Development of a Lightweight Prosthetic Hand for Patients with Amputated Fingers

Abstract

:Featured Application

Abstract

1. Introduction

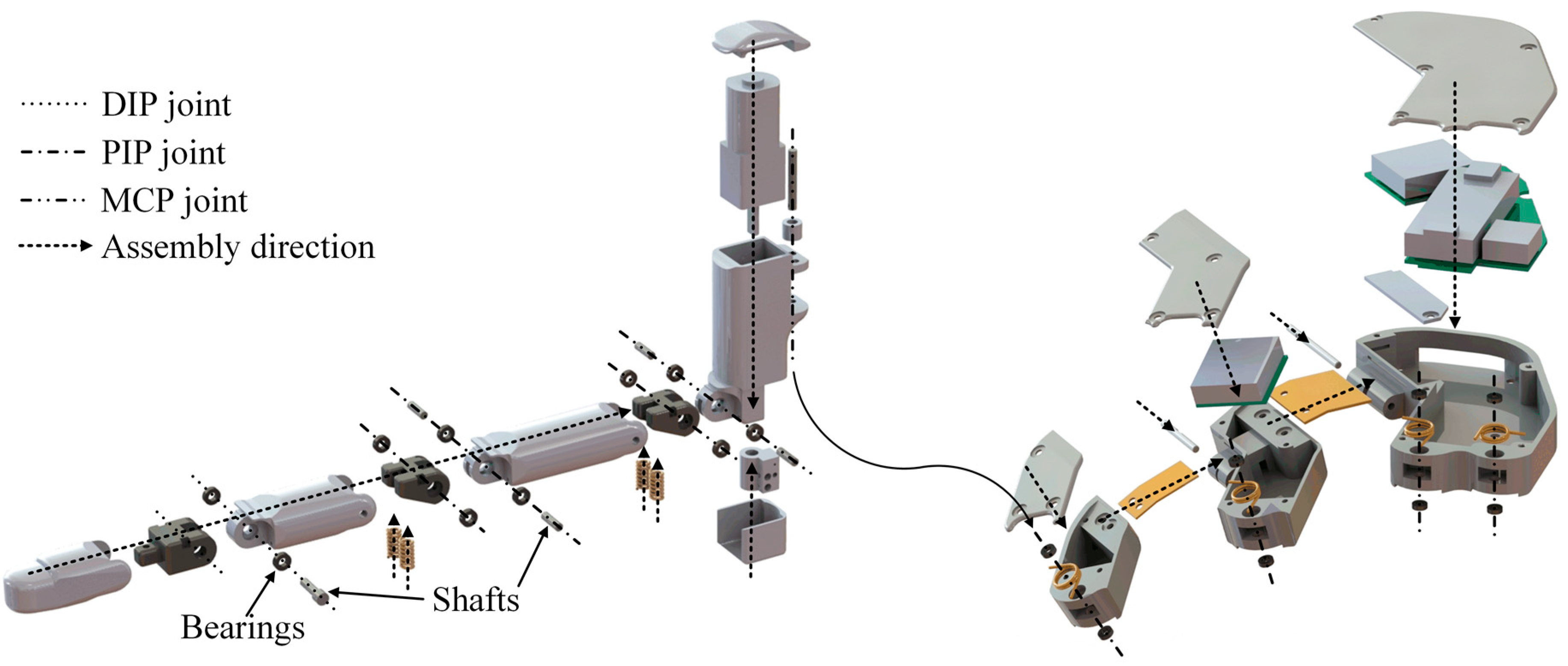

2. Design of the Prosthetic Hand

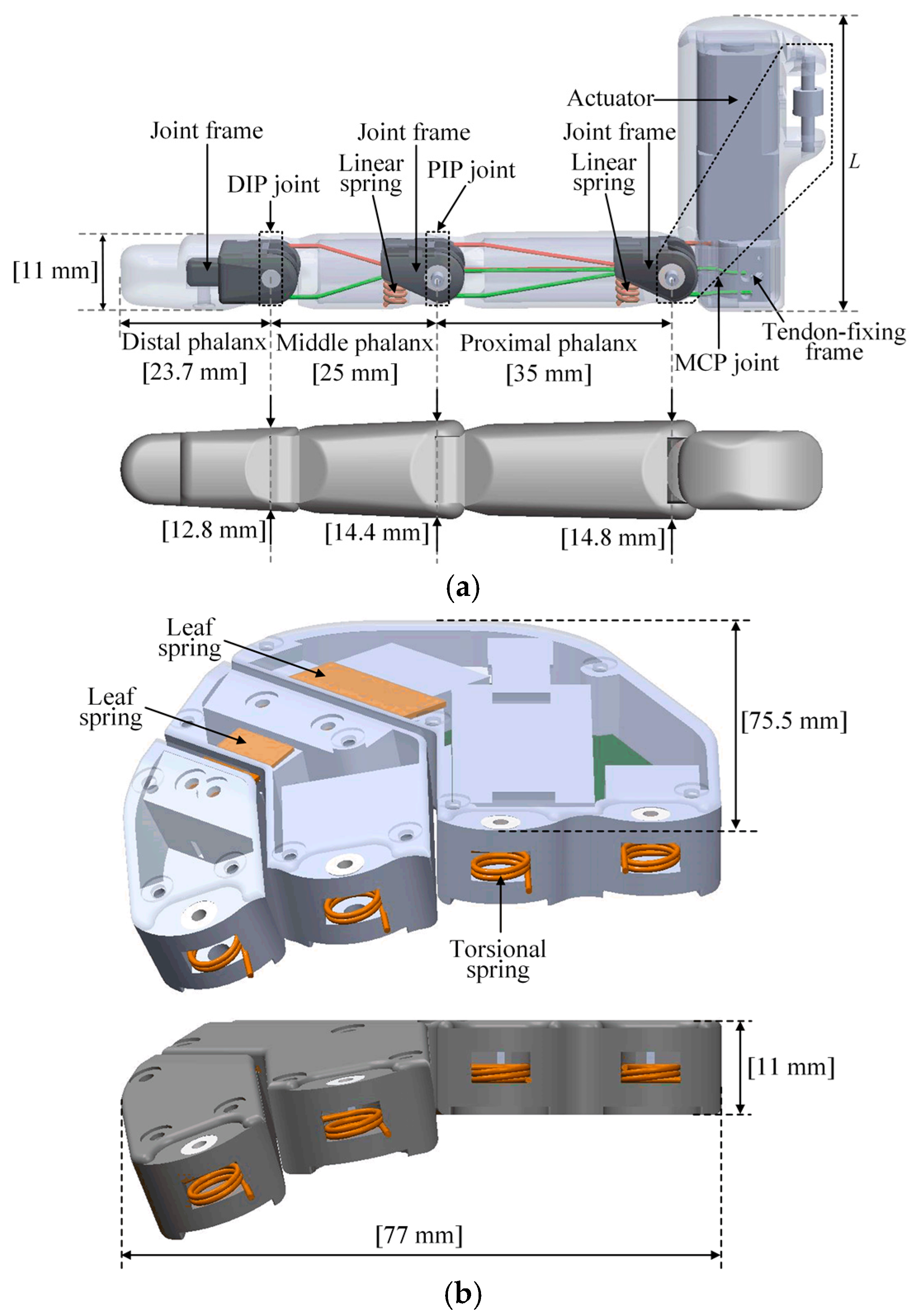

2.1. Design Concepts and 3D Models

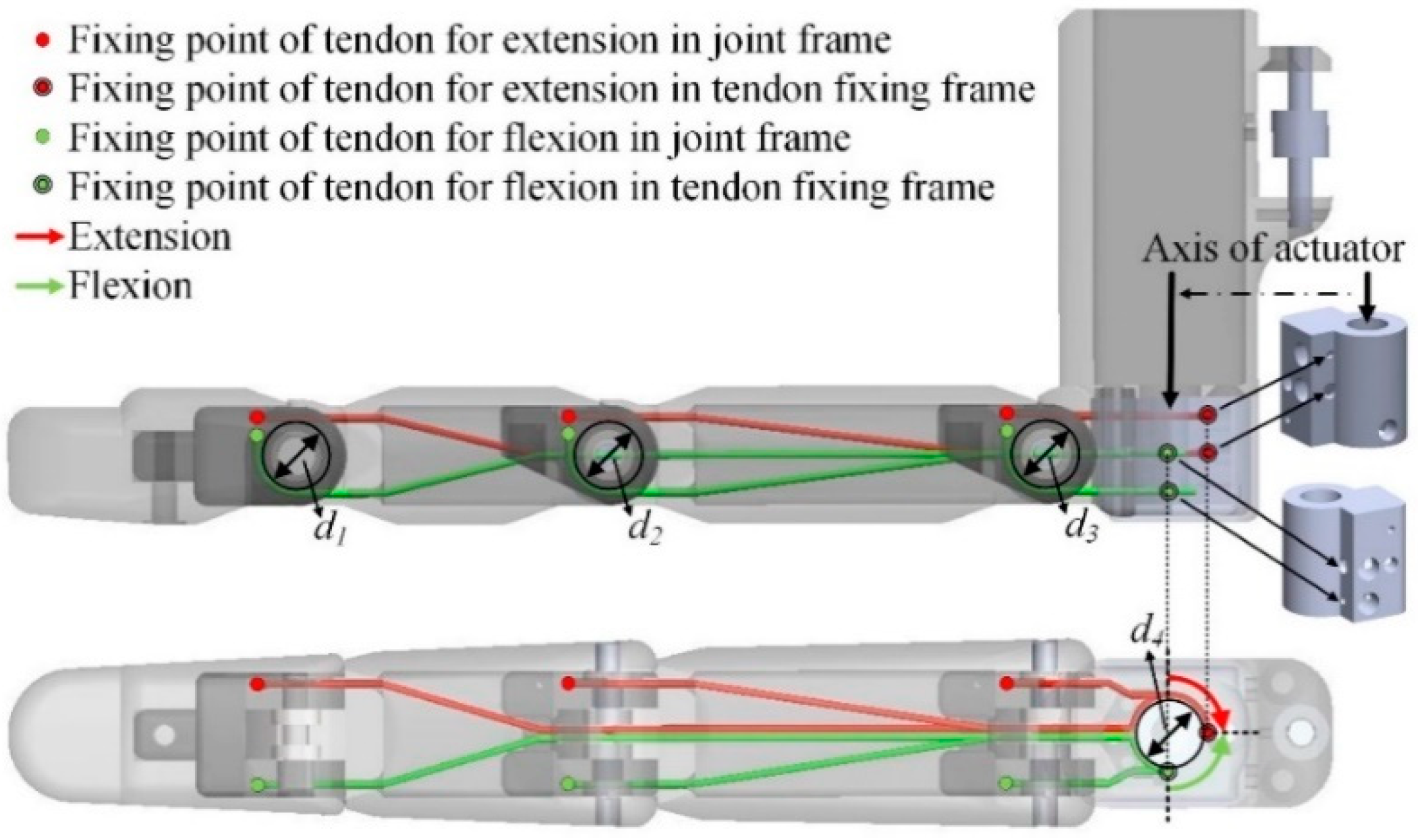

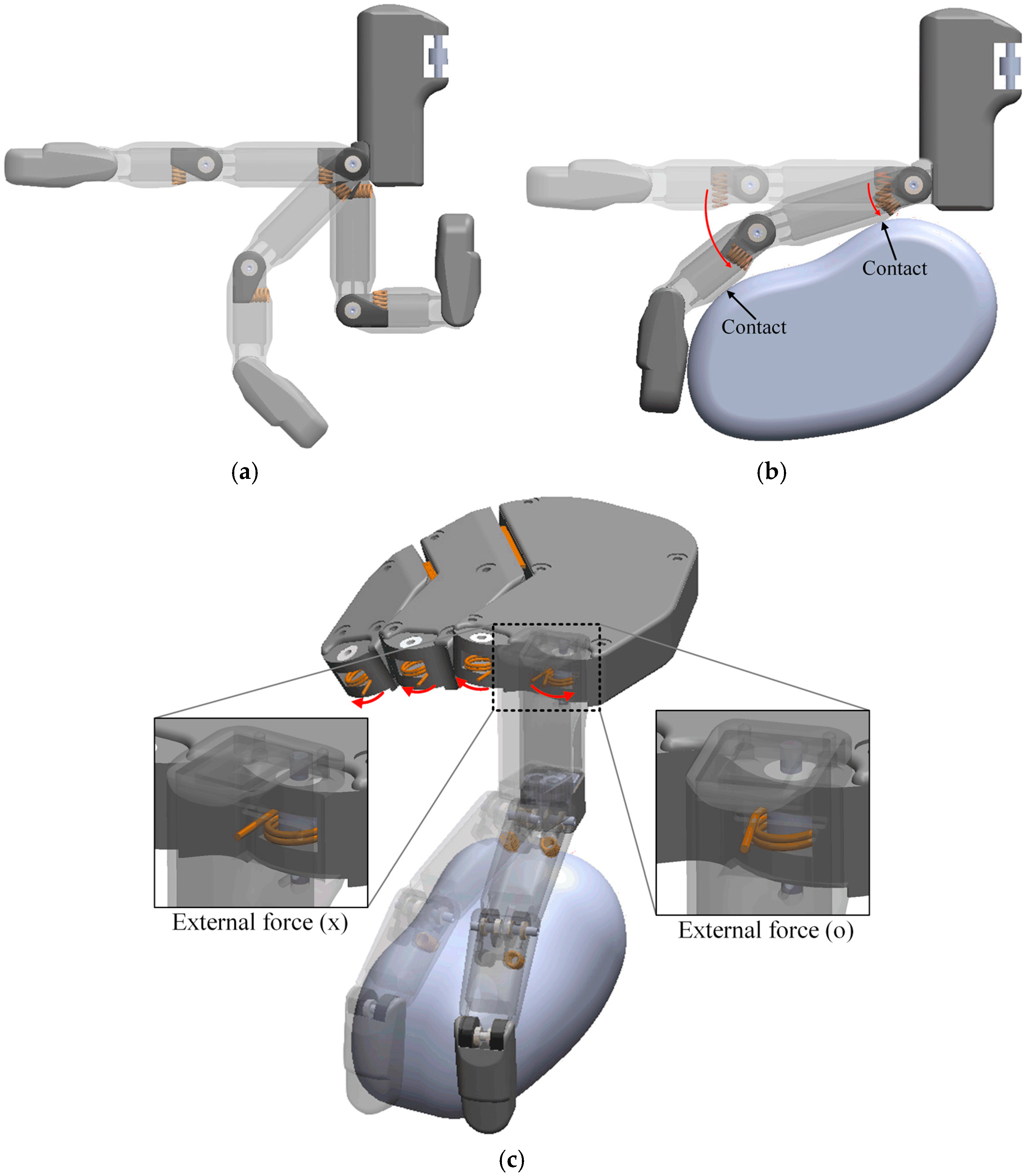

2.2. Principles of Operation

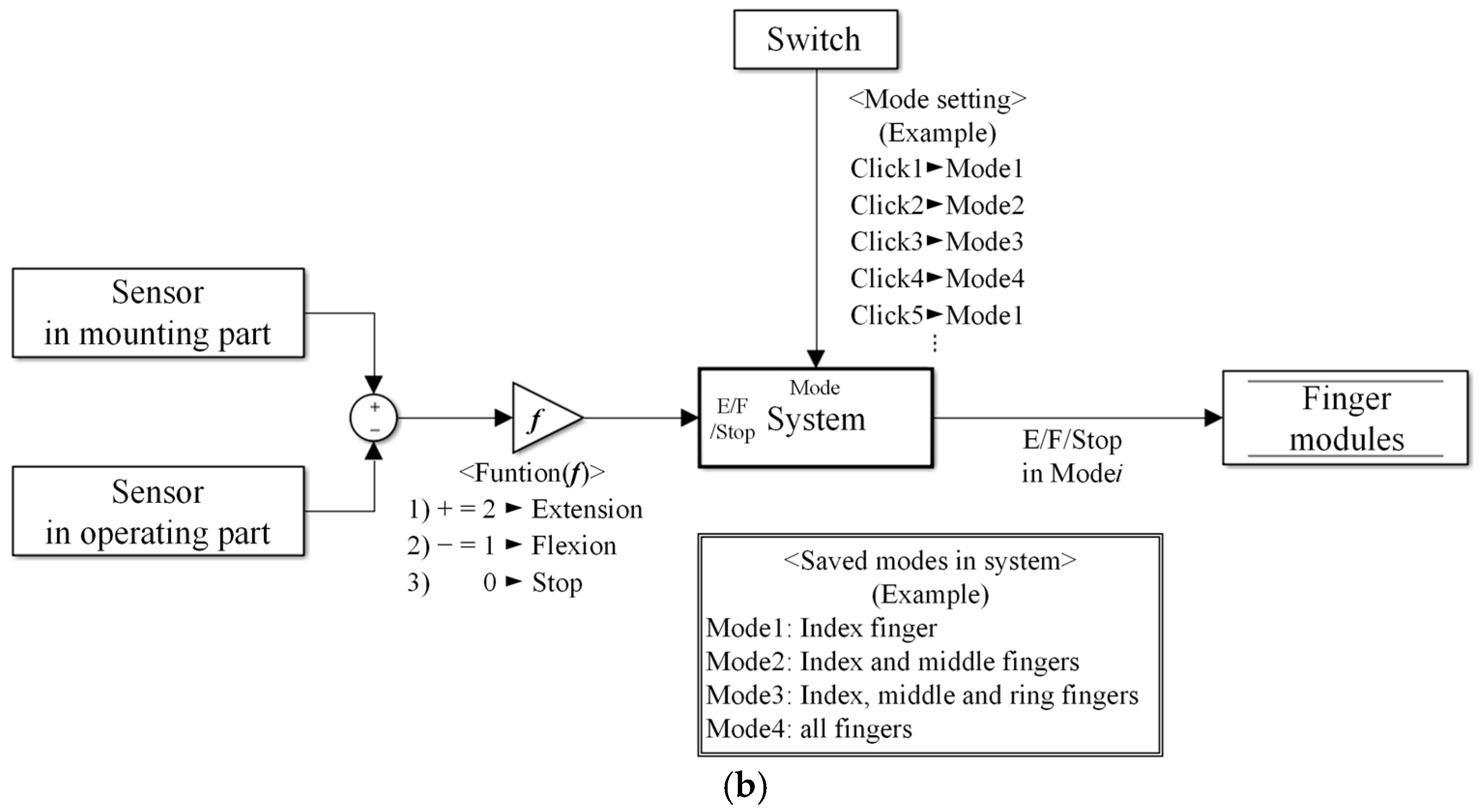

2.3. Control System

3. Analysis of the Prosthetic Hand

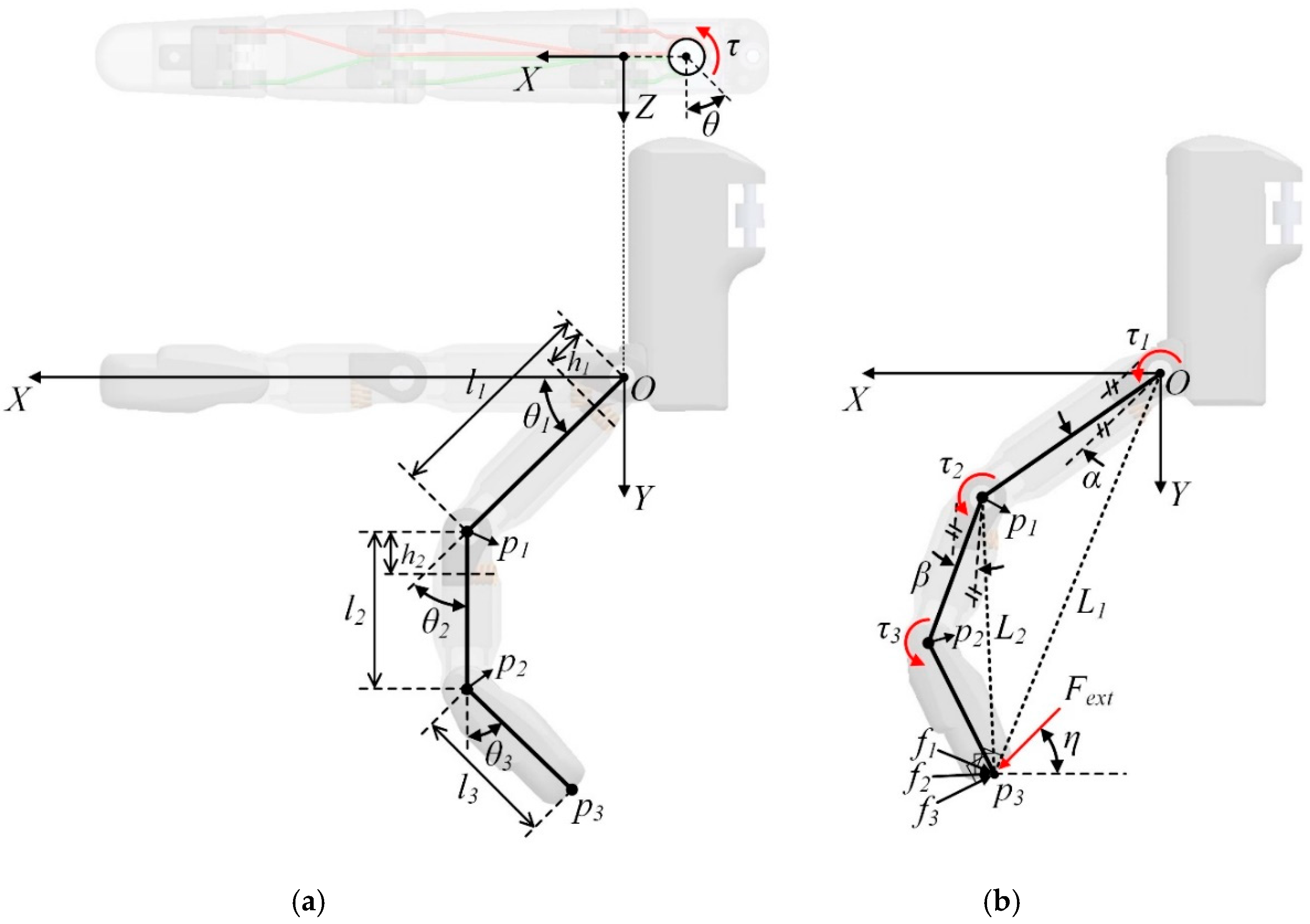

3.1. Kinematic Analysis

3.1.1. Position Analysis

3.1.2. Velocity Analysis

3.2. Static Analysis

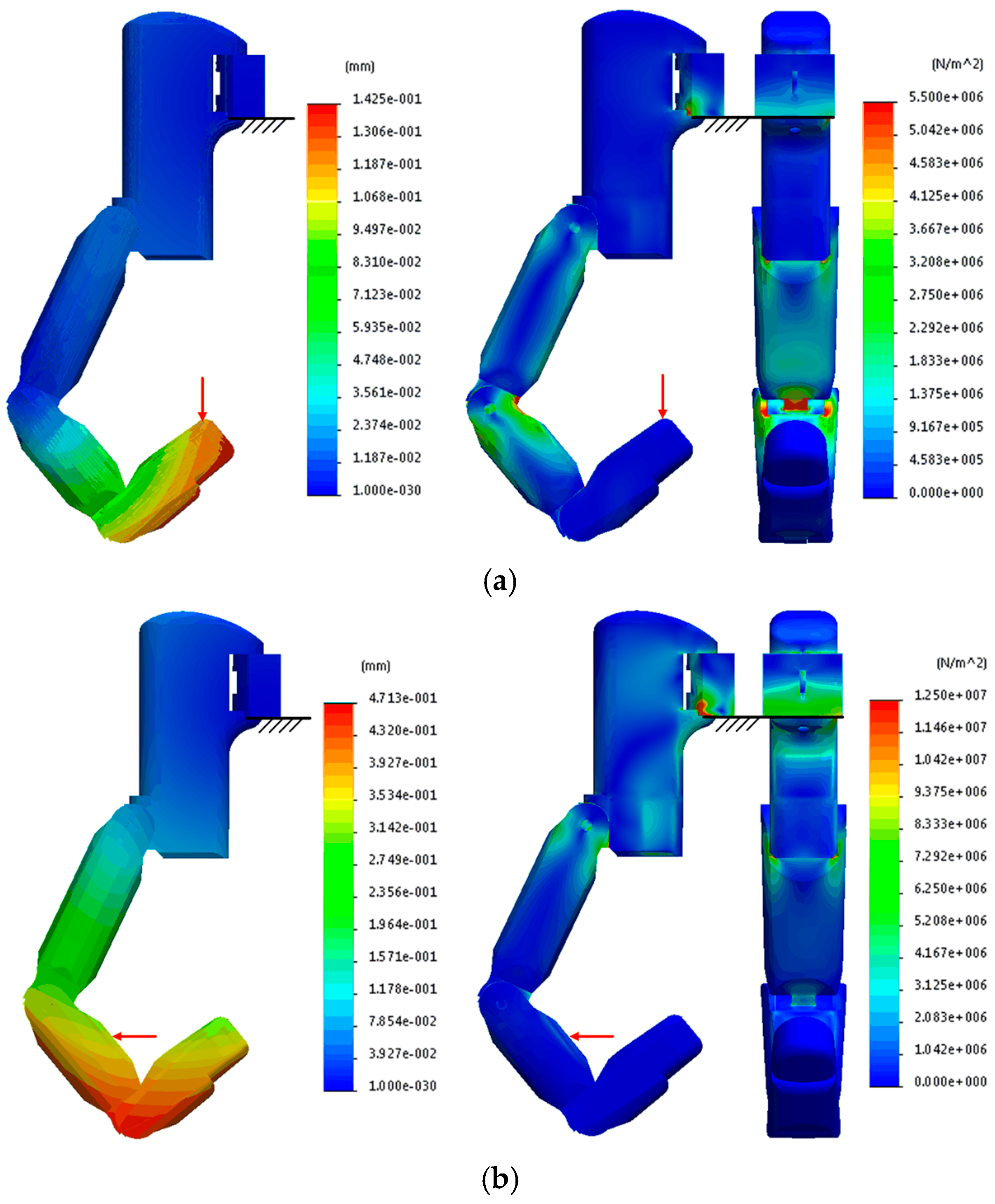

3.3. FEM Analysis

4. Results

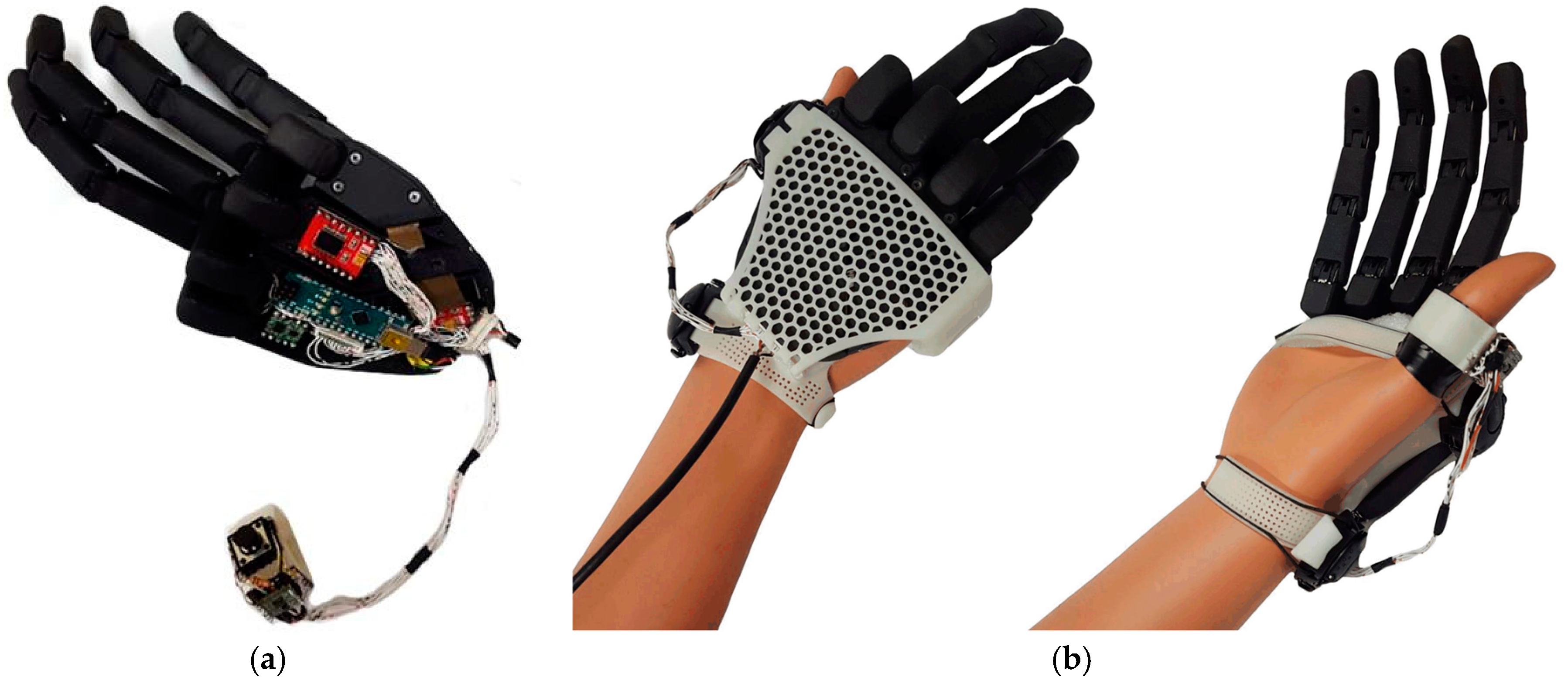

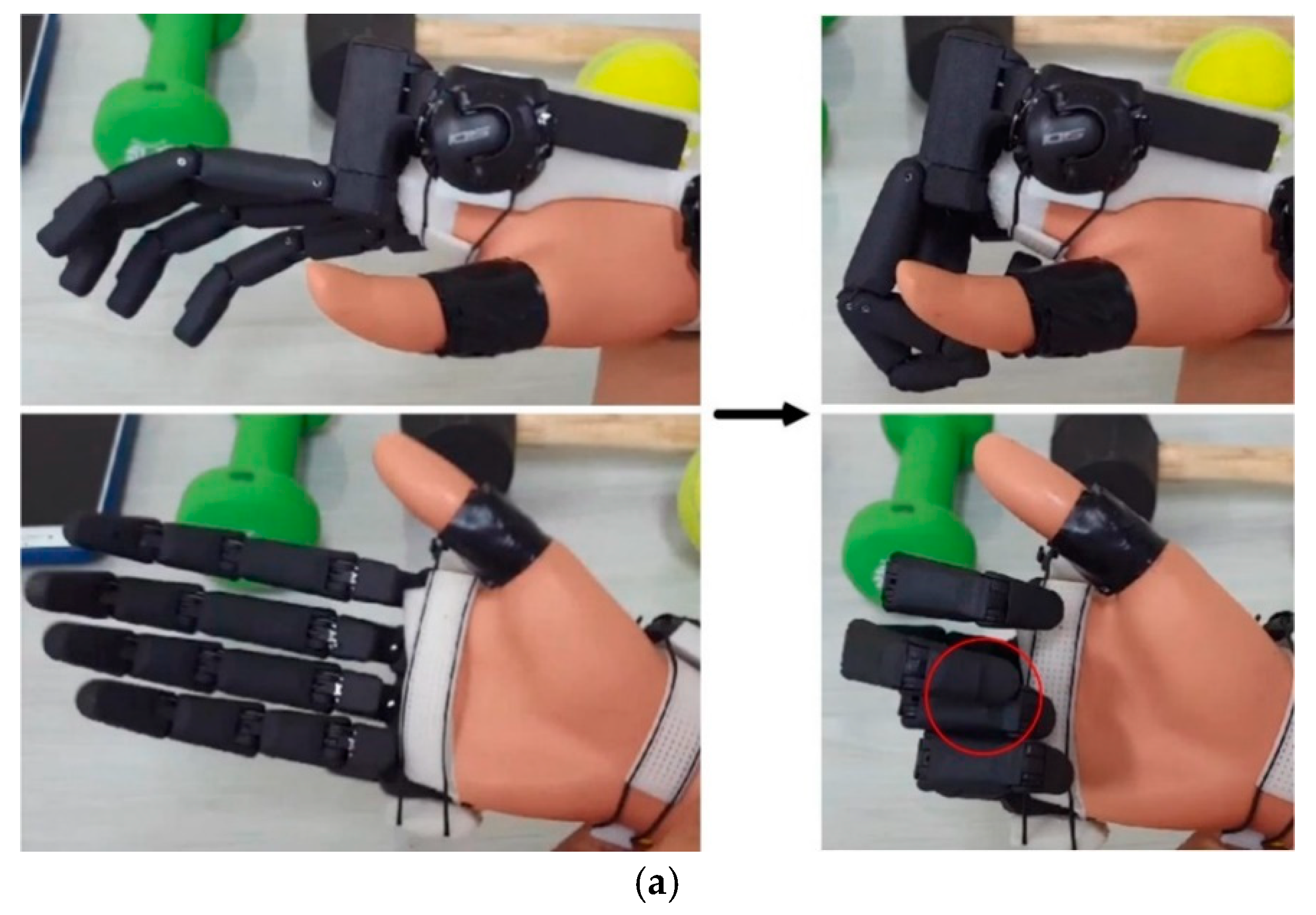

4.1. Prototype

- (1)

- The available range of linear springs installed on the joint frames was 4 mm, the spring constant was 2.667 N/mm, and the length for preload applied by frames was 1 mm,

- (2)

- The available range of torsional springs was 20°, the diameter and internal diameter of the coil and torsional spring were 1 mm and 5 mm, respectively, and the angle for preload was 5°, and

- (3)

- The available range of leaf spring was 20°, the thickness of leaf springs was 0.7 mm, and the lengths of the leaf springs were 10 mm and 20 mm, respectively.

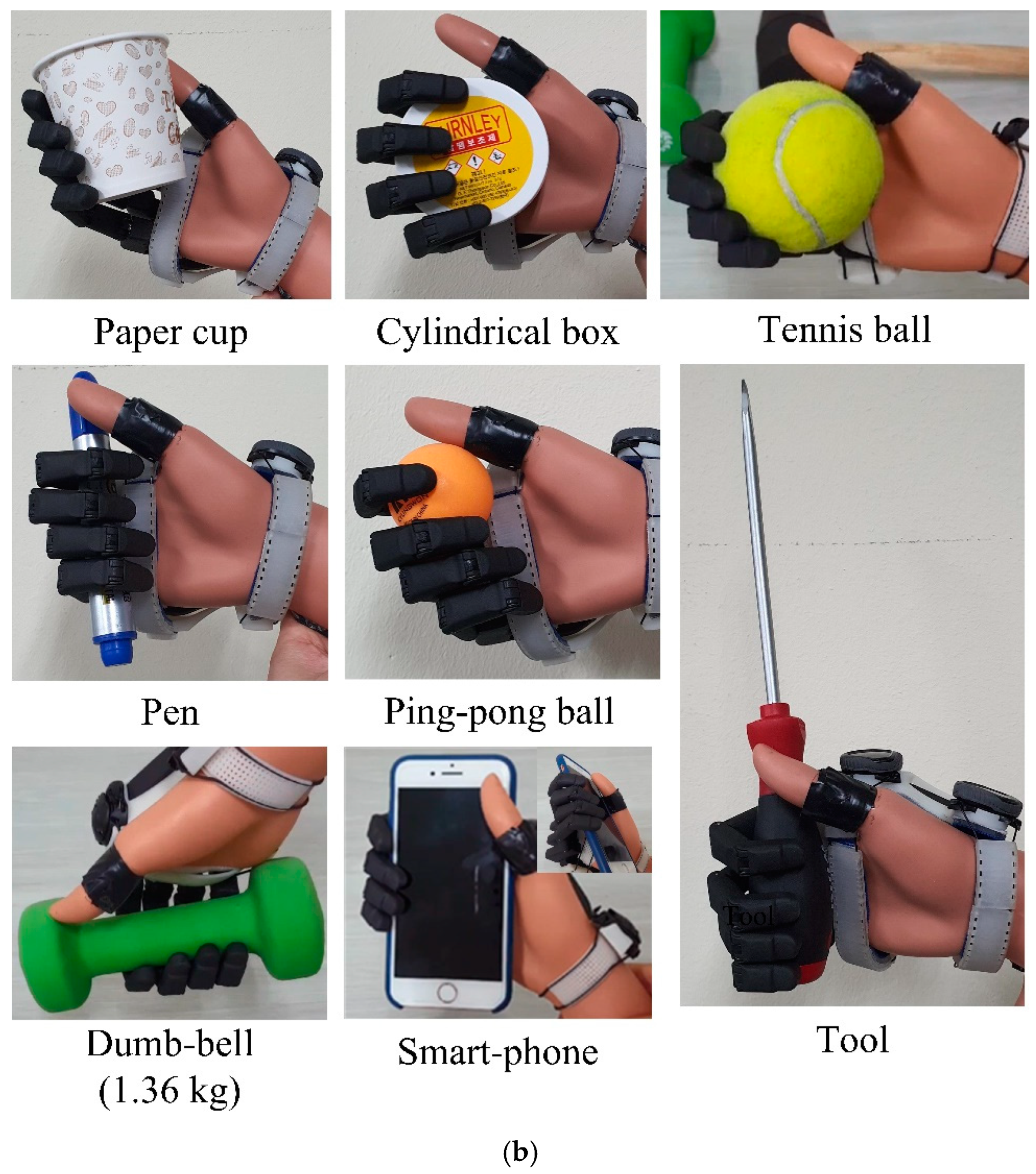

4.2. Experiment

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Hazani, R.; Buntic, R.F.; Brooks, D. Patterns in blast injuries to the hand. Hand 2009, 4, 44–49. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Venkatramani, H.; Bhardwaj, P.; Sierakowski, A.; Sabapathy, S.R. Functional outcomes of post-traumatic metacarpal hand reconstruction with free toe-to-hand transfer. Indian J. Plast. Surg. 2016, 49, 16–25. [Google Scholar] [CrossRef] [PubMed]

- Del Piñal, F. The indications for toe transfer after “minor” finger injuries. J. Hand Surg. 2004, 29, 120–129. [Google Scholar]

- Rodriguez, N.E.N.; Carbone, G.; Ceccarelli, M. Optimal design of driving mechanism in a 1-DOF anthropomorphic finger. Mech. Mach. Theory 2006, 41, 897–911. [Google Scholar] [CrossRef]

- Yoon, D.C.; Lee, C.; Choi, Y. Underactuated Finger Mechanism for Body-Powered Partial Prosthesis. J. Korea Robot. Soc. 2016, 11, 193–204. [Google Scholar] [CrossRef]

- Kamikawa, Y.; Maeno, T. Underactuated Five-Finger Prosthetic Hand Inspired by Grasping Force Distribution of Humans. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Acropolis Convention Center, Nice, France, 22–26 September 2008. [Google Scholar]

- Jing, X.; Yong, X.; Tian, L.; Togo, S.; Jiang, Y.; Yokoi, H.; Li, G. Development of Tendon Driven Under-Actuated Mechanism Applied in an EMG Prosthetic Hand with Three Major Grasps for Daily Life. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018. [Google Scholar]

- Mottard, A.; Laliberte, T.; Gosselin, C. Underactuated tendon-driven robotic/prosthetic hands: Design issues. In Proceedings of the Robotics: Science and Systems, Cambridge, MA, USA, 12–16 July 2017. [Google Scholar]

- RSL Steeper Website. Leeds (United Kingdom): RSL Steeper; 2013. Available online: http://rslsteeper.com/ (accessed on 15 April 2020).

- Touch Bionics Website. Mansfield (MA): Touch Bionics Inc.; 2013. Available online: http://www.touchbionics.com/ (accessed on 17 April 2020).

- Ryu, W.; Kim, D.; Choi, Y.; Lee, S. Development of Prosthetic Finger with Actuator. In Proceedings of the 16th International Conference on Ubiquitous Robots (UR), Jeju, Korea, 24–27 June 2019. [Google Scholar]

- Clement, R.G.E.; Bugler, K.E.; Oliver, C.W. Bionic prosthetic hands: A review of present technology and future aspirations. Surg. J. R. Coll. Surg. Edinb. Irel. 2011, 9, 336–340. [Google Scholar] [CrossRef] [PubMed]

- Belter, J.T.; Segil, J.L.; Dollar, A.M.; Weir, R.F. Mechanical design and performance specifications of anthropomorphic prosthetic hands: A review. J. Rehabil. Res. Dev. 2013, 50, 599–618. [Google Scholar] [CrossRef] [PubMed]

- Habib, F.N.; Iovenitti, P.; Massod, S.G.; Nikzad, M. Fabrication of polymeric lattice structures for optimum energy absorption using Multi Jet Fusion technology. Mater. Des. 2018, 155, 86–98. [Google Scholar] [CrossRef]

- Sillani, F.; Kleijnen, R.G.; Vetterli, M.; Schmid, M.; Wegener, K. Selective laser sintering and multi jet fusion: Process-induced modification of the raw materials and analyses of parts performance. Addit. Manuf. 2019, 27, 32–41. [Google Scholar] [CrossRef]

- Pons, J.L.; Rocon, E.; Ceres, R.; Reynaerts, D.; Saro, B.; Kevin, S.; Van Moorleghem, W. The MANUS-HAND∗ Dextrous Robotics Upper Limb Prosthesis: Mechanical and Manipulation Aspects. Auton. Robot. 2004, 16, 143–163. [Google Scholar] [CrossRef]

- Anthropometry and Biomechanics. Available online: https://msis.jsc.nasa.gov/sections/section03.htm (accessed on 17 April 2020).

| Developer [Ref.] | Type | Weight (g) | Overall Size (mm) [Length, Width, Thickness] | Number of Joints | Number of Actuators | Joint Coupling Method | Adaptive Grasping |

|---|---|---|---|---|---|---|---|

| Kamikawa [6] | 2 | 730 | [320, 80–90, 20] | 15 | 1 | Tendon & linkage | Yes |

| Jing [7] | 2 | 250 | - | - | 2 | Tendon | Yes |

| Mottard [8] | 2 | 298 (Except actuators) | - | 14 | 2 | Tendon | Yes |

| RSL Steeper [9] | 2 | 495–539 | [190–200, 84–92, 50] | 11 | 5 | Linkage | Yes |

| Touch Bionics [10] | 3 | 450–615 | [180–182, 75–80, 35–45] | 11 | 5 | Tendon | Yes |

| Ryu [11] | 3 | 320 | [120, 78, 13] | 16 | 4 | Tendon | Yes |

| This study | 3 | 152.32 (Except thumb) | [174, 77, 11] | 18 | 4 | Tendon | Yes |

| Weight | 152.32 g (Except thumb) | ||||

| Overall size [length, width, thickness] | [174 mm, 77 mm, 11 mm] | ||||

| Finger sizes [length, width, thickness] | Index finger | [83.7 mm, 14.8 mm, 11 mm] | |||

| Middle finger | [88.7 mm, 14.8 mm, 11 mm] | ||||

| Ring finger | [83.7 mm, 14.8 mm, 11 mm] | ||||

| Little finger | [73.7 mm, 14.8 mm, 11 mm] | ||||

| Degrees of freedom | 18 | ||||

| Active motions (The number of actuators) | 4 | ||||

| Passive motions | 14 * | ||||

| Joint coupling method | Tendon | ||||

| Adaptive grasping | Yes | ||||

| Grip Forces | Maximum force: 6.460 N (at ) and 7.487 N (at ) (for and in a finger module) | ||||

| Ranges of Motion | Extension/Flexion | DIP joint | – | ||

| PIP joint | – | ||||

| MCP joint | – | ||||

| Adduction/Abduction | – | ||||

| Adaptive grasping in PIP and MCP joints | – | ||||

| Palm | – | ||||

| Finger/Grasp speed | Up to 185.8°/s at each phalanx | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ryu, W.; Choi, Y.; Choi, Y.J.; Lee, S. Development of a Lightweight Prosthetic Hand for Patients with Amputated Fingers. Appl. Sci. 2020, 10, 3536. https://doi.org/10.3390/app10103536

Ryu W, Choi Y, Choi YJ, Lee S. Development of a Lightweight Prosthetic Hand for Patients with Amputated Fingers. Applied Sciences. 2020; 10(10):3536. https://doi.org/10.3390/app10103536

Chicago/Turabian StyleRyu, Wooseok, Youngjin Choi, Yong Je Choi, and Sungon Lee. 2020. "Development of a Lightweight Prosthetic Hand for Patients with Amputated Fingers" Applied Sciences 10, no. 10: 3536. https://doi.org/10.3390/app10103536

APA StyleRyu, W., Choi, Y., Choi, Y. J., & Lee, S. (2020). Development of a Lightweight Prosthetic Hand for Patients with Amputated Fingers. Applied Sciences, 10(10), 3536. https://doi.org/10.3390/app10103536