Use of Unbound Materials for Sustainable Road Infrastructures

Abstract

:1. Introduction

2. Reference Standard

3. Materials

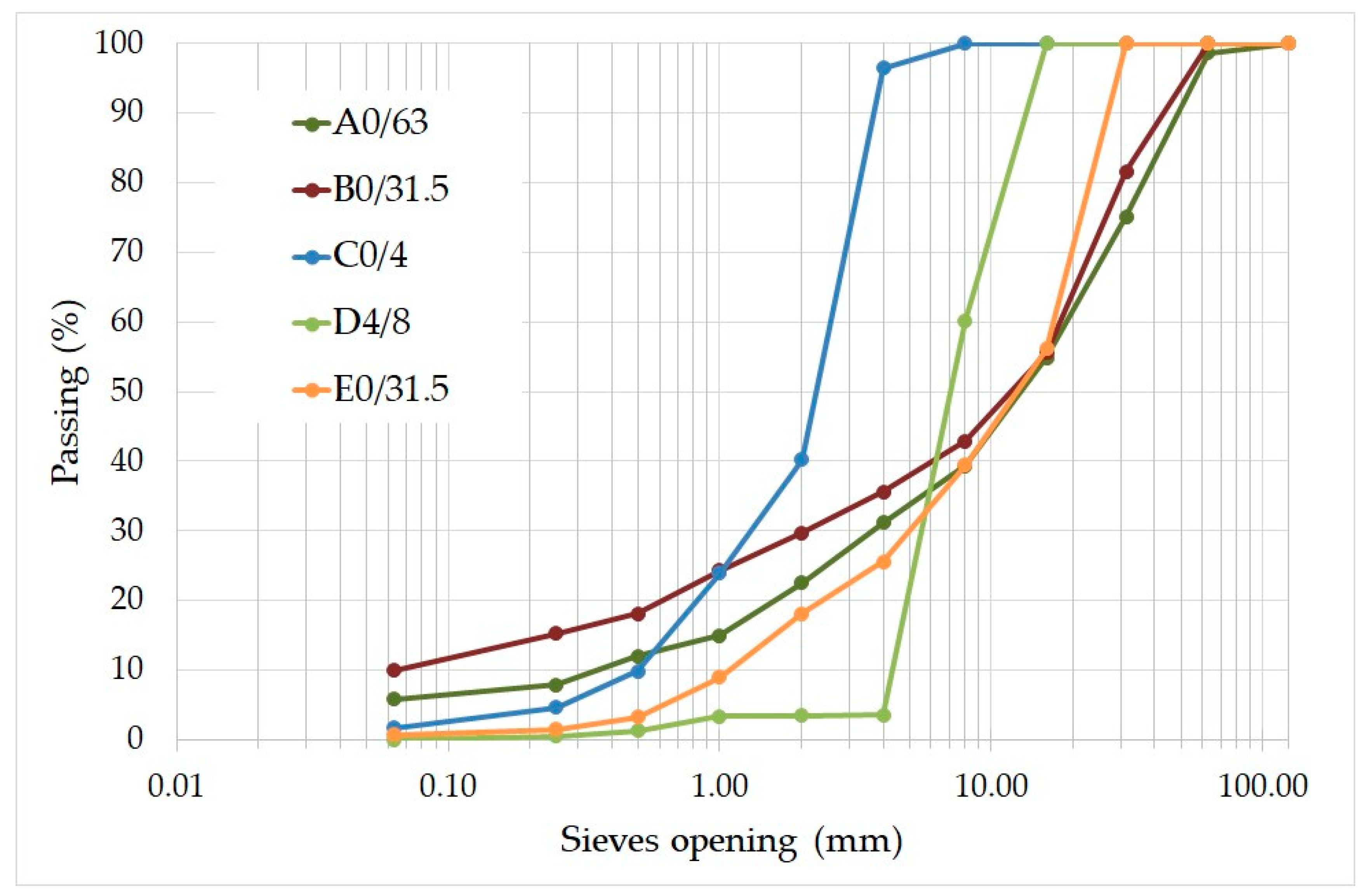

3.1. Base Materials

3.2. Leaching Test on the Base Materials

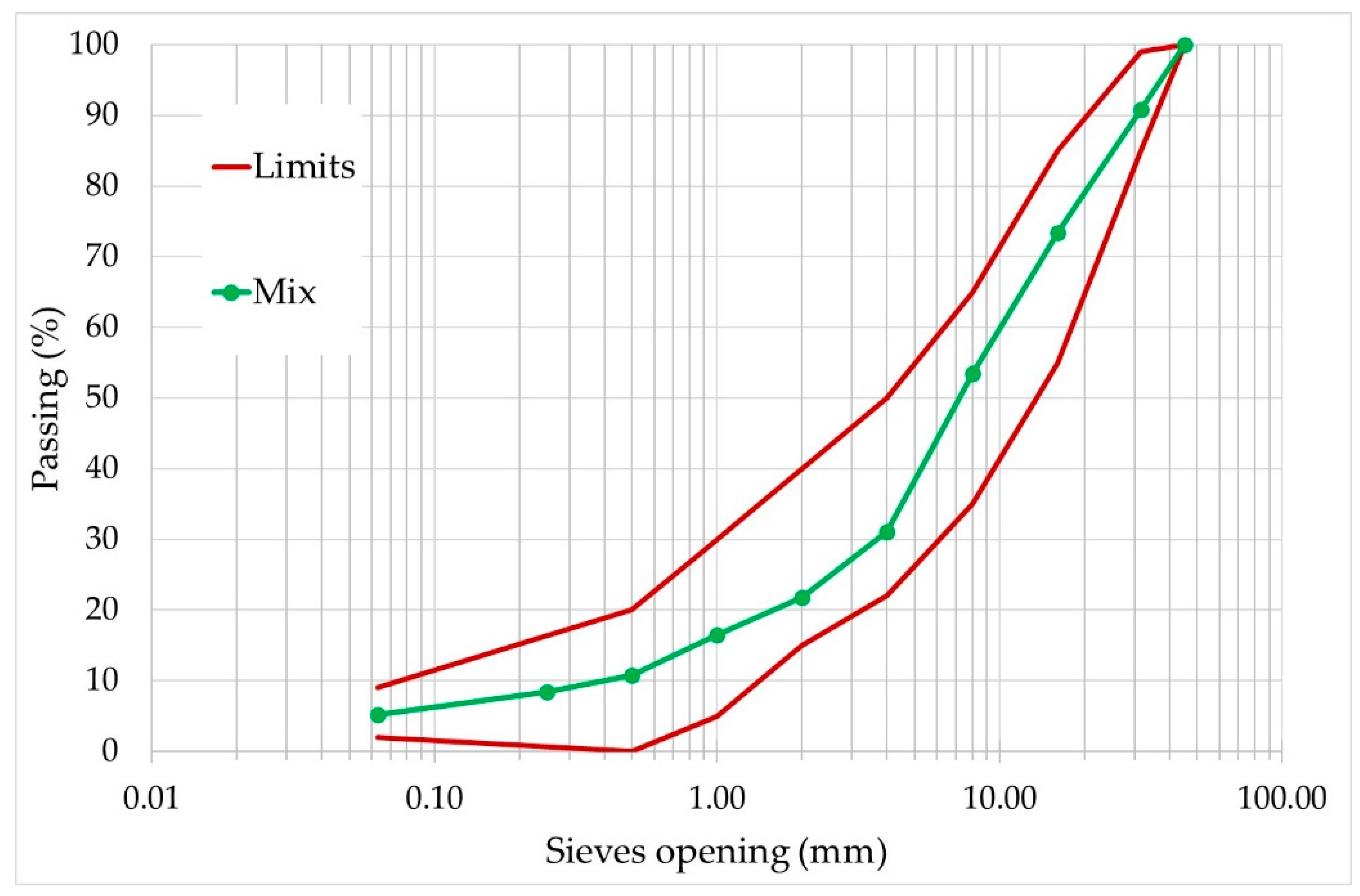

4. Mix-Design of Mixtures and Tests Results

4.1. Main Standard Requirements of Unbound Mixtures

4.2. CDW Mix Design Suitable for the Embankments

4.3. CDW and EAF Mix Design Suitable as Road Subgrade

- -

- there are no granules with a diameter greater than 63 mm;

- -

- the 0.063 mm passing is less than or equal to 15%;

- -

- the plasticity index is less than or equal to 6;

- -

- the 16 mm sieve passing is at least 50%;

- -

- the CBR lift index is higher than 10% after 4 days of immersion in water.

4.4. CDW and EAF Mix Design Suitable as Road Foundation

4.5. CDW and EAF Mix Design Suitable as Unbound Base

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bennert, T.; Papp, W.J., Jr.; Maher, A.; Gucunski, N. Utilization of Construction and Demolition Debris Under Traffic-Type Loading in Base and Subbase Applications. Transp. Res. Rec. 2000, 1714, 33–39. [Google Scholar] [CrossRef]

- Eurostat, Generation of Waste by Waste Category, Hazardousness and NACE Rev 2 Activity. Available online: http://appsso.eurostat.ec.europa.eu/nui/show.do?dataset=env_wasgen (accessed on 16 February 2020).

- Direttiva 2008/98/CE (2008). Direttiva 2008/98/CE del Parlamento Europeo e del Consiglio del 19 Novembre 2008 Relativa ai Rifiuti e che Abroga Alcune Direttive. Available online: https://eur-lex.europa.eu/legal-content/FR/TXT/?uri=celex%3A32008L0098 (accessed on 16 February 2020).

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Colangelo, F.; Cioffi, R.; Liguori, B.; Iucolano, F. Recycled polyolefins waste as aggregates for lightweight concrete. Compos. Part B Eng. 2016, 106, 234–241. [Google Scholar] [CrossRef]

- Martínez, I.; Etxeberria, M.; Pavón, E.; Díaz, N. Influence of demolition waste fine particles on the properties of recycled aggregate masonry mortar. Int. J. Civ. Eng. 2018, 16, 1213–1226. [Google Scholar] [CrossRef] [Green Version]

- Colangelo, F.; Cioffi, R. Mechanical properties and durability of mortar containing fine fraction of demolition wastes produced by selective demolition in South Italy. Compos. Part B Eng. 2017, 115, 43–50. [Google Scholar] [CrossRef]

- Ossa, A.; García, J.L.; Botero, E. Use of recycled construction and demolition waste (CDW) aggregates: A sustainable alternative for the pavement construction industry. J. Clean. Prod. 2016, 135, 379–386. [Google Scholar] [CrossRef]

- Zhang, J.; Gu, F.; Zhang, Y. Use of building-related construction and demolition wastes in highway embankment: Laboratory and field evaluations. J. Clean. Prod. 2019, 230, 1051–1060. [Google Scholar] [CrossRef]

- Zhang, J.; Ding, L.; Li, F.; Peng, J. Recycled aggregates from construction and demolition wastes as alternative filling materials for highway subgrades in China. J. Clean. Prod. 2020, 255, 120223. [Google Scholar] [CrossRef]

- Zou, G.; Zhang, J.; Liu, X.; Lin, Y.; Yu, H. Design and performance of emulsified asphalt mixtures containing construction and demolition waste. Constr. Build. Mater. 2020, 239, 117846. [Google Scholar] [CrossRef]

- Xuan, D.X.; Molenaar, A.A.A.; Houben, L.J.M. Evaluation of cement treatment of reclaimed construction and demolition waste as road bases. J. Clean. Prod. 2015, 100, 77–83. [Google Scholar] [CrossRef]

- Gómez-Meijide, B.; Pérez, I.; Pasandín, A.R. Recycled construction and demolition waste in cold asphalt mixtures: Evolutionary properties. J. Clean. Prod. 2016, 112, 588–598. [Google Scholar] [CrossRef] [Green Version]

- Buyle, M.; Braet, J.; Audenaert, A. Life cycle assessment of an apartment building: Comparison of an attributional and consequential approach. Energy Procedia 2014, 62, 132–140. [Google Scholar] [CrossRef] [Green Version]

- Barbudo, A.; Jiménez, J.R.; Ayuso, J.; Galvín, A.P.; Agrela, F. Catalogue of Pavements with Recycled Aggregates from Construction and Demolition Waste. Proceedings 2018, 2, 1282. [Google Scholar] [CrossRef] [Green Version]

- Puneeth, H.C.; Mahendra, S.P.; Rohith, M.; Naveenkumar, K. Replacement of Fine Aggregates by Recycled Construction and Demolition Waste in Pavement Quality Concrete. In Sustainable Construction and Building Materials; Das, B., Neithalath, N., Eds.; Springer: Singapore, 2019; Volume 25, pp. 685–695. [Google Scholar]

- Grabois, T.M.; Cordeiro, G.C.; Toledo Filho, R.D. The Influence of Recycled Concrete and Clay Brick Particles on the Strength and Porosity of Cement-Based Pastes. In Calcined Clays for Sustainable Concrete; Martirena, F., Favier, A., Scrivener, K., Eds.; Springer: Dordrecht, The Netherlands, 2018; Volume 16, pp. 189–194. [Google Scholar]

- Estanqueiro, B.; Dinis Silvestre, J.; de Brito, J.; Duarte Pinheiro, M. Environmental life cycle assessment of coarse natural and recycled aggregates for concrete. Eur. J. Environ. Civ. Eng. 2018, 22, 429–449. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, H.; Su, L.; Hou, H.; Dang, L. Investigation into the Application of Construction and Demolition Waste in Urban Roads. Adv. Mater. Sci. Eng. 2017, 2017, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Arisha, A.; Gabr, A.; El-badawy, S.; Shwally, S. Performance evaluation of construction and demolition waste materials for pavement construction in Egypt. J. Mater. Civ. Eng. 2018, 30, 04017270. [Google Scholar] [CrossRef]

- Saberian, M.; Shi, L.; Sidiq, A.; Li, J.; Setunge, S.; Li, C. Recycled concrete aggregate mixed with crumb rubber under elevated temperature. Constr. Build. Mater. 2019, 222, 119–129. [Google Scholar] [CrossRef]

- Poulikakos, L.D.; Papadaskalopoulou, C.; Hofko, B.; Gschösser, F.; Falchetto, A.C.; Bueno, M.; Loizidou, M. Harvesting the unexplored potential of European waste materials for road construction. Resour. Conserv. Recycl. 2017, 116, 32–44. [Google Scholar] [CrossRef]

- Su, N.; Chen, J.S. Engineering properties of asphalt concrete made with recycled glass. Resour. Conserv. Recycl. 2002, 35, 259–274. [Google Scholar] [CrossRef]

- Salas, M.Á.; Pérez-Acebo, H.; Calderón, V.; Gonzalo-Orden, H. Bitumen modified with recycled polyurethane foam for employment in hot mix asphalt. Ing. Investig. 2018, 38, 60–66. [Google Scholar] [CrossRef]

- Huang, Y.; Bird, R.N.; Heidrich, O. A review of the use of recycled solid waste materials in asphalt pavements. Resour. Conserv. Recycl. 2007, 52, 58–73. [Google Scholar] [CrossRef]

- Oluwasola, E.A.; Hainin, M.R.; Aziz, M.M.A. Evaluation of asphalt mixtures incorporating electric arc furnace steel slag and copper mine tailings for road construction. Transp. Geotech. 2015, 2, 47–55. [Google Scholar] [CrossRef]

- Pasetto, M.; Baldo, N. Performance comparative analysis of stone mastic asphalts with electric arc furnace steel slag: A laboratory evaluation. Mater. Struct. 2012, 45, 411–424. [Google Scholar] [CrossRef]

- Saha, A.K.; Khan, M.N.N.; Sarker, P.K. Value added utilization of by-product electric furnace ferronickel slag as construction materials: A review. Resour. Conserv. Recycl. 2018, 134, 10–24. [Google Scholar] [CrossRef] [Green Version]

- Masoudi, S.; Abtahi, S.M.; Goli, A. Evaluation of electric arc furnace steel slag coarse aggregate in warm mix asphalt subjected to long-term aging. Constr. Build. Mater. 2017, 135, 260–266. [Google Scholar] [CrossRef]

- Skaf, M.; Manso, J.M.; Aragón, Á.; Fuente-Alonso, J.A.; Ortega-López, V. EAF slag in asphalt mixes: A brief review of its possible re-use. Resour. Conserv. Recycl. 2017, 120, 176–185. [Google Scholar] [CrossRef]

- Fuente-Alonso, J.A.; Ortega-López, V.; Skaf, M.; Aragón, Á.; San-José, J.T. Performance of fiber-reinforced EAF slag concrete for use in pavements. Constr. Build. Mater. 2017, 149, 629–638. [Google Scholar] [CrossRef]

- Ochoa Díaz, R.; López Díaz, A. Electric Arc Furnace Slag and Blast Furnace Dust, Use for the Manufacture of Asphalt Concrete for Roads. Civ. Eng. Infrastruct. J. 2019, 52, 155–166. [Google Scholar]

- Fedrigo, W.; Núñez, W.P.; López, M.A.C.; Kleinert, T.R.; Ceratti, J.A.P. A study on the resilient modulus of cement-treated mixtures of RAP and aggregates using indirect tensile, triaxial and flexural tests. Constr. Build. Mater. 2018, 171, 161–169. [Google Scholar] [CrossRef]

- Linares-Unamunzaga, A.; Pérez-Acebo, H.; Rojo, M.; Gonzalo-Orden, H. Flexural Strength Prediction Models for Soil–Cement from Unconfined Compressive Strength at Seven Days. Materials 2019, 12, 387. [Google Scholar] [CrossRef] [Green Version]

- Colangelo, F.; Forcina, A.; Farina, I.; Petrillo, A. Life cycle assessment (LCA) of different kinds of concrete containing waste for sustainable construction. Buildings 2018, 8, 70. [Google Scholar] [CrossRef] [Green Version]

- Colangelo, F.; Petrillo, A.; Cioffi, R.; Borrelli, C.; Forcina, A. Life cycle assessment of recycled concretes: A case study in southern Italy. Sci. Total Environ. 2018, 615, 1506–1517. [Google Scholar] [CrossRef] [PubMed]

- Agostinacchio, M.; Diomedi, M.; Olita, S. The use of marginal materials in road constructions: Proposal of an eco-compatible section. In Advanced Testing and Characterization of Bituminous Materials; Loizos, A., Partl, M., Scarpas, T., Al-Qadi, I., Eds.; Taylor&Francis Group: London, UK, 2009; Volume 2, pp. 1131–1142. [Google Scholar]

- Aiban, S. Utilization of steel slag aggregate for road bases. J. Test. Eval. 2006, 34, 65–75. [Google Scholar] [CrossRef]

- Federacciai, L’industria Siderurgica Italiana, Sfida Acciaio-Relazione Annuale 2013. Available online: http://federacciai.it/wp-content/uploads/2016/11/RelazioneAnnuale_2013.pdf (accessed on 16 February 2020).

- Federacciai, La Valorizzazione Degli Aggregati di Origine Siderurgica-La Scoria Siderurgica: Da Problema a Risorsa. Available online: https://docplayer.it/12621424-La-valorizzazione-degli-aggregati-di-origine-siderurgica-la-scoria-siderurgica-da-problema-a-risorsa.html (accessed on 16 February 2020).

- UNI 11531-1. Construction and Maintenance for Infrastructure Civil Building—Criteria for Materials Use—Part 1: Soils and Mixtures of Unbound Aggregates; European Committee for Standardisation: Bruxelles, Belgium, 2014. [Google Scholar]

- EN 13242. Aggregates for Unbound and Hydraulically Bound Materials for Use in Civil Engineering Work and Road Construction; European Committee for Standardisation: Bruxelles, Belgium, 2013. [Google Scholar]

- EN 13285. Unbound Mixtures-Specifications; European Committee for Standardisation: Bruxelles, Belgium, 2018. [Google Scholar]

- EN ISO 14688-1. Geotechnical Investigation and Testing-Identification and Classification of Soil-Part 1: Identification and Description; European Committee for Standardisation: Bruxelles, Belgium, 2018. [Google Scholar]

- EN ISO 14688-2. Geotechnical Investigation and Testing—Identification and Classification of Soil-Part 2: Principles for a Classification; European Committee for Standardisation: Bruxelles, Belgium, 2018. [Google Scholar]

- Circolare n. 5205 del 15-07-2005. Indicazioni per L’operatività nel Settore Edile, Stradale e Ambientale, ai Sensi del Decreto Ministeriale 8 Maggio 2003, n. 203; Ministero dell’Ambiente e della Tutela del Territorio: Rome, Italy, 2005. [Google Scholar]

- Decreto Legislativo 3 Aprile 2006, n. 152, Norme in Materia Ambientale; Presidente della Repubblica: Rome, Italy, 2006.

- EN 12457-2. Characterization of Waste-Leaching-Compliance Test for Leaching of Granular Waste Materials and Sludges-Part 2: One Stage Batch Test at a Liquid to Solid Ratio of 10 l/kg for Materials with Particle Size below 4 mm (without or with Size Reduction); European Committee for Standardisation: Bruxelles, Belgium, 2002. [Google Scholar]

- EN 16192. Characterization of Waste-Analysis of Eluates; European Committee for Standardisation: Bruxelles, Belgium, 2011. [Google Scholar]

- EN 933-1. Tests for Geometrical Properties of Aggregates-Part 1: Determination of Particle Size Distribution-Sieving Method; European Committee for Standardisation: Bruxelles, Belgium, 2012. [Google Scholar]

- EN 1097-2. Tests for Mechanical and Physical Properties of Aggregates-Part 2: Methods for the Determination of Resistance to Fragmentation; European Committee for Standardisation: Bruxelles, Belgium, 2010. [Google Scholar]

- EN 933-8. Tests for Geometrical Properties of Aggregates-Part 8: Assessment of Fines-Sand Equivalent Test; European Committee for Standardisation: Bruxelles, Belgium, 2012. [Google Scholar]

- EN 933-3. Tests for Geometrical Properties of Aggregates-Part 3: Determination of Particle Shape-Flakiness Index; European Committee for Standardisation: Bruxelles, Belgium, 2012. [Google Scholar]

- EN 933-4. Tests for Geometrical Properties of Aggregates-Part 4: Determination of Particle Shape-Shape Index; European Committee for Standardisation: Bruxelles, Belgium, 2008. [Google Scholar]

- EN 13286-47. Unbound and Hydraulically Bound Mixtures-Part 47: Test Method for the Determination of California Bearing Ratio, Immediate Bearing Index and Linear Swelling; European Committee for Standardisation: Bruxelles, Belgium, 2012. [Google Scholar]

- EN 933-11. Tests for Geometrical Properties of Aggregates-Part 11: Classification Test for the Constituents of Coarse Recycled Aggregate; European Committee for Standardisation: Bruxelles, Belgium, 2009. [Google Scholar]

- EN 1744-1. Tests for Chemical Properties of Aggregates-Part 1: Chemical Analysis; European Committee for Standardisation: Bruxelles, Belgium, 2009. [Google Scholar]

- EN 933-5. Tests for Geometrical Properties of Aggregates-Part 5: Determination of Percentage of Crushed and Broken Surfaces in Coarse Aggregate Particles; European Committee for Standardisation: Bruxelles, Belgium, 1998. [Google Scholar]

| Parameters | Units of Measure | Results on the Base Materials | Threshold Limit Value from [23] | ||

|---|---|---|---|---|---|

| A, B, C | D | E | |||

| pH | pH Unit | 8.4 | 12.5 | 10.4 | 5.5–12.0 |

| COD | mg/l | 18 | 17 | 21 | 30 |

| Nitrates | mg/l NO3 | 5.2 | 3 | 4.8 | 50 |

| Fluorides | mg/l F | 0.42 | 0.2 | 0.51 | 1.5 |

| Solfates | mg/l SO4 | 33.5 | 9.2 | 45.8 | 250 |

| Chlorides | mg/l Cl | 8.6 | 8.0 | 26.8 | 100 |

| Copper | mg/l Cu | 0.01 | 0.04 | 0.04 | 0.05 |

| Zinc | mg/l Zn | 0.03 | 0.006 | 2.7 | 3 |

| Cobalt | μg/l Co | 6.2 | 2.0 | 36.7 | 250 |

| Chromium | μg/l Cr | 14.3 | 8.0 | 24.8 | 50 |

| Nichel | μg/l Ni | 3.9 | 5.0 | 6.8 | 10 |

| Arsenic | μg/l As | 6.3 | 0.7 | 5.1 | 50 |

| Cadmium | μg/l Cd | 0.7 | 0.8 | 3.8 | 5 |

| Lead | μg/l Pb | 16.4 | 57 | 18.2 | 50 |

| Characteristic | Standard | Usage | |||

|---|---|---|---|---|---|

| Embankment | Subgrade | Unbound Foundation | Unbound Base | ||

| Granulometric classification | EN 13285 | GN | GU | GA | GA |

| Upper-sieve | EN 13285 | OC85 | OC75 | OC75 | OC85 |

| Maximum content of fines | EN 13285 | UF35 | UF15 | UF9 | UF9 |

| Minimum content of fines | EN 13285 | - | - | LF2 | LF2 |

| Mixture designation | EN 13285 | 0/63 | 0/31.5 | 0/31.5 | 0/31.5 |

| Resistance to fragmentation | EN 1097-2 | LA50 | LA45 | LA30 | LA30 |

| Quality of fines | EN 933-8 | SE20 | SE30 | SE30 | SE50 |

| Content of cementitious conglomerate fragments, etc. | EN 933-11 | Rcug50 | Rcug70 | Rcug90 | Rcug90 |

| Content of floating materials: paper, wood, etc. | EN 933-11 | FL10- | FL5- | FL5- | FL5- |

| Flattening of coarse aggregate | EN 933-3 | Fl50 | Fl35 | Fl35 | Fl35 |

| Percentage of crushed/rounded particles | EN 933-5 | - | - | - | C90/3 |

| Sulfate soluble in water | EN-1744-1 | SS0.2 | SS0.2 | SS0.2 | SS0.2 |

| CBR bearing tests after four days of soaking in water on constipated samples, with humidity ±2% of the optimum at 94% of the maximum density of the modified Proctor test energy. | EN 13286-47 | - | ≥ 10 | ≥ 50 | - |

| CBR tests after four days of soaking in water on constipated samples, with humidity ±2% of the optimum at 99% of the maximum density of the modified Proctor test energy. | - | - | - | - | ≥ 100 |

| Embankment | Subgrade | Unbound Foundation | Unbound Base | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SO 1 (mm) | Passing | SO 1 (mm) | Passing | SO 1 (mm) | Passing | SO 1 (mm) | Passing | |||||

| LL 2 % | UL 3 % | LL 2 % | UL 3 % | LL 2 % | UL 3 % | LL 2 % | UL 3 % | |||||

| 125 | 100 | 100 | 63 | 100 | 100 | 63 | 100 | 100 | 45 | 100 | 100 | |

| 63 | 85 | 99 | 45 | 85 | 100 | 45 | 85 | 100 | 31.5 | 85 | 99 | |

| 31.5 | - | - | 31.5 | 75 | 99 | 31.5 | 75 | 99 | 16 | 55 | 85 | |

| 16 | - | - | 16 | 50 | 90 | 16 | 55 | 85 | 8 | 35 | 65 | |

| 8 | - | - | 8 | 30 | 75 | 8 | 35 | 65 | 4 | 22 | 50 | |

| 4 | - | - | 4 | 15 | 60 | 4 | 22 | 50 | 2 | 15 | 40 | |

| 2 | - | - | 0.063 | 0 | 15 | 2 | 15 | 40 | 1 | 5 | 30 | |

| 1 | - | - | - | - | - | 1 | 5 | 30 | 0.5 | 0 | 20 | |

| 0.4 | - | - | - | - | - | 0.5 | 0 | 20 | 0.063 | 2 | 9 | |

| 0.063 | 0 | 35 | - | - | - | 0.063 | 2 | 9 | - | - | - | |

| SO1 (mm) | Soil category additional limits | |||||||||||

| A1-a | A1-b | A3 | ||||||||||

| 2 | 50 | - | - | |||||||||

| 0.4 | 30 | 50 | 50 | |||||||||

| 0.063 | 15 | 25 | 10 | |||||||||

| Sieves Opening (mm) | Passing (%) | |||

|---|---|---|---|---|

| Embankment 1 (0/63) | Subgrade 2 (0/31.5) | Foundation 3 (0/31.5) | Base 4 (0/31.5) | |

| 125 | 100.00 | 100.00 | 100.00 | 100.00 |

| 63 | 98.60 | 100.00 | 100.00 | 100.00 |

| 45 | - | 5 | 5 | 100.00 |

| 31.5 | 75.10 | 86.79 | 90.46 | 90.83 |

| 16 | 54.90 | 65.84 | 72.53 | 73.42 |

| 8 | 39.40 | 55.86 | 56.30 | 53.47 |

| 4 | 31.20 | 49.11 | 39.16 | 31.09 |

| 2 | 22.50 | 31.54 | 25.19 | 21.73 |

| 1 | 15.00 | 23.44 | 18.52 | 16.46 |

| 0.5 | 12.00 | 15.47 | 11.79 | 10.77 |

| 0.25 | 7.90 | 12.17 | 9.05 | 8.42 |

| 0.063 | 5.80 | 7.63 | 5.58 | 5.25 |

| Characteristic | Standard | Results of laboratory tests according to EN standards | |||

|---|---|---|---|---|---|

| Embankment (0/63) | Subgrade (0/31.5) | Foundation (0/31.5) | Base (0/31.5) | ||

| Granulometric category | EN 13285 | GN | GU | GA | GA |

| Upper-sieve | EN 13285 | OC85 | OC75 | OC75 | OC85 |

| Maximum content of fines | EN 13285 | UF7 | UF9 | UF7 | UF7 |

| Minimum content of fines | EN 13285 | - | - | LF5 | LF5 |

| Resistance to fragmentation | EN 1097-2 | LA45 | LA40 | LA28 | LA25 |

| Quality of fines | EN 933-8 | SE47 | SE46 | SE71 | SE75 |

| Content of cementitious conglomerate fragments, etc. | EN 933-11 | Rcug90 | Rcug90 | Rcug90 | Rcug90 |

| Content of floating materials: paper, wood, etc. | EN 933-11 | FL5- | FL5- | FL5- | FL5- |

| Flattening of coarse aggregate | EN 933-3 | Fl20 | Fl20 | Fl20 | Fl20 |

| Percentage of crushed/rounded particles | EN 933-5 | - | - | - | C90/3 |

| Sulfate soluble in water | EN 1744-1 | SS0.2 | SS0.2 | SS0.2 | SS0.2 |

| CBR tests after four days of soaking in water on constipated samples with humidity ±2% of the optimum at 94% of the maximum density of the modified Proctor test energy. | EN 13286-47 | 65% | 65% | 70% | - |

| CBR tests after four days of soaking in water on constipated samples with humidity ±2% of the optimum at 99% of the maximum density of the modified Proctor test energy. | - | - | - | - | 110% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciampa, D.; Cioffi, R.; Colangelo, F.; Diomedi, M.; Farina, I.; Olita, S. Use of Unbound Materials for Sustainable Road Infrastructures. Appl. Sci. 2020, 10, 3465. https://doi.org/10.3390/app10103465

Ciampa D, Cioffi R, Colangelo F, Diomedi M, Farina I, Olita S. Use of Unbound Materials for Sustainable Road Infrastructures. Applied Sciences. 2020; 10(10):3465. https://doi.org/10.3390/app10103465

Chicago/Turabian StyleCiampa, Donato, Raffaele Cioffi, Francesco Colangelo, Maurizio Diomedi, Ilenia Farina, and Saverio Olita. 2020. "Use of Unbound Materials for Sustainable Road Infrastructures" Applied Sciences 10, no. 10: 3465. https://doi.org/10.3390/app10103465