Technological Aspects in Manufacturing of Non-Circular Gears

Abstract

:1. Introduction

- the calculation of cooperating tooth forms for which the meshing pole and reference rack’s roll lines change their positions over time. Additionally, in non-circular gears, each tooth’s flank has an independent baseline [9].

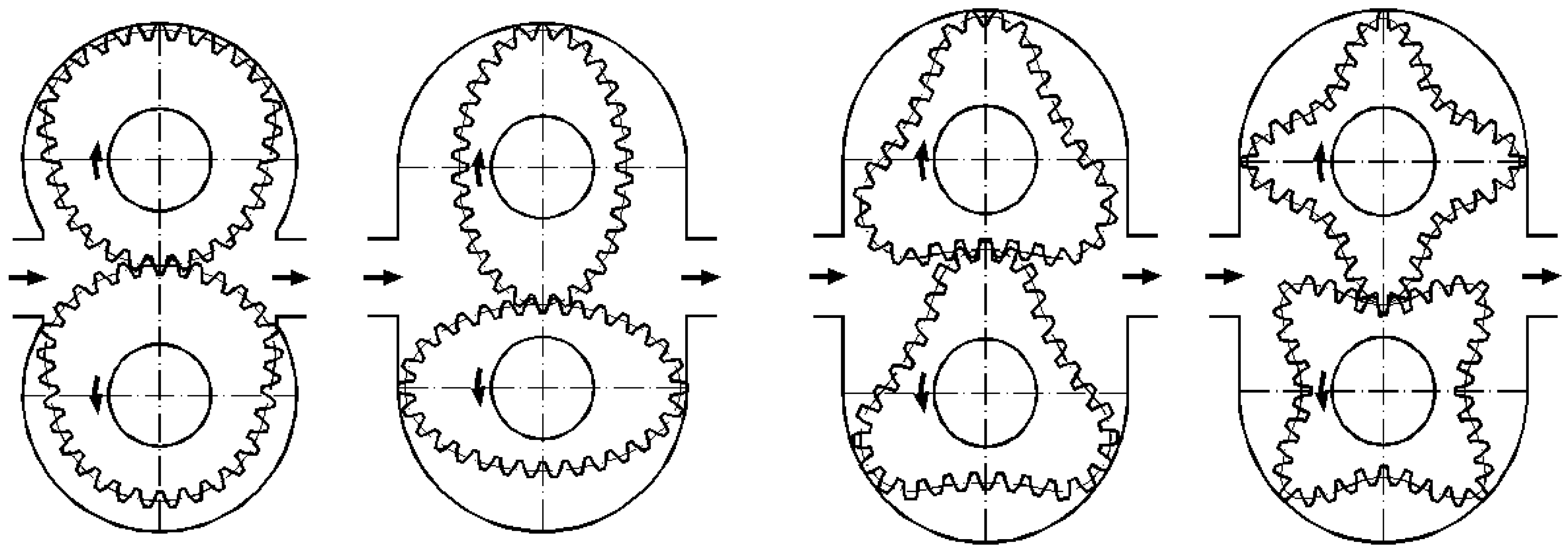

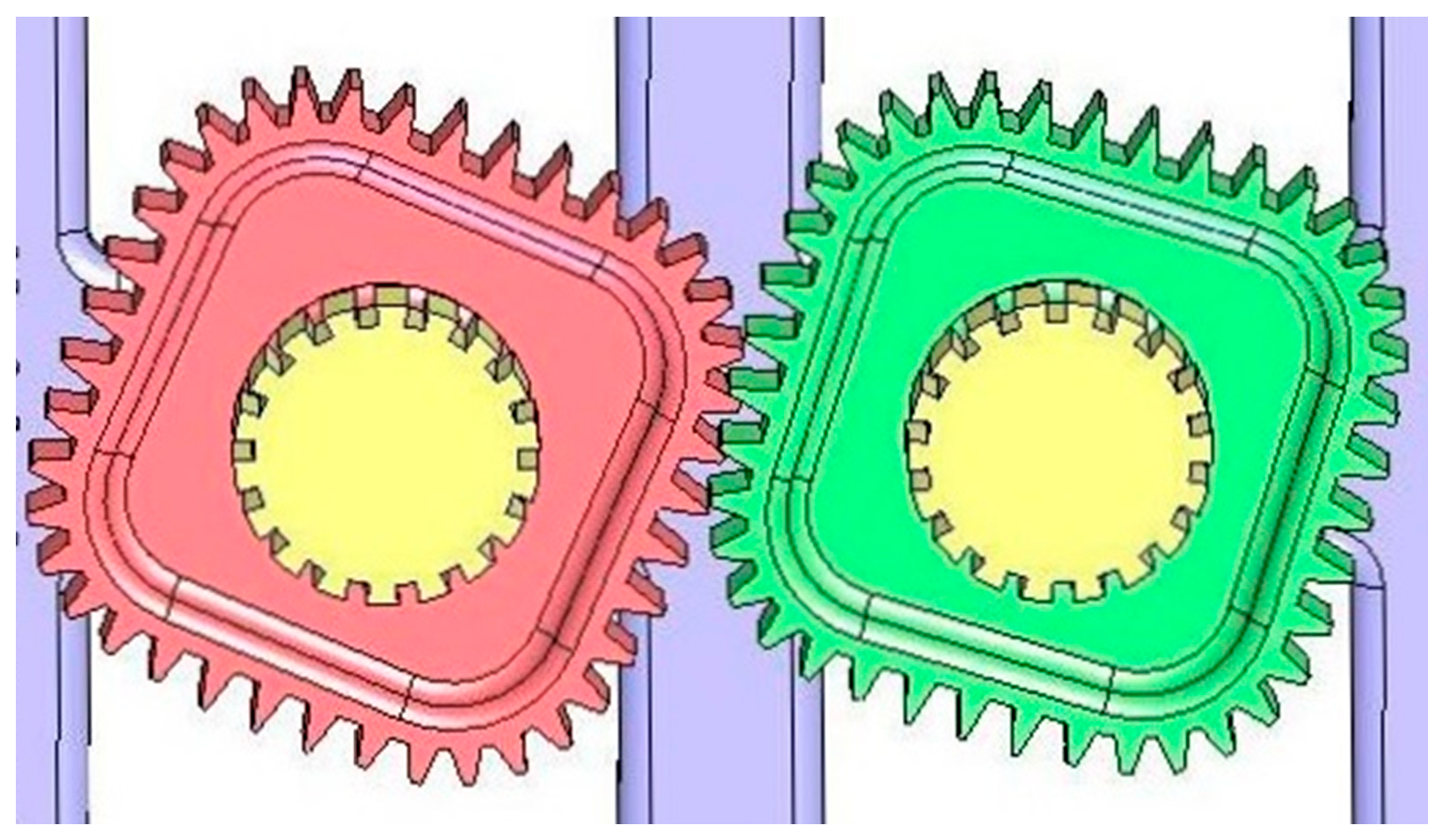

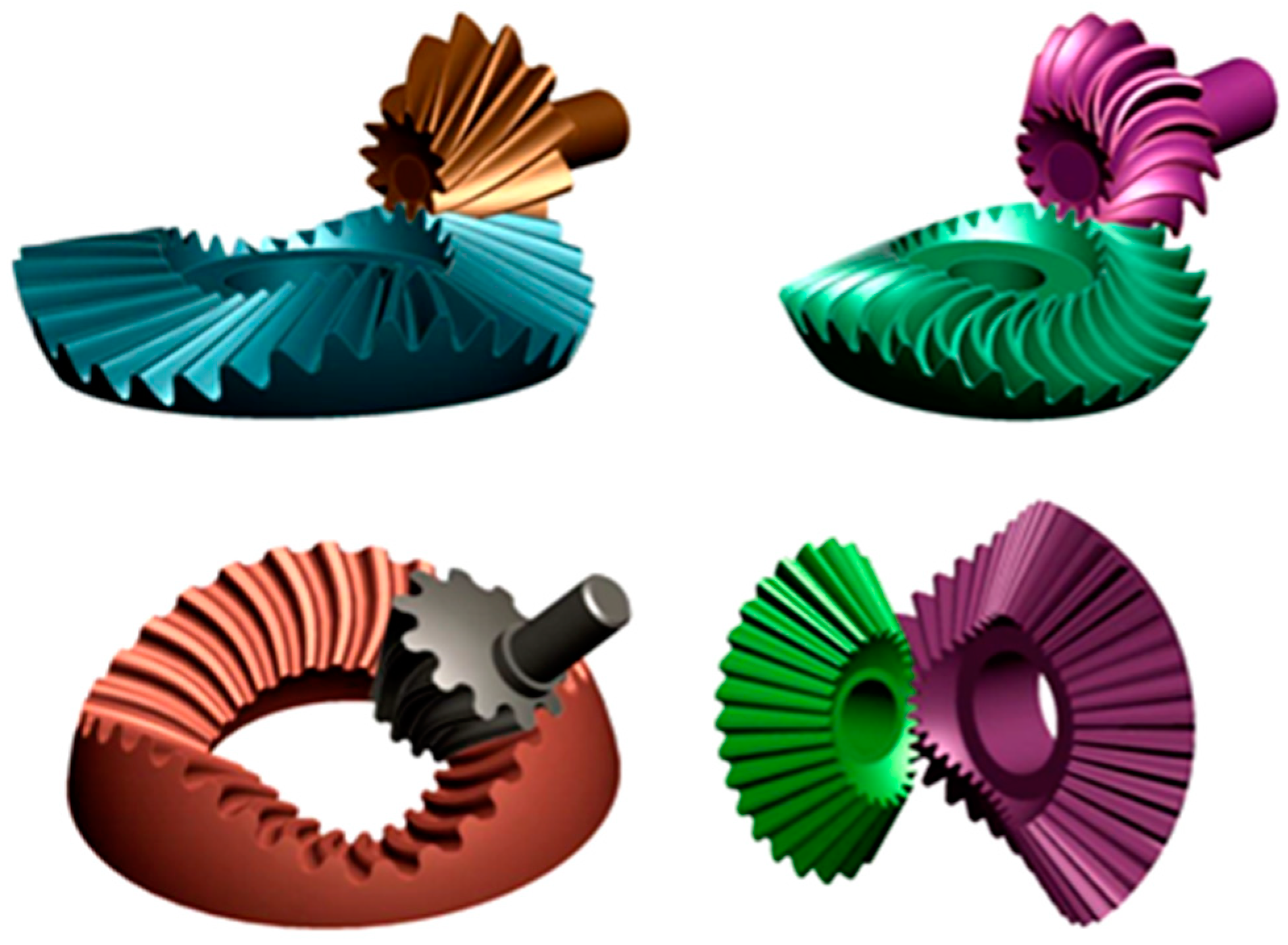

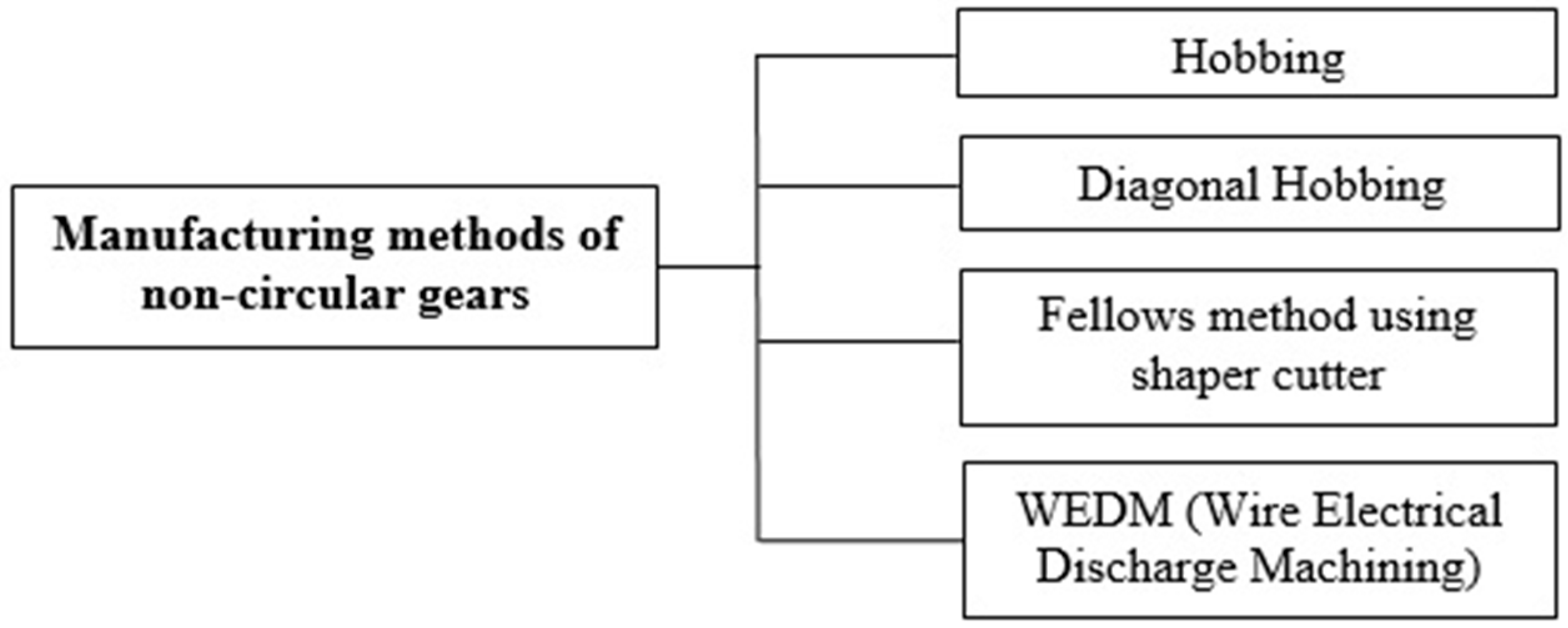

2. Methods of Manufacturing Non-Circular Gears

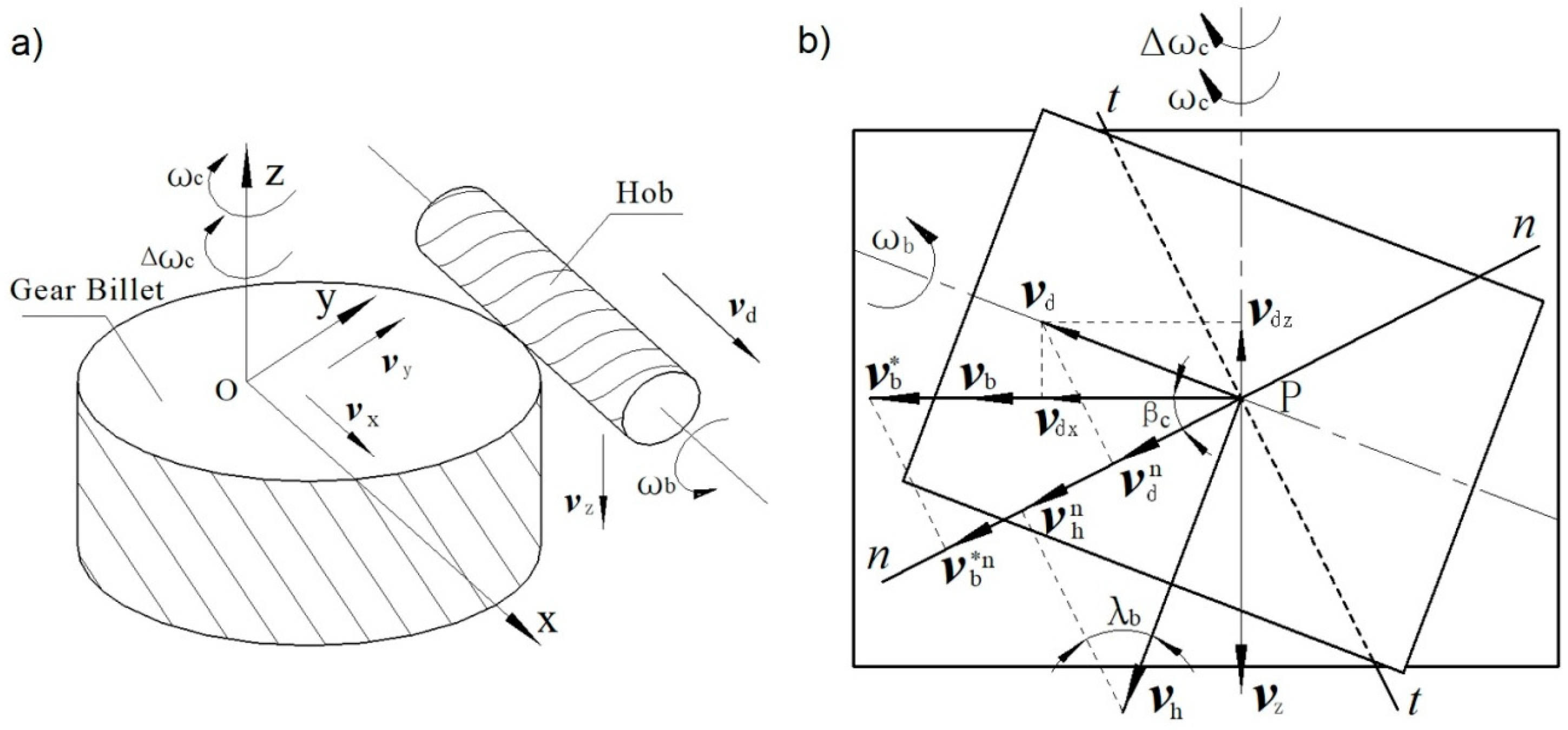

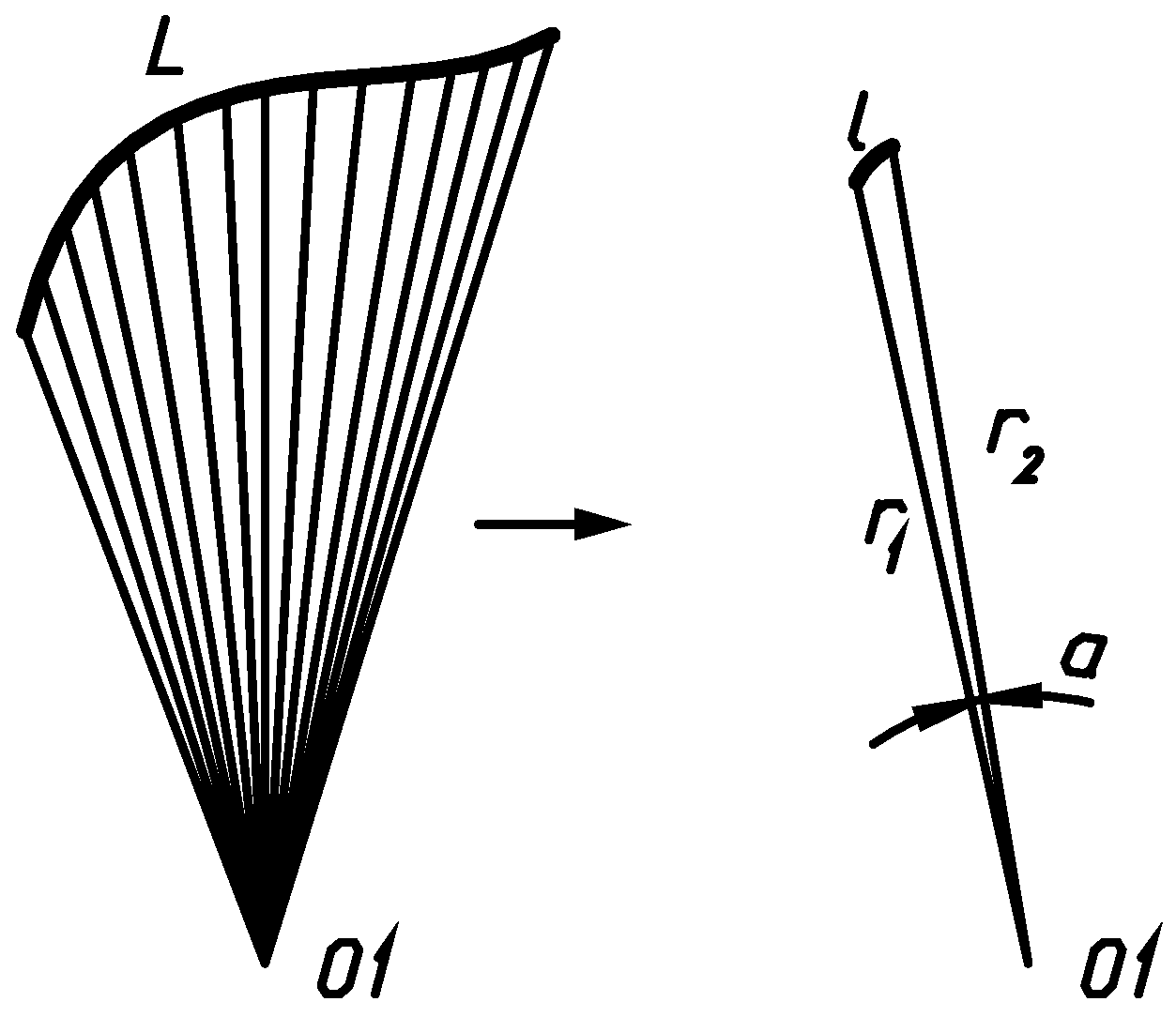

3. Diagonal Hobbing of a Non-Circular Gear

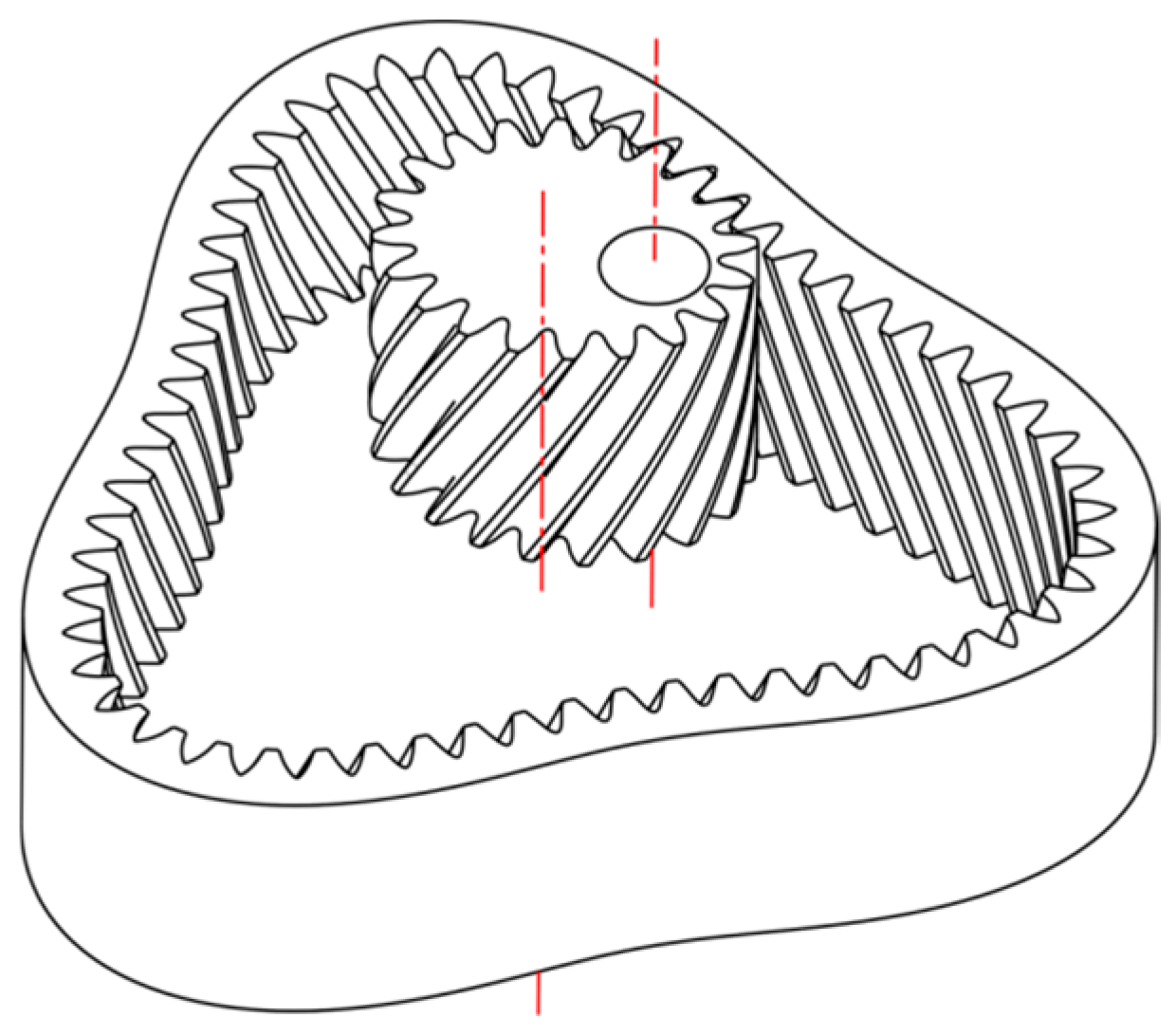

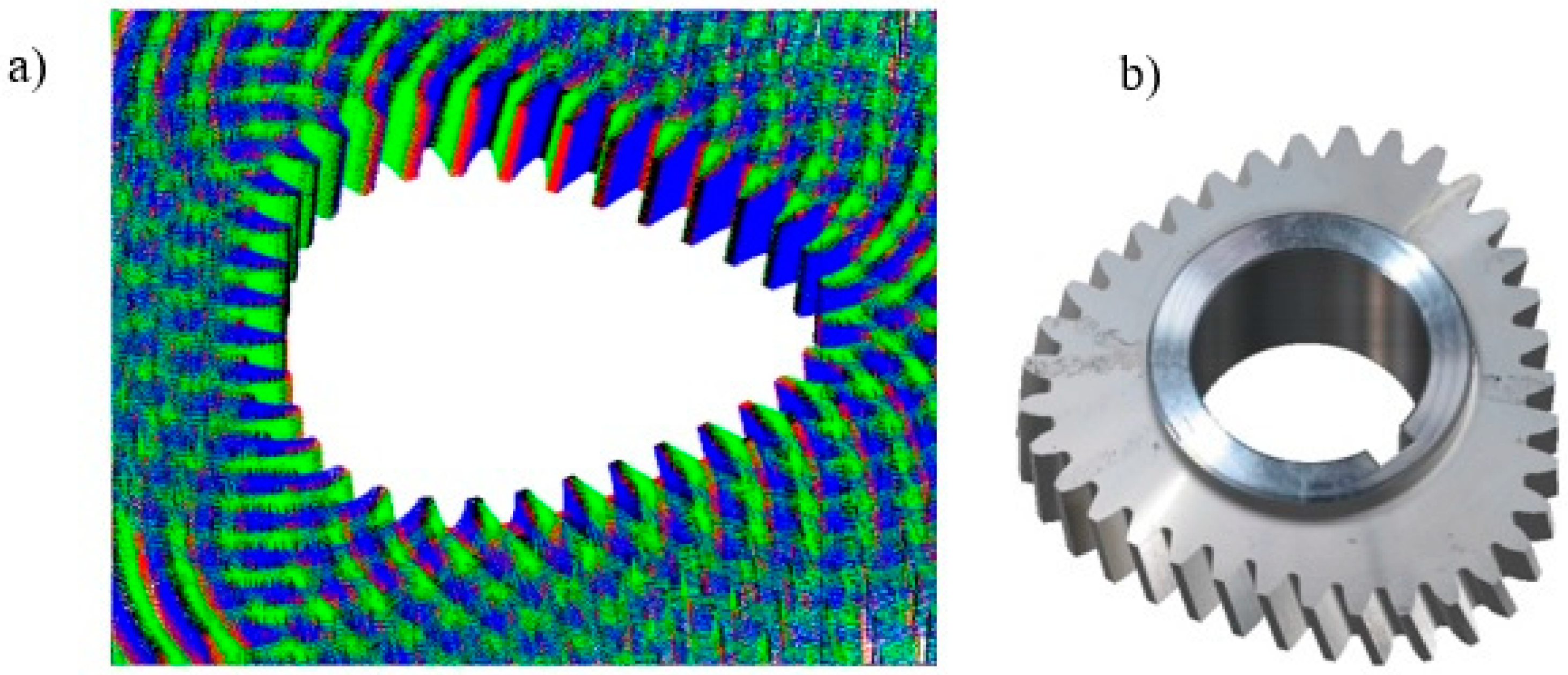

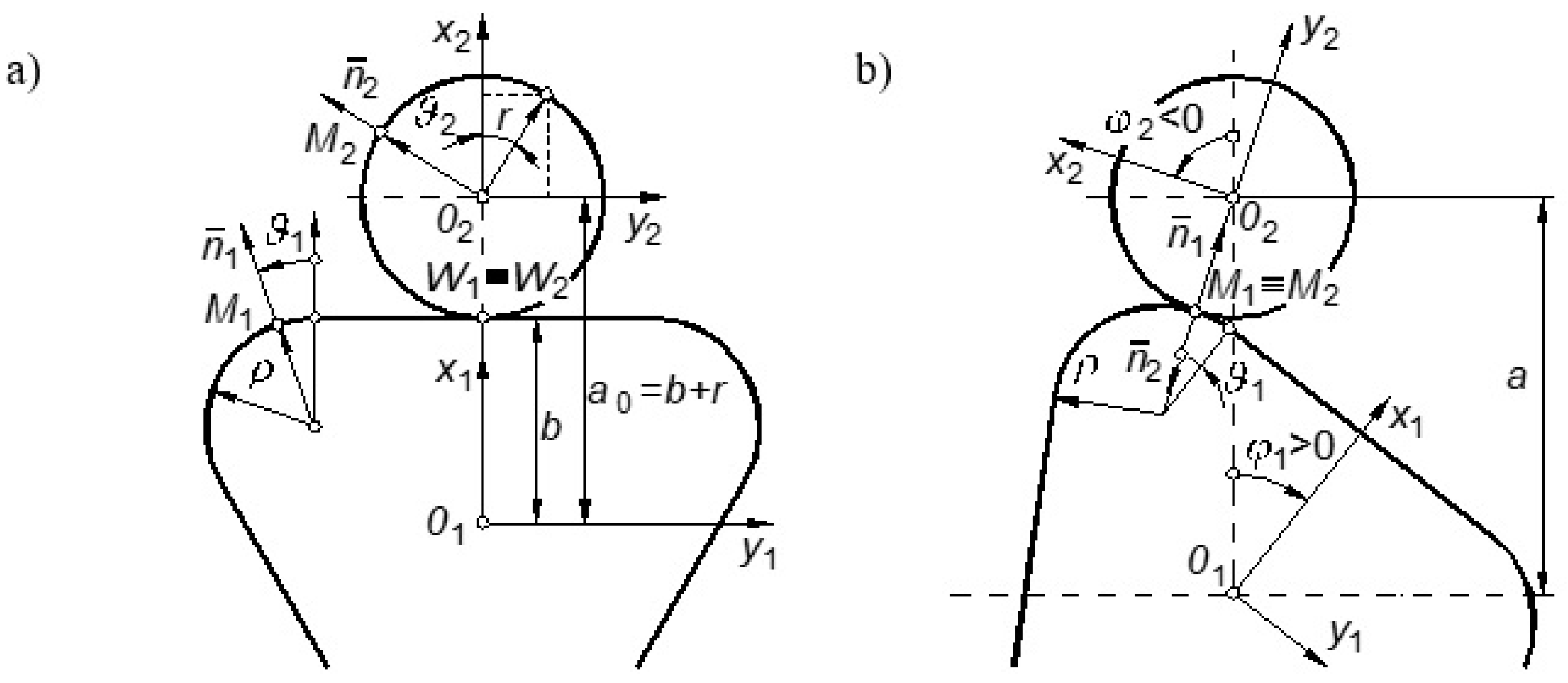

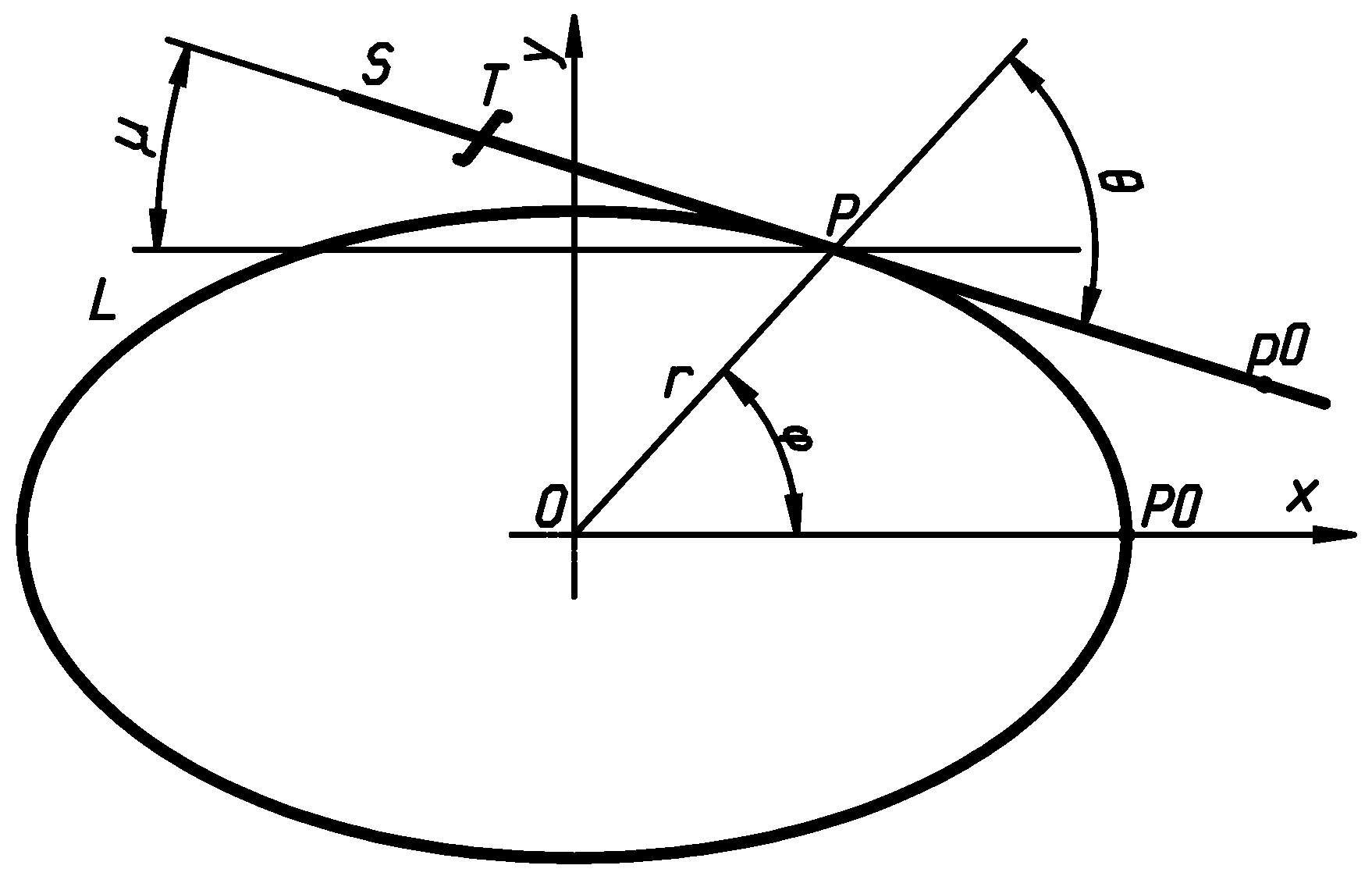

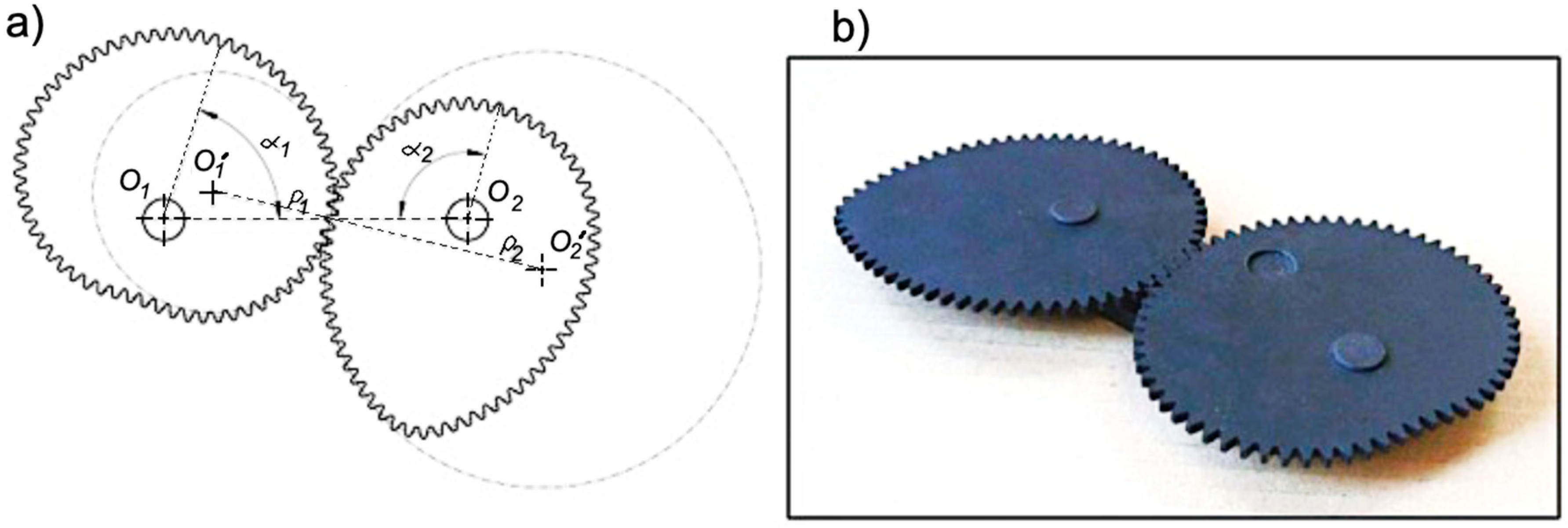

4. Machining of a Non-Circular Gear Using the Fellows Method and a Shaper Cutter

- Circular rolling curve of the satellite:

- Rectilinear part of the triangle:

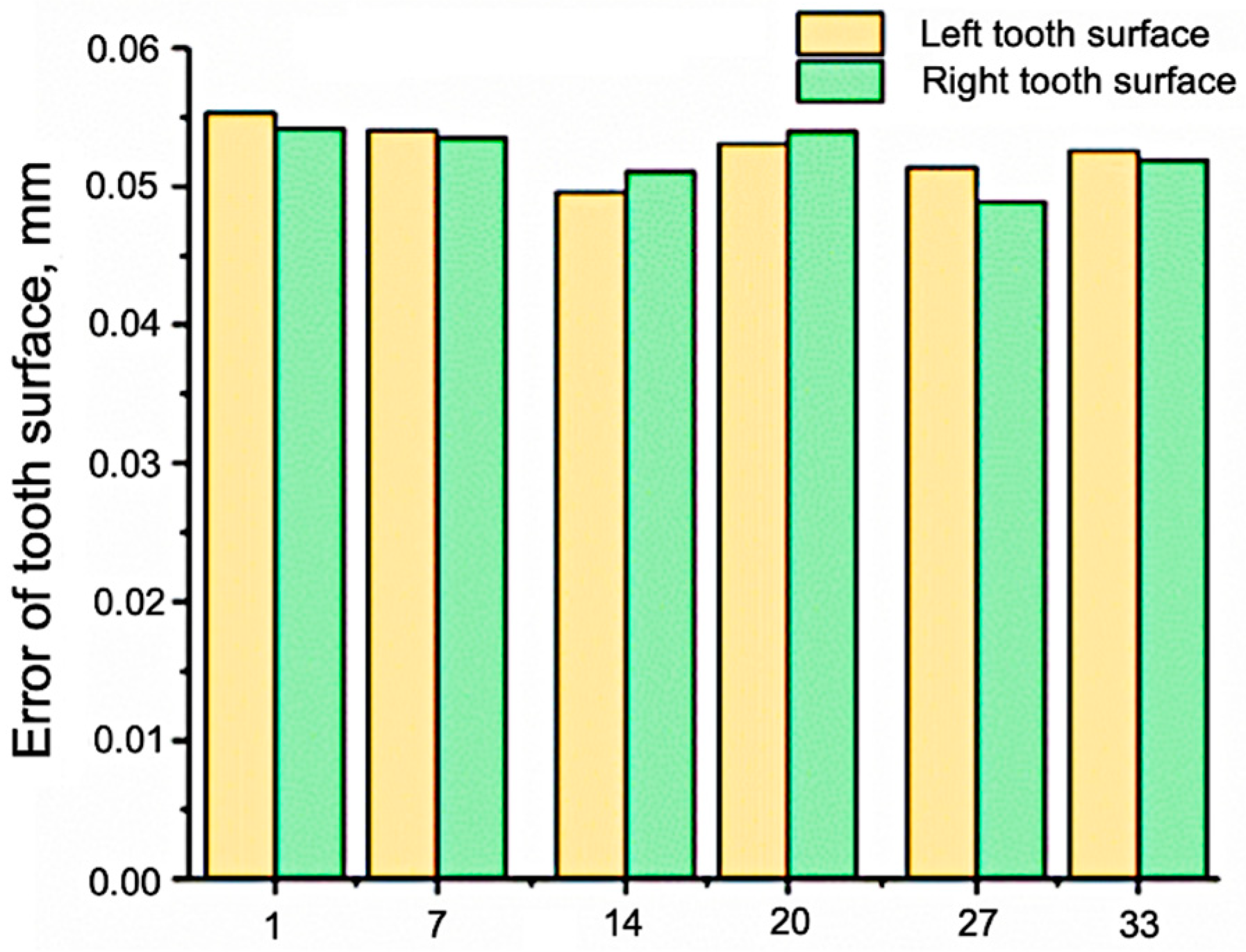

5. Machining of a Non-Circular Gear Using the WEDM Method

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chang, S.L.; Tsay, C.B. Computerised Tooth Profile Generation and Undercut Analysis of Noncircular Gears Manufactured with Shaper Cutters. ASME J. Mech. Des. 1998, 120, 92–99. [Google Scholar] [CrossRef]

- Doege, E.; Hindersmann, M. Optimized kinematics of mechanical presses with non-circular gears. CIRP Ann. 1997, 46, 213–216. [Google Scholar] [CrossRef]

- Doege, E.; Meinen, J.; Neumaier, T.; Schaprian, M. Numerical design of a new forging press drive incorporating non-circular gears. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2001, 215, 465–471. [Google Scholar] [CrossRef] [Green Version]

- Zheng, F.; Hua, L.; Hua, L.; Han, X.; Li, B.; Chen, D. Synthesis of Shaped Noncircular Gear Using a Three-Linkage Computer Numerical Control Shaping Machine. J. Manuf. Sci. Eng. 2017, 139, 071003. [Google Scholar] [CrossRef]

- Koć, A. Non-circular gears. Cutting tool selection and design. Adv. Manuf. Sci. Technol. 2001, 25, 49–59. [Google Scholar]

- Koć, A. Making out-of-round toothed wheels by means of numerically controlled slotting machines, Mathematical fundamentals for creating CAM software. Mechanik 2001, 74, 96–97. [Google Scholar]

- Laczik, B. Design and Manufacturing of Non-Circular Gears by Given Transfer Function. Available online: http://www.hexagon.de/pdf/noncgear.pdf (accessed on 12 October 2019).

- Laczik, B. Involute Profile of Non-Circular Gears. Institute of Mechanical Engineering; College of Dunaújváros: Dunaújváros, Hungary, 2008; Volume 126. [Google Scholar]

- Zarębski, I.; Sałaciński, T. Designing and WEDM manufacturing of non-circular gears. In Proceedings of the APE Conference, Warsaw, Poland, 21 April 2007. [Google Scholar]

- KMODDL. Available online: http://kmoddl.library.cornell.edu (accessed on 3 February 2020).

- Zheng, F.; Hua, L.; Han, X.; Chen, D. Generation of Noncircular Bevel Gears with Free-Form Tooth Profile and Curvilinear Tooth Lengthwise. J. Mech. Des. 2016, 138, 064501. [Google Scholar] [CrossRef]

- Liu, Y.; Han, J.; Xia, L.; Tian, X. Hobbing Strategy and Performance Analyses of Linkage Models for Non-Circular Helical Gears Based on Four-Axis Linkage. Stroj. Vestn.-J. Mech. Eng. 2012, 58, 701–708. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Diao, J. Six-Axis Linkage Strategy and Its Models for Non-Circular Helical Gears Based on Diagonal Hobbing. Stroj. Vestn.-J. Mech. Eng. 2015, 61, 330–342. [Google Scholar] [CrossRef]

- Koć, A. Manufacturing of non-circular gears on CNC Fellows Machines. In Proceedings of the Annals of MTeM for 2001&Proceedings of the 5th International MTeM Symposium, Cluj-Napoca, Romania, 4–6 October 2001; MTeM: Austin, TX, USA, 2001. [Google Scholar]

- Koć, A. Mathematical simulation for tooth machining of non-circular gears using Fellows-shapers. In Proceedings of the International Conference Advances in Production Engineering APE 2001, Warsaw, Poland, 7–9 June 2001. [Google Scholar]

- Li, J.G.; Mao, S. Numerical computing method of noncircular gear tooth profiles generated by shaper cutters. Int. J. Adv. Manuf. Technol. 2007, 33, 1098–1105. [Google Scholar] [CrossRef]

- Gao, T.; Han, J.; Tian, X.; Xia, L. Machining method with evenly distributed allowance based on the normal linkage model of non-circular gear shaping. INMATECH-Agric. Eng. 2017, 53, 113–122. [Google Scholar]

- Zarębski, I.; Sałaciński, T. Designing of non-circular gears. Arch. Mech. Eng. 2008, LV, 275–292. [Google Scholar]

- García-Hernández, C.; Gella-Marín, R.M.; Huertas-Talón, J.L.; Efkolidis, N.; Kyratsis, P. WEDM Manufacturing Method for Noncircular Gears, Using CAD/CAM Software. Stroj. Vestn.-J. Mech. Eng. 2016, 62, 2. [Google Scholar] [CrossRef] [Green Version]

- Salacinski, T.; Winiarski, M.; Chmielewski, T.; Swiercz, R. Surface finishing with ceramic fibre brush tools. In Proceedings of the International Conference METAL 2017, Brno, Czech Republic, 24–26 May 2017. [Google Scholar]

- Sałaciński, T.; Chmielewski, T.; Winiarski, M.; Cacko, R.; Świercz, R. Roughness of Metal Surface after Finishing Using Ceramic Brush Tools. Adv. Mater. Sci. 2018, 18, 20–27. [Google Scholar] [CrossRef] [Green Version]

- Sałaciński, T.; Winiarski, M.; Przesmycki, A.; Świercz, R.; Chmielewski, T. Applying titanium coatings on ceramic surfaces by rotating brushes. In Proceedings of the METAL 2018—27th International Conference on Metallurgy and Materials, Conference Proceedings, Brno, Czech Republic, 23–25 May 2018. [Google Scholar]

- Świercz, R.; Oniszczuk-Świercz, D.; Chmielewski, T. Multi-response optimization of electrical discharge machining using the desirability function. Micromachines 2019, 10, 72. [Google Scholar] [CrossRef] [Green Version]

- Świercz, R.; Oniszczuk-Świercz, D.; Chmielewski, T.; Sałaciński, T. Investigations on surface integrity processed by EDM. In Proceedings of the METAL 2018—27th International Conference on Metallurgy and Materials, Conference Proceedings, Brno, Czech Republic, 23–25 May 2018. [Google Scholar]

- Liu, Y.; Liao, F.; Dong, C. Research on Tooth Profile Error of Non-Circular Gears Based on Complex Surface Theory; Springer Nature Singapore Pte Ltd.: Singapore, 2020. [Google Scholar]

- Korzeniewski, H. Uzębienie ewolwentowe kół trochoidalnych. Arch. Technol. Masz. Autom. 2006, 26, 159–167. [Google Scholar]

- Kowalczyk, K.L.; Urbanek, U.S. The geometry and kinematics of a toothed gear of variable motion. Fibres Text. East. Eur. 2003, 11, 60–62. [Google Scholar]

- Smith, W.C. The Math of Noncircular Gearing. Gear Technology, July/August, 2000. Available online: https://www.geartechnology.com/issues/0700x/smith.pdf (accessed on 21 February 2019).

- Litvin, F.L.; Gonzalez-Perez, I.; Fuentes, A.; Hayasaka, K. Design and investigation of gear drives with non-circular gears applied for speed variation and generation of functions. Comput. Methods Appl. Mech. Eng. 2008, 197, 3783–3802. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sałaciński, T.; Przesmycki, A.; Chmielewski, T. Technological Aspects in Manufacturing of Non-Circular Gears. Appl. Sci. 2020, 10, 3420. https://doi.org/10.3390/app10103420

Sałaciński T, Przesmycki A, Chmielewski T. Technological Aspects in Manufacturing of Non-Circular Gears. Applied Sciences. 2020; 10(10):3420. https://doi.org/10.3390/app10103420

Chicago/Turabian StyleSałaciński, Tadeusz, Aleksander Przesmycki, and Tomasz Chmielewski. 2020. "Technological Aspects in Manufacturing of Non-Circular Gears" Applied Sciences 10, no. 10: 3420. https://doi.org/10.3390/app10103420

APA StyleSałaciński, T., Przesmycki, A., & Chmielewski, T. (2020). Technological Aspects in Manufacturing of Non-Circular Gears. Applied Sciences, 10(10), 3420. https://doi.org/10.3390/app10103420