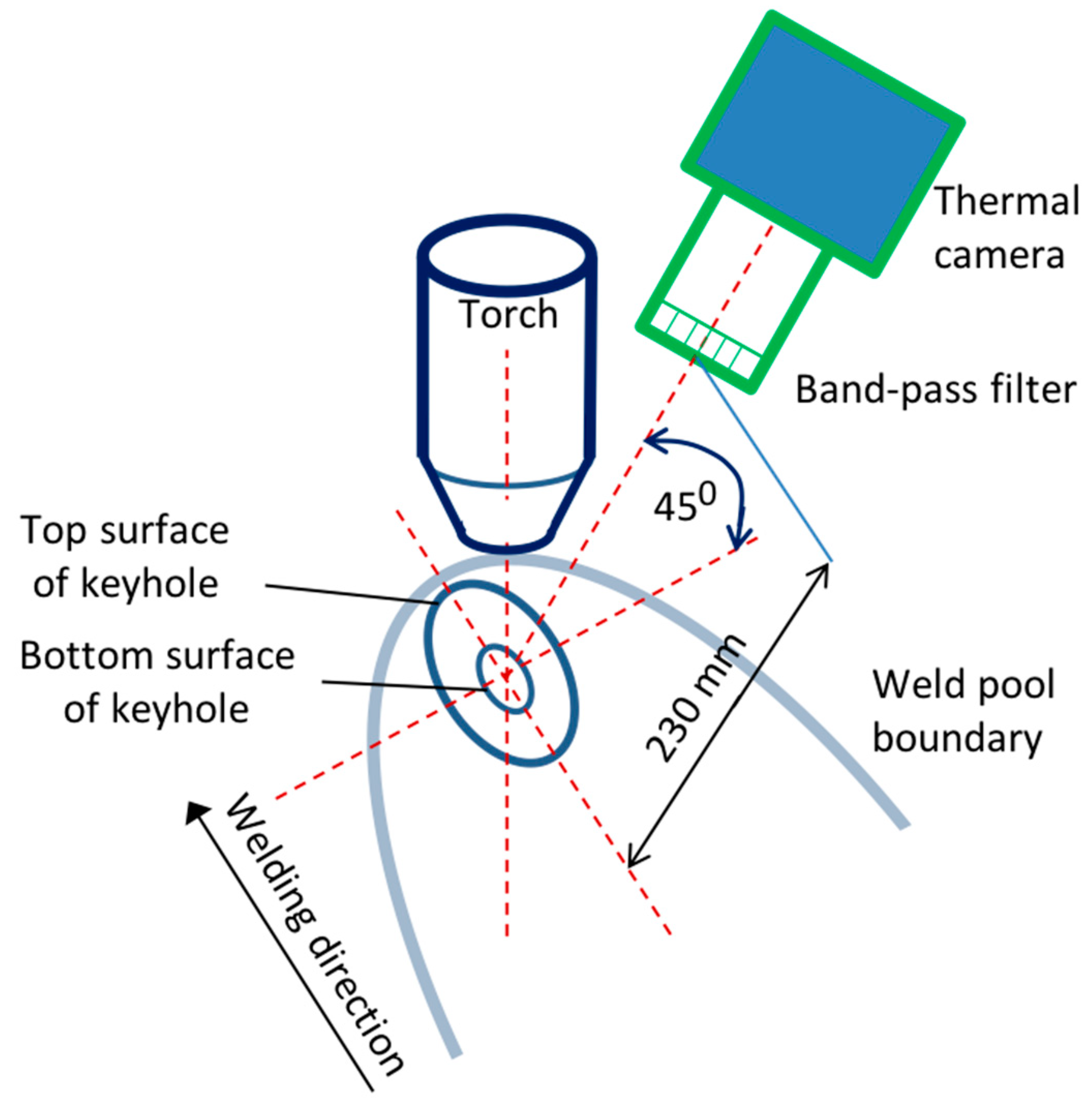

2.1. Measurement of Material Flow on Weld Pool Surface

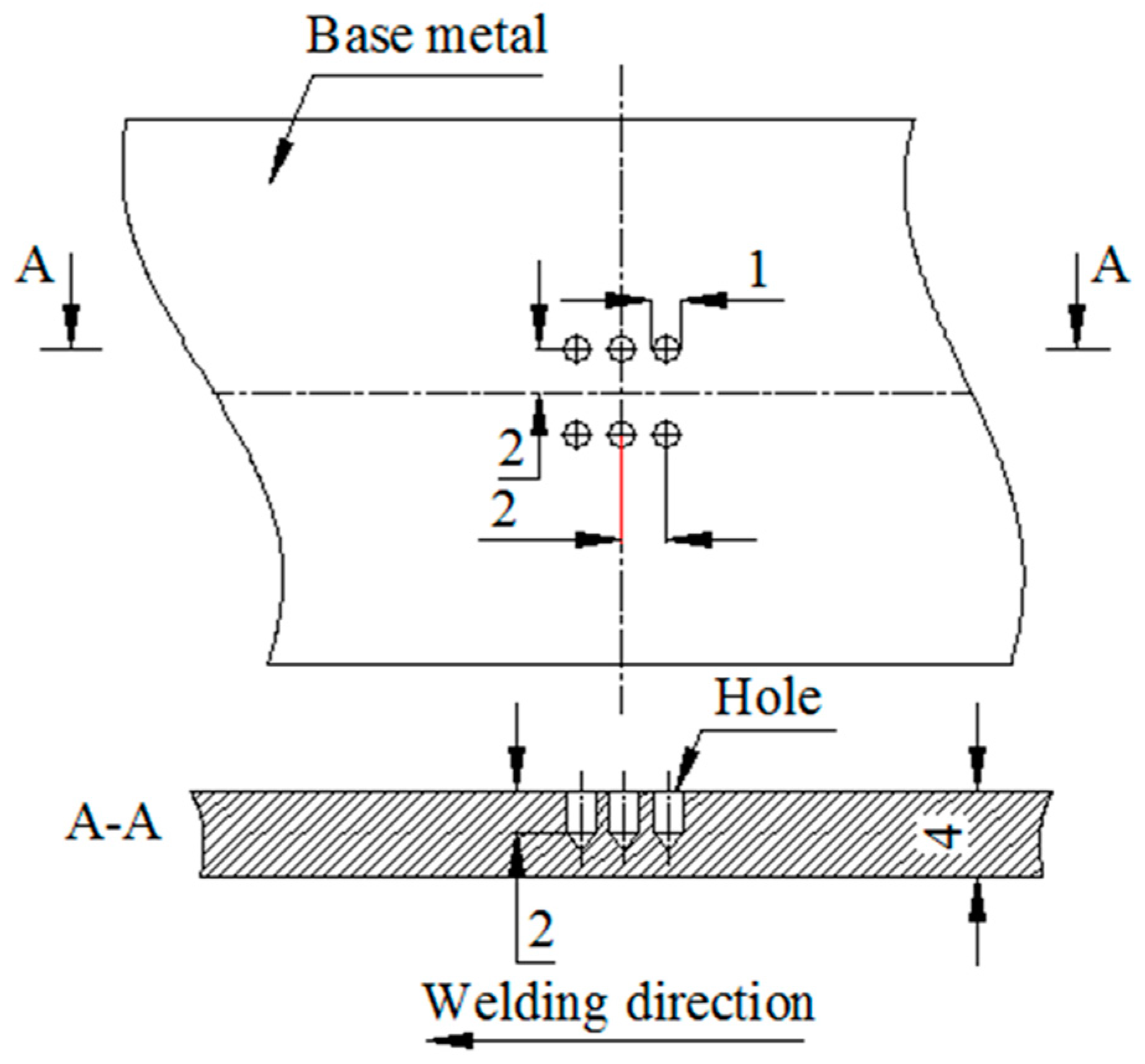

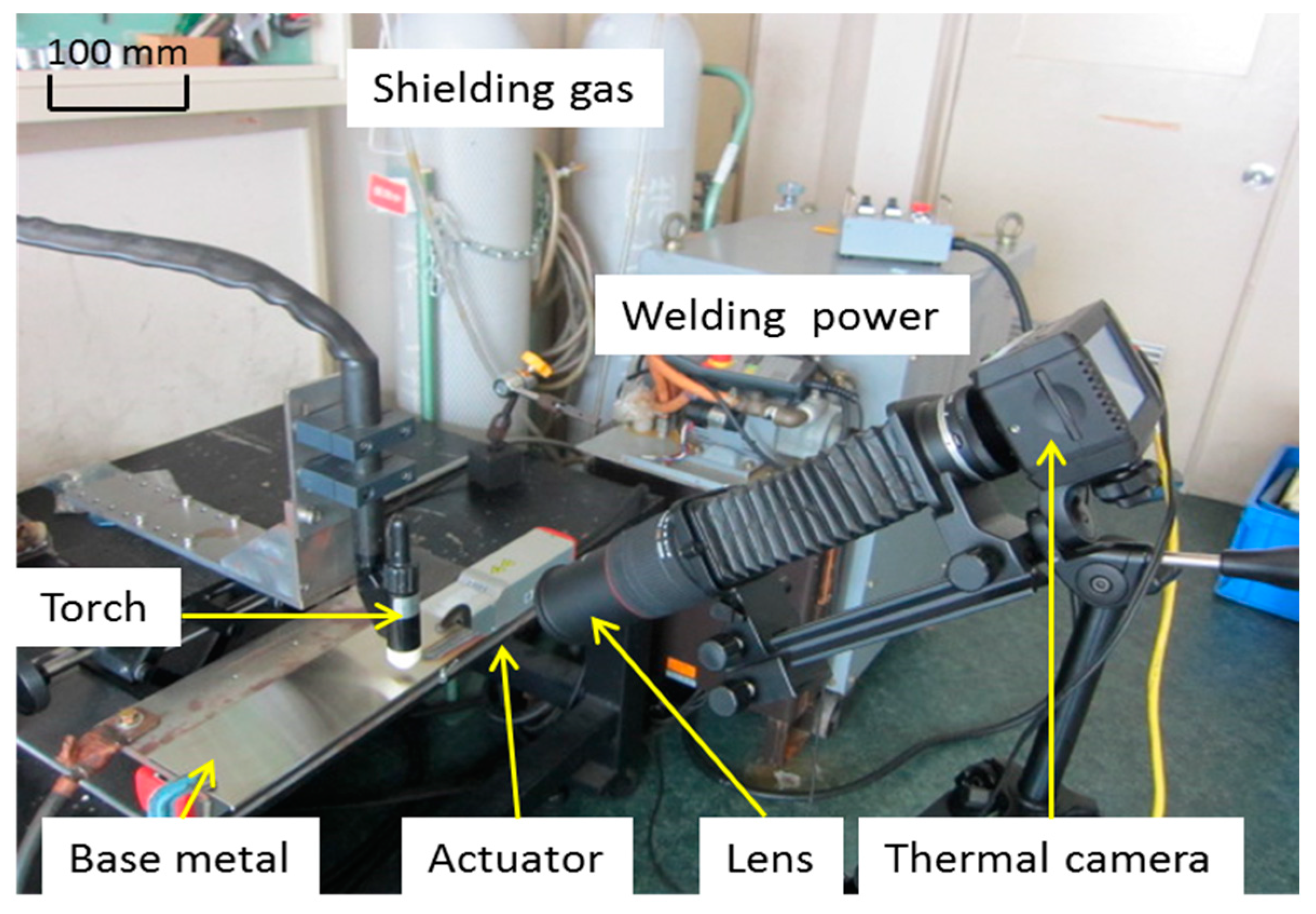

2.2. Temperature Measurement on the Surface along the Keyhole Wall

2.3. Two-Color Pyrometry Method

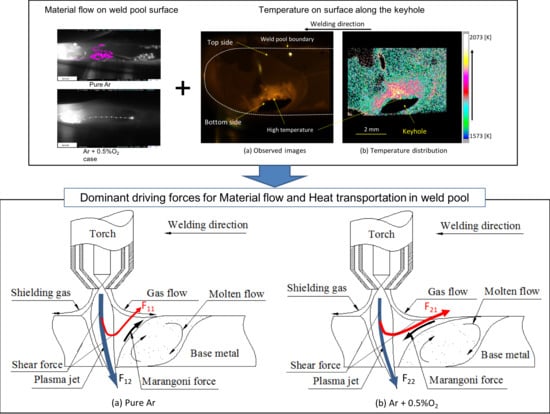

3. Experimental Results and Discussion

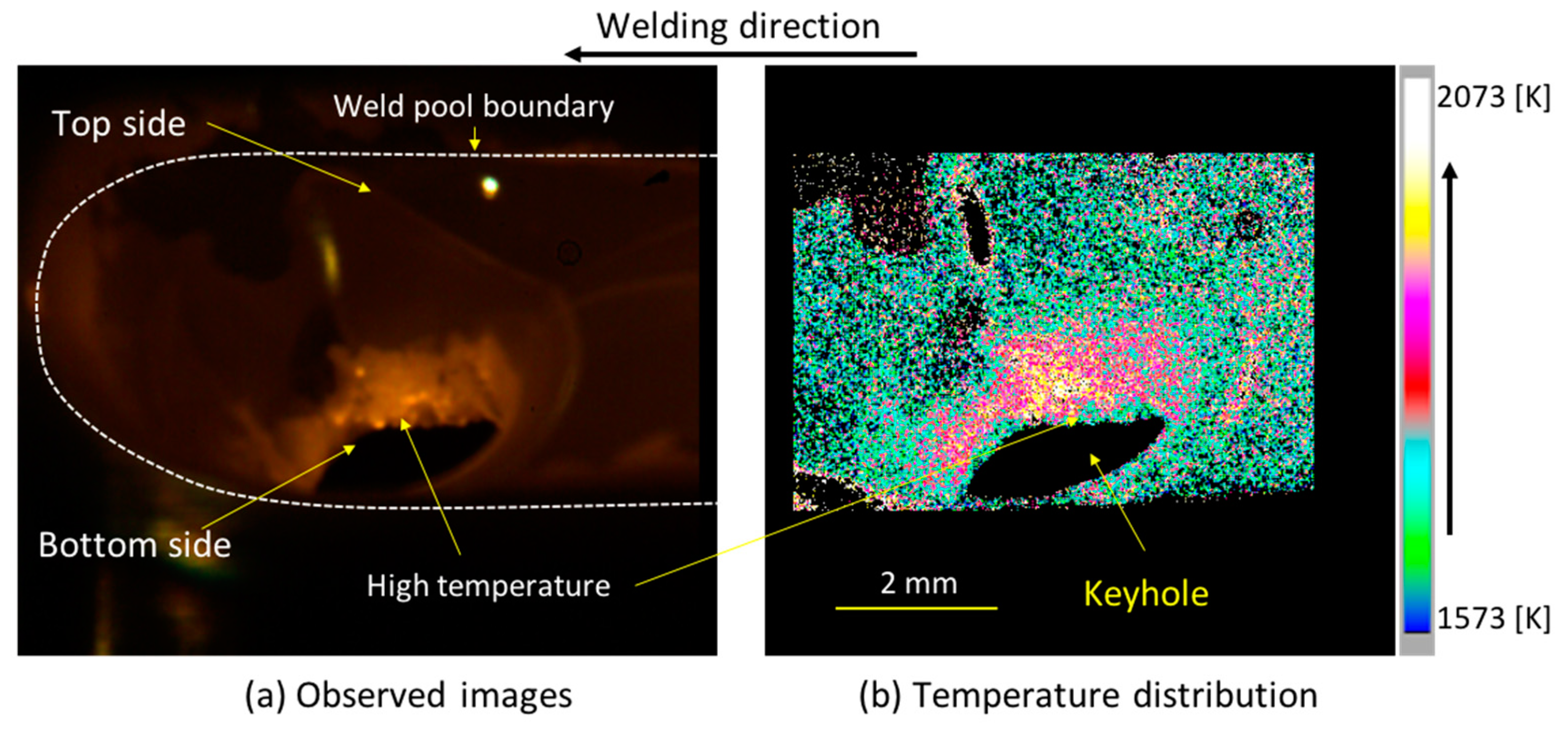

3.1. Temperature Distribution on Keyhole Wall Surface

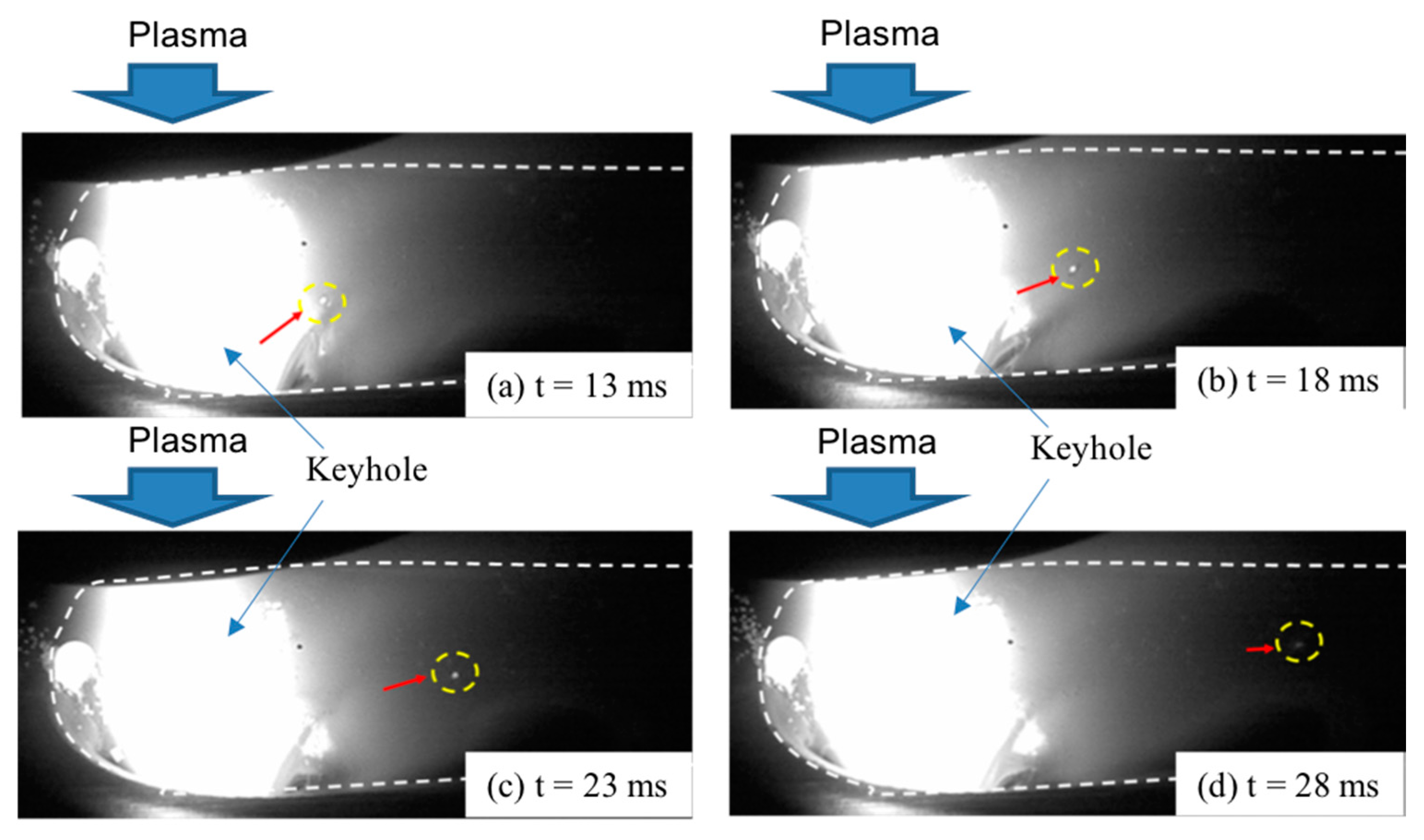

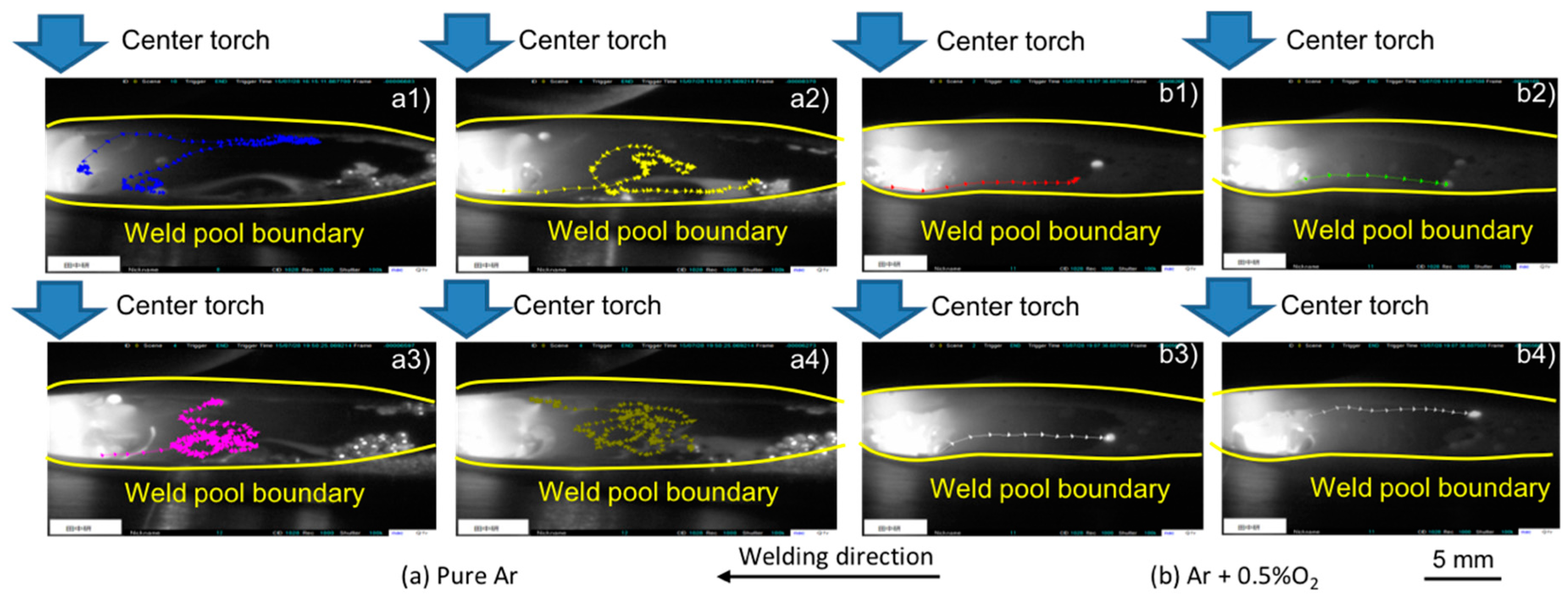

3.2. Material Flow Behavior on Weld Pool Surface

4. Conclusions

- (1)

- The temperature on the surface along the keyhole wall decreased gradually from the bottom toward the top surface.

- (2)

- The maximum temperature was about 2073 K at the bottom surface and about 1573 K at the top surface.

- (3)

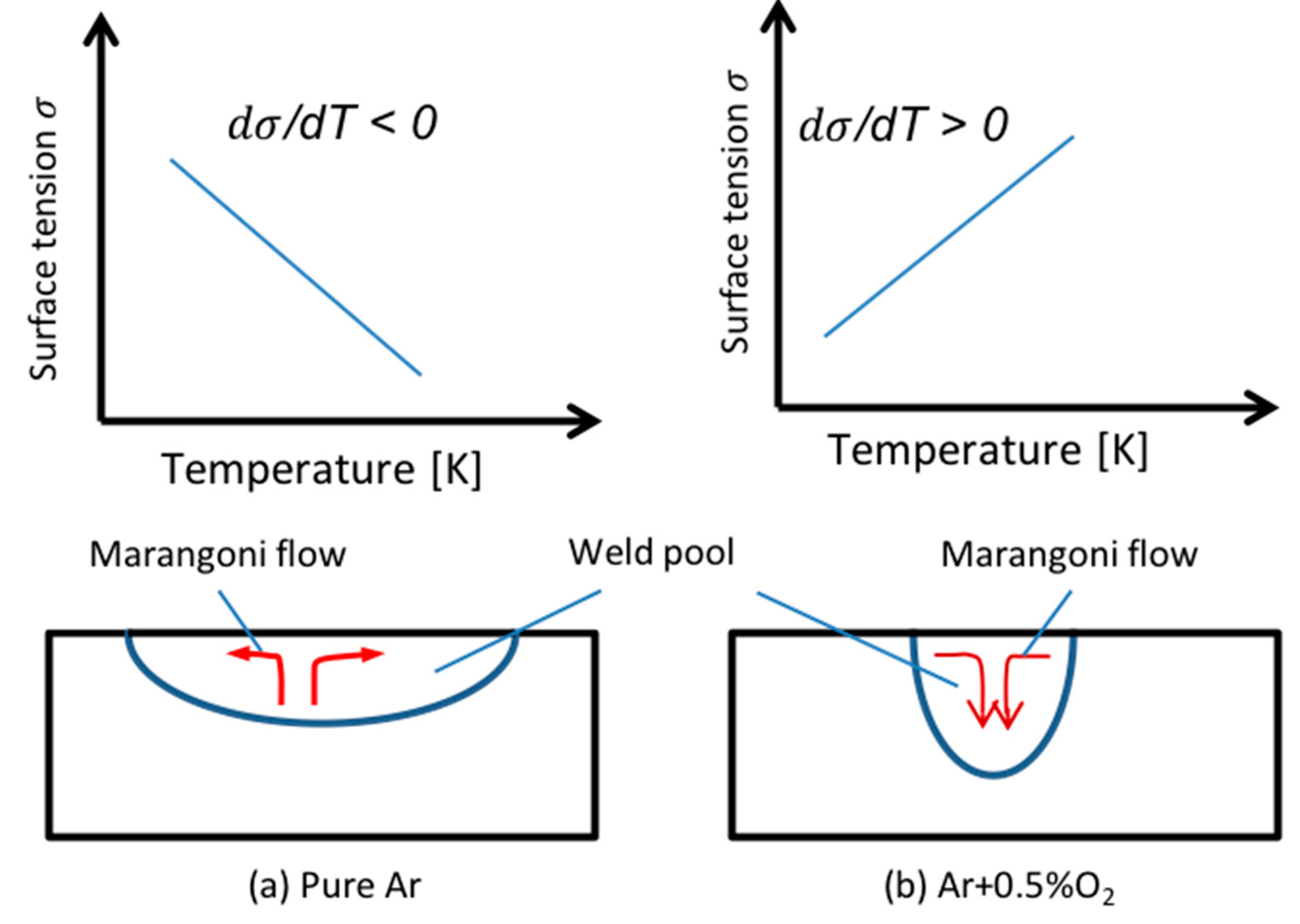

- The Marangoni force diverted the flow direction from upward and backward with pure Ar to downward with mixture shielding gas.

- (4)

- The molten flow tended toward the rotational motion behind the keyhole with the Ar case.

- (5)

- The molten flow occurred in a translational movement to the ending part of weld pool when 0.5% O2 was mixed with the shielding gas.

- (6)

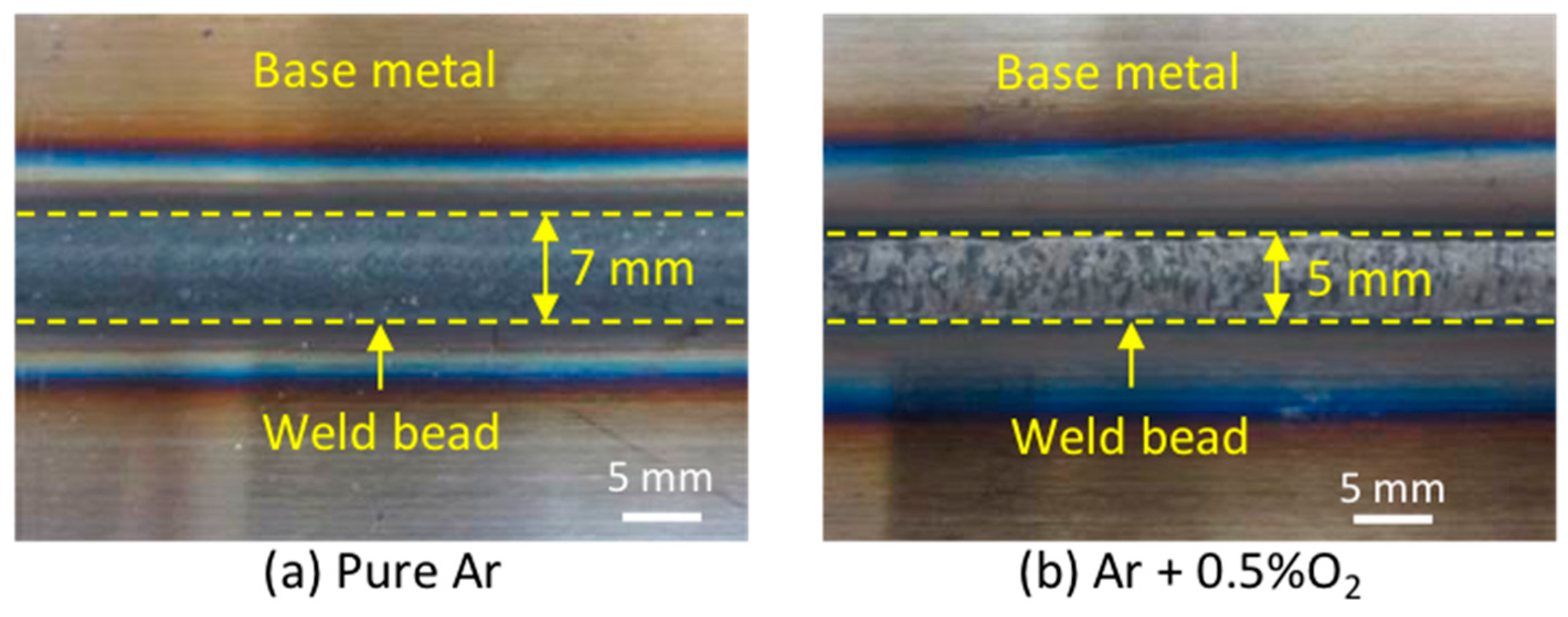

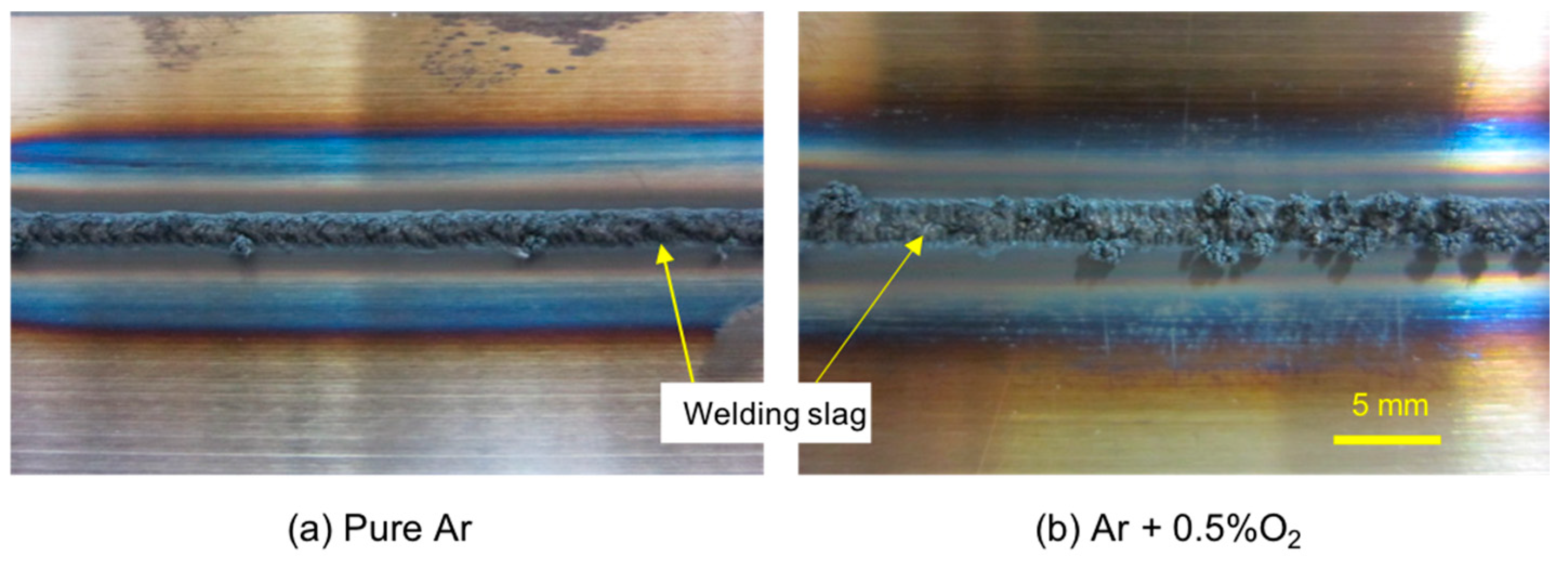

- The length of weld pool increased but the width of weld bead decreased when shielding gas was mixed with 0.5% O2.

- (7)

- The behavior of the material flow in the KPAW weld pool was mainly controlled by shear force.

- (8)

- Marangoni force was not a dominant driving force here, even though its direction was diverted when a small amount of oxygen was mixed with the shielding gas.

Author Contributions

Funding

Conflicts of Interest

References

- Tomsic, M.J.; Jackson, C.E. Energy distribution in keyhole mode plasma arc welds. Weld. J. 1974, 3, 109–116. [Google Scholar]

- Nguyen, A.V.; Tashiro, S.; Bui, H.V.; Tanaka, M. Influence of plasma gas on the behavior of convention flow on weld pool surface. Q. J. Jpn. Weld. Soc. 2017, 35, 98s–102s. [Google Scholar] [CrossRef] [Green Version]

- Fan, H.G.; Kovacevic, R. Keyhole formation and collapse in plasma arc welding. J. Phys. D 1999, 32, 2902–2909. [Google Scholar] [CrossRef] [Green Version]

- Patricio, F.M.; Thomas, W.E. Welding processes for aeronautics. Adv. Mater. Process. 2001, 159, 39–43. [Google Scholar]

- Geng, W.; Wu, D.; Sun, D.; Li, H.; Che, Y. Microstructures and Mechanical Properties of Plasma Arc Welded Joints of Ultra-high Strength Steel and Aluminum Alloy Using Al–Si and Al–Cu Fillers. ISIJ Int. 2018, 58, 1108–1116. [Google Scholar] [CrossRef] [Green Version]

- Tabal, E.; Dhooge, A.; Kaluc, E. Plasma Arc Welding of Modified 12% Cr Stainless Steel. Mater. Manuf. Process. 2009, 24, 649–656. [Google Scholar]

- Tanaka, M.; Lowke, J.J. Predictions of weld pool profiles using plasma physics. J. Phys. D 2007, 40, 1–23. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Zhang, S.B. Observation of the keyhole during plasma arc welding. Weld. J. 1999, 78, 53s–58s. [Google Scholar]

- Lu, W.; Zhang, Y.M.; Emmerson, J. Sensing of weld pool surface using non-transferred plasma charge sensor. Meas. Sci. Technol. 2004, 15, 991–999. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Zhang, S.B.; Liu, Y.C. Plasma cloud charge sensor for pulse keyhole process control. Trans. Sci. Technol. 2001, 12, 1365–1370. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.M.; Wu, C.S.; Chen, J. Sensing dynamic keyhole behaviors in controlled-pulse keyholing plasma arc welding. Weld. J. 2013, 92, 381–389. [Google Scholar]

- Wu, C.S.; Jia, C.B.; Chen, M.A. A control system for keyhole plasma arc welding of stainless steel with medium thickness. Weld. J. 2010, 89, 225–231. [Google Scholar]

- Liu, Z.M.; Wu, C.S.; Chen, M.A. Experimental study on PAW butt-welding process with controlled pulse key-holing strategy. J. Mech. Eng. 2011, 47, 45–50. [Google Scholar] [CrossRef]

- Wu, C.S.; Wang, L.; Ren, W.J.; Zhang, X.Y. Plasma arc welding: Process, sensing, control and modeling. J. Manuf. Process. 2014, 16, 74–85. [Google Scholar] [CrossRef]

- Yamane, S.; Suzuki, H.; Toma, J.; Godo, T.; Hosoya, K.; Nakajima, T.; Yamamoto, H. Imaging processing of the weld pool in robot plasma welding system. Q. J. Jpn. Weld. Soc. 2013, 31, 44–47. [Google Scholar] [CrossRef] [Green Version]

- Yamane, S.; Godo, T.; Hosoya, K.; Nakajima, T.; Yamamoto, H. Detecting and tracking of welding line in visual plasma robotic welding. Q. J. Jpn. Weld. Soc. 2013, 31, 175–180. [Google Scholar] [CrossRef]

- Yamane, S. Tracking of welding using image processing. Q. J. Jpn. Weld. Soc. 2015, 84, 35–42. [Google Scholar]

- Nguyen, A.V.; Tashiro, S.; Bui, H.V.; Tanaka, M. Experimental investigation of weld pool formation process in plasma keyhole arc welding. J. Phys. D Appl. Phys. 2018, 51, 015204. [Google Scholar]

- Nguyen, A.V.; Wu, D.; Tashiro, S.; Tanaka, M. Undercut formation mechanism in the keyhole plasma arc welding. Weld. J. 2020, 98, 204–212. [Google Scholar]

- Xu, B.; Jiang, F.; Chen, S.; Tanaka, M.; Tashiro, S.; Nguyen, A.V. Numerical analysis of plasma arc physical characteristics under additional constraint of keyhole. Chin. Phys. B 2018, 27, 034701. [Google Scholar] [CrossRef]

- Xu, B.; Chen, S.; Tashiro, S.; Jiang, F.; Nguyen, A.V.; Tanaka, M. Material flow analyses of high-efficiency joint process in VPPA keyhole flat welding by X-ray transmission system. J. Clean. Product. 2020, 250, 119450. [Google Scholar] [CrossRef]

- Lu, Z.; Zhang, W.; Jiang, F.; Chen, S.; Yan, Z. A Primary Study of Variable Polarity Plasma Arc Welding Using a Pulsed Plasma Gas. Materials 2019, 12, 1666. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiang, F.; Li, C.; Xu, B.; Tashiro, S.; Tanaka, M.; Chen, S. Study on the Decoupled Transfer of Heat and Mass in Wire Variable Polarity Plasma Arc Welding. Materials 2020, 13, 1073. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yamazaki, K.; Yamamoto, E.; Suzuku, K.; Koshiishi, F.; Miyazako, S.; Tashiro, S.; Tanaka, M.; Nakata, K. The Surface Temperature Measurement of Weld Pool by Infrared Two-Color Pyrometry. Q. J. Jpn. Weld. Soc. 2009, 27, 34–40. [Google Scholar] [CrossRef]

- Wu, D.S.; Nguyen, A.V.; Tahsiro, S.; Hua, X.; Tanaka, M. Elucidation of the weld pool convection and keyhole formation mechanism in the keyhole plasma arc welding. Int. J. Heat. Mass. Tranf. 2019, 131, 920–931. [Google Scholar] [CrossRef]

- Li, Y.; Feng, Y.; Li, Y.; Zhang, X.; Wu, C.S. Plasma arc and weld pool coupled modeling of transport phenomena in keyhole welding. Int. J. Heat. Mass. Tranf. 2016, 92, 628–638. [Google Scholar] [CrossRef]

- Lu, S.; Fujii, H.; Sugiyama, H.; Tanaka, M.; Nogi, K. Weld penetration and Marangoni convection with oxide fluxes in GTA welding. Mater. Tran. 2002, 11, 2926–2931. [Google Scholar] [CrossRef] [Green Version]

- Sahoo, P.; Debroy, T.; McNallan, M.J. Surface tension of Binary Metal-Surface Active Solute Systems under Conditions Relevant to Welding Metallurgy. Metall. Mater. Trans. B 1988, 19B, 483–491. [Google Scholar] [CrossRef]

- Kou, S.; Wang, Y.H. Weld pool convection and its effect. Weld. J. 1986, 65, 63–70. [Google Scholar]

- Masuda, S.; Yasushi, T. Effect of magnetic field on flows and temperature distribution of molten pool in electromagnetic controlled molten pool welding process. Q. J. Japan Weld. Soc. 2015, 4, 244–250. [Google Scholar] [CrossRef]

- Mougenot, J.; Gonzalez, J.J.; Freton, P.; Cressault, Y. Argon and Arcal.37 plasma characteristics in a TIG configuration. J. Phys. D Appl. Phys. 2013, 46, 495203. [Google Scholar] [CrossRef]

- Arunkumar, M.; Dhinakaran, V.; Shanmugam, N.S. Numerical prediction of temperature distribution and residual stresses on plasma arc welded thin titanium sheets. Int. J. Model. Simul. 2019, 39, 1–17. [Google Scholar] [CrossRef]

- Fujii, H.; Lu, S.; Sato, T.; Nogi, K. Effect of Oxygen Content in He-O2 Shielding Gas on Weld Shape for Ultra Deep Penetration TIG. Trans. JWRI 2008, 37, 19–26. [Google Scholar]

- Nguyen, A.V.; Tashiro, S.; Ngo, M.H.; Le, A.H.; Tanaka, M. Influence of shielding gas composition on molten metal flow behavior during plasma keyhole arc welding process. J. Manuf. Process. 2020, 53, 431–437. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | Ni | Cr |

|---|---|---|---|---|---|

| Wt % | 0.06 | 0.44 | 0.96 | 8.19 | 18.22 |

| Welding Parameters | Value (Unit) |

|---|---|

| Welding current | DC 120 (A) |

| Plasma gas | Pure Ar |

| Shielding gas | Pure Ar and Ar + 0.5% O2 |

| Arc length | 5 (mm) |

| Plasma gas flow rate | 1.6 (L min−1) |

| Shielding gas flow rate | 7.5 (L min−1) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ngo Huu, M.; Nguyen Van, A.; Nguyen Van, T.; Tran Hai, D.; Nguyen Van, T.; Nguyen Tien, D.; Nguyen, T.-H. Material Flow Behavior on Weld Pool Surface in Plasma Arc Welding Process Considering Dominant Driving Forces. Appl. Sci. 2020, 10, 3569. https://doi.org/10.3390/app10103569

Ngo Huu M, Nguyen Van A, Nguyen Van T, Tran Hai D, Nguyen Van T, Nguyen Tien D, Nguyen T-H. Material Flow Behavior on Weld Pool Surface in Plasma Arc Welding Process Considering Dominant Driving Forces. Applied Sciences. 2020; 10(10):3569. https://doi.org/10.3390/app10103569

Chicago/Turabian StyleNgo Huu, Manh, Anh Nguyen Van, Tuan Nguyen Van, Dang Tran Hai, Thanh Nguyen Van, Dung Nguyen Tien, and Thanh-Hai Nguyen. 2020. "Material Flow Behavior on Weld Pool Surface in Plasma Arc Welding Process Considering Dominant Driving Forces" Applied Sciences 10, no. 10: 3569. https://doi.org/10.3390/app10103569

APA StyleNgo Huu, M., Nguyen Van, A., Nguyen Van, T., Tran Hai, D., Nguyen Van, T., Nguyen Tien, D., & Nguyen, T.-H. (2020). Material Flow Behavior on Weld Pool Surface in Plasma Arc Welding Process Considering Dominant Driving Forces. Applied Sciences, 10(10), 3569. https://doi.org/10.3390/app10103569