Enhanced out of Plane Electrical Conductivity in Polymer Composites Induced by CO2 Laser Irradiation of Carbon Fibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

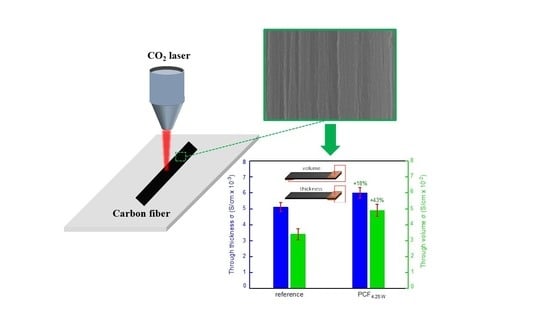

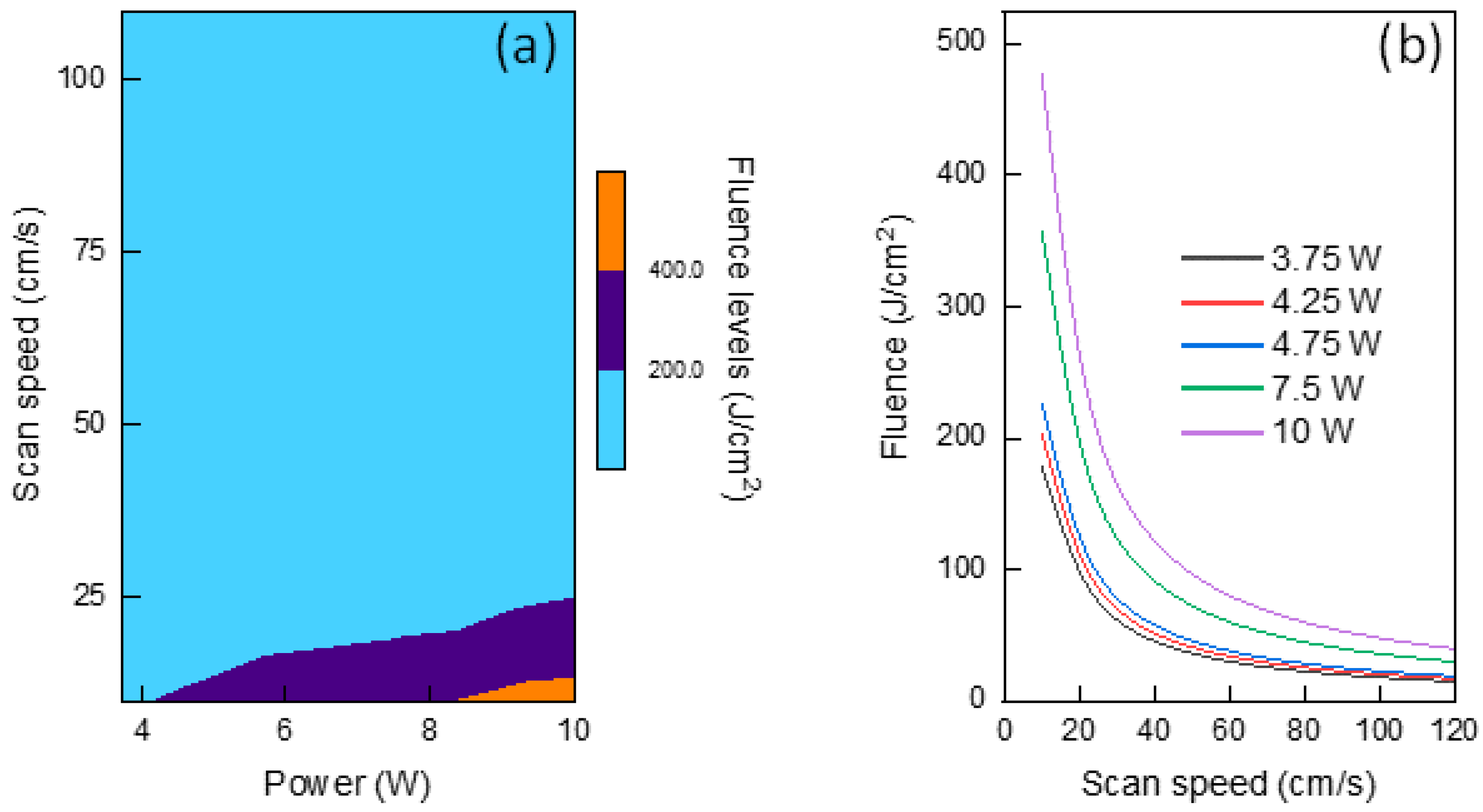

2.2. CO2 Irradiation/Activation of the CFs

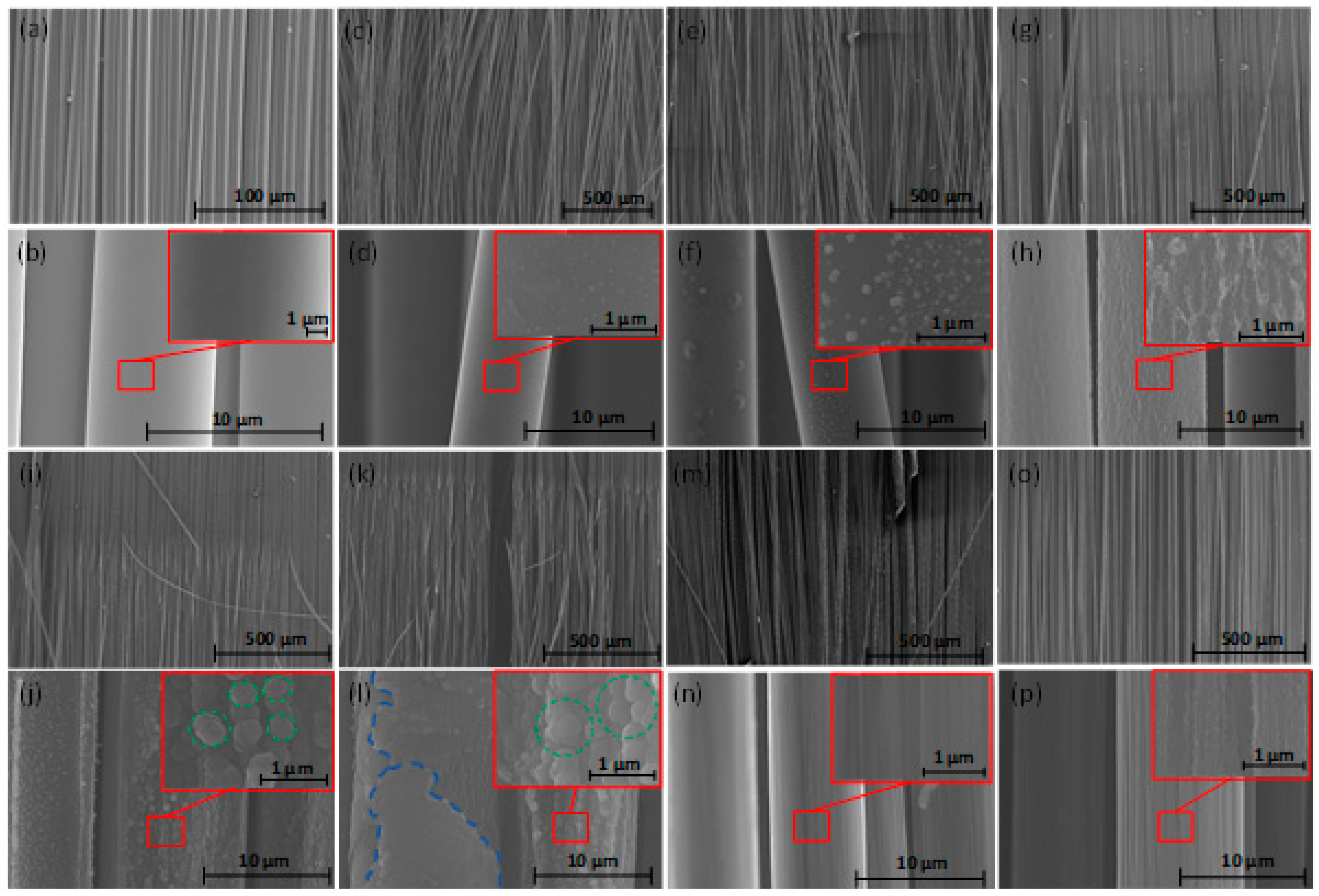

2.3. SEM Analysis

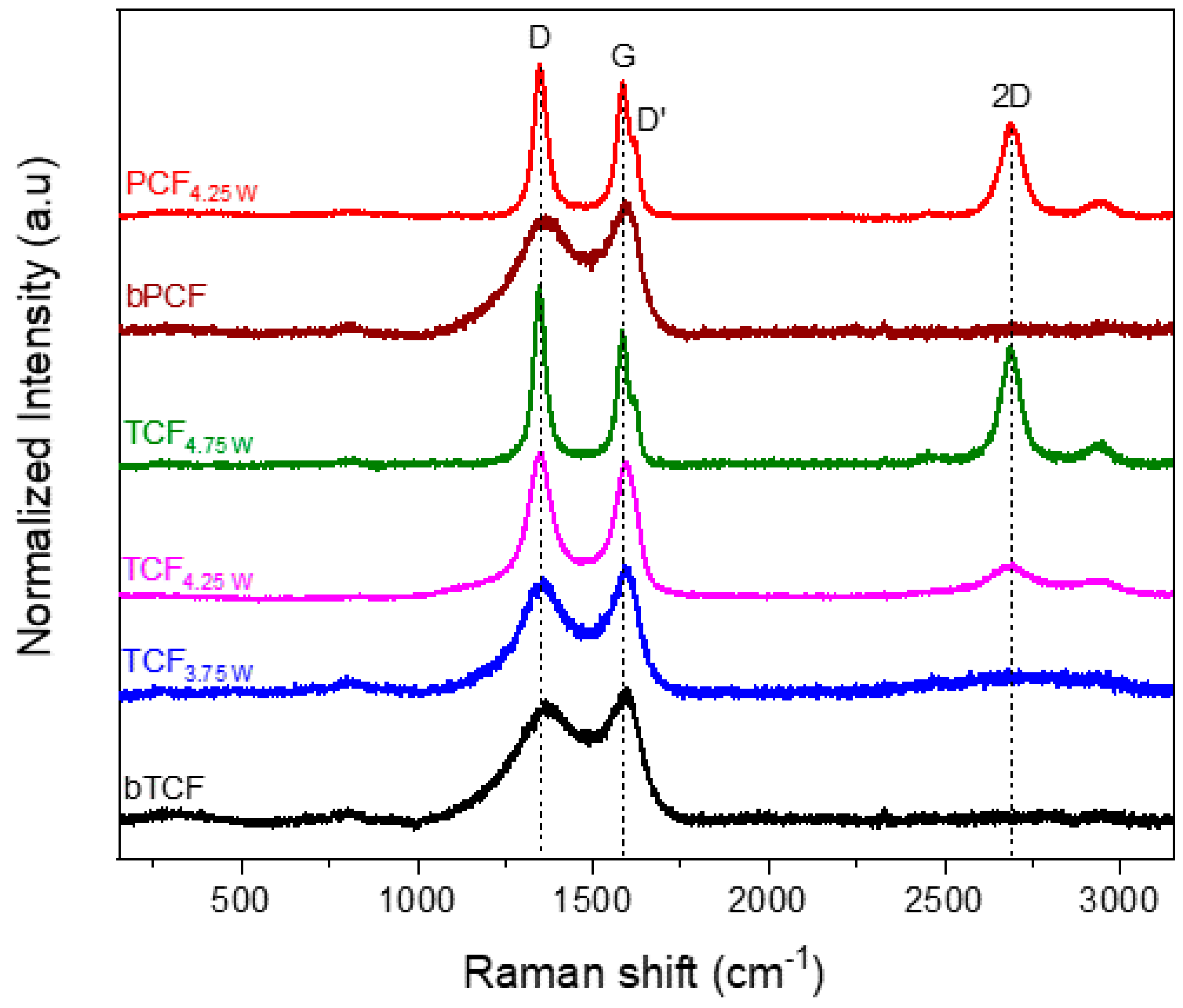

2.4. Raman Characterization

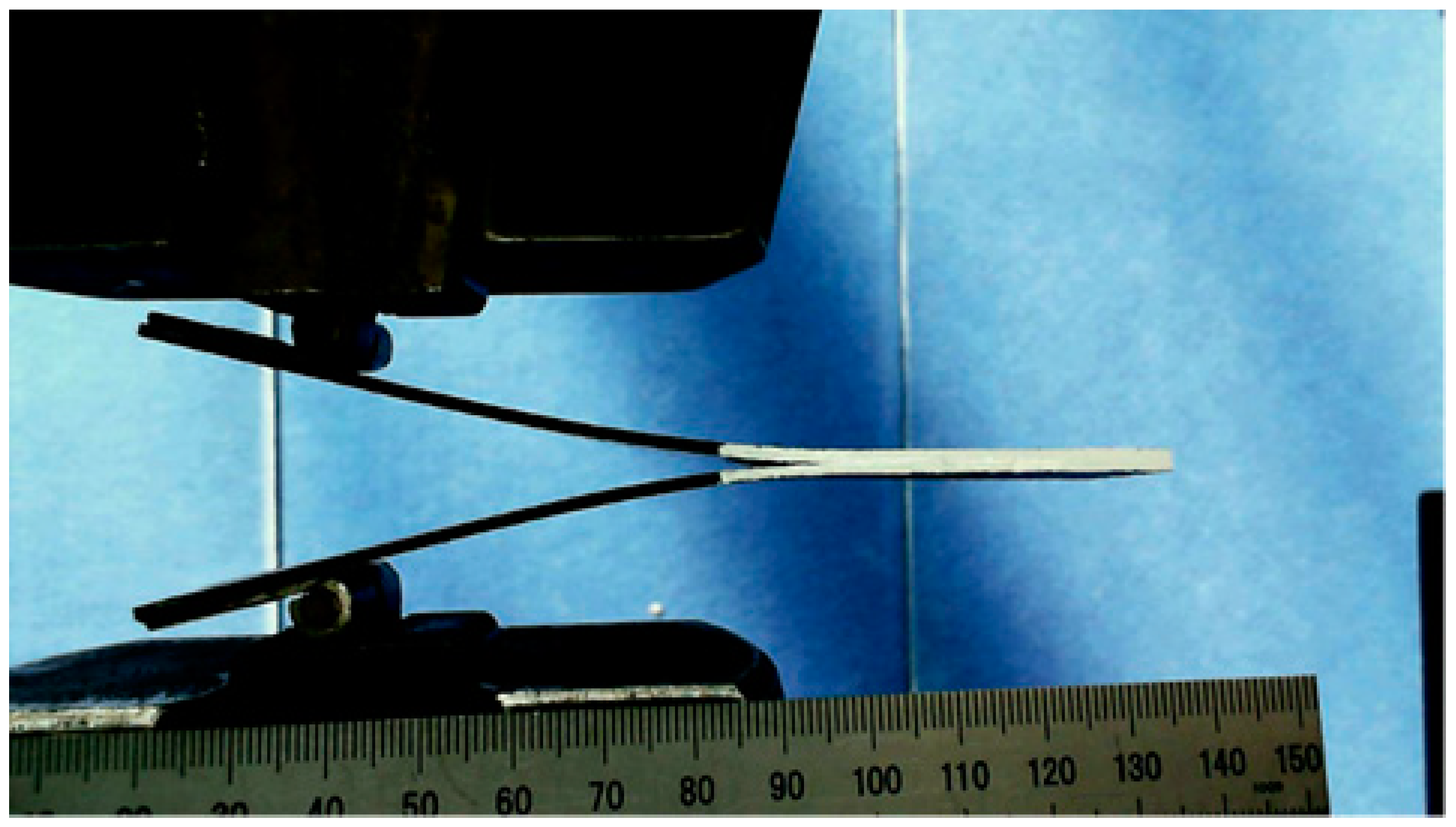

2.5. Single Carbon Fiber Tensile Strength Measurements

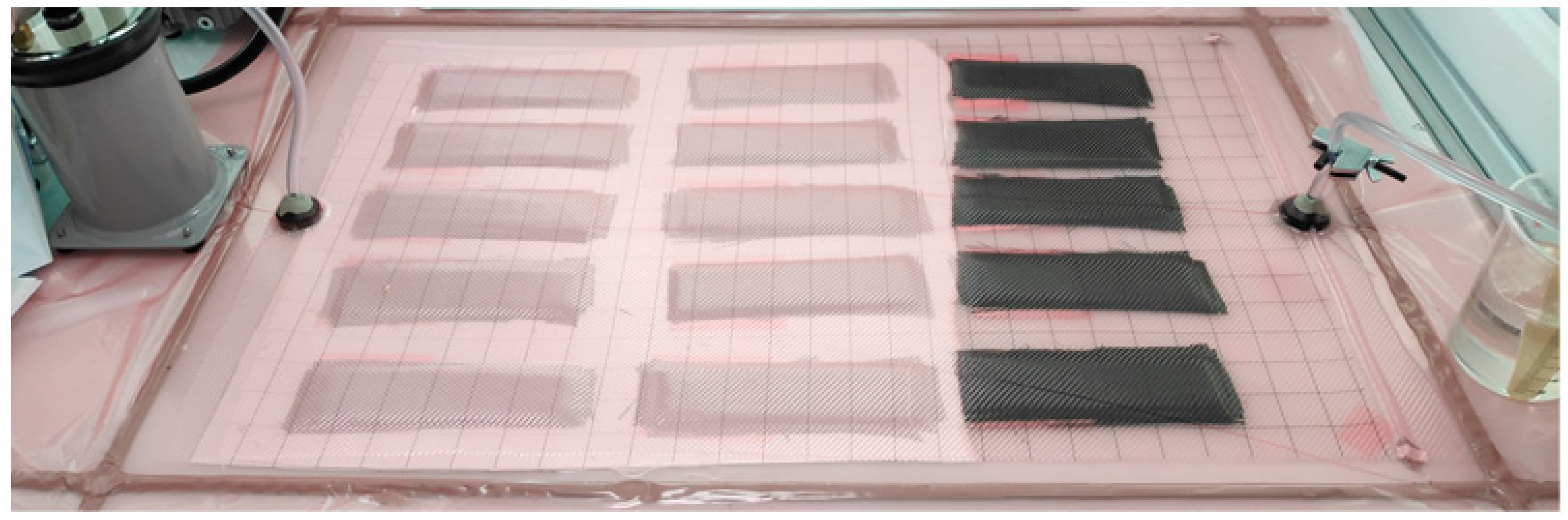

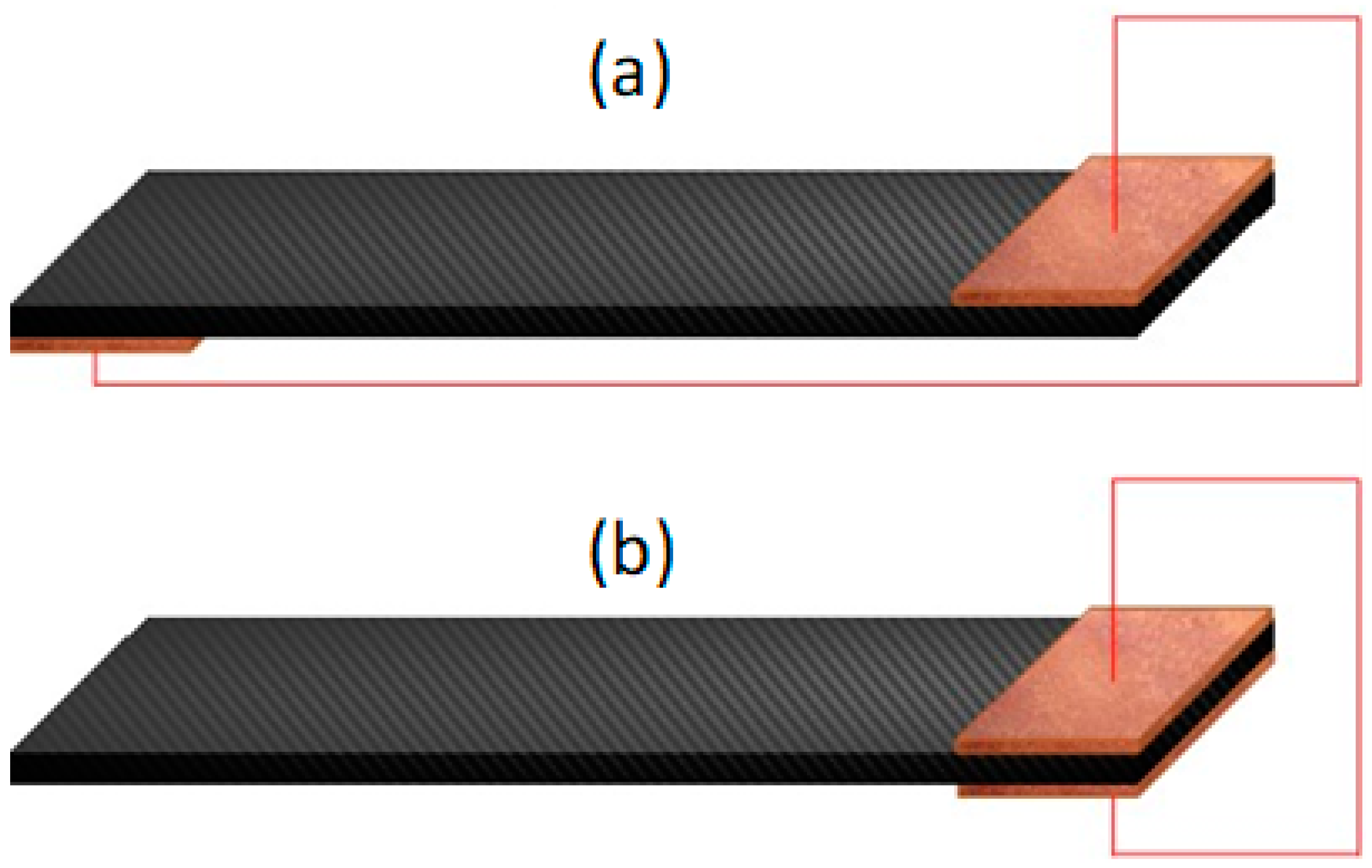

2.6. Laminate Preparation

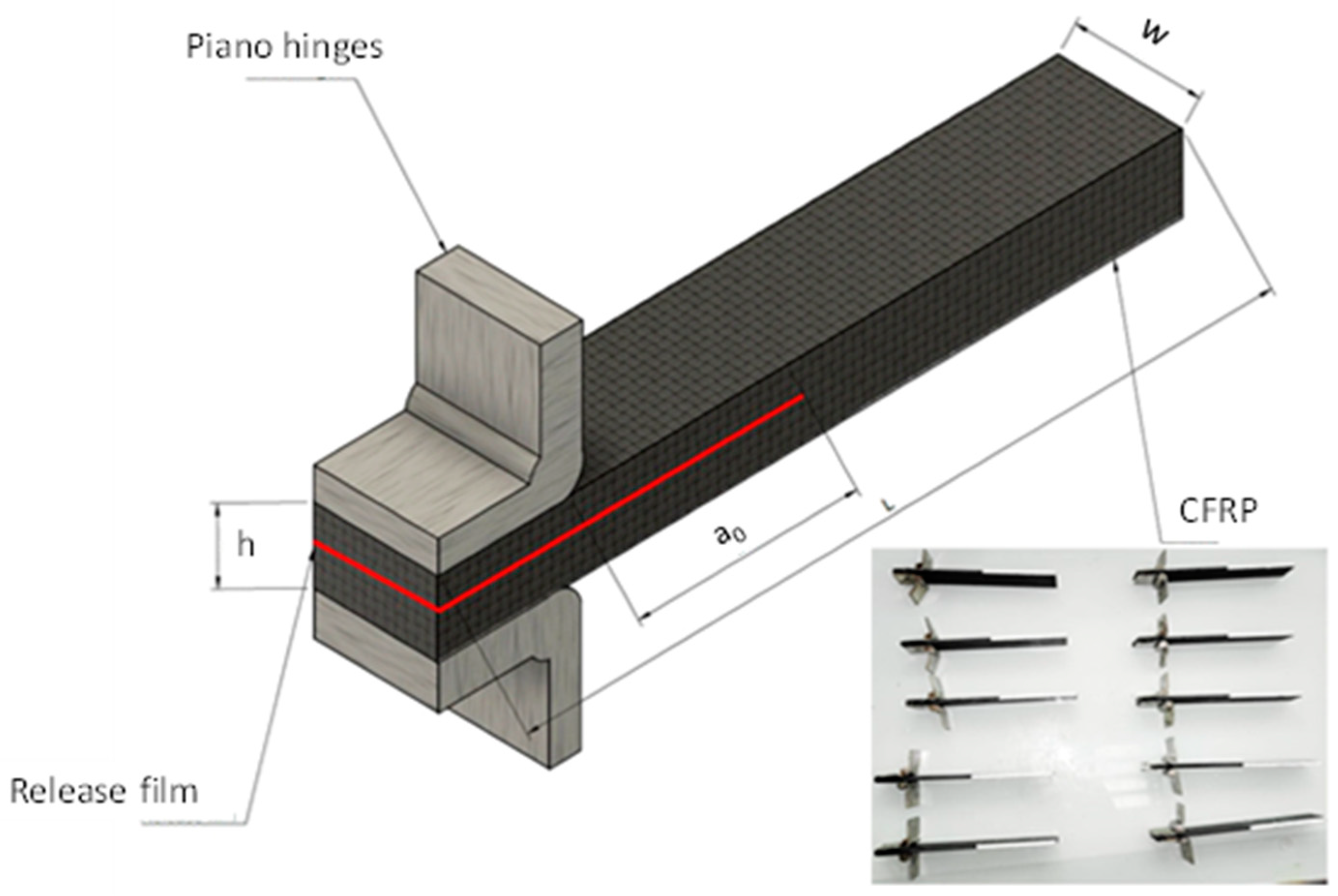

2.7. Mode-I Interlaminar Fracture Toughness Measurements

2.8. Electrical Conductivity Measurements

3. Results and Discussion

3.1. CO2 Irradiation of the CFs

3.2. SEM Analysis

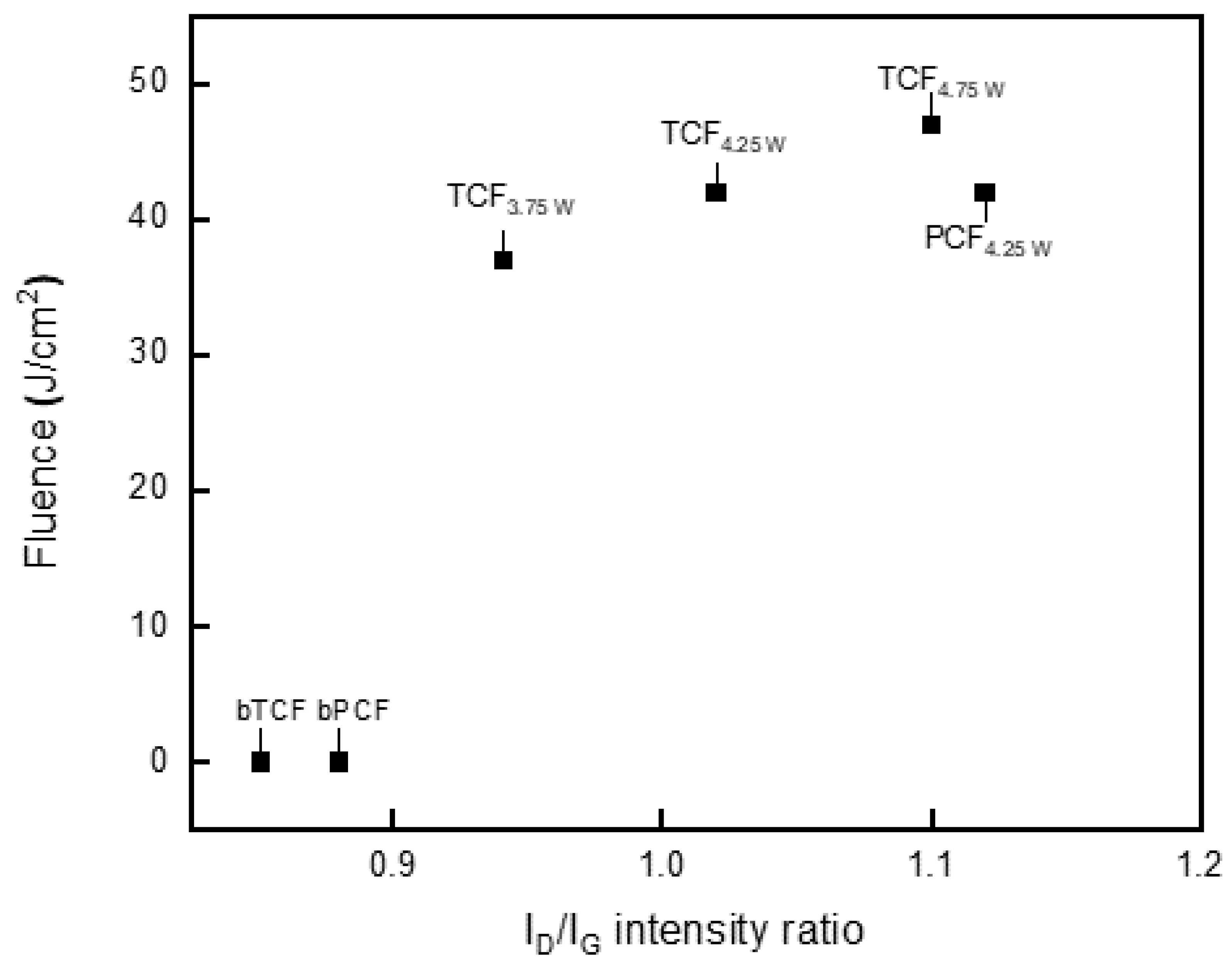

3.3. Raman Characterization

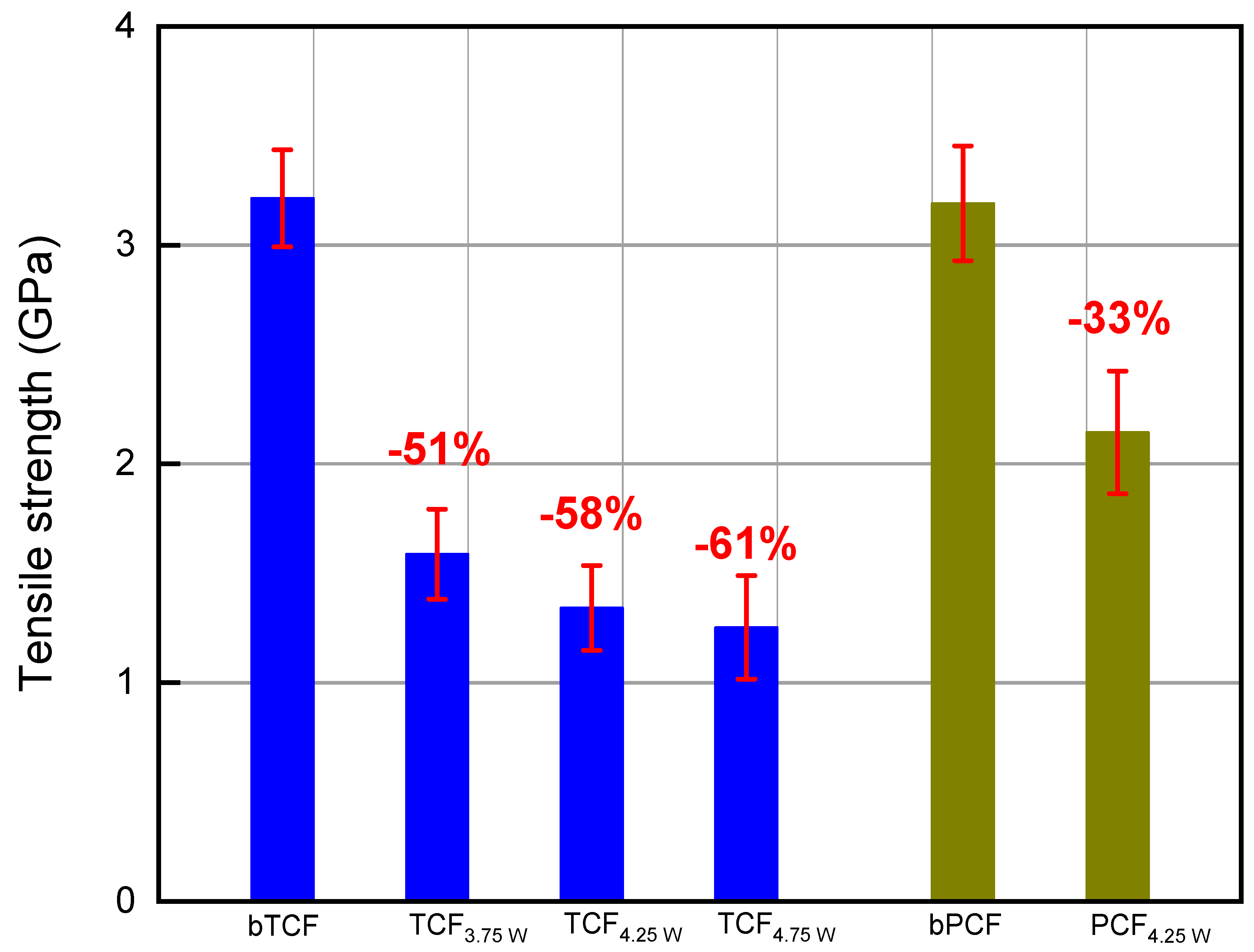

3.4. Single Carbon Fiber Tensile Strength Measurements

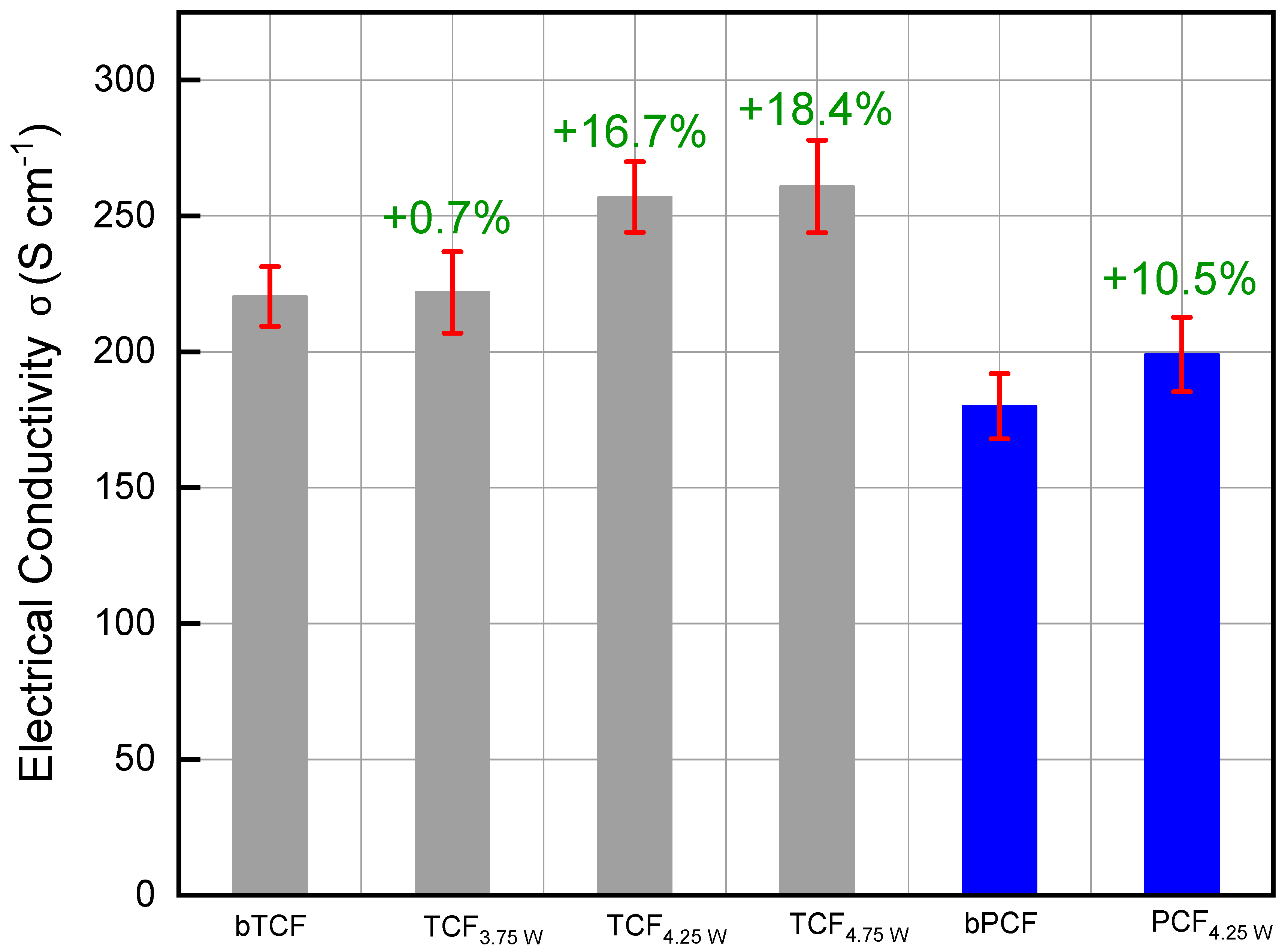

3.5. Electrical Conductivity Measurements on Activated CF Yarns

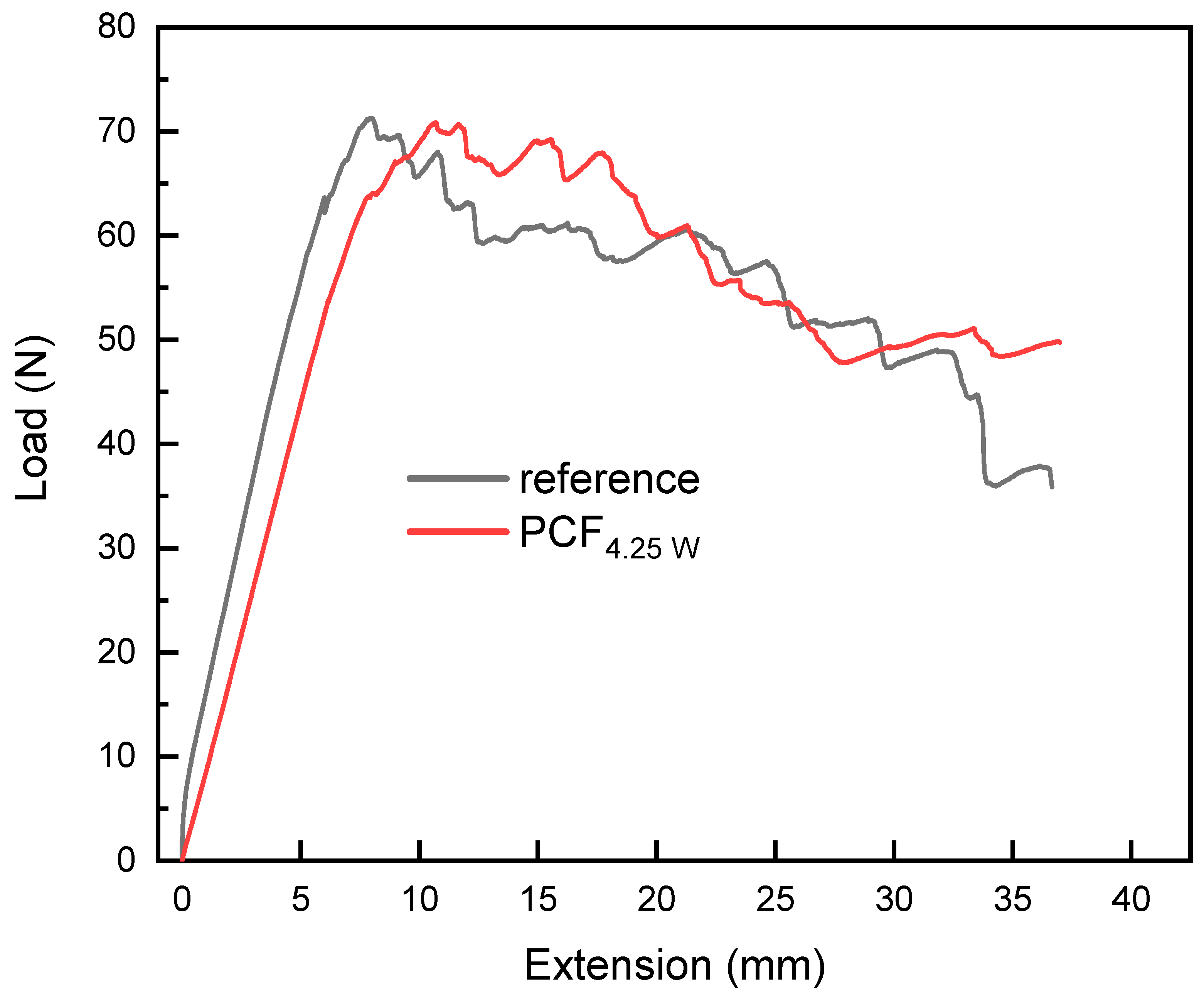

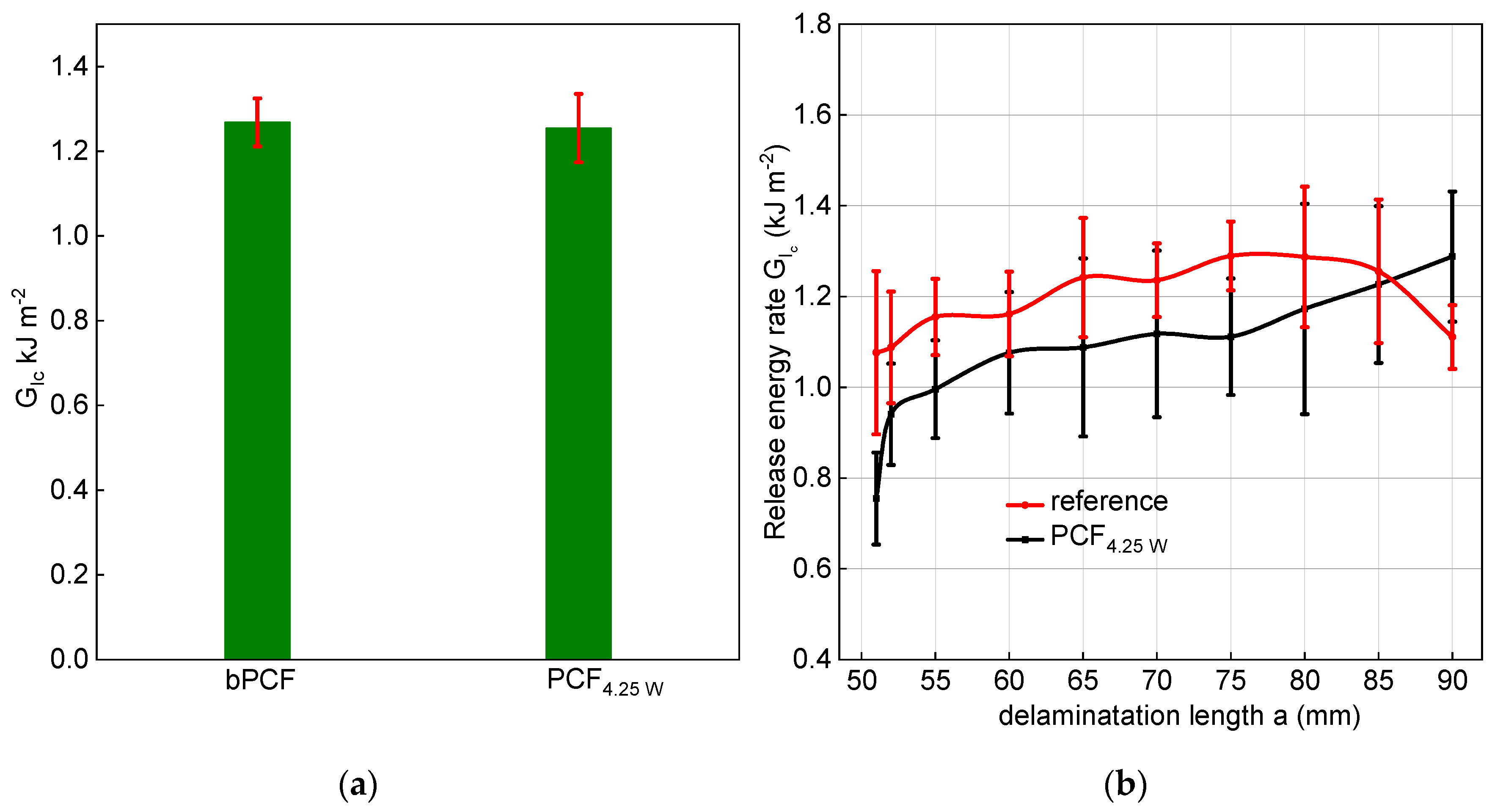

3.6. Mode-I Interlaminar Fracture Toughness Measurements

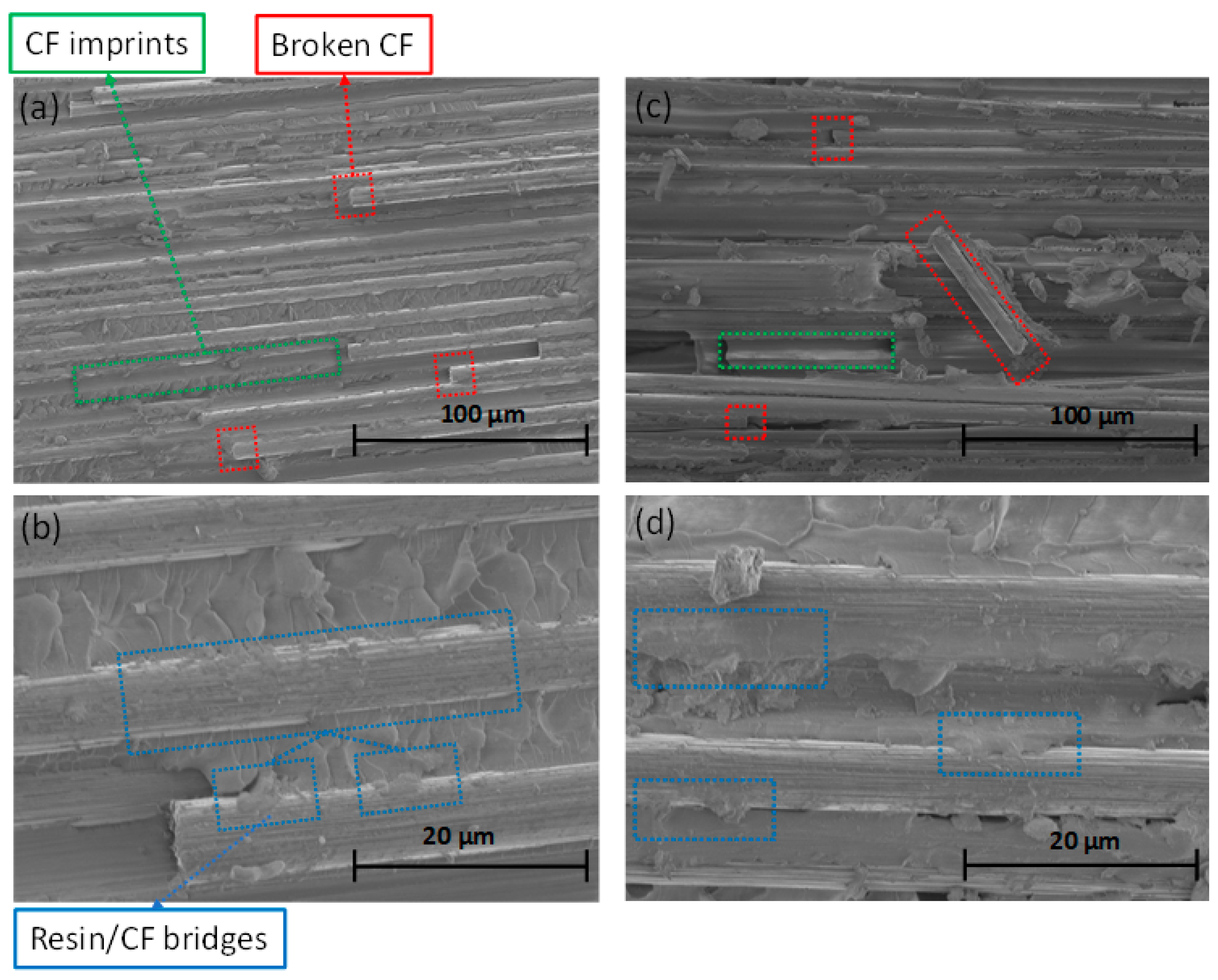

3.7. Fractography of the Tested Samples

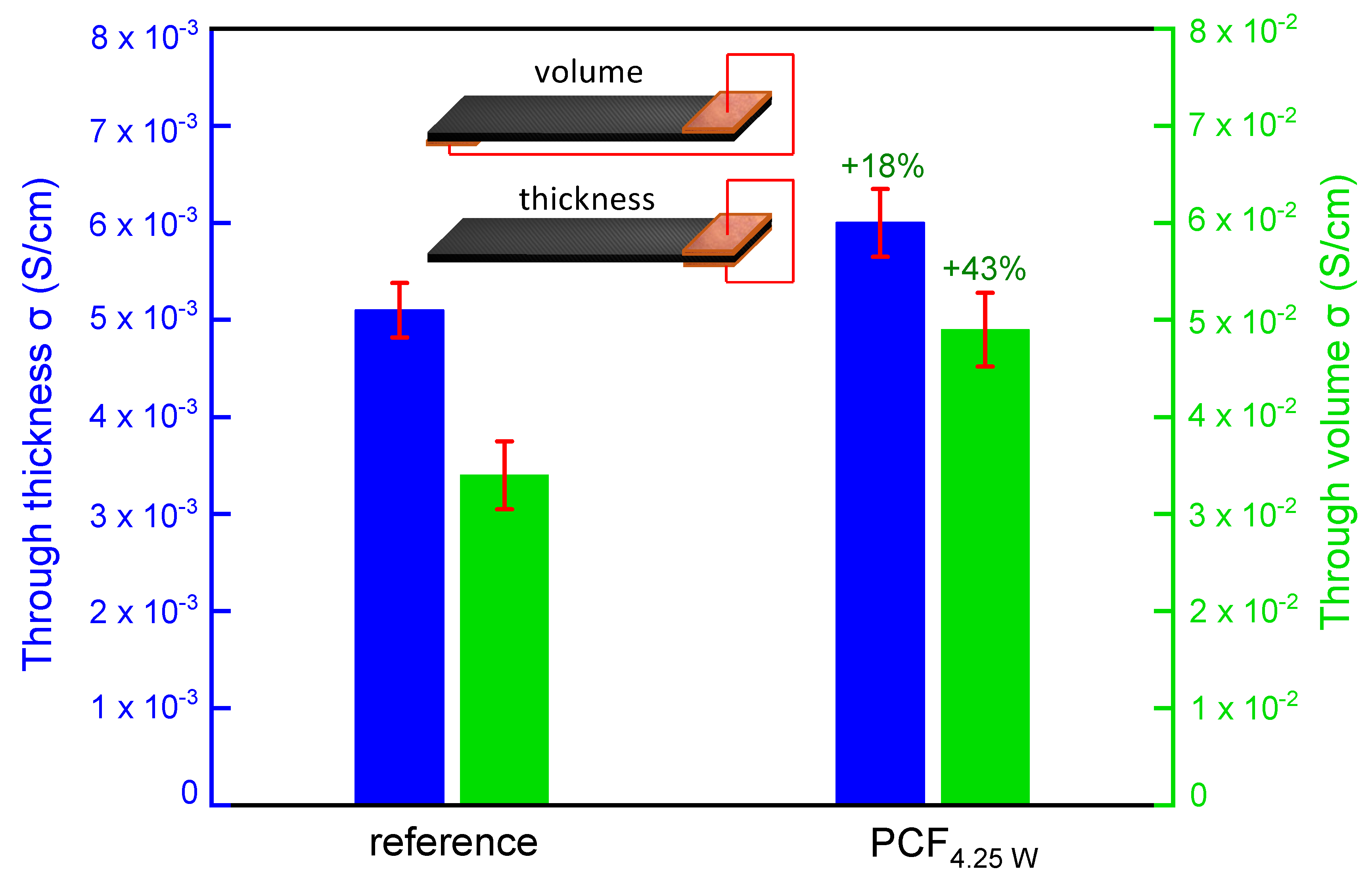

3.8. Electrical Conductivity of the Fabricated CFRP

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- De Rosa, I.M.; Sarasini, F.; Sarto, M.S.; Tamburrano, A. EMC Impact of Advanced Carbon Fiber/Carbon Nanotube Reinforced Composites for next-Generation Aerospace Applications. IEEE Trans. Electromagn. Compat. 2008, 50, 556–563. [Google Scholar] [CrossRef]

- Afshar, A.; Alkhader, M.; Korach, C.S.; Chiang, F.P. Effect of Long-Term Exposure to Marine Environments on the Flexural Properties of Carbon Fiber Vinylester Composites. Compos. Struct. 2015, 126, 72–77. [Google Scholar] [CrossRef]

- Feraboli, P.; Masini, A.; Taraborrelli, L.; Pivetti, A. Integrated Development of CFRP Structures for a Topless High Performance Vehicle. Compos. Struct. 2007, 78, 495–506. [Google Scholar] [CrossRef]

- Mishnaevsky, L.; Branner, K.; Petersen, H.N.; Beauson, J.; McGugan, M.; Sørensen, B.F. Materials for Wind Turbine Blades: An Overview. Materials 2017, 10, 1285. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alsaadi, A.; Meredith, J.; Swait, T.; Curiel-Sosa, J.L.; Jia, Y.; Hayes, S. Structural Health Monitoring for Woven Fabric CFRP Laminates. Compos. Part B Eng. 2019, 174, 107048. [Google Scholar] [CrossRef]

- Pereira, T.; Zhanhu, G.; Nieh, S.; Arias, J.; Hahn, H.T. Energy Storage Structural Composites: A Review. J. Compos. Mater. 2009, 43, 549–560. [Google Scholar] [CrossRef]

- Dhanya, T.M.; Yerramalli, C.S. Lightning Strike Effect on Carbon Fiber Reinforced Composites–Effect of Copper Mesh Protection. Mater. Today Commun. 2018, 16, 124–134. [Google Scholar] [CrossRef]

- Munalli, D.; Dimitrakis, G.; Chronopoulos, D.; Greedy, S.; Long, A. Electromagnetic Shielding Effectiveness of Carbon Fibre Reinforced Composites. Compos. Part B Eng. 2019, 173, 106906. [Google Scholar] [CrossRef]

- Jungwirth, M.E.L.; Wick, D.V.; Baker, M.S.; Wilcox, C.C.; Dereniak, E.L.; Romeo, R.C.; Martin, R.N. Actuation for Carbon Fiber Reinforced Polymer Active Optical Mirrors. In Proceedings of the IEEE Aerospace Conference Proceedings, Big Sky, MT, USA, 3–10 March 2012; pp. 1–9. [Google Scholar]

- Kim, K.J.; Yu, W.R.; Youk, J.H.; Lee, J. Degradation and Healing Mechanisms of Carbon Fibers during the Catalytic Growth of Carbon Nanotubes on Their Surfaces. ACS Appl. Mater. Interfaces 2012, 4, 2250–2258. [Google Scholar] [CrossRef]

- Kim, K.J.; Kim, J.; Yu, W.R.; Youk, J.H.; Lee, J. Improved Tensile Strength of Carbon Fibers Undergoing Catalytic Growth of Carbon Nanotubes on Their Surface. Carbon N. Y. 2013, 54, 258–267. [Google Scholar] [CrossRef]

- Qian, H.; Bismarck, A.; Greenhalgh, E.S.; Kalinka, G.; Shaffer, M.S.P. Hierarchical Composites Reinforced with Carbon Nanotube Grafted Fibers: The Potential Assessed at the Single Fiber Level. Chem. Mater. 2008, 20, 1862–1869. [Google Scholar] [CrossRef]

- Lee, G.; Youk, J.H.; Lee, J.; Sul, I.H.; Yu, W.R. Low-Temperature Grafting of Carbon Nanotubes on Carbon Fibers Using a Bimetallic Floating Catalyst. Diam. Relat. Mater. 2016, 68, 118–126. [Google Scholar] [CrossRef]

- Steiner, S.A.; Li, R.; Wardle, B.L. Circumventing the Mechanochemical Origins of Strength Loss in the Synthesis of Hierarchical Carbon Fibers. ACS Appl. Mater. Interfaces 2013, 5, 4892–4903. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Lachman, N.; Florin, P.; Wagner, H.D.; Wardle, B.L. Hierarchical Carbon Nanotube Carbon Fiber Unidirectional Composites with Preserved Tensile and Interfacial Properties. Compos. Sci. Technol. 2015, 117, 139–145. [Google Scholar] [CrossRef] [Green Version]

- Sager, R.J.; Klein, P.J.; Lagoudas, D.C.; Zhang, Q.; Liu, J.; Dai, L.; Baur, J.W. Effect of Carbon Nanotubes on the Interfacial Shear Strength of T650 Carbon Fiber in an Epoxy Matrix. Compos. Sci. Technol. 2009, 69, 898–904. [Google Scholar] [CrossRef]

- Karakassides, A.; Ganguly, A.; Tsirka, K.; Paipetis, A.S.; Papakonstantinou, P. Radially Grown Graphene Nanoflakes on Carbon Fibers as Reinforcing Interface for Polymer Composites. ACS Appl. Nano Mater. 2020, 3, 2402–2413. [Google Scholar] [CrossRef] [Green Version]

- Ganguly, A.; Karakassides, A.; Benson, J.; Hussain, S.; Papakonstantinou, P. Multifunctional Structural Supercapacitor Based on Urea Activated Graphene Nanoflakes Directly Grown on Carbon Fibre Electrodes. ACS Appl. Energy Mater. 2020. [Google Scholar] [CrossRef]

- Chi, Y.; Chu, J.; Chen, M.; Li, C.; Mao, W.; Piao, M.; Zhang, H.; Liu, B.S.; Shi, H. Directly Deposited Graphene Nanowalls on Carbon Fiber for Improving the Interface Strength in Composites. Appl. Phys. Lett. 2016, 108, 211601. [Google Scholar] [CrossRef]

- Shakir, I.; Shahid, M.; Rana, U.A.; Nashef, I.M.A.; Hussain, R. Nickel-Cobalt Layered Double Hydroxide Anchored Zinc Oxide Nanowires Grown on Carbon Fiber Cloth for High-Performance Flexible Pseudocapacitive Energy Storage Devices. Electrochim. Acta 2014, 129, 28–32. [Google Scholar] [CrossRef]

- Yang, Y.; Zhou, M.; Guo, W.; Cui, X.; Li, Y.; Liu, F.; Xiao, P.; Zhang, Y. NiCoO2 Nanowires Grown on Carbon Fiber Paper for Highly Efficient Water Oxidation. Electrochim. Acta 2015, 174, 246–253. [Google Scholar] [CrossRef]

- Deka, B.K.; Hazarika, A.; Kim, J.; Park, Y.B.; Park, H.W. Multifunctional CuO Nanowire Embodied Structural Supercapacitor Based on Woven Carbon Fiber/Ionic Liquid-Polyester Resin. Compos. Part A Appl. Sci. Manuf. 2016, 87, 256–262. [Google Scholar] [CrossRef]

- Zheng, N.; Huang, Y.; Sun, W.; Du, X.; Liu, H.Y.; Moody, S.; Gao, J.; Mai, Y.W. In-Situ Pull-off of ZnO Nanowire from Carbon Fiber and Improvement of Interlaminar Toughness of Hierarchical ZnO Nanowire/Carbon Fiber Hydrid Composite Laminates. Carbon N. Y. 2016, 110, 69–78. [Google Scholar] [CrossRef] [Green Version]

- Lin, Y.; Ehlert, G.; Sodano, H.A. Increased Interface Strength in Carbon Fiber Composites through a ZnO Nanowire Interphase. Adv. Funct. Mater. 2009, 19, 2654–2660. [Google Scholar] [CrossRef]

- Liao, Q.; Mohr, M.; Zhang, X.; Zhang, Z.; Zhang, Y.; Fecht, H.J. Carbon Fiber-ZnO Nanowire Hybrid Structures for Flexible and Adaptable Strain Sensors. Nanoscale 2013, 5, 12350–12355. [Google Scholar] [CrossRef] [PubMed]

- Reitz, V.; Meinhard, D.; Ruck, S.; Riegel, H.; Knoblauch, V. A Comparison of IR- and UV-Laser Pretreatment to Increase the Bonding Strength of Adhesively Joined Aluminum/CFRP Components. Compos. Part A Appl. Sci. Manuf. 2017, 96, 18–27. [Google Scholar] [CrossRef]

- Fischer, F.; Kreling, S.; Jäschke, P.; Frauenhofer, M.; Kracht, D.; Dilger, K. Laser Surface Pre-Treatment of CFRP for Adhesive Bonding in Consideration of the Absorption Behaviour. J. Adhes. 2012, 88, 350–363. [Google Scholar] [CrossRef]

- Schmutzler, H.; Popp, J.; Büchter, E.; Wittich, H.; Schulte, K.; Fiedler, B. Improvement of Bonding Strength of Scarf-Bonded Carbon Fibre/Epoxy Laminates by Nd:YAG Laser Surface Activation. Compos. Part A Appl. Sci. Manuf. 2014, 67, 123–130. [Google Scholar] [CrossRef]

- Leone, C.; Genna, S. Effects of Surface Laser Treatment on Direct Co-Bonding Strength of CFRP Laminates. Compos. Struct. 2018, 194, 240–251. [Google Scholar] [CrossRef]

- Xu, F.; Du, X.; Zhou, H. Building Hierarchical Micro-Structure on the Carbon Fabrics to Improve Their Reinforcing Effect in the CFRP Composites. In Recent Developments in the Field of Carbon Fibers; Chapter 5; IntechOpen: Rijeka, Croatia, 2018. [Google Scholar] [CrossRef] [Green Version]

- Saleem, M.; Toubal, L.; Zitoune, R.; Bougherara, H. Investigating the Effect of Machining Processes on the Mechanical Behavior of Composite Plates with Circular Holes. Compos. Part A Appl. Sci. Manuf. 2013, 55, 169–177. [Google Scholar] [CrossRef]

- Moreira, R.D.F.; Oliveira, V.; Silva, F.G.A.; Vilar, R.; de Moura, M.F.S.F. Mode II Fracture Toughness of Carbon–Epoxy Bonded Joints with Femtosecond Laser Treated Surfaces. Int. J. Mech. Sci. 2018, 148, 707–713. [Google Scholar] [CrossRef]

- Ledesma, R.I.; Palmieri, F.L.; Lin, Y.; Belcher, M.A.; Ferriell, D.R.; Thomas, S.K.; Connell, J.W. Picosecond Laser Surface Treatment and Analysis of Thermoplastic Composites for Structural Adhesive Bonding. Compos. Part B Eng. 2020, 191, 107939. [Google Scholar] [CrossRef]

- Moreira, R.D.F.; Oliveira, V.; Silva, F.G.A.; Vilar, R.; de Moura, M.F.S.F. Influence of Femtosecond Laser Treated Surfaces on the Mode I Fracture Toughness of Carbon-Epoxy Bonded Joints. Int. J. Adhes. Adhes. 2018, 82, 108–113. [Google Scholar] [CrossRef]

- Sajzew, R.; Schröder, J.; Kunz, C.; Engel, S.; Müller, F.A.; Gräf, S. Femtosecond Laser-Induced Surface Structures on Carbon Fibers. Opt. Lett. 2015, 40, 5734–5737. [Google Scholar] [CrossRef] [PubMed]

- Kunz, C.; Büttner, T.N.; Naumann, B.; Boehm, A.V.; Gnecco, E.; Bonse, J.; Neumann, C.; Turchanin, A.; Müller, F.A.; Gräf, S. Large-Area Fabrication of Low- and High-Spatial-Frequency Laser-Induced Periodic Surface Structures on Carbon Fibers. Carbon N. Y. 2018, 133, 176–185. [Google Scholar] [CrossRef] [Green Version]

- Blaker, J.J.; Anthony, D.B.; Tang, G.; Shamsuddin, S.R.; Kalinka, G.; Weinrich, M.; Abdolvand, A.; Shaffer, M.S.P.; Bismarck, A. Property and Shape Modulation of Carbon Fibers Using Lasers. ACS Appl. Mater. Interfaces 2016, 8, 16351–16358. [Google Scholar] [CrossRef] [Green Version]

- ASTM C1557–03. Standard Test Method Tensile Strength Young’s Modulus Fibers; ASTM: West Conshohocken, PA, USA, 2003. [Google Scholar]

- ASTM. Standard Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites 1; ASTM: West Conshohocken, PA, USA, 2001. [Google Scholar]

- Stratan, A.; Zorila, A.; Rusen, L.; Nemes, G. Measuring Effective Area of Spots from Pulsed Laser Beams. Opt. Eng. 2014, 53, 122513. [Google Scholar] [CrossRef]

- Van, H.H.; Badura, K.; Zhang, M. Laser-Induced Transformation of Freestanding Carbon Nanotubes into Graphene Nanoribbons. RSC Adv. 2015, 5, 44183–44191. [Google Scholar] [CrossRef]

- Daniels, E.O. Laser Heat Treatment Processing for Pan Based Carbon Fiber Structure Modification; Florida State University: Tallahassee, FL, USA, 2017. [Google Scholar]

- Cançado, L.G.; Jorio, A.; Ferreira, E.H.M.; Stavale, F.; Achete, C.A.; Capaz, R.B.; Moutinho, M.V.O.; Lombardo, A.; Kulmala, T.S.; Ferrari, A.C. Quantifying Defects in Graphene via Raman Spectroscopy at Different Excitation Energies. Nano Lett. 2011, 11, 3190–3196. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ferrari, A.C.; Meyer, J.C.; Scardaci, V.; Casiraghi, C.; Lazzeri, M.; Mauri, F.; Piscanec, S.; Jiang, D.; Novoselov, K.S.; Roth, S.; et al. Raman Spectrum of Graphene and Graphene Layers. Phys. Rev. Lett. 2006, 97, 187401. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nakamura, H.; Tanaka, Y.; Nakai, A.; Kobayashi, S.; Ikuta, N. Interfacial Properties of Carbon Fiber Reinforced Thermoplastic Composites. In Proceedings of the 10th International Conference on Flow Processes in Composite Materials, Ascona, Switzerland, 11–15 July 2020. [Google Scholar]

- Ferrari, A.C. Raman Spectroscopy of Graphene and Graphite: Disorder, Electron-Phonon Coupling, Doping and Nonadiabatic Effects. Solid State Commun. 2007, 143, 47–57. [Google Scholar] [CrossRef]

- Guigon, M.; Oberlin, A.; Desarmot, G. Microtexture and Structure of Some High Tensile Strength, PAN-Base Carbon Fibres. Fibre Sci. Technol. 1984, 20, 55–72. [Google Scholar] [CrossRef]

- Edie, D.D. The Effect of Processing on the Structure and Properties of Carbon Fibers. Carbon N. Y. 1998, 36, 345–362. [Google Scholar] [CrossRef]

- Kim, T.; Lee, J.; Lee, K.H. Full Graphitization of Amorphous Carbon by Microwave Heating. RSC Adv. 2016, 6, 24667. [Google Scholar] [CrossRef] [Green Version]

- Onodera, A.; Irie, Y.; Higashi, K.; Umemura, J.; Takenaka, T. Graphitization of Amorphous Carbon at High Pressures to 15 GPa. J. Appl. Phys. 1991, 69, 2611. [Google Scholar] [CrossRef]

- Walters, J.K.; Fox, D.M.; Burke, T.M.; Weedon, O.D.; Newport, R.J.; Howells, W.S. The Effect of Temperature on the Structure of Amorphous Hydrogenated Carbon. J. Chem. Phys. 1994, 101, 4288. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Mao, H.K. Solid Carbon at High Pressure: Electrical Resistivity and Phase Transition. Phys. Chem. Miner. 1994, 21, 1–5. [Google Scholar] [CrossRef]

- Jin, C.H.; Wang, J.Y.; Chen, Q.; Peng, L.M. In Situ Fabrication and Graphitization of Amorphous Carbon Nanowires and Their Electrical Properties. J. Phys. Chem. B 2006, 110, 5423–5428. [Google Scholar] [CrossRef]

| Sample | Scan Speed (cm/s) | Power (W) | PPI | Fluence (J/cm2) |

|---|---|---|---|---|

| TCF3.75 W | 48.5 | 3.75 | 1000 | 37 |

| TCF4.25 W | 48.5 | 4.25 | 1000 | 42 |

| TCF4.75 W | 48.5 | 4.75 | 1000 | 47 |

| TCF7.5 W | 48.5 | 7.5 | 1000 | 74 |

| TCF10 W | 48.5 | 10 | 1000 | 99 |

| PCF4.25 W | 48.5 | 4.25 | 1000 | 42 |

| Sample | Tensile Strength (GPa) | Electrical Conductivity σ (S/cm) |

|---|---|---|

| bTCF | 3.21 ± 0.22 | 220 ± 11 |

| TCF3.75 W | 1.59 ± 0.21 | 222 ± 15 |

| TCF4.25 W | 1.34 ± 0.19 | 257 ± 13 |

| TCF4.75 W | 1.25 ± 0.23 | 261 ± 17 |

| bPCF | 3.19 ± 0.26 | 180 ± 12 |

| PCF4.25 W | 2.14 ± 0.28 | 199 ± 14 |

| Mode-I GIc (J m−2) | Electrical Conductivity σ (S/cm) | ||

|---|---|---|---|

| Through Volume | Through Thickness | ||

| reference | 1268 ± 56 | 3.4 10−2 ± 3.5 10−3 | 5.1 10−3 ± 2.8 10−4 |

| PCF4.25 W | 1254 ± 80 | 4.9 10−2 ± 3.8 10−3 | 6.0 10−3 ± 3.5 10−4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karakassides, A.; Karakassides, A.; Konstantinidou, M.; Paipetis, A.S.; Papakonstantinou, P. Enhanced out of Plane Electrical Conductivity in Polymer Composites Induced by CO2 Laser Irradiation of Carbon Fibers. Appl. Sci. 2020, 10, 3561. https://doi.org/10.3390/app10103561

Karakassides A, Karakassides A, Konstantinidou M, Paipetis AS, Papakonstantinou P. Enhanced out of Plane Electrical Conductivity in Polymer Composites Induced by CO2 Laser Irradiation of Carbon Fibers. Applied Sciences. 2020; 10(10):3561. https://doi.org/10.3390/app10103561

Chicago/Turabian StyleKarakassides, Anastasios, Angeliki Karakassides, Michaella Konstantinidou, Alkiviadis S. Paipetis, and Pagona Papakonstantinou. 2020. "Enhanced out of Plane Electrical Conductivity in Polymer Composites Induced by CO2 Laser Irradiation of Carbon Fibers" Applied Sciences 10, no. 10: 3561. https://doi.org/10.3390/app10103561

APA StyleKarakassides, A., Karakassides, A., Konstantinidou, M., Paipetis, A. S., & Papakonstantinou, P. (2020). Enhanced out of Plane Electrical Conductivity in Polymer Composites Induced by CO2 Laser Irradiation of Carbon Fibers. Applied Sciences, 10(10), 3561. https://doi.org/10.3390/app10103561