A Dynamic Adjusted Aggregate Load Method to Support Workload Control Policies

Abstract

:1. Introduction

2. Literature Review

3. Reference Context

3.1. Order Release

3.2. Dispatching Rules

3.3. Workload Computations

4. Simulation Model

- -

- The order release, which includes the evaluation of the norm on the bottleneck of all workstations;

- -

- The three pre-shop ranking methods: EDD, SPT and workload balance;

- -

- The classical corrected and proposed (dynamic) workload computation.

- Total throughput time (unit time): this is the total time from the enter to the exit of the order from the manufacturing system.

- Average shop floor throughput time (unit time): this is the time from the release time of the order in the manufacturing system and the exit from it.

- Average machine queues (number of parts): this is the number of parts in the queue of each machine.

- Standard deviation of the queues by the coefficient of variation to evaluate the distribution of the direct workload among the machines.

5. Numerical Results

- -

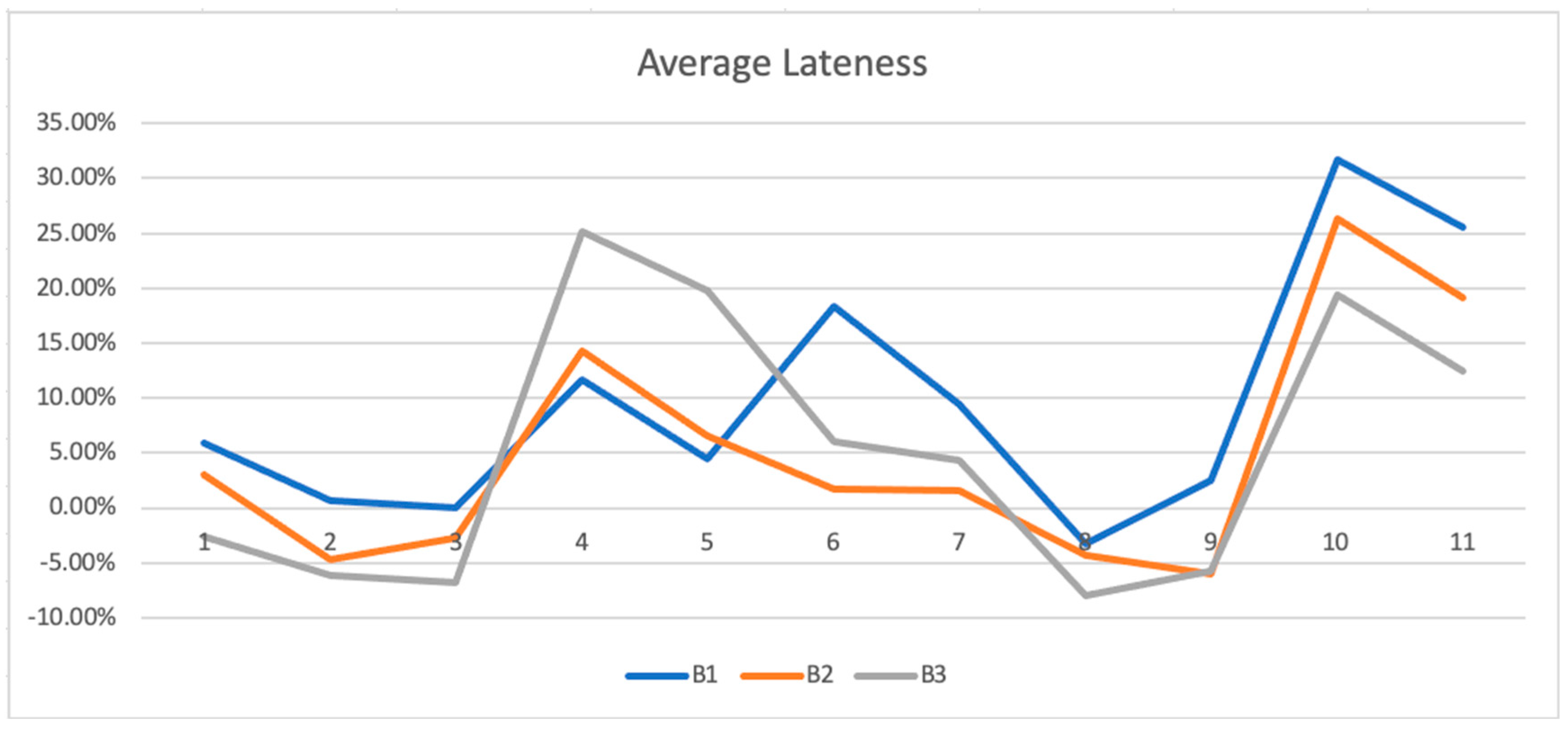

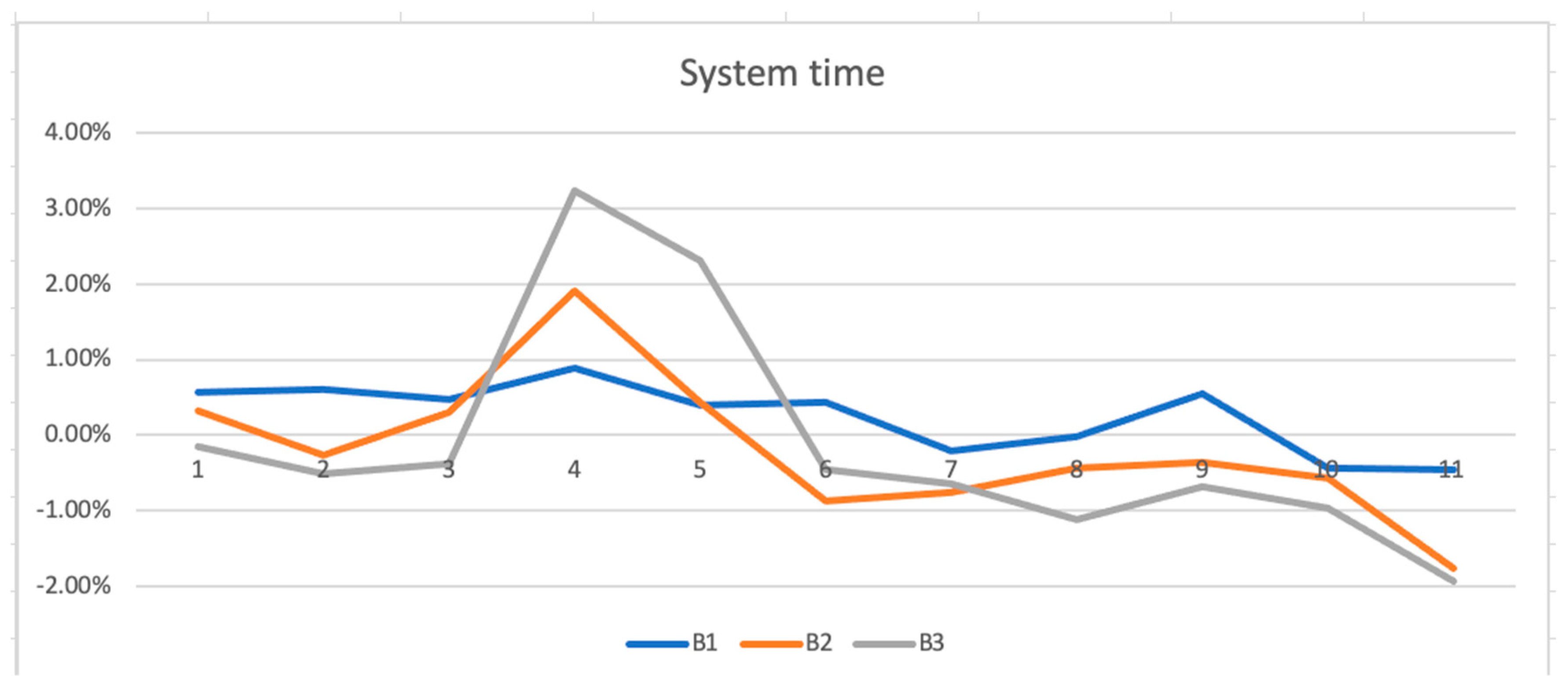

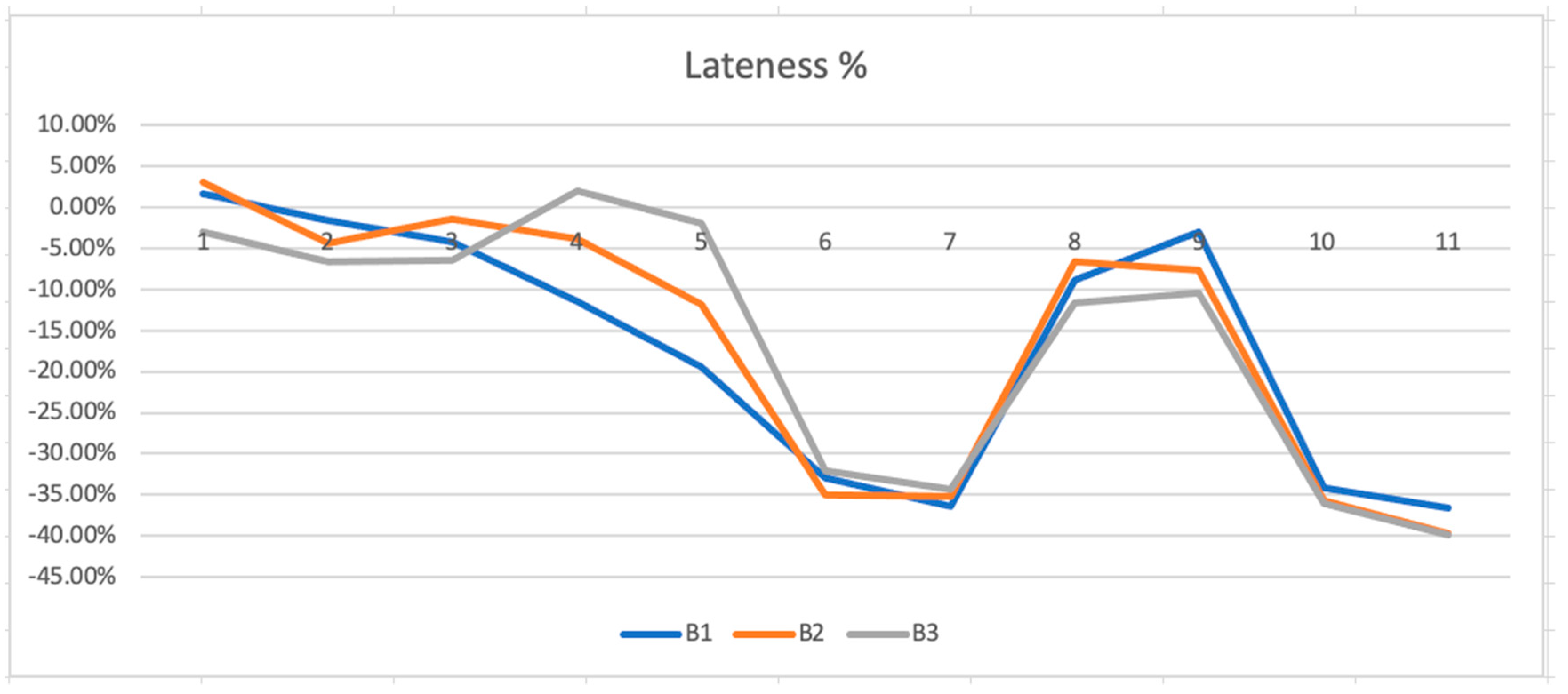

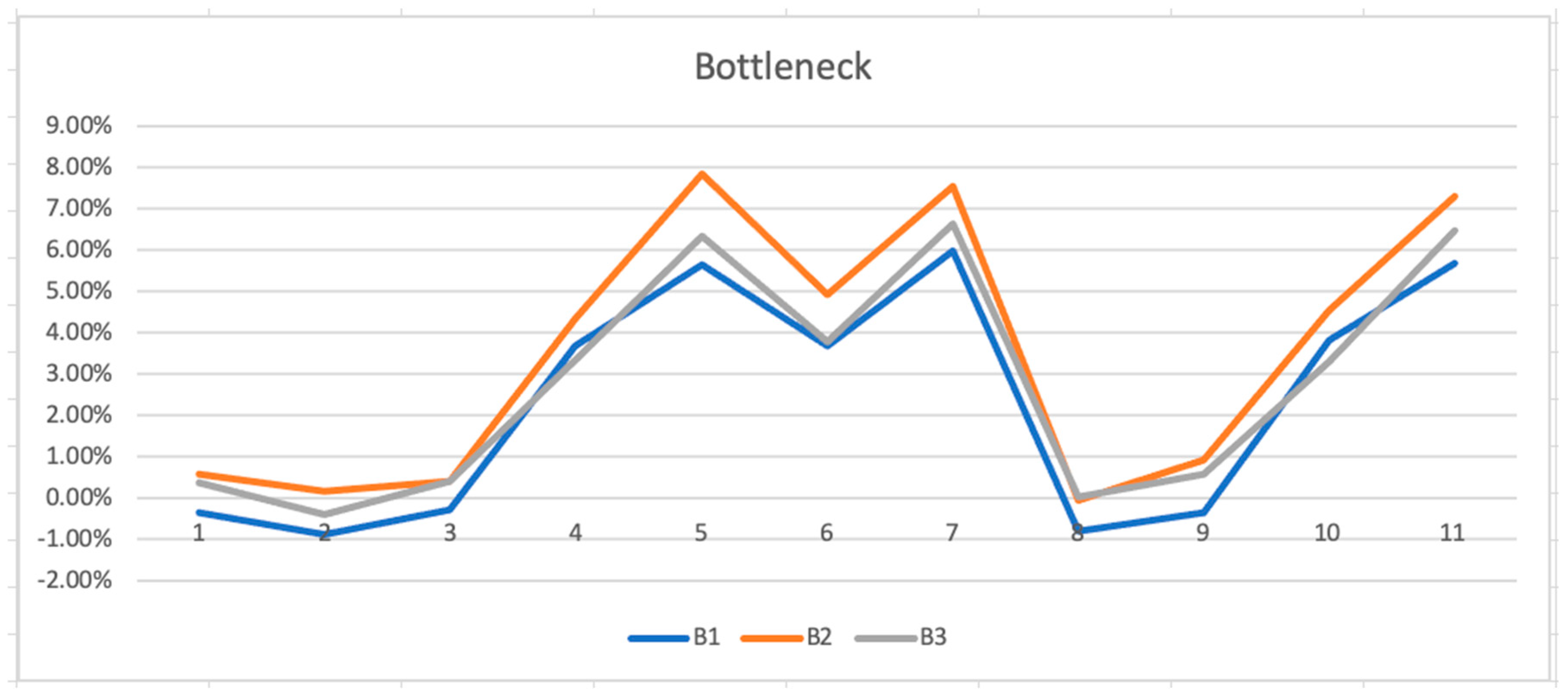

- The proposed model improves the performance measures of the percentage of jobs in delay, reduces the standard deviation among the queue with more uniform workload among the machines and drastically reduces the total time of lateness accumulated. The main drawback is the increase of the average lateness for a single job.

- -

- The proposed model is robust to the different number of bottlenecks, different norm evaluation (all machines or only the bottleneck) and to the different types of pre-shop queue management (FIFO, SPT and balance).

- -

- The number of bottlenecks affects the results, but it cannot de defined a direct relation between the increase of the bottlenecks and the variations of the performance measures.

6. Conclusion and Future Development Paths

6.1. Managerial Implication

6.2. Limitations and Future Research

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| m = 1,..,M | denotes the machine of the work center that performs a specific operation |

| i | denotes the job in pre-shop queue |

| t | time of the decision |

| Topim | the process time that the job i performs in the machine m |

| aim | a binary value to set the routing of the job i to the machine m |

| WLnorm | denotes the norm for the workload |

| Utm(t) | denotes the average utilization of the machine m at time t |

| DDi | denotes the due date of the part i |

| TT i | denotes the total processing time of the part i |

| WLav(t) | denotes the workload average of the machines at time t |

| WLm | denotes the workload of the machine m |

| Wm | denotes the weight to computed corrected workload |

| Ranki | denotes the priority index of the part i in the pre-shop queue |

References

- Kingsman, B.G.; Hendry, L.C. The relative contributions of input and output controls on the performance of a workload control system in Make-To-Order companies. Prod. Plan Control. 2002, 13, 8579–8590. [Google Scholar] [CrossRef]

- Hendry, L.C.; Stevenson, M.; Huang, Y. Workload Control: Successful Implementation Taking a Contingency-Based View of Production Planning & Control. Int. J. Oper. Prod. Man. 2013, 33, 69–103. [Google Scholar]

- Silva, C.; Stevenson, M.; Thurer, M. A Case Study of the Successful Implementation of Workload Control. J. Man. Tech. Man. 2015, 26, 280–296. [Google Scholar] [CrossRef]

- Stevenson, M.; Vanharanta, M. The effects of managerial decision making behaviour and order book size on workload control system implementation in Make-To-Order companies. Prod. Plan Control. 2015, 26, 97–115. [Google Scholar] [CrossRef]

- Bertrand, J.W.M.; Van Ooijen, H.P.G. Workload based order release and productivity: A missing link. Prod. Plan Control. 2002, 13, 665–678. [Google Scholar] [CrossRef]

- Breithaupt, J.W.; Land, J.; Nyhuis, P. The workload control concept: Theory and practical extensions of load oriented order release. Prod. Plan Control. 2002, 13, 625–638. [Google Scholar] [CrossRef]

- Missbauer, H. Models of the transient behaviour of production units to optimize the aggregate material flow. Int. J. Prod. Econ 2009, 118, 387–397. [Google Scholar] [CrossRef]

- Stevenson, M.; Silva, C. Theoretical development of work- load control methodology: Evidence from two case studies. Int. J. Prod. Res. 2008, 46, 3107–3131. [Google Scholar] [CrossRef] [Green Version]

- Thu¨rer, M.; Silva, C.; Stevenson, M. Controlled order release: A performance assessment in job shops with sequence dependent set-up times. Prod. Plan Control. 2014, 25, 603–615. [Google Scholar] [CrossRef]

- Thürer, M.; Qu, T.; Stevenson, M.; Maschek, T.; Godinho Filho, M. Continuous workload control order release revisited: An assessment by simulation. Int. J. Prod. Res. 2014, 52, 6664–6680. [Google Scholar] [CrossRef] [Green Version]

- Oosterman, B.J.; Land, M.J.; Gaalman, G.J.C. The influence of shop characteristics on workload control. Int. J. Prod. Econ. 2000, 68, 107–119. [Google Scholar] [CrossRef] [Green Version]

- Gao, R.; Wang, L.; Teti, R.; Dornfeld, D.; Kumara, S.; Mori, M.; Helug, M. Cloud-enabled prognosis for manufacturing. CIRP Ann. Manuf. Tech. 2015, 64, 749–772. [Google Scholar] [CrossRef] [Green Version]

- Stevenson, M.; Hendry, L.C.; Kingsman, B.G. A review of production planning and control: The applicability of key concepts to the make-to-order industry. Int. J. Prod. Res. 2005, 43, 869–898. [Google Scholar] [CrossRef]

- Thürer, M.; Stevenson, M.; Cristovao, S. Three decades of workload control research: A systematic review of the literature. Int. J. Prod. Res. 2011, 49, 6905–6935. [Google Scholar] [CrossRef]

- Missbauer, H.; Uzsoy, R. Production Planning with Capacitated Resources and Congestion; Springer: New York, NY, USA, 2020. [Google Scholar]

- Thürer, M.; Silva, C.; Stevenson, M. Optimising workload norms: The influence of shop floor characteristics on setting workload norms for the workload control concept. Int. J. Prod. Res. 2011, 49, 1151–1171. [Google Scholar] [CrossRef]

- Tatsiopoulos, I.P. A Microcomputer-Based Interactive System for Managing Production and Marketing in Small Component Manufacturing Firms Using a Hierarchical Backlog Control and Lead Time Management Technology. Ph.D. Thesis, Lancaster University, Lancaster, UK, 1983. [Google Scholar]

- Hendry, L.C. A Decision Support System to Manage Delivery and Manufacturing Lead Times in Make to Order Companies. Ph.D. Thesis, Lancaster University, Lancaster, UK, 1989. [Google Scholar]

- Land, M.J.; Gaalman, G. Towards simple and robust workload norms. In Proceedings of the Workshop on Production Planning and Control, Mons, Belgium, 9–11 September 1996; pp. 66–96. [Google Scholar]

- Thürer, M.; Silva, C.; Stevenson, M. Workload control release mechanisms: From practice back to theory building. Int. J. Prod. Res. 2010, 48, 3593–3617. [Google Scholar] [CrossRef] [Green Version]

- Renna, P. Workload control policies under continuous order release. Prod. Eng. 2015, 9, 655–664. [Google Scholar] [CrossRef]

- Stevenson, M.; Huang, Y.; Hendry, L.C.; Soepenberg, E. The Theory & Practice of Workload Control: A Research Agenda & Implementation Strategy. Int. J. Prod. Econ 2011, 131, 689–700. [Google Scholar]

- Land, M.J. Cobacabana (control of balance by card-based navigation): A card-based system for job shop control. Int. J. Prod. Econ. 2009, 117, 97–103. [Google Scholar] [CrossRef]

- Thürer, M.; Land, M.J.; Stevenson, M. Card-based workload control for job shops: Improving COBACABANA. Int. J. Prod. Econ. 2014, 147, 180–188. [Google Scholar] [CrossRef]

- Thürer, M.; Fernandes, N.O.; Ziengs, N.; Stevenson, M. On the meaning of ConWIP cards: An assessment by simulation. J. Ind. Prod. Eng. 2019, 36, 49–58. [Google Scholar] [CrossRef] [Green Version]

- Fredendall, L.D.; Divesh, O.; Patterson, J.W. Concerning the theory of workload control. Eur. J. Oper. Res. 2010, 201, 99–111. [Google Scholar] [CrossRef]

- Martins, L.; Varela, M.L.R.; Fernandes, N.O.; Carmo–Silva, S.; Machado, J. Literature review on autonomous production control methods. Ent. Inf. Syst. 2020. [Google Scholar] [CrossRef]

- Melnyk, S.A.; Ragatz, G.L. Order review/release: Research issues and perspectives. Int. J. Prod. Res. 1989, 27, 1081–1096. [Google Scholar] [CrossRef]

| Model | Order Release | Pre-Shop Pool Ranking | Workload Computation |

|---|---|---|---|

| Benchmark1 | Bottleneck norm | EDD | OOsterman et al. (2000) |

| Benchmark2 | All workstations norm | EDD | OOsterman et al. (2000) |

| Benchmark3 | Bottleneck norm | SPT | OOsterman et al. (2000) |

| Benchmark4 | All workstations norm | SPT | OOsterman et al. (2000) |

| Benchmark5 | Bottleneck norm | Balance | OOsterman et al. (2000) |

| Benchmark6 | All workstations norm | Balance | OOsterman et al. (2000) |

| Dyn1 | Bottleneck norm | EDD | Dynamic WL |

| Dyn2 | All workstations norm | EDD | Dynamic WL |

| Dyn3 | Bottleneck norm | SPT | Dynamic WL |

| Dyn4 | All workstations norm | SPT | Dynamic WL |

| Dyn5 | Bottleneck norm | Balance | Dynamic WL |

| Dyn6 | All workstations norm | Balance | Dynamic WL |

| Number of Machines | |||

| 6 (1 bottleneck and 5 no bottleneck) | 6 (2 bottleneck and 4 no bottleneck) | 6 (3 bottleneck and 3 no bottleneck) | |

| Interarrival | EXPO 0.642 | ||

| Number of operations | Discrete uniform [1,6] | ||

| Due date | (Total processing time) multiplied uniform [5,10] | ||

| Processing time No bottleneck | 2-Erlang with mean 1 | ||

| Processing time bottleneck | 2-Erlang with mean 1.15 (utilization about 90%) | ||

| Cases | Benchmark | 1 | 2 | 3 |

| Workload: adjusted | Workload: adjusted | Workload: adjusted | Workload: adjusted | |

| Norm: machines | Norm: bottleneck | Norm: machines | Norm: bottleneck | |

| Pre-shop: FIFO | Pre-shop: FIFO | Pre-shop: SPT | Pre-shop: SPT | |

| Cases | 4 | 5 | 6 | 7 |

| Workload: dynamic | Workload: dynamic | Workload: dynamic | Workload: dynamic | |

| Norm: machines | Norm: bottleneck | Norm: machines | Norm: bottleneck | |

| Pre-shop: FIFO | Pre-shop: FIFO | Pre-shop: SPT | Pre-shop: SPT | |

| Cases | 8 | 9 | 10 | 11 |

| Workload: adjusted | Workload: adjusted | Workload: dynamic | Workload: dynamic | |

| Norm: machines | Norm: bottleneck | Norm: machines | Norm: bottleneck | |

| Pre-shop: balance | Pre-shop: balance | Pre-shop: balance | Pre-shop: balance |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Renna, P. A Dynamic Adjusted Aggregate Load Method to Support Workload Control Policies. Appl. Sci. 2020, 10, 3497. https://doi.org/10.3390/app10103497

Renna P. A Dynamic Adjusted Aggregate Load Method to Support Workload Control Policies. Applied Sciences. 2020; 10(10):3497. https://doi.org/10.3390/app10103497

Chicago/Turabian StyleRenna, Paolo. 2020. "A Dynamic Adjusted Aggregate Load Method to Support Workload Control Policies" Applied Sciences 10, no. 10: 3497. https://doi.org/10.3390/app10103497

APA StyleRenna, P. (2020). A Dynamic Adjusted Aggregate Load Method to Support Workload Control Policies. Applied Sciences, 10(10), 3497. https://doi.org/10.3390/app10103497